872942f43d205e876e0204f867edbef4.ppt

- Количество слайдов: 65

Землеройные инструменты для горных работ компании Bradken

© 2011 BRADKEN®

Землеройные инструменты для горных работ компании Bradken Система землеройных инструментов Bradken для капитального строительства и горных работ Twistlok. TM предлагает полный спектр конструкций коронок для всех типов пород. Система Bradken Twistlok предлагает улучшенную фиксацию коронки к носу адаптера, максимизируя сопряжение коронки с адаптером для наилучшего распределения силы копания по всей системе. Bradken уверен в том, что, используя уникальный металлический фиксатор с резиновым сайлентом, обеспечивающим максимальную фиксацию в течение всего срока службы коронки, система Twistlok гарантирует превосходную производительность в самых экстремальных условиях, . Нет необходимости в смене вашей существующей системы, т. к. коронка Twistlok просто одевается на ваш адаптер с винтообразным носом и закрепляется фиксатором Bradken может также предложить специфический дизайн коронок, спроектированных индивидуально именно для вашего месторождения. Представитель компании Bradken в вашем регионе может рассказать вам об оптимизации продукции для условий вашего месторождения. Превосходные характеристики Twistlok обеспечивают бескомпромиссную надежность системы с максимальной производительностью. © 2011 BRADKEN® oto ew h e p of n ts c pla hoto duc Re h p pro wit nted i pa

Землеройные инструменты для горных работ компании Bradken © 2011 BRADKEN®

Землеройные инструменты для горных работ компании Bradken Коронки Bradken Twistlok монгт быть установлены непосредственно на любой адаптер с винтовым носом с использованием нашего блокирующего фиксатора Ваш адаптер Коронки Bradken подходят на все винтовые носы Фиксатор Bradken используется вместе с коронкой Twistlok Особым преимуществом использования системы Bradken Twistlok полностью является добавленная защитная крышка адаптера, крторая обеспечивает ваш адаптер дополнительной защитой, и полный спектр конструкций коронок. Адаптеры Bradken изготовлены из высококачествен-ных материалов и сконструированы для использования в любых условиях работы Защитная крышка Twistlok предоставляет адаптеру дополнительную защиту © 2011 BRADKEN®

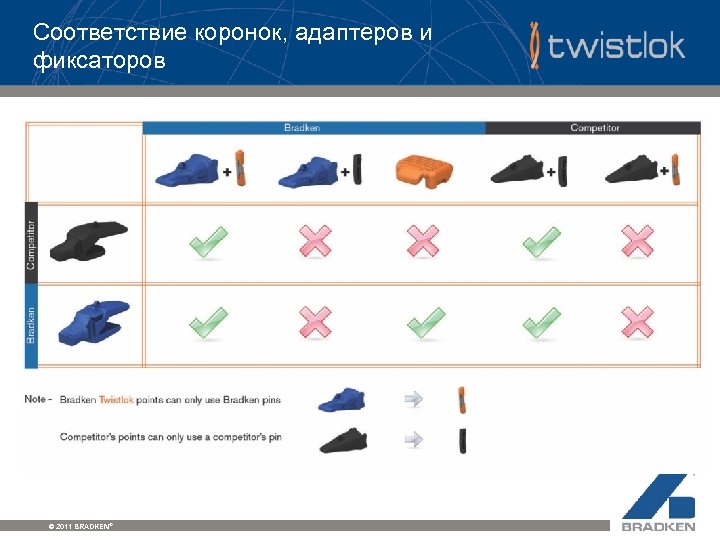

Соответствие коронок, адаптеров и фиксаторов © 2011 BRADKEN®

Землеройные инструменты для горных работ компании Bradken Система адаптеров и коронок для листовых кромок • Доступна в строительных и горных размерах • Адаптеры и короеки для экскаваторов и погрузчиков • Коронки и фиксаторы подходят к существующим адаптерам с винтовым носом • Нет необходимости замены адаптеров • Защитные крышки на адаптерах Bradken ВСЕХ горных размеров (серии T 610 -T 810) © 2011 BRADKEN®

Землеройные инструменты для горных работ компании Bradken • • • Уникальный двухсоставной дизайн Прочная конструкция корпуса фиксатора Цельный блокирующий элемент с прочной резиновой вставкой Фиксатор может быть использован неоднократно Блокирующий элемент может быть заменен Увеличенный блокирующий элемент улучшает удержание коронки © 2011 BRADKEN®

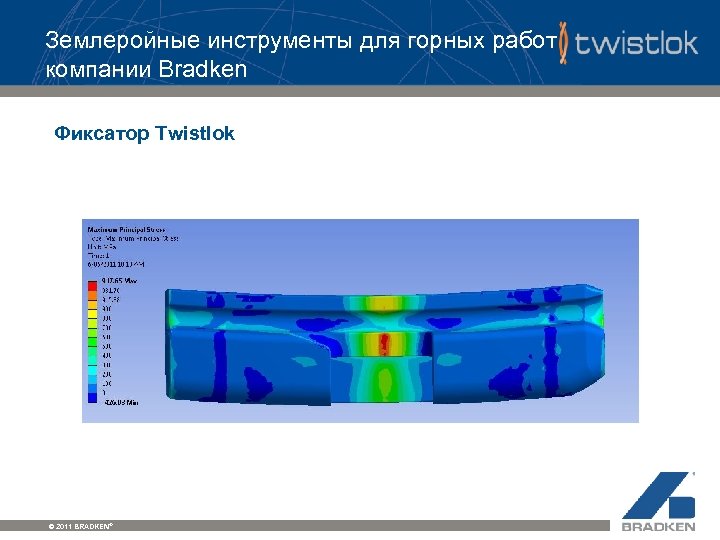

Землеройные инструменты для горных работ компании Bradken Фиксатор Twistlok © 2011 BRADKEN®

Землеройные инструменты для горных работ компании Bradken Характерные выступы на коронке, расположенные сверху и снизу, удерживают фиксатор в коронке Блокирующий механизм расположен на нейтральной оси © 2011 BRADKEN® Задняя кромка блокирующего механизма препятствует выпадению фиксатора

Bradken Mining GET Products Pin “take up” Mechanism Point retention and automatic take-up © 2011 BRADKEN®

Bradken Mining GET Products Site Trials • • • QLD, WA, NT, NSW 14 successful T 710 & T 810 trials Trials useful in identifying any problems with the design Pin Design Evolution © 2011 BRADKEN®

Bradken Mining GET Products Site Trials completed at both hard rock and coal mine sites. © 2011 BRADKEN®

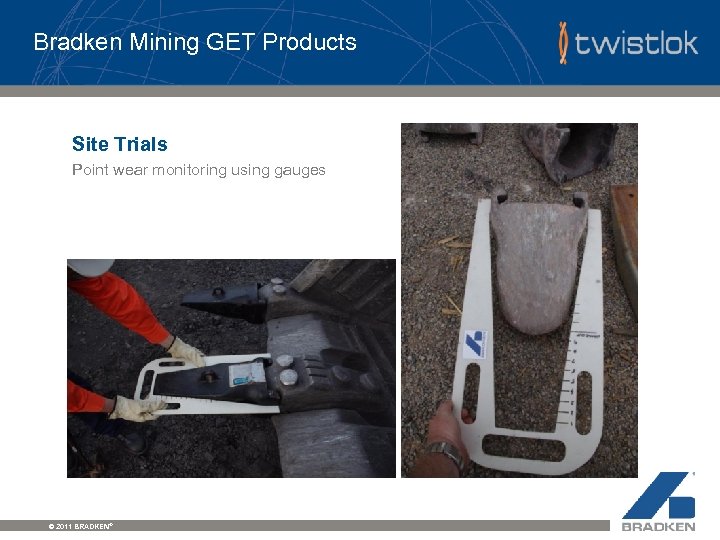

Bradken Mining GET Products Site Trials Point wear monitoring using gauges © 2011 BRADKEN®

