9d711f2198949dd07b059aa13cc1ddd7.ppt

- Количество слайдов: 38

WRI 400 WIRELESS READER INTERFACE Technical Services Training for the WRI 400 Launched April 2011 March 18 Technical Services – Engineering Support 1

WRI 400 WIRELESS READER INTERFACE Technical Services Training for the WRI 400 Launched April 2011 March 18 Technical Services – Engineering Support 1

Training Overview WRI 400 Description Information Installation Comparison to Legacy WRI SUS/HHD “Ah-Ha’s”

Training Overview WRI 400 Description Information Installation Comparison to Legacy WRI SUS/HHD “Ah-Ha’s”

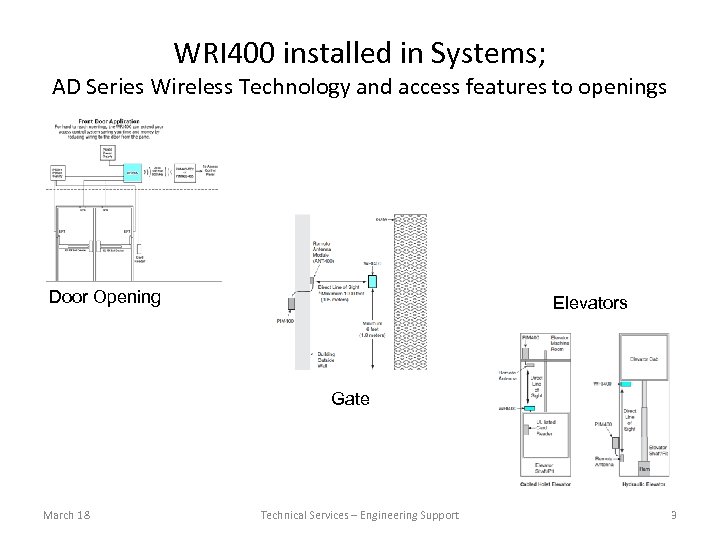

WRI 400 installed in Systems; AD Series Wireless Technology and access features to openings Door Opening Elevators Gate March 18 Technical Services – Engineering Support 3

WRI 400 installed in Systems; AD Series Wireless Technology and access features to openings Door Opening Elevators Gate March 18 Technical Services – Engineering Support 3

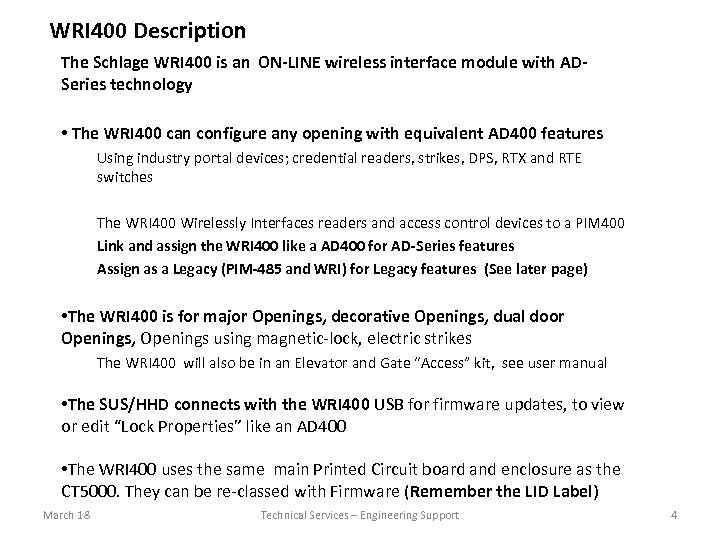

WRI 400 Description The Schlage WRI 400 is an ON-LINE wireless interface module with ADSeries technology • The WRI 400 can configure any opening with equivalent AD 400 features Using industry portal devices; credential readers, strikes, DPS, RTX and RTE switches The WRI 400 Wirelessly Interfaces readers and access control devices to a PIM 400 Link and assign the WRI 400 like a AD 400 for AD-Series features Assign as a Legacy (PIM-485 and WRI) for Legacy features (See later page) • The WRI 400 is for major Openings, decorative Openings, dual door Openings, Openings using magnetic-lock, electric strikes The WRI 400 will also be in an Elevator and Gate “Access” kit, see user manual • The SUS/HHD connects with the WRI 400 USB for firmware updates, to view or edit “Lock Properties” like an AD 400 • The WRI 400 uses the same main Printed Circuit board and enclosure as the CT 5000. They can be re-classed with Firmware (Remember the LID Label) March 18 Technical Services – Engineering Support 4

WRI 400 Description The Schlage WRI 400 is an ON-LINE wireless interface module with ADSeries technology • The WRI 400 can configure any opening with equivalent AD 400 features Using industry portal devices; credential readers, strikes, DPS, RTX and RTE switches The WRI 400 Wirelessly Interfaces readers and access control devices to a PIM 400 Link and assign the WRI 400 like a AD 400 for AD-Series features Assign as a Legacy (PIM-485 and WRI) for Legacy features (See later page) • The WRI 400 is for major Openings, decorative Openings, dual door Openings, Openings using magnetic-lock, electric strikes The WRI 400 will also be in an Elevator and Gate “Access” kit, see user manual • The SUS/HHD connects with the WRI 400 USB for firmware updates, to view or edit “Lock Properties” like an AD 400 • The WRI 400 uses the same main Printed Circuit board and enclosure as the CT 5000. They can be re-classed with Firmware (Remember the LID Label) March 18 Technical Services – Engineering Support 4

WRI 400 Description • The WRI 400 can be used with up to two (2) credential readers that have Wiegand or Clock and Data outputs (wave 58171) • • • WRI 400 Supports three optional status inputs: , • • • Left-side/right-side readers, ADA reader and mullion reader, Gates, and Elevators NOTE ; Both readers are the same Opening, they have the same identical access rights Request to Enter (RTE) Request to Exit (RTX) Door Position Switch (DSP) Reader 1 Tamper and Reader 2 Tamper are reported by the WRI 400; but not indentified by Access Control Panels yet - Will call Tamper 1/2 “Lock Clutch Engaged” or “Dead bolt” or “Latch bolt Engaged” Supports TWO (2) Form C, dry contact relays outputs, • • Strike - Electric Strike, magnetic lock, Auxiliary – ADA door opener (Automatic operator) CONTROLED BY ACCESS CONTROL PANEL

WRI 400 Description • The WRI 400 can be used with up to two (2) credential readers that have Wiegand or Clock and Data outputs (wave 58171) • • • WRI 400 Supports three optional status inputs: , • • • Left-side/right-side readers, ADA reader and mullion reader, Gates, and Elevators NOTE ; Both readers are the same Opening, they have the same identical access rights Request to Enter (RTE) Request to Exit (RTX) Door Position Switch (DSP) Reader 1 Tamper and Reader 2 Tamper are reported by the WRI 400; but not indentified by Access Control Panels yet - Will call Tamper 1/2 “Lock Clutch Engaged” or “Dead bolt” or “Latch bolt Engaged” Supports TWO (2) Form C, dry contact relays outputs, • • Strike - Electric Strike, magnetic lock, Auxiliary – ADA door opener (Automatic operator) CONTROLED BY ACCESS CONTROL PANEL

WRI 400 Description • The Alarm relay Is not used by the WRI 400 firmware • The WRI 400 has no “Buzz-in” reporting feature – Buzz-in switches can be wired across the STRIKE relay output • The WRI 400 is a powered device and must have +12 or +24 volt power, – No AA battery operation for the WRI 400, relay control requires more power than batteries – No coin cell is needed or used by the WRI 400, (Like the AD 400) wave 58154 • Coin Cell batteries are not shipped in the WRI 400 • The PCB silk screen says “COIN CELL NOT NEEDED IF RADIO BOARD PRESENT” • The WRI 400 needs a UL 294 Listed Class 2 power supply, not included. (example: Schlage models PS 902, PS 904, and PS 906) • Note: The WRI 400 will not power the readers wave 57830 • When sharing the power supply you must get the polarities correct, and select a supply which is compatible with the reader and the WRI 400. The WRI 400 requires 12 volt 500 ma; and READERS are typically 12 VDC to 5 VDC 200 ma each

