5cea260676215a4aa4cd50d796d9e78e.ppt

- Количество слайдов: 34

Workshop on the role of International Standards in Economic Development Use of Standards in the Textile Sector and the Challenges for the SMEs Presentation by The Pakistan Permanent Mission to the WTO

Workshop on the role of International Standards in Economic Development Use of Standards in the Textile Sector and the Challenges for the SMEs Presentation by The Pakistan Permanent Mission to the WTO

HOW DOES THE SYSTEM WORK? HOW THE SYSTEM WORKS?

HOW DOES THE SYSTEM WORK? HOW THE SYSTEM WORKS?

Pakistan textile industry Textiles is the premier industry & backbone of Pakistan’s Economy: Ø Major Agrarian industrial sector. Ø Generates about 60 % of exports Ø Constitutes 46 % of Manufacturing Industry Ø Employs 38 % of country’s work force Ø Contributes 8. 5% to the total GDP Ø Major products are cotton yarn, fabrics, bed wear, towels, woven & knit garments. Ø Drives Banking, Shipping , Transport , Insurance, Machinery, Dyes/Chemicals , Printing/Packaging & allied sectors.

Pakistan textile industry Textiles is the premier industry & backbone of Pakistan’s Economy: Ø Major Agrarian industrial sector. Ø Generates about 60 % of exports Ø Constitutes 46 % of Manufacturing Industry Ø Employs 38 % of country’s work force Ø Contributes 8. 5% to the total GDP Ø Major products are cotton yarn, fabrics, bed wear, towels, woven & knit garments. Ø Drives Banking, Shipping , Transport , Insurance, Machinery, Dyes/Chemicals , Printing/Packaging & allied sectors.

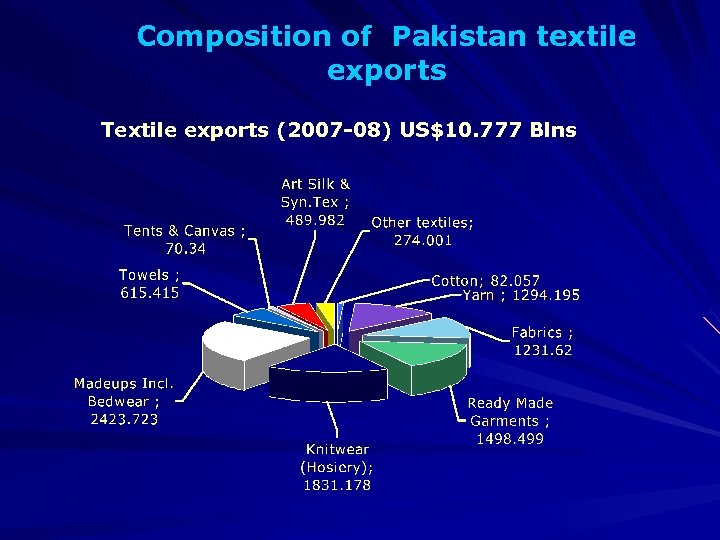

Composition of Pakistan textile exports Textile exports (2007 -08) US$10. 777 Blns

Composition of Pakistan textile exports Textile exports (2007 -08) US$10. 777 Blns

SMEs the backbone of economy Role in the Textile Industry: v Involved at processing, stitching and various levels of the value chain v Labour intensive work therefore trained manpower and quality control mechanisms are extremely important v Case study of a Company and two clusters of SMEs

SMEs the backbone of economy Role in the Textile Industry: v Involved at processing, stitching and various levels of the value chain v Labour intensive work therefore trained manpower and quality control mechanisms are extremely important v Case study of a Company and two clusters of SMEs

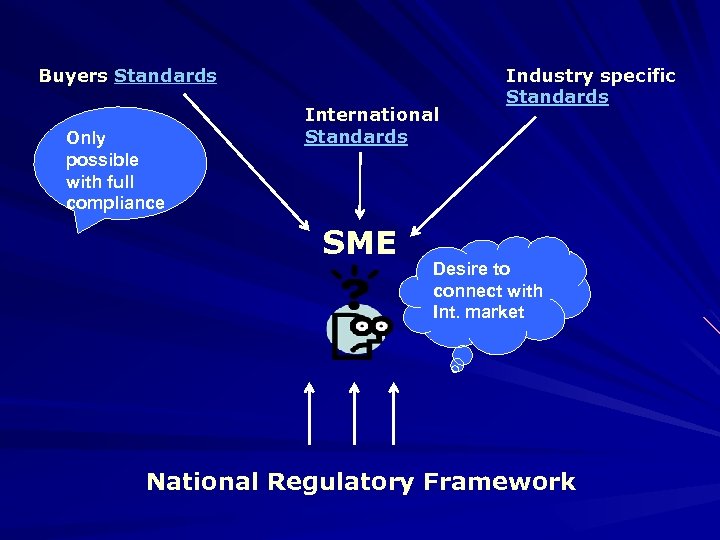

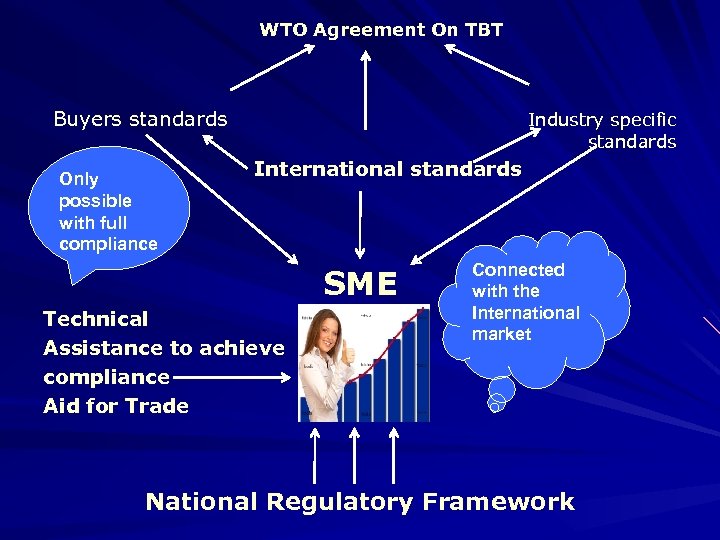

Buyers Standards Only possible with full compliance International Standards SME Industry specific Standards Desire to connect with Int. market National Regulatory Framework

