661525180c3611a31ba1cdda4f6099bc.ppt

- Количество слайдов: 19

Zinc Redox Technology - Confidential -

Zinc Redox Technology - Confidential -

In-House Experience and World-Class Partners Management Team Technical Team - Extensive entrepreneurial and - Industrial experience startup experience in wireless, finance and hi-tech industries Board Advisors - Industry professionals with expertise in the area of storage, smart grid, wet processing equipment, semiconductors, and manufacturing - National laboratory-caliber R&D background Technology Partner - Semitool/Applied Materials - a leading hi-tech, wet processing equipment manufacturer

In-House Experience and World-Class Partners Management Team Technical Team - Extensive entrepreneurial and - Industrial experience startup experience in wireless, finance and hi-tech industries Board Advisors - Industry professionals with expertise in the area of storage, smart grid, wet processing equipment, semiconductors, and manufacturing - National laboratory-caliber R&D background Technology Partner - Semitool/Applied Materials - a leading hi-tech, wet processing equipment manufacturer

Management Team Dave Wilkins, President Craig Wilkins, VP/COO Dave founded Glacier Stone Supply in 2003 to focus on mining, manufacturing, and distributing the best Montana stone products. Dave is currently responsible for the overall strategic direction and operating results of Glacier Stone Supply. Prior to Glacier Stone Supply, Dave spent over 10 years in the wireless industry. Mr. Wilkins founded Net. Wireless in 1996 to focus on reselling and distributing cutting edge wireless products and services to medium and large corporations. Net. Wireless was Nextel’s largest Nationwide Distributor with over 250 employees. Mr. Wilkins managed Net Wireless from a startup with under $100, 000 in starting capital to negotiating the sale of the company with a revenue run rate of over $38, 000. Dave started with Nextel during the launch of their 1 st digital market in the U. S. and received the #1 management awards in Southern California including Top Regional Sales Manager and the Commitment to Excellence Award. Mr. Wilkins studied business at both Loyola Marymount University and the University of Southern California Craig has 25 years of sales and business management experience with a variety of startups and privately held companies. Mr. Wilkins is currently working as the VP/CFO of Zinc Air, Inc. Previously, Craig was the founder and President/CEO of Acceptance Capital Mortgage Corporation, which was the 11 th largest mortgage broker in the United States in 2007 and continues to operate today. Craig was also a founder and principal owner in Net. Wireless and managed the eastern United States while developing the corporate account team. When Net. Wireless sold to Bearcom, Craig managed the combined corporate account teams for the company. Prior to his work at Net. Wireless, Craig was the Director of Sales for CSI Financial, the second largest purchaser of hospital receivables in the United States. Craig has a BA in Finance from University of Montana and completed his graduate studies in Economics.

Management Team Dave Wilkins, President Craig Wilkins, VP/COO Dave founded Glacier Stone Supply in 2003 to focus on mining, manufacturing, and distributing the best Montana stone products. Dave is currently responsible for the overall strategic direction and operating results of Glacier Stone Supply. Prior to Glacier Stone Supply, Dave spent over 10 years in the wireless industry. Mr. Wilkins founded Net. Wireless in 1996 to focus on reselling and distributing cutting edge wireless products and services to medium and large corporations. Net. Wireless was Nextel’s largest Nationwide Distributor with over 250 employees. Mr. Wilkins managed Net Wireless from a startup with under $100, 000 in starting capital to negotiating the sale of the company with a revenue run rate of over $38, 000. Dave started with Nextel during the launch of their 1 st digital market in the U. S. and received the #1 management awards in Southern California including Top Regional Sales Manager and the Commitment to Excellence Award. Mr. Wilkins studied business at both Loyola Marymount University and the University of Southern California Craig has 25 years of sales and business management experience with a variety of startups and privately held companies. Mr. Wilkins is currently working as the VP/CFO of Zinc Air, Inc. Previously, Craig was the founder and President/CEO of Acceptance Capital Mortgage Corporation, which was the 11 th largest mortgage broker in the United States in 2007 and continues to operate today. Craig was also a founder and principal owner in Net. Wireless and managed the eastern United States while developing the corporate account team. When Net. Wireless sold to Bearcom, Craig managed the combined corporate account teams for the company. Prior to his work at Net. Wireless, Craig was the Director of Sales for CSI Financial, the second largest purchaser of hospital receivables in the United States. Craig has a BA in Finance from University of Montana and completed his graduate studies in Economics.

