9d60f0091de24e27d0602073529e566a.ppt

- Количество слайдов: 76

IE 101 -Industrial Engineering Orientation Fall 2009 Motion and Time Study Engin Topan

IE 101 -Industrial Engineering Orientation Fall 2009 Motion and Time Study Engin Topan

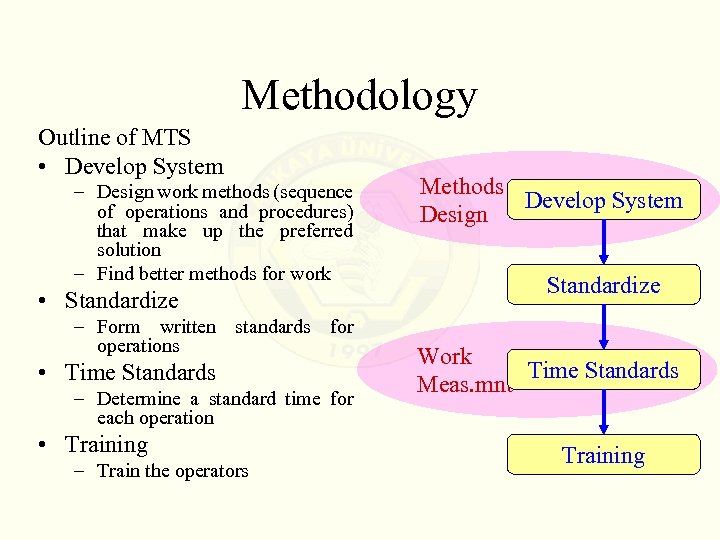

Methodology Outline of MTS • Develop System – Design work methods (sequence of operations and procedures) that make up the preferred solution – Find better methods for work • Standardize – Form written standards for operations • Time Standards – Determine a standard time for each operation • Training – Train the operators Methods Develop System Design Standardize Work Time Standards Meas. mnt Training

Methodology Outline of MTS • Develop System – Design work methods (sequence of operations and procedures) that make up the preferred solution – Find better methods for work • Standardize – Form written standards for operations • Time Standards – Determine a standard time for each operation • Training – Train the operators Methods Develop System Design Standardize Work Time Standards Meas. mnt Training

Defining Work Systems Work • Is our primary means of livelihood • Serves an important economic function in the global world of commerce • Creates opportunities for social interactions and friendships • Provides the products and services that sustain and improve our standard of living

Defining Work Systems Work • Is our primary means of livelihood • Serves an important economic function in the global world of commerce • Creates opportunities for social interactions and friendships • Provides the products and services that sustain and improve our standard of living

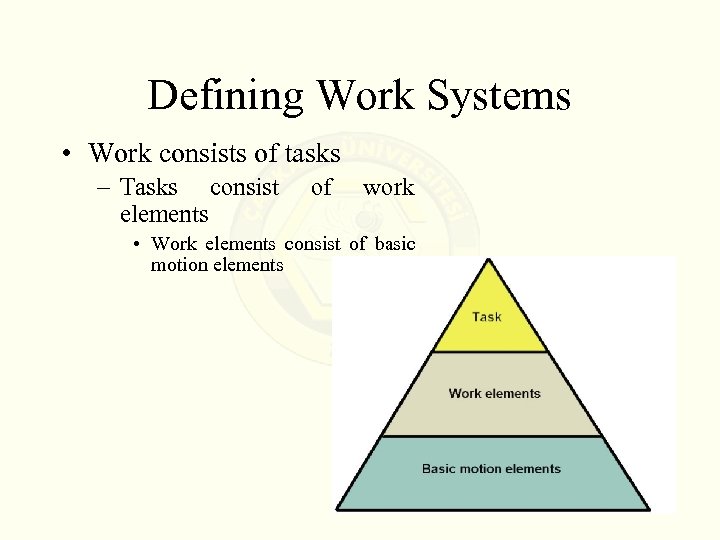

Defining Work Systems • Work consists of tasks – Tasks consist elements of work • Work elements consist of basic motion elements

Defining Work Systems • Work consists of tasks – Tasks consist elements of work • Work elements consist of basic motion elements

Defining Work Systems Task • An amount of work that is assigned to a worker or for which a worker is responsible – Repetitive task – as in mass production – Non-repetitive task – performed periodically, infrequently, or only once Work Element • A series of work activities that are logically grouped together because they have a unified function in the task – Example: assembling a component to a base part using several nuts and bolts

Defining Work Systems Task • An amount of work that is assigned to a worker or for which a worker is responsible – Repetitive task – as in mass production – Non-repetitive task – performed periodically, infrequently, or only once Work Element • A series of work activities that are logically grouped together because they have a unified function in the task – Example: assembling a component to a base part using several nuts and bolts

Defining Work Systems Basic Motion Elements • Actuations of the limbs and other body parts – Examples: • • • Reaching for an object Grasping the object Moving the object Walking Eye movement – A work element consists of multiple basic motion elements

Defining Work Systems Basic Motion Elements • Actuations of the limbs and other body parts – Examples: • • • Reaching for an object Grasping the object Moving the object Walking Eye movement – A work element consists of multiple basic motion elements

1. 3 Defining Work Systems • “Time=Money”? How? – New product introduction – Product cost – Delivery time – Overnight delivery – Competitive bidding – Production scheduling • Increase profit using less time!

1. 3 Defining Work Systems • “Time=Money”? How? – New product introduction – Product cost – Delivery time – Overnight delivery – Competitive bidding – Production scheduling • Increase profit using less time!

Defining Work Systems • Importance of Time in Work – Time is the most frequently used measure of work • How many minutes or hours are required to perform a given task? – Most workers are paid by the time they work • Hourly wage rate • Salary – Workers must arrive at work on time – Labor and staffing requirements computed in units of time

Defining Work Systems • Importance of Time in Work – Time is the most frequently used measure of work • How many minutes or hours are required to perform a given task? – Most workers are paid by the time they work • Hourly wage rate • Salary – Workers must arrive at work on time – Labor and staffing requirements computed in units of time

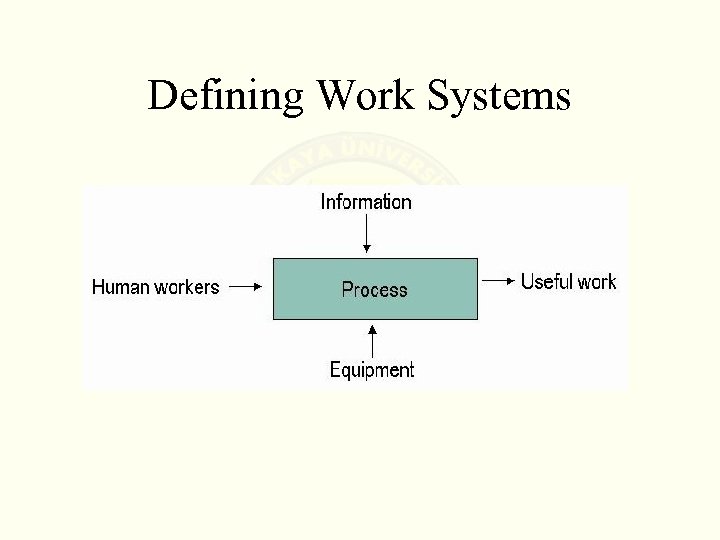

Defining Work Systems • A work system is a system consisting of humans, information, and equipment designed to perform useful work – Contributes to the production of a product or delivery of a service – Examples: • Worker operating a machine tool in a factory • Robotic welding line in an automobile plant • A receptionist answering incoming phone calls

Defining Work Systems • A work system is a system consisting of humans, information, and equipment designed to perform useful work – Contributes to the production of a product or delivery of a service – Examples: • Worker operating a machine tool in a factory • Robotic welding line in an automobile plant • A receptionist answering incoming phone calls

Defining Work Systems

Defining Work Systems

Productivity Production as a function in Economics Q=f(K, L) • Q: Output, K: Capital, L: Labor • Is there a way to change function f with a better function g? • Better Function=Higher Productivity

Productivity Production as a function in Economics Q=f(K, L) • Q: Output, K: Capital, L: Labor • Is there a way to change function f with a better function g? • Better Function=Higher Productivity

Productivity • The level of output of a given process relative to the level of input • Process can refer to – Individual production or service operations – A national economy • Productivity is an important metric in work systems because – Improving productivity is the means by which worker compensation can be increased without increasing the costs of products and services they produce

Productivity • The level of output of a given process relative to the level of input • Process can refer to – Individual production or service operations – A national economy • Productivity is an important metric in work systems because – Improving productivity is the means by which worker compensation can be increased without increasing the costs of products and services they produce

