fdc4b93c03dc05c59e4a1d24b3a49560.ppt

- Количество слайдов: 21

Your Technology Experts… 2017

Your Technology Experts… 2017

Your Full Service, Time Sensitive, Printed Circuit Board Solution Located in the Heart of Silicon Valley, Streamline Circuits is your premier PCB manufacture of leading edge Technology and Innovation. We offer full service solutions for Rigid PCB’s, Flex PCB’s and Rigid-Flex PCB’s in both Ultra Quick Turn options along with Standard Production lead times. You will find that Streamline holds the necessary certifications to insure the highest standards of workmanship while supporting your companies specifications. Mil / Aerospace Tele. Com Data. Com Medical Industrial 2

Your Full Service, Time Sensitive, Printed Circuit Board Solution Located in the Heart of Silicon Valley, Streamline Circuits is your premier PCB manufacture of leading edge Technology and Innovation. We offer full service solutions for Rigid PCB’s, Flex PCB’s and Rigid-Flex PCB’s in both Ultra Quick Turn options along with Standard Production lead times. You will find that Streamline holds the necessary certifications to insure the highest standards of workmanship while supporting your companies specifications. Mil / Aerospace Tele. Com Data. Com Medical Industrial 2

STREAMLINE CIRCUIT CORP’S FACILITY • Manufacturing all levels of technology – • The facility was established in 1982 – • • Delivery convenience for out of state customers Located in Silicon Valley – Located in Silicon Valley Complete manufacturing process under one roof 1 mile from the San Jose Airport – • New management team installed September 2003 70, 000 sq. ft. PCB manufacturing facility – • Time sensitive prototyping through production Short car ride away for pick up & deliveries Financially secure in current market conditions – Low cost infrastructure 3

STREAMLINE CIRCUIT CORP’S FACILITY • Manufacturing all levels of technology – • The facility was established in 1982 – • • Delivery convenience for out of state customers Located in Silicon Valley – Located in Silicon Valley Complete manufacturing process under one roof 1 mile from the San Jose Airport – • New management team installed September 2003 70, 000 sq. ft. PCB manufacturing facility – • Time sensitive prototyping through production Short car ride away for pick up & deliveries Financially secure in current market conditions – Low cost infrastructure 3

Management and their Experience Chuck Dimick –CEO / Founder • Over 35 years of experience in PCB manufacturing. Former CEO of Dynamic Details Inc. and founder of the company's predecessor, Dynamic Circuits Inc. (1991) Greg Halvorson – President / Founder • Over 33 years of experience in PCB manufacturing. Former VP of Operations of Dynamic Details Inc. and Dynamic Circuits Inc. Tom Doslak – Sr. Vice President of Sales & Marketing / Founder • Over 25 years of industry experience. Former Director of Sales for Braztek Intl. and Western Regional Sales Manager for Dynamic Details Inc. Gary Greenberg – VP of Operations • Over 31 years of industry experience. Previously VP of West Coast Operations for the EMS Division. Has held roles in Operations, Engineering, and Quality at DDI, Teradyne and Raytheon. Glenn Holland – Director of Quality • Over 31 years of Industry experience. Previously held position of Director of Quality at TTM / Via Systems. Has experience in Operations, Assembly, Engineering and Quality. Mike Trammel – Director of Engineering • Over 27 years of industry experience. Former Director of Engineering for DDI and Dynavision. 12 years of Materials Application Engineering and R&D experience.

Management and their Experience Chuck Dimick –CEO / Founder • Over 35 years of experience in PCB manufacturing. Former CEO of Dynamic Details Inc. and founder of the company's predecessor, Dynamic Circuits Inc. (1991) Greg Halvorson – President / Founder • Over 33 years of experience in PCB manufacturing. Former VP of Operations of Dynamic Details Inc. and Dynamic Circuits Inc. Tom Doslak – Sr. Vice President of Sales & Marketing / Founder • Over 25 years of industry experience. Former Director of Sales for Braztek Intl. and Western Regional Sales Manager for Dynamic Details Inc. Gary Greenberg – VP of Operations • Over 31 years of industry experience. Previously VP of West Coast Operations for the EMS Division. Has held roles in Operations, Engineering, and Quality at DDI, Teradyne and Raytheon. Glenn Holland – Director of Quality • Over 31 years of Industry experience. Previously held position of Director of Quality at TTM / Via Systems. Has experience in Operations, Assembly, Engineering and Quality. Mike Trammel – Director of Engineering • Over 27 years of industry experience. Former Director of Engineering for DDI and Dynavision. 12 years of Materials Application Engineering and R&D experience.

