2b1a0c9119522c977ad2512e45120b5d.ppt

- Количество слайдов: 113

Worksite Hazard Analysis Presented By: Thomas Dean Georgia Tech

Objectives n Discuss the sub elements of worksite hazard analysis n Identify typical hazards in the workplace n Review various techniques that can be used to identify hazards in the workplace

Hazards Vs. Unsafe Behavior n Unsafe behavior sometimes leads to unsafe conditions that can cause accidents. n Consider Maintenance Operations n Unsafe behaviors may show weakness in the safety management system.

Effective Worksite Analysis n Worksite analysis involves a variety of worksite examinations, to identify not only existing hazards, but also conditions and operations where changes might occur to create hazards n Effective management actively analyzes the work and the worksite to anticipate and prevent harmful occurrences

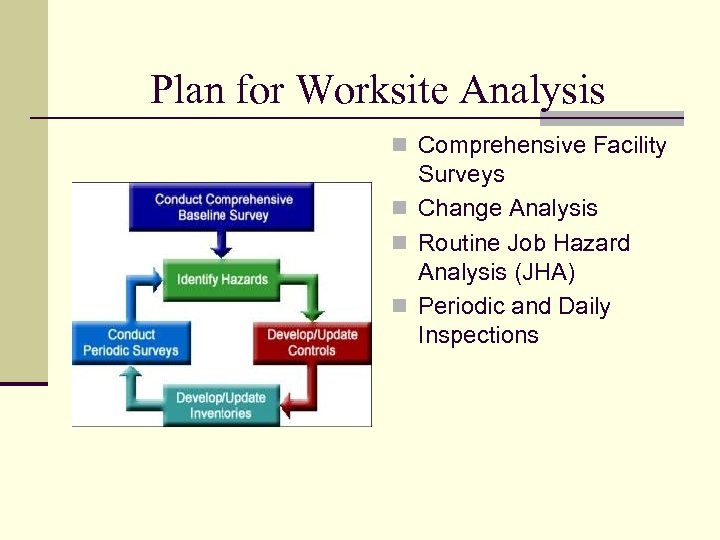

Plan for Worksite Analysis n Comprehensive Facility Surveys n Change Analysis n Routine Job Hazard Analysis (JHA) n Periodic and Daily Inspections

Comprehensive Survey n Comprehensive surveys should be performed depending on the business size and hazardousness every 1 -3 years n Resources for comprehensive survey: private consultants, insurance company, and state funded programs

Change Analysis n Change analysis is simply the management of change in the work environment. n Changes in the following items need to be reviewed: n n Facilities Materials Process Technology Equipment

Change Analysis n A competent team consisting of managers, engineers, superintendents and employees should be involved n How can you best manage change in the work environment?

Job Hazard Analysis n A job hazard analysis is a technique that focuses on job tasks as a way to identify hazards before they occur. n It focuses on the relationship between the worker, the task, the tools, and the work environment. n After uncontrolled hazards are identified, take action to eliminate them or reduce risk.

Job Hazard Analysis n Performing a job hazard analysis is one of the best methods to develop safe work procedures for the equipment that is operated. n The JHA can also be used to train employees in the hazards associated with task and what control measures should be practiced.

JHA Team n A Job Hazard Analysis requires the cooperation of all parties involved that includes: Safety Professional n Engineers-Technical Advisor n Supervisors-Frontline Personnel responsible for making change n Employee-Person most familiar with job n

Communication of the JHA n Safety Meetings n Distribution of Copies n SOP and Operations Manual n What are some other methods? n ___________________

What are the Possible Uses of a JHA n 1. _____________ n 2. _____________ n 3. _____________

Prioritization of JHA n Jobs with the highest injury and illness rates n Jobs that have the potential to cause serious injury n Jobs in which one simple human error could cause injury n Jobs complex enough to have written instructions n Jobs that are new to you facility n Jobs that significantly had changes in process technology or procedures

Steps for JHA n Involve Employees n List, rank, and set n Review accident history priorities for hazardous jobs n Outline the steps or tasks n Conduct preliminary job review

Involvement of Employees n They have a unique understanding of the job, and this knowledge is invaluable for finding hazards. n Involving employees will help minimize oversights, ensure a quality analysis. n Get workers to “buy in” to the solutions because they will share ownership

Job Review n Discuss with employees the hazards that they know exist. n Brainstorm with them for ideas to eliminate or control those hazards. n If any hazards exist that pose an immediate danger, to an employee’s life or health, take immediate action to protect the worker. n Any problems that can be corrected easily should be corrected as soon as possible.

Outline the Steps n Watch the employee perform the job and list each step as the worker takes it. n Be sure to record enough information to describe each job action without getting overly detailed. n Avoid making the breakdown of steps so detailed that it becomes unnecessarily long or so broad that it does not include basic steps.

Outline the Steps n Review the job steps with the employee to make sure you have not omitted something. n Include the employee in all phases of the analysis—from reviewing the job steps and procedures to discussing uncontrolled hazards and recommended solutions.

Identifying the Hazards n A job hazard analysis is an exercise in detective work. Your goal is to discover the following: What can go wrong? n What are the consequences? n How could it arise? n What are other contributing factors? n How likely is it that the hazard will occur? n

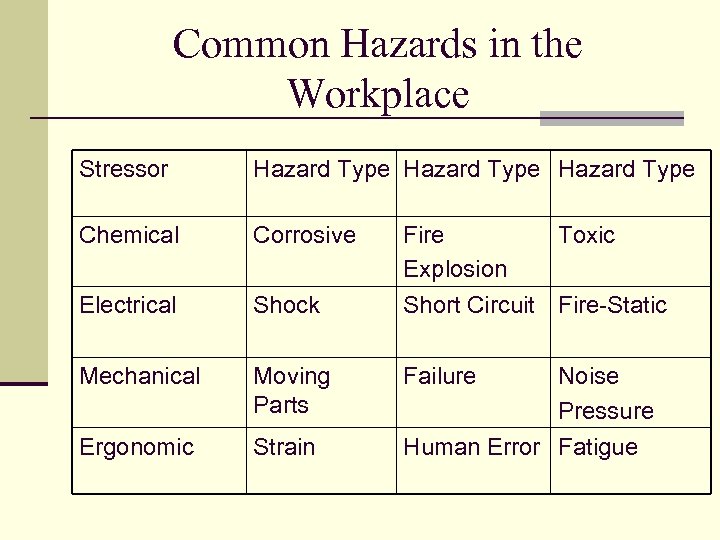

Common Hazards in the Workplace Stressor Hazard Type Chemical Corrosive Fire Explosion Electrical Shock Short Circuit Fire-Static Mechanical Moving Parts Failure Ergonomic Strain Toxic Noise Pressure Human Error Fatigue

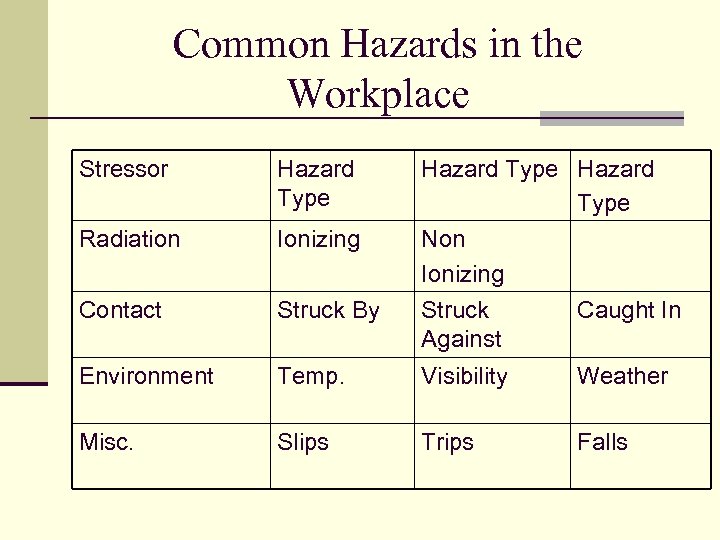

Common Hazards in the Workplace Stressor Hazard Type Non Ionizing Radiation Ionizing Contact Struck By Struck Against Caught In Environment Temp. Visibility Weather Misc. Slips Trips Falls

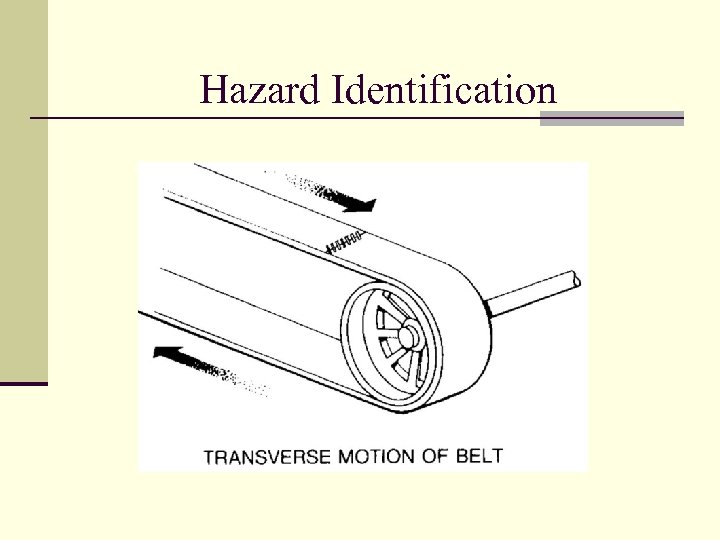

Hazard Identification Workshop n Based on the following slides of machinery, identify the potential hazards. n Hint: Use the previous tables and analyze the machinery and work environment n Prepare to discuss your findings.