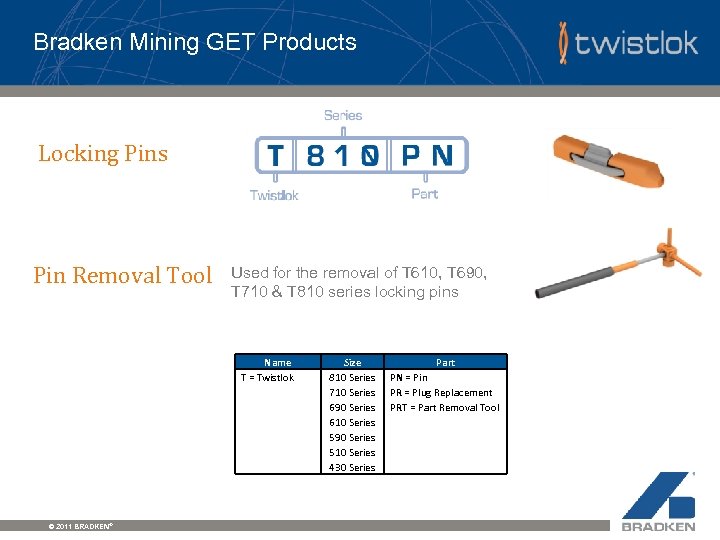

Bradken Mining GET Products Locking Pins Pin Removal Tool Used for the removal of T 610, T 690, T 710 & T 810 series locking pins Name T = Twistlok © 2011 BRADKEN® Size 810 Series 710 Series 690 Series 610 Series 590 Series 510 Series 430 Series Part PN = Pin PR = Plug Replacement PRT = Part Removal Tool

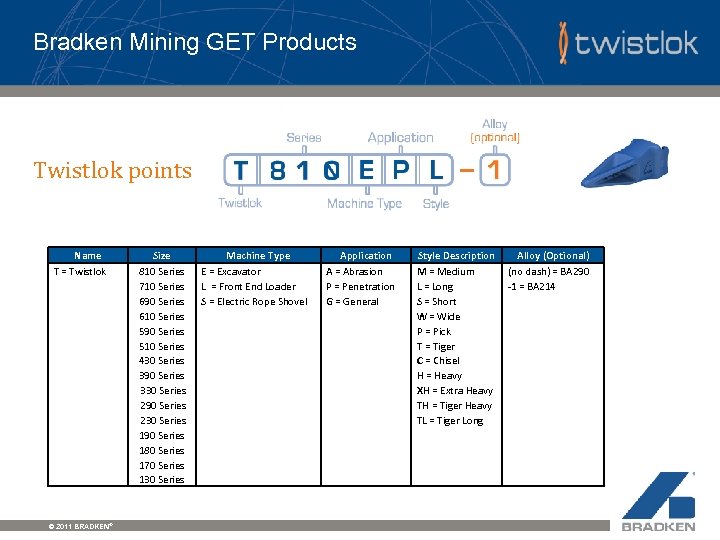

Bradken Mining GET Products Twistlok points Name T = Twistlok © 2011 BRADKEN® Size 810 Series 710 Series 690 Series 610 Series 590 Series 510 Series 430 Series 390 Series 330 Series 290 Series 230 Series 190 Series 180 Series 170 Series 130 Series Machine Type E = Excavator L = Front End Loader S = Electric Rope Shovel Application A = Abrasion P = Penetration G = General Style Description M = Medium L = Long S = Short W = Wide P = Pick T = Tiger C = Chisel H = Heavy XH = Extra Heavy TH = Tiger Heavy TL = Tiger Long Alloy (Optional) (no dash) = BA 290 -1 = BA 214

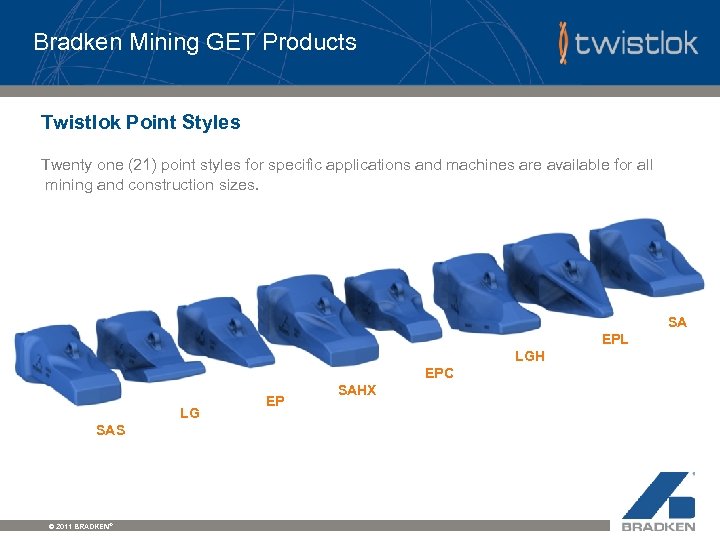

Bradken Mining GET Products Twistlok Point Styles Twenty one (21) point styles for specific applications and machines are available for all mining and construction sizes. SA EPL LGH EPC LG SAS © 2011 BRADKEN® EP SAHX

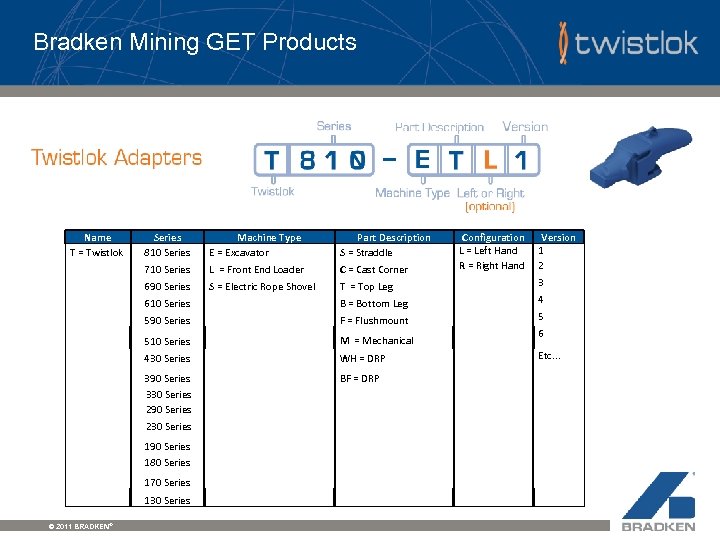

Bradken Mining GET Products Name T = Twistlok Series 810 Series Machine Type E = Excavator Part Description S = Straddle 710 Series L = Front End Loader C = Cast Corner 690 Series S = Electric Rope Shovel T = Top Leg 610 Series 590 Series F = Flushmount 510 Series M = Mechanical 430 Series WH = DRP 390 Series 330 Series 290 Series 230 Series 190 Series 180 Series 170 Series 130 Series © 2011 BRADKEN® B = Bottom Leg BF = DRP Configuration L = Left Hand R = Right Hand Version 1 2 3 4 5 6 Etc. . .

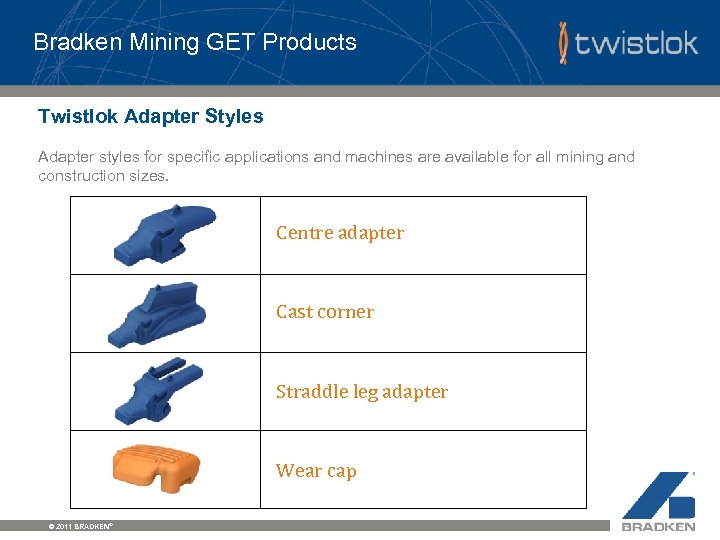

Bradken Mining GET Products Twistlok Adapter Styles Adapter styles for specific applications and machines are available for all mining and construction sizes. Centre adapter Cast corner Straddle leg adapter Wear cap © 2011 BRADKEN®