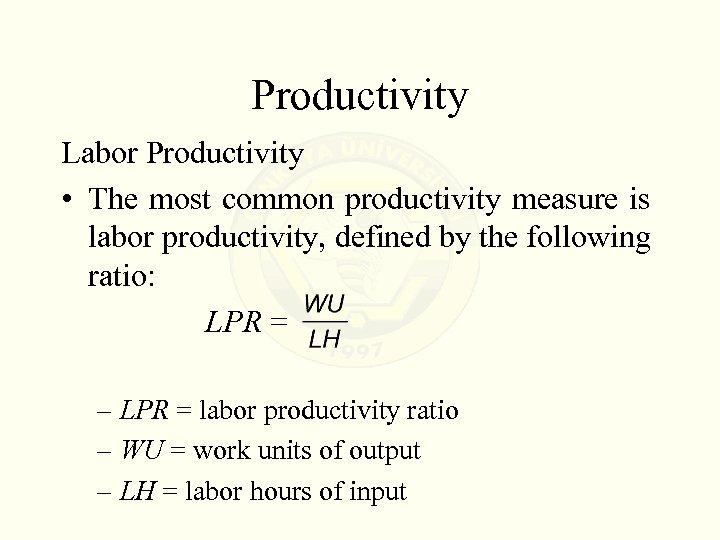

Productivity Labor Productivity • The most common productivity measure is labor productivity, defined by the following ratio: LPR = – LPR = labor productivity ratio – WU = work units of output – LH = labor hours of input

Productivity Labor Productivity • The most common productivity measure is labor productivity, defined by the following ratio: LPR = – LPR = labor productivity ratio – WU = work units of output – LH = labor hours of input

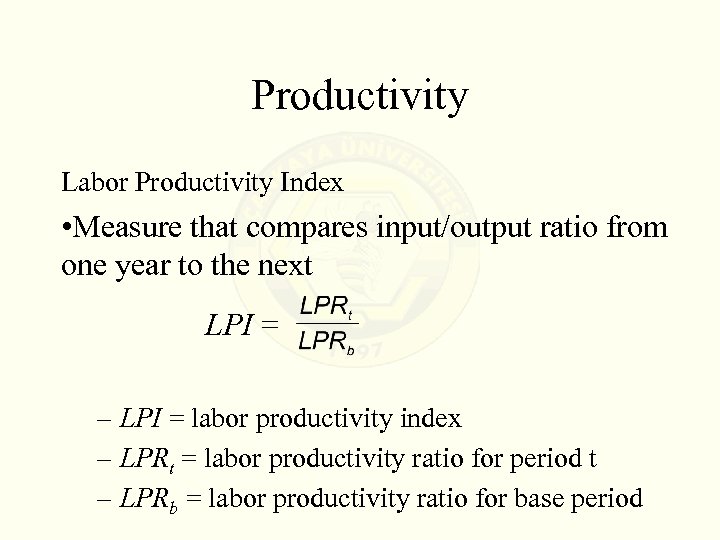

Productivity Labor Productivity Index • Measure that compares input/output ratio from one year to the next LPI = – LPI = labor productivity index – LPRt = labor productivity ratio for period t – LPRb = labor productivity ratio for base period

Productivity Labor Productivity Index • Measure that compares input/output ratio from one year to the next LPI = – LPI = labor productivity index – LPRt = labor productivity ratio for period t – LPRb = labor productivity ratio for base period

Productivity Example • During the base year in a small steel mill, 326, 000 tons of steel were produced using 203, 000 labor hours. In the next year, the output was 341, 000 tons using 246, 000 labor hours. Determine: (a) the labor productivity ratio for the base year, (b) the labor productivity ratio for the second year, and (c) the productivity index for the second year.

Productivity Example • During the base year in a small steel mill, 326, 000 tons of steel were produced using 203, 000 labor hours. In the next year, the output was 341, 000 tons using 246, 000 labor hours. Determine: (a) the labor productivity ratio for the base year, (b) the labor productivity ratio for the second year, and (c) the productivity index for the second year.

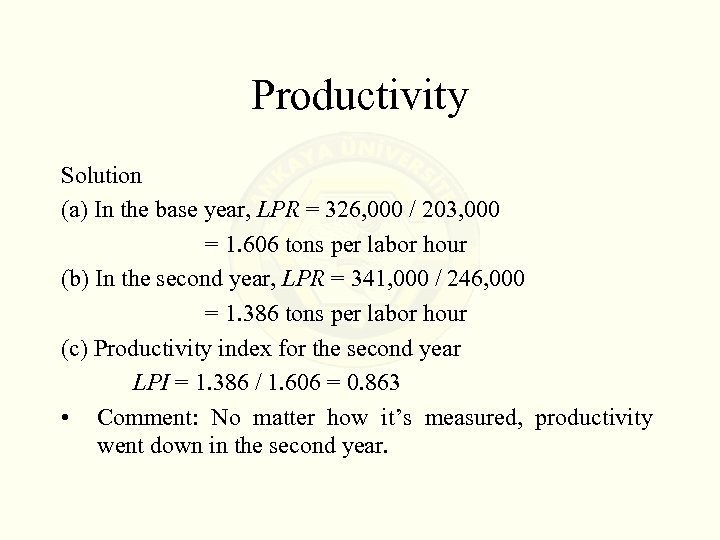

Productivity Solution (a) In the base year, LPR = 326, 000 / 203, 000 = 1. 606 tons per labor hour (b) In the second year, LPR = 341, 000 / 246, 000 = 1. 386 tons per labor hour (c) Productivity index for the second year LPI = 1. 386 / 1. 606 = 0. 863 • Comment: No matter how it’s measured, productivity went down in the second year.

Productivity Solution (a) In the base year, LPR = 326, 000 / 203, 000 = 1. 606 tons per labor hour (b) In the second year, LPR = 341, 000 / 246, 000 = 1. 386 tons per labor hour (c) Productivity index for the second year LPI = 1. 386 / 1. 606 = 0. 863 • Comment: No matter how it’s measured, productivity went down in the second year.

Productivity Labor Factor in Productivity • Labor itself does not contribute much to improving productivity • More important factors: – Capital - substitution of machines for human labor – Technology - fundamental change in the way some activity or function is accomplished

Productivity Labor Factor in Productivity • Labor itself does not contribute much to improving productivity • More important factors: – Capital - substitution of machines for human labor – Technology - fundamental change in the way some activity or function is accomplished

Productivity Horse-drawn carts Railroad trains Steam locomotive Diesel locomotive Telephone operator Dial phone Manually operated milling machine Numerically controlled (NC) milling machine

Productivity Horse-drawn carts Railroad trains Steam locomotive Diesel locomotive Telephone operator Dial phone Manually operated milling machine Numerically controlled (NC) milling machine

Productivity Measuring Productivity • Not as easy as it seems because of the following problems: – Nonhomogeneous output units – Multiple input factors • Labor, capital, technology, materials, energy – Price and cost changes due to economic forces – Product mix changes • Relative proportions of products that a company sells change over time

Productivity Measuring Productivity • Not as easy as it seems because of the following problems: – Nonhomogeneous output units – Multiple input factors • Labor, capital, technology, materials, energy – Price and cost changes due to economic forces – Product mix changes • Relative proportions of products that a company sells change over time

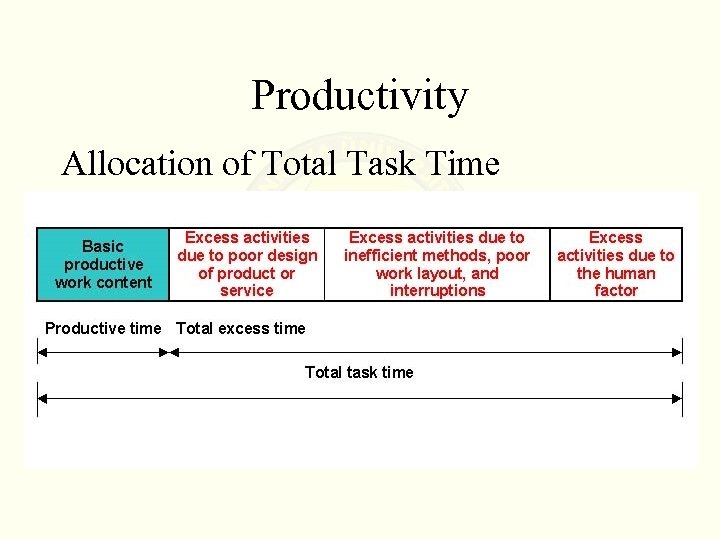

Productivity Productive Work Content • A given task performed by a worker can be considered to consist of – Basic productive work content • Theoretical minimum amount of work required to accomplish the task – Excess nonproductive activities • • Extra physical and mental actions of worker Do not add value to the task Do not facilitate the productive work content Take time

Productivity Productive Work Content • A given task performed by a worker can be considered to consist of – Basic productive work content • Theoretical minimum amount of work required to accomplish the task – Excess nonproductive activities • • Extra physical and mental actions of worker Do not add value to the task Do not facilitate the productive work content Take time

Productivity • Excess Nonproductive Activities can be classified into three categories: – Excess activities due to poor design of product or service – Excess activities caused by inefficient methods, poor workplace layout, and interruptions – Excessive activities cause by the human factor

Productivity • Excess Nonproductive Activities can be classified into three categories: – Excess activities due to poor design of product or service – Excess activities caused by inefficient methods, poor workplace layout, and interruptions – Excessive activities cause by the human factor

Productivity Allocation of Total Task Time

Productivity Allocation of Total Task Time

Work Systems 1. Manual work system – Worker performing one or more tasks without the aid of powered tools 2. Worker-machine system – Human worker operates powered equipment 3. Automated work system – Process performed without the direct participation of a human worker

Work Systems 1. Manual work system – Worker performing one or more tasks without the aid of powered tools 2. Worker-machine system – Human worker operates powered equipment 3. Automated work system – Process performed without the direct participation of a human worker