Technical Team Kevin Witt, Chief Technology Officer Kevin Witt started Semitool’s Disruptive Technology group in 2006 to focus and streamline development efforts on enabling technologies for the semiconductor and other technology fields. He joined Semitool in 2001 as the Director of Business Development for the Electrochemical Deposition (ECD) group and engineered Semitool’s resurgence in the memory copper plating market while expanding the portfolio of new ECD processes. He has held global marketing positions at Rodel and Solution Technology, and manufacturing engineering positions at AMD (memory and logic) for copper deposition, CMP, wet cleans, diffusion and as a SEMATECH assignee for post-CMP cleans. He was involved with the start-up of AMD’s fabs 25 and 30 in Austin, TX and Dresden, Germany respectively. He started his formal technical career in 1989 at Perkin-Elmer in the analytical instrumentation division. Kevin holds an MS degree in Materials Science and Engineering, and a BS in Physics, both from the Rochester Institute of Technology. John Cooper, Ph. D. , Research Scientist Dr. Cooper received his Ph. D. in Chemistry at the University of California at Berkeley (1975) in the Chemical Engineering group of Prof. Charles Tobias. He has conducted R&D in diverse topics of electrochemical science and engineering for 30 years, including research on fuel cells and batteries using reactive-metal or elemental carbon anodes. Recently, he directed projects at the Lawrence Livermore National Laboratory that are developing practical fuel cells of high efficiency for use in distributed power generation as well as specialty carbon batteries and fuel cells. His current research is directed towards the development of fuel cells that convert coal or petroleum coke chars to electric power at efficiencies of 70 -80% HHV. He is the author of 120+ papers and 20+ patents, primarily in the fields of electrochemical energy conversion, electrochemical processes, and laser materials. He has recently retired from Lawrence Livermore National Laboratory, where he was Senior Scientist for Energy Technologies in the Chemistry and Materials Science Directorate.

Technical Team Kevin Witt, Chief Technology Officer Kevin Witt started Semitool’s Disruptive Technology group in 2006 to focus and streamline development efforts on enabling technologies for the semiconductor and other technology fields. He joined Semitool in 2001 as the Director of Business Development for the Electrochemical Deposition (ECD) group and engineered Semitool’s resurgence in the memory copper plating market while expanding the portfolio of new ECD processes. He has held global marketing positions at Rodel and Solution Technology, and manufacturing engineering positions at AMD (memory and logic) for copper deposition, CMP, wet cleans, diffusion and as a SEMATECH assignee for post-CMP cleans. He was involved with the start-up of AMD’s fabs 25 and 30 in Austin, TX and Dresden, Germany respectively. He started his formal technical career in 1989 at Perkin-Elmer in the analytical instrumentation division. Kevin holds an MS degree in Materials Science and Engineering, and a BS in Physics, both from the Rochester Institute of Technology. John Cooper, Ph. D. , Research Scientist Dr. Cooper received his Ph. D. in Chemistry at the University of California at Berkeley (1975) in the Chemical Engineering group of Prof. Charles Tobias. He has conducted R&D in diverse topics of electrochemical science and engineering for 30 years, including research on fuel cells and batteries using reactive-metal or elemental carbon anodes. Recently, he directed projects at the Lawrence Livermore National Laboratory that are developing practical fuel cells of high efficiency for use in distributed power generation as well as specialty carbon batteries and fuel cells. His current research is directed towards the development of fuel cells that convert coal or petroleum coke chars to electric power at efficiencies of 70 -80% HHV. He is the author of 120+ papers and 20+ patents, primarily in the fields of electrochemical energy conversion, electrochemical processes, and laser materials. He has recently retired from Lawrence Livermore National Laboratory, where he was Senior Scientist for Energy Technologies in the Chemistry and Materials Science Directorate.

Grid Storage Zinc Redox Technology § Begin With the End in Mind § Low Cost – Zinc Redox will provide grid storage at a cost below existing storage technologies. § Green Technology – Zinc Redox is the greenest battery solution with all reactants being “sewerable”. § National Security – Zinc Redox uses abundant and locally controlled natural resources. § Scalable – Zinc Redox can be scaled up to meet storage demands in excess of 100 MWs § Durability – Zinc Redox’s expected lifespan is 20 years with scheduled period maintenance.