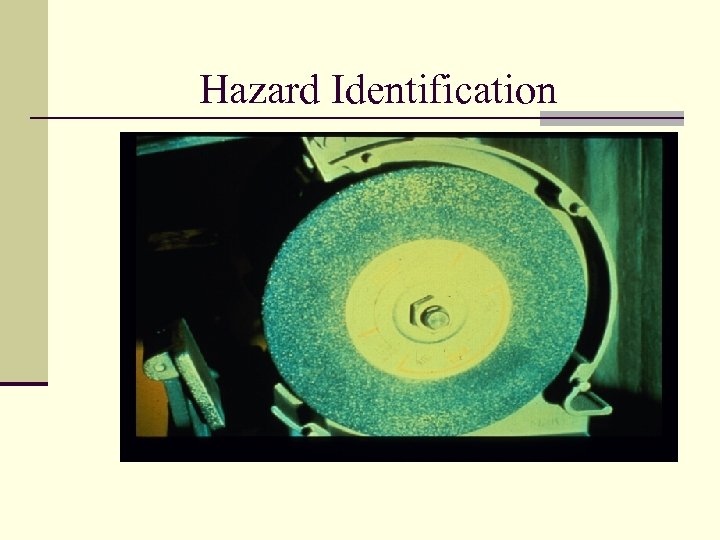

Hazard Identification

Hazard Identification

Hazard Identification

Hazard Identification

Controlling the Hazards n The order of precedence and effectiveness of hazard control is the following: 1. Engineering controls. n 2. Administrative controls. n 3. Personal protective equipment. n

Controlling the Hazards n The most effective controls are engineering controls that physically change a machine or work environment to prevent employee exposure to the hazard. n The more reliable or less likely a hazard control can be circumvented, the better. n If this is not feasible, administrative controls may be appropriate. n This may involve changing how employees do their jobs.

Controlling the Hazards n Discuss your recommendations with all employees who perform the job and consider their responses carefully. n If you plan to introduce new or modified job procedures, be sure they understand what they are required to do and the reasons for the changes.

Engineering Controls n Engineering controls include the following: n Elimination/minimization of the hazard n Substitution of equipment or process to decrease hazard n Isolation of the hazard with interlocks, machine guards, blast shields, or other means; and n Removal or redirection of the hazard such as with local and exhaust ventilation.

Administrative Controls n Administrative controls include the following: n Written operating procedures, work permits, and safe work practices; n Exposure time limitations (used most commonly to control heat stress and ergonomic hazards); n Monitoring the use of highly hazardous materials; n Alarms, signs, and warnings; n Buddy system; and training

PPE n Personal Protective Equipment is acceptable as a control method in the following circumstances: n n When engineering controls are not feasible or do not totally eliminate the hazard; While engineering controls are being developed; When safe work practices do not provide sufficient additional protection; and During emergencies when engineering controls may not be feasible.

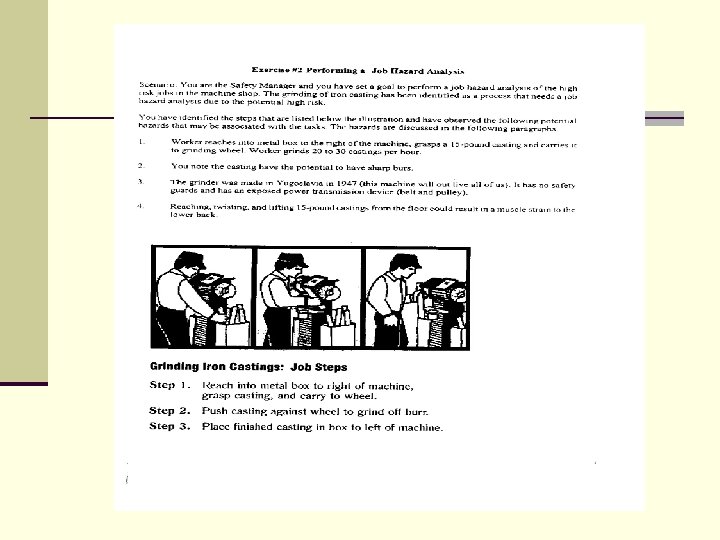

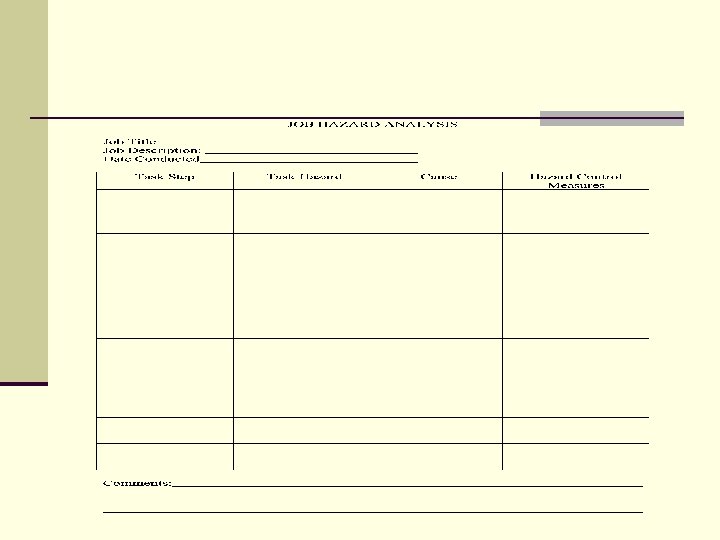

JHA Exercise n We are going to perform an exercise on grinding metal casting. n Based on the steps, please identify the hazards and controls.

Periodic Review of JHA n Reviewing job hazard analysis ensures that it remains current and continues to prevent accidents and injuries. n It is possible that during the review process you will identify hazards that were not identified in the initial analysis. n Review the JHA after accidents, you may determine that you need to change the job procedure to prevent similar incidents. n Review after all close calls and discuss the situation with all employees that do the job.

Safety and Health Inspections n Cover entire worksite n Regular intervals n Inspectors trained n Hazards tracked to correction

Objectives for Inspections n There may be many objectives to the inspection process: Meet OSHA or other legal responsibility n Involve the team n Identify areas of undue risk and control hazards n Identify and develop positive attitudes n Suggest better methods of doing job n

Inspections n OSHA recommends that you perform general workplace inspections. n Check the standard so that you know what must be inspected. n What are some examples of items that must be inspected?

Employee Involvement n What are some reasons for involving employees in the process? Demonstrate commitment to safety n Allow them to become familiar with the process safety requirement. n _____________________ n

Documenting the Inspection n A checklist of workplace specific hazards should be developed. To accomplish this: List the potential hazards in the workplace n Examine the work areas to locate hazards n Check with employees and records n

Resources for Checklist n Insurance and safety consultants n Accident/incident investigation reports (past problems) n Small business handbook n Manufacturer Specifications n JHA and/or employee input n Standards that apply to industry

Checklist Development n Avoid making the checklist: vague, excessive detail, and overwhelming. n Checklist is a tool. n As the inspectors become more skilled, the less reliance there will be on this checklist. n You should get the point that hazards rarely are identified and hazards are corrected immediately.