Buyers Standards Only possible with full compliance International Standards SME Industry specific Standards Desire to connect with Int. market National Regulatory Framework

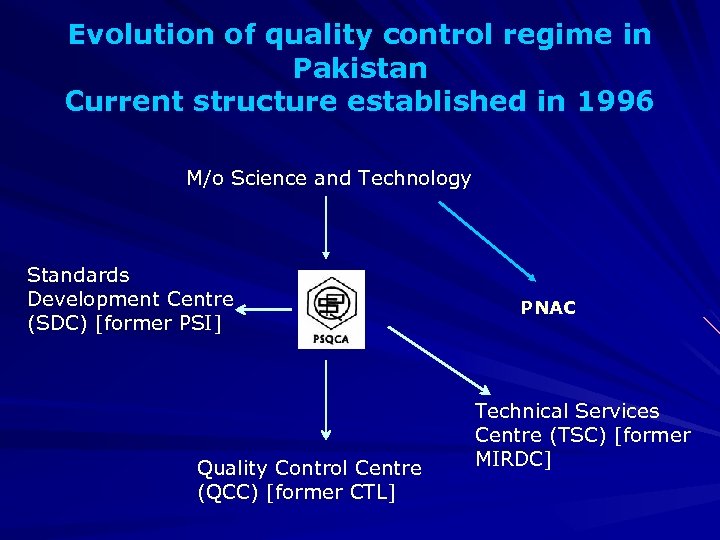

Evolution of quality control regime in Pakistan Quality control and standardization institutional framework exists since early 50 s, few year after independence in 1947. The various components of this institutional arrangement were: v Pakistan Standards Institution (PSI) v Central Testing Laboratory (CTL) v Metallurgical and Industrial Research Development Centre (MIRDC)

Evolution of quality control regime in Pakistan Quality control and standardization institutional framework exists since early 50 s, few year after independence in 1947. The various components of this institutional arrangement were: v Pakistan Standards Institution (PSI) v Central Testing Laboratory (CTL) v Metallurgical and Industrial Research Development Centre (MIRDC)

Evolution of quality control regime in Pakistan Current structure established in 1996 M/o Science and Technology Standards Development Centre (SDC) [former PSI] Quality Control Centre (QCC) [former CTL] PNAC Technical Services Centre (TSC) [former MIRDC]

Evolution of quality control regime in Pakistan Current structure established in 1996 M/o Science and Technology Standards Development Centre (SDC) [former PSI] Quality Control Centre (QCC) [former CTL] PNAC Technical Services Centre (TSC) [former MIRDC]

Pakistan’s global affiliation Signature of MOU’s & MRA’s in the fields of Science & Technology, Standardization, Quality Assurance/Management, Product Certification and exchange of technical information, human resource development and capacity building to achieve the objectives of TBT Agreement: A) Between governments Pakistan and the sovereign Governments of Saudi Arabia, Morocco, Algeria, Sri Lanka B) PSQCA and another standardization bodies: Ø PSQCA and Turkish Standards Institution (TSE). Ø PSQCA and Yemen Authority for Specification, Standardization and Quality Control (YASSC). Ø MRA signed with SASO, ASTM International USA, DIN Germany, ANSI

Pakistan’s global affiliation Signature of MOU’s & MRA’s in the fields of Science & Technology, Standardization, Quality Assurance/Management, Product Certification and exchange of technical information, human resource development and capacity building to achieve the objectives of TBT Agreement: A) Between governments Pakistan and the sovereign Governments of Saudi Arabia, Morocco, Algeria, Sri Lanka B) PSQCA and another standardization bodies: Ø PSQCA and Turkish Standards Institution (TSE). Ø PSQCA and Yemen Authority for Specification, Standardization and Quality Control (YASSC). Ø MRA signed with SASO, ASTM International USA, DIN Germany, ANSI

Pakistan’s global affiliation (Continued) C) Affiliation in progress between : Ø Pakistan and the sovereign Governments of Asia Cooperation Dialogue (ACD) Countries, Brunei Darussalam, Sultanate of Oman, Republic of South Africa, Kingdom of Jordan, Republic of India, Malaysia, Russian Federation, Kingdom of Norway, Peoples Republic of China Ø PSQCA and SIRIM QAS International, Malaysia. Ø PSQCA and Bangladesh Standards Testing Institution (BSTI).

Pakistan’s global affiliation (Continued) C) Affiliation in progress between : Ø Pakistan and the sovereign Governments of Asia Cooperation Dialogue (ACD) Countries, Brunei Darussalam, Sultanate of Oman, Republic of South Africa, Kingdom of Jordan, Republic of India, Malaysia, Russian Federation, Kingdom of Norway, Peoples Republic of China Ø PSQCA and SIRIM QAS International, Malaysia. Ø PSQCA and Bangladesh Standards Testing Institution (BSTI).

Institutional and regulatory support by the Government to protect environment v National Conservation Strategy (NCS) adopted in 1992 v The Environmental Protection Ordinance of 1983 was replaced by a new Act of Parliament in 1997 i. e. Pakistan Environmental Protection Act 1997 v The federal government offered incentives of reduction in customs duties on import of anti pollution equipment

Institutional and regulatory support by the Government to protect environment v National Conservation Strategy (NCS) adopted in 1992 v The Environmental Protection Ordinance of 1983 was replaced by a new Act of Parliament in 1997 i. e. Pakistan Environmental Protection Act 1997 v The federal government offered incentives of reduction in customs duties on import of anti pollution equipment

Pakistan National Accreditation Council Mission Statement PNAC strives for improvement, competence and integrity of conformity assessment bodies by providing them an internationally recognized accreditation service and also promote quality culture, which ultimately benefit the consumers, producers, regulators and other stakeholders. International Linkages PNAC represents Pakistan in the following regional and international forum: International Laboratory Accreditation Cooperation (ILAC) ► International Accreditation Forum (IAF) ► Asia Pacific Laboratory Accreditation Cooperation (APLAC) ► ► Pacific Accreditation Cooperation (PAC)

Pakistan National Accreditation Council Mission Statement PNAC strives for improvement, competence and integrity of conformity assessment bodies by providing them an internationally recognized accreditation service and also promote quality culture, which ultimately benefit the consumers, producers, regulators and other stakeholders. International Linkages PNAC represents Pakistan in the following regional and international forum: International Laboratory Accreditation Cooperation (ILAC) ► International Accreditation Forum (IAF) ► Asia Pacific Laboratory Accreditation Cooperation (APLAC) ► ► Pacific Accreditation Cooperation (PAC)