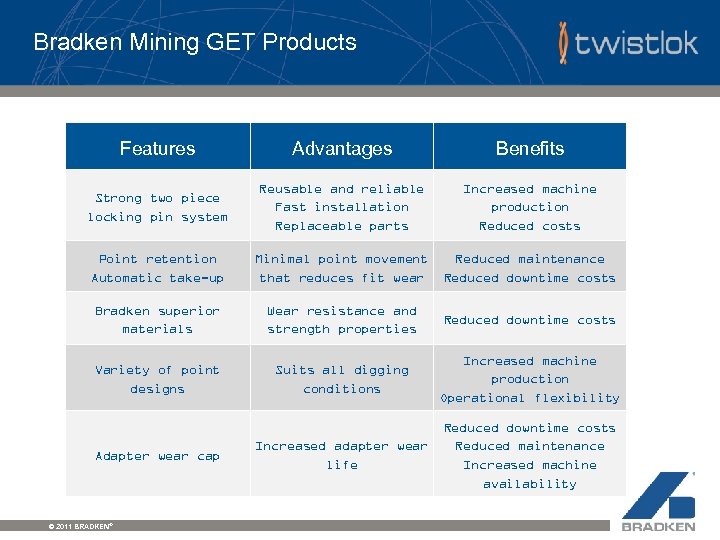

Bradken Mining GET Products Features Advantages Benefits Strong two piece locking pin system Reusable and reliable Fast installation Replaceable parts Increased machine production Reduced costs Point retention Automatic take-up Minimal point movement that reduces fit wear Reduced maintenance Reduced downtime costs Bradken superior materials Wear resistance and strength properties Reduced downtime costs Variety of point designs Suits all digging conditions Increased machine production Operational flexibility Increased adapter wear life Reduced downtime costs Reduced maintenance Increased machine availability Adapter wear cap © 2011 BRADKEN®

Bradken Mining GET Products Hammerless locking pin design COM IN SOO G N 2012 Unlocked Position © 2011 BRADKEN® Locked Position

© 2011 BRADKEN®

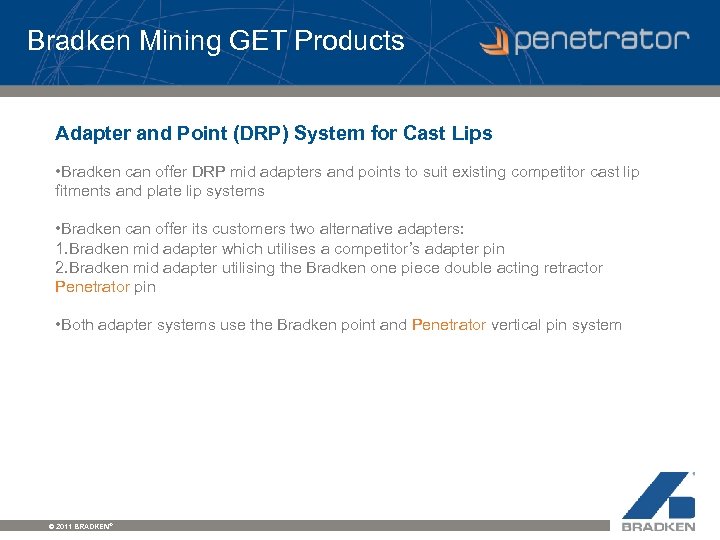

Bradken Mining GET Products Adapter and Point (DRP) System for Cast Lips • Bradken can offer DRP mid adapters and points to suit existing competitor cast lip fitments and plate lip systems • Bradken can offer its customers two alternative adapters: 1. Bradken mid adapter which utilises a competitor’s adapter pin 2. Bradken mid adapter utilising the Bradken one piece double acting retractor Penetrator pin • Both adapter systems use the Bradken point and Penetrator vertical pin system © 2011 BRADKEN®

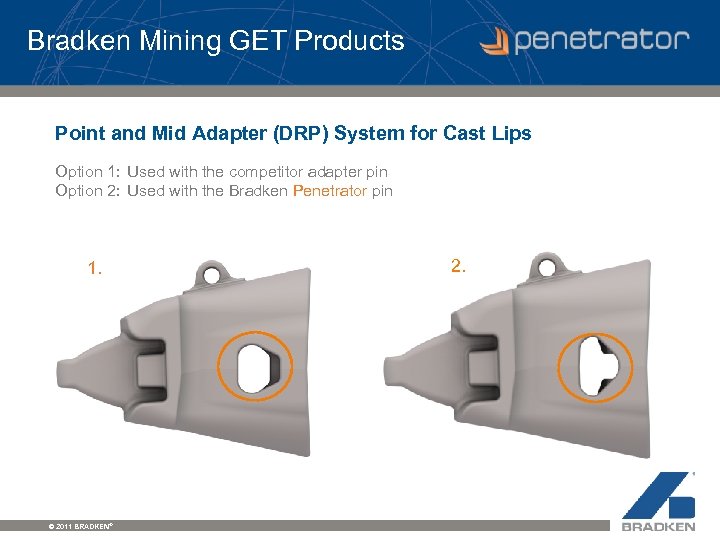

Bradken Mining GET Products Point and Mid Adapter (DRP) System for Cast Lips Option 1: Used with the competitor adapter pin Option 2: Used with the Bradken Penetrator pin 1. © 2011 BRADKEN® 2.

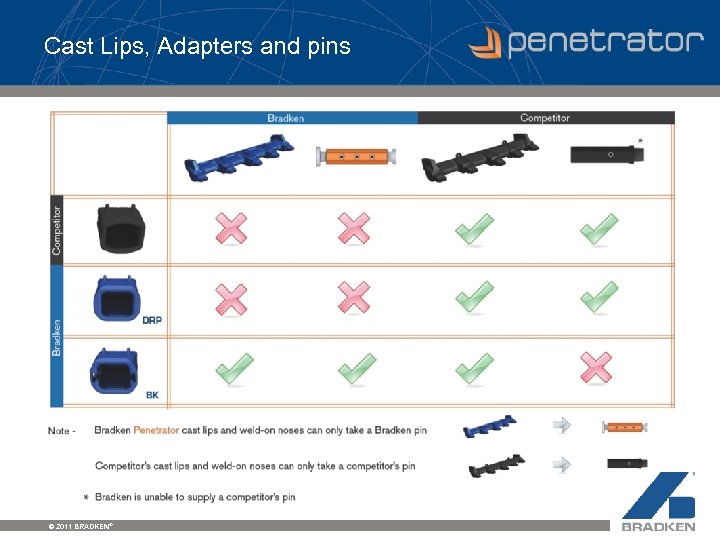

Cast Lips, Adapters and pins © 2011 BRADKEN®

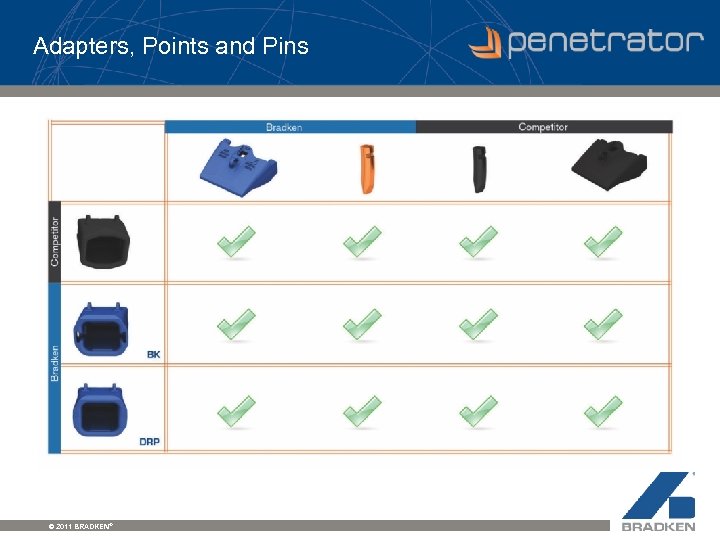

Adapters, Points and Pins © 2011 BRADKEN®

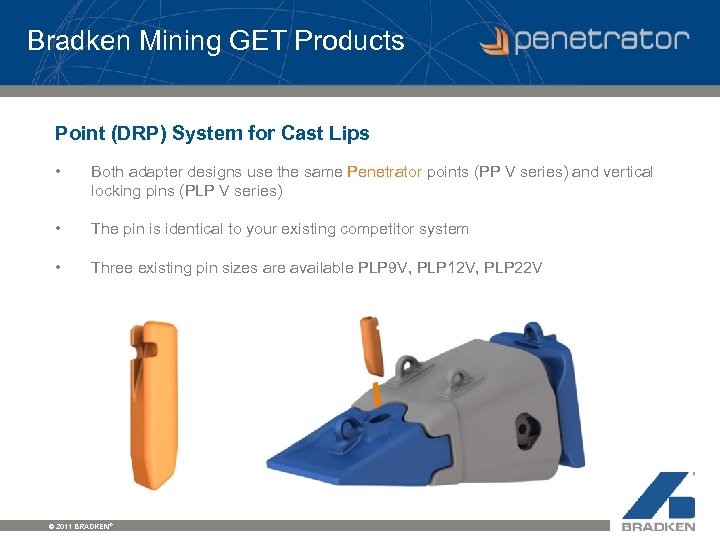

Bradken Mining GET Products Point (DRP) System for Cast Lips • Both adapter designs use the same Penetrator points (PP V series) and vertical locking pins (PLP V series) • The pin is identical to your existing competitor system • Three existing pin sizes are available PLP 9 V, PLP 12 V, PLP 22 V © 2011 BRADKEN®