Grid Storage Zinc Redox Technology § Begin With the End in Mind § Low Cost – Zinc Redox will provide grid storage at a cost below existing storage technologies. § Green Technology – Zinc Redox is the greenest battery solution with all reactants being “sewerable”. § National Security – Zinc Redox uses abundant and locally controlled natural resources. § Scalable – Zinc Redox can be scaled up to meet storage demands in excess of 100 MWs § Durability – Zinc Redox’s expected lifespan is 20 years with scheduled period maintenance.

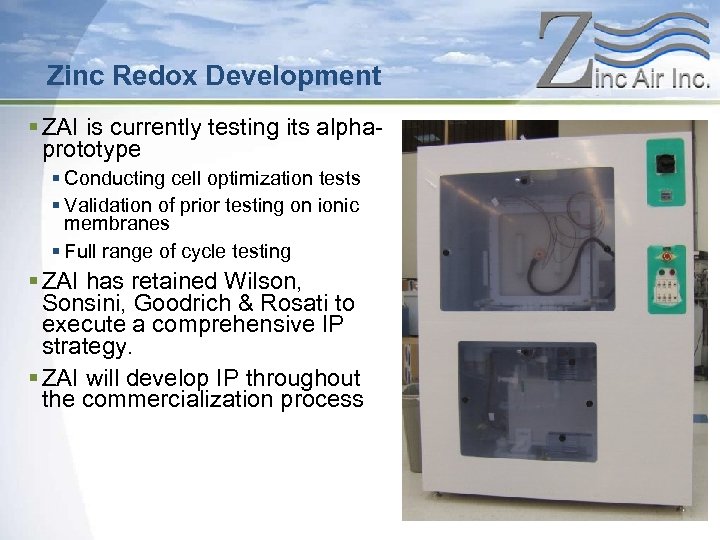

Zinc Redox Development § ZAI is currently testing its alphaprototype § Conducting cell optimization tests § Validation of prior testing on ionic membranes § Full range of cycle testing § ZAI has retained Wilson, Sonsini, Goodrich & Rosati to execute a comprehensive IP strategy. § ZAI will develop IP throughout the commercialization process

Zinc Redox Development § ZAI is currently testing its alphaprototype § Conducting cell optimization tests § Validation of prior testing on ionic membranes § Full range of cycle testing § ZAI has retained Wilson, Sonsini, Goodrich & Rosati to execute a comprehensive IP strategy. § ZAI will develop IP throughout the commercialization process

