a7c190245f2bf23af654a1f813d0c127.ppt

- Количество слайдов: 24

XAPPER Progress: Summer 2004 Are we having fun yet? New postdoc? Presented by: Jeff Latkowski XAPPER Team: Ryan Abbott, Robert Schmitt, and Brad Bell XAPPER HAPL Program Workshop Princeton Plasma Physics Laboratory October 27 -28, 2004 Work performed under the auspices of the U. S. Department of Energy by Lawrence Livermore National Laboratory under Contract W-7405 -Eng-48.

XAPPER Progress: Summer 2004 Are we having fun yet? New postdoc? Presented by: Jeff Latkowski XAPPER Team: Ryan Abbott, Robert Schmitt, and Brad Bell XAPPER HAPL Program Workshop Princeton Plasma Physics Laboratory October 27 -28, 2004 Work performed under the auspices of the U. S. Department of Energy by Lawrence Livermore National Laboratory under Contract W-7405 -Eng-48.

Overview q Finally, a decent fluence measurement! q Rad. Heat update q New tungsten exposures q Upcoming improvements JFL— 10/28/04

Overview q Finally, a decent fluence measurement! q Rad. Heat update q New tungsten exposures q Upcoming improvements JFL— 10/28/04

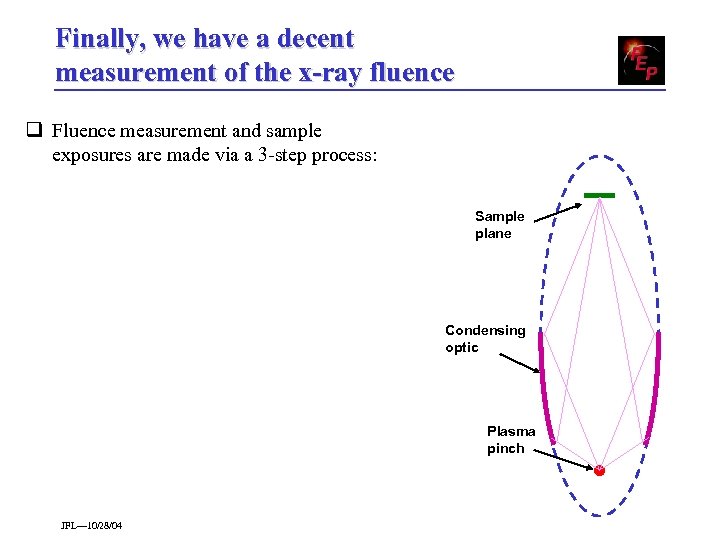

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: Sample plane Condensing optic Plasma pinch JFL— 10/28/04

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: Sample plane Condensing optic Plasma pinch JFL— 10/28/04

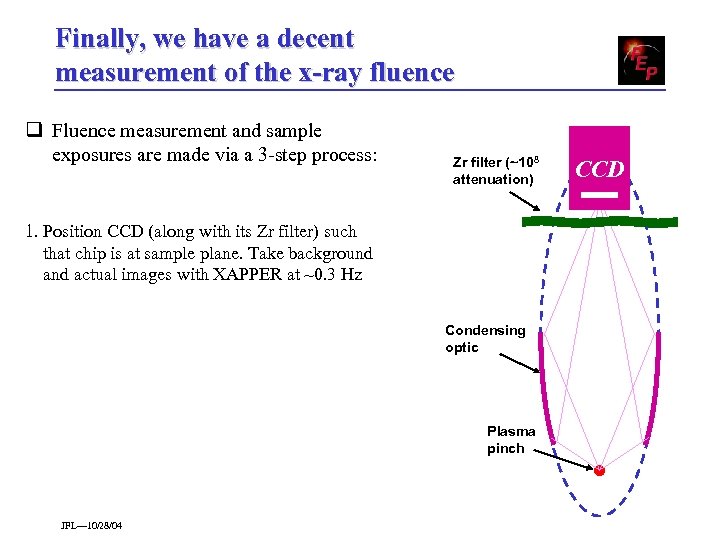

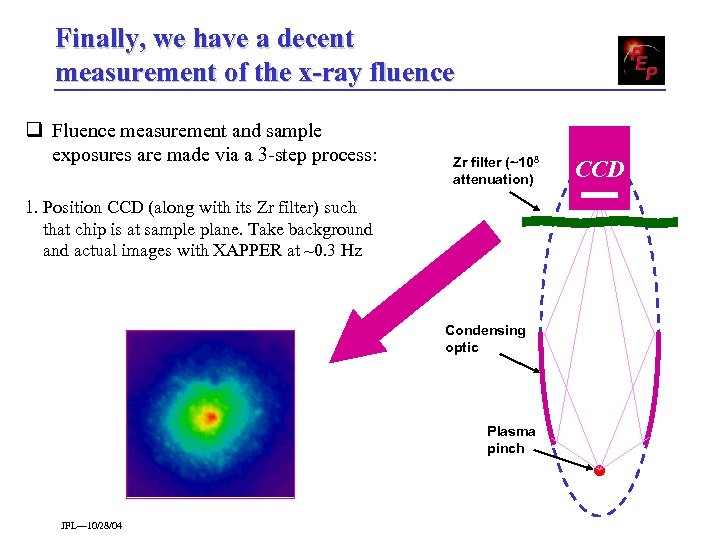

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: Zr filter (~108 attenuation) 1. Position CCD (along with its Zr filter) such that chip is at sample plane. Take background actual images with XAPPER at ~0. 3 Hz Condensing optic Plasma pinch JFL— 10/28/04 CCD