WRI 400 Description • The Alarm relay Is not used by the WRI 400 firmware • The WRI 400 has no “Buzz-in” reporting feature – Buzz-in switches can be wired across the STRIKE relay output • The WRI 400 is a powered device and must have +12 or +24 volt power, – No AA battery operation for the WRI 400, relay control requires more power than batteries – No coin cell is needed or used by the WRI 400, (Like the AD 400) wave 58154 • Coin Cell batteries are not shipped in the WRI 400 • The PCB silk screen says “COIN CELL NOT NEEDED IF RADIO BOARD PRESENT” • The WRI 400 needs a UL 294 Listed Class 2 power supply, not included. (example: Schlage models PS 902, PS 904, and PS 906) • Note: The WRI 400 will not power the readers wave 57830 • When sharing the power supply you must get the polarities correct, and select a supply which is compatible with the reader and the WRI 400. The WRI 400 requires 12 volt 500 ma; and READERS are typically 12 VDC to 5 VDC 200 ma each

Assigning Bright. Blue Templates Bright. Blue will be updated late this fall to include WRI 400 assignment templates. Below Work Around With Bright. Blue as it is now; AD-Series, Assign the WRI 400 as an AD 400 • • Request to Enter (RTE) Request to Exit (RTX) Door Position Switch (DSP) NO AUX function, (NO ALRAM function) Assign as a Legacy, • • Assign a PIM 400 using a BB Legacy Template WRI 400 as a Legacy WRI This PIM 400 can now only link to a device on a Legacy Template, it can not be shared with AD 400 locks) LINK the PIM 400 and the WRI 400 and they now report like a Legacy WRI with AUX operations

Assigning Bright. Blue Templates Bright. Blue will be updated late this fall to include WRI 400 assignment templates. Below Work Around With Bright. Blue as it is now; AD-Series, Assign the WRI 400 as an AD 400 • • Request to Enter (RTE) Request to Exit (RTX) Door Position Switch (DSP) NO AUX function, (NO ALRAM function) Assign as a Legacy, • • Assign a PIM 400 using a BB Legacy Template WRI 400 as a Legacy WRI This PIM 400 can now only link to a device on a Legacy Template, it can not be shared with AD 400 locks) LINK the PIM 400 and the WRI 400 and they now report like a Legacy WRI with AUX operations

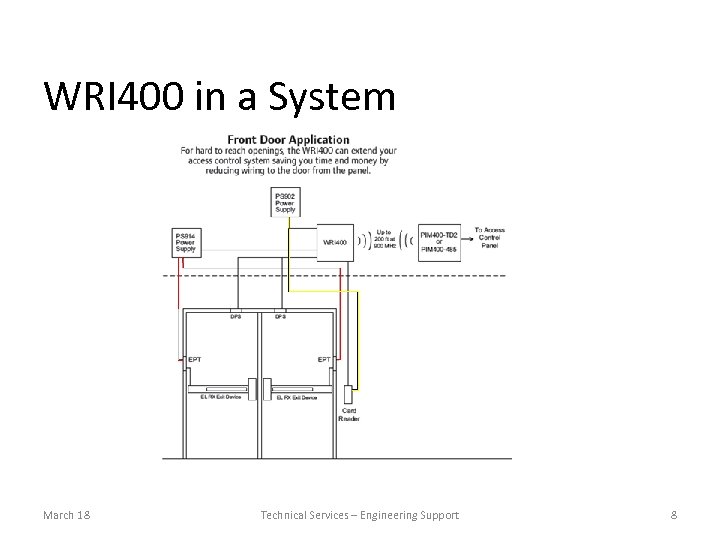

WRI 400 in a System March 18 Technical Services – Engineering Support 8

WRI 400 in a System March 18 Technical Services – Engineering Support 8

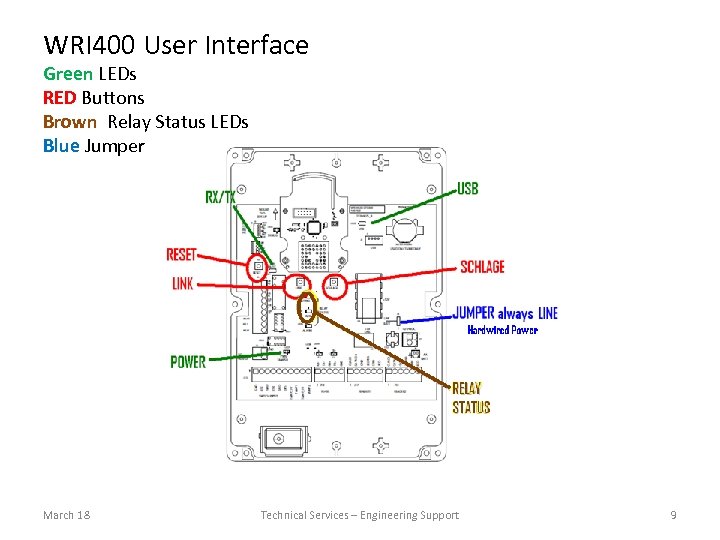

WRI 400 User Interface Green LEDs RED Buttons Brown Relay Status LEDs Blue Jumper March 18 Technical Services – Engineering Support 9

WRI 400 User Interface Green LEDs RED Buttons Brown Relay Status LEDs Blue Jumper March 18 Technical Services – Engineering Support 9

WRI 400 Information www. Schlage. com/Support • User guides - P 516 -100 • Data Sheets • Technical Bulletins • Firmware down loads Knowledge Center for technical questions RADAR Reporting • Siebel SR reports with actions into Test Track Pro March 18 Technical Services – Engineering Support 10

WRI 400 Information www. Schlage. com/Support • User guides - P 516 -100 • Data Sheets • Technical Bulletins • Firmware down loads Knowledge Center for technical questions RADAR Reporting • Siebel SR reports with actions into Test Track Pro March 18 Technical Services – Engineering Support 10

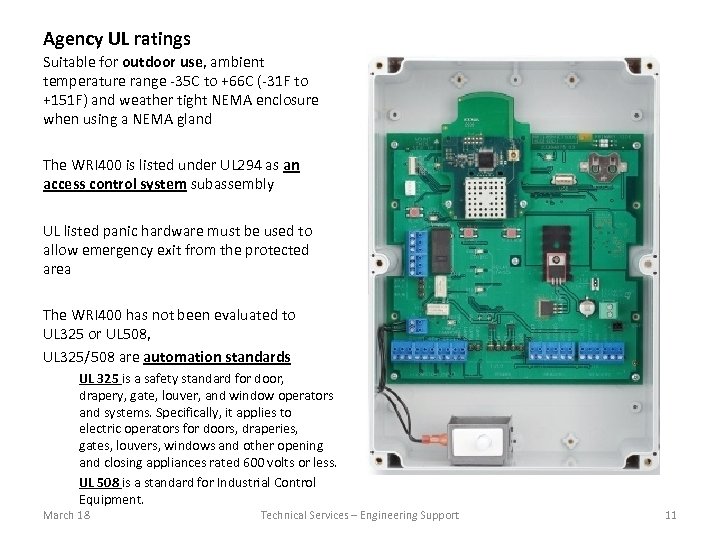

Agency UL ratings Suitable for outdoor use, ambient temperature range -35 C to +66 C (-31 F to +151 F) and weather tight NEMA enclosure when using a NEMA gland The WRI 400 is listed under UL 294 as an access control system subassembly UL listed panic hardware must be used to allow emergency exit from the protected area The WRI 400 has not been evaluated to UL 325 or UL 508, UL 325/508 are automation standards UL 325 is a safety standard for door, drapery, gate, louver, and window operators and systems. Specifically, it applies to electric operators for doors, draperies, gates, louvers, windows and other opening and closing appliances rated 600 volts or less. UL 508 is a standard for Industrial Control Equipment. March 18 Technical Services – Engineering Support 11