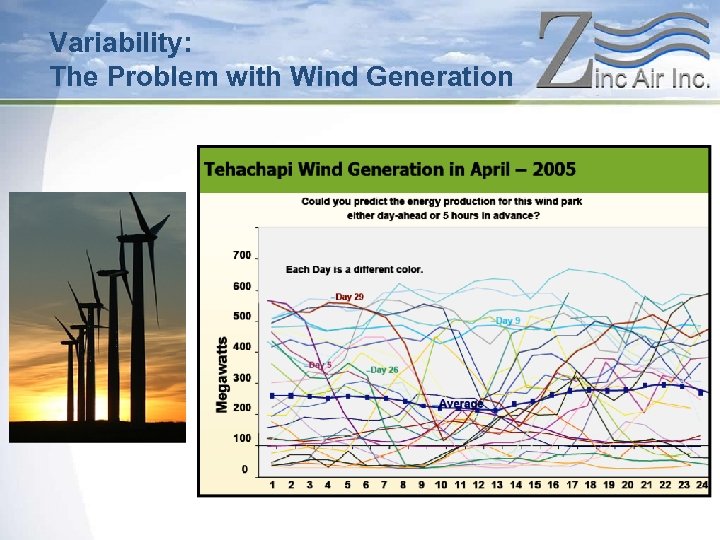

Variability: The Problem with Wind Generation

Variability: The Problem with Wind Generation

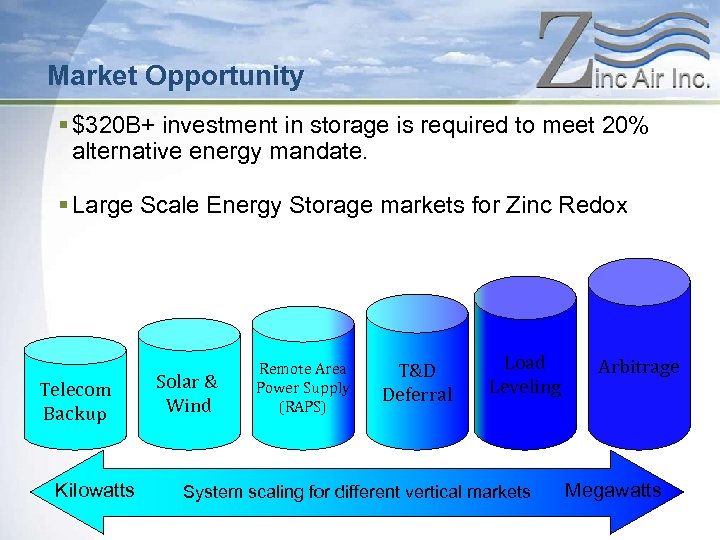

Market Opportunity § $320 B+ investment in storage is required to meet 20% alternative energy mandate. § Large Scale Energy Storage markets for Zinc Redox MW Telecom Backup Kilowatts Solar & Wind Remote Area Power Supply (RAPS) T&D Deferral Load Leveling System scaling for different vertical markets Arbitrage Megawatts

Market Opportunity § $320 B+ investment in storage is required to meet 20% alternative energy mandate. § Large Scale Energy Storage markets for Zinc Redox MW Telecom Backup Kilowatts Solar & Wind Remote Area Power Supply (RAPS) T&D Deferral Load Leveling System scaling for different vertical markets Arbitrage Megawatts

Market Opportunity Wind Power Load Shifting TAM estimated at $200 B (DOE Estimate*) “Hours-to-days of power for daily energy peak shifting. For this application power capacity on the order of 200 GW and 1, 000 GW-hr would necessary for up to 20% integration of renewables. ” Statement from ARPA-GRIDS Grant Redox Flow Battery Price: $1 M for a 4 MW-Hr system

Market Opportunity Wind Power Load Shifting TAM estimated at $200 B (DOE Estimate*) “Hours-to-days of power for daily energy peak shifting. For this application power capacity on the order of 200 GW and 1, 000 GW-hr would necessary for up to 20% integration of renewables. ” Statement from ARPA-GRIDS Grant Redox Flow Battery Price: $1 M for a 4 MW-Hr system

Market Opportunity Firming/Smoothing TAM estimated at $5 B (DOE Estimate*) “Minutes-to-hours for smoothing and firming intermittent power from renewable generation. For this application, reserve power for up to one hour duration providing standby support at a power rating on the order of 20% of the power from renewable sources, currently at 25 GW nationally yields a total storage capacity of 5 GWh needed today. . ” Statement from ARPA-GRIDS Grant Redox Flow Battery Price: $1 M for a 4 MW-Hr system

Market Opportunity Firming/Smoothing TAM estimated at $5 B (DOE Estimate*) “Minutes-to-hours for smoothing and firming intermittent power from renewable generation. For this application, reserve power for up to one hour duration providing standby support at a power rating on the order of 20% of the power from renewable sources, currently at 25 GW nationally yields a total storage capacity of 5 GWh needed today. . ” Statement from ARPA-GRIDS Grant Redox Flow Battery Price: $1 M for a 4 MW-Hr system