Examination of the Workplace n Identify conditions that might develop n Location of the hazard n Severity potential

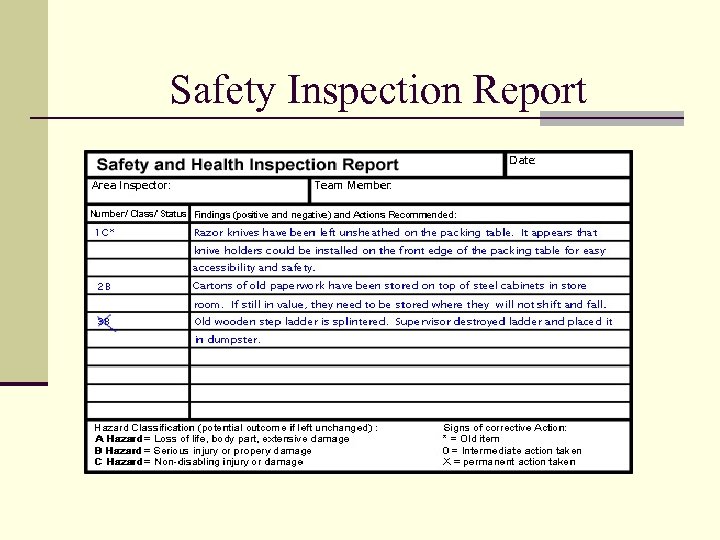

Safety Inspection Report

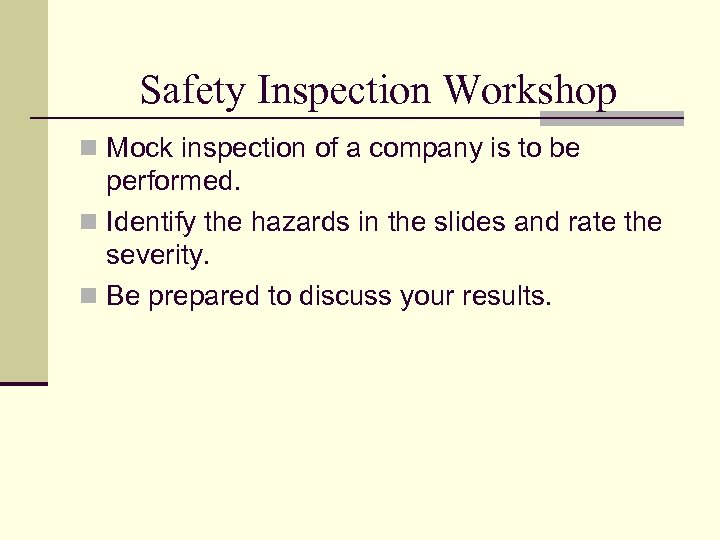

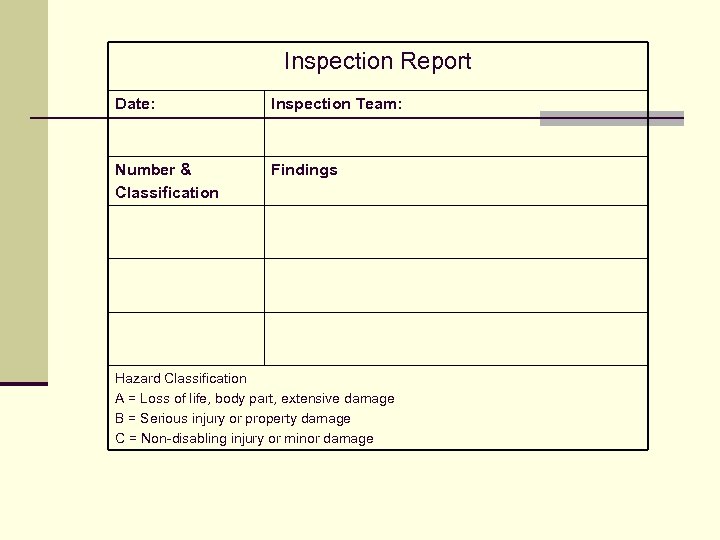

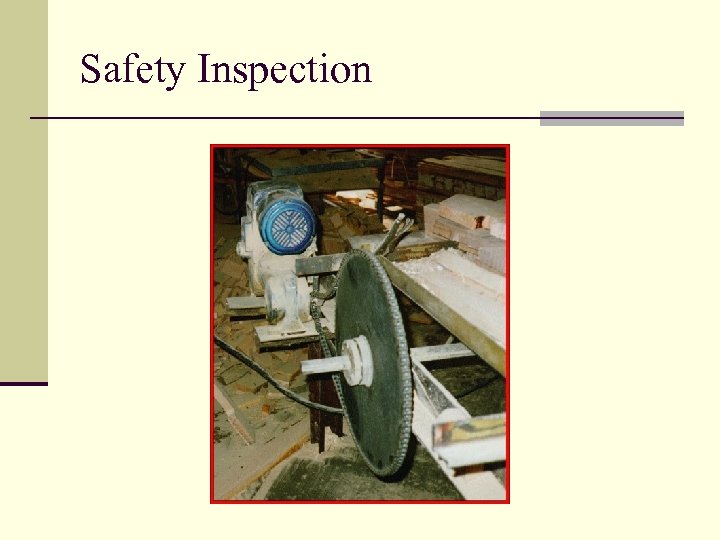

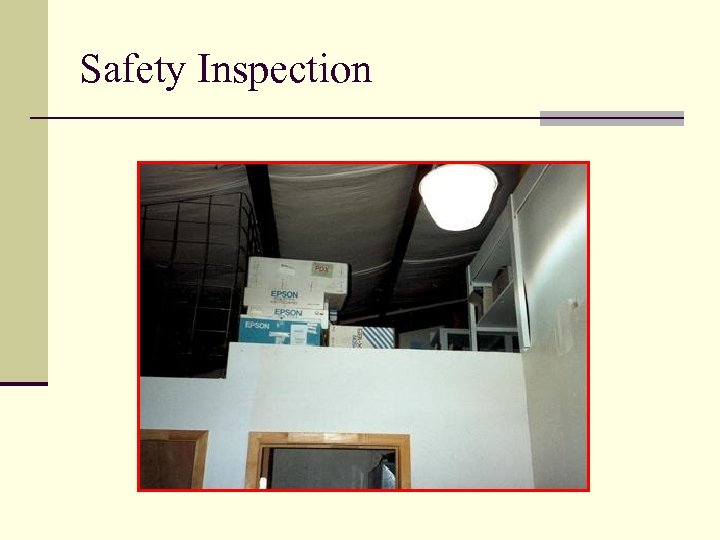

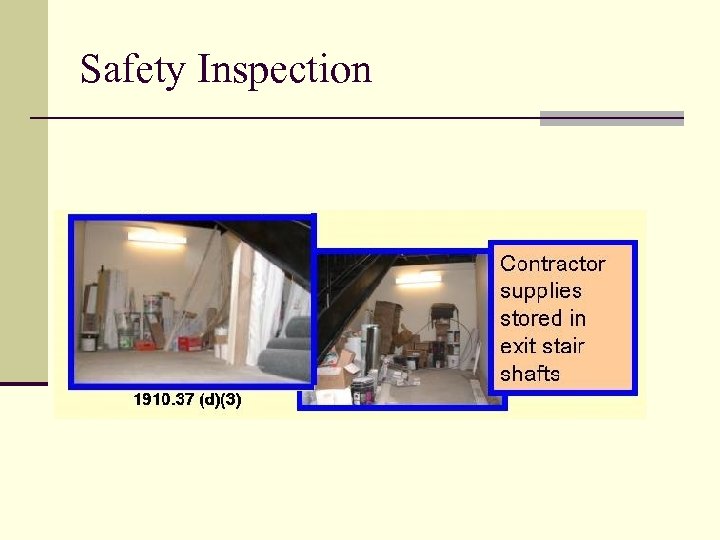

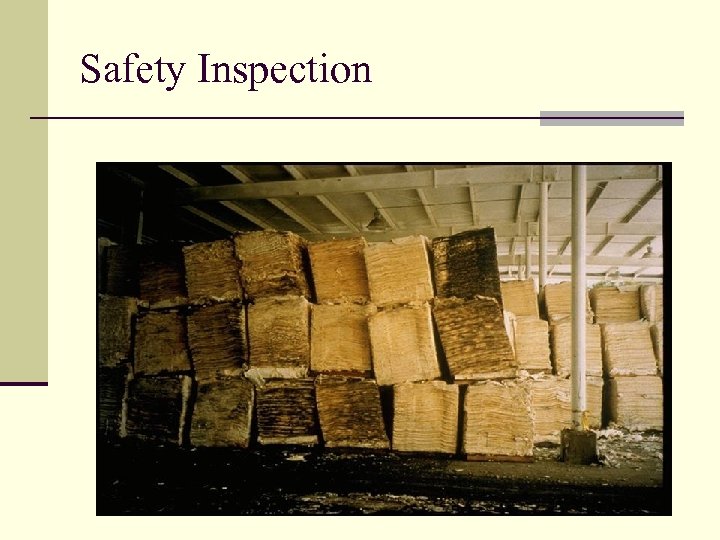

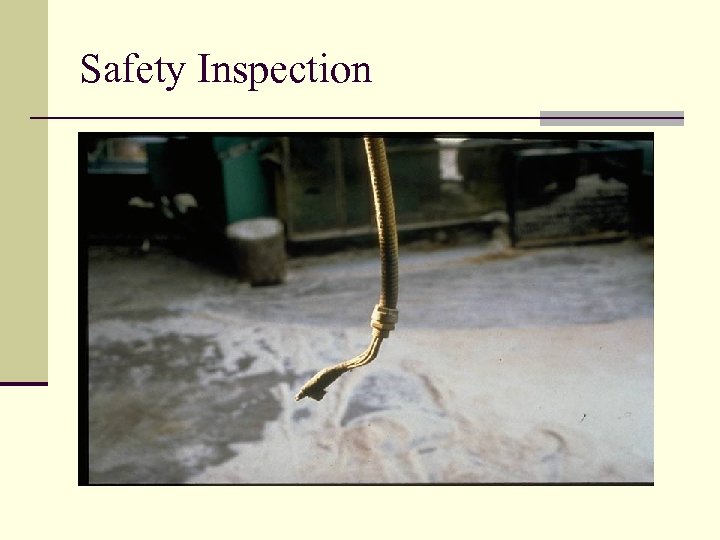

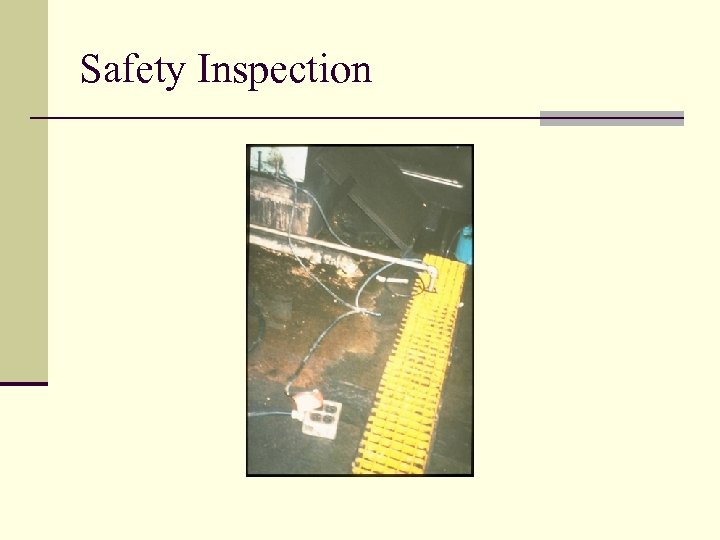

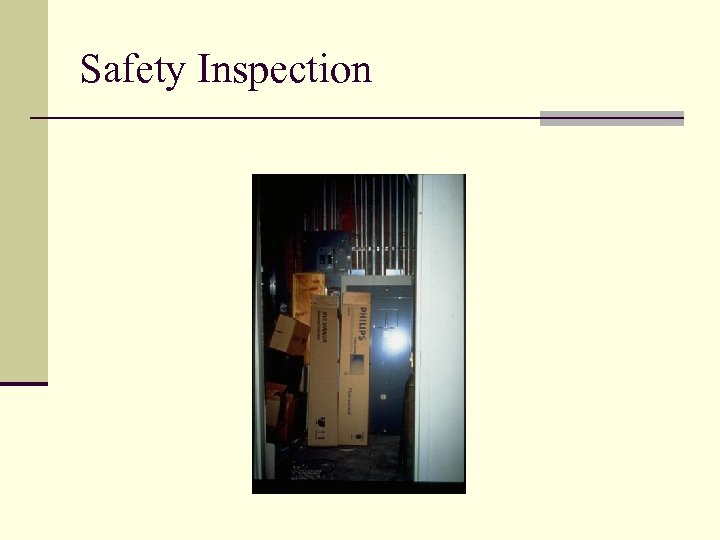