Agency UL ratings Suitable for outdoor use, ambient temperature range -35 C to +66 C (-31 F to +151 F) and weather tight NEMA enclosure when using a NEMA gland The WRI 400 is listed under UL 294 as an access control system subassembly UL listed panic hardware must be used to allow emergency exit from the protected area The WRI 400 has not been evaluated to UL 325 or UL 508, UL 325/508 are automation standards UL 325 is a safety standard for door, drapery, gate, louver, and window operators and systems. Specifically, it applies to electric operators for doors, draperies, gates, louvers, windows and other opening and closing appliances rated 600 volts or less. UL 508 is a standard for Industrial Control Equipment. March 18 Technical Services – Engineering Support 11

PIM 400 and WRI 400 Installation Location WRI 400 mounting location is similar to the AD Series for RF communication to the PIM 400 • Secured side of the access portal • The maximum RF distance indoors between a PIM 400 and a WRI 400 is 200 feet (61 meters) • Same floor in a building normal construction materials • The maximum distance for a line-of-sight installation is 1000 feet (305 meters) March 18 Technical Services – Engineering Support 12

PIM 400 and WRI 400 Installation Location WRI 400 mounting location is similar to the AD Series for RF communication to the PIM 400 • Secured side of the access portal • The maximum RF distance indoors between a PIM 400 and a WRI 400 is 200 feet (61 meters) • Same floor in a building normal construction materials • The maximum distance for a line-of-sight installation is 1000 feet (305 meters) March 18 Technical Services – Engineering Support 12

PIM 400 and WRI 400 Installation Location • WRI 400 can use the ANT 400 antenna kits for increased RF communication range • • • Use of high-gain antenna (ANT 400 -REM I/O +6 DB) will improve range The antenna KIT includes a 15 foot cable (4. 5 meters) Don’t exceed this cable length Do not locate the WRI 400 and remote antenna, or the PIM 400 (and its remote antenna, if used) on separate floors within a building (However having both antennas on the same floor is OK) Mounting a WRI 400 is just like a PIM 400 • Vertically with the radio board at the top of the enclosure • If on a metallic surface, stand the WRI 400 off 1 inch (25 mm) from the metal 13

PIM 400 and WRI 400 Installation Location • WRI 400 can use the ANT 400 antenna kits for increased RF communication range • • • Use of high-gain antenna (ANT 400 -REM I/O +6 DB) will improve range The antenna KIT includes a 15 foot cable (4. 5 meters) Don’t exceed this cable length Do not locate the WRI 400 and remote antenna, or the PIM 400 (and its remote antenna, if used) on separate floors within a building (However having both antennas on the same floor is OK) Mounting a WRI 400 is just like a PIM 400 • Vertically with the radio board at the top of the enclosure • If on a metallic surface, stand the WRI 400 off 1 inch (25 mm) from the metal 13

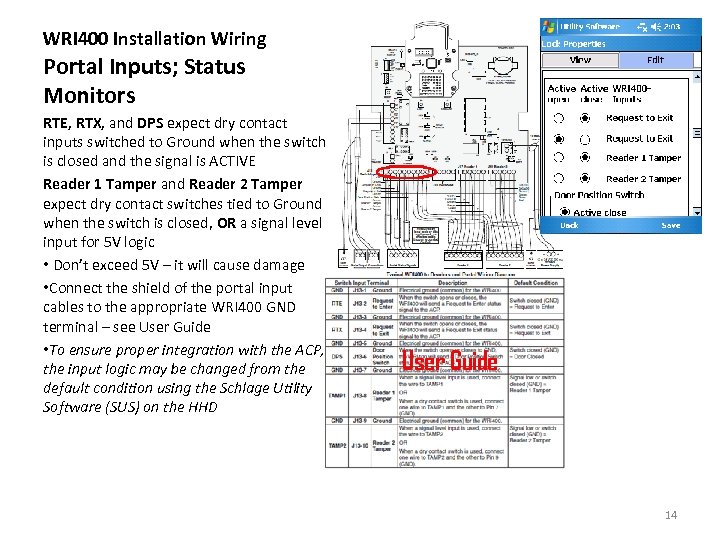

WRI 400 Installation Wiring Portal Inputs; Status Monitors RTE, RTX, and DPS expect dry contact inputs switched to Ground when the switch is closed and the signal is ACTIVE Reader 1 Tamper and Reader 2 Tamper expect dry contact switches tied to Ground when the switch is closed, OR a signal level input for 5 V logic • Don’t exceed 5 V – it will cause damage • Connect the shield of the portal input cables to the appropriate WRI 400 GND terminal – see User Guide • To ensure proper integration with the ACP, the input logic may be changed from the default condition using the Schlage Utility Software (SUS) on the HHD 14

WRI 400 Installation Wiring Portal Inputs; Status Monitors RTE, RTX, and DPS expect dry contact inputs switched to Ground when the switch is closed and the signal is ACTIVE Reader 1 Tamper and Reader 2 Tamper expect dry contact switches tied to Ground when the switch is closed, OR a signal level input for 5 V logic • Don’t exceed 5 V – it will cause damage • Connect the shield of the portal input cables to the appropriate WRI 400 GND terminal – see User Guide • To ensure proper integration with the ACP, the input logic may be changed from the default condition using the Schlage Utility Software (SUS) on the HHD 14

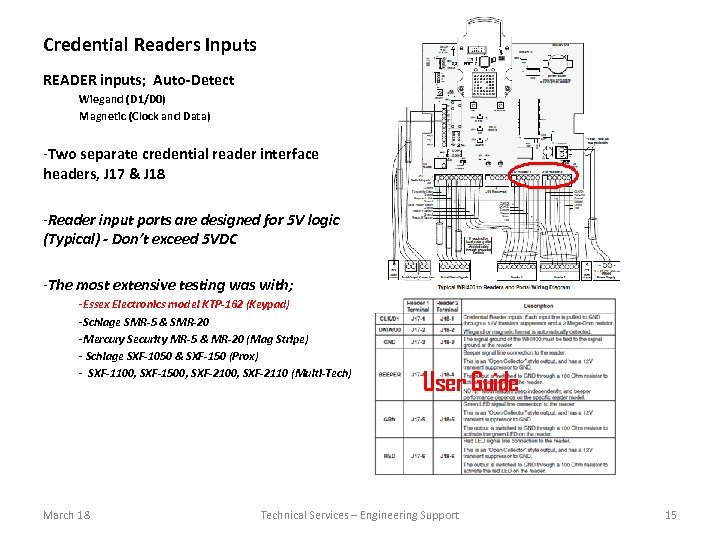

Credential Readers Inputs READER inputs; Auto-Detect Wiegand (D 1/D 0) Magnetic (Clock and Data) -Two separate credential reader interface headers, J 17 & J 18 -Reader input ports are designed for 5 V logic (Typical) - Don’t exceed 5 VDC -The most extensive testing was with; -Essex Electronics model KTP-162 (Keypad) -Schlage SMR-5 & SMR-20 -Mercury Security MR-5 & MR-20 (Mag Stripe) - Schlage SXF-1050 & SXF-150 (Prox) - SXF-1100, SXF-1500, SXF-2110 (Multi-Tech) March 18 Technical Services – Engineering Support 15

Credential Readers Inputs READER inputs; Auto-Detect Wiegand (D 1/D 0) Magnetic (Clock and Data) -Two separate credential reader interface headers, J 17 & J 18 -Reader input ports are designed for 5 V logic (Typical) - Don’t exceed 5 VDC -The most extensive testing was with; -Essex Electronics model KTP-162 (Keypad) -Schlage SMR-5 & SMR-20 -Mercury Security MR-5 & MR-20 (Mag Stripe) - Schlage SXF-1050 & SXF-150 (Prox) - SXF-1100, SXF-1500, SXF-2110 (Multi-Tech) March 18 Technical Services – Engineering Support 15

WRI 400 control of the READER - Beeper, Green LED, RED LED ! The WRI 400 does not provide power to the readers ! The WRI 400 will use the reader beeper with a FDR. -Please consult with the reader’s manufacturer for reader configuration, readers typically beep with a card present. - Reader beeper and LED controls are configured by the reader factory per order. Configuration can sometimes be changed in the field using a "Configuration Card" from the reader manufacturer -Example: If the reader is ordered with RED LED always ON (Indicating power at the READER), the WRI 400 can not turn the RED LED off