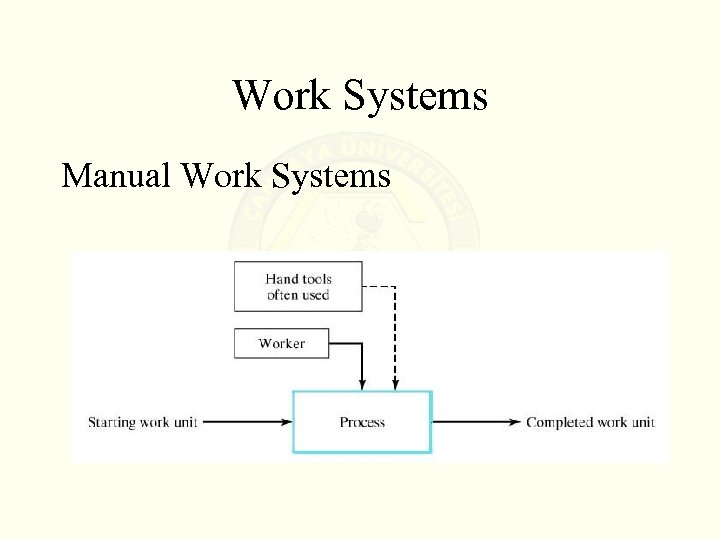

Work Systems Manual Work Systems • Human body accomplishing some physical task without an external source of power – With or without hand tools • When hand tools are used, the power to operate them is derived from the strength and stamina of a human worker – Other human faculties are required, such as hand-eye coordination and mental effort

Work Systems Manual Work Systems • Human body accomplishing some physical task without an external source of power – With or without hand tools • When hand tools are used, the power to operate them is derived from the strength and stamina of a human worker – Other human faculties are required, such as hand-eye coordination and mental effort

Work Systems Manual Work Systems

Work Systems Manual Work Systems

Work Systems Pure Manual Work • Material handler moving cartons in a warehouse • Assembly worker snap-fitting two parts together Manual Work with Hand Tools • Material handling worker using a dolly to move furniture • Assembly worker using screwdriver

Work Systems Pure Manual Work • Material handler moving cartons in a warehouse • Assembly worker snap-fitting two parts together Manual Work with Hand Tools • Material handling worker using a dolly to move furniture • Assembly worker using screwdriver

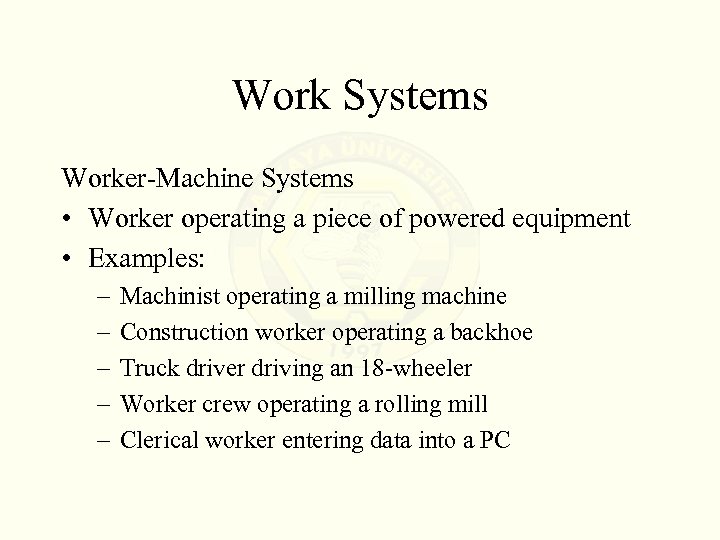

Work Systems Worker-Machine Systems • Worker operating a piece of powered equipment • Examples: – – – Machinist operating a milling machine Construction worker operating a backhoe Truck driver driving an 18 -wheeler Worker crew operating a rolling mill Clerical worker entering data into a PC

Work Systems Worker-Machine Systems • Worker operating a piece of powered equipment • Examples: – – – Machinist operating a milling machine Construction worker operating a backhoe Truck driver driving an 18 -wheeler Worker crew operating a rolling mill Clerical worker entering data into a PC

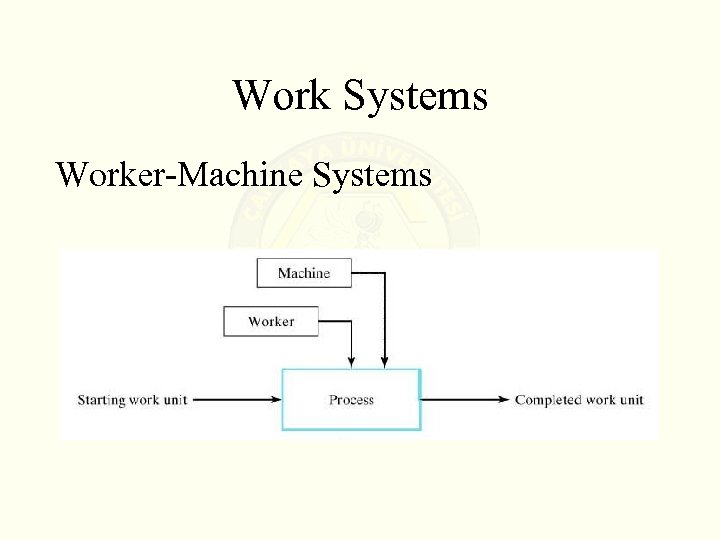

Work Systems Worker-Machine Systems

Work Systems Worker-Machine Systems

Work Systems Automated Work Systems • Automation is the technology by which a process or procedure is accomplished without human assistance – Implemented using a program of instructions combined with a control system that executes the instructions – Power is required to drive the process and operate the control system

Work Systems Automated Work Systems • Automation is the technology by which a process or procedure is accomplished without human assistance – Implemented using a program of instructions combined with a control system that executes the instructions – Power is required to drive the process and operate the control system

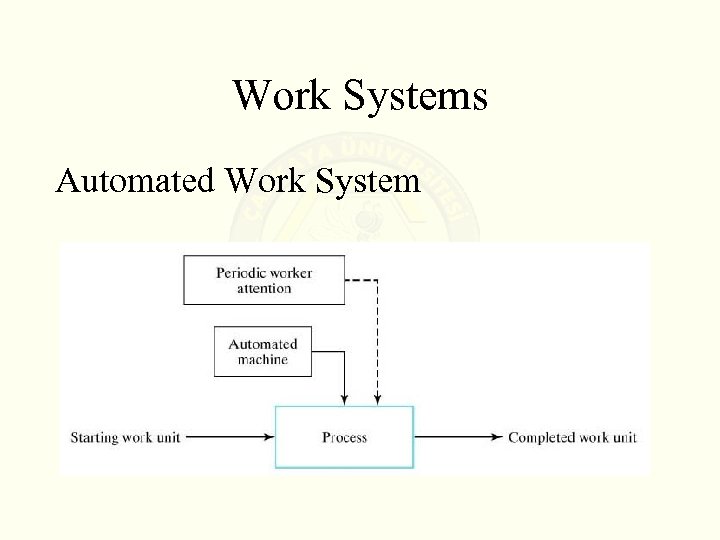

Work Systems Automated Work System

Work Systems Automated Work System

Methods Design Develop System Standardize Time Standards Training Methods Design • Motion study - analysis of the basic hand, arm, and body movements of workers as they perform work • Work design - design of the methods and motions used to perform a task • Includes: – Workplace layout and environment – Tooling and equipment used in the task

Methods Design Develop System Standardize Time Standards Training Methods Design • Motion study - analysis of the basic hand, arm, and body movements of workers as they perform work • Work design - design of the methods and motions used to perform a task • Includes: – Workplace layout and environment – Tooling and equipment used in the task

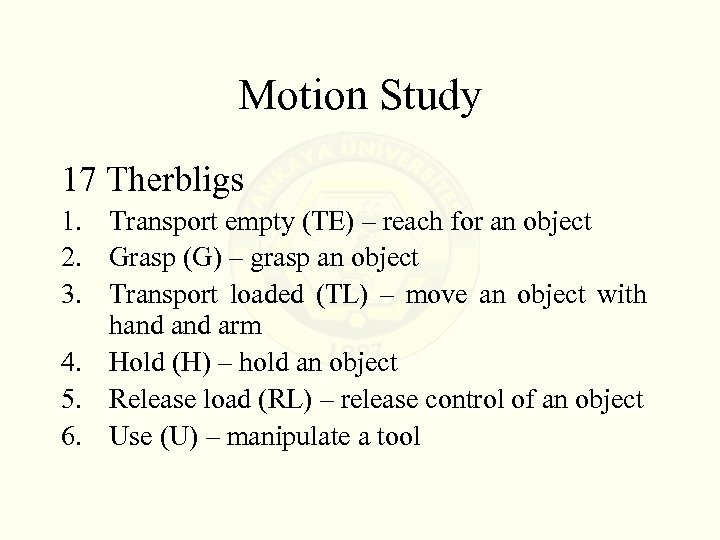

Motion Study Basic Motion Elements • Therbligs – 17 basic motion elements – Basic building blocks of virtually all manual work performed at a single location – With modification, used today in several work measurement systems, e. g. , MTM and MOST • Some of the motion element names and definitions have been revised

Motion Study Basic Motion Elements • Therbligs – 17 basic motion elements – Basic building blocks of virtually all manual work performed at a single location – With modification, used today in several work measurement systems, e. g. , MTM and MOST • Some of the motion element names and definitions have been revised

