0547f4525ee9de4ac58f577a0a2688c1.ppt

- Количество слайдов: 33

X-RAY Wor. X Three Rivers Technical Conference August 3 rd & 4 th, 2010 Elk River, MN X-RAY Wor. X Gmb. H Siemensstraße 26 D-30827 Garbsen Germany info@x-ray-worx. com http: //www. x-ray-worx. com

X-RAY Wor. X Three Rivers Technical Conference August 3 rd & 4 th, 2010 Elk River, MN X-RAY Wor. X Gmb. H Siemensstraße 26 D-30827 Garbsen Germany info@x-ray-worx. com http: //www. x-ray-worx. com

►Company Presentation ►Microfocus X-Ray tube technology ►Rod anode technology

►Company Presentation ►Microfocus X-Ray tube technology ►Rod anode technology

X-RAY Wor. X Company Presentation X-RAY Wor. X Gmb. H Siemensstraße 26 D-30827 Garbsen Germany info@x-ray-worx. com http: //www. x-ray-worx. com

X-RAY Wor. X Company Presentation X-RAY Wor. X Gmb. H Siemensstraße 26 D-30827 Garbsen Germany info@x-ray-worx. com http: //www. x-ray-worx. com

Words of Welcome Alfred Reinhold … X-RAY Wor. X is a group of highly experienced and competent experts, partly working in this business from the very beginning of microfocus technology. As the founder of the former company Feinfocus, that introduced the first microfocus X-ray system for industrial application with focal spot sizes below 5µm, I highly appreciate the pioneering spirit of the young team of X-RAY Wor. X… Alfred Reinhold, Pioneer of Microfocus X-ray Technology (February 2010) Source: http: //www. alf-reinhold. de/

Words of Welcome Alfred Reinhold … X-RAY Wor. X is a group of highly experienced and competent experts, partly working in this business from the very beginning of microfocus technology. As the founder of the former company Feinfocus, that introduced the first microfocus X-ray system for industrial application with focal spot sizes below 5µm, I highly appreciate the pioneering spirit of the young team of X-RAY Wor. X… Alfred Reinhold, Pioneer of Microfocus X-ray Technology (February 2010) Source: http: //www. alf-reinhold. de/

Vision ► Sole independent supplier of high resolution micro- and submicrofocus X-ray tubes ► Preferred supplier for OEMs and building up of long-term relationships ► Development of innovative microfocus technology ► Joint development with technical universities and scientific institutions

Vision ► Sole independent supplier of high resolution micro- and submicrofocus X-ray tubes ► Preferred supplier for OEMs and building up of long-term relationships ► Development of innovative microfocus technology ► Joint development with technical universities and scientific institutions

History ► February 2010: Foundation of X-RAY Wor. X by Thorsten Fröba and Holger Behnsen ► March 2010: First orders of OEM customers ► March 2010: Finishing of the first high resolution microfocus X-ray tube of the new XWT-series ► June 2010: Presentation of 160 k. V rod anode on ECNDT conference in Moscow ► July 2010: Delivery of the first 160 k. V and 225 k. V dual-head microfocus X-ray tube

History ► February 2010: Foundation of X-RAY Wor. X by Thorsten Fröba and Holger Behnsen ► March 2010: First orders of OEM customers ► March 2010: Finishing of the first high resolution microfocus X-ray tube of the new XWT-series ► June 2010: Presentation of 160 k. V rod anode on ECNDT conference in Moscow ► July 2010: Delivery of the first 160 k. V and 225 k. V dual-head microfocus X-ray tube

The Founders ► Thorsten Fröba ► 15 years experience in the development of open micro- and submicrofocus X-ray tubes ►Excellent personal relationships to many prospective OEM customers ► Holger Behnsen ► 8 years experience in international marketing and sales of microfocus X-ray systems and tubes ►Very trustful contact to OEMs, end customers and local representatives

The Founders ► Thorsten Fröba ► 15 years experience in the development of open micro- and submicrofocus X-ray tubes ►Excellent personal relationships to many prospective OEM customers ► Holger Behnsen ► 8 years experience in international marketing and sales of microfocus X-ray systems and tubes ►Very trustful contact to OEMs, end customers and local representatives

Organisation ► Thorsten Fröba, Technical GM (15) ► Andreas Kösterke, Production & QA (24) ► Benjamin Dostal, SW Development (5) ► Mario Fiedrich, HW Development (2) ► Holger Behnsen, Commercial GM (8) ► Dr. Jens Peter Steffen, Sales (4) ► Zoran Zecevic, Service & Training (10) ► Matthias Stoeber, Service & Training (2) ► Marc Fisker, Service & Sales Administration (3) Altogether more than 73 years of experience in the business with microfocus X-ray tubes and systems