There is cooperation between accreditation bodies in international organisations Pakistan PNAC

There is cooperation between accreditation bodies in international organisations Pakistan PNAC

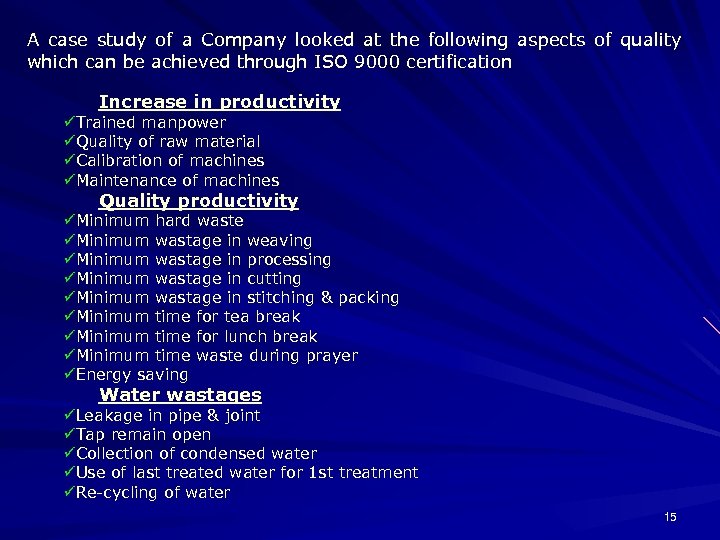

A case study of a Company looked at the following aspects of quality which can be achieved through ISO 9000 certification Increase in productivity üTrained manpower üQuality of raw material üCalibration of machines üMaintenance of machines Quality productivity üMinimum hard waste üMinimum wastage in weaving üMinimum wastage in processing üMinimum wastage in cutting üMinimum wastage in stitching & packing üMinimum time for tea break üMinimum time for lunch break üMinimum time waste during prayer üEnergy saving Water wastages üLeakage in pipe & joint üTap remain open üCollection of condensed water üUse of last treated water for 1 st treatment üRe-cycling of water 15

A case study of a Company looked at the following aspects of quality which can be achieved through ISO 9000 certification Increase in productivity üTrained manpower üQuality of raw material üCalibration of machines üMaintenance of machines Quality productivity üMinimum hard waste üMinimum wastage in weaving üMinimum wastage in processing üMinimum wastage in cutting üMinimum wastage in stitching & packing üMinimum time for tea break üMinimum time for lunch break üMinimum time waste during prayer üEnergy saving Water wastages üLeakage in pipe & joint üTap remain open üCollection of condensed water üUse of last treated water for 1 st treatment üRe-cycling of water 15

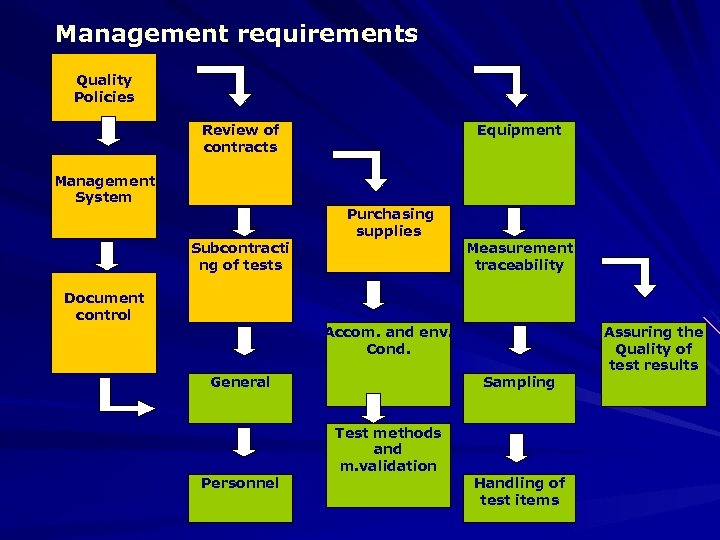

Management requirements Quality Policies Management System Document control Review of contracts Subcontracti ng of tests 1 1 Equipment Purchasing supplies 1 Measurement 2 traceability Accom. and env. Cond. General Personnel 1 3 Sampling Test methods and m. validation 1 Handling of 4 test items Assuring the Quality of 15 test results

Management requirements Quality Policies Management System Document control Review of contracts Subcontracti ng of tests 1 1 Equipment Purchasing supplies 1 Measurement 2 traceability Accom. and env. Cond. General Personnel 1 3 Sampling Test methods and m. validation 1 Handling of 4 test items Assuring the Quality of 15 test results

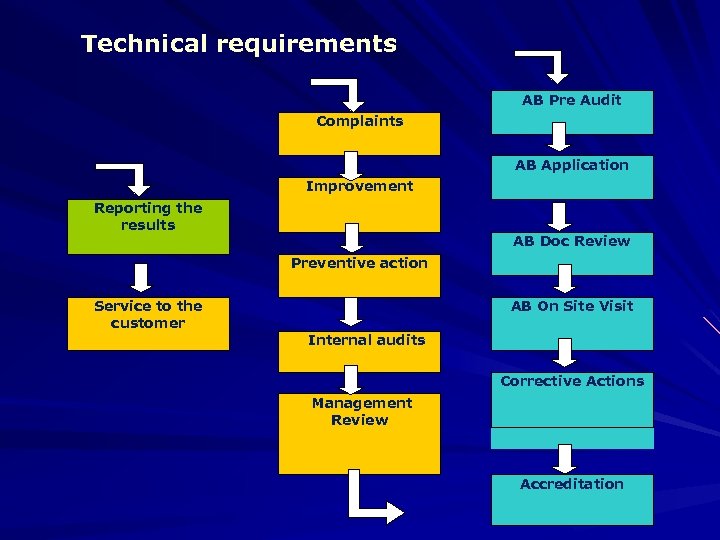

Technical requirements AB Pre Audit Complaints AB Application Reporting the results Improvement AB Doc Review Preventive action Service to the customer AB On Site Visit Internal audits Corrective Actions Management Review Accreditation