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: Zr filter (~108 attenuation) 1. Position CCD (along with its Zr filter) such that chip is at sample plane. Take background actual images with XAPPER at ~0. 3 Hz Condensing optic Plasma pinch JFL— 10/28/04 CCD

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: Zr filter (~108 attenuation) 1. Position CCD (along with its Zr filter) such that chip is at sample plane. Take background actual images with XAPPER at ~0. 3 Hz Condensing optic Plasma pinch JFL— 10/28/04 CCD

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: Zr filter (~108 attenuation) 1. Position CCD (along with its Zr filter) such that chip is at sample plane. Take background actual images with XAPPER at ~0. 3 Hz Condensing optic Plasma pinch JFL— 10/28/04 CCD

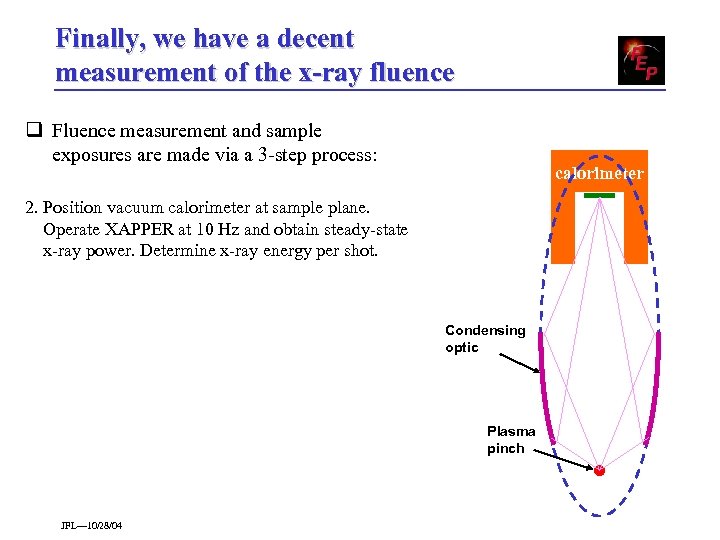

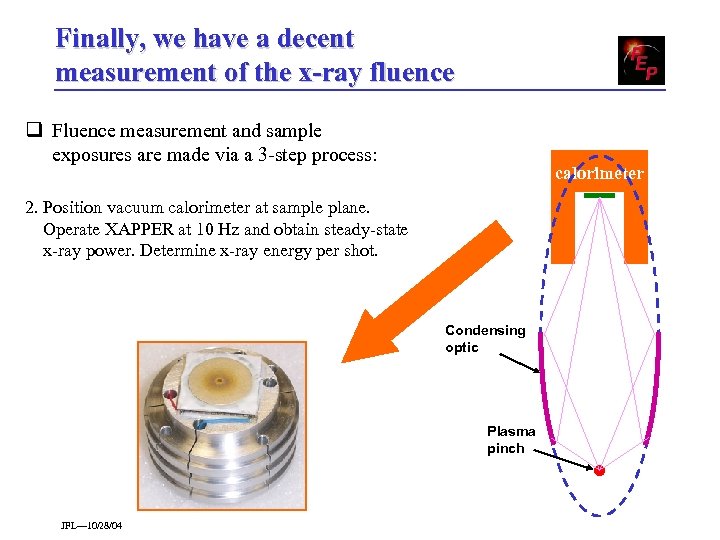

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: calorimeter 2. Position vacuum calorimeter at sample plane. Operate XAPPER at 10 Hz and obtain steady-state x-ray power. Determine x-ray energy per shot. Condensing optic Plasma pinch JFL— 10/28/04

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: calorimeter 2. Position vacuum calorimeter at sample plane. Operate XAPPER at 10 Hz and obtain steady-state x-ray power. Determine x-ray energy per shot. Condensing optic Plasma pinch JFL— 10/28/04

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: calorimeter 2. Position vacuum calorimeter at sample plane. Operate XAPPER at 10 Hz and obtain steady-state x-ray power. Determine x-ray energy per shot. Condensing optic Plasma pinch JFL— 10/28/04

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: calorimeter 2. Position vacuum calorimeter at sample plane. Operate XAPPER at 10 Hz and obtain steady-state x-ray power. Determine x-ray energy per shot. Condensing optic Plasma pinch JFL— 10/28/04

