cdb4553b670a6628bccf18539c982a61.ppt

- Количество слайдов: 52

Workshop on Silicon Photonics Mainz, November 10 2006 Silicon-on-Insulator based Nanophotonics Why, How, What for? Roel Baets Ghent University - IMEC Wim Bogaerts, Pieter Dumon, Dirk Taillaert, Dries Van Thourhout, Shankar Kumar Selvaraja, Gunther Roelkens, Joris Van Campenhout, Joost Brouckaert Photonics Research Group http: //photonics. intec. ugent. be

Overview • Introduction to SOI nanophotonics • Why? • What for? • How? • Conclusions © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

The key bottleneck of photonic integration (By far too) many degrees of freedom l many different materials l many different component types l many different wavelength ranges Hence: l no generic integration technology for many different applications l no high volume technology platforms l too high cost Hence: Integration is not an industrial reality (yet) © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

The way out - a roadmap 1. Use mainstream Silicon(-based) technology l wherever possible, CMOS fab compatible l otherwise, use dedicated Silicon fab 2. Add other materials where needed for specialty functions l if the added value motivates it l 3. By using l wherever possible : wafer-scale front-end and back-end technology l otherwise, die-scale technology 4. Build a photonic IC industry on this basis © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

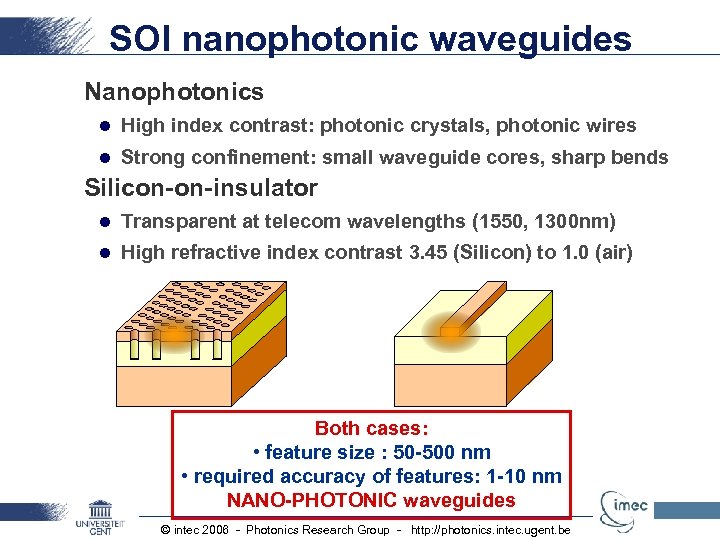

SOI nanophotonic waveguides Nanophotonics l High index contrast: photonic crystals, photonic wires l Strong confinement: small waveguide cores, sharp bends Silicon-on-insulator l Transparent at telecom wavelengths (1550, 1300 nm) l High refractive index contrast 3. 45 (Silicon) to 1. 0 (air) Both cases: • feature size : 50 -500 nm • required accuracy of features: 1 -10 nm NANO-PHOTONIC waveguides © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

![SOI-nanophotonic wires Group Date IMEC loss [d. B/cm] BOX [um] top clad Fab. h SOI-nanophotonic wires Group Date IMEC loss [d. B/cm] BOX [um] top clad Fab. h](https://present5.com/presentation/cdb4553b670a6628bccf18539c982a61/image-6.jpg)

SOI-nanophotonic wires Group Date IMEC loss [d. B/cm] BOX [um] top clad Fab. h [nm] w [nm] Apr. '04 220 500 2. 4 1 no DUV IBM Apr. '04 220 445 3. 6 2 no EBeam Cornell Aug. '03 270 470 5. 0 3 no EBeam NTT Feb. '05 300 200 300 400 7. 8 2. 8 3 yes EBeam Yokohama Dec. '02 320 400 105. 0 1 no EBeam MIT Dec. '01 200 500 32. 0 1 yes G-line LETI / LPM Apr. '05 300 15. 0 1 yes DUV 200 500 5. 0 Columbia Oct. 03 260 600 110. 0 1 yes EBeam NEC Oct. ‘ 04 300 19. 0 1 yes EBeam And many others … © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Why? Photonics Research Group http: //photonics. intec. ugent. be

Why? 3 sets of good reasons: • Functionality + performance • Technology • Cost Or why not? • The polarisation problem • The extreme accuracy problem • The source problem © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

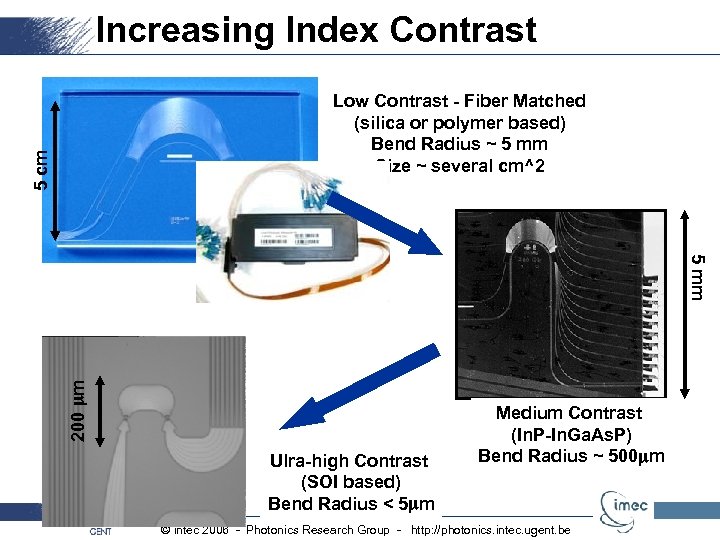

Increasing Index Contrast 5 cm Low Contrast - Fiber Matched (silica or polymer based) Bend Radius ~ 5 mm Size ~ several cm^2 200 mm 5 mm Ulra-high Contrast (SOI based) Bend Radius < 5 mm Medium Contrast (In. P-In. Ga. As. P) Bend Radius ~ 500 mm © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