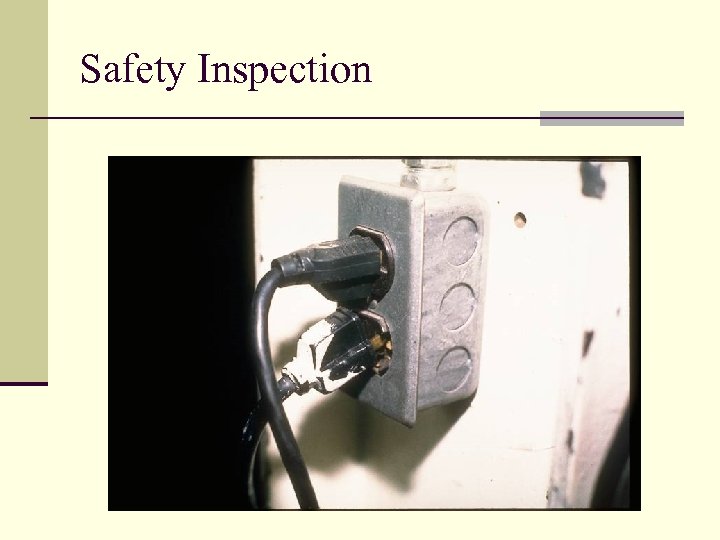

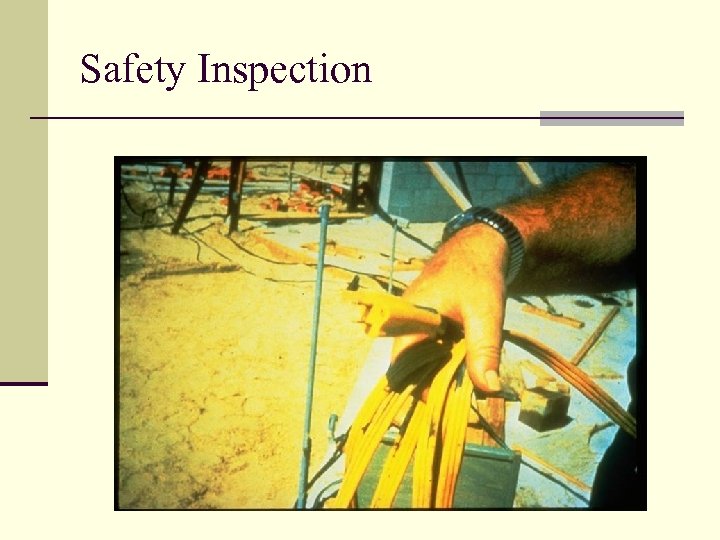

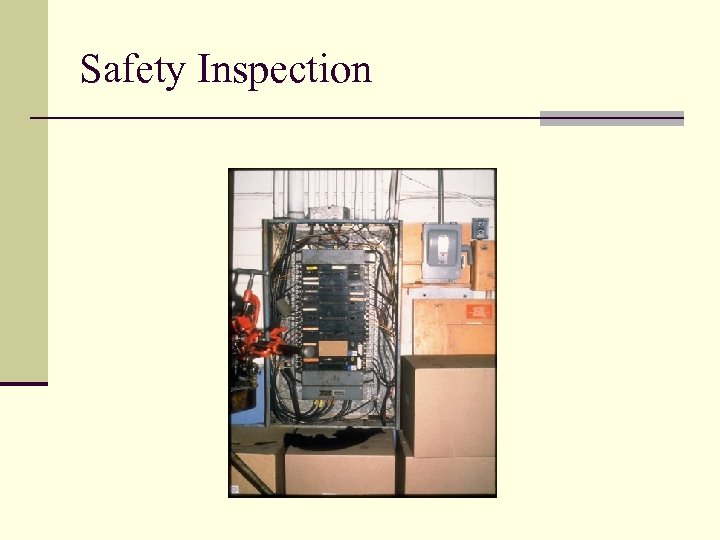

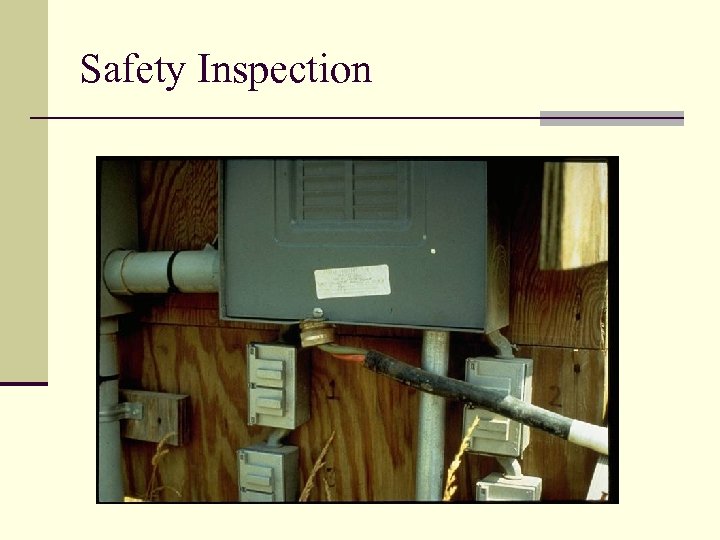

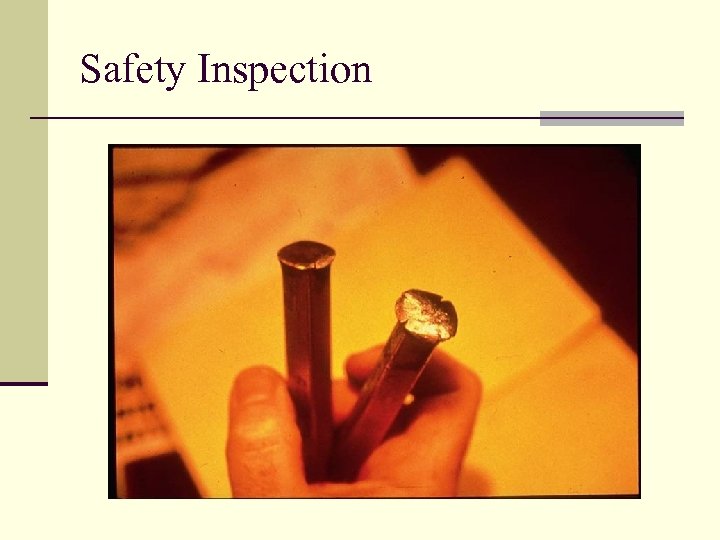

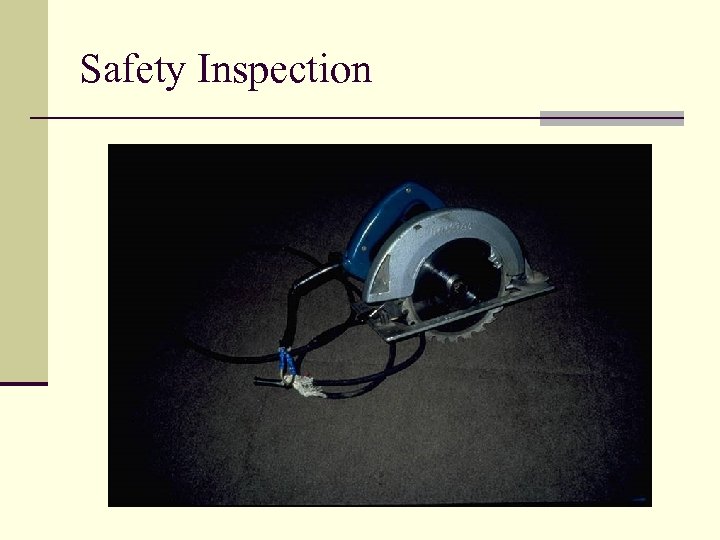

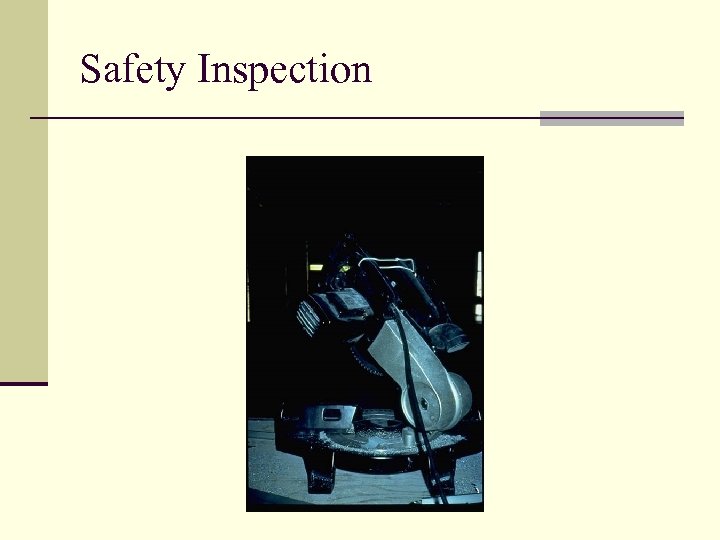

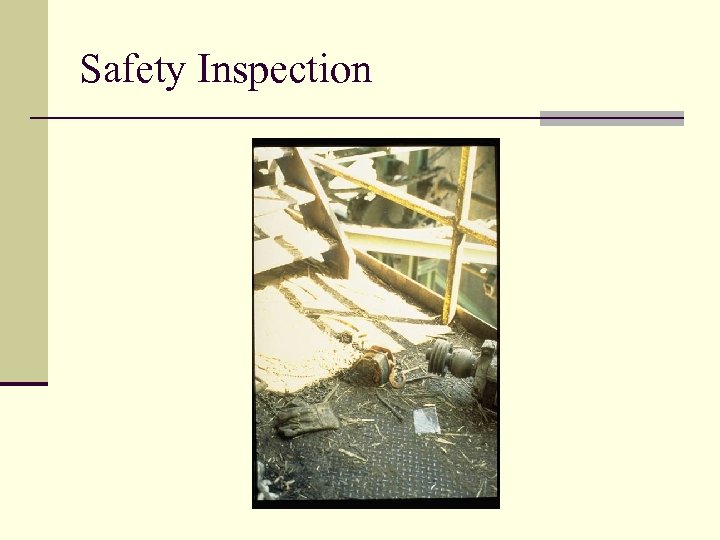

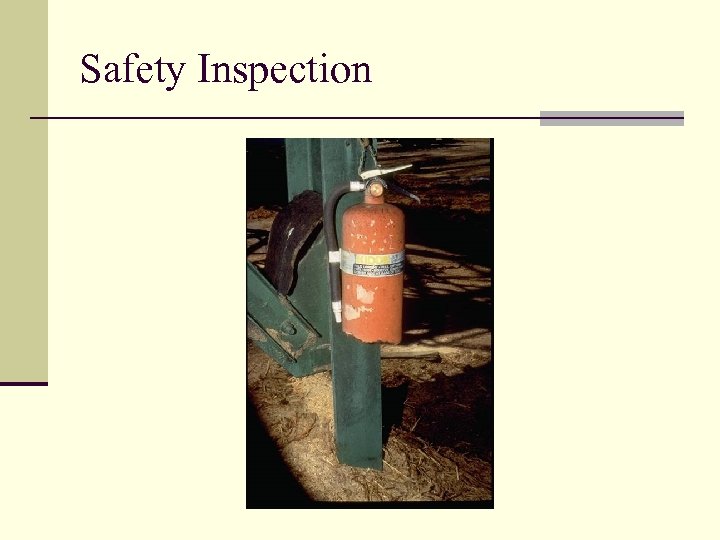

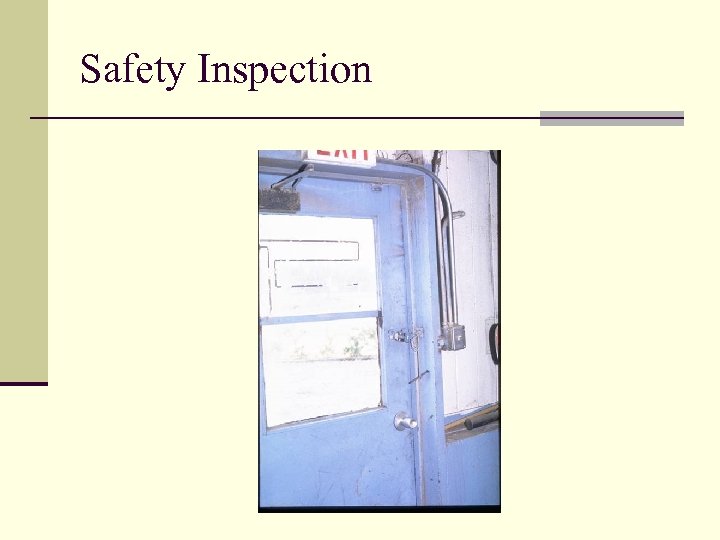

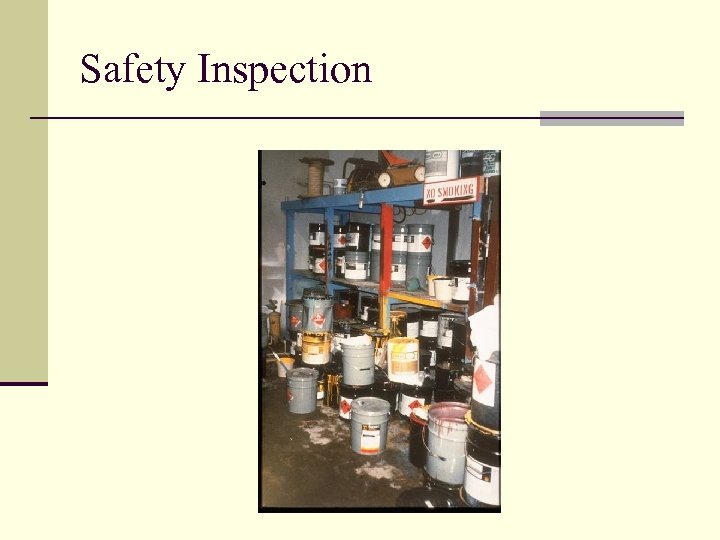

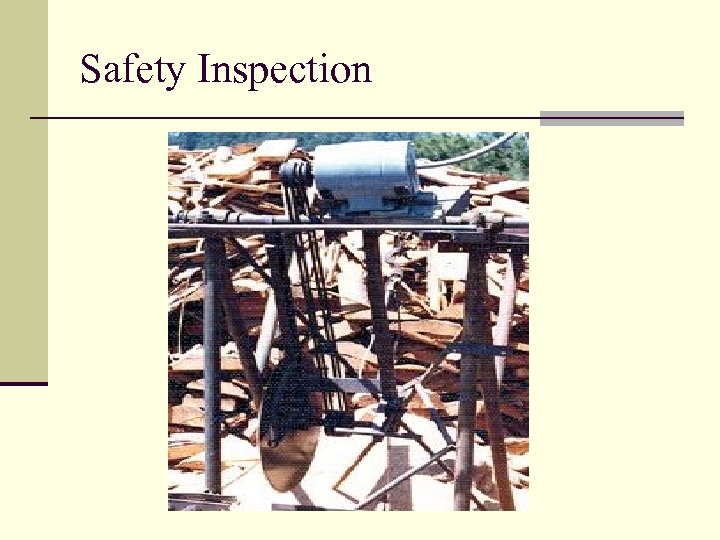

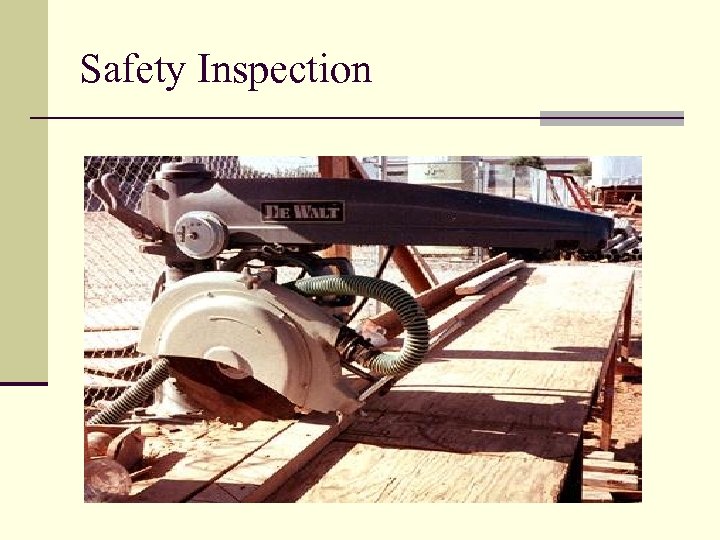