Organisation ► Thorsten Fröba, Technical GM (15) ► Andreas Kösterke, Production & QA (24) ► Benjamin Dostal, SW Development (5) ► Mario Fiedrich, HW Development (2) ► Holger Behnsen, Commercial GM (8) ► Dr. Jens Peter Steffen, Sales (4) ► Zoran Zecevic, Service & Training (10) ► Matthias Stoeber, Service & Training (2) ► Marc Fisker, Service & Sales Administration (3) Altogether more than 73 years of experience in the business with microfocus X-ray tubes and systems

Fields of Business X-RAY Wor. X Microfocus X-ray Technology Services Microfocus X-ray tubes Maintenance Special X-ray tubes for CT Repair Rod anode tubes Training Special projects OEM+R&D Used systems Microfocus X-ray tubes and systems Development & Production

Fields of Business X-RAY Wor. X Microfocus X-ray Technology Services Microfocus X-ray tubes Maintenance Special X-ray tubes for CT Repair Rod anode tubes Training Special projects OEM+R&D Used systems Microfocus X-ray tubes and systems Development & Production

Products ► Microfocus X-ray tubes 160/225 k. V ►Transmission target ►Reflection target ►Exchangeable tube head ► High resolution submicrofocus tubes 80/100 k. V ►Special targets ►Special cathodes ► Special tubes for CT ► Rod anode tubes

Products ► Microfocus X-ray tubes 160/225 k. V ►Transmission target ►Reflection target ►Exchangeable tube head ► High resolution submicrofocus tubes 80/100 k. V ►Special targets ►Special cathodes ► Special tubes for CT ► Rod anode tubes

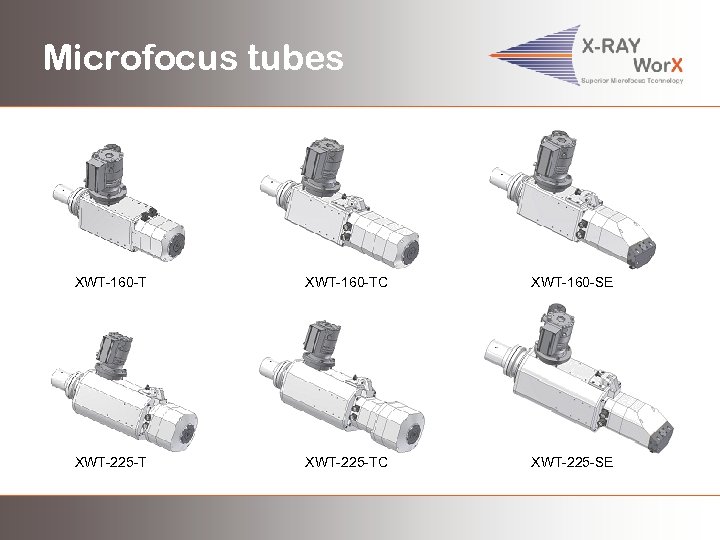

Microfocus tubes XWT-160 -TC XWT-160 -SE XWT-225 -TC XWT-225 -SE

Microfocus tubes XWT-160 -TC XWT-160 -SE XWT-225 -TC XWT-225 -SE

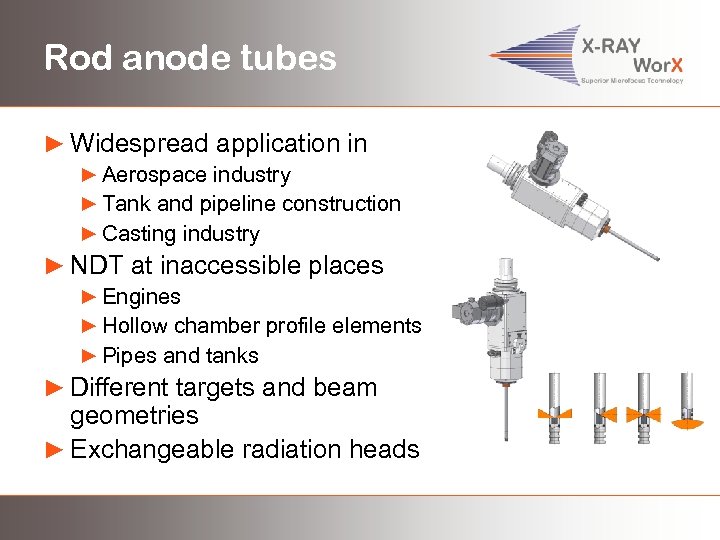

Rod anode tubes ► Widespread application in ► Aerospace industry ► Tank and pipeline construction ► Casting industry ► NDT at inaccessible places ► Engines ► Hollow chamber profile elements ► Pipes and tanks ► Different targets and beam geometries ► Exchangeable radiation heads

Rod anode tubes ► Widespread application in ► Aerospace industry ► Tank and pipeline construction ► Casting industry ► NDT at inaccessible places ► Engines ► Hollow chamber profile elements ► Pipes and tanks ► Different targets and beam geometries ► Exchangeable radiation heads