Management and their Experience Cont. JR Ramirez – Production Manager / Founder • Over 35 years of industry experience. Former Production Manager for both Dynamic Details Inc. and Dynamic Circuits Inc. Louis Oliveira – Pre-Production Engineering Manager • Over 28 years of CAM “Computer Aided Manufacturing” experience to Streamline Circuits. Previously was Pre-Production Engineering at Dynamic Details. Held various key positions at Davila International Circuits. Phil Ramon – Pre-Production Engineering Supervisor • Over 37 years of experience in the PCB industry. Previously worked for 16 years on the management team for South Bay Circuits, more than 9 years as Pre-Production Engineering Manager and 10 years at CTS Printex.

Management and their Experience Cont. JR Ramirez – Production Manager / Founder • Over 35 years of industry experience. Former Production Manager for both Dynamic Details Inc. and Dynamic Circuits Inc. Louis Oliveira – Pre-Production Engineering Manager • Over 28 years of CAM “Computer Aided Manufacturing” experience to Streamline Circuits. Previously was Pre-Production Engineering at Dynamic Details. Held various key positions at Davila International Circuits. Phil Ramon – Pre-Production Engineering Supervisor • Over 37 years of experience in the PCB industry. Previously worked for 16 years on the management team for South Bay Circuits, more than 9 years as Pre-Production Engineering Manager and 10 years at CTS Printex.

CUSTOMER SERVICE SUPPORT • Customer Service (24 hours - 7 days a week) – Sales, Engineering, Manufacturing and Quality • Dedicated customer service readily available-our support group’s located onsite in the facility • Quick response to all requests such as: Inside Sales Customer Support – – Job status Delivery pull-in Quantity Increases Engineering design modification 6

CUSTOMER SERVICE SUPPORT • Customer Service (24 hours - 7 days a week) – Sales, Engineering, Manufacturing and Quality • Dedicated customer service readily available-our support group’s located onsite in the facility • Quick response to all requests such as: Inside Sales Customer Support – – Job status Delivery pull-in Quantity Increases Engineering design modification 6

PROACTIVE ENGINEERING SERVICES • Manufacturing Capabilities – Prototype though volume – All time sensitive builds • DFM (Design for Manufacturability) Cam Valor Stations – – – DFM Software (reviews in 10 minutes) Net list compare to customer data Custom Verification programs Looking for customer design error In plan Smart data Collection System • Controlled Impedance Verification 4 Laser Direct Imaging units – Stack up assistance – Copper distribution – Material verification 7

PROACTIVE ENGINEERING SERVICES • Manufacturing Capabilities – Prototype though volume – All time sensitive builds • DFM (Design for Manufacturability) Cam Valor Stations – – – DFM Software (reviews in 10 minutes) Net list compare to customer data Custom Verification programs Looking for customer design error In plan Smart data Collection System • Controlled Impedance Verification 4 Laser Direct Imaging units – Stack up assistance – Copper distribution – Material verification 7

Pre-Production Engineering Services • “In Plan” planning software • Customer Specific Rules Based Automation • Valor front end CAM (Unlimited Seats) • Industry Standard for front end engineering • Stack up consultations, Service Offered No Charge $ • Insight Frontline DFM’s, Service Offered No Charge $ • Tech Seminars /Webinars • Material Science, Latest in Laminates and Preg’s • R&D, Building the Toughest to Gain the Knowledge When you need it, we will be ready! 8