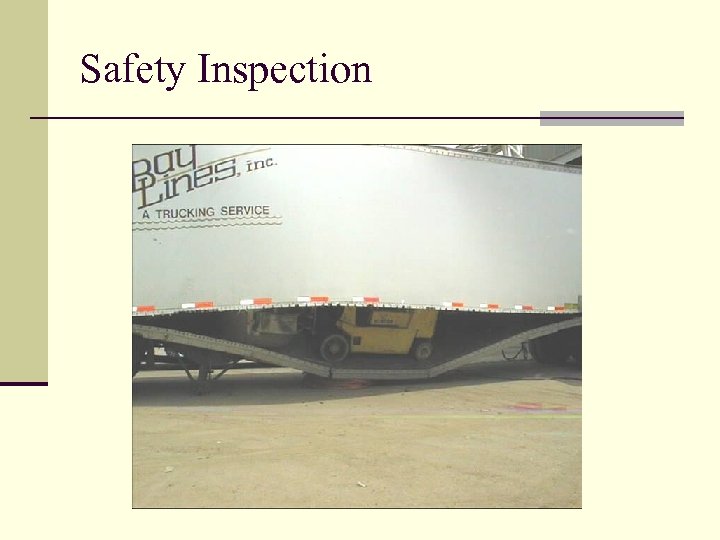

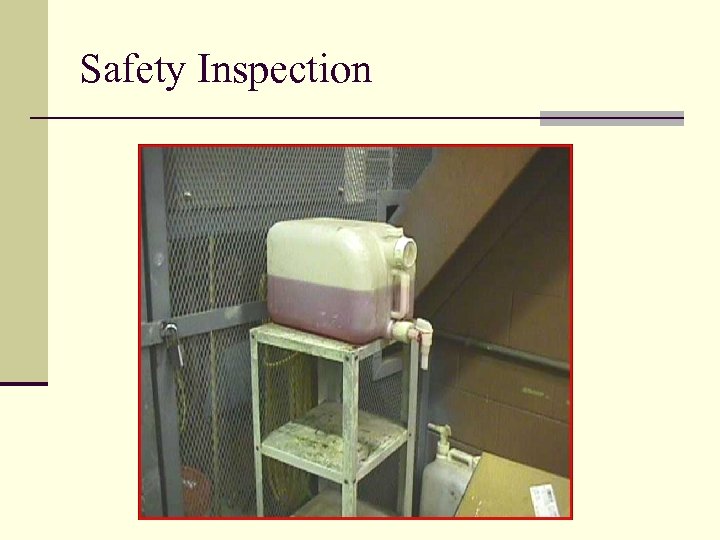

Safety Inspection Workshop n Mock inspection of a company is to be performed. n Identify the hazards in the slides and rate the severity. n Be prepared to discuss your results.

Inspection Report Date: Inspection Team: Number & Classification Findings Hazard Classification A = Loss of life, body part, extensive damage B = Serious injury or property damage C = Non-disabling injury or minor damage

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Safety Inspection