Summary ► Sole independent supplier of high resolution open micro- and submicrofocus X-ray tubes ► Concentration on core competence: Future development and production of X-ray tubes ► More than 73 years of experience in microfocus technology ► Worldwide sales & service

Summary ► Sole independent supplier of high resolution open micro- and submicrofocus X-ray tubes ► Concentration on core competence: Future development and production of X-ray tubes ► More than 73 years of experience in microfocus technology ► Worldwide sales & service

X-RAY Wor. X Microfocus X-ray tube technology X-RAY Wor. X Gmb. H Siemensstraße 26 D-30827 Garbsen Germany info@x-ray-worx. com http: //www. x-ray-worx. com

X-RAY Wor. X Microfocus X-ray tube technology X-RAY Wor. X Gmb. H Siemensstraße 26 D-30827 Garbsen Germany info@x-ray-worx. com http: //www. x-ray-worx. com

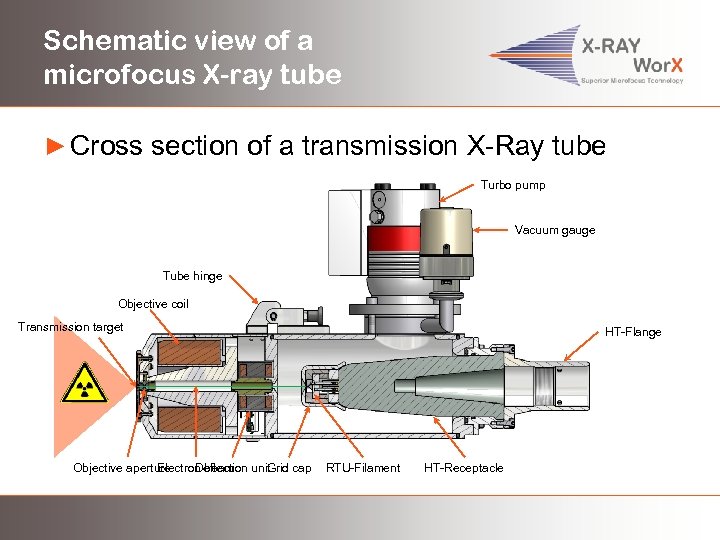

Schematic view of a microfocus X-ray tube ► Cross section of a transmission X-Ray tube Turbo pump Vacuum gauge Tube hinge Objective coil Transmission target Objective aperture Electron beam unit Deflection Grid cap HT-Flange RTU-Filament HT-Receptacle

Schematic view of a microfocus X-ray tube ► Cross section of a transmission X-Ray tube Turbo pump Vacuum gauge Tube hinge Objective coil Transmission target Objective aperture Electron beam unit Deflection Grid cap HT-Flange RTU-Filament HT-Receptacle

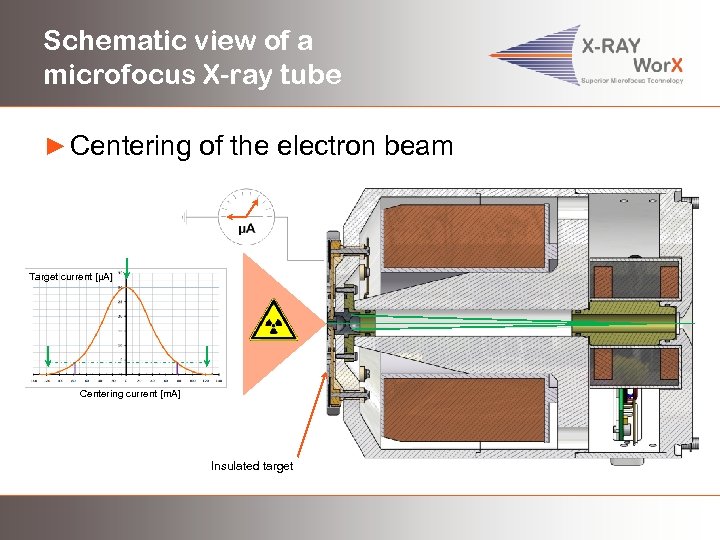

Schematic view of a microfocus X-ray tube ► Centering of the electron beam Target current [µA] Centering current [m. A] Insulated target

Schematic view of a microfocus X-ray tube ► Centering of the electron beam Target current [µA] Centering current [m. A] Insulated target