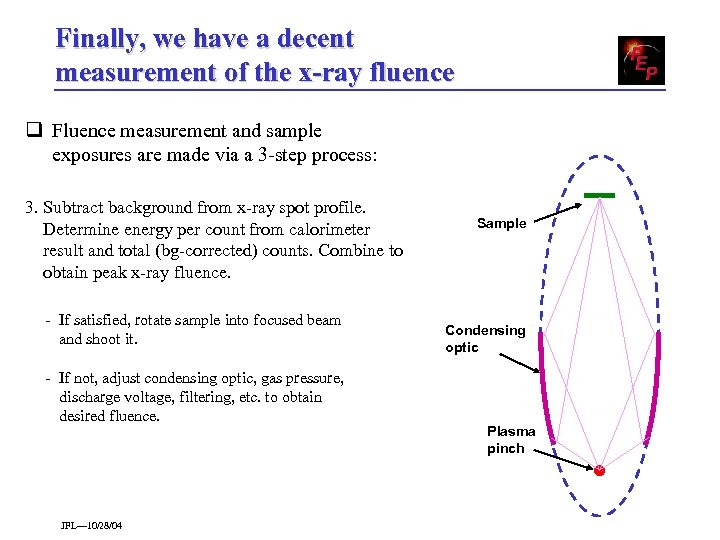

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: 3. Subtract background from x-ray spot profile. Determine energy per count from calorimeter result and total (bg-corrected) counts. Combine to obtain peak x-ray fluence. - If satisfied, rotate sample into focused beam and shoot it. - If not, adjust condensing optic, gas pressure, discharge voltage, filtering, etc. to obtain desired fluence. JFL— 10/28/04 Sample Condensing optic Plasma pinch

Finally, we have a decent measurement of the x-ray fluence q Fluence measurement and sample exposures are made via a 3 -step process: 3. Subtract background from x-ray spot profile. Determine energy per count from calorimeter result and total (bg-corrected) counts. Combine to obtain peak x-ray fluence. - If satisfied, rotate sample into focused beam and shoot it. - If not, adjust condensing optic, gas pressure, discharge voltage, filtering, etc. to obtain desired fluence. JFL— 10/28/04 Sample Condensing optic Plasma pinch

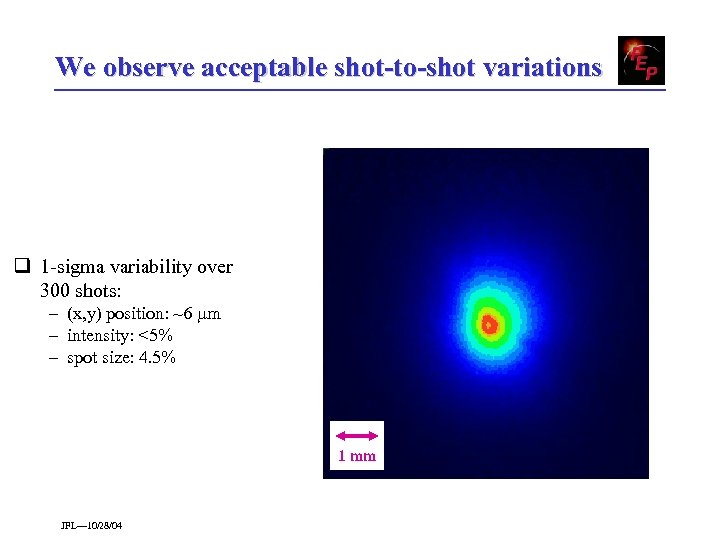

We observe acceptable shot-to-shot variations q 1 -sigma variability over 300 shots: – (x, y) position: ~6 mm – intensity: <5% – spot size: 4. 5% 1 mm JFL— 10/28/04

We observe acceptable shot-to-shot variations q 1 -sigma variability over 300 shots: – (x, y) position: ~6 mm – intensity: <5% – spot size: 4. 5% 1 mm JFL— 10/28/04

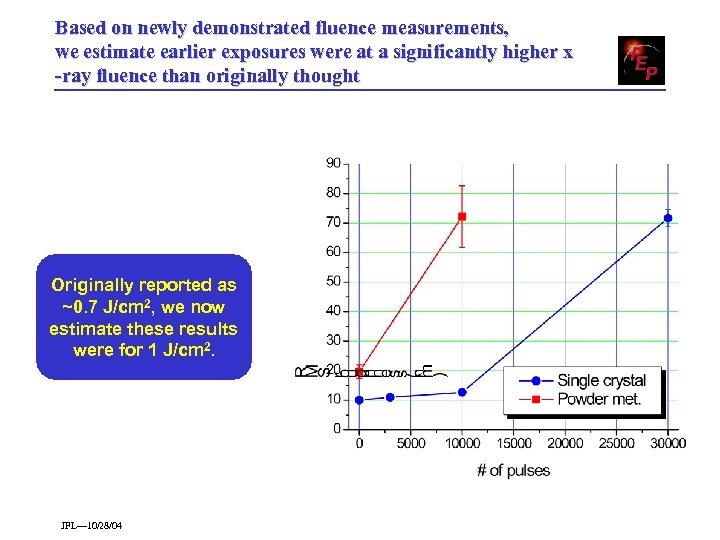

Based on newly demonstrated fluence measurements, we estimate earlier exposures were at a significantly higher x -ray fluence than originally thought Originally reported as ~0. 7 J/cm 2, we now estimate these results were for 1 J/cm 2. JFL— 10/28/04

Based on newly demonstrated fluence measurements, we estimate earlier exposures were at a significantly higher x -ray fluence than originally thought Originally reported as ~0. 7 J/cm 2, we now estimate these results were for 1 J/cm 2. JFL— 10/28/04