Hazard Reporting n Effective hazard reporting systems will: n encourage employees to report hazards and effectively track them for prioritizing. n create feedback between management and the employee reporting the hazard. n have a system to analysis the hazards reported to determine its effectiveness.

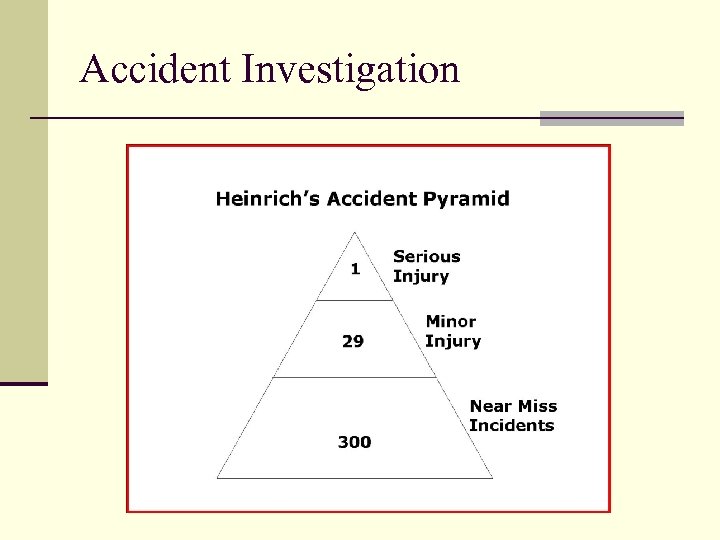

Accident Investigation n All accidents and incidents need to be investigated. n What is an accident? n Why do we investigate accidents? n Why should near misses be investigated?