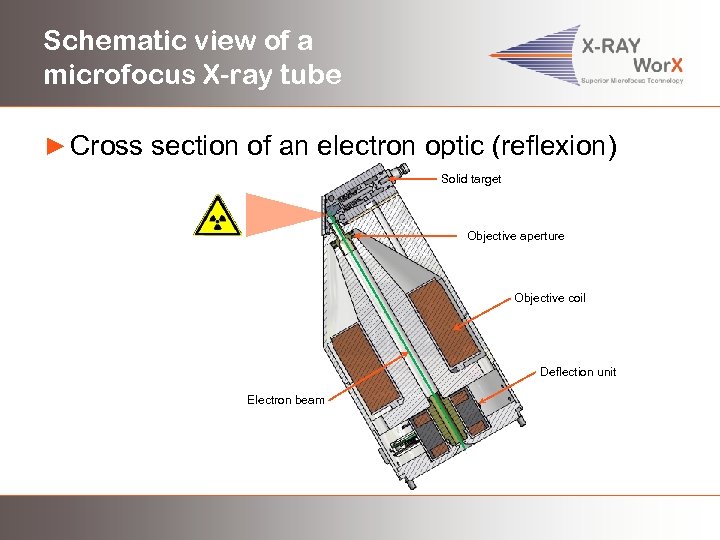

Schematic view of a microfocus X-ray tube ► Cross section of an electron optic (reflexion) Solid target Objective aperture Objective coil Deflection unit Electron beam

Schematic view of a microfocus X-ray tube ► Cross section of an electron optic (reflexion) Solid target Objective aperture Objective coil Deflection unit Electron beam

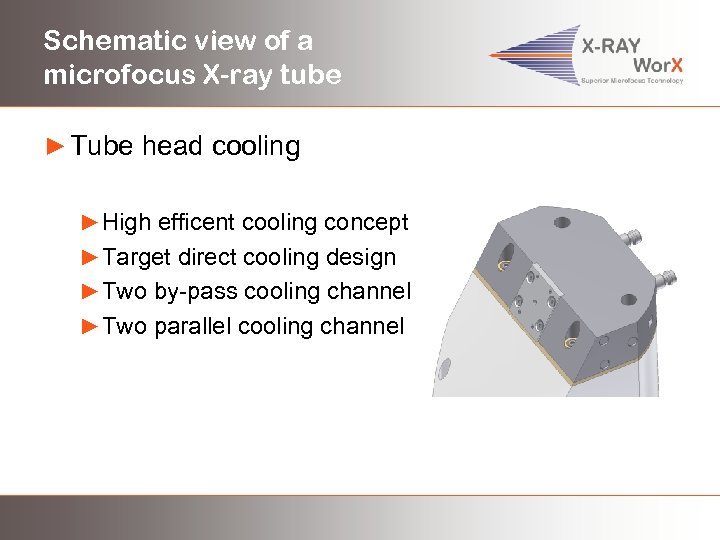

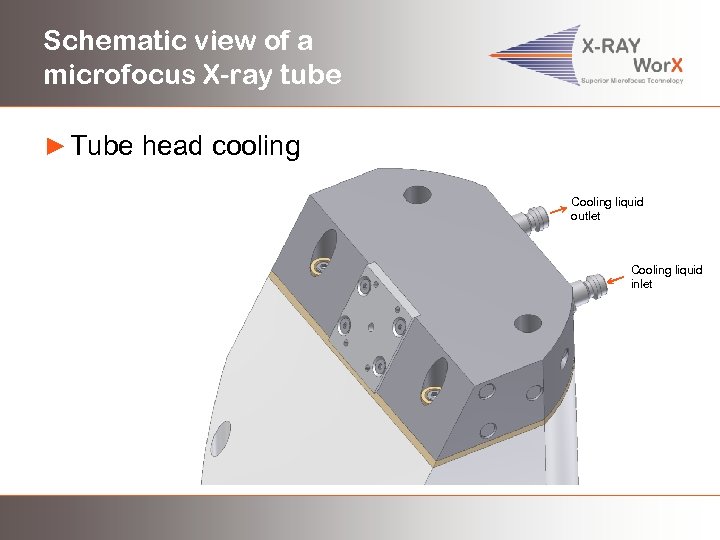

Schematic view of a microfocus X-ray tube ► Tube head cooling ►High efficent cooling concept ►Target direct cooling design ►Two by-pass cooling channel ►Two parallel cooling channel

Schematic view of a microfocus X-ray tube ► Tube head cooling ►High efficent cooling concept ►Target direct cooling design ►Two by-pass cooling channel ►Two parallel cooling channel

Schematic view of a microfocus X-ray tube ► Tube head cooling Cooling liquid outlet Cooling liquid inlet

Schematic view of a microfocus X-ray tube ► Tube head cooling Cooling liquid outlet Cooling liquid inlet