Motion Study 17 Therbligs 1. Transport empty (TE) – reach for an object 2. Grasp (G) – grasp an object 3. Transport loaded (TL) – move an object with hand arm 4. Hold (H) – hold an object 5. Release load (RL) – release control of an object 6. Use (U) – manipulate a tool

Motion Study 17 Therbligs 1. Transport empty (TE) – reach for an object 2. Grasp (G) – grasp an object 3. Transport loaded (TL) – move an object with hand arm 4. Hold (H) – hold an object 5. Release load (RL) – release control of an object 6. Use (U) – manipulate a tool

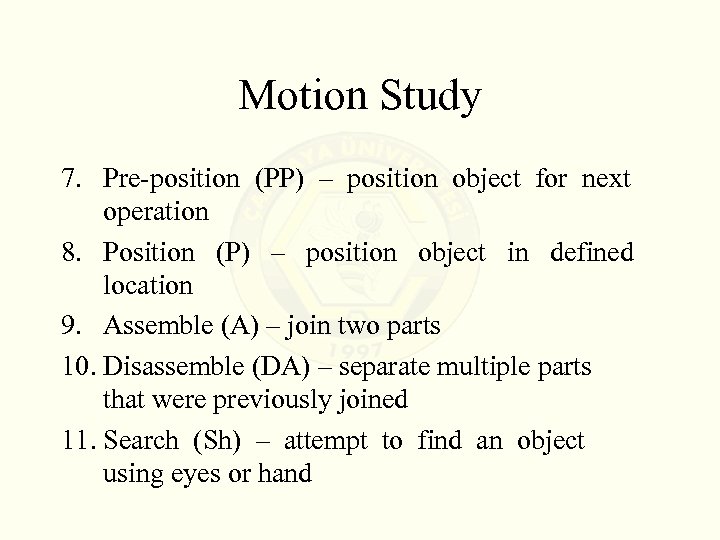

Motion Study 7. Pre-position (PP) – position object for next operation 8. Position (P) – position object in defined location 9. Assemble (A) – join two parts 10. Disassemble (DA) – separate multiple parts that were previously joined 11. Search (Sh) – attempt to find an object using eyes or hand

Motion Study 7. Pre-position (PP) – position object for next operation 8. Position (P) – position object in defined location 9. Assemble (A) – join two parts 10. Disassemble (DA) – separate multiple parts that were previously joined 11. Search (Sh) – attempt to find an object using eyes or hand

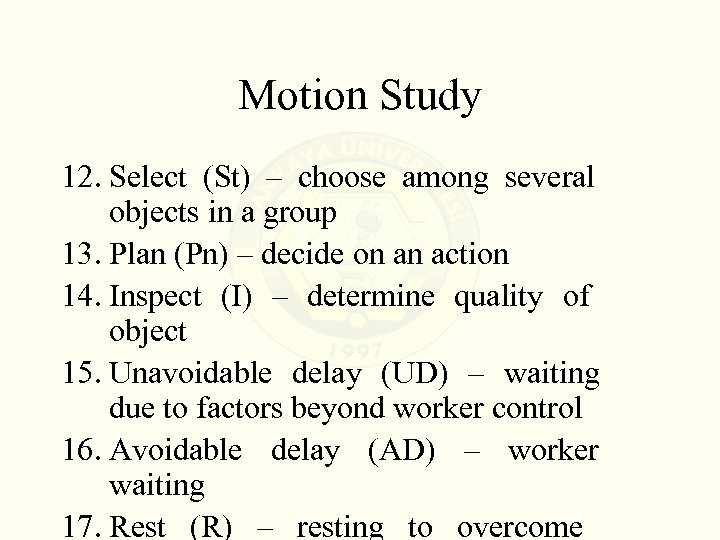

Motion Study 12. Select (St) – choose among several objects in a group 13. Plan (Pn) – decide on an action 14. Inspect (I) – determine quality of object 15. Unavoidable delay (UD) – waiting due to factors beyond worker control 16. Avoidable delay (AD) – worker waiting 17. Rest (R) – resting to overcome

Motion Study 12. Select (St) – choose among several objects in a group 13. Plan (Pn) – decide on an action 14. Inspect (I) – determine quality of object 15. Unavoidable delay (UD) – waiting due to factors beyond worker control 16. Avoidable delay (AD) – worker waiting 17. Rest (R) – resting to overcome

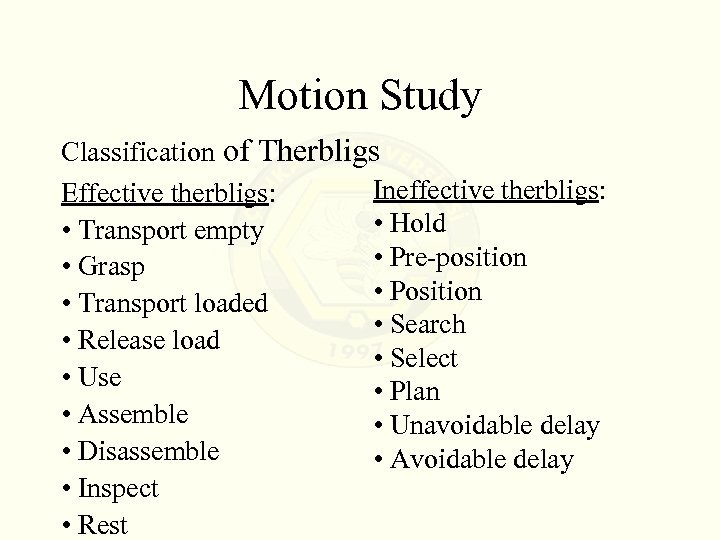

Motion Study Classification of Therbligs Ineffective therbligs: Effective therbligs: • Hold • Transport empty • Pre-position • Grasp • Position • Transport loaded • Search • Release load • Select • Use • Plan • Assemble • Unavoidable delay • Disassemble • Avoidable delay • Inspect • Rest

Motion Study Classification of Therbligs Ineffective therbligs: Effective therbligs: • Hold • Transport empty • Pre-position • Grasp • Position • Transport loaded • Search • Release load • Select • Use • Plan • Assemble • Unavoidable delay • Disassemble • Avoidable delay • Inspect • Rest

Motion Study Micromotion Analysis • Objectives: – Eliminate ineffective therbligs if possible – Avoid holding objects with hand – Use workholder – Combine therbligs – Perform right-hand left-hand motions simultaneously – Simplify overall method – Reduce time for a motion, e. g. , shorten distance

Motion Study Micromotion Analysis • Objectives: – Eliminate ineffective therbligs if possible – Avoid holding objects with hand – Use workholder – Combine therbligs – Perform right-hand left-hand motions simultaneously – Simplify overall method – Reduce time for a motion, e. g. , shorten distance

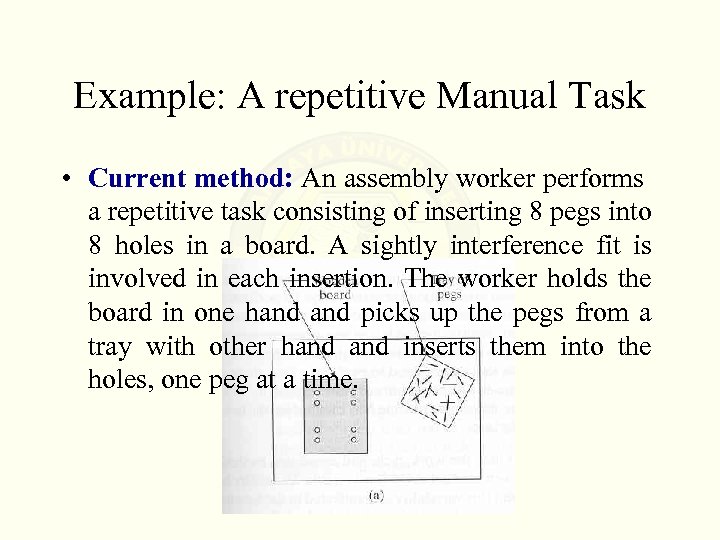

Example: A repetitive Manual Task • Current method: An assembly worker performs a repetitive task consisting of inserting 8 pegs into 8 holes in a board. A sightly interference fit is involved in each insertion. The worker holds the board in one hand picks up the pegs from a tray with other hand inserts them into the holes, one peg at a time.

Example: A repetitive Manual Task • Current method: An assembly worker performs a repetitive task consisting of inserting 8 pegs into 8 holes in a board. A sightly interference fit is involved in each insertion. The worker holds the board in one hand picks up the pegs from a tray with other hand inserts them into the holes, one peg at a time.