Technical requirements AB Pre Audit Complaints AB Application Reporting the results Improvement AB Doc Review Preventive action Service to the customer AB On Site Visit Internal audits Corrective Actions Management Review Accreditation

House of Accreditation Standards Accreditation AB Application AB Pre-Audit Corrective Actions and AB Report AB Document Review AB On Site Visit 22 Management Review (4. 15) 21 Internal audits (4. 14) 16 Reporting the results (5. 10) 20 Preventive action (4. 12) / records (4. 13) 19 Improvement (4. 10) and corr action (4. 11) 18 Complaints (4. 8) / non conf. work (4. 9) 15 Assuring the Quality of test results (5. 9) 17 Service to the customer (4. 7) 12 Measurement traceability (5. 6) 8 Purchasing supplies (4. 6) 11 Equipment (5. 5) 5 Subcontracting of tests (4. 5) 10 Test methods and m validation (5. 4) 4 Review of contracts (4. 4) 9 Accom. and env. Cond. (5. 3) 3 Document control (4. 3) 7 Personnel (5. 2) 2 Management System (4. 2) 6 General (5. 1) 14 Handling of test items (5. 8) 13 Sampling (5. 7) 1 Quality Policies (Organization) (4. 1) Technical Requirements Management Requirements

House of Accreditation Standards Accreditation AB Application AB Pre-Audit Corrective Actions and AB Report AB Document Review AB On Site Visit 22 Management Review (4. 15) 21 Internal audits (4. 14) 16 Reporting the results (5. 10) 20 Preventive action (4. 12) / records (4. 13) 19 Improvement (4. 10) and corr action (4. 11) 18 Complaints (4. 8) / non conf. work (4. 9) 15 Assuring the Quality of test results (5. 9) 17 Service to the customer (4. 7) 12 Measurement traceability (5. 6) 8 Purchasing supplies (4. 6) 11 Equipment (5. 5) 5 Subcontracting of tests (4. 5) 10 Test methods and m validation (5. 4) 4 Review of contracts (4. 4) 9 Accom. and env. Cond. (5. 3) 3 Document control (4. 3) 7 Personnel (5. 2) 2 Management System (4. 2) 6 General (5. 1) 14 Handling of test items (5. 8) 13 Sampling (5. 7) 1 Quality Policies (Organization) (4. 1) Technical Requirements Management Requirements

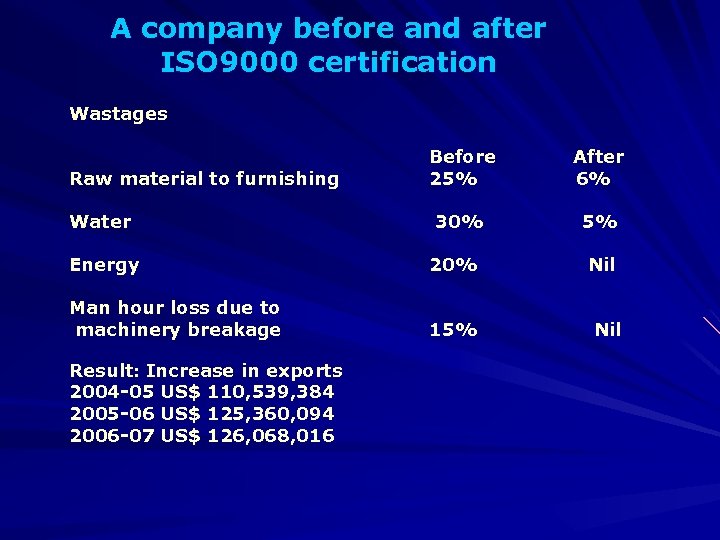

A company before and after ISO 9000 certification Wastages Raw material to furnishing Before After 25% 6% Water 30% 5% Energy 20% Nil Man hour loss due to machinery breakage 15% Nil Result: Increase in exports 2004 -05 US$ 110, 539, 384 2005 -06 US$ 125, 360, 094 2006 -07 US$ 126, 068, 016

A company before and after ISO 9000 certification Wastages Raw material to furnishing Before After 25% 6% Water 30% 5% Energy 20% Nil Man hour loss due to machinery breakage 15% Nil Result: Increase in exports 2004 -05 US$ 110, 539, 384 2005 -06 US$ 125, 360, 094 2006 -07 US$ 126, 068, 016

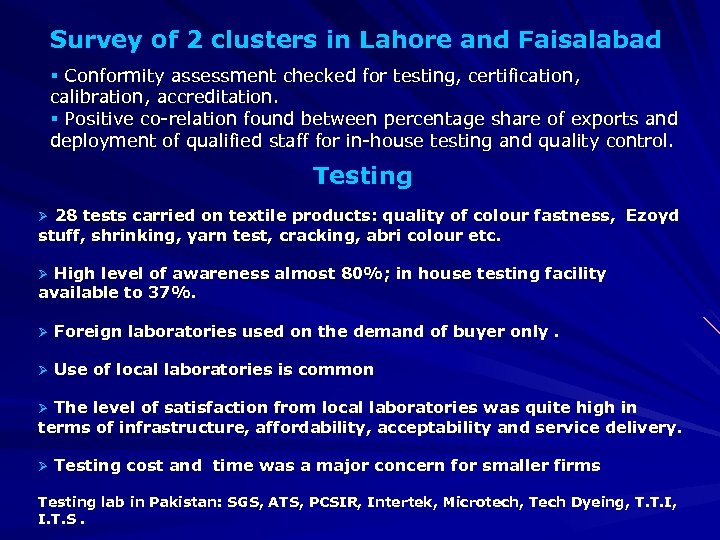

Survey of 2 clusters in Lahore and Faisalabad § Conformity assessment checked for testing, certification, calibration, accreditation. § Positive co-relation found between percentage share of exports and deployment of qualified staff for in-house testing and quality control. Testing 28 tests carried on textile products: quality of colour fastness, Ezoyd stuff, shrinking, yarn test, cracking, abri colour etc. Ø Ø High level of awareness almost 80%; in house testing facility available to 37%. Ø Foreign laboratories used on the demand of buyer only. Ø Use of local laboratories is common Ø The level of satisfaction from local laboratories was quite high in terms of infrastructure, affordability, acceptability and service delivery. Ø Testing cost and time was a major concern for smaller firms Testing lab in Pakistan: SGS, ATS, PCSIR, Intertek, Microtech, Tech Dyeing, T. T. I, I. T. S.