WRI 400 control of the READER - Beeper, Green LED, RED LED ! The WRI 400 does not provide power to the readers ! The WRI 400 will use the reader beeper with a FDR. -Please consult with the reader’s manufacturer for reader configuration, readers typically beep with a card present. - Reader beeper and LED controls are configured by the reader factory per order. Configuration can sometimes be changed in the field using a "Configuration Card" from the reader manufacturer -Example: If the reader is ordered with RED LED always ON (Indicating power at the READER), the WRI 400 can not turn the RED LED off

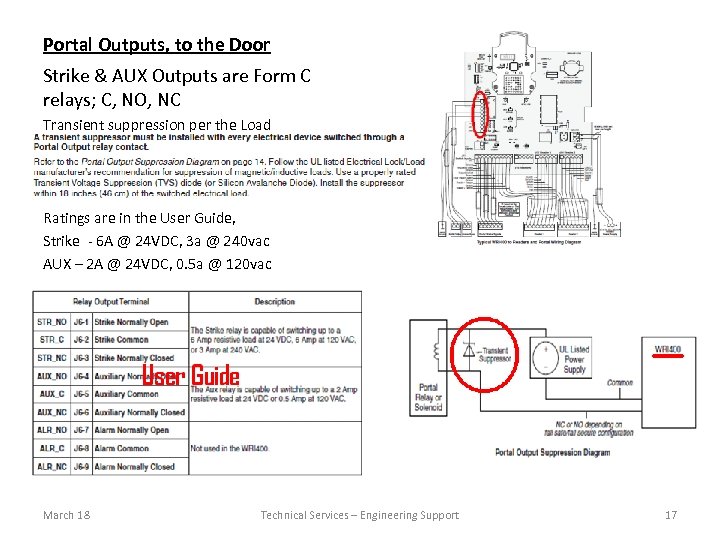

Portal Outputs, to the Door Strike & AUX Outputs are Form C relays; C, NO, NC Transient suppression per the Load Ratings are in the User Guide, Strike - 6 A @ 24 VDC, 3 a @ 240 vac AUX – 2 A @ 24 VDC, 0. 5 a @ 120 vac March 18 Technical Services – Engineering Support 17

Portal Outputs, to the Door Strike & AUX Outputs are Form C relays; C, NO, NC Transient suppression per the Load Ratings are in the User Guide, Strike - 6 A @ 24 VDC, 3 a @ 240 vac AUX – 2 A @ 24 VDC, 0. 5 a @ 120 vac March 18 Technical Services – Engineering Support 17

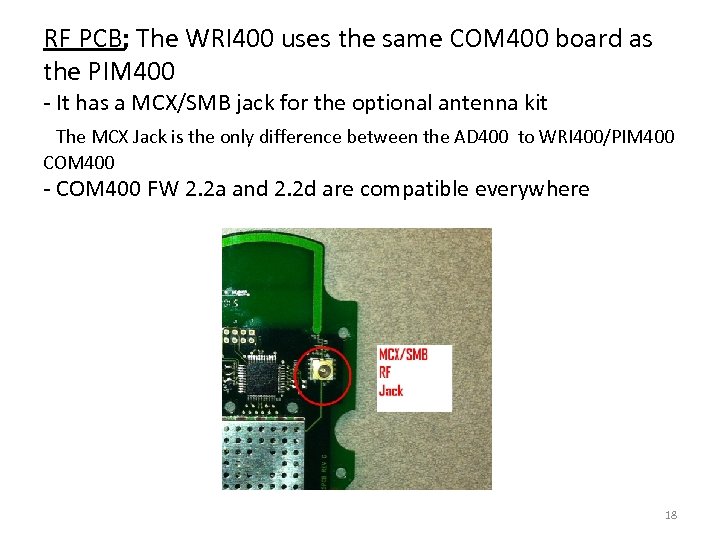

RF PCB; The WRI 400 uses the same COM 400 board as the PIM 400 - It has a MCX/SMB jack for the optional antenna kit The MCX Jack is the only difference between the AD 400 to WRI 400/PIM 400 COM 400 - COM 400 FW 2. 2 a and 2. 2 d are compatible everywhere 18

RF PCB; The WRI 400 uses the same COM 400 board as the PIM 400 - It has a MCX/SMB jack for the optional antenna kit The MCX Jack is the only difference between the AD 400 to WRI 400/PIM 400 COM 400 - COM 400 FW 2. 2 a and 2. 2 d are compatible everywhere 18

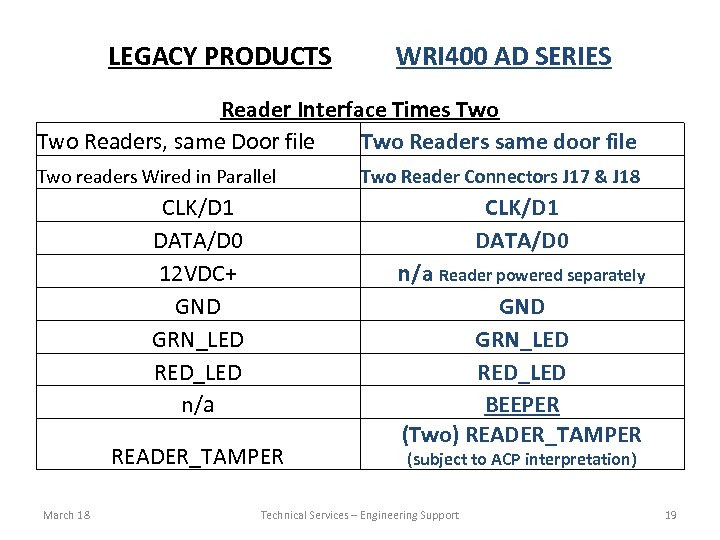

LEGACY PRODUCTS WRI 400 AD SERIES Reader Interface Times Two Readers, same Door file Two Readers same door file Two readers Wired in Parallel CLK/D 1 DATA/D 0 12 VDC+ GND GRN_LED RED_LED n/a CLK/D 1 DATA/D 0 READER_TAMPER March 18 Two Reader Connectors J 17 & J 18 n/a Reader powered separately GND GRN_LED RED_LED BEEPER (Two) READER_TAMPER (subject to ACP interpretation) Technical Services – Engineering Support 19

LEGACY PRODUCTS WRI 400 AD SERIES Reader Interface Times Two Readers, same Door file Two Readers same door file Two readers Wired in Parallel CLK/D 1 DATA/D 0 12 VDC+ GND GRN_LED RED_LED n/a CLK/D 1 DATA/D 0 READER_TAMPER March 18 Two Reader Connectors J 17 & J 18 n/a Reader powered separately GND GRN_LED RED_LED BEEPER (Two) READER_TAMPER (subject to ACP interpretation) Technical Services – Engineering Support 19

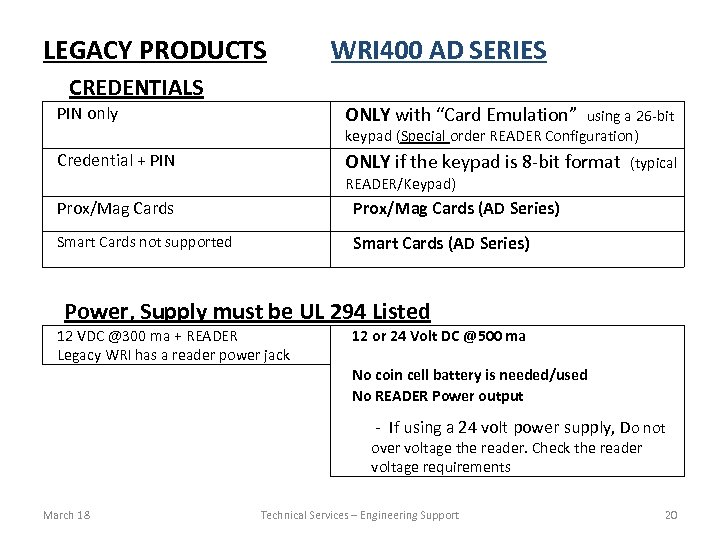

LEGACY PRODUCTS WRI 400 AD SERIES CREDENTIALS ONLY with “Card Emulation” using a 26 -bit PIN only keypad (Special order READER Configuration) ONLY if the keypad is 8 -bit format (typical Credential + PIN READER/Keypad) Prox/Mag Cards (AD Series) Smart Cards not supported Smart Cards (AD Series) Power, Supply must be UL 294 Listed 12 VDC @300 ma + READER Legacy WRI has a reader power jack 12 or 24 Volt DC @500 ma No coin cell battery is needed/used No READER Power output - If using a 24 volt power supply, Do not over voltage the reader. Check the reader voltage requirements March 18 Technical Services – Engineering Support 20