Flow Batteries Are Best Suited For Grid Storage - Cost Basis Metal Air

Flow Batteries Are Best Suited For Grid Storage - Cost Basis Metal Air

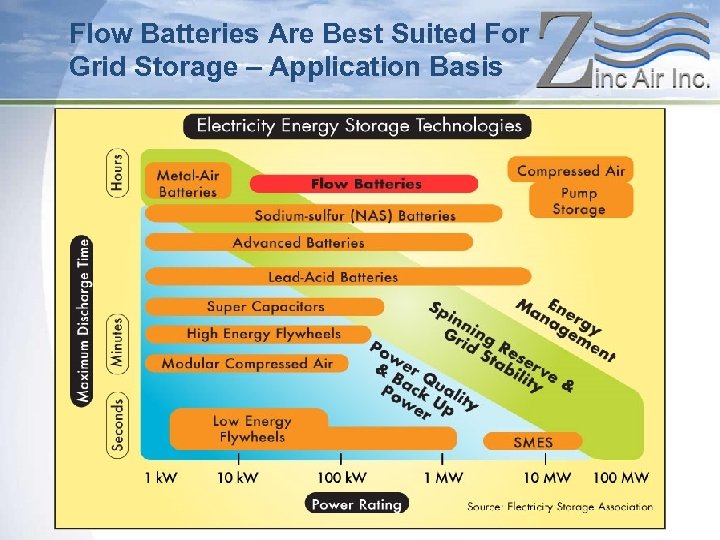

Flow Batteries Are Best Suited For Grid Storage – Application Basis

Flow Batteries Are Best Suited For Grid Storage – Application Basis

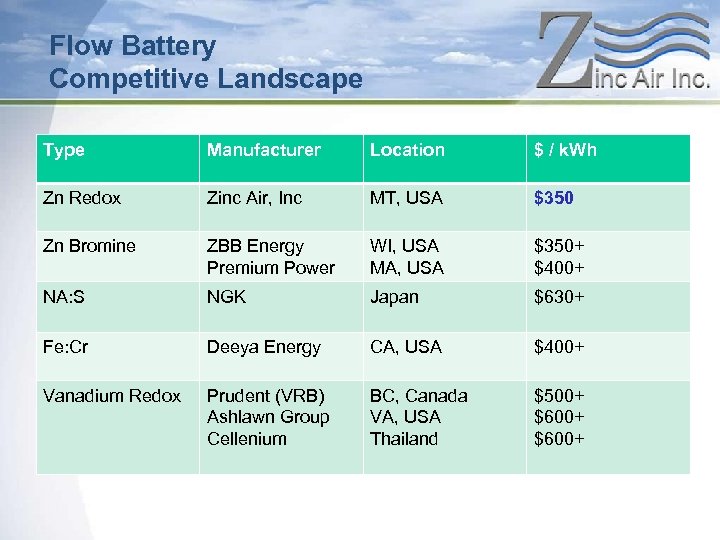

Flow Battery Competitive Landscape Type Manufacturer Location $ / k. Wh Zn Redox Zinc Air, Inc MT, USA $350 Zn Bromine ZBB Energy Premium Power WI, USA MA, USA $350+ $400+ NA: S NGK Japan $630+ Fe: Cr Deeya Energy CA, USA $400+ Vanadium Redox Prudent (VRB) Ashlawn Group Cellenium BC, Canada VA, USA Thailand $500+ $600+

Flow Battery Competitive Landscape Type Manufacturer Location $ / k. Wh Zn Redox Zinc Air, Inc MT, USA $350 Zn Bromine ZBB Energy Premium Power WI, USA MA, USA $350+ $400+ NA: S NGK Japan $630+ Fe: Cr Deeya Energy CA, USA $400+ Vanadium Redox Prudent (VRB) Ashlawn Group Cellenium BC, Canada VA, USA Thailand $500+ $600+

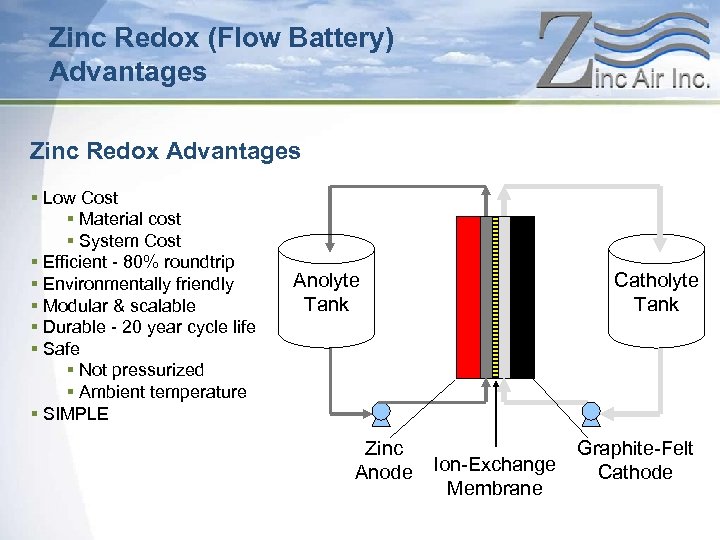

Zinc Redox (Flow Battery) Advantages Zinc Redox Advantages § Low Cost § Material cost § System Cost § Efficient - 80% roundtrip § Environmentally friendly § Modular & scalable § Durable - 20 year cycle life § Safe § Not pressurized § Ambient temperature § SIMPLE Anolyte Tank Zinc Anode Catholyte Tank Ion-Exchange Membrane Graphite-Felt Cathode