Pre-Production Engineering Services • “In Plan” planning software • Customer Specific Rules Based Automation • Valor front end CAM (Unlimited Seats) • Industry Standard for front end engineering • Stack up consultations, Service Offered No Charge $ • Insight Frontline DFM’s, Service Offered No Charge $ • Tech Seminars /Webinars • Material Science, Latest in Laminates and Preg’s • R&D, Building the Toughest to Gain the Knowledge When you need it, we will be ready! 8

QUALITY REASSURANCE • Net list compare prior to MFG – • Front End DRC (design rule check) – • • Verifying inner & outer layers X-Ray Verification – • After Lam (Inspecta), After Drilling Cross Section Verification – • Hole Integrity True-Chem Software Controlled Impedance Testing – • TDR test of panel coupons 100% Net List Test On All Product – • Searching for customer design mistakes AOI Automated Optical Inspection – Automated Optical Inspection Matching Net list to Gerber data Eliminator Tester & flying probe Coordinate Measurement Machine – First articles, 100% measurement verification In house Mil & deliverable Lab 9

QUALITY REASSURANCE • Net list compare prior to MFG – • Front End DRC (design rule check) – • • Verifying inner & outer layers X-Ray Verification – • After Lam (Inspecta), After Drilling Cross Section Verification – • Hole Integrity True-Chem Software Controlled Impedance Testing – • TDR test of panel coupons 100% Net List Test On All Product – • Searching for customer design mistakes AOI Automated Optical Inspection – Automated Optical Inspection Matching Net list to Gerber data Eliminator Tester & flying probe Coordinate Measurement Machine – First articles, 100% measurement verification In house Mil & deliverable Lab 9

ON TIME DELIVERY REASSURANCE • 100% In-house manufacturing from start to finish – – – 8 flying Probe Testers • Control delivery & customer flexibility In-process quality verification system No out sourcing delivery delays Employee Training program – • Performance evaluation every 6 months In-house Chemical Laboratory – – – Cross Sections Chemical analysis Mil spec verification Vacuum Lamination press 10

ON TIME DELIVERY REASSURANCE • 100% In-house manufacturing from start to finish – – – 8 flying Probe Testers • Control delivery & customer flexibility In-process quality verification system No out sourcing delivery delays Employee Training program – • Performance evaluation every 6 months In-house Chemical Laboratory – – – Cross Sections Chemical analysis Mil spec verification Vacuum Lamination press 10

CONTINUOUS IMPROVEMENT PROGRAMS • Working daily on: Management meetings – – – – Research and Development Pre-Engineering Programs Improvement Process Program Department Performance Reviews Preventative maintenance program Employee Training Program Planned Capital expense program 7 Laser drills 11

CONTINUOUS IMPROVEMENT PROGRAMS • Working daily on: Management meetings – – – – Research and Development Pre-Engineering Programs Improvement Process Program Department Performance Reviews Preventative maintenance program Employee Training Program Planned Capital expense program 7 Laser drills 11