LEGACY PRODUCTS WRI 400 AD SERIES CREDENTIALS ONLY with “Card Emulation” using a 26 -bit PIN only keypad (Special order READER Configuration) ONLY if the keypad is 8 -bit format (typical Credential + PIN READER/Keypad) Prox/Mag Cards (AD Series) Smart Cards not supported Smart Cards (AD Series) Power, Supply must be UL 294 Listed 12 VDC @300 ma + READER Legacy WRI has a reader power jack 12 or 24 Volt DC @500 ma No coin cell battery is needed/used No READER Power output - If using a 24 volt power supply, Do not over voltage the reader. Check the reader voltage requirements March 18 Technical Services – Engineering Support 20

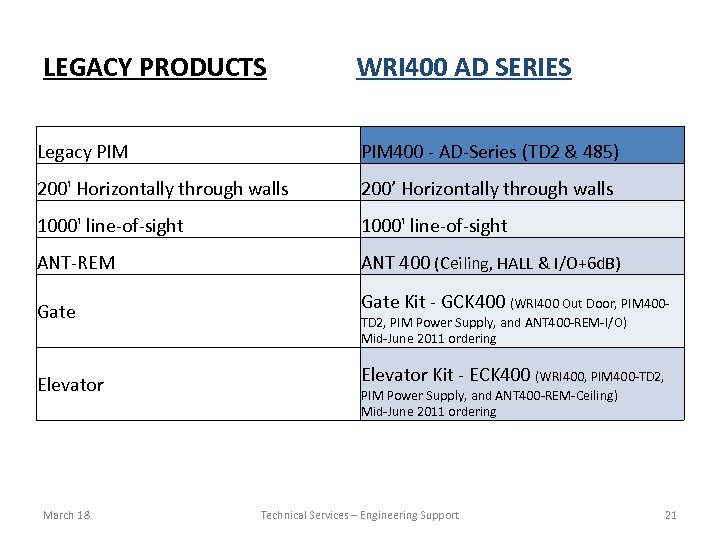

LEGACY PRODUCTS WRI 400 AD SERIES Legacy PIM 400 - AD-Series (TD 2 & 485) 200' Horizontally through walls 200’ Horizontally through walls 1000' line-of-sight ANT-REM ANT 400 (Ceiling, HALL & I/O+6 d. B) Gate Kit - GCK 400 (WRI 400 Out Door, PIM 400 - Elevator Kit - ECK 400 (WRI 400, PIM 400 -TD 2, March 18 TD 2, PIM Power Supply, and ANT 400 -REM-I/O) Mid-June 2011 ordering PIM Power Supply, and ANT 400 -REM-Ceiling) Mid-June 2011 ordering Technical Services – Engineering Support 21

LEGACY PRODUCTS WRI 400 AD SERIES Legacy PIM 400 - AD-Series (TD 2 & 485) 200' Horizontally through walls 200’ Horizontally through walls 1000' line-of-sight ANT-REM ANT 400 (Ceiling, HALL & I/O+6 d. B) Gate Kit - GCK 400 (WRI 400 Out Door, PIM 400 - Elevator Kit - ECK 400 (WRI 400, PIM 400 -TD 2, March 18 TD 2, PIM Power Supply, and ANT 400 -REM-I/O) Mid-June 2011 ordering PIM Power Supply, and ANT 400 -REM-Ceiling) Mid-June 2011 ordering Technical Services – Engineering Support 21

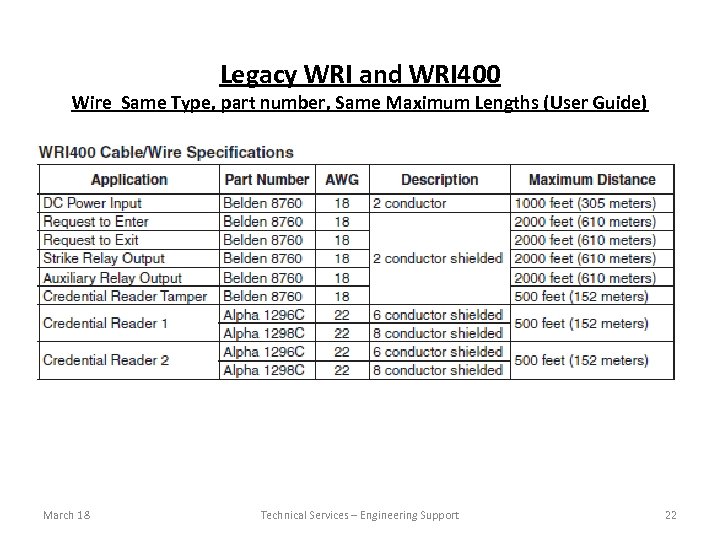

Legacy WRI and WRI 400 Wire Same Type, part number, Same Maximum Lengths (User Guide) March 18 Technical Services – Engineering Support 22

Legacy WRI and WRI 400 Wire Same Type, part number, Same Maximum Lengths (User Guide) March 18 Technical Services – Engineering Support 22

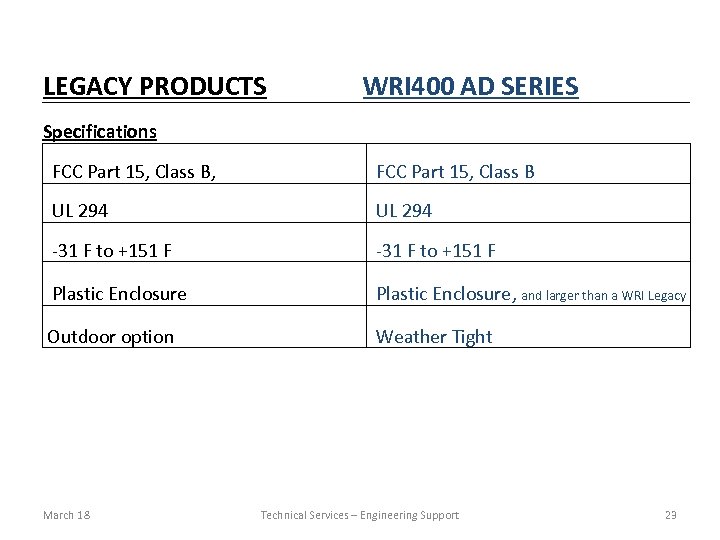

LEGACY PRODUCTS WRI 400 AD SERIES Specifications FCC Part 15, Class B, FCC Part 15, Class B UL 294 -31 F to +151 F Plastic Enclosure, and larger than a WRI Legacy Outdoor option Weather Tight March 18 Technical Services – Engineering Support 23

LEGACY PRODUCTS WRI 400 AD SERIES Specifications FCC Part 15, Class B, FCC Part 15, Class B UL 294 -31 F to +151 F Plastic Enclosure, and larger than a WRI Legacy Outdoor option Weather Tight March 18 Technical Services – Engineering Support 23