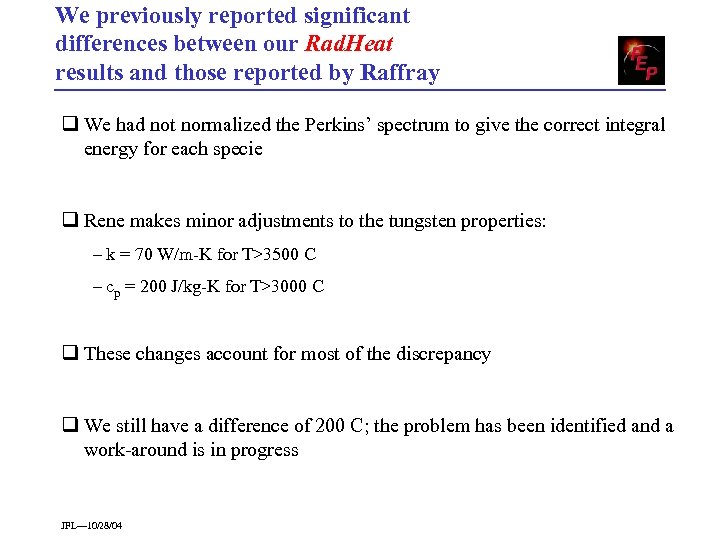

We previously reported significant differences between our Rad. Heat results and those reported by Raffray q We had not normalized the Perkins’ spectrum to give the correct integral energy for each specie q Rene makes minor adjustments to the tungsten properties: – k = 70 W/m-K for T>3500 C – cp = 200 J/kg-K for T>3000 C q These changes account for most of the discrepancy q We still have a difference of 200 C; the problem has been identified and a work-around is in progress JFL— 10/28/04

We previously reported significant differences between our Rad. Heat results and those reported by Raffray q We had not normalized the Perkins’ spectrum to give the correct integral energy for each specie q Rene makes minor adjustments to the tungsten properties: – k = 70 W/m-K for T>3500 C – cp = 200 J/kg-K for T>3000 C q These changes account for most of the discrepancy q We still have a difference of 200 C; the problem has been identified and a work-around is in progress JFL— 10/28/04

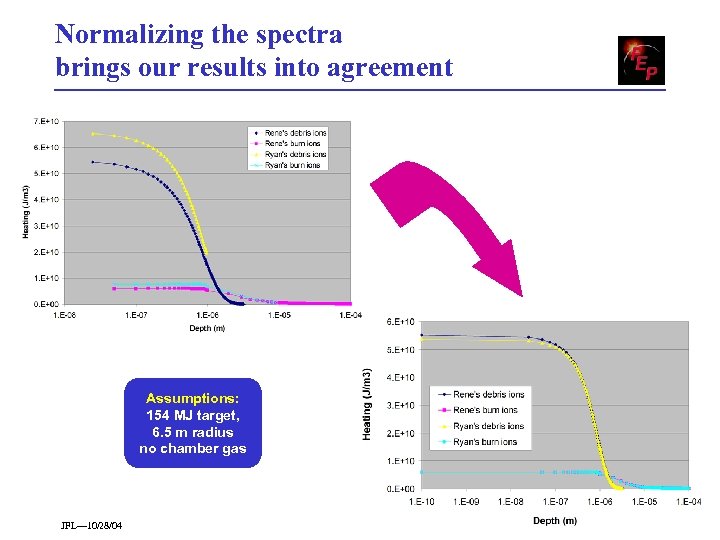

Normalizing the spectra brings our results into agreement Assumptions: 154 MJ target, 6. 5 m radius no chamber gas JFL— 10/28/04

Normalizing the spectra brings our results into agreement Assumptions: 154 MJ target, 6. 5 m radius no chamber gas JFL— 10/28/04

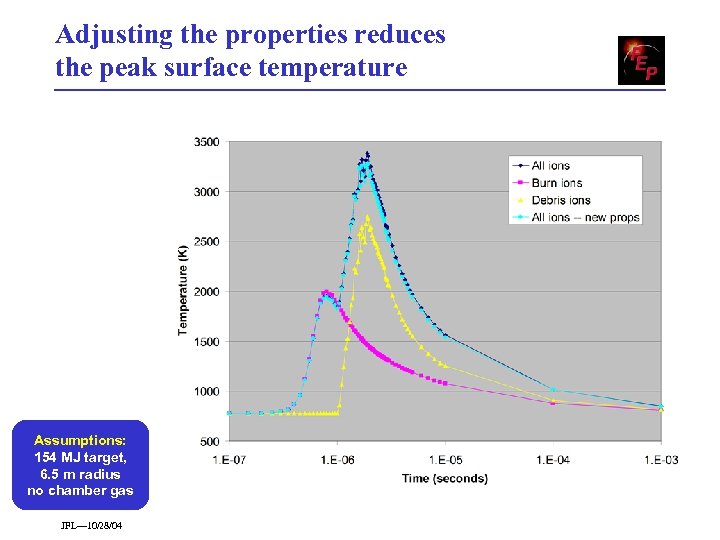

Adjusting the properties reduces the peak surface temperature Assumptions: 154 MJ target, 6. 5 m radius no chamber gas JFL— 10/28/04

Adjusting the properties reduces the peak surface temperature Assumptions: 154 MJ target, 6. 5 m radius no chamber gas JFL— 10/28/04