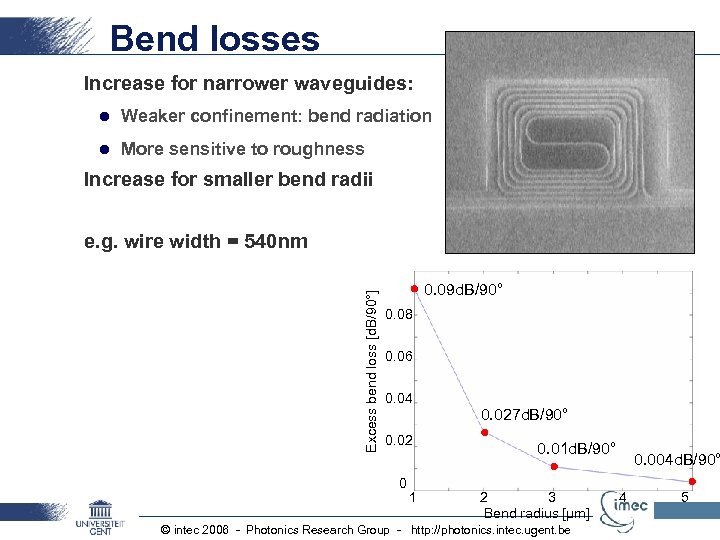

Bend losses Increase for narrower waveguides: l Weaker confinement: bend radiation l More sensitive to roughness Increase for smaller bend radii Excess bend loss [d. B/90°] e. g. wire width = 540 nm 0. 09 d. B/90° 0. 08 0. 06 0. 04 0. 02 0 1 0. 027 d. B/90° 0. 01 d. B/90° 2 3 Bend radius [µm] © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be 0. 004 d. B/90° 4 5

Technology Need: • smallest feature size : 50 -500 nm • required accuracy of features: 1 -10 nm • required aspect ratios: mostly < 1: 1 This matches amazingly well with the capabilities of advanced CMOS © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Fabrication with deep UV Litho 248 nm excimer laser Lithography l ASML PAS 5500/750 Step-and-scan l Automated in-line processing (spin-coating, pre- and post-bake, development) l 4 X reticles l Standard process 193 nm excimer laser Lithography l ASML PAS 5500/1100 Step-and-scan l 4 X reticles © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Low cost • Wafer-scale fabrication on large wafers with high yield • Wafer-scale testing • Low cost packaging © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

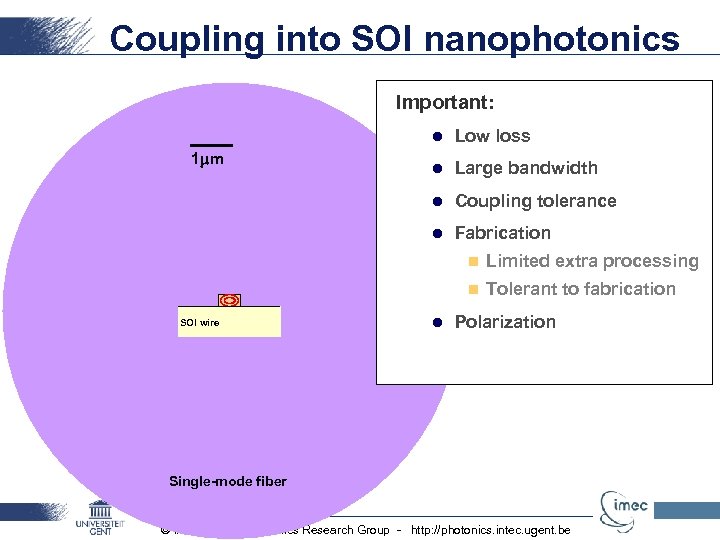

Coupling into SOI nanophotonics Important: l l Large bandwidth l Coupling tolerance l 1 mm Low loss Fabrication n n SOI wire l Limited extra processing Tolerant to fabrication Polarization Single-mode fiber © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

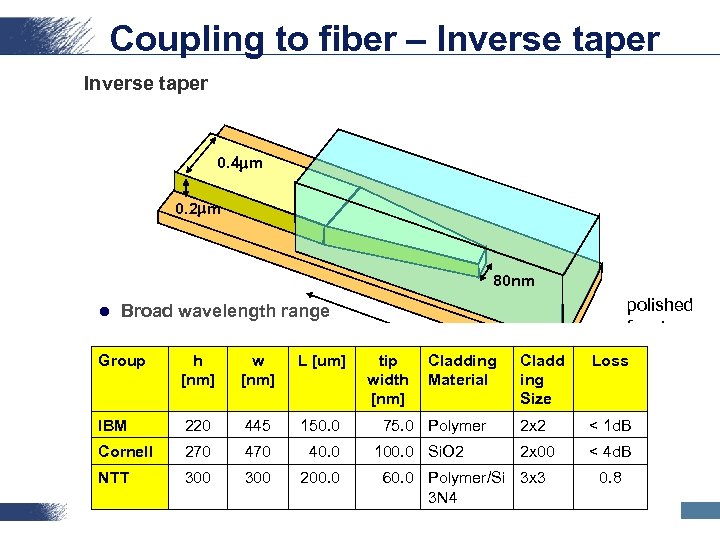

Coupling to fiber – Inverse taper 0. 4 mm 0. 2 mm 80 nm l polished facet Broad wavelength range 500 mm Group h w L [um] tip Cladding l Easy to fabricate (if you can do the tips) [nm] width Material [nm] Cladd ing Size Loss IBM 220 445 150. 0 2 x 2 < 1 d. B Cornell 270 40. 0 2 x 00 < 4 d. B NTT 300 200. 0 l Single mode l Low facet reflections 75. 0 Polymer 100. 0 Si. O 2 60. 0 Polymer/Si 3 x 3 3 N 4 © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be 0. 8