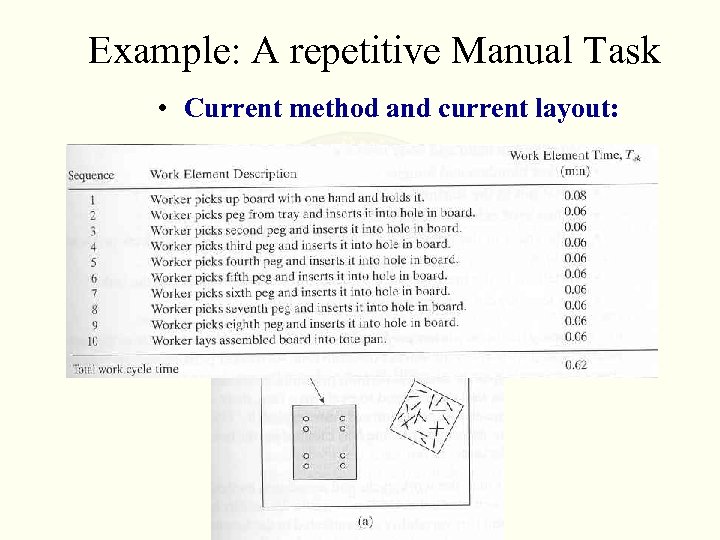

Example: A repetitive Manual Task • Current method and current layout:

Example: A repetitive Manual Task • Current method and current layout:

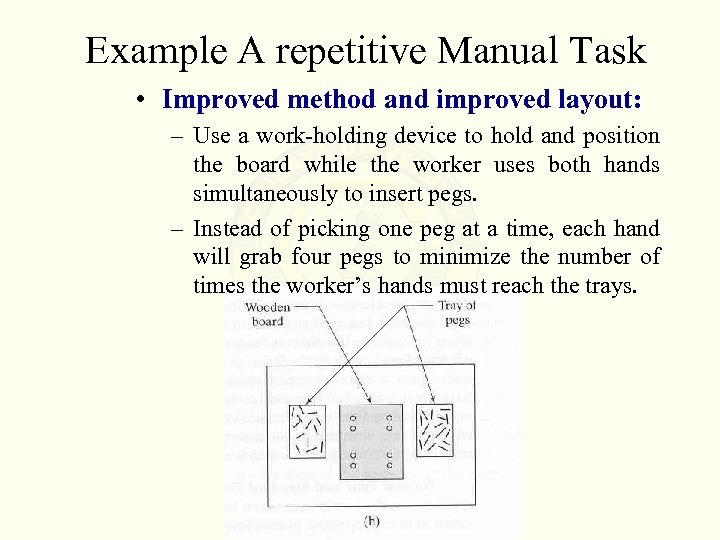

Example A repetitive Manual Task • Improved method and improved layout: – Use a work-holding device to hold and position the board while the worker uses both hands simultaneously to insert pegs. – Instead of picking one peg at a time, each hand will grab four pegs to minimize the number of times the worker’s hands must reach the trays.

Example A repetitive Manual Task • Improved method and improved layout: – Use a work-holding device to hold and position the board while the worker uses both hands simultaneously to insert pegs. – Instead of picking one peg at a time, each hand will grab four pegs to minimize the number of times the worker’s hands must reach the trays.

Motion Study Principles of Motion Economy • Developed over many years experience in work design • Guidelines to help determine of practical – Work method – Workplace layout – Tools, and equipment • Objective: to maximize efficiency and minimize worker fatigue

Motion Study Principles of Motion Economy • Developed over many years experience in work design • Guidelines to help determine of practical – Work method – Workplace layout – Tools, and equipment • Objective: to maximize efficiency and minimize worker fatigue

Work Methods Design To select preferred work method: 1. 2. 3. 4. Eliminate all unnecessary work Combine operations or elements Change the sequence of operations Simplify the necessary operations

Work Methods Design To select preferred work method: 1. 2. 3. 4. Eliminate all unnecessary work Combine operations or elements Change the sequence of operations Simplify the necessary operations

Develop System Standardize Work Meas. mnt Time Standards Training Time Study and Work Measurement Time Is Important • Most workers are paid for their time on the job • The labor content (cost of labor time) is often a major factor in the total cost of a product or service • For any organization, it is important to know how much time will be required to accomplish a given amount of work

Develop System Standardize Work Meas. mnt Time Standards Training Time Study and Work Measurement Time Is Important • Most workers are paid for their time on the job • The labor content (cost of labor time) is often a major factor in the total cost of a product or service • For any organization, it is important to know how much time will be required to accomplish a given amount of work

Time Study and Work Measurement • Work measurement – evaluation of a task in terms of the time that should be allowed by an average worker to perform the task • Time study – all the ways in which time is analyzed in work situations • Standard time – amount of time that should be allowed for an average worker to process one work unit using the standard method and working at normal pace

Time Study and Work Measurement • Work measurement – evaluation of a task in terms of the time that should be allowed by an average worker to perform the task • Time study – all the ways in which time is analyzed in work situations • Standard time – amount of time that should be allowed for an average worker to process one work unit using the standard method and working at normal pace

Time Study and Work Measurement Standard times • define a “fair day’s work” • provide a means to convert workload into staffing and equipment needs • provide a basis for wage incentives and evaluation of worker performance • provide time data for: – Production planning and scheduling – Cost estimating – Material requirements planning

Time Study and Work Measurement Standard times • define a “fair day’s work” • provide a means to convert workload into staffing and equipment needs • provide a basis for wage incentives and evaluation of worker performance • provide time data for: – Production planning and scheduling – Cost estimating – Material requirements planning

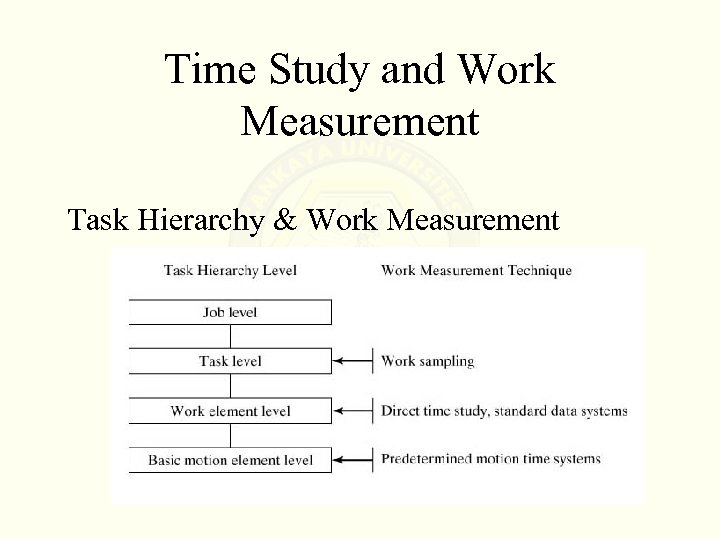

Time Study and Work Measurement Task Hierarchy & Work Measurement

Time Study and Work Measurement Task Hierarchy & Work Measurement

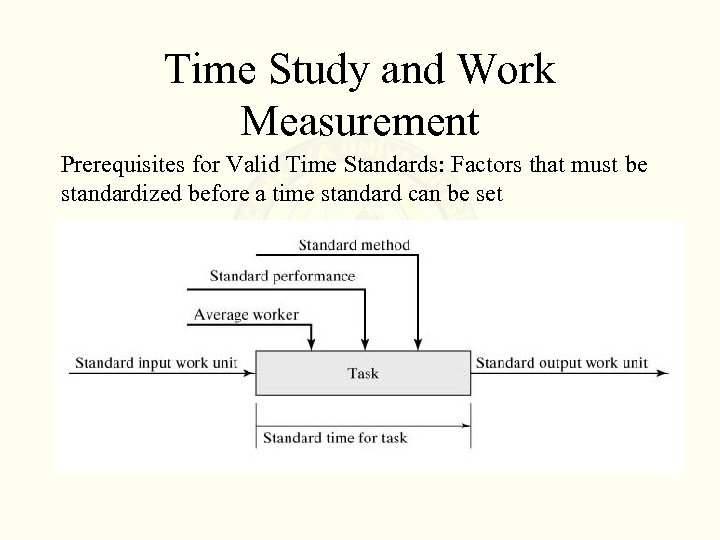

Time Study and Work Measurement Prerequisites for Valid Time Standards: Factors that must be standardized before a time standard can be set

Time Study and Work Measurement Prerequisites for Valid Time Standards: Factors that must be standardized before a time standard can be set

Time Study and Work Measurement Normal Performance • A pace of working that can be maintained by a properly trained average worker throughout an entire work shift without deleterious short-term or long-term effects on the worker’s health or physical well-being – Normal performance = 100% performance – Common benchmark of normal performance: • Walking at 3 mi/hr

Time Study and Work Measurement Normal Performance • A pace of working that can be maintained by a properly trained average worker throughout an entire work shift without deleterious short-term or long-term effects on the worker’s health or physical well-being – Normal performance = 100% performance – Common benchmark of normal performance: • Walking at 3 mi/hr

Time Study and Work Measurement Performance Rating • Analyst judges the performance or pace of the worker relative to the definition of standard performance used by the organization – Standard performance Pw = 100% • Slower pace than standard Pw < 100% • Faster pace than standard Pw > 100% – Normal time Tn = Tobs(Pw )

Time Study and Work Measurement Performance Rating • Analyst judges the performance or pace of the worker relative to the definition of standard performance used by the organization – Standard performance Pw = 100% • Slower pace than standard Pw < 100% • Faster pace than standard Pw > 100% – Normal time Tn = Tobs(Pw )

Time Study and Work Measurement Normal Time • The time to complete a task when working at normal performance Tn = Tobs(Pw ) where Tobs = observed time, Tn = normal time, and Pw = worker performance or pace

Time Study and Work Measurement Normal Time • The time to complete a task when working at normal performance Tn = Tobs(Pw ) where Tobs = observed time, Tn = normal time, and Pw = worker performance or pace

Time Study and Work Measurement Example: Normal Performance • Given: A man walks in the early morning for health and fitness. His usual route is 1. 85 miles. A typical time is 30 min. The benchmark of normal performance = 3 mi/hr. • Determine: (a) how long the route would take at normal performance and (b) the man’s performance when he completes the route in 30 min.