Accident Investigation

Causes of Injuries and Accidents n Direct Causes n Indirect Causes n Root Causes

Trend Analysis n Trends need to analyzed over time to identify any emerging patterns of injury and intervene to prevent its recurrence. n Review injury records over time n What items should be trended over time to determine any emerging pattern?

Summary n Worksite hazard analysis consists of: n Change analysis n JHA n Workplace inspections n Hazard Reporting n Trend Analysis n Effective programs will result in the identification of potential and existing hazards.

Task Analysis Tools

Review the Basics n Risk Factors n Ergonomic Body Divisions

Risk Factors n Force n Frequency n Posture n Duration n Contact Stress n Environment n Vibration

Ergonomic Body Division n Upper Extremity n Lower Extremity n Trunk

Recognizing a WMSD Problem n Use OSHA 200/300 logs n Accident Reports n Workman’s Compensation info n Employee Surveys n Visual Cues

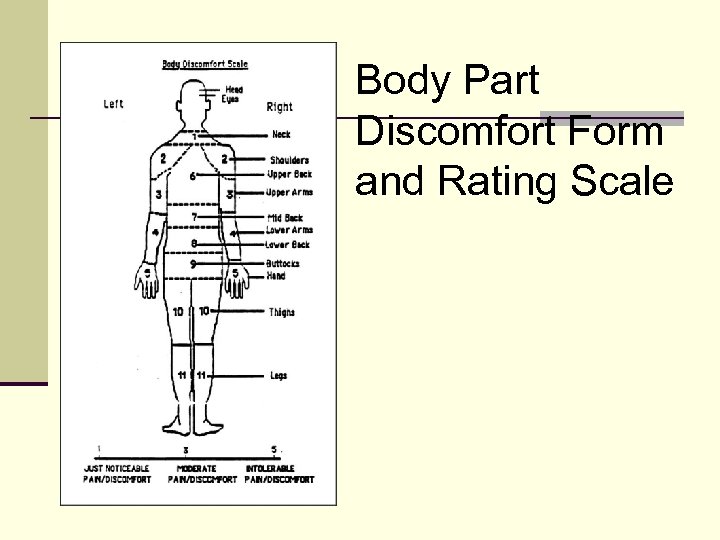

Body Part Discomfort Form and Rating Scale

What is a Task Analysis Tool n A narrative, quantitative and/or checklist system that provides a standardized evaluation of a job/task n Tools based on biomechanical and physiological information compiled and calculated providing a relative risk of injury probability n Can be specific for body region and/or risk factors

Why do we need these tools? n Provide guidance • • Where to begin corrective actions Helps direct efforts toward specific body division, risk factors n Involve employees • Employees can perform assessments n Provide a level of measurement • • Shows improvement of tasks Baseline data

How do we use them? Two criteria for use: • What are you trying to find out? n • General vs. Specific information What limitations must be considered? n Various tools are only able to assess specific body regions

Types of Analysis Tools Checklists • Easy to use • Less time consuming • Minimal training • Very sensitive: One check, task must be considered

Types of Analysis Tools Quantitative • Less sensitive More specific training • Provide a relative risk assessment

Types of Analysis Tools Narrative • More formal training and experience required • Provides specific areas for improvement • Very time consuming

Checklists n Washington State Checklist (WISHA) n NIOSH n University of Michigan

WISHA n Checklist system that identifies “caution or hazard zone jobs” n Incorporates each of the risk factors including vibration and contact stress n Has separate evaluation for heavy, frequent or awkward lifting n Uses verbal cues to guide user through evaluation criteria n Not generally left or right side independent

WISHA n Does address combination of risk factors n Great “first cut” ergonomic tool n Draw Backs • • High sensitivity: identify many jobs Doesn’t separate frequency component by body part

Using WISHA n 3 basic sections • • • Entire body checklist Lifting hazard section Vibration hazard analysis n Entire body checklist • • Identify if a particular hazard exist as a result of a risk factor for a body part If a hazard exists then corrective action is needed

Using WISHA n Lifting hazard analysis • Calculated weight limit is adjusted by: • Compares the actual weight lifted to a calculated weight limit • Actual weight lifted > Weight limit = Hazard exists

Using WISHA n Vibration hazard analysis • Compares the time an employee uses the machine to a pre-measured vibration value • Plot time vs. vibration data on graph • Intersection point indicates degree of hazard • Vibration data: www. lni. wa. gov/wisha/ergo

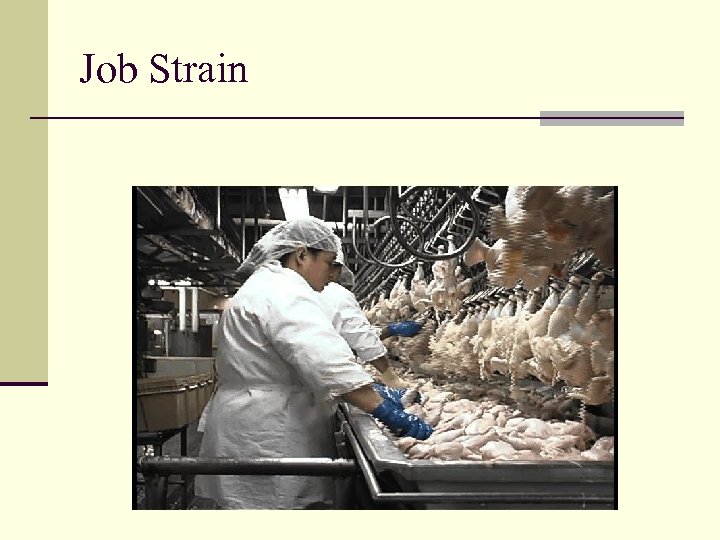

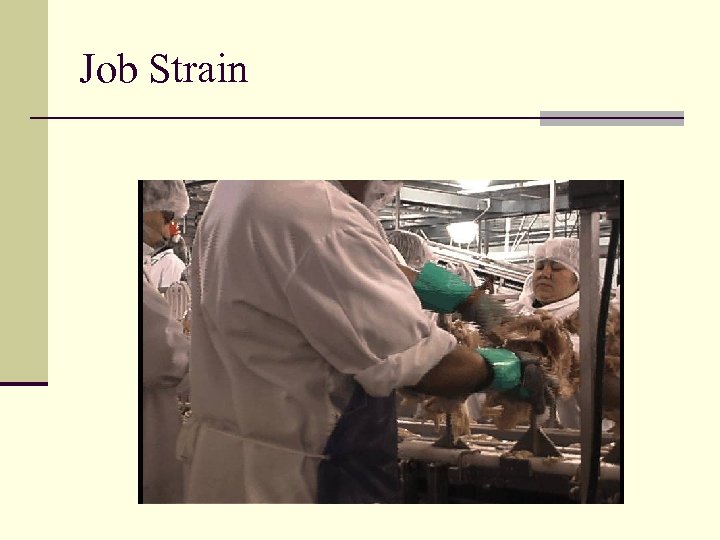

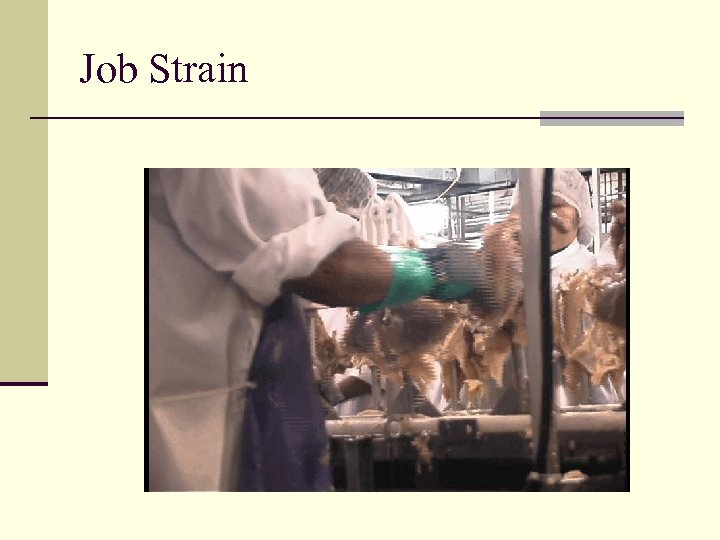

Job Strain

Quantitative Tools n Job Strain Index n Rapid Upper Limb Assessment n ACGIH Threshold Limit Value – HAL n Rapid Entire Body Assessment n Rodgers Muscle Fatigue Analysis n Snook Push/Pull Hazard Tables