Survey of 2 clusters in Lahore and Faisalabad § Conformity assessment checked for testing, certification, calibration, accreditation. § Positive co-relation found between percentage share of exports and deployment of qualified staff for in-house testing and quality control. Testing 28 tests carried on textile products: quality of colour fastness, Ezoyd stuff, shrinking, yarn test, cracking, abri colour etc. Ø Ø High level of awareness almost 80%; in house testing facility available to 37%. Ø Foreign laboratories used on the demand of buyer only. Ø Use of local laboratories is common Ø The level of satisfaction from local laboratories was quite high in terms of infrastructure, affordability, acceptability and service delivery. Ø Testing cost and time was a major concern for smaller firms Testing lab in Pakistan: SGS, ATS, PCSIR, Intertek, Microtech, Tech Dyeing, T. T. I, I. T. S.

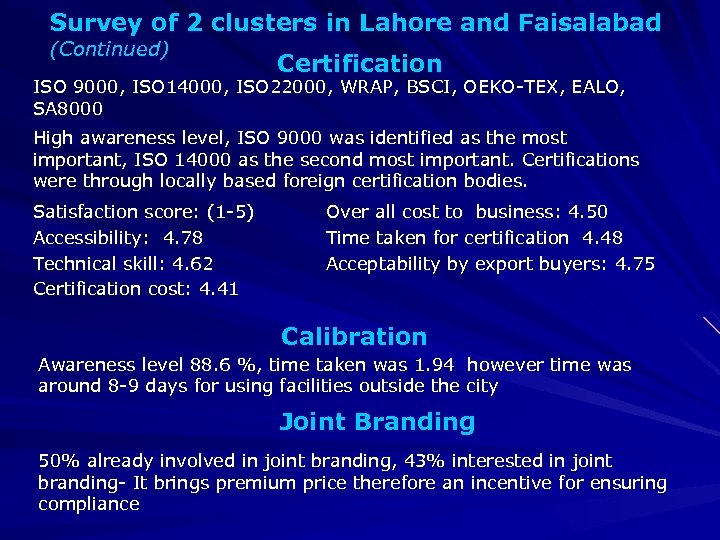

Survey of 2 clusters in Lahore and Faisalabad (Continued) Certification ISO 9000, ISO 14000, ISO 22000, WRAP, BSCI, OEKO-TEX, EALO, SA 8000 High awareness level, ISO 9000 was identified as the most important, ISO 14000 as the second most important. Certifications were through locally based foreign certification bodies. Satisfaction score: (1 -5) Accessibility: 4. 78 Technical skill: 4. 62 Certification cost: 4. 41 Over all cost to business: 4. 50 Time taken for certification 4. 48 Acceptability by export buyers: 4. 75 Calibration Awareness level 88. 6 %, time taken was 1. 94 however time was around 8 -9 days for using facilities outside the city Joint Branding 50% already involved in joint branding, 43% interested in joint branding- It brings premium price therefore an incentive for ensuring compliance

Survey of 2 clusters in Lahore and Faisalabad (Continued) Certification ISO 9000, ISO 14000, ISO 22000, WRAP, BSCI, OEKO-TEX, EALO, SA 8000 High awareness level, ISO 9000 was identified as the most important, ISO 14000 as the second most important. Certifications were through locally based foreign certification bodies. Satisfaction score: (1 -5) Accessibility: 4. 78 Technical skill: 4. 62 Certification cost: 4. 41 Over all cost to business: 4. 50 Time taken for certification 4. 48 Acceptability by export buyers: 4. 75 Calibration Awareness level 88. 6 %, time taken was 1. 94 however time was around 8 -9 days for using facilities outside the city Joint Branding 50% already involved in joint branding, 43% interested in joint branding- It brings premium price therefore an incentive for ensuring compliance

Fields of determinations requested A. Care Label Instructions: Many countries have mandatory or voluntary standards for care label instructions that apply to either apparel or soft home furnishing products. Ø Colourfastness to bleaching Ø Dimensional stability Ø Appearance retention Ø Ironing (EU & US joint proposal on textile labelling in NAMA negotiation is supported by Pakistan)

Fields of determinations requested A. Care Label Instructions: Many countries have mandatory or voluntary standards for care label instructions that apply to either apparel or soft home furnishing products. Ø Colourfastness to bleaching Ø Dimensional stability Ø Appearance retention Ø Ironing (EU & US joint proposal on textile labelling in NAMA negotiation is supported by Pakistan)

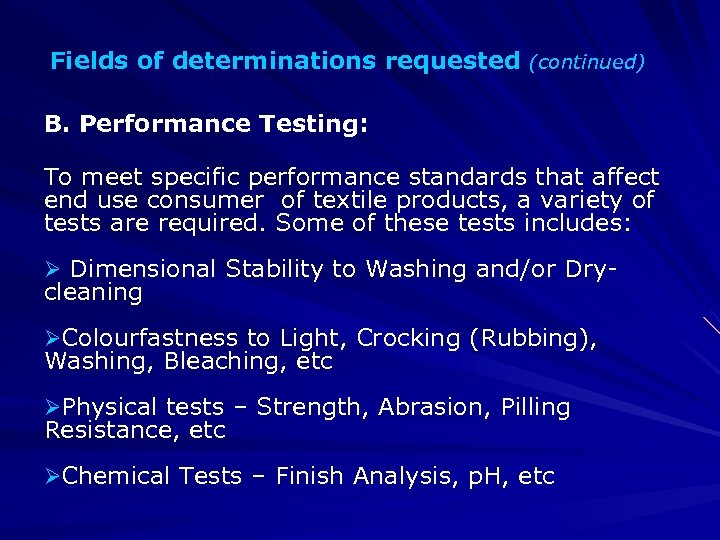

Fields of determinations requested (continued) B. Performance Testing: To meet specific performance standards that affect end use consumer of textile products, a variety of tests are required. Some of these tests includes: Ø Dimensional Stability to Washing and/or Dry- cleaning ØColourfastness to Light, Crocking (Rubbing), Washing, Bleaching, etc ØPhysical tests – Strength, Abrasion, Pilling Resistance, etc ØChemical Tests – Finish Analysis, p. H, etc