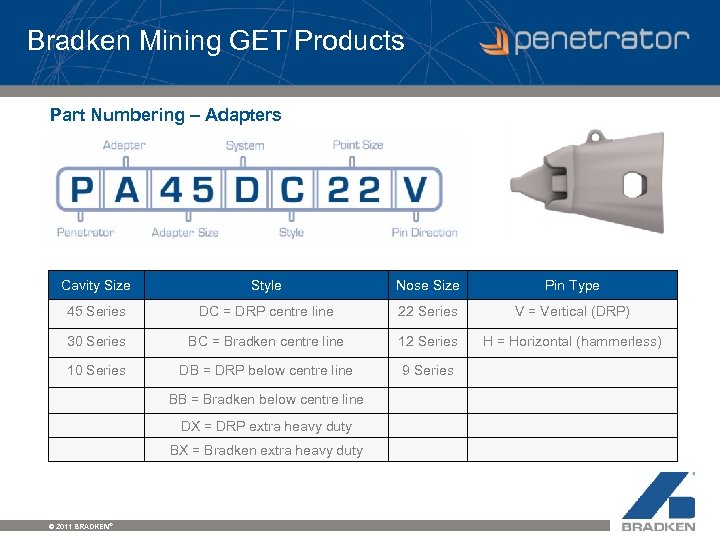

Bradken Mining GET Products Part Numbering – Adapters Cavity Size Style Nose Size Pin Type 45 Series DC = DRP centre line 22 Series V = Vertical (DRP) 30 Series BC = Bradken centre line 12 Series H = Horizontal (hammerless) 10 Series DB = DRP below centre line 9 Series BB = Bradken below centre line DX = DRP extra heavy duty BX = Bradken extra heavy duty © 2011 BRADKEN®

Bradken Mining GET Products Adapter Styles Penetrator Retractor pin used on BC, BB, BX style adapters only PA 30 DC 22 V (DRP Centreline) PA 30 BC 22 V (Bradken Centreline) Part numbers: PA 30 DB 12 V (DRP Below Centreline) © 2011 BRADKEN® • • • PA 45 DX 22 V (DRP Extra Heavy Duty) PLP 10 H PLP 30 H PLP 45 H

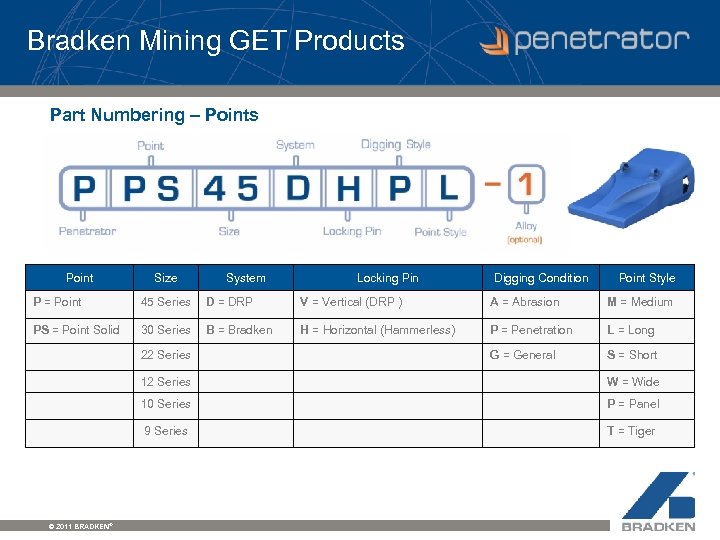

Bradken Mining GET Products Part Numbering – Points Point Size System Locking Pin Digging Condition Point Style P = Point 45 Series D = DRP V = Vertical (DRP ) A = Abrasion M = Medium PS = Point Solid 30 Series B = Bradken H = Horizontal (Hammerless) P = Penetration L = Long G = General S = Short 22 Series 10 Series P = Panel 9 Series © 2011 BRADKEN® W = Wide T = Tiger

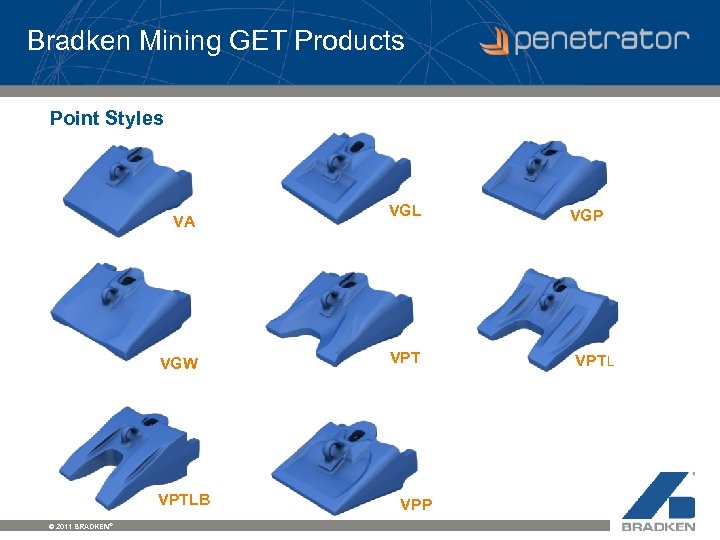

Bradken Mining GET Products Point Styles VA VGW VPTLB © 2011 BRADKEN® VGL VPT VPP VGP VPTL

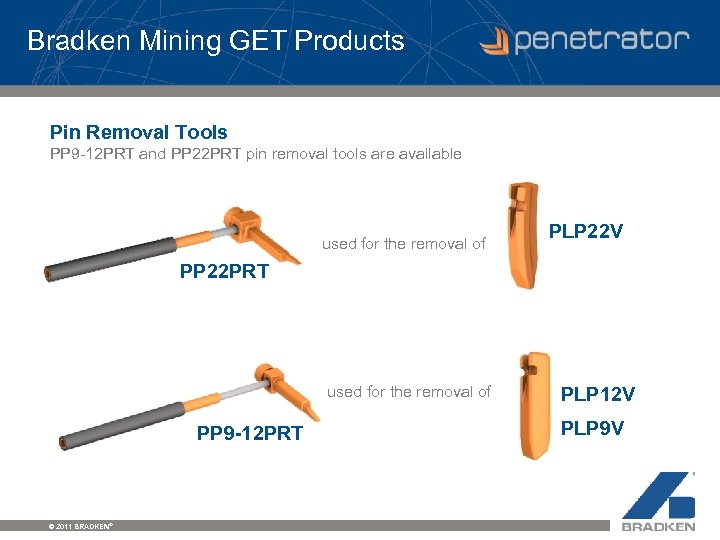

Bradken Mining GET Products Pin Removal Tools PP 9 -12 PRT and PP 22 PRT pin removal tools are available used for the removal of PLP 22 V PP 22 PRT used for the removal of PP 9 -12 PRT © 2011 BRADKEN® PLP 12 V PLP 9 V

Bradken Mining GET Products Field Trials – Bradken Penetrator Pin System © 2011 BRADKEN®

