b89dd3f3a15be4939b86296ee364005c.ppt

- Количество слайдов: 24

Xyloy ™ Injection Moldable Metal Alloys

Xyloy™ Injection Moldable Metal Alloys Bringing Design Freedom and Parts Consolidation to Metals

Xyloy™ Injection Moldable Metal Alloys Topics § § § Xyloy IS and IS NOTs Manufacturing Steps Material Properties Markets & Case Studies Compliance and Sustainability

Xyloy™ Injection Moldable Metal IS NOT… § Xyloy injection moldable metal IS NOT metal or powder injection molding (MIM/PIM)…

Xyloy™ Injection Moldable Metal IS NOT… § Xyloy injection moldable metal IS NOT metal filled plastic…

Xyloy™ Injection Moldable Metal IS NOT… § Xyloy injection moldable metal IS NOT thixomolding…

Xyloy™ Injection Moldable Metal IS NOT… § Xyloy injection moldable metal IS NOT die casting…

Xyloy™ Injection Moldable Metal IS… § Xyloy injection moldable metal IS injection molding of nonferrous alloys on plastic injection molding equipment with conventional molds

Xyloy™ Injection Moldable Metal IS… § Xyloy injection moldable metal IS for OEMs with captive injection molding who want to bring metal part supply inhouse

Xyloy™ Injection Moldable Metal IS… § Xyloy injection moldable metal IS for custom injection molders who want to offer plastic AND metal parts to OEMs and component manufacturers

Xyloy™ Injection Moldable Metal Alloys Manufacturing Steps § Pellets § Tooling § Injection Molding § Part Finishes (optional)

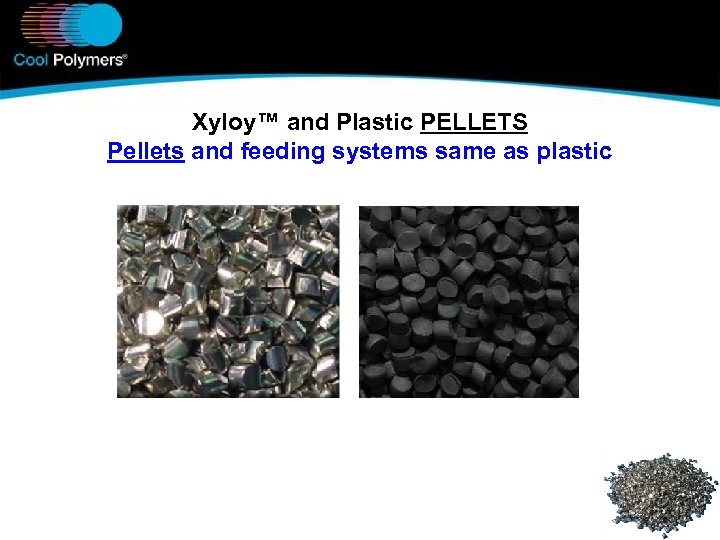

Xyloy™ and Plastic PELLETS Pellets and feeding systems same as plastic

Xyloy™ and Plastic TOOLING Same Tool – Same Part – Different Properties

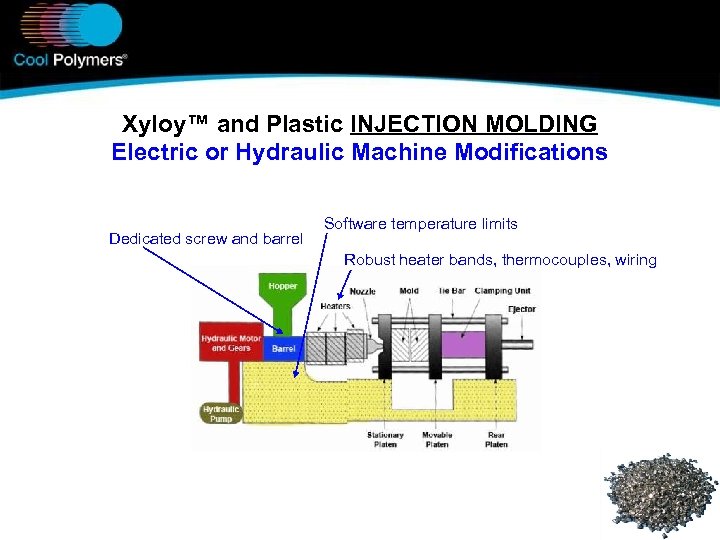

Xyloy™ and Plastic INJECTION MOLDING Electric or Hydraulic Machine Modifications Dedicated screw and barrel Software temperature limits Robust heater bands, thermocouples, wiring

Xyloy™ Injection Moldable Metal Coatings, Conversions & Finishes A variety of coatings, conversions and finishes are possible for meeting aesthetic, chemical, and corrosion resistance requirements § § Surface texturing Conversions (phosphate, chromate) E-coat Powder coat (polyester, epoxy) § colors § textures § Paint § Plating (copper, nickel, chrome) § Depositions