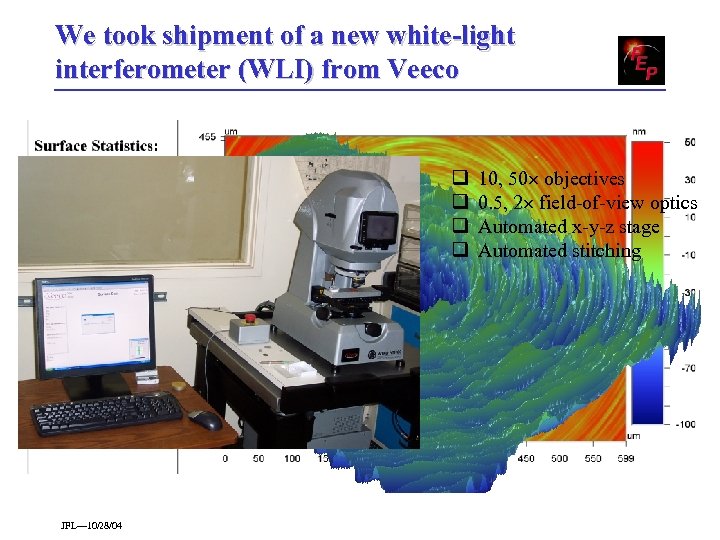

We took shipment of a new white-light interferometer (WLI) from Veeco q q JFL— 10/28/04 10, 50 objectives 0. 5, 2 field-of-view optics Automated x-y-z stage Automated stitching

We took shipment of a new white-light interferometer (WLI) from Veeco q q JFL— 10/28/04 10, 50 objectives 0. 5, 2 field-of-view optics Automated x-y-z stage Automated stitching

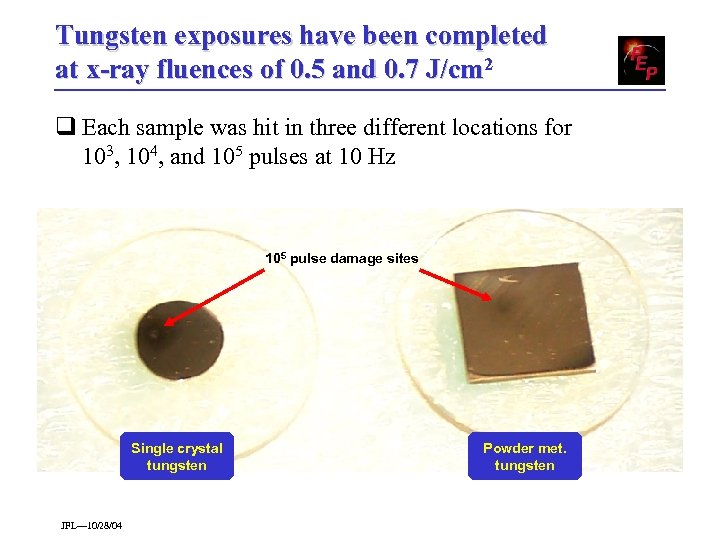

Tungsten exposures have been completed at x-ray fluences of 0. 5 and 0. 7 J/cm 2 q Each sample was hit in three different locations for 103, 104, and 105 pulses at 10 Hz 105 pulse damage sites Single crystal tungsten JFL— 10/28/04 Powder met. tungsten

Tungsten exposures have been completed at x-ray fluences of 0. 5 and 0. 7 J/cm 2 q Each sample was hit in three different locations for 103, 104, and 105 pulses at 10 Hz 105 pulse damage sites Single crystal tungsten JFL— 10/28/04 Powder met. tungsten

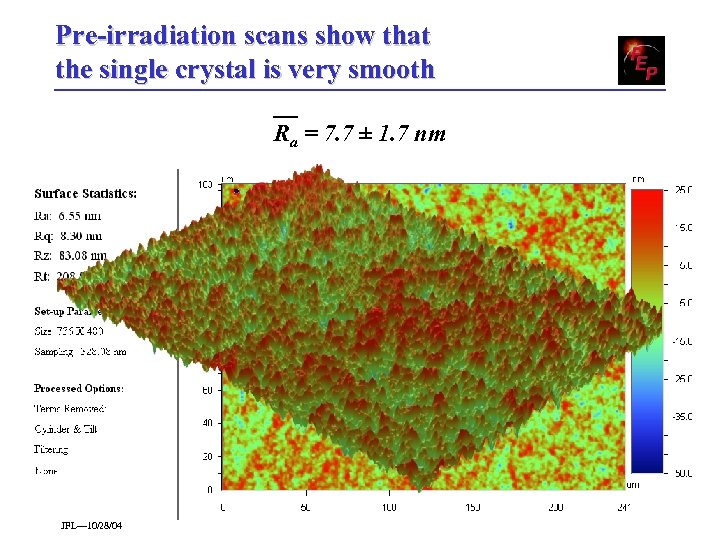

Pre-irradiation scans show that the single crystal is very smooth Ra = 7. 7 ± 1. 7 nm JFL— 10/28/04

Pre-irradiation scans show that the single crystal is very smooth Ra = 7. 7 ± 1. 7 nm JFL— 10/28/04