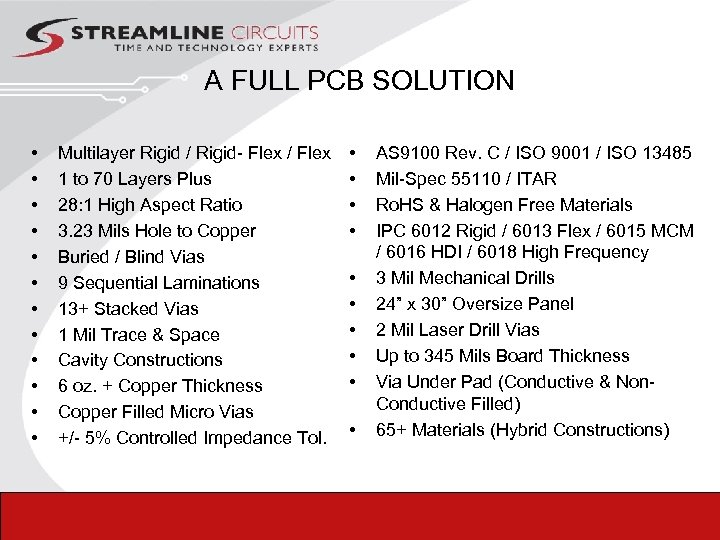

A FULL PCB SOLUTION • • • Multilayer Rigid / Rigid- Flex / Flex 1 to 70 Layers Plus 28: 1 High Aspect Ratio 3. 23 Mils Hole to Copper Buried / Blind Vias 9 Sequential Laminations 13+ Stacked Vias 1 Mil Trace & Space Cavity Constructions 6 oz. + Copper Thickness Copper Filled Micro Vias +/- 5% Controlled Impedance Tol. • • • AS 9100 Rev. C / ISO 9001 / ISO 13485 Mil-Spec 55110 / ITAR Ro. HS & Halogen Free Materials IPC 6012 Rigid / 6013 Flex / 6015 MCM / 6016 HDI / 6018 High Frequency 3 Mil Mechanical Drills 24” x 30” Oversize Panel 2 Mil Laser Drill Vias Up to 345 Mils Board Thickness Via Under Pad (Conductive & Non. Conductive Filled) 65+ Materials (Hybrid Constructions) 12

A FULL PCB SOLUTION • • • Multilayer Rigid / Rigid- Flex / Flex 1 to 70 Layers Plus 28: 1 High Aspect Ratio 3. 23 Mils Hole to Copper Buried / Blind Vias 9 Sequential Laminations 13+ Stacked Vias 1 Mil Trace & Space Cavity Constructions 6 oz. + Copper Thickness Copper Filled Micro Vias +/- 5% Controlled Impedance Tol. • • • AS 9100 Rev. C / ISO 9001 / ISO 13485 Mil-Spec 55110 / ITAR Ro. HS & Halogen Free Materials IPC 6012 Rigid / 6013 Flex / 6015 MCM / 6016 HDI / 6018 High Frequency 3 Mil Mechanical Drills 24” x 30” Oversize Panel 2 Mil Laser Drill Vias Up to 345 Mils Board Thickness Via Under Pad (Conductive & Non. Conductive Filled) 65+ Materials (Hybrid Constructions) 12