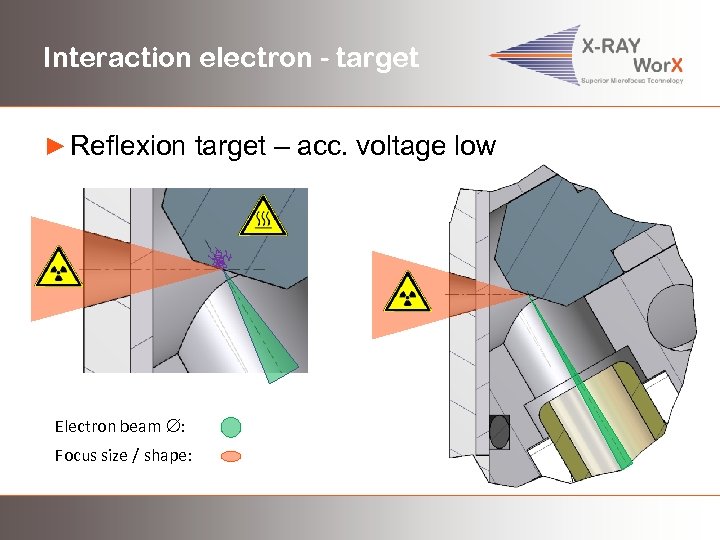

Interaction electron - target ► Reflexion target – acc. voltage low Electron beam : Focus size / shape:

Interaction electron - target ► Reflexion target – acc. voltage low Electron beam : Focus size / shape:

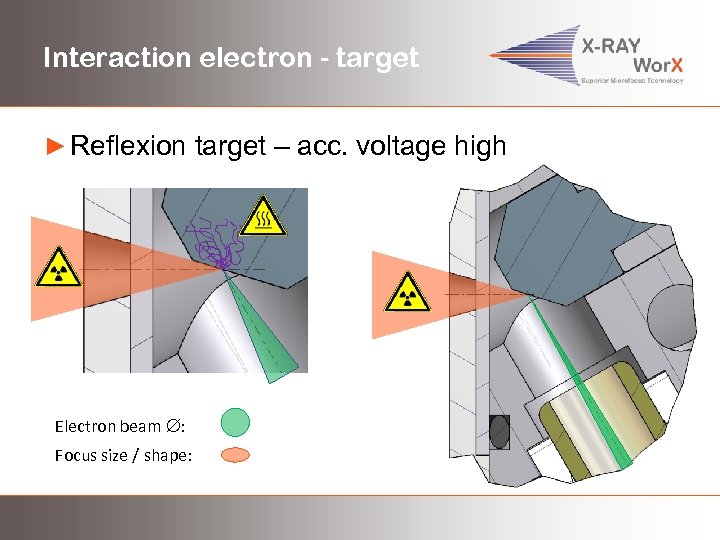

Interaction electron - target ► Reflexion target – acc. voltage high Electron beam : Focus size / shape:

Interaction electron - target ► Reflexion target – acc. voltage high Electron beam : Focus size / shape:

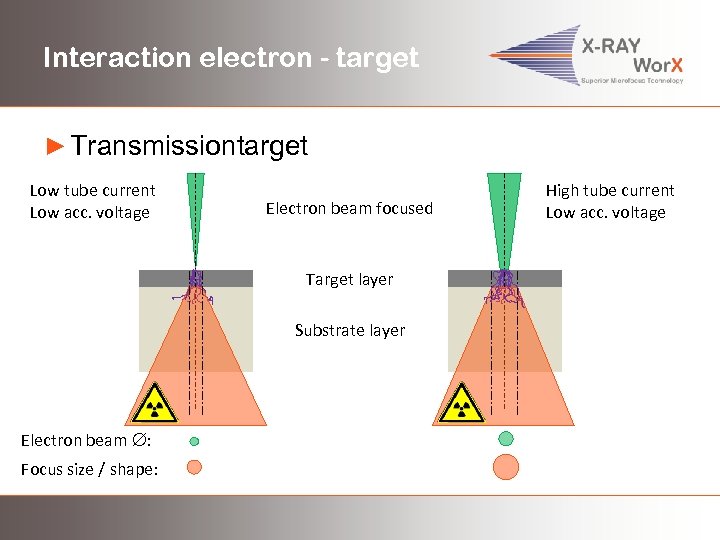

Interaction electron - target ► Transmissiontarget Low tube current Low acc. voltage Electron beam focused Target layer Substrate layer Electron beam : Focus size / shape: High tube current Low acc. voltage

Interaction electron - target ► Transmissiontarget Low tube current Low acc. voltage Electron beam focused Target layer Substrate layer Electron beam : Focus size / shape: High tube current Low acc. voltage

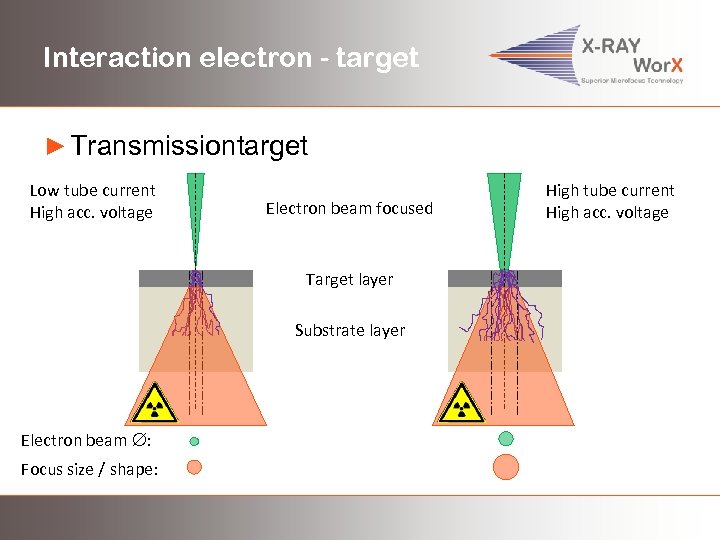

Interaction electron - target ► Transmissiontarget Low tube current High acc. voltage Electron beam focused Target layer Substrate layer Electron beam : Focus size / shape: High tube current High acc. voltage