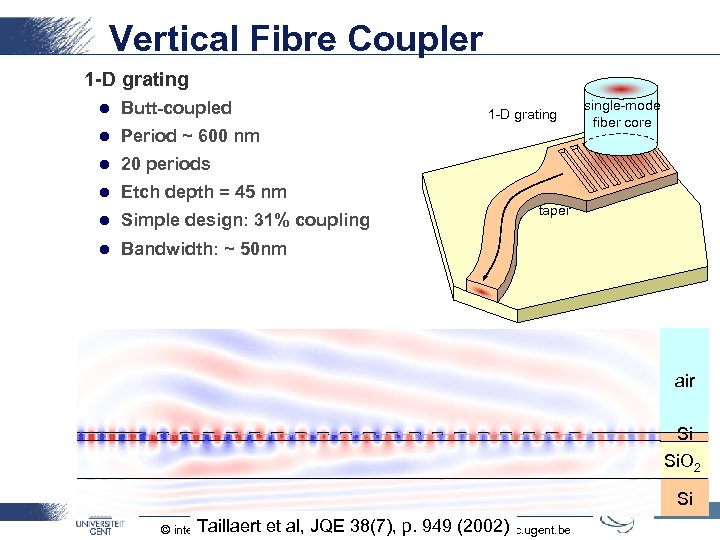

Vertical Fibre Coupler 1 -D grating l Butt-coupled l Period ~ 600 nm l l Etch depth = 45 nm l Simple design: 31% coupling l single-mode fiber core 20 periods Bandwidth: ~ 50 nm 1 -D grating taper air air Si Si. O 2 air Si Taillaert et al, JQE 38(7), p. 949 (2002) © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

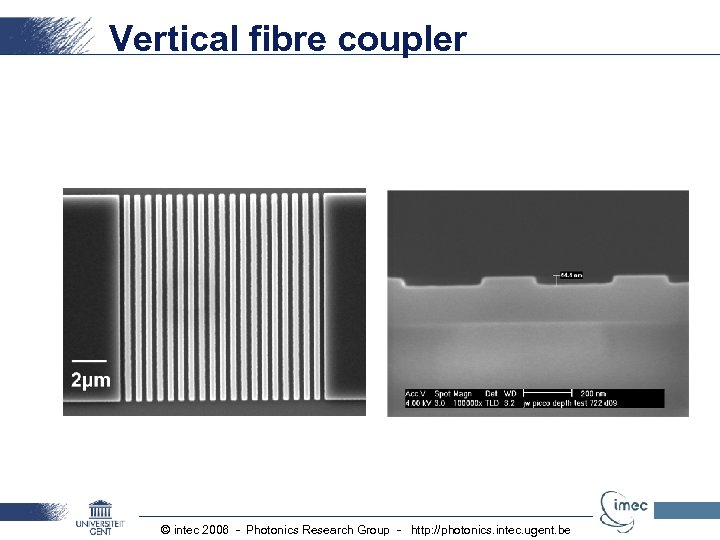

Vertical fibre coupler © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

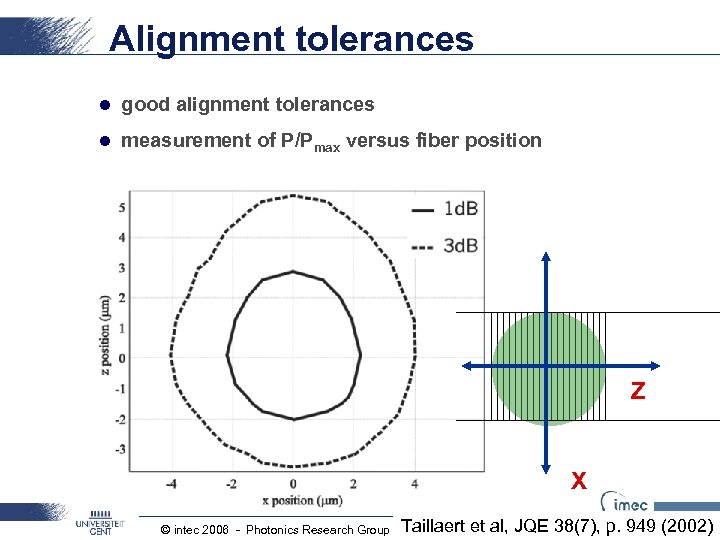

Alignment tolerances l good alignment tolerances l measurement of P/Pmax versus fiber position Z X Taillaert et al, JQE 38(7), p. 949 (2002) © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

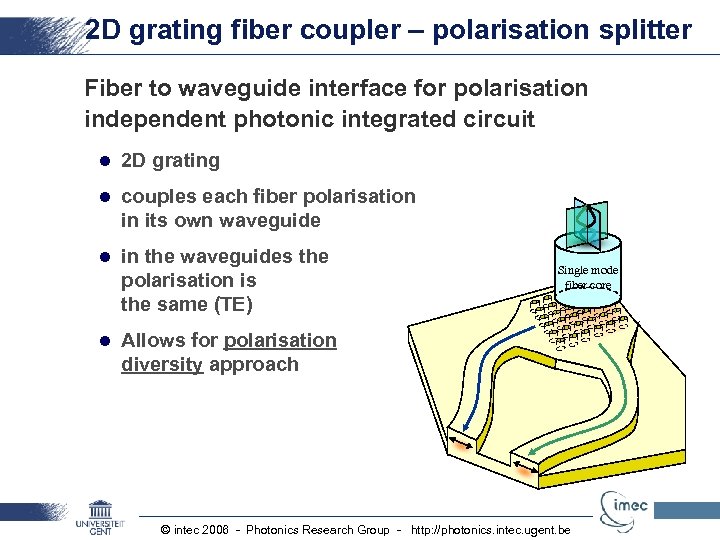

The polarisation problem High index contrast makes polarisation independence (almost) impossible. © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

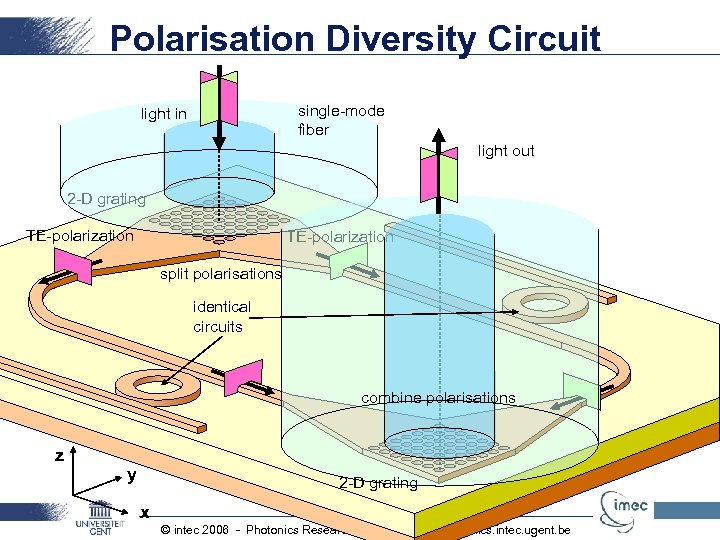

2 D grating fiber coupler – polarisation splitter Fiber to waveguide interface for polarisation independent photonic integrated circuit l 2 D grating l couples each fiber polarisation in its own waveguide l in the waveguides the polarisation is the same (TE) l Allows for polarisation diversity approach Single mode fiber core © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Polarisation Diversity Circuit single-mode fiber light in light out 2 -D grating TE-polarization split polarisations identical circuits combine polarisations z y 2 -D grating x © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Experimental results Fabrication l SOI: 220 nm Si / 1000 nm Si. O 2 l Etch depth: 90 nm l Square lattice of holes: 580 nm period © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