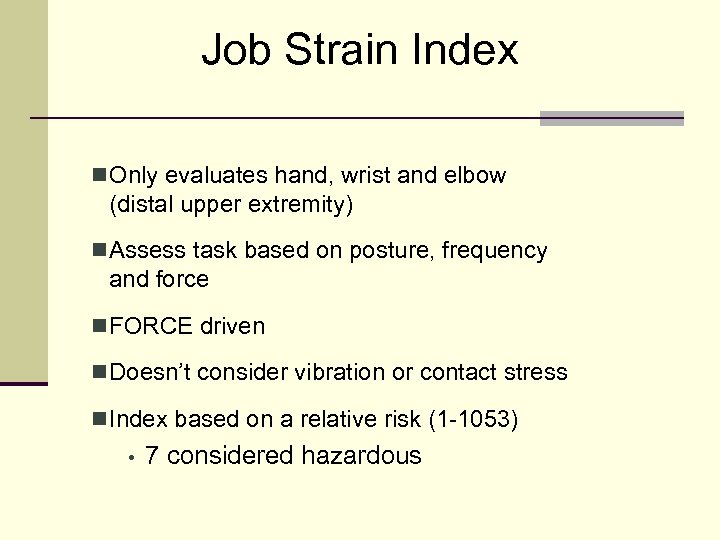

Job Strain Index n Only evaluates hand, wrist and elbow (distal upper extremity) n Assess task based on posture, frequency and force n FORCE driven n Doesn’t consider vibration or contact stress n Index based on a relative risk (1 -1053) • 7 considered hazardous

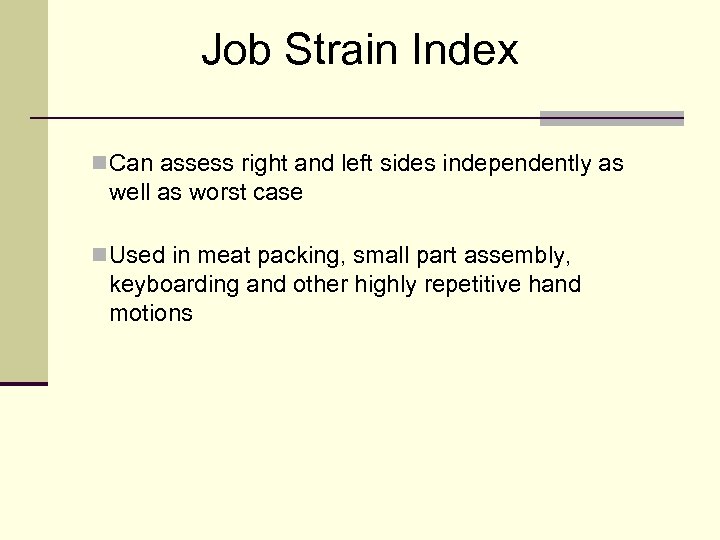

Job Strain Index n Can assess right and left sides independently as well as worst case n Used in meat packing, small part assembly, keyboarding and other highly repetitive hand motions

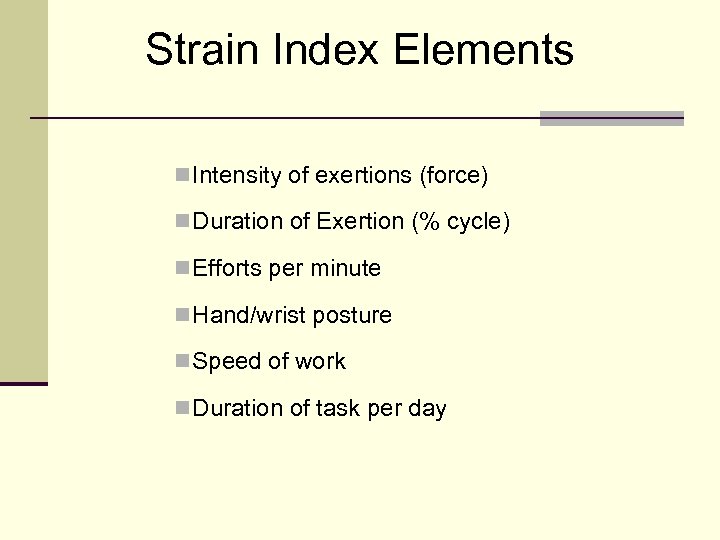

Strain Index Elements n Intensity of exertions (force) n Duration of Exertion (% cycle) n Efforts per minute n Hand/wrist posture n Speed of work n Duration of task per day

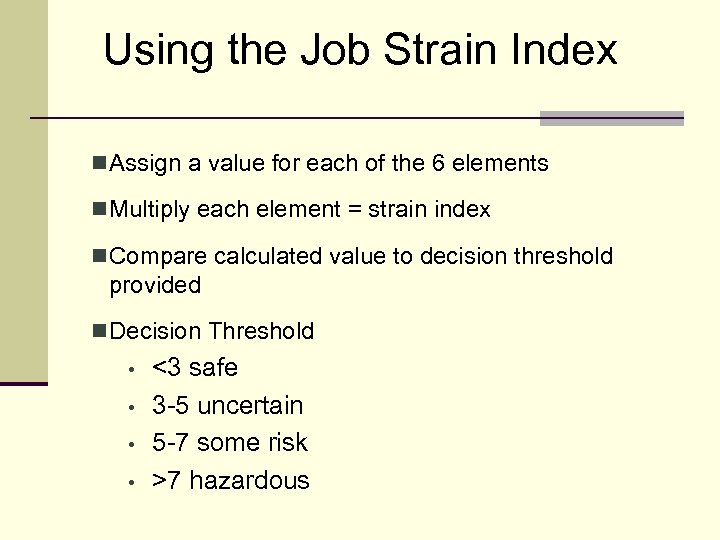

Using the Job Strain Index n Assign a value for each of the 6 elements n Multiply each element = strain index n Compare calculated value to decision threshold provided n Decision Threshold • • <3 safe 3 -5 uncertain 5 -7 some risk >7 hazardous

Job Strain

Job Strain

JHA/Work Methods

JHA/Work Methods Videotaping Tips n Announce the name of the job on the tape n Tape 5 to 10 minutes for each task n At least 3 -4 cycles n Start with whole body shots and then zoom in on problems areas n Try different angles to get the best shot

JHA/Work Methods Step 1: Breaking The Job Down n List each step in order of occurrence n Be sure to record enough information n Can use Gilbreth’s terms to describe steps n Can use video or photos

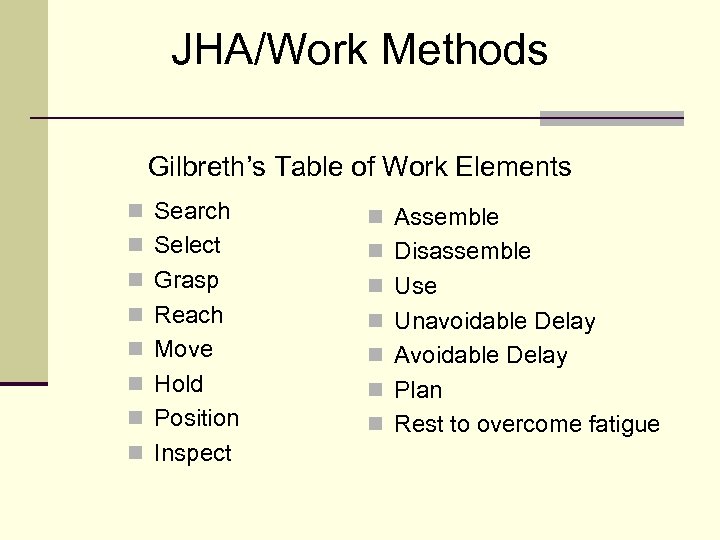

JHA/Work Methods Gilbreth’s Table of Work Elements n Search n Assemble n Select n Disassemble n Grasp n Use n Reach n Unavoidable Delay n Move n Avoidable Delay n Hold n Plan n Position n Rest to overcome fatigue n Inspect

JHA/Work Methods Step 2: Identify the Hazards n Look for Risk Factors in each job n Repeat the job observation until all hazards identified • Video and photos can be especially helpful n Consider abnormal activities and conditions

JHA/Work Methods Step 3: New Procedure or Protection n Can the job be performed in another way? n Can you make physical changes to the job? n Does the job have to be performed? Can it be done less often?

Work Methods

Work Methods

What does the worker need to know from this presentation?

2b1a0c9119522c977ad2512e45120b5d.ppt