Zinc Redox (Flow Battery) Advantages Zinc Redox Advantages § Low Cost § Material cost § System Cost § Efficient - 80% roundtrip § Environmentally friendly § Modular & scalable § Durable - 20 year cycle life § Safe § Not pressurized § Ambient temperature § SIMPLE Anolyte Tank Zinc Anode Catholyte Tank Ion-Exchange Membrane Graphite-Felt Cathode

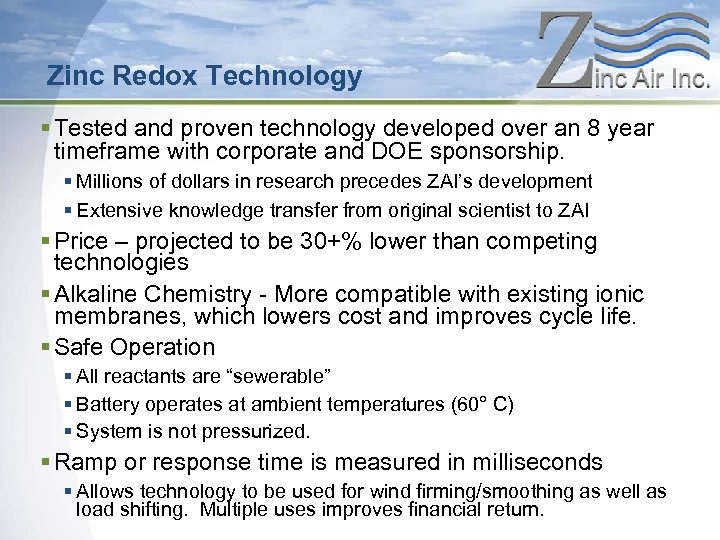

Zinc Redox Technology § Tested and proven technology developed over an 8 year timeframe with corporate and DOE sponsorship. § Millions of dollars in research precedes ZAI’s development § Extensive knowledge transfer from original scientist to ZAI § Price – projected to be 30+% lower than competing technologies § Alkaline Chemistry - More compatible with existing ionic membranes, which lowers cost and improves cycle life. § Safe Operation § All reactants are “sewerable” § Battery operates at ambient temperatures (60° C) § System is not pressurized. § Ramp or response time is measured in milliseconds § Allows technology to be used for wind firming/smoothing as well as load shifting. Multiple uses improves financial return.

Zinc Redox Technology § Tested and proven technology developed over an 8 year timeframe with corporate and DOE sponsorship. § Millions of dollars in research precedes ZAI’s development § Extensive knowledge transfer from original scientist to ZAI § Price – projected to be 30+% lower than competing technologies § Alkaline Chemistry - More compatible with existing ionic membranes, which lowers cost and improves cycle life. § Safe Operation § All reactants are “sewerable” § Battery operates at ambient temperatures (60° C) § System is not pressurized. § Ramp or response time is measured in milliseconds § Allows technology to be used for wind firming/smoothing as well as load shifting. Multiple uses improves financial return.