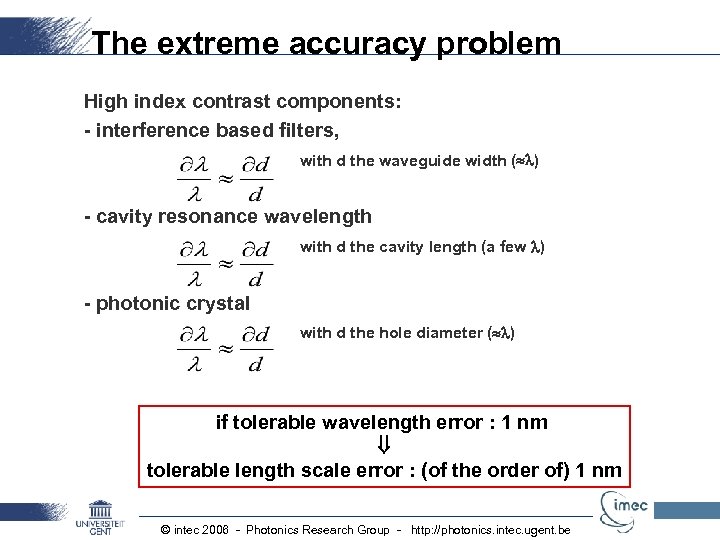

The extreme accuracy problem High index contrast components: - interference based filters, with d the waveguide width ( ) - cavity resonance wavelength with d the cavity length (a few ) - photonic crystal with d the hole diameter ( ) if tolerable wavelength error : 1 nm tolerable length scale error : (of the order of) 1 nm © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

The source problem How to integrate sources: • that are compact • that are efficient • that have high modulation bandwidth • by means of wafer-scale processes ? ? ? ? ? ? ? ? ? ? Approaches: gain from • optical pumping l Raman gain l Four wave mixing gain l Nanocrystals • electrical pumping l nanocrystals? l Impurity doped Silicon? l bonded III-V layers : most successful approach to date © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

What for? Photonics Research Group http: //photonics. intec. ugent. be

Applications • Transceivers • WDM components • Intra-chip optical interconnect • Sensors • Digital photonics • … © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

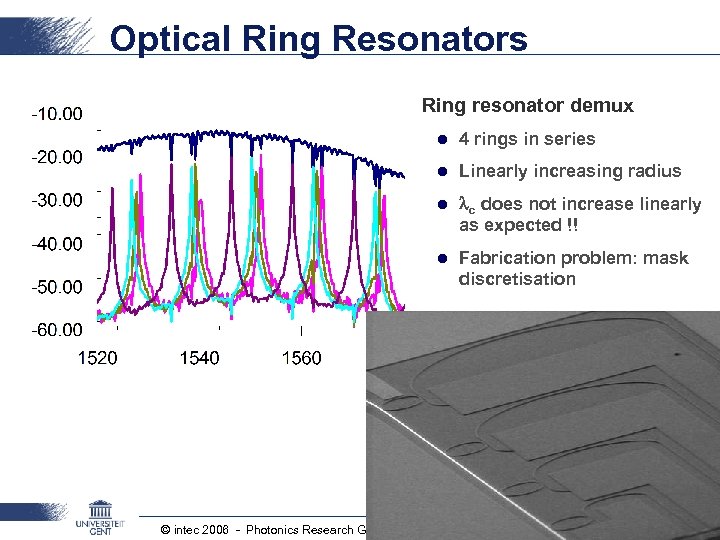

Optical Ring Resonators Ring resonator demux l 4 rings in series l Linearly increasing radius l c does not increase linearly as expected !! l Fabrication problem: mask discretisation © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

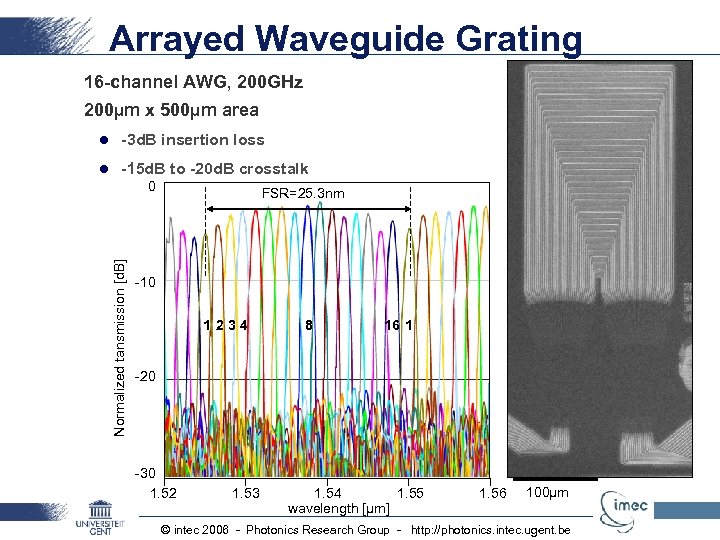

Arrayed Waveguide Grating 16 -channel AWG, 200 GHz 200µm x 500µm area l -3 d. B insertion loss l -15 d. B to -20 d. B crosstalk Normalized tansmission [d. B] 0 FSR=25. 3 nm -10 1 2 34 8 16 1 -20 -30 1. 52 1. 53 1. 54 1. 55 wavelength [µm] 1. 56 100µm © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