Fields of determinations requested (continued) B. Performance Testing: To meet specific performance standards that affect end use consumer of textile products, a variety of tests are required. Some of these tests includes: Ø Dimensional Stability to Washing and/or Dry- cleaning ØColourfastness to Light, Crocking (Rubbing), Washing, Bleaching, etc ØPhysical tests – Strength, Abrasion, Pilling Resistance, etc ØChemical Tests – Finish Analysis, p. H, etc

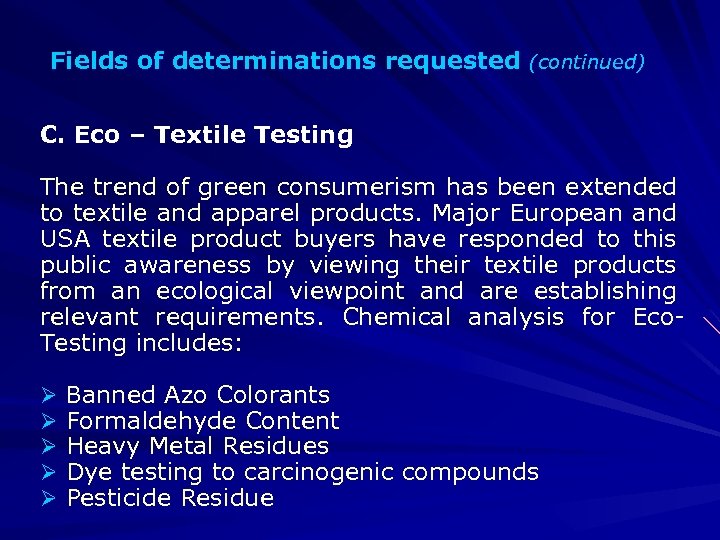

Fields of determinations requested (continued) C. Eco – Textile Testing The trend of green consumerism has been extended to textile and apparel products. Major European and USA textile product buyers have responded to this public awareness by viewing their textile products from an ecological viewpoint and are establishing relevant requirements. Chemical analysis for Eco. Testing includes: Ø Banned Azo Colorants Ø Formaldehyde Content Ø Heavy Metal Residues Ø Dye testing to carcinogenic compounds Ø Pesticide Residue

Fields of determinations requested (continued) C. Eco – Textile Testing The trend of green consumerism has been extended to textile and apparel products. Major European and USA textile product buyers have responded to this public awareness by viewing their textile products from an ecological viewpoint and are establishing relevant requirements. Chemical analysis for Eco. Testing includes: Ø Banned Azo Colorants Ø Formaldehyde Content Ø Heavy Metal Residues Ø Dye testing to carcinogenic compounds Ø Pesticide Residue

Fields of determinations requested (continued) D. FLAMMABILITY TESTING For apparel, it is especially important that the material used are in compliance with the flammability regulations. In particular, adult apparel and children’s sleeper.

Fields of determinations requested (continued) D. FLAMMABILITY TESTING For apparel, it is especially important that the material used are in compliance with the flammability regulations. In particular, adult apparel and children’s sleeper.

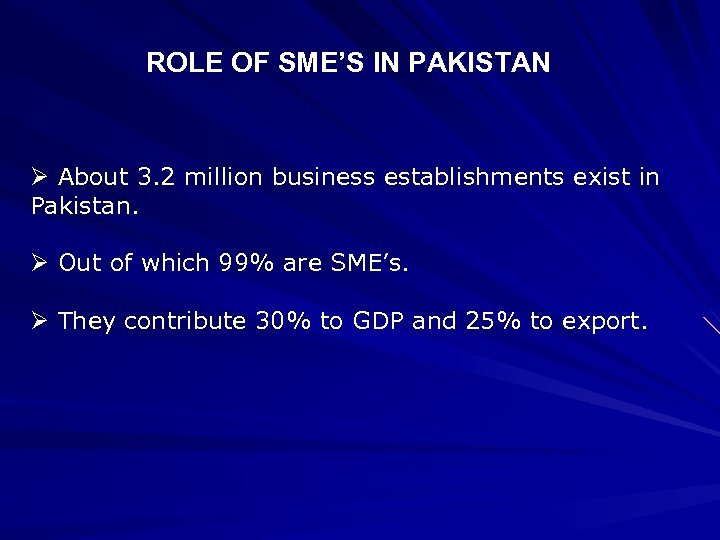

ROLE OF SME’S IN PAKISTAN Ø About 3. 2 million business establishments exist in Pakistan. Ø Out of which 99% are SME’s. Ø They contribute 30% to GDP and 25% to export.

ROLE OF SME’S IN PAKISTAN Ø About 3. 2 million business establishments exist in Pakistan. Ø Out of which 99% are SME’s. Ø They contribute 30% to GDP and 25% to export.

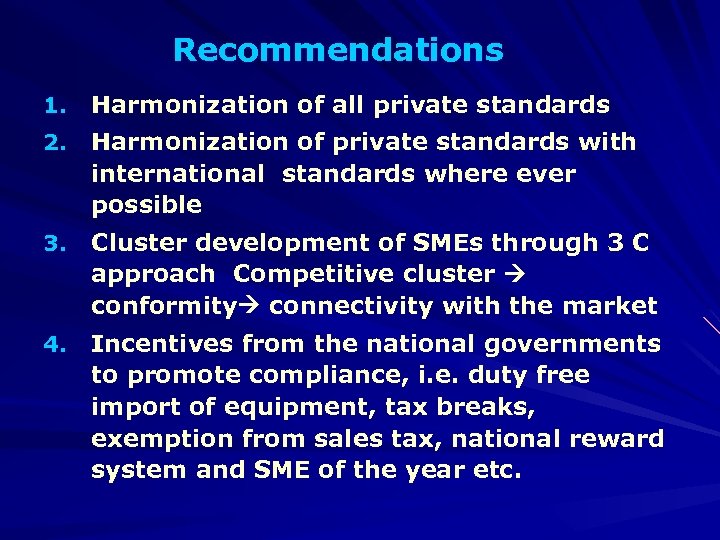

Recommendations 1. Harmonization of all private standards 2. Harmonization of private standards with international standards where ever possible 3. Cluster development of SMEs through 3 C approach Competitive cluster conformity connectivity with the market 4. Incentives from the national governments to promote compliance, i. e. duty free import of equipment, tax breaks, exemption from sales tax, national reward system and SME of the year etc.