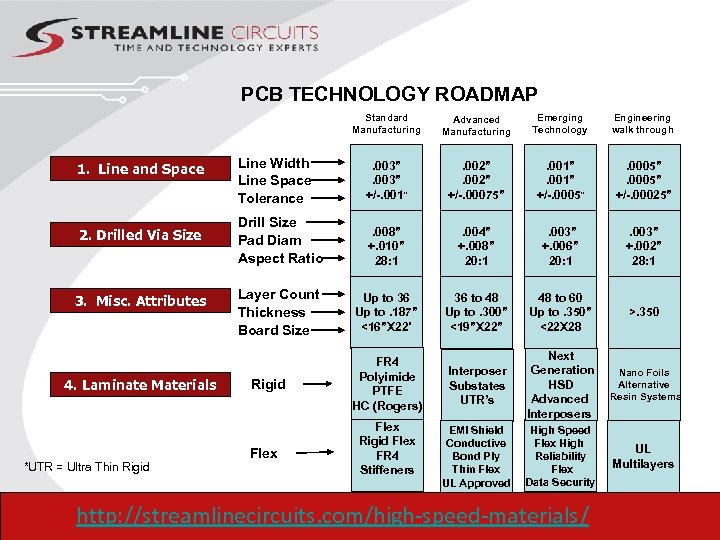

PCB TECHNOLOGY ROADMAP Standard Manufacturing 1. Line and Space 2. Drilled Via Size 3. Misc. Attributes 4. Laminate Materials *UTR = Ultra Thin Rigid Advanced Manufacturing Emerging Technology Engineering walk through Line Width Line Space Tolerance . 003”. 0038”. 003” +/-. 001”” +/-. 001 . 002” +/-. 00075” . 001” +/-. 0005” +/-. 00025” Drill Size Pad Diam Aspect Ratio . 008” +. 010” 28: 1 . 004” +. 008” 20: 1 . 003” +. 006” 20: 1 . 003” +. 002” 28: 1 Up to 36 Up to. 187” <16”X 22” 36 to 48 Up to. 300” <19”X 22” 48 to 60 Up to. 350” <22 X 28 >. 350 Interposer Substates UTR’s Next Generation HSD Advanced Interposers Nano Foils Alternative Resin Systems EMI Shield Conductive Bond Ply Thin Flex UL Approved High Speed Flex High Reliability Flex Data Security UL Multilayers Layer Count Thickness Board Size Rigid Flex FR 4 Polyimide PTFE HC (Rogers) Flex Rigid Flex FR 4 Stiffeners http: //streamlinecircuits. com/high-speed-materials/ 13

PCB TECHNOLOGY ROADMAP Standard Manufacturing 1. Line and Space 2. Drilled Via Size 3. Misc. Attributes 4. Laminate Materials *UTR = Ultra Thin Rigid Advanced Manufacturing Emerging Technology Engineering walk through Line Width Line Space Tolerance . 003”. 0038”. 003” +/-. 001”” +/-. 001 . 002” +/-. 00075” . 001” +/-. 0005” +/-. 00025” Drill Size Pad Diam Aspect Ratio . 008” +. 010” 28: 1 . 004” +. 008” 20: 1 . 003” +. 006” 20: 1 . 003” +. 002” 28: 1 Up to 36 Up to. 187” <16”X 22” 36 to 48 Up to. 300” <19”X 22” 48 to 60 Up to. 350” <22 X 28 >. 350 Interposer Substates UTR’s Next Generation HSD Advanced Interposers Nano Foils Alternative Resin Systems EMI Shield Conductive Bond Ply Thin Flex UL Approved High Speed Flex High Reliability Flex Data Security UL Multilayers Layer Count Thickness Board Size Rigid Flex FR 4 Polyimide PTFE HC (Rogers) Flex Rigid Flex FR 4 Stiffeners http: //streamlinecircuits. com/high-speed-materials/ 13

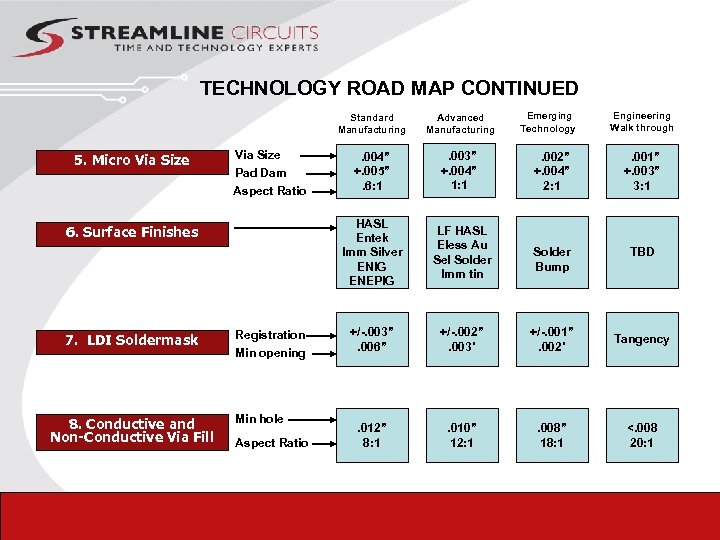

TECHNOLOGY ROAD MAP CONTINUED Emerging Technology Engineering Walk through Standard Manufacturing 5. Micro Via Size 6. Surface Finishes 7. LDI Soldermask 8. Conductive and Non-Conductive Via Fill Registration Min opening Min hole Aspect Ratio . 004” +. 005”. 6: 1 . 003” +. 004” 1: 1 HASL Entek Imm Silver ENIG ENEPIG Via Size Pad Dam Aspect Ratio Advanced Manufacturing LF HASL Eless Au Sel Solder Imm tin +/-. 003”. 006” +/-. 002”. 003” +/-. 001”. 002” Tangency . 012” 8: 1 . 010” 12: 1 . 008” 18: 1 <. 008 20: 1 . 002” +. 004” 2: 1 . 001” +. 003” 3: 1 Solder Bump TBD 14

