1d181b2fdd3ae3156c01747de34cade1.ppt

- Количество слайдов: 35

Wonderware Operations Software improve production consistency, visibility and agility Andrea Sartori Solution Architect EMEA

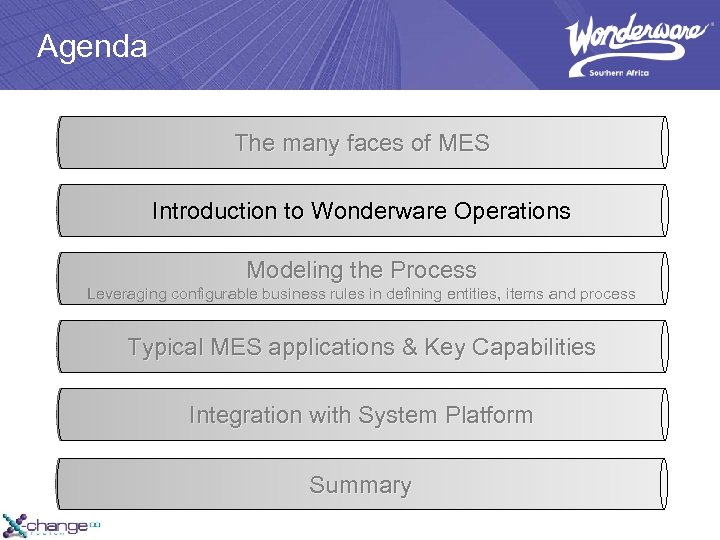

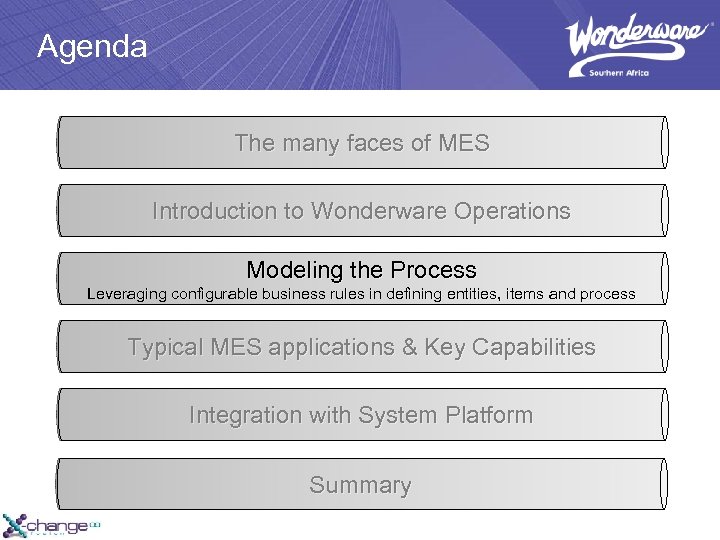

Agenda The many faces of MES Introduction to Wonderware Operations Modeling the Process Leveraging configurable business rules in defining entities, items and process Typical MES applications & Key Capabilities Integration with System Platform S u mma ry

Agenda The many faces of MES Introduction to Wonderware Operations Modeling the Process Leveraging configurable business rules in defining entities, items and process Typical MES applications & Key Capabilities Integration with System Platform S u mma ry

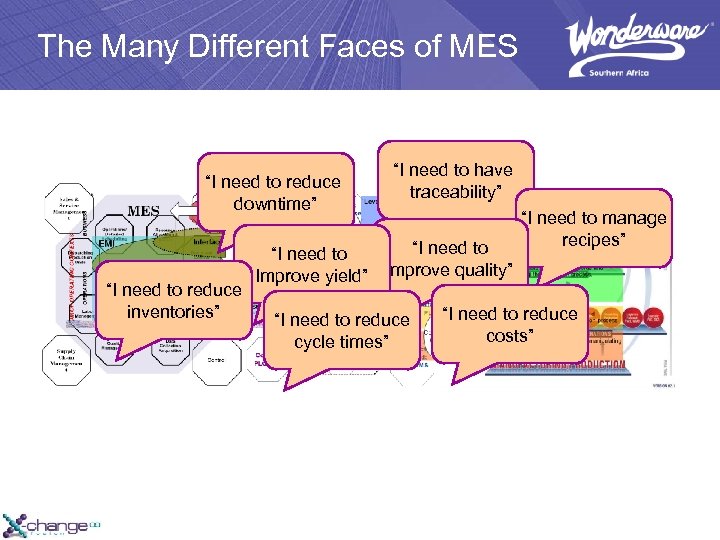

The Many Different Faces of MES “I need to reduce downtime” “I need to reduce inventories” “I need to Improve yield” “I need to have traceability” “I need to improve quality” “I need to reduce cycle times” “I need to manage recipes” “I need to reduce costs”

Challenges Even if Need for MES Has Been Identified Can’t tell exactly what I need or how much it’s worth to me… “I need MES!” Need to reduce production losses / errors but don’t know where or how to get started Need to track what’s happening in production but it shouldn’t interfere with my production process Have defined 50+ pages of requirements but who do I select?

Wonderware Provides Unique Value with Incremental Approach ► Increased Business Agility and Performance through Improved Manufacturing Operations ► Wonderware MES & EMI Software Solutions enable: ▪ Productivity Increase from Existing Resources ▪ Lead Time Reduction ▪ Production Throughput and Efficiency Increase ▪ Manufacturing Costs Reduction ▪ Regulatory Compliance ► Underlying System Platform and adoption of market standards dramatically reduces total cost of ownership and enables a flexible approach to evolve as you require.