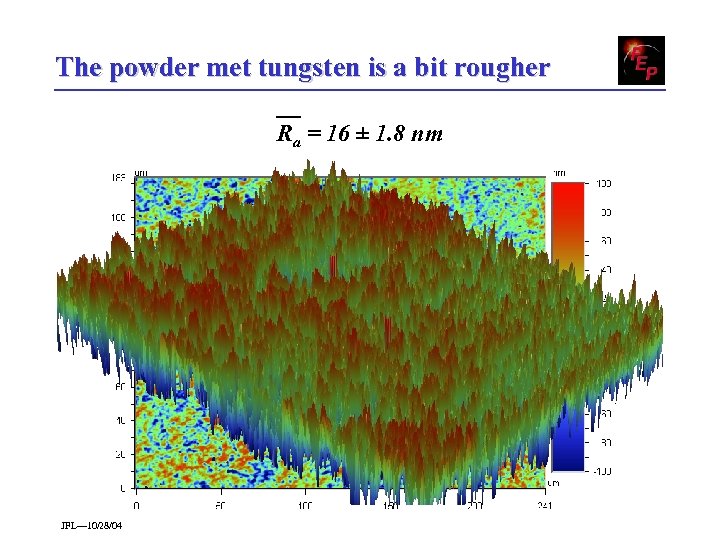

The powder met tungsten is a bit rougher Ra = 16 ± 1. 8 nm JFL— 10/28/04

The powder met tungsten is a bit rougher Ra = 16 ± 1. 8 nm JFL— 10/28/04

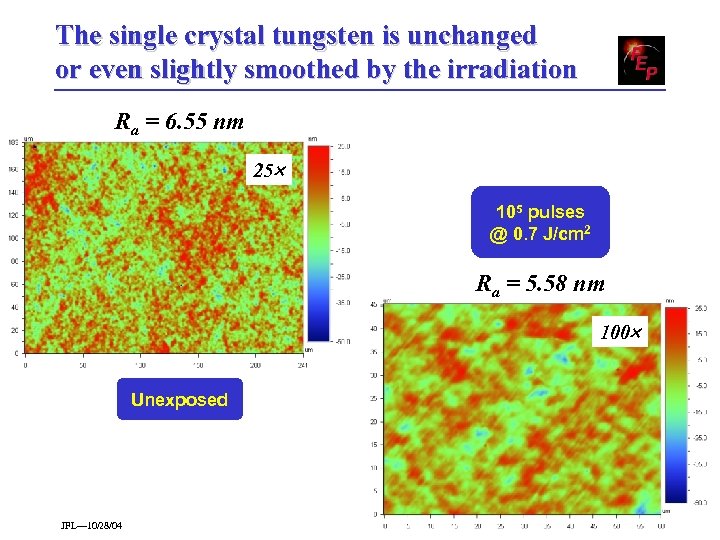

The single crystal tungsten is unchanged or even slightly smoothed by the irradiation Ra = 6. 55 nm 25 105 pulses @ 0. 7 J/cm 2 Ra = 5. 58 nm 100 Unexposed JFL— 10/28/04

The single crystal tungsten is unchanged or even slightly smoothed by the irradiation Ra = 6. 55 nm 25 105 pulses @ 0. 7 J/cm 2 Ra = 5. 58 nm 100 Unexposed JFL— 10/28/04

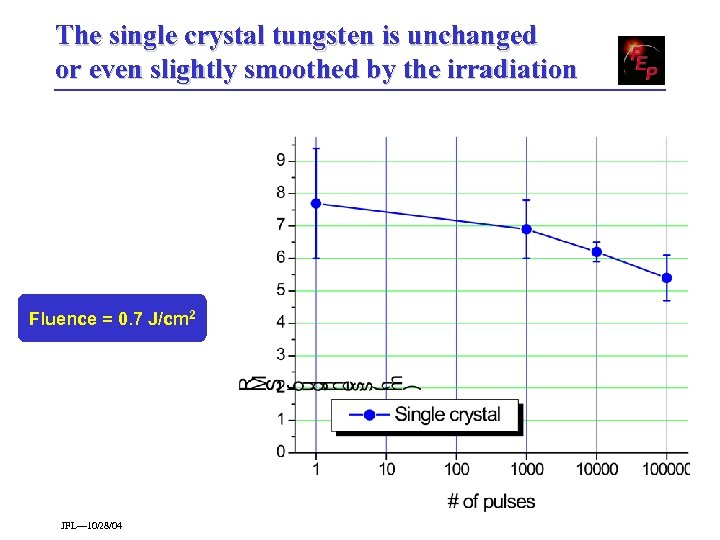

The single crystal tungsten is unchanged or even slightly smoothed by the irradiation Fluence = 0. 7 J/cm 2 JFL— 10/28/04

The single crystal tungsten is unchanged or even slightly smoothed by the irradiation Fluence = 0. 7 J/cm 2 JFL— 10/28/04