Time Study and Work Measurement Example: Normal Performance • Given: A man walks in the early morning for health and fitness. His usual route is 1. 85 miles. A typical time is 30 min. The benchmark of normal performance = 3 mi/hr. • Determine: (a) how long the route would take at normal performance and (b) the man’s performance when he completes the route in 30 min.

Time Study and Work Measurement (a) At 3 mi/hr, time = 1. 85 mi / 3 mi/hr = 0. 6167 hr = 37 min (b) Rearranging equation, Pw = Tn / Tc Pw = 37 min / 30 min = 1. 233 = 123. 3 %

Time Study and Work Measurement (a) At 3 mi/hr, time = 1. 85 mi / 3 mi/hr = 0. 6167 hr = 37 min (b) Rearranging equation, Pw = Tn / Tc Pw = 37 min / 30 min = 1. 233 = 123. 3 %

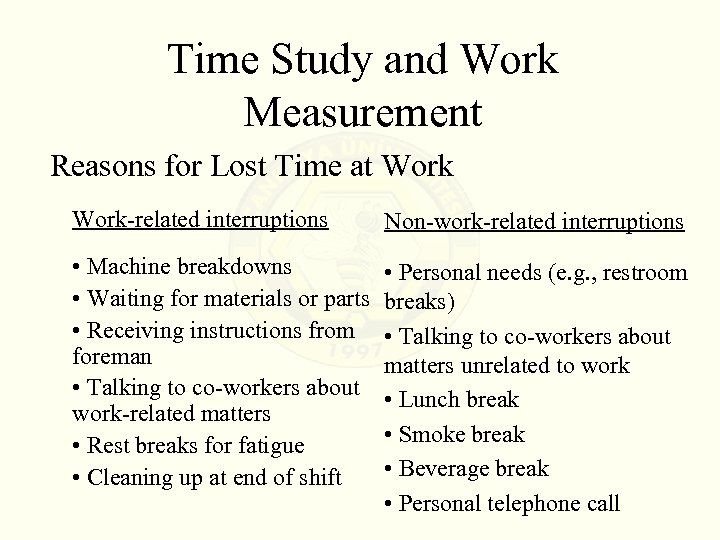

Time Study and Work Measurement Reasons for Lost Time at Work-related interruptions Non-work-related interruptions • Machine breakdowns • Waiting for materials or parts • Receiving instructions from foreman • Talking to co-workers about work-related matters • Rest breaks for fatigue • Cleaning up at end of shift • Personal needs (e. g. , restroom breaks) • Talking to co-workers about matters unrelated to work • Lunch break • Smoke break • Beverage break • Personal telephone call

Time Study and Work Measurement Reasons for Lost Time at Work-related interruptions Non-work-related interruptions • Machine breakdowns • Waiting for materials or parts • Receiving instructions from foreman • Talking to co-workers about work-related matters • Rest breaks for fatigue • Cleaning up at end of shift • Personal needs (e. g. , restroom breaks) • Talking to co-workers about matters unrelated to work • Lunch break • Smoke break • Beverage break • Personal telephone call

Time Study and Work Measurement How to Allow for Lost Time • Two approaches used by companies: 1. Scheduled rest breaks during the shift • Typical - one 15 -minute break in mid-morning and another in mid-afternoon 2. A PFD allowance is added to the normal time n This allows the worker to take a break on his/her own time

Time Study and Work Measurement How to Allow for Lost Time • Two approaches used by companies: 1. Scheduled rest breaks during the shift • Typical - one 15 -minute break in mid-morning and another in mid-afternoon 2. A PFD allowance is added to the normal time n This allows the worker to take a break on his/her own time

Time Study and Work Measurement PFD Allowance • Personal time – Rest room breaks, phone calls, water fountain stops, cigarette breaks (5% typical) • Fatigue – Rest allowance to overcome fatigue due to work-related stresses and conditions (5% or more) • Delays – Machine breakdowns, foreman instructions (5% typical)

Time Study and Work Measurement PFD Allowance • Personal time – Rest room breaks, phone calls, water fountain stops, cigarette breaks (5% typical) • Fatigue – Rest allowance to overcome fatigue due to work-related stresses and conditions (5% or more) • Delays – Machine breakdowns, foreman instructions (5% typical)

Time Study and Work Measurement Allowances in Time Standards • Normal time is adjusted by an allowance factor Apfd to obtain the standard time • Purpose of allowance factor is to compensate for lost time due to work interruptions and other reasons

Time Study and Work Measurement Allowances in Time Standards • Normal time is adjusted by an allowance factor Apfd to obtain the standard time • Purpose of allowance factor is to compensate for lost time due to work interruptions and other reasons

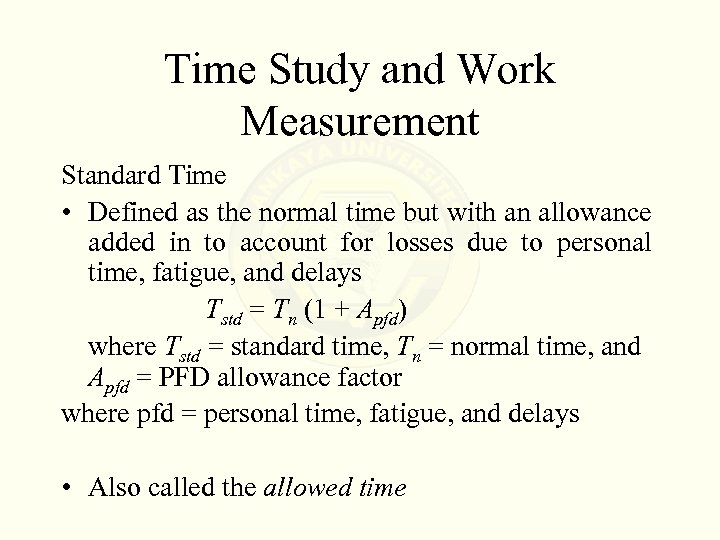

Time Study and Work Measurement Standard Time • Defined as the normal time but with an allowance added in to account for losses due to personal time, fatigue, and delays Tstd = Tn (1 + Apfd) where Tstd = standard time, Tn = normal time, and Apfd = PFD allowance factor where pfd = personal time, fatigue, and delays • Also called the allowed time

Time Study and Work Measurement Standard Time • Defined as the normal time but with an allowance added in to account for losses due to personal time, fatigue, and delays Tstd = Tn (1 + Apfd) where Tstd = standard time, Tn = normal time, and Apfd = PFD allowance factor where pfd = personal time, fatigue, and delays • Also called the allowed time

Time Study and Work Measurement Standard Performance • Same as normal performance, but acknowledges that periodic rest breaks must be taken by the worker – Periodic rest breaks are allowed during the work shift – Other interruptions and delays also occur during the shift

Time Study and Work Measurement Standard Performance • Same as normal performance, but acknowledges that periodic rest breaks must be taken by the worker – Periodic rest breaks are allowed during the work shift – Other interruptions and delays also occur during the shift

Time Study and Work Measurement Standard Method • Must include all of the details on how the task is performed, including: – – – – Procedure - hand body motions Tools Equipment Workplace layout Irregular work Working conditions Setup

Time Study and Work Measurement Standard Method • Must include all of the details on how the task is performed, including: – – – – Procedure - hand body motions Tools Equipment Workplace layout Irregular work Working conditions Setup

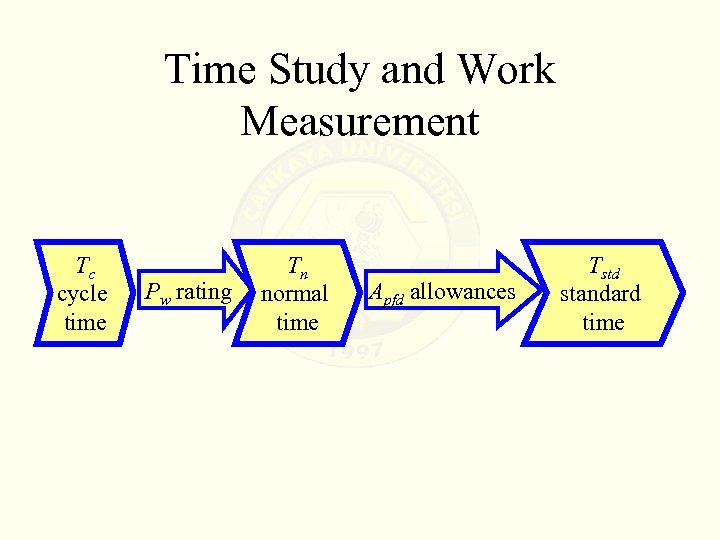

Time Study and Work Measurement Tc cycle time Pw rating Tn normal time Apfd allowances Tstd standard time

Time Study and Work Measurement Tc cycle time Pw rating Tn normal time Apfd allowances Tstd standard time

Time Study and Work Measurement Irregular Work Elements • Elements that are performed with a frequency of less than once per cycle • Examples: – Changing a tool – Exchanging tote pans of parts • Irregular elements are prorated into the regular cycle according to their frequency

Time Study and Work Measurement Irregular Work Elements • Elements that are performed with a frequency of less than once per cycle • Examples: – Changing a tool – Exchanging tote pans of parts • Irregular elements are prorated into the regular cycle according to their frequency

Time Study and Work Measurement Example: Determining Standard Time • Given: The normal time to perform the regular work cycle is 3. 23 min. In addition, an irregular work element with a normal time = 1. 25 min is performed every 5 cycles. The PFD allowance factor is 15%. • Determine (a) the standard time and (b) the number of work units produced during an 8 -hr shift if the worker's pace is consistent with standard performance.