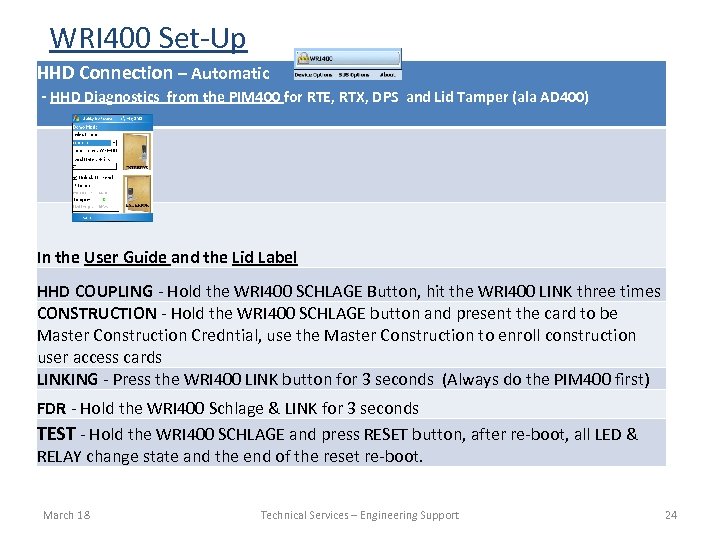

WRI 400 Set-Up HHD Connection – Automatic - HHD Diagnostics from the PIM 400 for RTE, RTX, DPS and Lid Tamper (ala AD 400) In the User Guide and the Lid Label HHD COUPLING - Hold the WRI 400 SCHLAGE Button, hit the WRI 400 LINK three times CONSTRUCTION - Hold the WRI 400 SCHLAGE button and present the card to be Master Construction Credntial, use the Master Construction to enroll construction user access cards LINKING - Press the WRI 400 LINK button for 3 seconds (Always do the PIM 400 first) FDR - Hold the WRI 400 Schlage & LINK for 3 seconds TEST - Hold the WRI 400 SCHLAGE and press RESET button, after re-boot, all LED & RELAY change state and the end of the reset re-boot. March 18 Technical Services – Engineering Support 24

WRI 400 Set-Up HHD Connection – Automatic - HHD Diagnostics from the PIM 400 for RTE, RTX, DPS and Lid Tamper (ala AD 400) In the User Guide and the Lid Label HHD COUPLING - Hold the WRI 400 SCHLAGE Button, hit the WRI 400 LINK three times CONSTRUCTION - Hold the WRI 400 SCHLAGE button and present the card to be Master Construction Credntial, use the Master Construction to enroll construction user access cards LINKING - Press the WRI 400 LINK button for 3 seconds (Always do the PIM 400 first) FDR - Hold the WRI 400 Schlage & LINK for 3 seconds TEST - Hold the WRI 400 SCHLAGE and press RESET button, after re-boot, all LED & RELAY change state and the end of the reset re-boot. March 18 Technical Services – Engineering Support 24

WRI 400 AD SERIES LINKING LINK to PIM 400 -485/TD 2 Door number assignment LINKING to a PIM 400 - HHD assigns door number when LINKING to a PIM 400 -485, 0 - 15 LINK 0 or LINK 1 manually when LINKING to a PIM 400 -TD 2 Just like an AD 400 March 18 Technical Services – Engineering Support 25

WRI 400 AD SERIES LINKING LINK to PIM 400 -485/TD 2 Door number assignment LINKING to a PIM 400 - HHD assigns door number when LINKING to a PIM 400 -485, 0 - 15 LINK 0 or LINK 1 manually when LINKING to a PIM 400 -TD 2 Just like an AD 400 March 18 Technical Services – Engineering Support 25

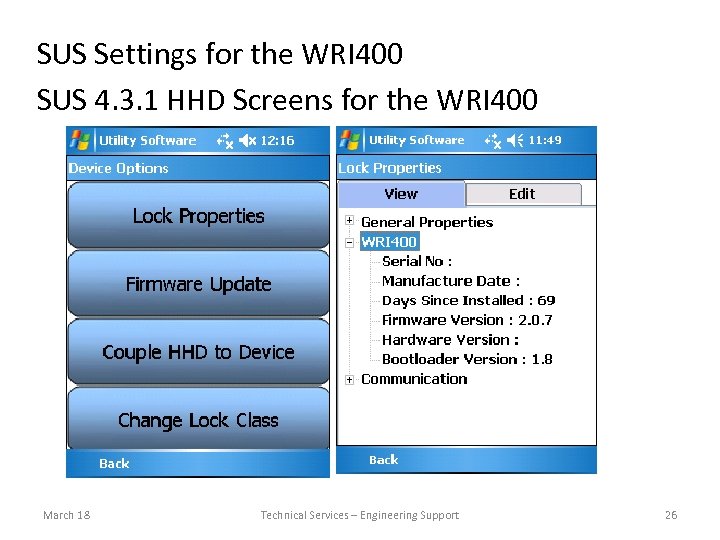

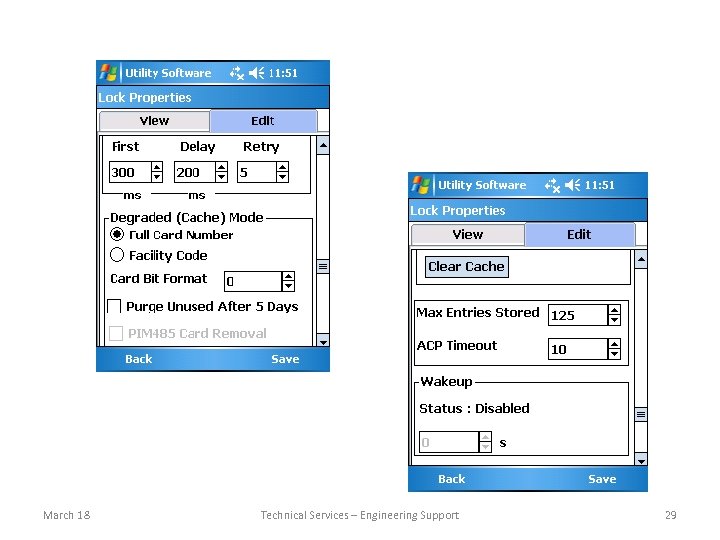

SUS Settings for the WRI 400 SUS 4. 3. 1 HHD Screens for the WRI 400 March 18 Technical Services – Engineering Support 26

SUS Settings for the WRI 400 SUS 4. 3. 1 HHD Screens for the WRI 400 March 18 Technical Services – Engineering Support 26