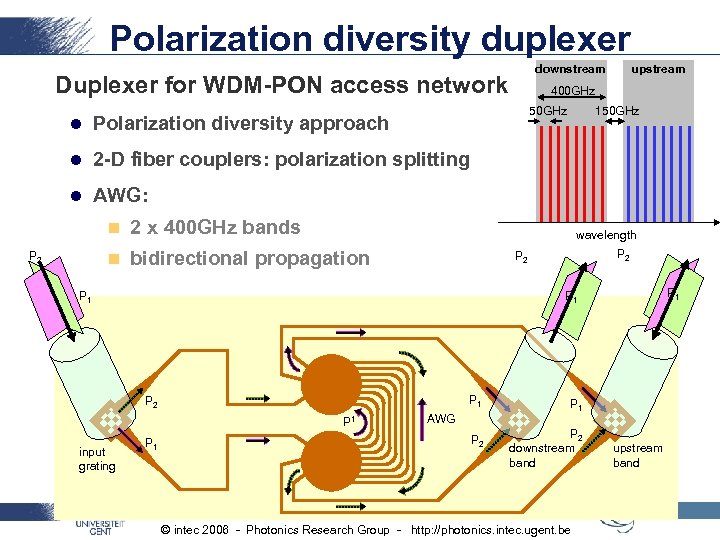

Polarization diversity duplexer downstream Duplexer for WDM-PON access network 400 GHz 50 GHz l Polarization diversity approach l 150 GHz 2 -D fiber couplers: polarization splitting l upstream AWG: n n P 2 2 x 400 GHz bands bidirectional propagation wavelength P 1 P 1 P 2 input grating P 2 P 2 downstream band AWG © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be upstream band

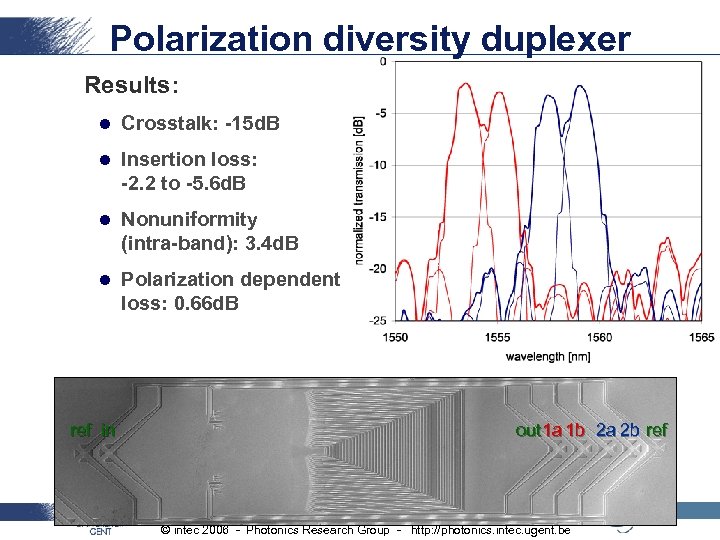

Polarization diversity duplexer Results: l Crosstalk: -15 d. B l Insertion loss: -2. 2 to -5. 6 d. B l Nonuniformity (intra-band): 3. 4 d. B 100µml ref in Polarization dependent loss: 0. 66 d. B out 1 a 1 b 2 a 2 b ref © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

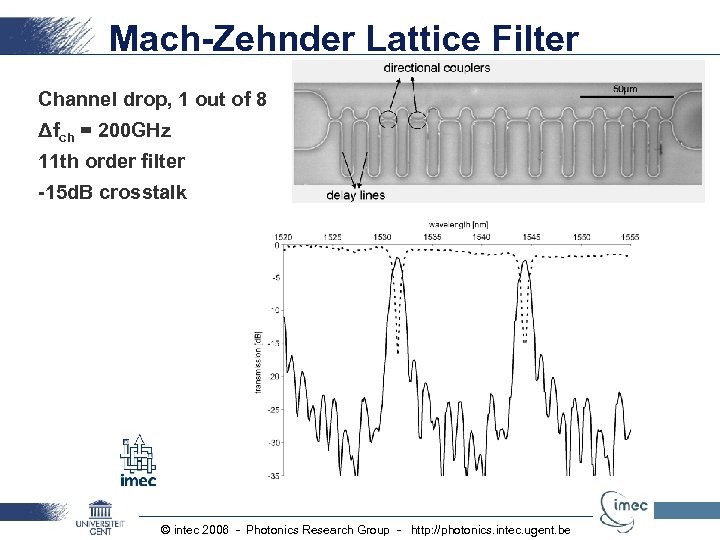

Mach-Zehnder Lattice Filter Channel drop, 1 out of 8 Δfch = 200 GHz 11 th order filter -15 d. B crosstalk © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

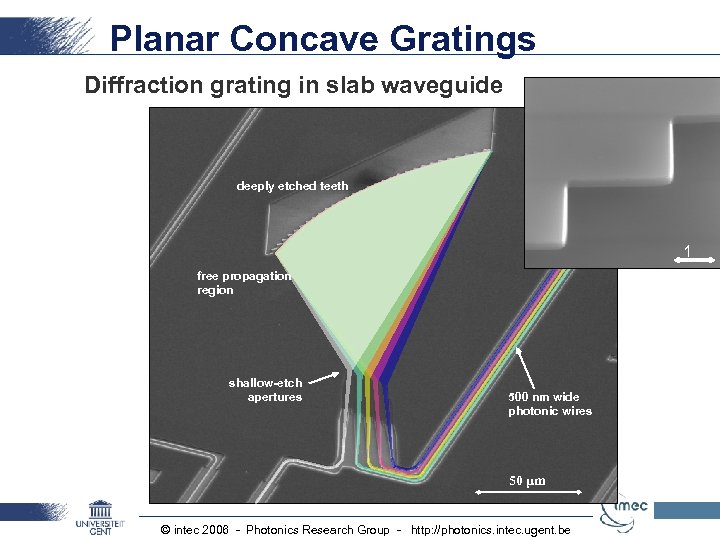

Planar Concave Gratings Diffraction grating in slab waveguide deeply etched teeth 1 μm free propagation region shallow-etch apertures 500 nm wide photonic wires 50 μm © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Results Channel spacing: Insertion loss: Channel uniformity: Crosstalk: Footprint: 20 nm 7. 5 d. B 0. 6 d. B better than -30 d. B 250 x 150 μm 2 © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

