4943ab9668132eaa7563670f13719615.ppt

- Количество слайдов: 23

Zircon Info. Tech Presents Autoconer Automation System

Zircon Info. Tech Presents Autoconer Automation System

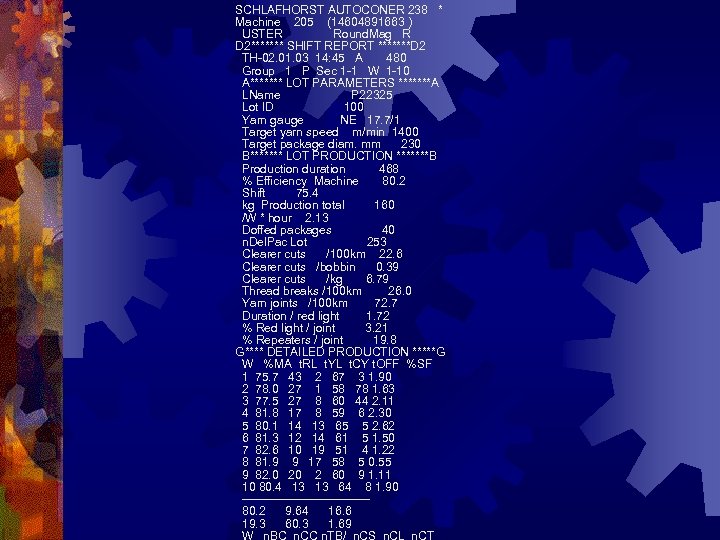

Present Working ® Each Autoconer gives an Automatic Report at each shift end. ® It prints report on thermal printer. ® If all the 30 items are printed (i. e. drum no, red light, yellow right, cycle % etc) the length of report is 3 meters. ® The style of report like this : -

Present Working ® Each Autoconer gives an Automatic Report at each shift end. ® It prints report on thermal printer. ® If all the 30 items are printed (i. e. drum no, red light, yellow right, cycle % etc) the length of report is 3 meters. ® The style of report like this : -

SCHLAFHORST AUTOCONER 238 * Machine 205 (14604891663 ) USTER Round. Mag R D 2******* SHIFT REPORT *******D 2 TH-02. 01. 03 14: 45 A 480 Group 1 P Sec 1 -1 W 1 -10 A******* LOT PARAMETERS *******A LName P 22325 Lot ID 100 Yarn gauge NE 17. 7/1 Target yarn speed m/min 1400 Target package diam. mm 230 B******* LOT PRODUCTION *******B Production duration 468 % Efficiency Machine 80. 2 Shift 75. 4 kg Production total 160 /W * hour 2. 13 Doffed packages 40 n. Del. Pac Lot 253 Clearer cuts /100 km 22. 6 Clearer cuts /bobbin 0. 39 Clearer cuts /kg 6. 79 Thread breaks /100 km 26. 0 Yarn joints /100 km 72. 7 Duration / red light 1. 72 % Red light / joint 3. 21 % Repeaters / joint 19. 8 G**** DETAILED PRODUCTION *****G W %MA t. RL t. YL t. CY t. OFF %SF 1 75. 7 43 2 67 3 1. 90 2 78. 0 27 1 58 78 1. 63 3 77. 5 27 8 60 44 2. 11 4 81. 8 17 8 59 6 2. 30 5 80. 1 14 13 65 5 2. 62 6 81. 3 12 14 61 5 1. 50 7 82. 6 10 19 51 4 1. 22 8 81. 9 9 17 58 5 0. 55 9 82. 0 20 2 60 9 1. 11 10 80. 4 13 13 64 8 1. 90 ----------------80. 2 9. 64 16. 6 19. 3 60. 3 1. 69 W n. BC n. CC n. TB/ n. CS n. CL n. CT