Recommendations 1. Harmonization of all private standards 2. Harmonization of private standards with international standards where ever possible 3. Cluster development of SMEs through 3 C approach Competitive cluster conformity connectivity with the market 4. Incentives from the national governments to promote compliance, i. e. duty free import of equipment, tax breaks, exemption from sales tax, national reward system and SME of the year etc.

Recommendations (Continued) 5. Best use of Aid for Trade (Skill development, mobile vans with training equipment, strengthening of testing labs-chemicals. 6. Effective participation of SME sector in the standard setting process 7. Effective implementation of special and differential treatment provisions (article 12 of TBT) for developing countries 8. See things in a context, ban on trade is not a solution. Country specific solutions is another option. 9. Promote public-private investment in testing laboratories.

Recommendations (Continued) 5. Best use of Aid for Trade (Skill development, mobile vans with training equipment, strengthening of testing labs-chemicals. 6. Effective participation of SME sector in the standard setting process 7. Effective implementation of special and differential treatment provisions (article 12 of TBT) for developing countries 8. See things in a context, ban on trade is not a solution. Country specific solutions is another option. 9. Promote public-private investment in testing laboratories.

WTO Agreement On TBT Buyers standards Industry specific standards International standards Only possible with full compliance SME Technical Assistance to achieve compliance Aid for Trade Connected with the International market National Regulatory Framework

WTO Agreement On TBT Buyers standards Industry specific standards International standards Only possible with full compliance SME Technical Assistance to achieve compliance Aid for Trade Connected with the International market National Regulatory Framework

THANK YOU

THANK YOU

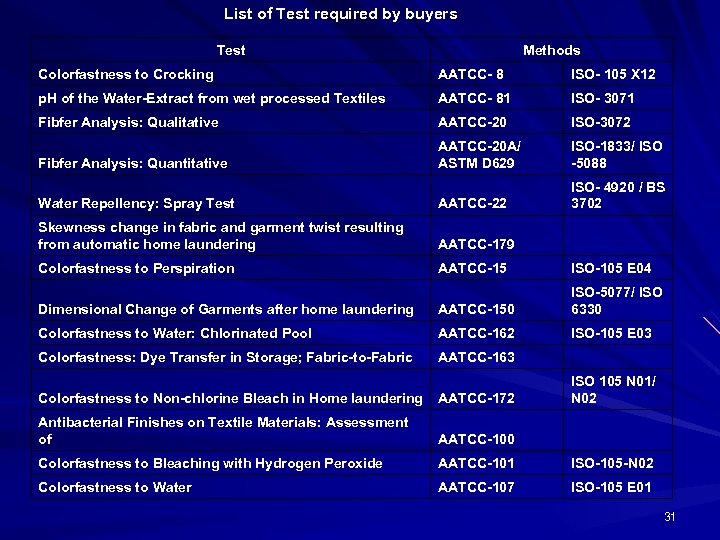

List of Test required by buyers Test Methods Colorfastness to Crocking AATCC- 8 ISO- 105 X 12 p. H of the Water-Extract from wet processed Textiles AATCC- 81 ISO- 3071 Fibfer Analysis: Qualitative AATCC-20 ISO-3072 Fibfer Analysis: Quantitative AATCC-20 A/ ASTM D 629 ISO-1833/ ISO -5088 Water Repellency: Spray Test AATCC-22 ISO- 4920 / BS 3702 Skewness change in fabric and garment twist resulting from automatic home laundering AATCC-179 Colorfastness to Perspiration AATCC-15 ISO-105 E 04 Dimensional Change of Garments after home laundering AATCC-150 ISO-5077/ ISO 6330 Colorfastness to Water: Chlorinated Pool AATCC-162 ISO-105 E 03 Colorfastness: Dye Transfer in Storage; Fabric-to-Fabric AATCC-163 Colorfastness to Non-chlorine Bleach in Home laundering AATCC-172 ISO 105 N 01/ N 02 Antibacterial Finishes on Textile Materials: Assessment of AATCC-100 Colorfastness to Bleaching with Hydrogen Peroxide AATCC-101 ISO-105 -N 02 Colorfastness to Water AATCC-107 ISO-105 E 01 31

List of Test required by buyers Test Methods Colorfastness to Crocking AATCC- 8 ISO- 105 X 12 p. H of the Water-Extract from wet processed Textiles AATCC- 81 ISO- 3071 Fibfer Analysis: Qualitative AATCC-20 ISO-3072 Fibfer Analysis: Quantitative AATCC-20 A/ ASTM D 629 ISO-1833/ ISO -5088 Water Repellency: Spray Test AATCC-22 ISO- 4920 / BS 3702 Skewness change in fabric and garment twist resulting from automatic home laundering AATCC-179 Colorfastness to Perspiration AATCC-15 ISO-105 E 04 Dimensional Change of Garments after home laundering AATCC-150 ISO-5077/ ISO 6330 Colorfastness to Water: Chlorinated Pool AATCC-162 ISO-105 E 03 Colorfastness: Dye Transfer in Storage; Fabric-to-Fabric AATCC-163 Colorfastness to Non-chlorine Bleach in Home laundering AATCC-172 ISO 105 N 01/ N 02 Antibacterial Finishes on Textile Materials: Assessment of AATCC-100 Colorfastness to Bleaching with Hydrogen Peroxide AATCC-101 ISO-105 -N 02 Colorfastness to Water AATCC-107 ISO-105 E 01 31