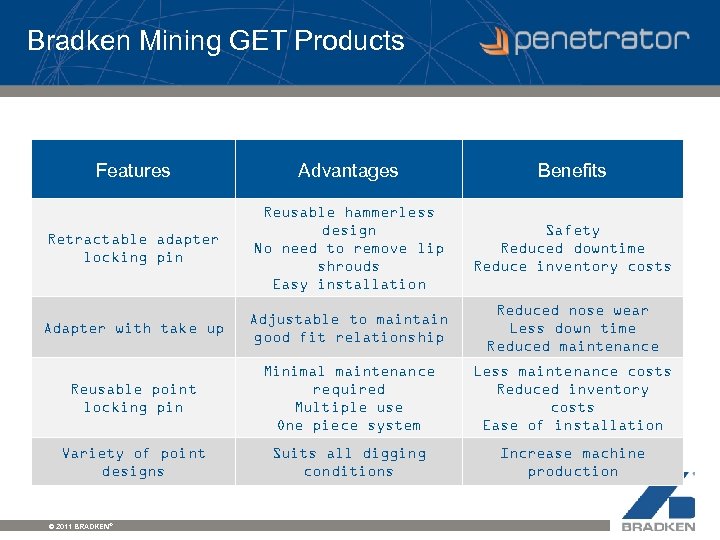

Bradken Mining GET Products Features Advantages Benefits Retractable adapter locking pin Reusable hammerless design No need to remove lip shrouds Easy installation Safety Reduced downtime Reduce inventory costs Adapter with take up Adjustable to maintain good fit relationship Reduced nose wear Less down time Reduced maintenance Reusable point locking pin Minimal maintenance required Multiple use One piece system Less maintenance costs Reduced inventory costs Ease of installation Variety of point designs Suits all digging conditions Increase machine production © 2011 BRADKEN®

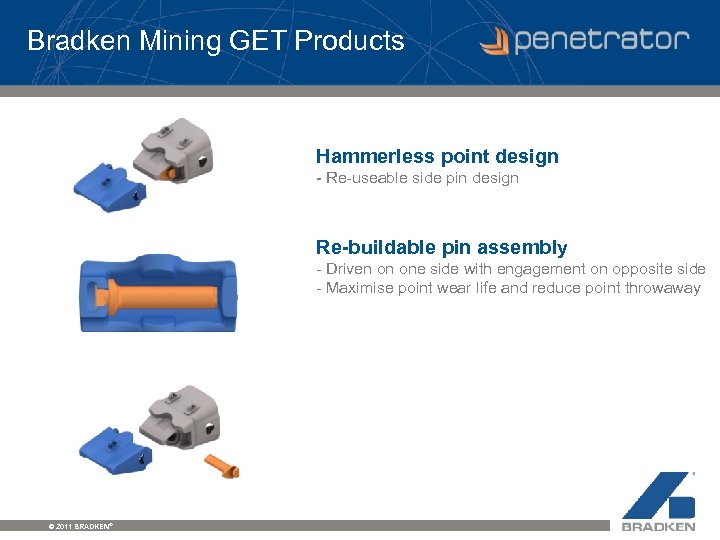

Bradken Mining GET Products Hammerless point design - Re-useable side pin design Re-buildable pin assembly - Driven on one side with engagement on opposite side - Maximise point wear life and reduce point throwaway © 2011 BRADKEN®

© 2011 BRADKEN®

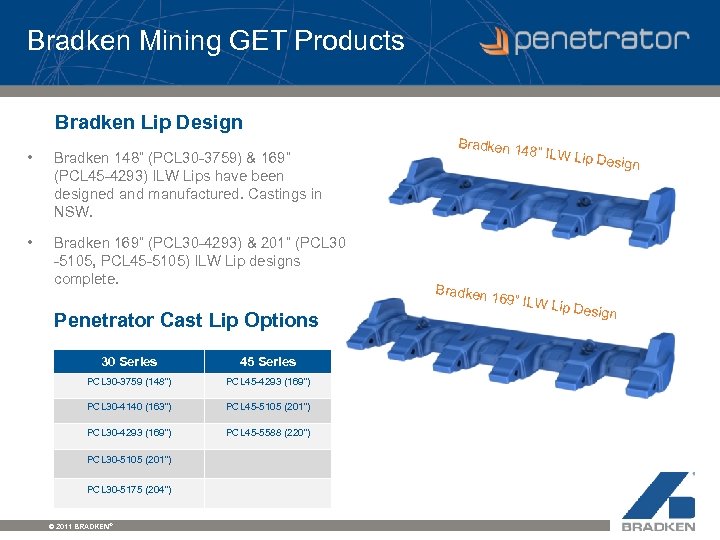

Bradken Mining GET Products Bradken Lip Design • Bradken 148” (PCL 30 -3759) & 169” (PCL 45 -4293) ILW Lips have been designed and manufactured. Castings in NSW. • Bradken 169” (PCL 30 -4293) & 201” (PCL 30 -5105, PCL 45 -5105) ILW Lip designs complete. Penetrator Cast Lip Options 30 Series 45 Series PCL 30 -3759 (148”) PCL 45 -4293 (169”) PCL 30 -4140 (163”) PCL 45 -5105 (201”) PCL 30 -4293 (169”) PCL 45 -5588 (220”) PCL 30 -5105 (201”) PCL 30 -5175 (204”) © 2011 BRADKEN® Bradken 1 48” ILW L ip Bradken 169” ILW Design Lip Desig n

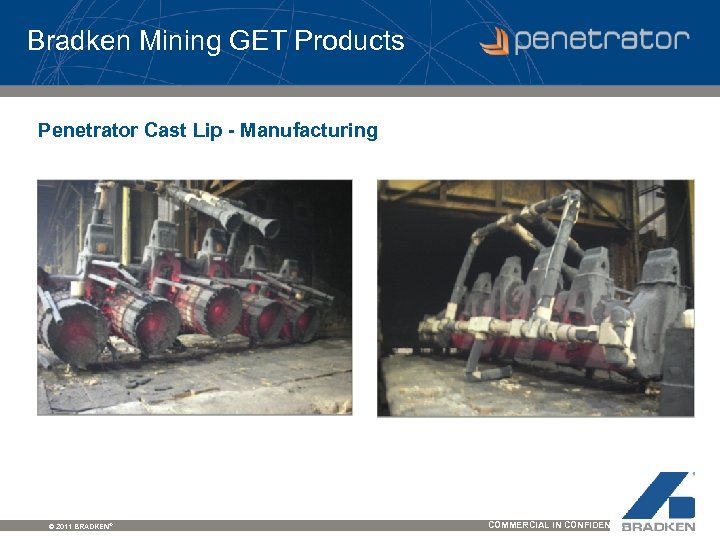

Bradken Mining GET Products Penetrator Cast Lip - Manufacturing © 2011 BRADKEN® COMMERCIAL IN CONFIDENCE

Bradken Mining GET Products Penetrator Cast Lip PCL 30 -3759 © 2011 BRADKEN®

Bradken Mining GET Products Atchison foundry • Lips shall be manufacturing in one piece at Bradken Atchison foundry in North America • Atchison foundry is known for their high quality production of steel castings in AOD melted steel • With 135 years of experience and a rich history in the Industrial, Military, Locomotive Rail, Transit, Mining & Construction markets they are well placed to manufacture high quality cast lips © 2011 BRADKEN®

Bradken Mining GET Products Reverse Engineered Eversharp Lip Reverse Engineered Loadmaster Lip • A range of existing lips were reverse engineered • Features from each lip were reviewed analyzed to access their merit • Features with merit were then integrated into the Bradken lip design © 2011 BRADKEN® Reverse Engineered Pac Lip

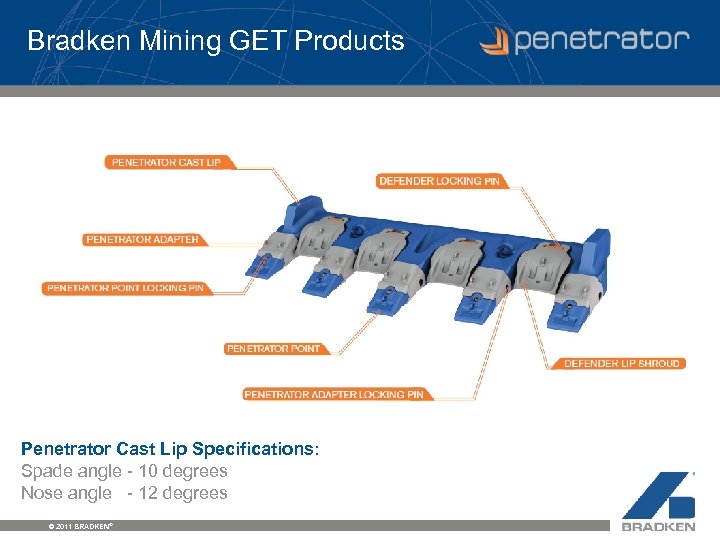

Bradken Mining GET Products Penetrator Cast Lip Specifications: Spade angle - 10 degrees Nose angle - 12 degrees © 2011 BRADKEN®