SCHLAFHORST AUTOCONER 238 * Machine 205 (14604891663 ) USTER Round. Mag R D 2******* SHIFT REPORT *******D 2 TH-02. 01. 03 14: 45 A 480 Group 1 P Sec 1 -1 W 1 -10 A******* LOT PARAMETERS *******A LName P 22325 Lot ID 100 Yarn gauge NE 17. 7/1 Target yarn speed m/min 1400 Target package diam. mm 230 B******* LOT PRODUCTION *******B Production duration 468 % Efficiency Machine 80. 2 Shift 75. 4 kg Production total 160 /W * hour 2. 13 Doffed packages 40 n. Del. Pac Lot 253 Clearer cuts /100 km 22. 6 Clearer cuts /bobbin 0. 39 Clearer cuts /kg 6. 79 Thread breaks /100 km 26. 0 Yarn joints /100 km 72. 7 Duration / red light 1. 72 % Red light / joint 3. 21 % Repeaters / joint 19. 8 G**** DETAILED PRODUCTION *****G W %MA t. RL t. YL t. CY t. OFF %SF 1 75. 7 43 2 67 3 1. 90 2 78. 0 27 1 58 78 1. 63 3 77. 5 27 8 60 44 2. 11 4 81. 8 17 8 59 6 2. 30 5 80. 1 14 13 65 5 2. 62 6 81. 3 12 14 61 5 1. 50 7 82. 6 10 19 51 4 1. 22 8 81. 9 9 17 58 5 0. 55 9 82. 0 20 2 60 9 1. 11 10 80. 4 13 13 64 8 1. 90 ----------------80. 2 9. 64 16. 6 19. 3 60. 3 1. 69 W n. BC n. CC n. TB/ n. CS n. CL n. CT

PROBLEMS FACED BY WINDING DEPARTMENT • Compilation of voluminous data for long period is tedious. • Loss of production in bad drums due to delayed reporting. • Identifying abnormal drums failing in any of the multiple items. • Limitations due to expensive thermal paper & thermal printer repairs. • Focusing on abnormal drums with periodic failure tendency. • Repetitive & boring manual calculation for statistical analysis. • Frustration due to lack of previous day’s/week’s/month’s data.

PROBLEMS FACED BY WINDING DEPARTMENT • Compilation of voluminous data for long period is tedious. • Loss of production in bad drums due to delayed reporting. • Identifying abnormal drums failing in any of the multiple items. • Limitations due to expensive thermal paper & thermal printer repairs. • Focusing on abnormal drums with periodic failure tendency. • Repetitive & boring manual calculation for statistical analysis. • Frustration due to lack of previous day’s/week’s/month’s data.

General Practice Adopted ® Either do not print report at shift end or print a very small report (i. e. limited 6 or 12 items). ® Do not analyze all items for all machines at a glance.

General Practice Adopted ® Either do not print report at shift end or print a very small report (i. e. limited 6 or 12 items). ® Do not analyze all items for all machines at a glance.

What is Automation ® Personal Computer captures data from Autoconer machines at every shift end automatically. ® No need to print 3 meter long report. ® Analyze all the data within half an hour. ® Analyze all the 30 items. ® View different types of report.

What is Automation ® Personal Computer captures data from Autoconer machines at every shift end automatically. ® No need to print 3 meter long report. ® Analyze all the data within half an hour. ® Analyze all the 30 items. ® View different types of report.

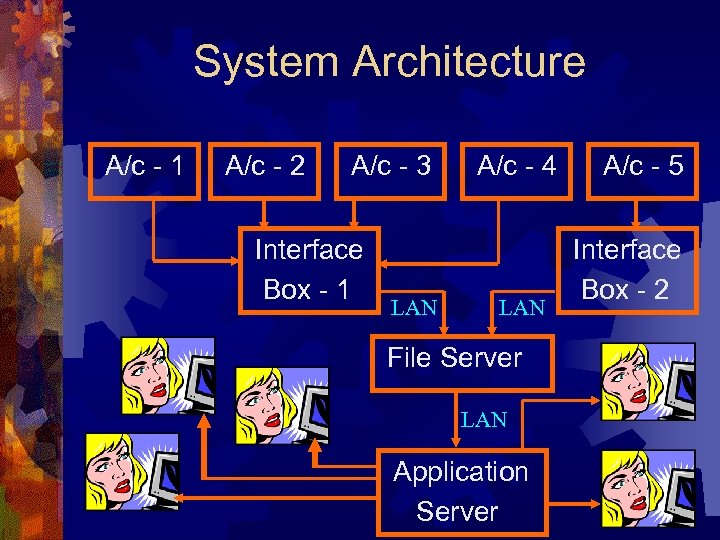

System Architecture A/c - 1 A/c - 2 A/c - 3 Interface Box - 1 LAN A/c - 4 LAN File Server LAN Application Server A/c - 5 Interface Box - 2

System Architecture A/c - 1 A/c - 2 A/c - 3 Interface Box - 1 LAN A/c - 4 LAN File Server LAN Application Server A/c - 5 Interface Box - 2

Benefits of Automations • • • Highlights Abnormal/Rouge drums. Increased efficiency due to reduced drum down–time and hard waste. Achieve better quality due to reduced number of cuts. Eliminates expensive thermal paper and printers. Lot to Lot comparisons. Reduced typing & processing manpower. Long term storage & easy recall of data. Easy & faster reporting. Faster decision making. Elimination of duplicity. Unlimited intangible benefits of computerization.