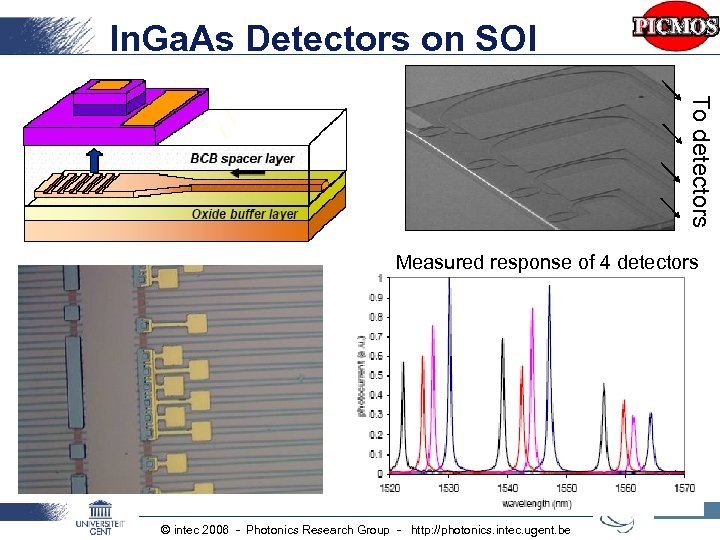

In. Ga. As Detectors on SOI To detectors Measured response of 4 detectors © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

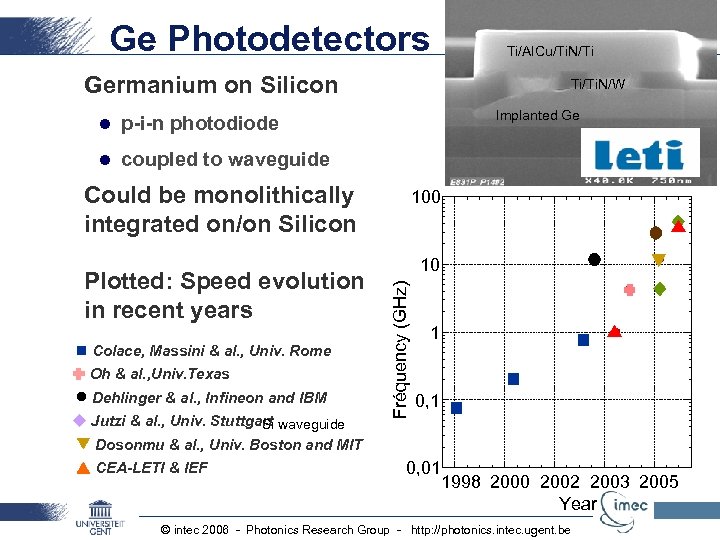

Ge Photodetectors Germanium on Silicon l Ti/Ti. N/W Implanted Ge p-i-n photodiode l Ti/Al. Cu/Ti. N/Ti coupled to waveguide Could be monolithically integrated on/on Silicon Colace, Massini & al. , Univ. Rome Oh & al. , Univ. Texas Dehlinger & al. , Infineon and IBM Jutzi & al. , Univ. Stuttgart Si waveguide 10 Fréquency (GHz) Plotted: Speed evolution in recent years 100 1 0, 1 Dosonmu & al. , Univ. Boston and MIT CEA-LETI & IEF 0, 01 1998 2000 2002 2003 2005 Year © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

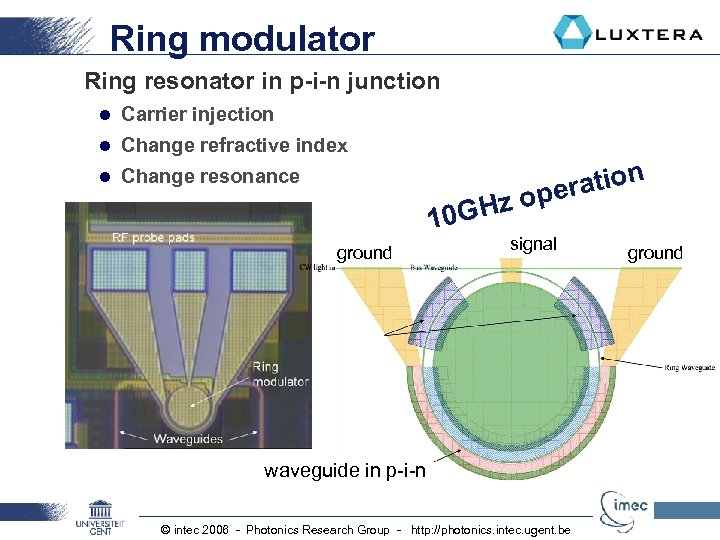

Ring modulator Ring resonator in p-i-n junction l Carrier injection l Change refractive index l Change resonance GHz 10 ground ation oper signal waveguide in p-i-n © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be ground

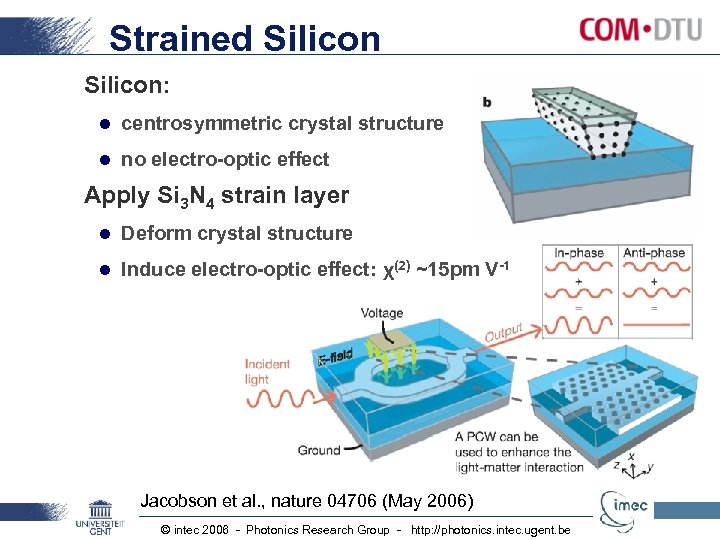

Strained Silicon: l centrosymmetric crystal structure l no electro-optic effect Apply Si 3 N 4 strain layer l Deform crystal structure l Induce electro-optic effect: χ(2) ~15 pm V-1 Jacobson et al. , nature 04706 (May 2006) © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