Interaction electron - target ► Transmissiontarget Low tube current High acc. voltage Electron beam focused Target layer Substrate layer Electron beam : Focus size / shape: High tube current High acc. voltage

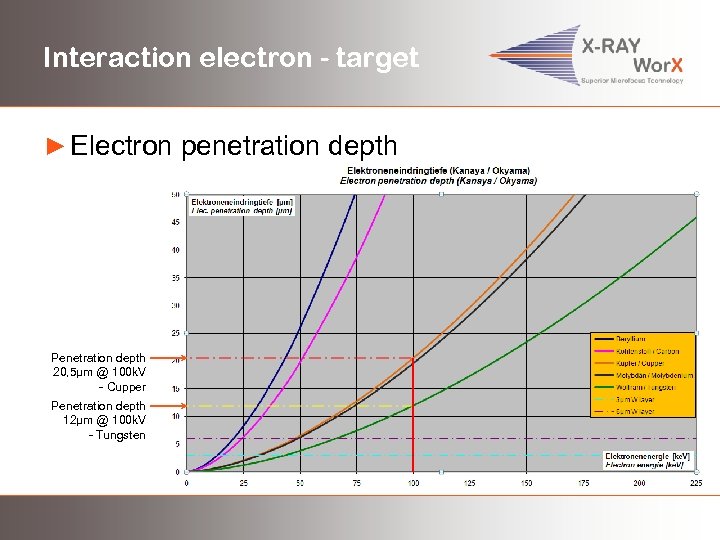

Interaction electron - target ► Electron penetration depth Penetration depth 20, 5µm @ 100 k. V - Cupper Penetration depth 12µm @ 100 k. V - Tungsten

Interaction electron - target ► Electron penetration depth Penetration depth 20, 5µm @ 100 k. V - Cupper Penetration depth 12µm @ 100 k. V - Tungsten

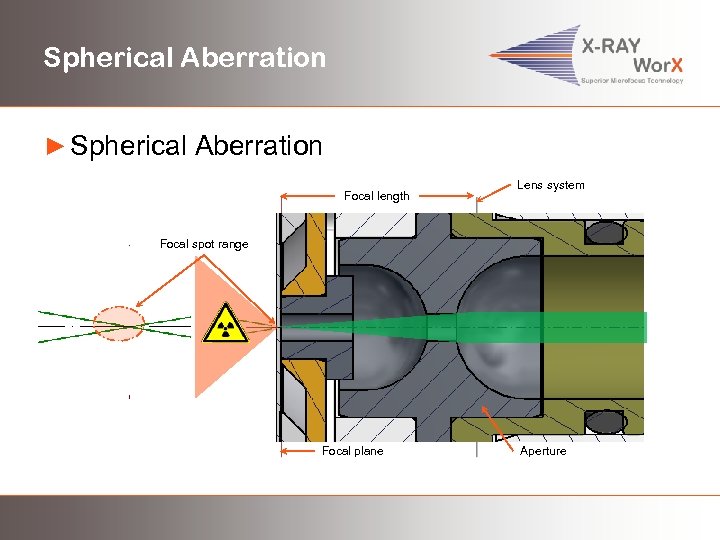

Spherical Aberration ► Spherical Aberration Focal length Lens system Focal spot range Focal plane Aperture

Spherical Aberration ► Spherical Aberration Focal length Lens system Focal spot range Focal plane Aperture

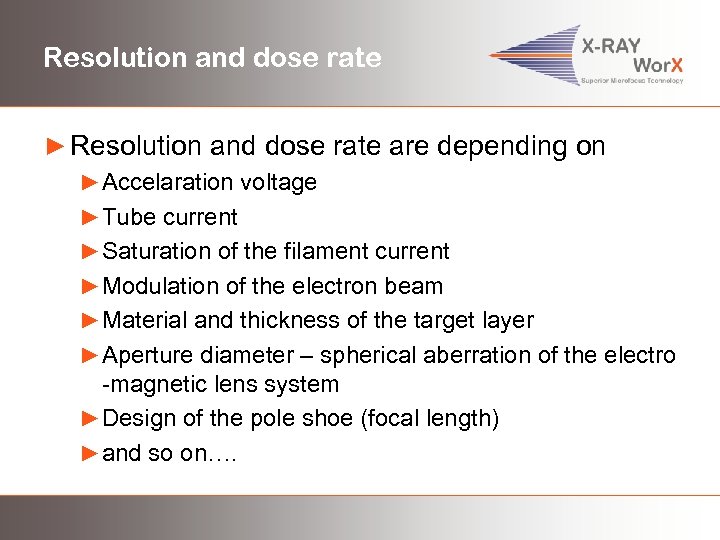

Resolution and dose rate ► Resolution and dose rate are depending on ►Accelaration voltage ►Tube current ►Saturation of the filament current ►Modulation of the electron beam ►Material and thickness of the target layer ►Aperture diameter – spherical aberration of the electro -magnetic lens system ►Design of the pole shoe (focal length) ►and so on….