Benefits of Automations • • • Highlights Abnormal/Rouge drums. Increased efficiency due to reduced drum down–time and hard waste. Achieve better quality due to reduced number of cuts. Eliminates expensive thermal paper and printers. Lot to Lot comparisons. Reduced typing & processing manpower. Long term storage & easy recall of data. Easy & faster reporting. Faster decision making. Elimination of duplicity. Unlimited intangible benefits of computerization.

REPORTS § Production : This report shows production duration, speed, M/c efficiency, shift efficiency, Efficiency losses (Red & yellow lights, suction failure and cycling losses), Breakup of cycling losses, no. of cuts, yarn contents, total production, rate of production on the basis of standard production. etc. on a single sheet. § View report in different ways § Lot wise Machine wise § Machine wise Lot wise § Lot wise Clearer wise § Clearer wise Lot wise § Winding Register

REPORTS § Production : This report shows production duration, speed, M/c efficiency, shift efficiency, Efficiency losses (Red & yellow lights, suction failure and cycling losses), Breakup of cycling losses, no. of cuts, yarn contents, total production, rate of production on the basis of standard production. etc. on a single sheet. § View report in different ways § Lot wise Machine wise § Machine wise Lot wise § Lot wise Clearer wise § Clearer wise Lot wise § Winding Register

REPORTS…. § Abnormal Drum : This report shows machine wise lot wise abnormal drums for a shift/day based on sigma value (select by user). Standard Abnormal drum report checks 12 items (i. e. toff, t. RL, t. YL, t. CY, %SF, %CP, %AO, n. TB/, n. CC/, n. CL, n. CT, n. CS) while periodical report shows report for a selected item fortnight/month. § View report in different ways § General Abnormal Drum for a Shift/Day § Abnormal Drum Report for a Item for a Period ® ® With Average Value Without Average Value

REPORTS…. § Abnormal Drum : This report shows machine wise lot wise abnormal drums for a shift/day based on sigma value (select by user). Standard Abnormal drum report checks 12 items (i. e. toff, t. RL, t. YL, t. CY, %SF, %CP, %AO, n. TB/, n. CC/, n. CL, n. CT, n. CS) while periodical report shows report for a selected item fortnight/month. § View report in different ways § General Abnormal Drum for a Shift/Day § Abnormal Drum Report for a Item for a Period ® ® With Average Value Without Average Value

REPORTS…. § Drum wise Day wise Original Values : This report shows machine wise drum wise actual value for a selected item for a month. This report allows you to select the normal value for the selected item and print report only either for normal value or abnormal values. § Drum wise Machine wise Values : This report shows drum wise machines wise actual value for a selected item for a given period. This report allows you to select the normal value for the selected item and print report only either for normal value or abnormal values.

REPORTS…. § Drum wise Day wise Original Values : This report shows machine wise drum wise actual value for a selected item for a month. This report allows you to select the normal value for the selected item and print report only either for normal value or abnormal values. § Drum wise Machine wise Values : This report shows drum wise machines wise actual value for a selected item for a given period. This report allows you to select the normal value for the selected item and print report only either for normal value or abnormal values.

REPORTS…. § Summary : This report shows Cuts/100 Km and shift efficiency for a given period. § View report in different ways § Count wise Lot wise § Count wise Machine wise § Machine wise Count wise § Lot wise Machine wise § Machine wise Lot wise § Lot wise Clearer wise

REPORTS…. § Summary : This report shows Cuts/100 Km and shift efficiency for a given period. § View report in different ways § Count wise Lot wise § Count wise Machine wise § Machine wise Count wise § Lot wise Machine wise § Machine wise Lot wise § Lot wise Clearer wise

REPORTS…. § Daily Productivity Index : This report shows Lot wise M/c efficiency, shift efficiency, Cuts/100 Km, standard production per drum, rate of production, production in kg, % of losses, capacity utilization and productivity index for a shift/day for a given period.

REPORTS…. § Daily Productivity Index : This report shows Lot wise M/c efficiency, shift efficiency, Cuts/100 Km, standard production per drum, rate of production, production in kg, % of losses, capacity utilization and productivity index for a shift/day for a given period.

REPORTS…. § Machine wise Breakup : In this report user can divide all the drums in any machine into four groups based on their performance in a selected item. This helps to set and achieve the performance target. § Drum wise Analysis : in this user can apply his own conditions on 8 selected items on selected groups of a machine for a period/day. If the value of drums does not fulfill the defined conditions, it will highlights the values.