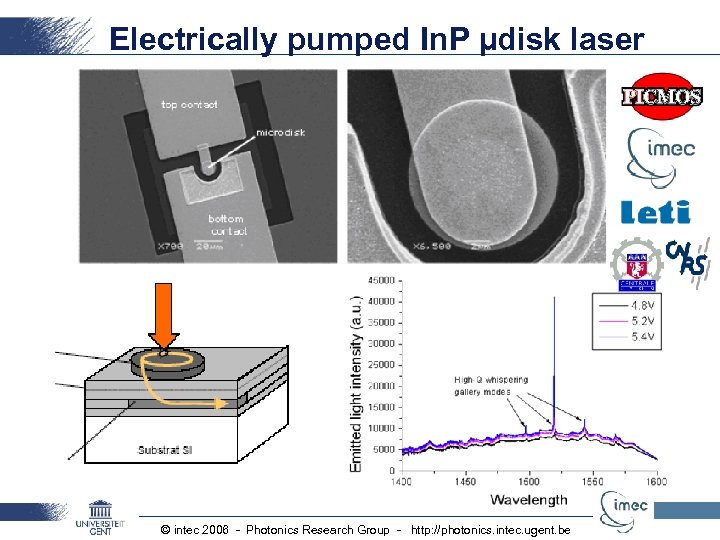

Electrically pumped In. P µdisk laser © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

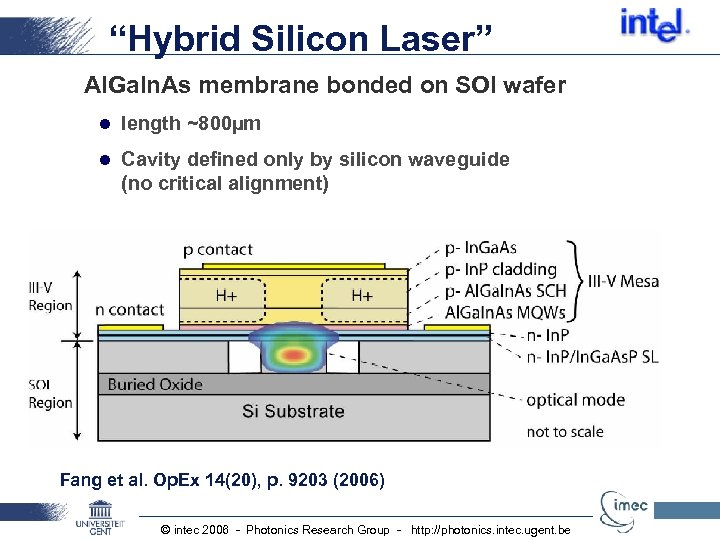

“Hybrid Silicon Laser” Al. Ga. In. As membrane bonded on SOI wafer l length ~800µm l Cavity defined only by silicon waveguide (no critical alignment) Fang et al. Op. Ex 14(20), p. 9203 (2006) © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

SOI microring sensor Measure salt concentration l Fluid overcladding l Refr. index ~ Salt concentration l Response of ring ~ refr. index l Q = 20000 minimum n ~ 5. 10 -5 2% Na. Cl 2, 05% Na. Cl 2, 15% Na. Cl 4% Na. Cl © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

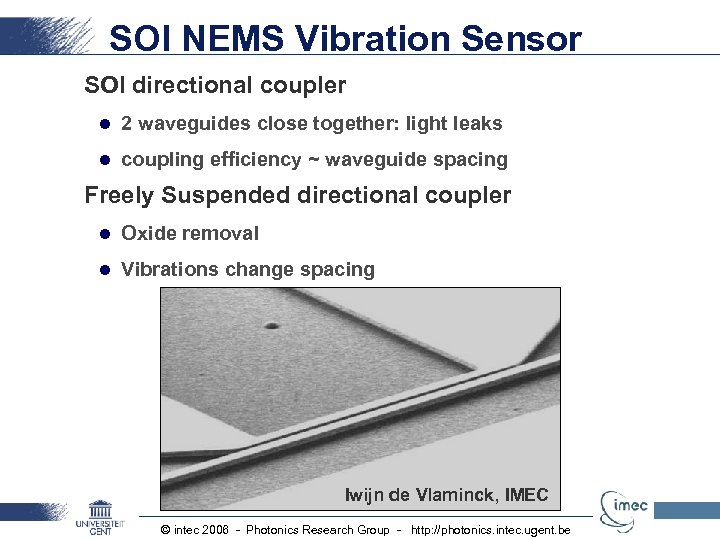

SOI NEMS Vibration Sensor SOI directional coupler l 2 waveguides close together: light leaks l coupling efficiency ~ waveguide spacing Freely Suspended directional coupler l Oxide removal l Vibrations change spacing Iwijn de Vlaminck, IMEC © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Photonic Crystals NTT l E-beam lithography l Low propagation losses: 6 d. B/cm l Low-loss interface to fiber IBM l In-house CMOS processes l e-beam lithography is the only out-of-the-line step l Photonic crystals: low propagation losses l Slow light in Photonic crystals (Nature, 3/11) © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

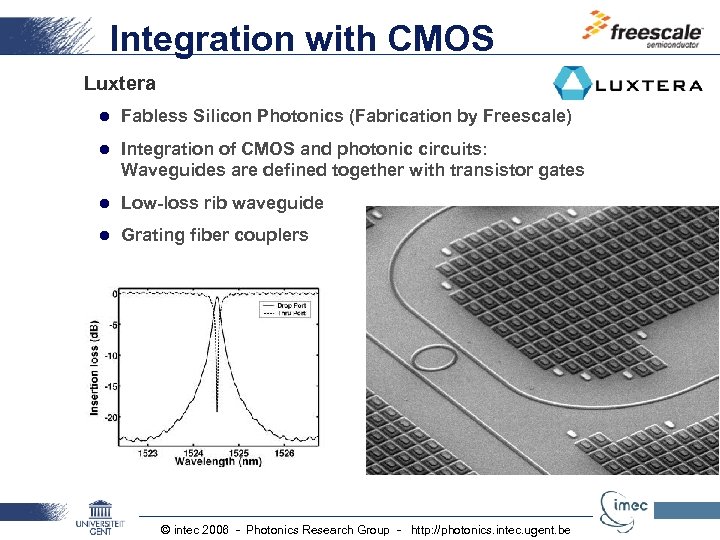

Integration with CMOS Luxtera l Fabless Silicon Photonics (Fabrication by Freescale) l Integration of CMOS and photonic circuits: Waveguides are defined together with transistor gates l Low-loss rib waveguide l Grating fiber couplers © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