Resolution and dose rate ► Resolution and dose rate are depending on ►Accelaration voltage ►Tube current ►Saturation of the filament current ►Modulation of the electron beam ►Material and thickness of the target layer ►Aperture diameter – spherical aberration of the electro -magnetic lens system ►Design of the pole shoe (focal length) ►and so on….

X-RAY Wor. X Rod anode technology X-RAY Wor. X Gmb. H Siemensstraße 26 D-30827 Garbsen Germany info@x-ray-worx. com http: //www. x-ray-worx. com

X-RAY Wor. X Rod anode technology X-RAY Wor. X Gmb. H Siemensstraße 26 D-30827 Garbsen Germany info@x-ray-worx. com http: //www. x-ray-worx. com

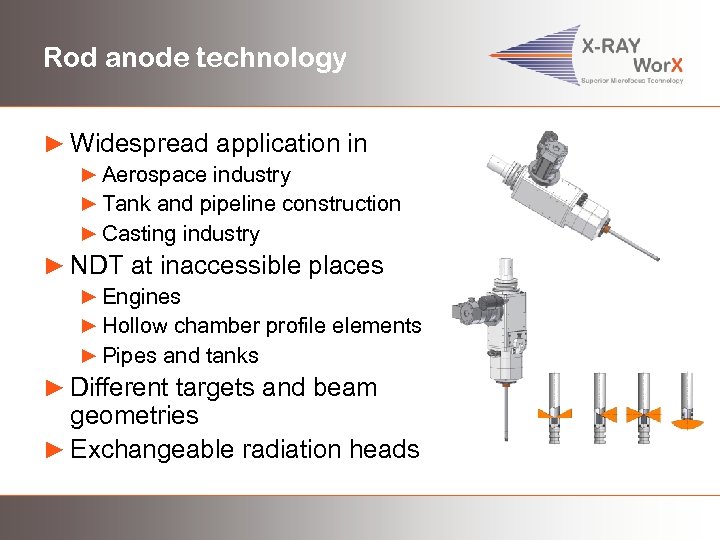

Rod anode technology ► Widespread application in ► Aerospace industry ► Tank and pipeline construction ► Casting industry ► NDT at inaccessible places ► Engines ► Hollow chamber profile elements ► Pipes and tanks ► Different targets and beam geometries ► Exchangeable radiation heads

Rod anode technology ► Widespread application in ► Aerospace industry ► Tank and pipeline construction ► Casting industry ► NDT at inaccessible places ► Engines ► Hollow chamber profile elements ► Pipes and tanks ► Different targets and beam geometries ► Exchangeable radiation heads

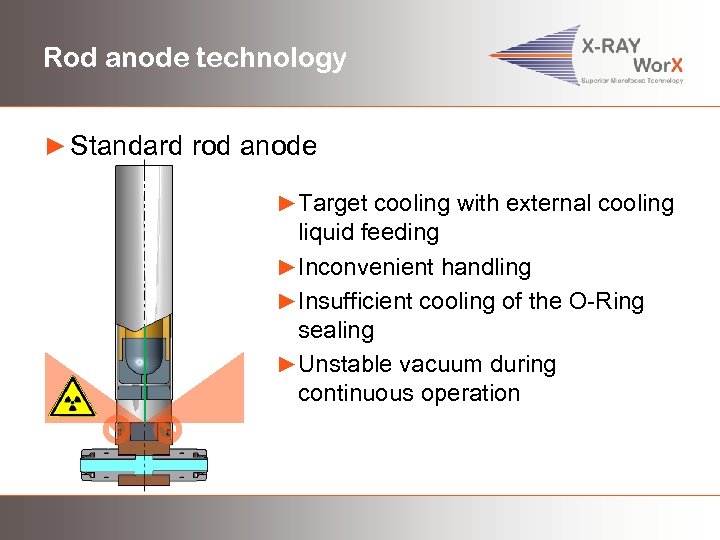

Rod anode technology ► Standard rod anode ►Target cooling with external cooling liquid feeding ►Inconvenient handling ►Insufficient cooling of the O-Ring sealing ►Unstable vacuum during continuous operation

Rod anode technology ► Standard rod anode ►Target cooling with external cooling liquid feeding ►Inconvenient handling ►Insufficient cooling of the O-Ring sealing ►Unstable vacuum during continuous operation