REPORTS…. § Machine wise Breakup : In this report user can divide all the drums in any machine into four groups based on their performance in a selected item. This helps to set and achieve the performance target. § Drum wise Analysis : in this user can apply his own conditions on 8 selected items on selected groups of a machine for a period/day. If the value of drums does not fulfill the defined conditions, it will highlights the values.

REPORTS…. § Informator : This report shows the drum wise MIC report for all 30 items on a single line. . § View report in different ways § For a shift for a Machine § Day wise Average values § Week wise Average values § Fortnight wise Average Values § Month wise Average values

REPORTS…. § Informator : This report shows the drum wise MIC report for all 30 items on a single line. . § View report in different ways § For a shift for a Machine § Day wise Average values § Week wise Average values § Fortnight wise Average Values § Month wise Average values

COST BENEFITS ® Saving in Thermal Paper Cost ® Increased Earning due to Increase in efficiency ® Reduction in Hard Waste ® Reduction in Manpower Costs

COST BENEFITS ® Saving in Thermal Paper Cost ® Increased Earning due to Increase in efficiency ® Reduction in Hard Waste ® Reduction in Manpower Costs

COST BENEFITS…. ® Saving in Thermal Paper Cost Every Autoconer prints data for 60 drums for all 30 parameters per shift and it takes 3 meters of roll. It costs Rs. 3 per meter. The total paper cost for 11 11 Autoconers x 3 shifts x 365 days x 3 meters x Rs. 3 per meter = Rs. 1, 08, 405

COST BENEFITS…. ® Saving in Thermal Paper Cost Every Autoconer prints data for 60 drums for all 30 parameters per shift and it takes 3 meters of roll. It costs Rs. 3 per meter. The total paper cost for 11 11 Autoconers x 3 shifts x 365 days x 3 meters x Rs. 3 per meter = Rs. 1, 08, 405

COST BENEFITS…. ® Increased Efficiency Earning due to Increase in Due to reduced drum down–time the expected efficiency increases by as much as 5%. Even if we expect a modest figure of 1%, which is not at all difficult to achieve, this will lead to a increased production of 1%. Each Autoconer produces 2000 Kg. of yarn @Rs. 10 per Kg i. e. Rs. 20, 000 per day. The increased earning due 1% efficiency will be Rs. 200 per day per Autoconer. For 11 Autoconers and for 365 days, the additional earnings will be Rs. 200 x 11 Autoconers x 365 days = Rs. 8, 03, 000

COST BENEFITS…. ® Increased Efficiency Earning due to Increase in Due to reduced drum down–time the expected efficiency increases by as much as 5%. Even if we expect a modest figure of 1%, which is not at all difficult to achieve, this will lead to a increased production of 1%. Each Autoconer produces 2000 Kg. of yarn @Rs. 10 per Kg i. e. Rs. 20, 000 per day. The increased earning due 1% efficiency will be Rs. 200 per day per Autoconer. For 11 Autoconers and for 365 days, the additional earnings will be Rs. 200 x 11 Autoconers x 365 days = Rs. 8, 03, 000

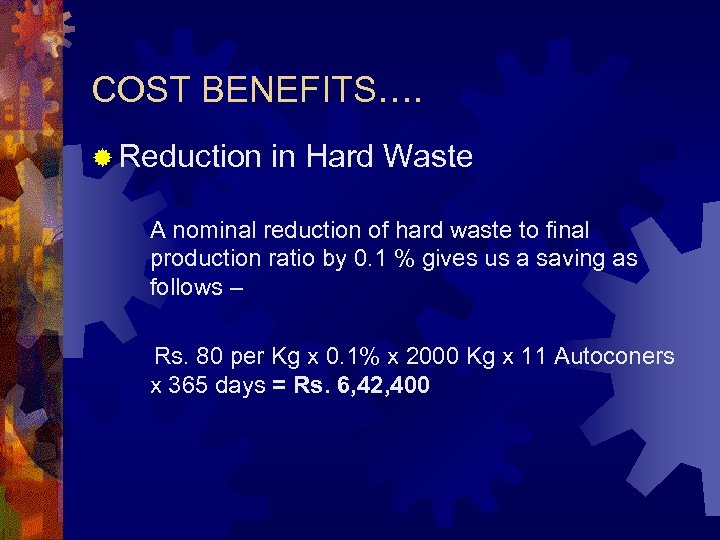

COST BENEFITS…. ® Reduction in Hard Waste A nominal reduction of hard waste to final production ratio by 0. 1 % gives us a saving as follows – Rs. 80 per Kg x 0. 1% x 2000 Kg x 11 Autoconers x 365 days = Rs. 6, 42, 400