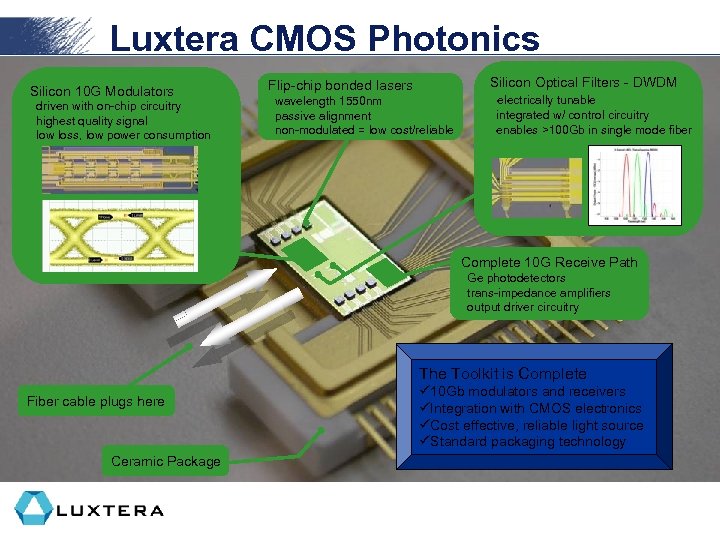

Luxtera CMOS Photonics Silicon 10 G Modulators driven with on-chip circuitry highest quality signal low loss, low power consumption Flip-chip bonded lasers wavelength 1550 nm passive alignment non-modulated = low cost/reliable Silicon Optical Filters - DWDM electrically tunable integrated w/ control circuitry enables >100 Gb in single mode fiber Complete 10 G Receive Path Ge photodetectors trans-impedance amplifiers output driver circuitry The Toolkit is Complete Fiber cable plugs here ü 10 Gb modulators and receivers üIntegration with CMOS electronics üCost effective, reliable light source üStandard packaging technology Ceramic Package © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

How? Photonics Research Group http: //photonics. intec. ugent. be

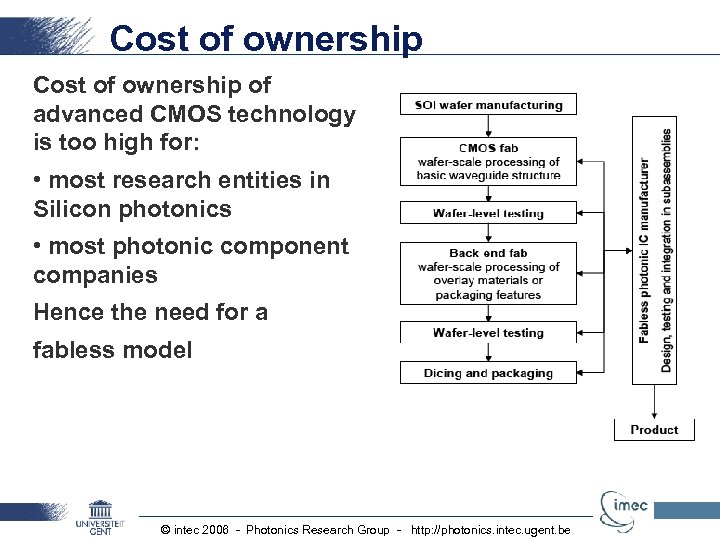

Cost of ownership of advanced CMOS technology is too high for: • most research entities in Silicon photonics • most photonic component companies Hence the need for a fabless model © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

THE challenge of Silicon photonics CMOS l large, mature technology base l strong, focused innovative drive l large organisations, big budgets Silicon Photonics l Recent rapid progress l (still) relatively small actors l Challenge: overcome this mismatch with a critical mass limited budgets Successful industrial deployment requires extensive interaction between CMOS and photonics community © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Silicon Photonics Platform Network of Excellence e. PIXnet develops platforms for photonic integration: • Silicon photonics platform • In. P photonics platform • Nanostructuring platform • Packaging platform • High speed measurement platform • Modelling platform www. epixnet. org © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Si Photonics platform Long-term objective: • to enable a route towards commercial deployment of silicon photonics. Methodology: • Facility Access Programme (foundry service) for Research and Prototyping: l Making mature fabrication processes on high-end industrial CMOS tools available to many research groups or projects l Sharing masks and processing: dramatic cost reduction • Roadmap for Silicon Photonics Technologies: l Identifying the challenges and evolutionary solutions in this field • Commercial Manufacturing Routes: l Gradual involvement of commercial foundries • Promotion and lobbying l For the field of Silicon photonics in the interest of Europe’s position in this field. © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Platform structure • Steering group: strategic decisions • Coordinator : daily operation • Core fabrication partners l IMEC (Gent-Leuven) l CEA-LETI (Grenoble) l Other in the future? • Members l Anybody interested in and committed to the mission • Users l Those who use the foundry service © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

How does it work? Platform coordination Platform users IMEC Line LETI Line • Submit design • Designs are grouped • Designs are fabricated • Wafers are distributed © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

Summary SOI Photonics l Nanophotonic high index contrast waveguides open up a new paradigm in photonic integration l The use of the mature silicon CMOS technology base provides an enormous opportunity l But the cost of ownership of CMOS technology is a barrier Silicon Photonics Platform l Support transition to industrial deployment of Silicon photonics l By building a fabless industry model l By organizing a foundry service for Research & Prototyping l Affordable by cost sharing © intec 2006 - Photonics Research Group - http: //photonics. intec. ugent. be

cdb4553b670a6628bccf18539c982a61.ppt