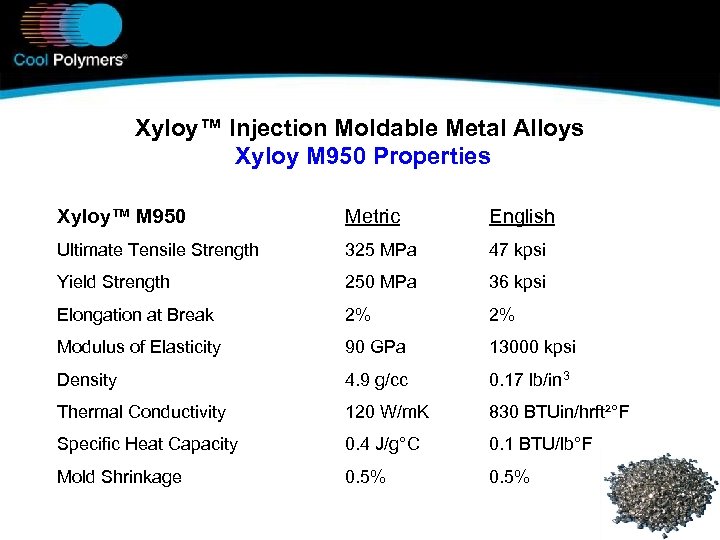

Xyloy™ Injection Moldable Metal Alloys Xyloy M 950 Properties Xyloy™ M 950 Metric English Ultimate Tensile Strength 325 MPa 47 kpsi Yield Strength 250 MPa 36 kpsi Elongation at Break 2% 2% Modulus of Elasticity 90 GPa 13000 kpsi Density 4. 9 g/cc 0. 17 lb/in 3 Thermal Conductivity 120 W/m. K 830 BTUin/hrft²°F Specific Heat Capacity 0. 4 J/g°C 0. 1 BTU/lb°F Mold Shrinkage 0. 5%

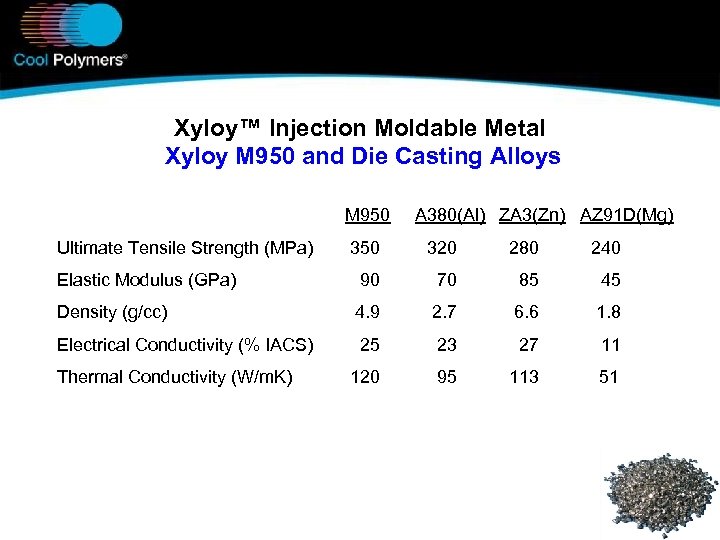

Xyloy™ Injection Moldable Metal Xyloy M 950 and Die Casting Alloys M 950 Ultimate Tensile Strength (MPa) A 380(Al) ZA 3(Zn) AZ 91 D(Mg) 350 320 280 240 Elastic Modulus (GPa) 90 70 85 45 Density (g/cc) 4. 9 2. 7 6. 6 1. 8 Electrical Conductivity (% IACS) 25 23 27 11 120 95 113 51 Thermal Conductivity (W/m. K)

Xyloy™ Injection Moldable Metal Alloys Market Segments Aerospace Automotive Computer/IT Consumer Electrical/Electronics Health Care Industrial

Xyloy™ Injection Moldable Metal Alloys Case Study – Valves & Controls Problem: Reinforced engineering plastic failed due to mechanical load. Machined metal was 4 X the price even with design changes. Solution: Xyloy M 950 molded in existing plastic tooling (3 -plate). Low cost and high performance.

Xyloy™ Injection Moldable Metal Alloys Case Study – Electronic Enclosure Problem: Enclosure and thermal management for computer component. Features and dimensional tolerances required expensive machining. Solution: Xyloy M 950 molded in multicavity tooling. Molded-in features eliminate machining. High degree of flatness and dimensional accuracy.

Xyloy™ Regulatory Compliance Meets Current and Future Requirements Ro. HS/WEEE compliant finishes Non-flammable No halogen content No low melting components No heavy metals No organics

Xyloy™ Injection Moldable Metal Alloys Sustainable / Recyclable Ability to reuse regrind (runner, sprue) Recycling via standard automobile and scrap metal recovery True recyclability – infinitely recyclable Fully restored properties versus degradation in polymers

Xyloy™ Injection Moldable Metal Alloys Summary Xyloy injection moldable metal alloys are molded on conventional plastic injection molding equipment to produce parts in high volumes § § § § 3 -dimensional, net shape parts No porosity, stronger than die cast Can be used with existing tooling for plastics Fast cycle times Standard conversions, coatings and finishes 120 W/m. K thermal conductivity Minimal tool wear Recyclable and sustainable

Cool. Poly® Thermally Conductive Plastics Xyloy™ Injection Moldable Metal Alloys www. coolpolymers. com ISO 9001: 2000 CERTIFIED

b89dd3f3a15be4939b86296ee364005c.ppt