COST BENEFITS…. ® Reduction in Hard Waste A nominal reduction of hard waste to final production ratio by 0. 1 % gives us a saving as follows – Rs. 80 per Kg x 0. 1% x 2000 Kg x 11 Autoconers x 365 days = Rs. 6, 42, 400

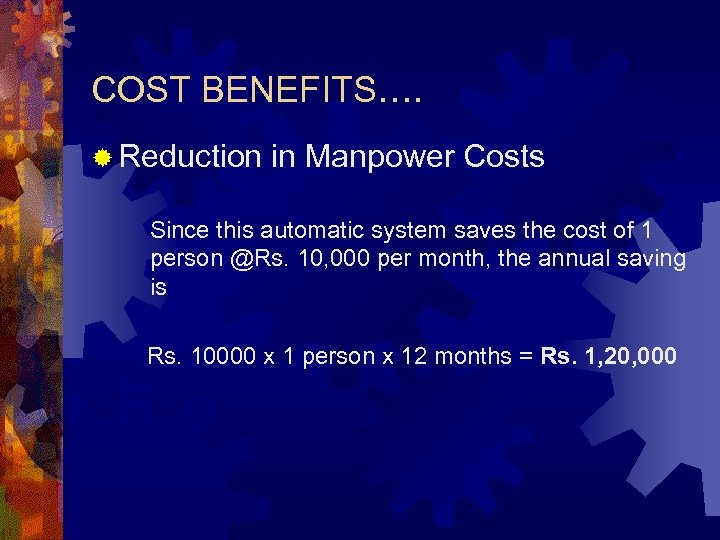

COST BENEFITS…. ® Reduction in Manpower Costs Since this automatic system saves the cost of 1 person @Rs. 10, 000 per month, the annual saving is Rs. 10000 x 1 person x 12 months = Rs. 1, 20, 000

COST BENEFITS…. ® Reduction in Manpower Costs Since this automatic system saves the cost of 1 person @Rs. 10, 000 per month, the annual saving is Rs. 10000 x 1 person x 12 months = Rs. 1, 20, 000

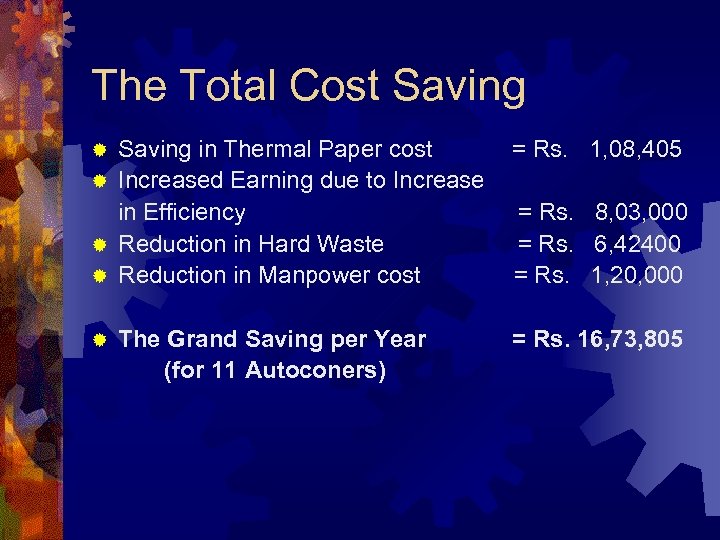

The Total Cost Saving in Thermal Paper cost ® Increased Earning due to Increase in Efficiency ® Reduction in Hard Waste ® Reduction in Manpower cost ® = Rs. 1, 08, 405 = Rs. 8, 03, 000 = Rs. 6, 42400 = Rs. 1, 20, 000 The Grand Saving per Year = Rs. 16, 73, 805 (for 11 Autoconers) ®

The Total Cost Saving in Thermal Paper cost ® Increased Earning due to Increase in Efficiency ® Reduction in Hard Waste ® Reduction in Manpower cost ® = Rs. 1, 08, 405 = Rs. 8, 03, 000 = Rs. 6, 42400 = Rs. 1, 20, 000 The Grand Saving per Year = Rs. 16, 73, 805 (for 11 Autoconers) ®

For Further Details Contact : Govind Garg Zircon Info. Tech 102, Trade Centre, 18 South Tukoganj, Indore-452001 Tel : 731 -2523954 Cell no. : 98263 -85954 e-mail: zirconinfo@gmail. com

For Further Details Contact : Govind Garg Zircon Info. Tech 102, Trade Centre, 18 South Tukoganj, Indore-452001 Tel : 731 -2523954 Cell no. : 98263 -85954 e-mail: zirconinfo@gmail. com

Autoconer Automation System The Beginning

Autoconer Automation System The Beginning