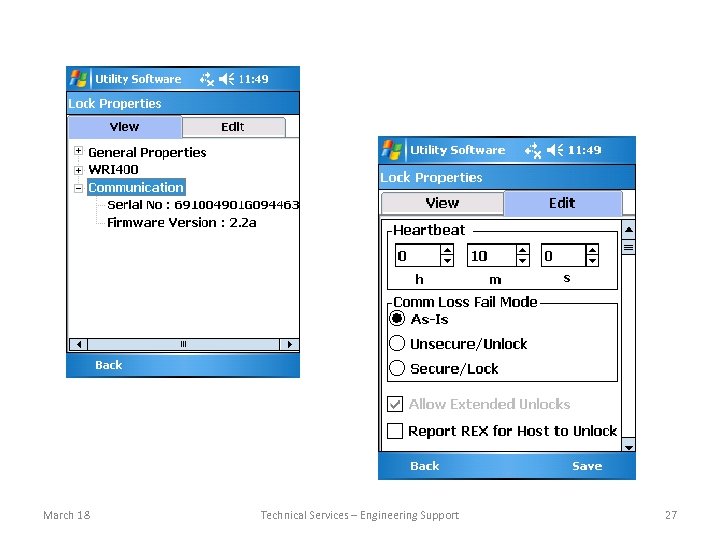

March 18 Technical Services – Engineering Support 27

March 18 Technical Services – Engineering Support 27

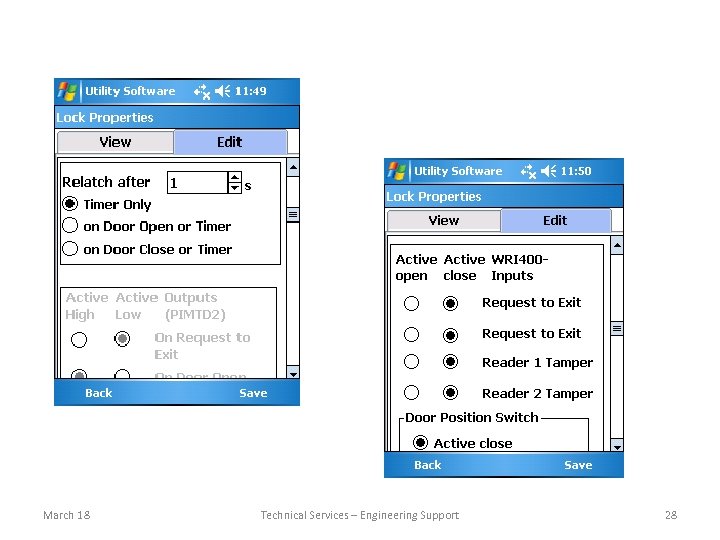

March 18 Technical Services – Engineering Support 28

March 18 Technical Services – Engineering Support 28

March 18 Technical Services – Engineering Support 29

March 18 Technical Services – Engineering Support 29

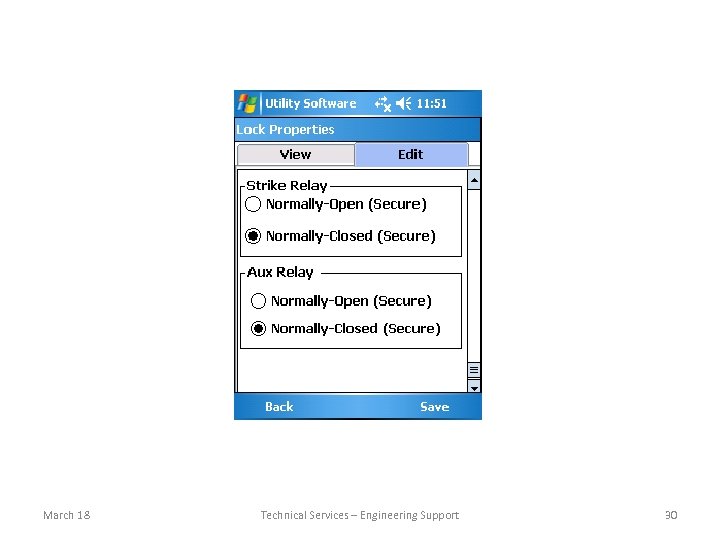

March 18 Technical Services – Engineering Support 30

March 18 Technical Services – Engineering Support 30

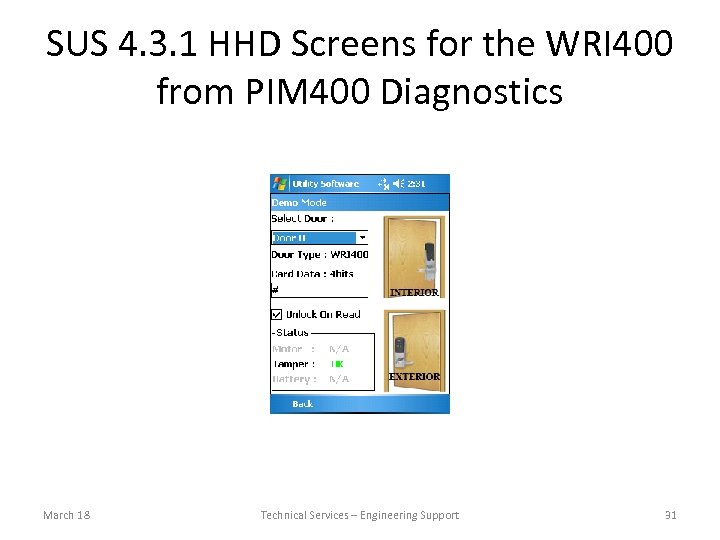

SUS 4. 3. 1 HHD Screens for the WRI 400 from PIM 400 Diagnostics March 18 Technical Services – Engineering Support 31

SUS 4. 3. 1 HHD Screens for the WRI 400 from PIM 400 Diagnostics March 18 Technical Services – Engineering Support 31

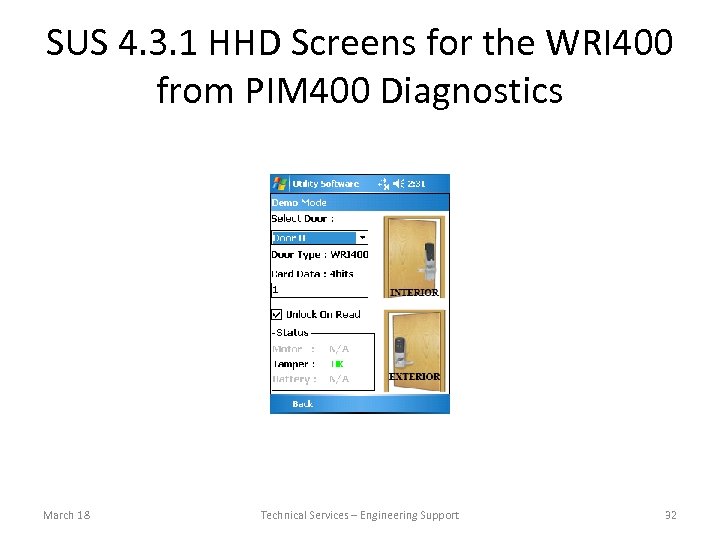

SUS 4. 3. 1 HHD Screens for the WRI 400 from PIM 400 Diagnostics March 18 Technical Services – Engineering Support 32

SUS 4. 3. 1 HHD Screens for the WRI 400 from PIM 400 Diagnostics March 18 Technical Services – Engineering Support 32

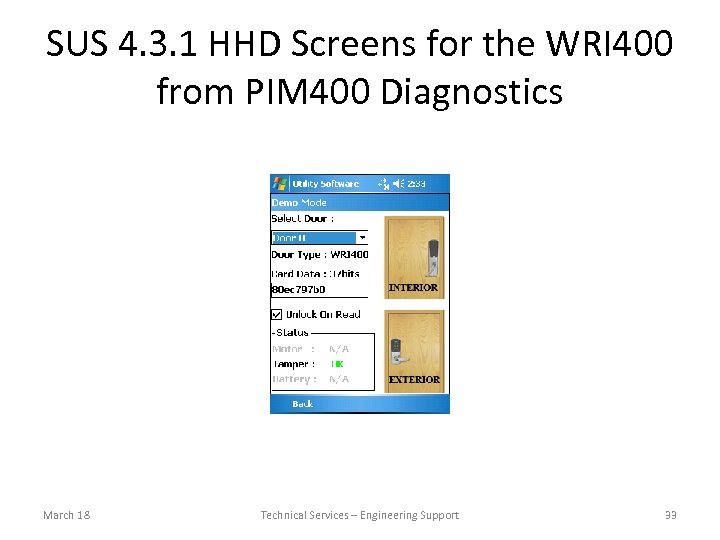

SUS 4. 3. 1 HHD Screens for the WRI 400 from PIM 400 Diagnostics March 18 Technical Services – Engineering Support 33

SUS 4. 3. 1 HHD Screens for the WRI 400 from PIM 400 Diagnostics March 18 Technical Services – Engineering Support 33

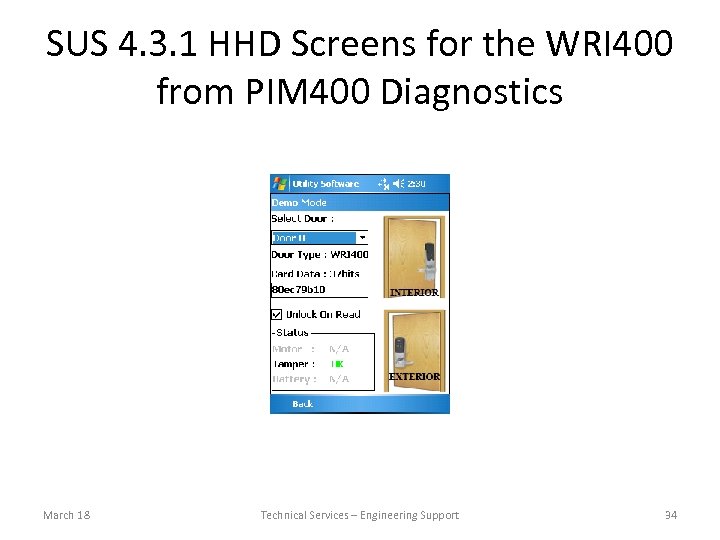

SUS 4. 3. 1 HHD Screens for the WRI 400 from PIM 400 Diagnostics March 18 Technical Services – Engineering Support 34