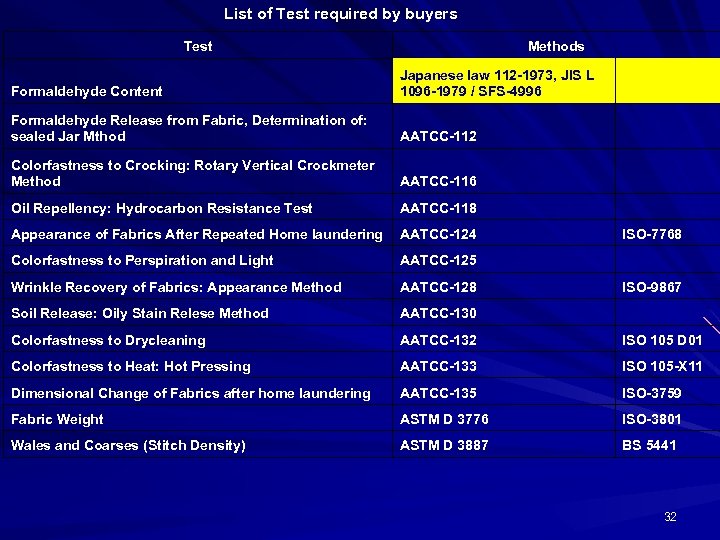

List of Test required by buyers Test Methods Formaldehyde Content Japanese law 112 -1973, JIS L 1096 -1979 / SFS-4996 Formaldehyde Release from Fabric, Determination of: sealed Jar Mthod AATCC-112 Colorfastness to Crocking: Rotary Vertical Crockmeter Method AATCC-116 Oil Repellency: Hydrocarbon Resistance Test AATCC-118 Appearance of Fabrics After Repeated Home laundering AATCC-124 ISO-7768 Colorfastness to Perspiration and Light AATCC-125 Wrinkle Recovery of Fabrics: Appearance Method AATCC-128 ISO-9867 Soil Release: Oily Stain Relese Method AATCC-130 Colorfastness to Drycleaning AATCC-132 ISO 105 D 01 Colorfastness to Heat: Hot Pressing AATCC-133 ISO 105 -X 11 Dimensional Change of Fabrics after home laundering AATCC-135 ISO-3759 Fabric Weight ASTM D 3776 ISO-3801 Wales and Coarses (Stitch Density) ASTM D 3887 BS 5441 32

List of Test required by buyers Test Methods Formaldehyde Content Japanese law 112 -1973, JIS L 1096 -1979 / SFS-4996 Formaldehyde Release from Fabric, Determination of: sealed Jar Mthod AATCC-112 Colorfastness to Crocking: Rotary Vertical Crockmeter Method AATCC-116 Oil Repellency: Hydrocarbon Resistance Test AATCC-118 Appearance of Fabrics After Repeated Home laundering AATCC-124 ISO-7768 Colorfastness to Perspiration and Light AATCC-125 Wrinkle Recovery of Fabrics: Appearance Method AATCC-128 ISO-9867 Soil Release: Oily Stain Relese Method AATCC-130 Colorfastness to Drycleaning AATCC-132 ISO 105 D 01 Colorfastness to Heat: Hot Pressing AATCC-133 ISO 105 -X 11 Dimensional Change of Fabrics after home laundering AATCC-135 ISO-3759 Fabric Weight ASTM D 3776 ISO-3801 Wales and Coarses (Stitch Density) ASTM D 3887 BS 5441 32

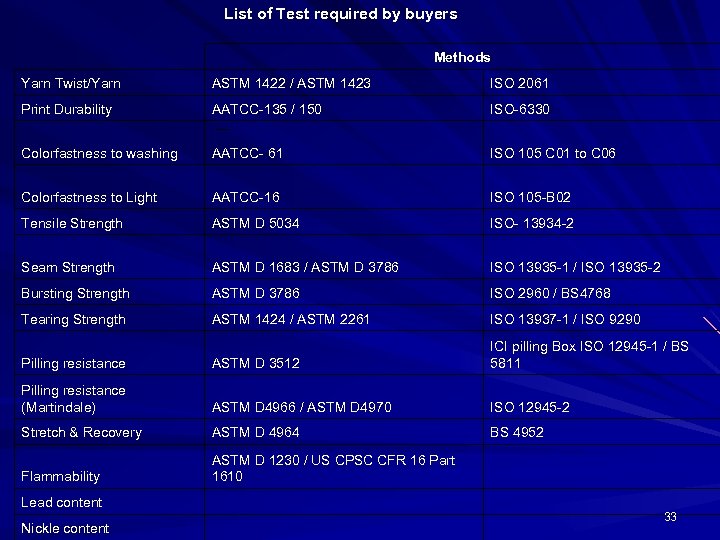

List of Test required by buyers Methods Yarn Twist/Yarn ASTM 1422 / ASTM 1423 ISO 2061 Print Durability AATCC-135 / 150 ISO-6330 Colorfastness to washing AATCC- 61 ISO 105 C 01 to C 06 Colorfastness to Light AATCC-16 ISO 105 -B 02 Tensile Strength ASTM D 5034 ISO- 13934 -2 Seam Strength ASTM D 1683 / ASTM D 3786 ISO 13935 -1 / ISO 13935 -2 Bursting Strength ASTM D 3786 ISO 2960 / BS 4768 Tearing Strength ASTM 1424 / ASTM 2261 ISO 13937 -1 / ISO 9290 Pilling resistance ASTM D 3512 ICI pilling Box ISO 12945 -1 / BS 5811 Pilling resistance (Martindale) ASTM D 4966 / ASTM D 4970 ISO 12945 -2 Stretch & Recovery ASTM D 4964 BS 4952 Flammability ASTM D 1230 / US CPSC CFR 16 Part 1610 Lead content Nickle content 33

List of Test required by buyers Methods Yarn Twist/Yarn ASTM 1422 / ASTM 1423 ISO 2061 Print Durability AATCC-135 / 150 ISO-6330 Colorfastness to washing AATCC- 61 ISO 105 C 01 to C 06 Colorfastness to Light AATCC-16 ISO 105 -B 02 Tensile Strength ASTM D 5034 ISO- 13934 -2 Seam Strength ASTM D 1683 / ASTM D 3786 ISO 13935 -1 / ISO 13935 -2 Bursting Strength ASTM D 3786 ISO 2960 / BS 4768 Tearing Strength ASTM 1424 / ASTM 2261 ISO 13937 -1 / ISO 9290 Pilling resistance ASTM D 3512 ICI pilling Box ISO 12945 -1 / BS 5811 Pilling resistance (Martindale) ASTM D 4966 / ASTM D 4970 ISO 12945 -2 Stretch & Recovery ASTM D 4964 BS 4952 Flammability ASTM D 1230 / US CPSC CFR 16 Part 1610 Lead content Nickle content 33

Besides International Standards some private Standards are also incorporated making the things more complicated. These are as under: ØWALMART ØNIKE ØCARRFOUR ØKOHLS ØJCPENNY etc. 34

Besides International Standards some private Standards are also incorporated making the things more complicated. These are as under: ØWALMART ØNIKE ØCARRFOUR ØKOHLS ØJCPENNY etc. 34