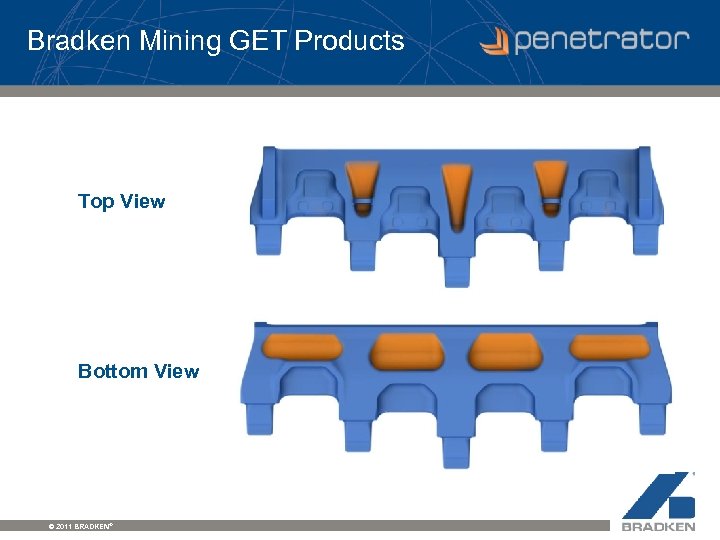

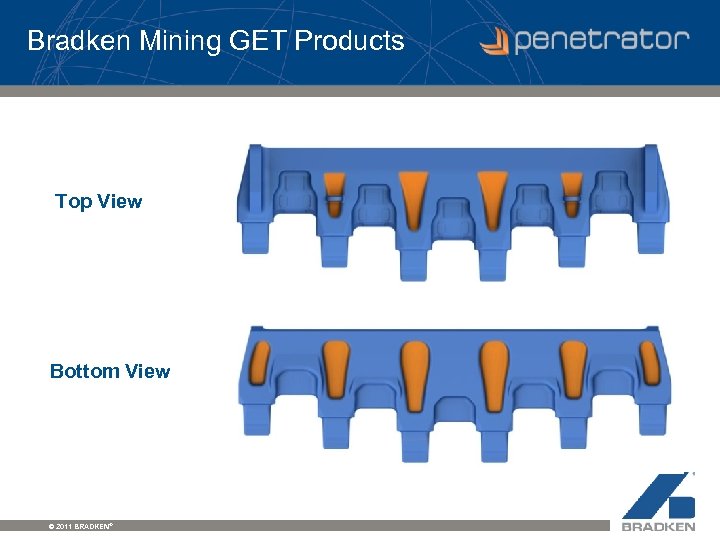

Bradken Mining GET Products Top View Bottom View © 2011 BRADKEN®

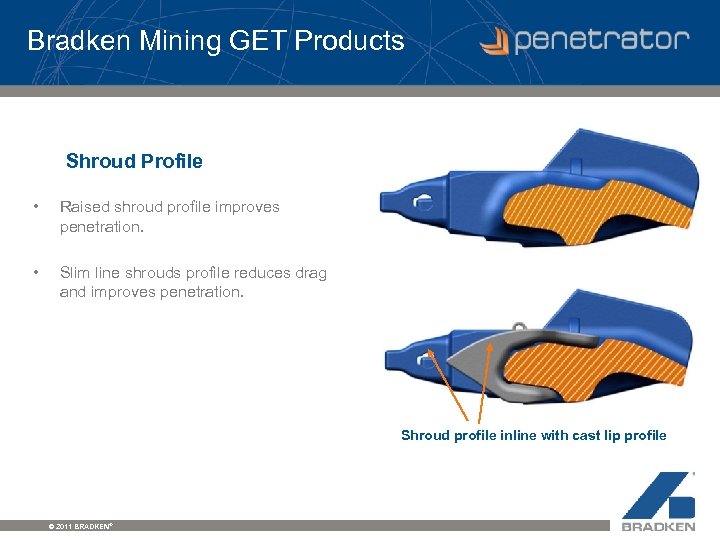

Bradken Mining GET Products Shroud Profile • Raised shroud profile improves penetration. • Slim line shrouds profile reduces drag and improves penetration. Shroud profile inline with cast lip profile © 2011 BRADKEN®

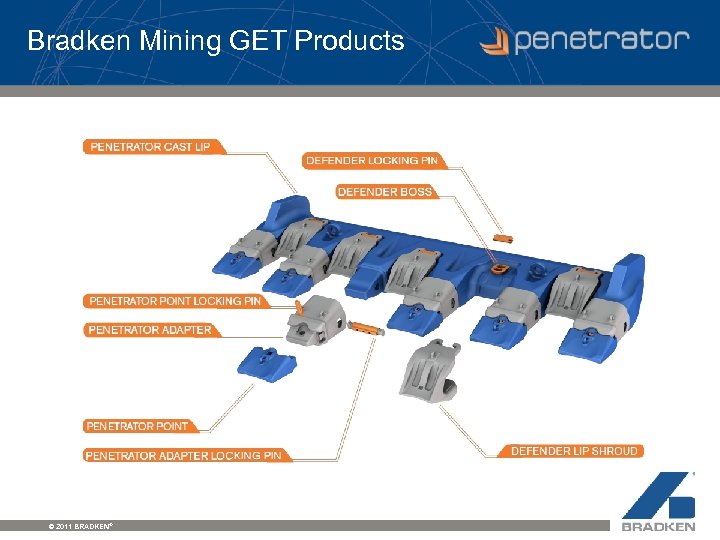

Bradken Mining GET Products © 2011 BRADKEN®

Bradken Mining GET Products Top View Bottom View © 2011 BRADKEN®

© 2011 BRADKEN®

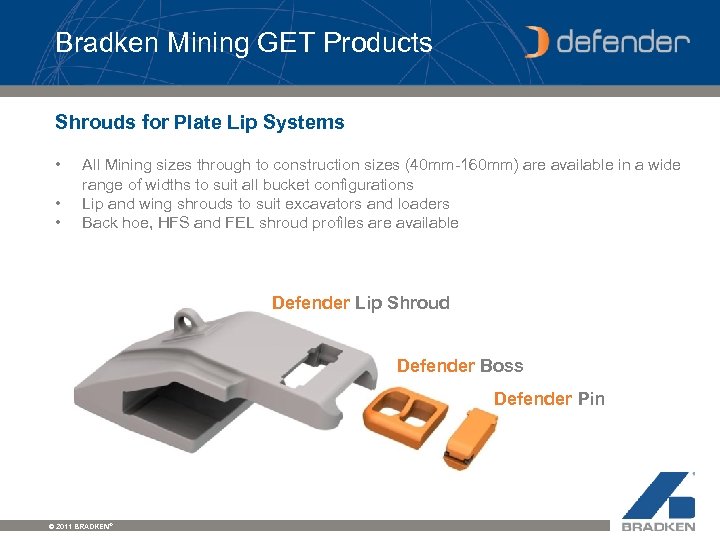

Bradken Mining GET Products Shrouds for Plate Lip Systems • • • All Mining sizes through to construction sizes (40 mm-160 mm) are available in a wide range of widths to suit all bucket configurations Lip and wing shrouds to suit excavators and loaders Back hoe, HFS and FEL shroud profiles are available Defender Lip Shroud Defender Boss Defender Pin © 2011 BRADKEN®

Bradken Mining GET Products Shrouds for Plate Lip Systems • • • Shrouds are designed to suit the competitor “T” profile bosses on existing lip systems There is no need to replace existing competitor “T” profile bosses on bucket lips If existing bosses are worn they can be replaced with a new Bradken Defender “Dovetail” boss Bradken Defender shroud with competitor “T” profile boss © 2011 BRADKEN® Bradken Defender shroud with Bradken boss

Lip Shrouds, Bosses & Pins © 2011 BRADKEN®

Bradken Mining GET Products Shrouds for Plate Lip Systems Profiles are designed to suit all machines and applications. HFS External Profile © 2011 BRADKEN® Back Hoe External Profile