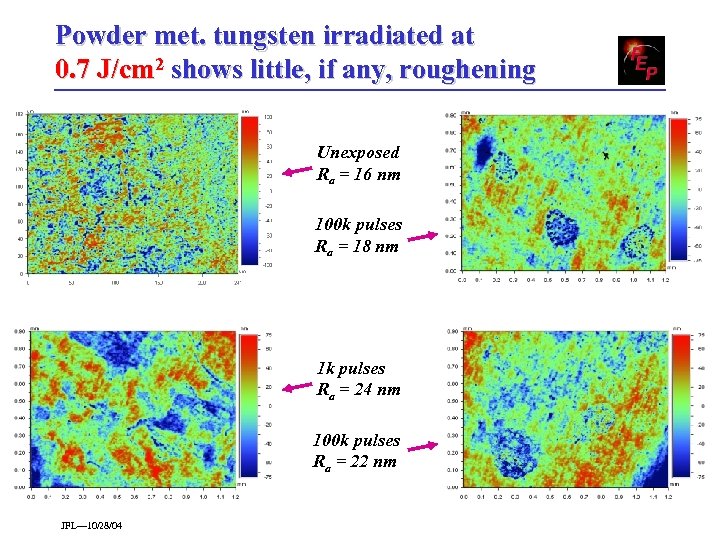

Powder met. tungsten irradiated at 0. 7 J/cm 2 shows little, if any, roughening Unexposed Ra = 16 nm 100 k pulses Ra = 18 nm 1 k pulses Ra = 24 nm 100 k pulses Ra = 22 nm JFL— 10/28/04

Powder met. tungsten irradiated at 0. 7 J/cm 2 shows little, if any, roughening Unexposed Ra = 16 nm 100 k pulses Ra = 18 nm 1 k pulses Ra = 24 nm 100 k pulses Ra = 22 nm JFL— 10/28/04

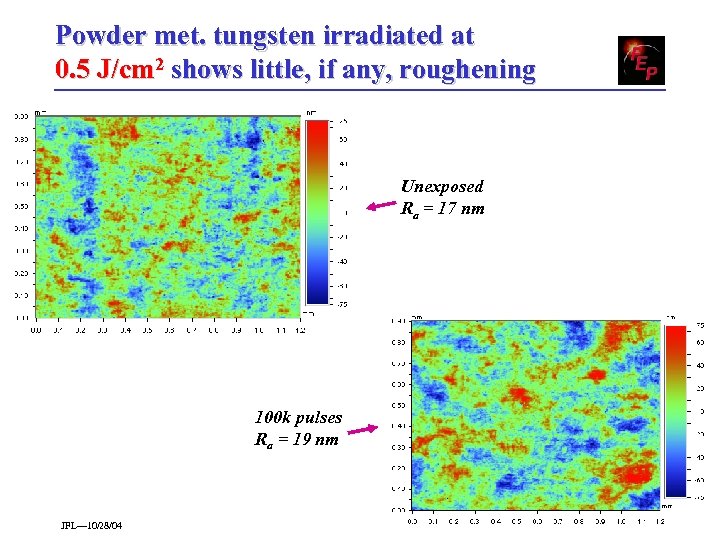

Powder met. tungsten irradiated at 0. 5 J/cm 2 shows little, if any, roughening Unexposed Ra = 17 nm 100 k pulses Ra = 19 nm JFL— 10/28/04

Powder met. tungsten irradiated at 0. 5 J/cm 2 shows little, if any, roughening Unexposed Ra = 17 nm 100 k pulses Ra = 19 nm JFL— 10/28/04

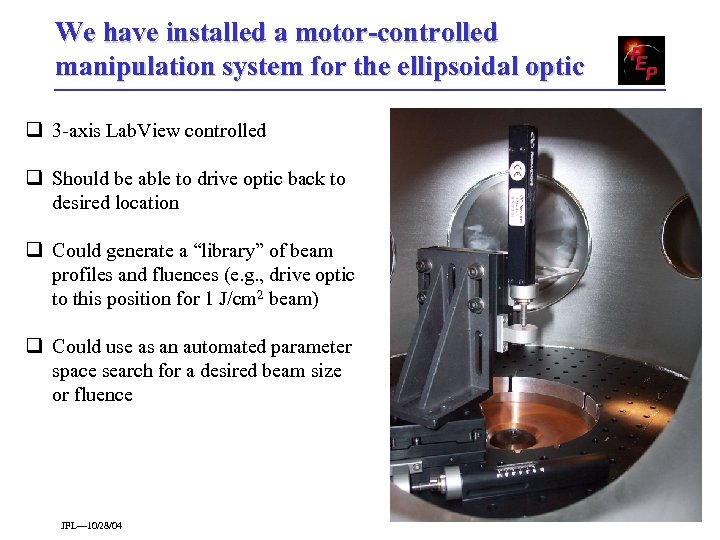

We have installed a motor-controlled manipulation system for the ellipsoidal optic q 3 -axis Lab. View controlled q Should be able to drive optic back to desired location q Could generate a “library” of beam profiles and fluences (e. g. , drive optic to this position for 1 J/cm 2 beam) q Could use as an automated parameter space search for a desired beam size or fluence JFL— 10/28/04

We have installed a motor-controlled manipulation system for the ellipsoidal optic q 3 -axis Lab. View controlled q Should be able to drive optic back to desired location q Could generate a “library” of beam profiles and fluences (e. g. , drive optic to this position for 1 J/cm 2 beam) q Could use as an automated parameter space search for a desired beam size or fluence JFL— 10/28/04