SUS 4. 3. 1 HHD Screens for the WRI 400 from PIM 400 Diagnostics March 18 Technical Services – Engineering Support 34

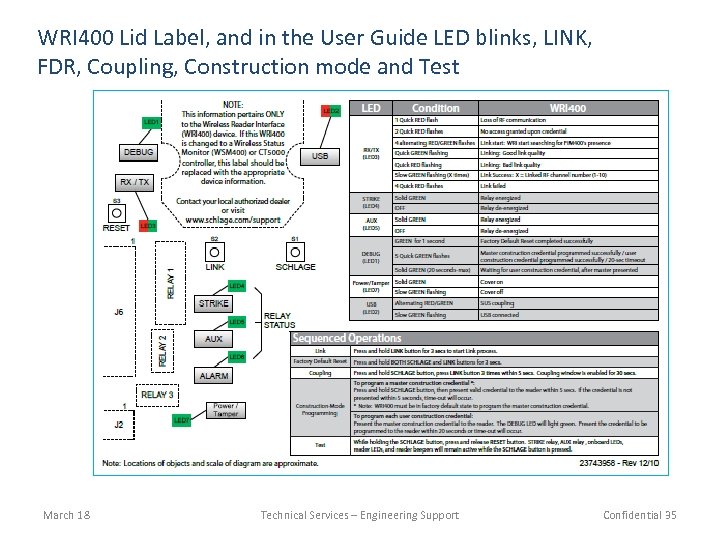

WRI 400 Lid Label, and in the User Guide LED blinks, LINK, FDR, Coupling, Construction mode and Test March 18 Technical Services – Engineering Support Confidential 35

WRI 400 Lid Label, and in the User Guide LED blinks, LINK, FDR, Coupling, Construction mode and Test March 18 Technical Services – Engineering Support Confidential 35

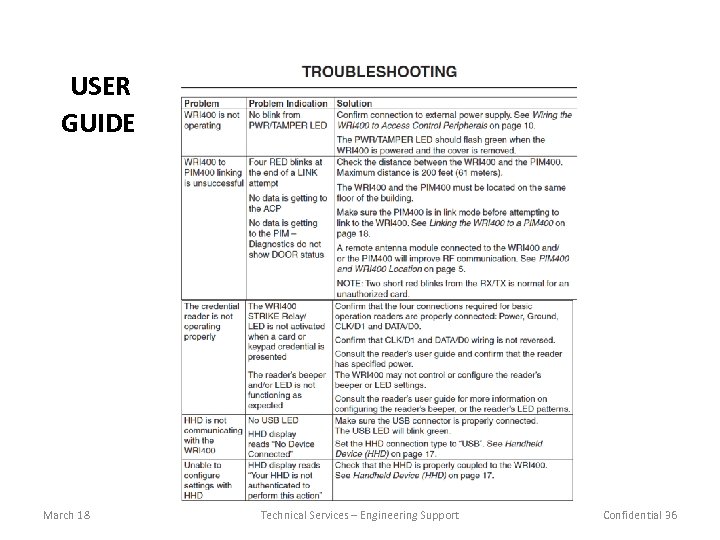

USER GUIDE March 18 Technical Services – Engineering Support Confidential 36

USER GUIDE March 18 Technical Services – Engineering Support Confidential 36

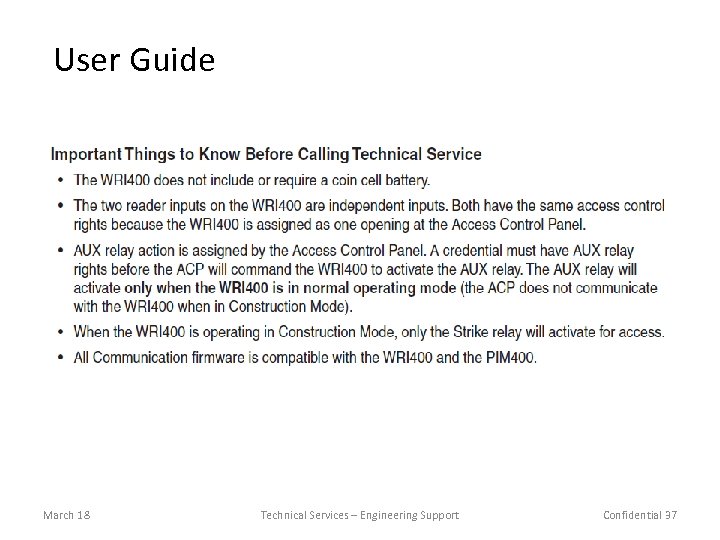

User Guide March 18 Technical Services – Engineering Support Confidential 37

User Guide March 18 Technical Services – Engineering Support Confidential 37

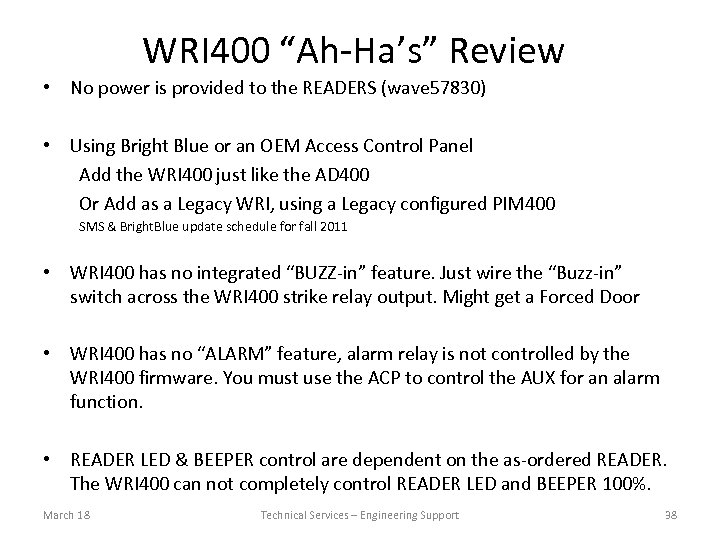

WRI 400 “Ah-Ha’s” Review • No power is provided to the READERS (wave 57830) • Using Bright Blue or an OEM Access Control Panel Add the WRI 400 just like the AD 400 Or Add as a Legacy WRI, using a Legacy configured PIM 400 SMS & Bright. Blue update schedule for fall 2011 • WRI 400 has no integrated “BUZZ-in” feature. Just wire the “Buzz-in” switch across the WRI 400 strike relay output. Might get a Forced Door • WRI 400 has no “ALARM” feature, alarm relay is not controlled by the WRI 400 firmware. You must use the ACP to control the AUX for an alarm function. • READER LED & BEEPER control are dependent on the as-ordered READER. The WRI 400 can not completely control READER LED and BEEPER 100%. March 18 Technical Services – Engineering Support 38

WRI 400 “Ah-Ha’s” Review • No power is provided to the READERS (wave 57830) • Using Bright Blue or an OEM Access Control Panel Add the WRI 400 just like the AD 400 Or Add as a Legacy WRI, using a Legacy configured PIM 400 SMS & Bright. Blue update schedule for fall 2011 • WRI 400 has no integrated “BUZZ-in” feature. Just wire the “Buzz-in” switch across the WRI 400 strike relay output. Might get a Forced Door • WRI 400 has no “ALARM” feature, alarm relay is not controlled by the WRI 400 firmware. You must use the ACP to control the AUX for an alarm function. • READER LED & BEEPER control are dependent on the as-ordered READER. The WRI 400 can not completely control READER LED and BEEPER 100%. March 18 Technical Services – Engineering Support 38