Time Study and Work Measurement Example: Determining Standard Time • Given: The normal time to perform the regular work cycle is 3. 23 min. In addition, an irregular work element with a normal time = 1. 25 min is performed every 5 cycles. The PFD allowance factor is 15%. • Determine (a) the standard time and (b) the number of work units produced during an 8 -hr shift if the worker's pace is consistent with standard performance.

Time Study and Work Measurement (a) Normal time Tn = 3. 23 + 1. 25/5 = 3. 48 min Standard time Tstd = 3. 48 (1 + 0. 15) = 4. 00 min (b) Number of work units produced during an 8 -hr shift Qstd = 8. 0(60)/4. 00 = 120 work units

Time Study and Work Measurement (a) Normal time Tn = 3. 23 + 1. 25/5 = 3. 48 min Standard time Tstd = 3. 48 (1 + 0. 15) = 4. 00 min (b) Number of work units produced during an 8 -hr shift Qstd = 8. 0(60)/4. 00 = 120 work units

Direct Time Study • Direct and continuous observation of a task using a stopwatch or other timekeeping device to record the time taken to accomplish the task • While observing and recording the time, an appraisal of the worker’s performance level is made to obtain the normal time for the task • The data are then used to compute a standard time for the task

Direct Time Study • Direct and continuous observation of a task using a stopwatch or other timekeeping device to record the time taken to accomplish the task • While observing and recording the time, an appraisal of the worker’s performance level is made to obtain the normal time for the task • The data are then used to compute a standard time for the task

Direct Time Study Procedure 1. Define and document the standard method 2. Divide the task into work elements 3. Time the work elements to obtain the observed time Tobs 4. Evaluate worker’s pace relative to standard performance to obtain normal time Tn – Called performance rating (PR) Tn = Tobs(PR) 5. Apply allowance factor to compute standard time Tstd = Tn(1 + Apfd)

Direct Time Study Procedure 1. Define and document the standard method 2. Divide the task into work elements 3. Time the work elements to obtain the observed time Tobs 4. Evaluate worker’s pace relative to standard performance to obtain normal time Tn – Called performance rating (PR) Tn = Tobs(PR) 5. Apply allowance factor to compute standard time Tstd = Tn(1 + Apfd)

Direct Time Study Document the Standard Method • Determine the “one best method” – Seek worker’s advice if possible • Documentation should include: – All of the steps in the method – Special tools, gauges, equipment and equipment settings (e. g. , feeds and speeds) if applicable – Irregular elements and their frequency • Once the standard method is defined, it should not be possible for the operator to make further improvements

Direct Time Study Document the Standard Method • Determine the “one best method” – Seek worker’s advice if possible • Documentation should include: – All of the steps in the method – Special tools, gauges, equipment and equipment settings (e. g. , feeds and speeds) if applicable – Irregular elements and their frequency • Once the standard method is defined, it should not be possible for the operator to make further improvements

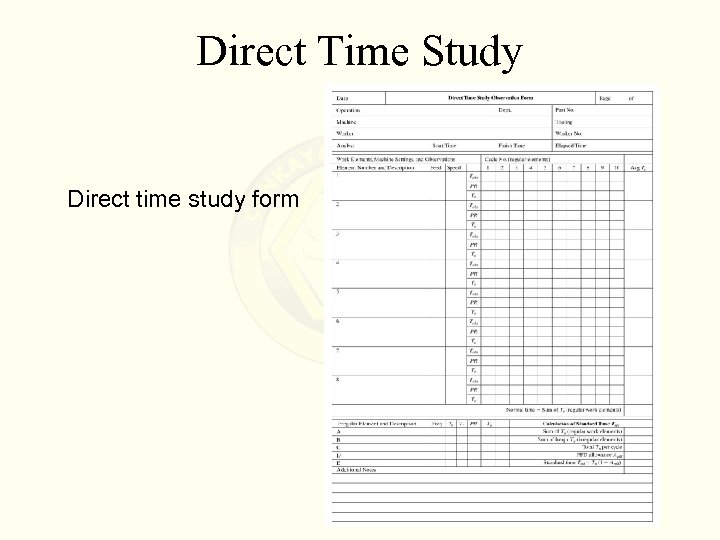

Direct Time Study Direct time study form

Direct Time Study Direct time study form

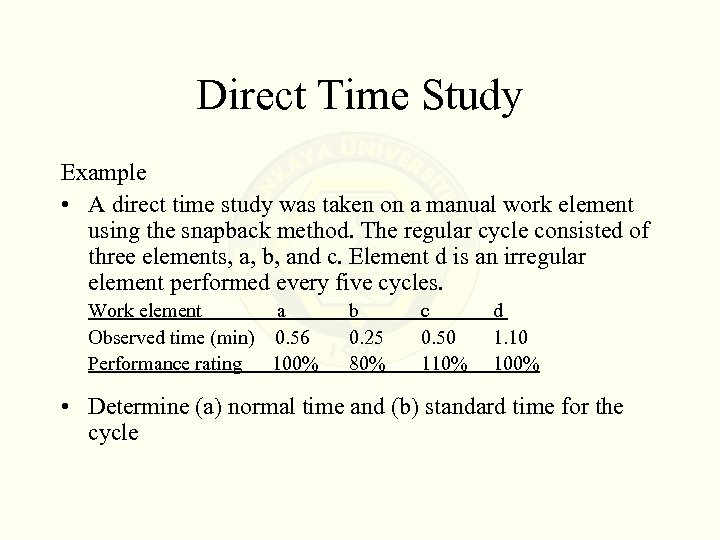

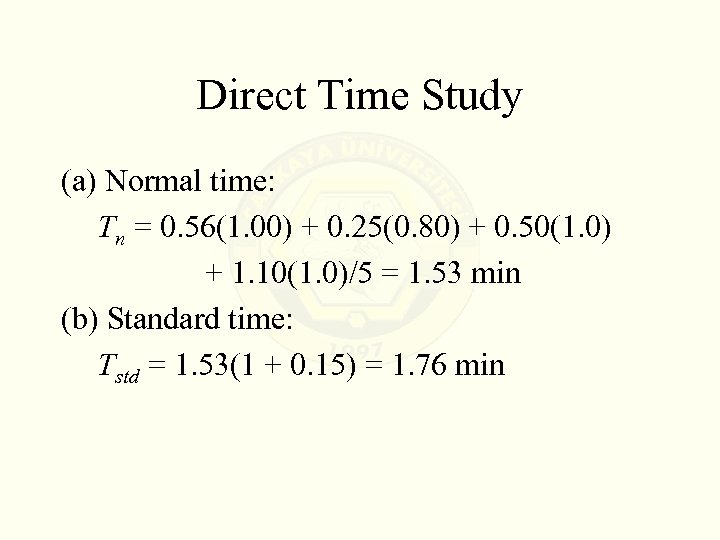

Direct Time Study Example • A direct time study was taken on a manual work element using the snapback method. The regular cycle consisted of three elements, a, b, and c. Element d is an irregular element performed every five cycles. Work element a Observed time (min) 0. 56 Performance rating 100% b 0. 25 80% c 0. 50 110% d 1. 10 100% • Determine (a) normal time and (b) standard time for the cycle

Direct Time Study Example • A direct time study was taken on a manual work element using the snapback method. The regular cycle consisted of three elements, a, b, and c. Element d is an irregular element performed every five cycles. Work element a Observed time (min) 0. 56 Performance rating 100% b 0. 25 80% c 0. 50 110% d 1. 10 100% • Determine (a) normal time and (b) standard time for the cycle

Direct Time Study (a) Normal time: Tn = 0. 56(1. 00) + 0. 25(0. 80) + 0. 50(1. 0) + 1. 10(1. 0)/5 = 1. 53 min (b) Standard time: Tstd = 1. 53(1 + 0. 15) = 1. 76 min

Direct Time Study (a) Normal time: Tn = 0. 56(1. 00) + 0. 25(0. 80) + 0. 50(1. 0) + 1. 10(1. 0)/5 = 1. 53 min (b) Standard time: Tstd = 1. 53(1 + 0. 15) = 1. 76 min