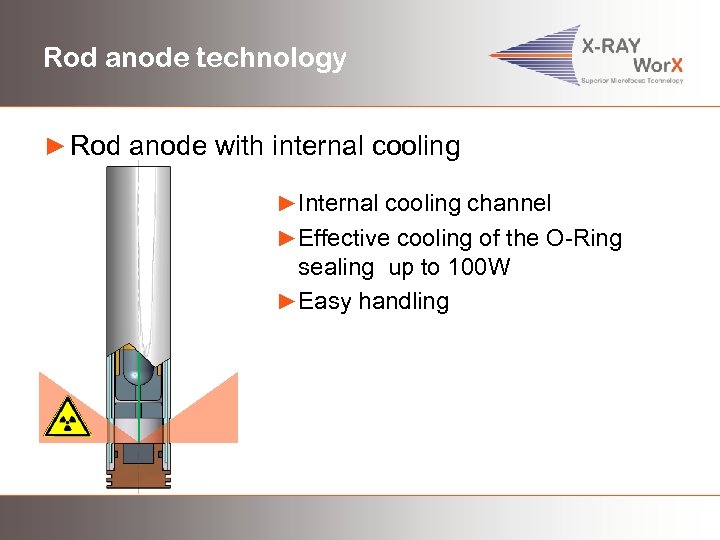

Rod anode technology ► Rod anode with internal cooling ►Internal cooling channel ►Effective cooling of the O-Ring sealing up to 100 W ►Easy handling

Rod anode technology ► Rod anode with internal cooling ►Internal cooling channel ►Effective cooling of the O-Ring sealing up to 100 W ►Easy handling

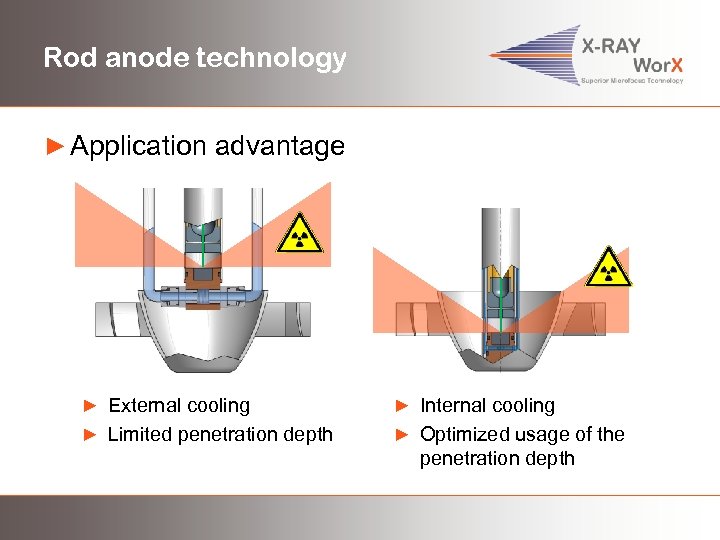

Rod anode technology ► Application advantage ► External cooling ► Internal cooling ► Limited penetration depth ► Optimized usage of the penetration depth

Rod anode technology ► Application advantage ► External cooling ► Internal cooling ► Limited penetration depth ► Optimized usage of the penetration depth

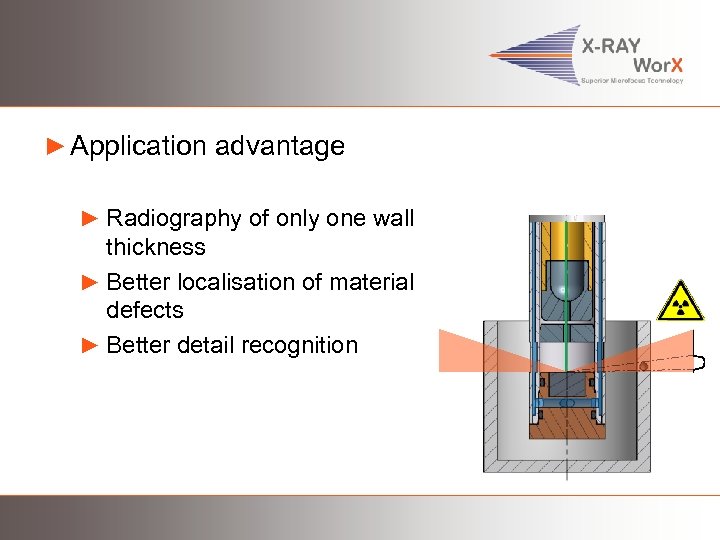

► Application advantage ► Radiography of only one wall thickness ► Better localisation of material defects ► Better detail recognition

► Application advantage ► Radiography of only one wall thickness ► Better localisation of material defects ► Better detail recognition

►Thank you for your attention ►Any questions?

►Thank you for your attention ►Any questions?