Bradken Mining GET Products Shrouds for Plate Lip Systems Profiles are designed to suit all machines and applications. 80 mm wing shroud with alternative retention systems © 2011 BRADKEN® 80 mm wing shroud

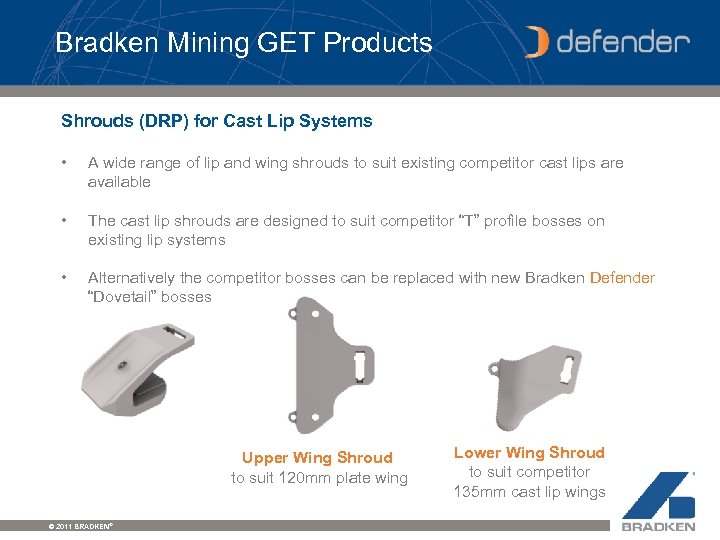

Bradken Mining GET Products Shrouds (DRP) for Cast Lip Systems • A wide range of lip and wing shrouds to suit existing competitor cast lips are available • The cast lip shrouds are designed to suit competitor “T” profile bosses on existing lip systems • Alternatively the competitor bosses can be replaced with new Bradken Defender “Dovetail” bosses Upper Wing Shroud to suit 120 mm plate wing © 2011 BRADKEN® Lower Wing Shroud to suit competitor 135 mm cast lip wings

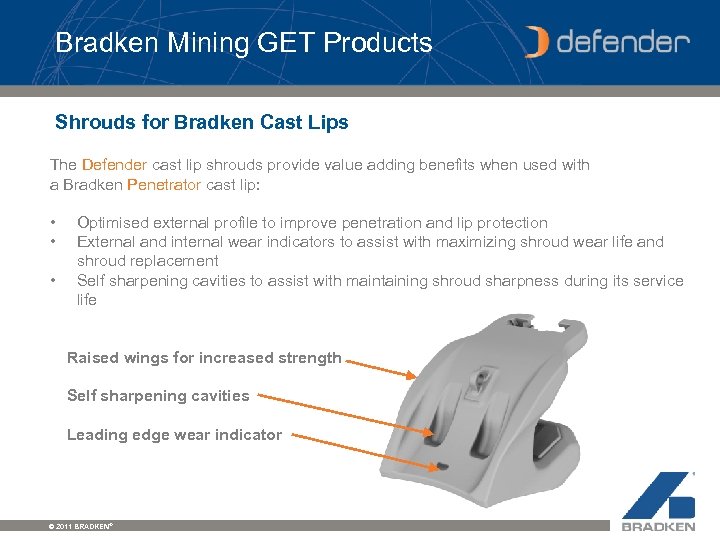

Bradken Mining GET Products Shrouds for Bradken Cast Lips The Defender cast lip shrouds provide value adding benefits when used with a Bradken Penetrator cast lip: • • • Optimised external profile to improve penetration and lip protection External and internal wear indicators to assist with maximizing shroud wear life and shroud replacement Self sharpening cavities to assist with maintaining shroud sharpness during its service life Raised wings for increased strength Self sharpening cavities Leading edge wear indicator © 2011 BRADKEN®

Bradken Mining GET Products Shrouds for Bradken Penetrator Cast Lips • • Unique concave sidewalls for maximum lip protection Elevated leading edge profile for optimum penetration © 2011 BRADKEN®

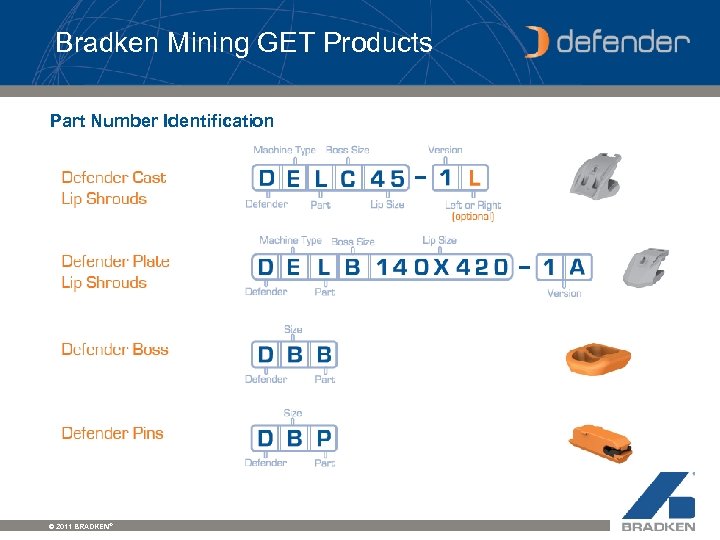

Bradken Mining GET Products Part Number Identification © 2011 BRADKEN®

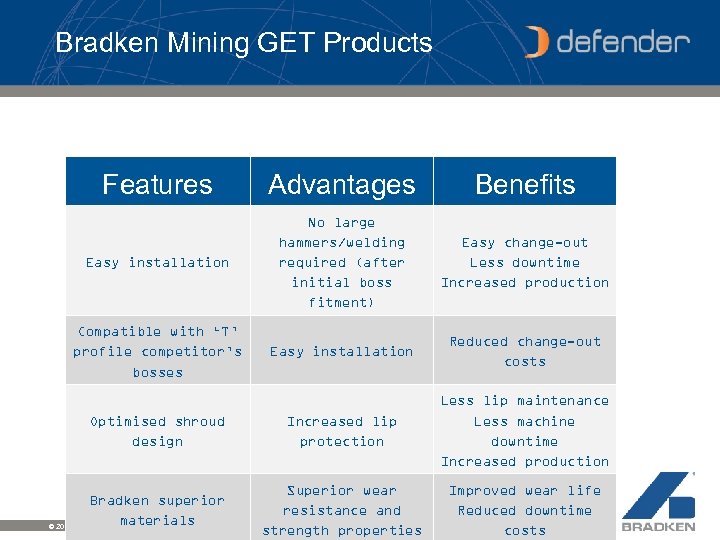

Bradken Mining GET Products Features Advantages Benefits Easy installation No large hammers/welding required (after initial boss fitment) Easy change-out Less downtime Increased production Compatible with ‘T’ profile competitor’s bosses Easy installation Reduced change-out costs Increased lip protection Less lip maintenance Less machine downtime Increased production Superior wear resistance and strength properties Improved wear life Reduced downtime costs Optimised shroud design Bradken superior materials © 2011 BRADKEN ®

Bradken Mining GET Products Hammerless Locking Systems • Bradken has a number of hammerless shroud retention systems with and without take-up under development. • Our goal is to design a system to suit existing shrouds. © 2011 BRADKEN®

PROUD TO BELONG Click to edit date By <insert name >

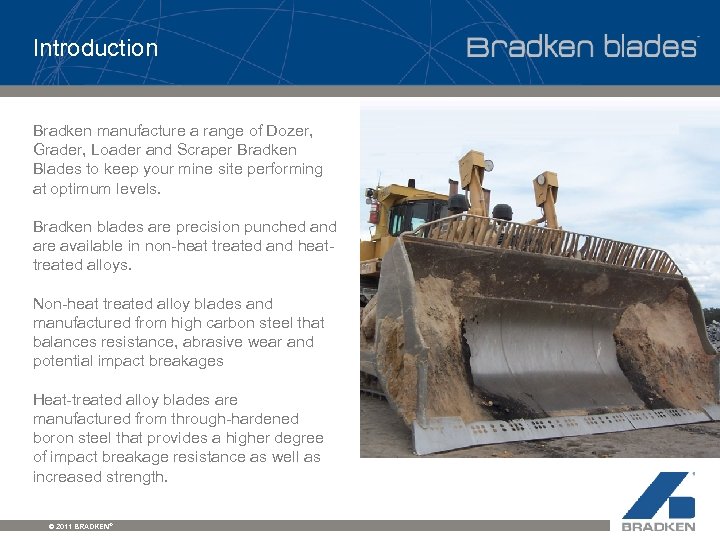

Introduction Bradken manufacture a range of Dozer, Grader, Loader and Scraper Bradken Blades to keep your mine site performing at optimum levels. Bradken blades are precision punched and are available in non-heat treated and heattreated alloys. Non-heat treated alloy blades and manufactured from high carbon steel that balances resistance, abrasive wear and potential impact breakages Heat-treated alloy blades are manufactured from through-hardened boron steel that provides a higher degree of impact breakage resistance as well as increased strength. © 2011 BRADKEN®