TECHNOLOGY ROAD MAP CONTINUED Emerging Technology Engineering Walk through Standard Manufacturing 5. Micro Via Size 6. Surface Finishes 7. LDI Soldermask 8. Conductive and Non-Conductive Via Fill Registration Min opening Min hole Aspect Ratio . 004” +. 005”. 6: 1 . 003” +. 004” 1: 1 HASL Entek Imm Silver ENIG ENEPIG Via Size Pad Dam Aspect Ratio Advanced Manufacturing LF HASL Eless Au Sel Solder Imm tin +/-. 003”. 006” +/-. 002”. 003” +/-. 001”. 002” Tangency . 012” 8: 1 . 010” 12: 1 . 008” 18: 1 <. 008 20: 1 . 002” +. 004” 2: 1 . 001” +. 003” 3: 1 Solder Bump TBD 14

Nadcap ISO 9001: 2000 IPC 6012, 13, 15, 16, 18 Class 3 ITAR AS 9100 Rev C Mil-Spec 55110 Mil-Spec 31032 in process

Nadcap ISO 9001: 2000 IPC 6012, 13, 15, 16, 18 Class 3 ITAR AS 9100 Rev C Mil-Spec 55110 Mil-Spec 31032 in process

Q-Pulse Total Quality Management • Quality Assurance Systems – Q-Pulse Quality System • NCMR’s and Corrective Actions • Audits • Training • Equipment Calibrations 16

Q-Pulse Total Quality Management • Quality Assurance Systems – Q-Pulse Quality System • NCMR’s and Corrective Actions • Audits • Training • Equipment Calibrations 16

Streamline’s Capital Expenditures Laser Direct Imaging • Use advanced equipment technologies to manufacture today's printed circuit board requirements • The future in PCB manufacturing is about technology and automation Cuposit & Electroless Line • Hire and Train equipment operators DES Inner Layer Stripline • High percentage engineering personnel and staff 17

Streamline’s Capital Expenditures Laser Direct Imaging • Use advanced equipment technologies to manufacture today's printed circuit board requirements • The future in PCB manufacturing is about technology and automation Cuposit & Electroless Line • Hire and Train equipment operators DES Inner Layer Stripline • High percentage engineering personnel and staff 17

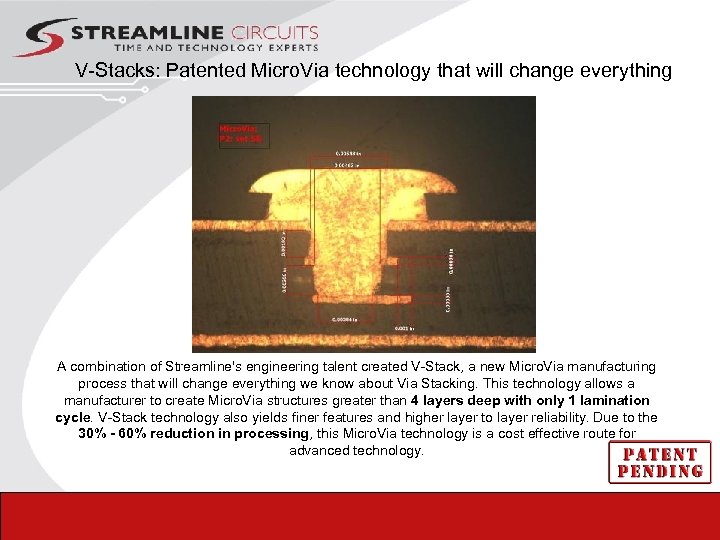

V-Stacks: Patented Micro. Via technology that will change everything A combination of Streamline's engineering talent created V-Stack, a new Micro. Via manufacturing process that will change everything we know about Via Stacking. This technology allows a manufacturer to create Micro. Via structures greater than 4 layers deep with only 1 lamination cycle. V-Stack technology also yields finer features and higher layer to layer reliability. Due to the 30% - 60% reduction in processing, this Micro. Via technology is a cost effective route for advanced technology. 18