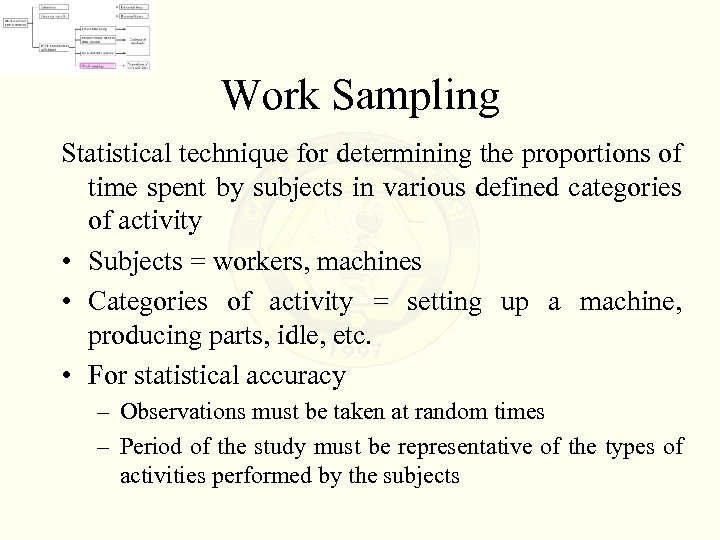

Work Sampling Statistical technique for determining the proportions of time spent by subjects in various defined categories of activity • Subjects = workers, machines • Categories of activity = setting up a machine, producing parts, idle, etc. • For statistical accuracy – Observations must be taken at random times – Period of the study must be representative of the types of activities performed by the subjects

Work Sampling Statistical technique for determining the proportions of time spent by subjects in various defined categories of activity • Subjects = workers, machines • Categories of activity = setting up a machine, producing parts, idle, etc. • For statistical accuracy – Observations must be taken at random times – Period of the study must be representative of the types of activities performed by the subjects

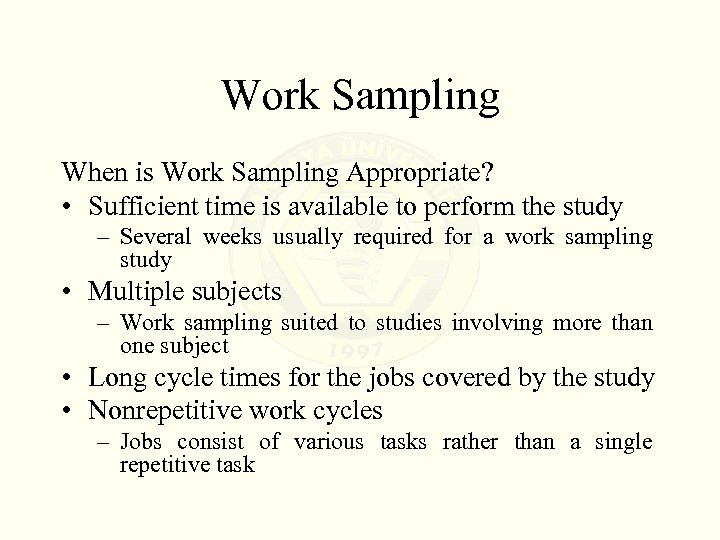

Work Sampling When is Work Sampling Appropriate? • Sufficient time is available to perform the study – Several weeks usually required for a work sampling study • Multiple subjects – Work sampling suited to studies involving more than one subject • Long cycle times for the jobs covered by the study • Nonrepetitive work cycles – Jobs consist of various tasks rather than a single repetitive task

Work Sampling When is Work Sampling Appropriate? • Sufficient time is available to perform the study – Several weeks usually required for a work sampling study • Multiple subjects – Work sampling suited to studies involving more than one subject • Long cycle times for the jobs covered by the study • Nonrepetitive work cycles – Jobs consist of various tasks rather than a single repetitive task

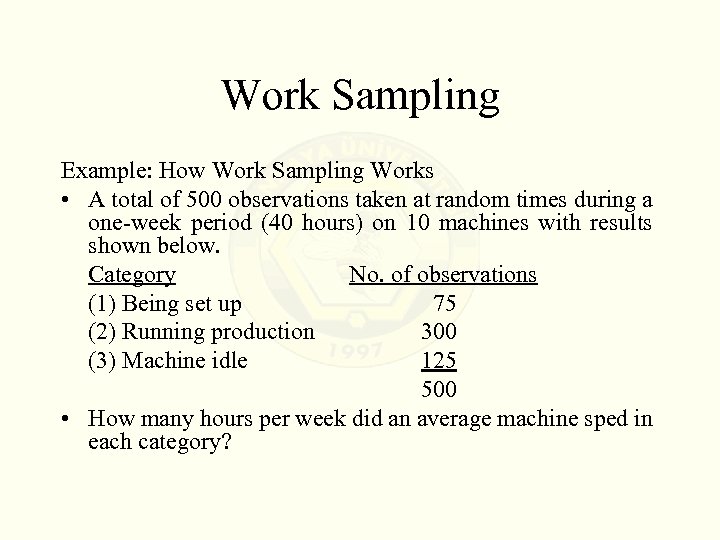

Work Sampling Example: How Work Sampling Works • A total of 500 observations taken at random times during a one-week period (40 hours) on 10 machines with results shown below. Category No. of observations (1) Being set up 75 (2) Running production 300 (3) Machine idle 125 500 • How many hours per week did an average machine sped in each category?

Work Sampling Example: How Work Sampling Works • A total of 500 observations taken at random times during a one-week period (40 hours) on 10 machines with results shown below. Category No. of observations (1) Being set up 75 (2) Running production 300 (3) Machine idle 125 500 • How many hours per week did an average machine sped in each category?

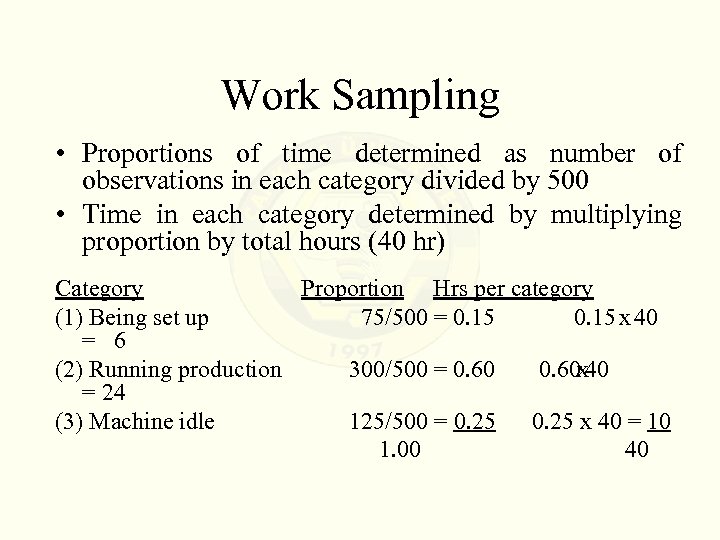

Work Sampling • Proportions of time determined as number of observations in each category divided by 500 • Time in each category determined by multiplying proportion by total hours (40 hr) Category Proportion Hrs per category (1) Being set up 75/500 = 0. 15 x 40 = 6 (2) Running production 300/500 = 0. 60 x 40 = 24 (3) Machine idle 125/500 = 0. 25 x 40 = 10 1. 00 40

Work Sampling • Proportions of time determined as number of observations in each category divided by 500 • Time in each category determined by multiplying proportion by total hours (40 hr) Category Proportion Hrs per category (1) Being set up 75/500 = 0. 15 x 40 = 6 (2) Running production 300/500 = 0. 60 x 40 = 24 (3) Machine idle 125/500 = 0. 25 x 40 = 10 1. 00 40

Work Sampling Applications • Machine utilization - how much time is spent by machines in various categories of activity – Previous example • Worker utilization - how workers spend their time • Allowances for time standards - assessment of delay components in PFD allowance factor • Average unit time - determining the average time on each work unit • Time standards - limited statistical accuracy when standards set by work sampling

Work Sampling Applications • Machine utilization - how much time is spent by machines in various categories of activity – Previous example • Worker utilization - how workers spend their time • Allowances for time standards - assessment of delay components in PFD allowance factor • Average unit time - determining the average time on each work unit • Time standards - limited statistical accuracy when standards set by work sampling

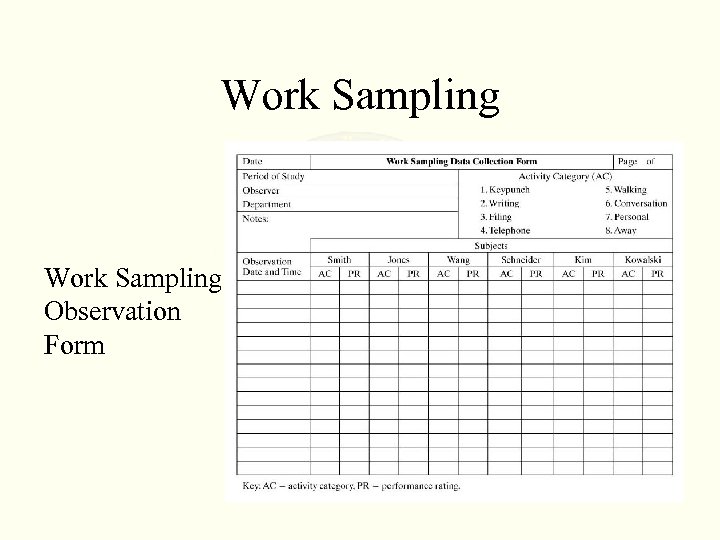

Work Sampling Observation Form

Work Sampling Observation Form

References • Groover, Mikell P. , Work Systems: The Methods, Measurement & Management of Work, 2007, Prentice Hall • Barnes, Ralph M. , Motion and Time Study: Design and Measurement of Work, 1990, John Wiley & Sons Inc.

References • Groover, Mikell P. , Work Systems: The Methods, Measurement & Management of Work, 2007, Prentice Hall • Barnes, Ralph M. , Motion and Time Study: Design and Measurement of Work, 1990, John Wiley & Sons Inc.