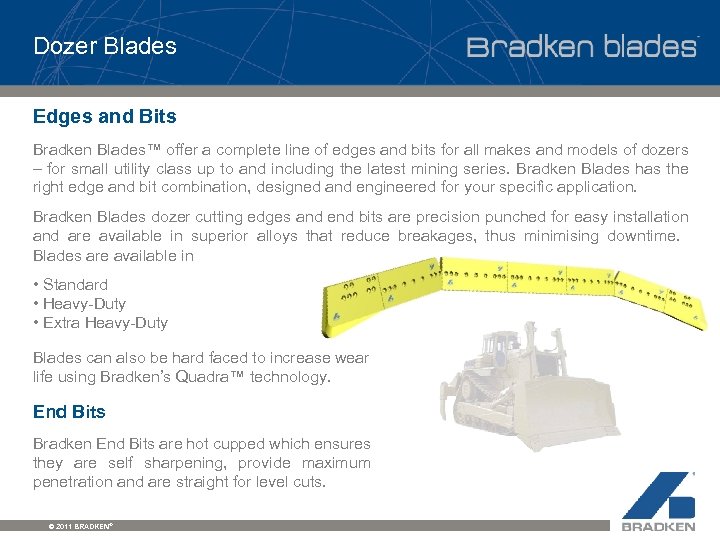

Dozer Blades Edges and Bits Bradken Blades™ offer a complete line of edges and bits for all makes and models of dozers – for small utility class up to and including the latest mining series. Bradken Blades has the right edge and bit combination, designed and engineered for your specific application. Bradken Blades dozer cutting edges and end bits are precision punched for easy installation and are available in superior alloys that reduce breakages, thus minimising downtime. Blades are available in • Standard • Heavy-Duty • Extra Heavy-Duty Blades can also be hard faced to increase wear life using Bradken’s Quadra™ technology. End Bits Bradken End Bits are hot cupped which ensures they are self sharpening, provide maximum penetration and are straight for level cuts. © 2011 BRADKEN®

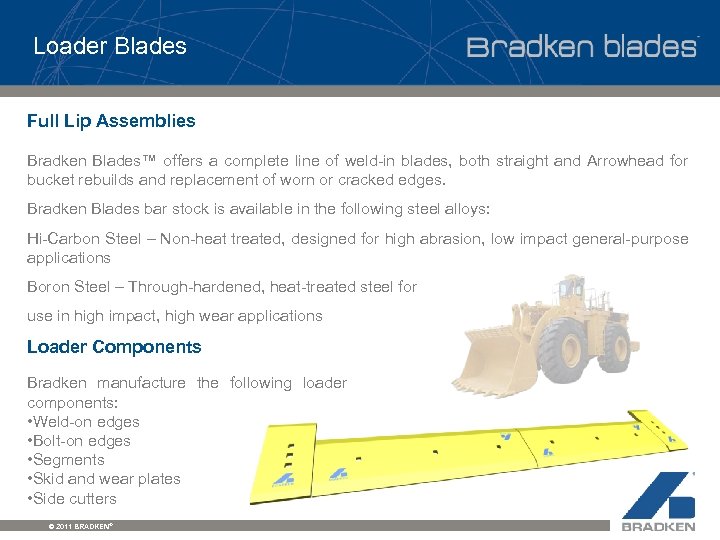

Loader Blades Full Lip Assemblies Bradken Blades™ offers a complete line of weld-in blades, both straight and Arrowhead for bucket rebuilds and replacement of worn or cracked edges. Bradken Blades bar stock is available in the following steel alloys: Hi-Carbon Steel – Non-heat treated, designed for high abrasion, low impact general-purpose applications Boron Steel – Through-hardened, heat-treated steel for use in high impact, high wear applications Loader Components Bradken manufacture the following loader components: • Weld-on edges • Bolt-on edges • Segments • Skid and wear plates • Side cutters © 2011 BRADKEN®

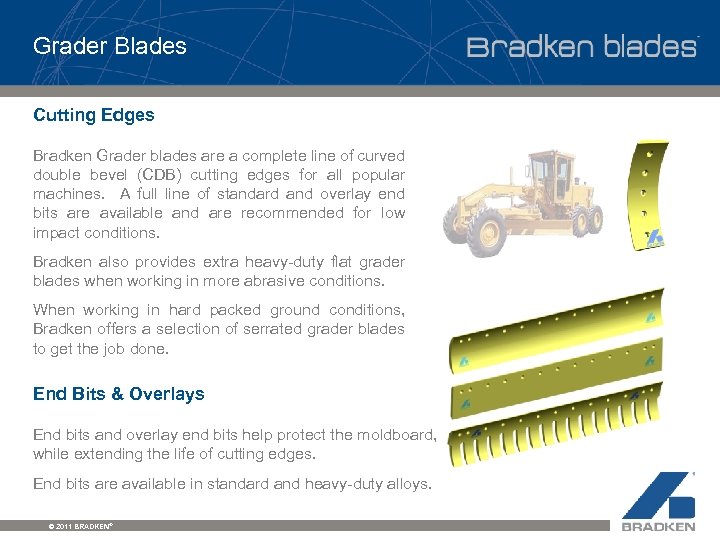

Grader Blades Cutting Edges Bradken Grader blades are a complete line of curved double bevel (CDB) cutting edges for all popular machines. A full line of standard and overlay end bits are available and are recommended for low impact conditions. Bradken also provides extra heavy-duty flat grader blades when working in more abrasive conditions. When working in hard packed ground conditions, Bradken offers a selection of serrated grader blades to get the job done. End Bits & Overlays End bits and overlay end bits help protect the moldboard, while extending the life of cutting edges. End bits are available in standard and heavy-duty alloys. © 2011 BRADKEN®

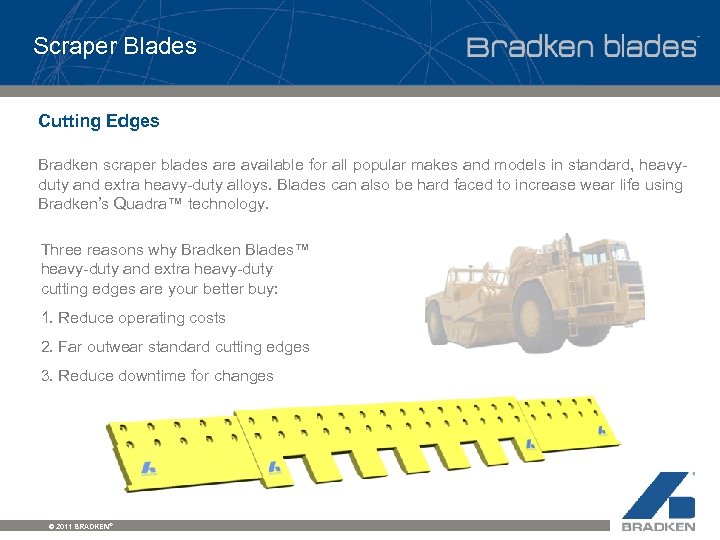

Scraper Blades Cutting Edges Bradken scraper blades are available for all popular makes and models in standard, heavyduty and extra heavy-duty alloys. Blades can also be hard faced to increase wear life using Bradken’s Quadra™ technology. Three reasons why Bradken Blades™ heavy-duty and extra heavy-duty cutting edges are your better buy: 1. Reduce operating costs 2. Far outwear standard cutting edges 3. Reduce downtime for changes © 2011 BRADKEN®

Thank You

872942f43d205e876e0204f867edbef4.ppt