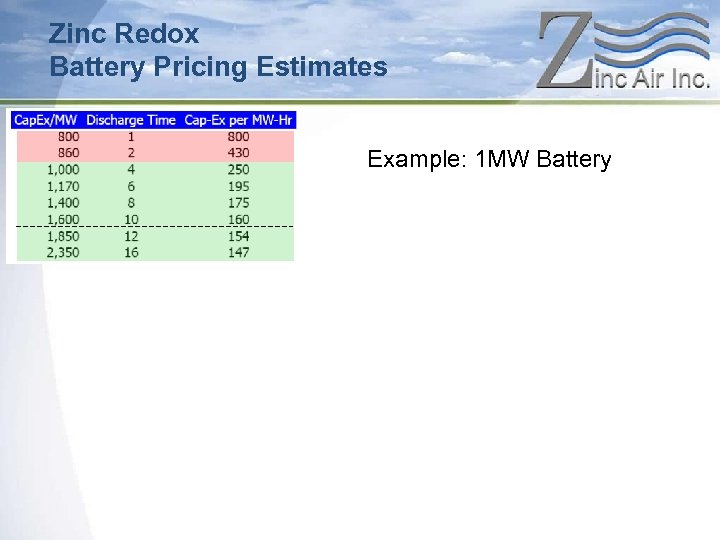

Zinc Redox Battery Pricing Estimates Example: 1 MW Battery

Zinc Redox Battery Pricing Estimates Example: 1 MW Battery

Zinc Redox Preliminary Specification Summary Preliminary analysis suggests the optimum configuration will be: Cell Size: ~ 4 ft 2 cell (24”x 24”) Stack Voltage: >300 VDC For a 1 MW, 4 -hour discharge system with 24” cell, operating at 480 VDC, the system current is projected to be 260 A per stack with a total of 9 stacks each having 276 cells. (Total power off 1. 124 MW) Assuming each cell is 1” thick, a stack would measure 4’x 23’. Two tanks having a capacity of 1300 gallons would be required. System materials cost is estimated to be $381 K, or approximately $84. 60/KW-Hr in capital.

Zinc Redox Preliminary Specification Summary Preliminary analysis suggests the optimum configuration will be: Cell Size: ~ 4 ft 2 cell (24”x 24”) Stack Voltage: >300 VDC For a 1 MW, 4 -hour discharge system with 24” cell, operating at 480 VDC, the system current is projected to be 260 A per stack with a total of 9 stacks each having 276 cells. (Total power off 1. 124 MW) Assuming each cell is 1” thick, a stack would measure 4’x 23’. Two tanks having a capacity of 1300 gallons would be required. System materials cost is estimated to be $381 K, or approximately $84. 60/KW-Hr in capital.

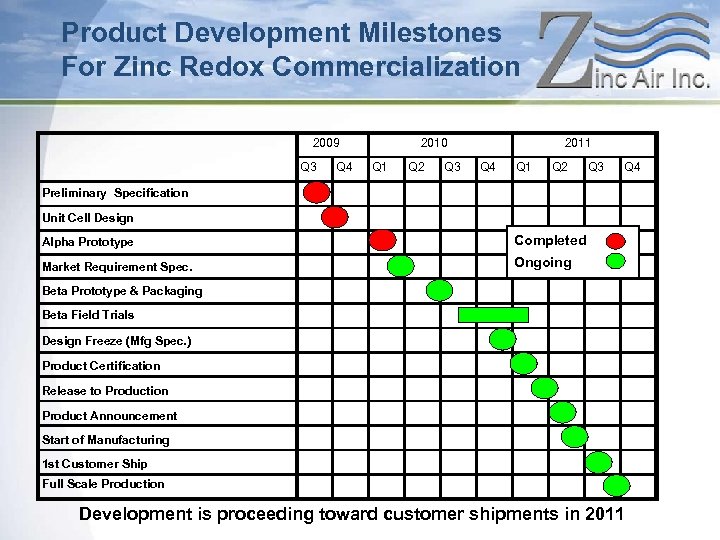

Product Development Milestones For Zinc Redox Commercialization 2009 Q 3 Q 4 2010 Q 1 Q 2 Q 3 2011 Q 4 Q 1 Q 2 Q 3 Q 4 Preliminary Specification Unit Cell Design Alpha Prototype Completed Market Requirement Spec. Ongoing Beta Prototype & Packaging Beta Field Trials Design Freeze (Mfg Spec. ) Product Certification Release to Production Product Announcement Start of Manufacturing 1 st Customer Ship Full Scale Production Development is proceeding toward customer shipments in 2011

Product Development Milestones For Zinc Redox Commercialization 2009 Q 3 Q 4 2010 Q 1 Q 2 Q 3 2011 Q 4 Q 1 Q 2 Q 3 Q 4 Preliminary Specification Unit Cell Design Alpha Prototype Completed Market Requirement Spec. Ongoing Beta Prototype & Packaging Beta Field Trials Design Freeze (Mfg Spec. ) Product Certification Release to Production Product Announcement Start of Manufacturing 1 st Customer Ship Full Scale Production Development is proceeding toward customer shipments in 2011

Thank You For Your Consideration Contact Information 215 Browns Gulch Road Kalispell, MT 59901 Dave Wilkins, President/CEO dave. wilkins@zincairinc. com (406) 249 -7930

Thank You For Your Consideration Contact Information 215 Browns Gulch Road Kalispell, MT 59901 Dave Wilkins, President/CEO dave. wilkins@zincairinc. com (406) 249 -7930