V-Stacks: Patented Micro. Via technology that will change everything A combination of Streamline's engineering talent created V-Stack, a new Micro. Via manufacturing process that will change everything we know about Via Stacking. This technology allows a manufacturer to create Micro. Via structures greater than 4 layers deep with only 1 lamination cycle. V-Stack technology also yields finer features and higher layer to layer reliability. Due to the 30% - 60% reduction in processing, this Micro. Via technology is a cost effective route for advanced technology. 18

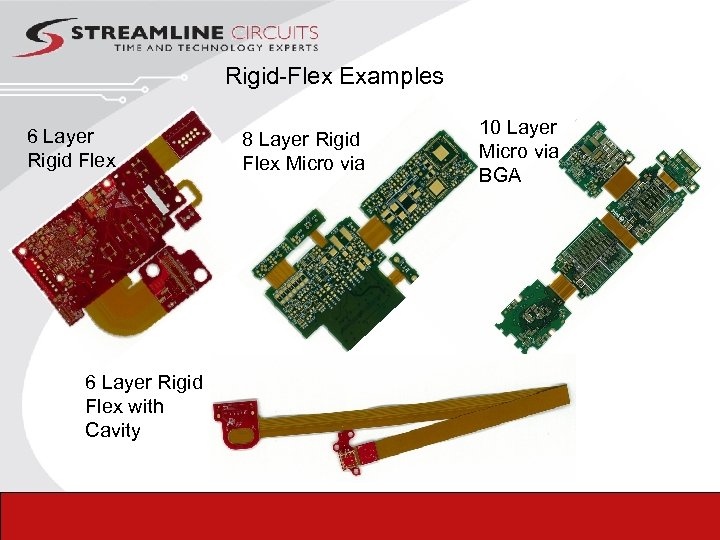

Rigid-Flex Examples 6 Layer Rigid Flex with Cavity 8 Layer Rigid Flex Micro via 10 Layer Micro via BGA

Rigid-Flex Examples 6 Layer Rigid Flex with Cavity 8 Layer Rigid Flex Micro via 10 Layer Micro via BGA

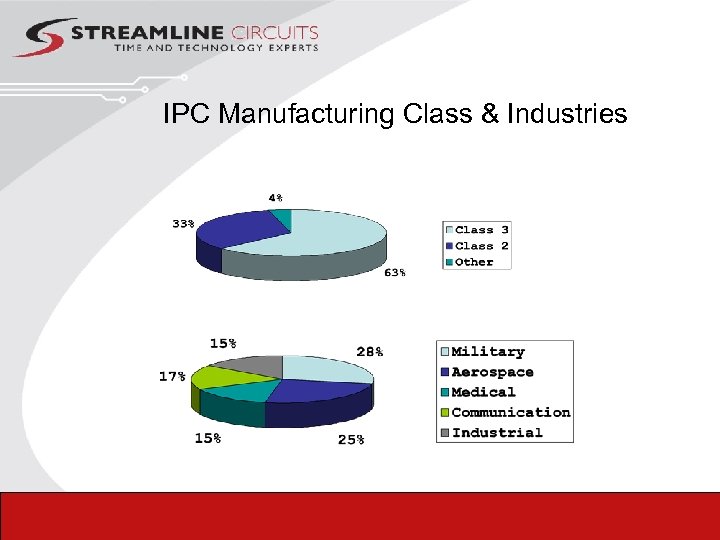

IPC Manufacturing Class & Industries 20

IPC Manufacturing Class & Industries 20

Streamline Circuits Corp. 1401 Martin Ave, Santa Clara, CA 95050 USA (877) 264 -0343 sales@streamlinecircuits. com

Streamline Circuits Corp. 1401 Martin Ave, Santa Clara, CA 95050 USA (877) 264 -0343 sales@streamlinecircuits. com