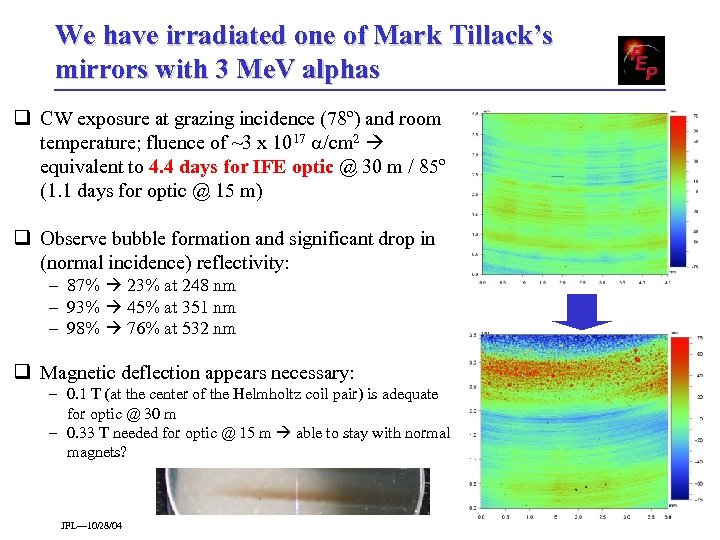

We have irradiated one of Mark Tillack’s mirrors with 3 Me. V alphas q CW exposure at grazing incidence (78º) and room temperature; fluence of ~3 x 1017 a/cm 2 equivalent to 4. 4 days for IFE optic @ 30 m / 85º (1. 1 days for optic @ 15 m) q Observe bubble formation and significant drop in (normal incidence) reflectivity: – 87% 23% at 248 nm – 93% 45% at 351 nm – 98% 76% at 532 nm q Magnetic deflection appears necessary: – 0. 1 T (at the center of the Helmholtz coil pair) is adequate for optic @ 30 m – 0. 33 T needed for optic @ 15 m able to stay with normal magnets? JFL— 10/28/04

We have irradiated one of Mark Tillack’s mirrors with 3 Me. V alphas q CW exposure at grazing incidence (78º) and room temperature; fluence of ~3 x 1017 a/cm 2 equivalent to 4. 4 days for IFE optic @ 30 m / 85º (1. 1 days for optic @ 15 m) q Observe bubble formation and significant drop in (normal incidence) reflectivity: – 87% 23% at 248 nm – 93% 45% at 351 nm – 98% 76% at 532 nm q Magnetic deflection appears necessary: – 0. 1 T (at the center of the Helmholtz coil pair) is adequate for optic @ 30 m – 0. 33 T needed for optic @ 15 m able to stay with normal magnets? JFL— 10/28/04

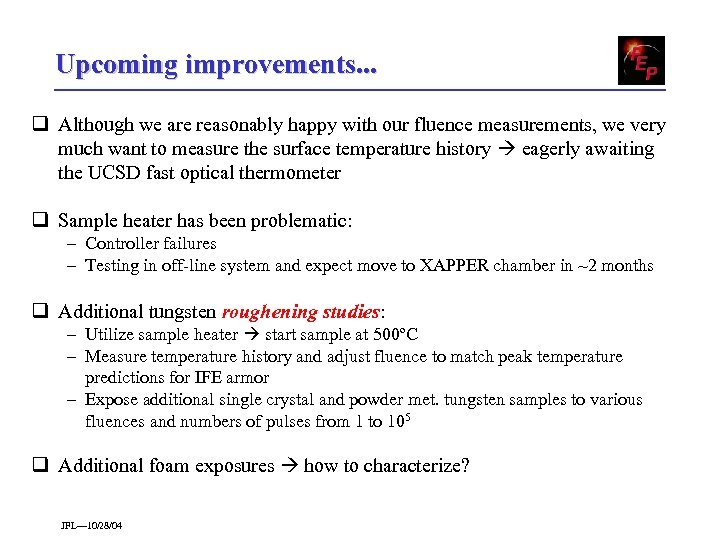

Upcoming improvements. . . q Although we are reasonably happy with our fluence measurements, we very much want to measure the surface temperature history eagerly awaiting the UCSD fast optical thermometer q Sample heater has been problematic: – Controller failures – Testing in off-line system and expect move to XAPPER chamber in ~2 months q Additional tungsten roughening studies: – Utilize sample heater start sample at 500ºC – Measure temperature history and adjust fluence to match peak temperature predictions for IFE armor – Expose additional single crystal and powder met. tungsten samples to various fluences and numbers of pulses from 1 to 105 q Additional foam exposures how to characterize? JFL— 10/28/04

Upcoming improvements. . . q Although we are reasonably happy with our fluence measurements, we very much want to measure the surface temperature history eagerly awaiting the UCSD fast optical thermometer q Sample heater has been problematic: – Controller failures – Testing in off-line system and expect move to XAPPER chamber in ~2 months q Additional tungsten roughening studies: – Utilize sample heater start sample at 500ºC – Measure temperature history and adjust fluence to match peak temperature predictions for IFE armor – Expose additional single crystal and powder met. tungsten samples to various fluences and numbers of pulses from 1 to 105 q Additional foam exposures how to characterize? JFL— 10/28/04