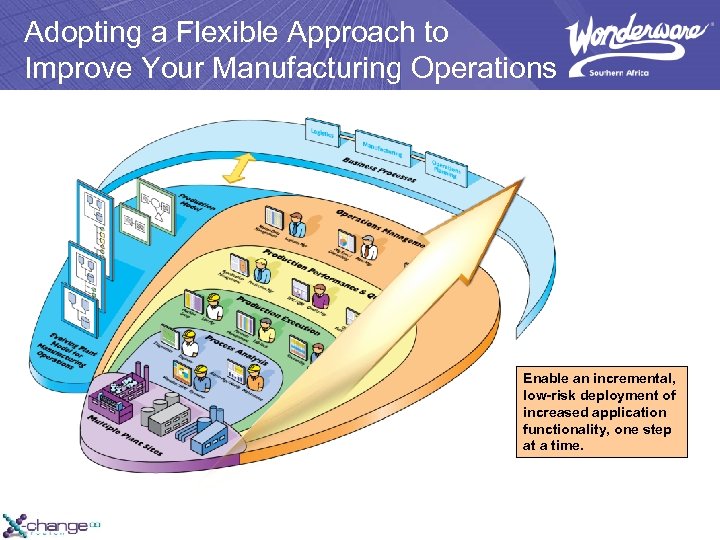

Adopting a Flexible Approach to Improve Your Manufacturing Operations Enable an incremental, low-risk deployment of increased application functionality, one step at a time.

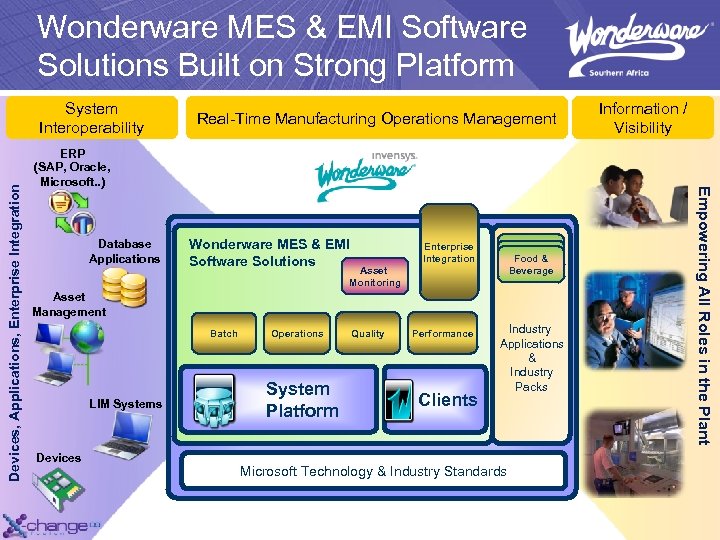

Wonderware MES & EMI Software Solutions Built on Strong Platform Real-Time Manufacturing Operations Management ERP (SAP, Oracle, Microsoft. . ) Database Applications Wonderware MES & EMI Software Solutions Enterprise Integration Food & Beverage Asset Monitoring Asset Management Batch LIM Systems Devices Operations System Platform Quality Performance Clients Industry Applications & Industry Packs Microsoft Technology & Industry Standards Information / Visibility Empowering All Roles in the Plant Devices, Applications, Enterprise Integration System Interoperability

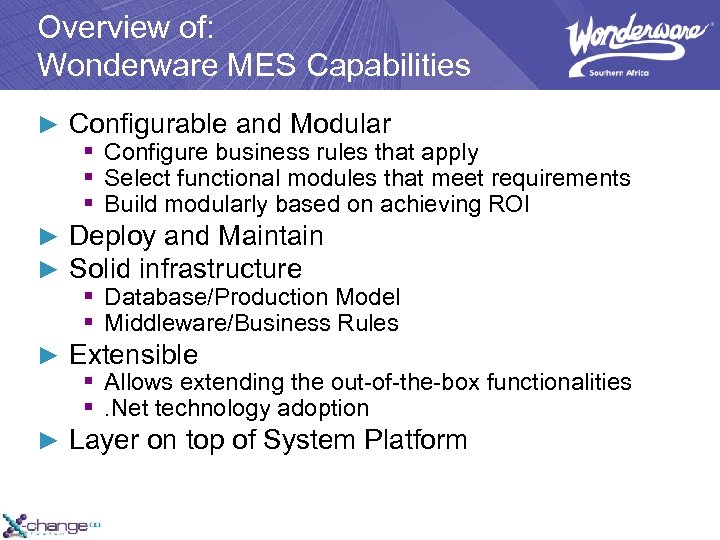

Overview of: Wonderware MES Capabilities ► Configurable and Modular ▪ Configure business rules that apply ▪ Select functional modules that meet requirements ▪ Build modularly based on achieving ROI ► Deploy and Maintain ► Solid infrastructure ▪ Database/Production Model ▪ Middleware/Business Rules ► Extensible ▪ Allows extending the out-of-the-box functionalities ▪. Net technology adoption ► Layer on top of System Platform

Agenda The many faces of MES Introduction to Wonderware Operations Modeling the Process Leveraging configurable business rules in defining entities, items and process Typical MES applications & Key Capabilities Integration with System Platform S u mma ry

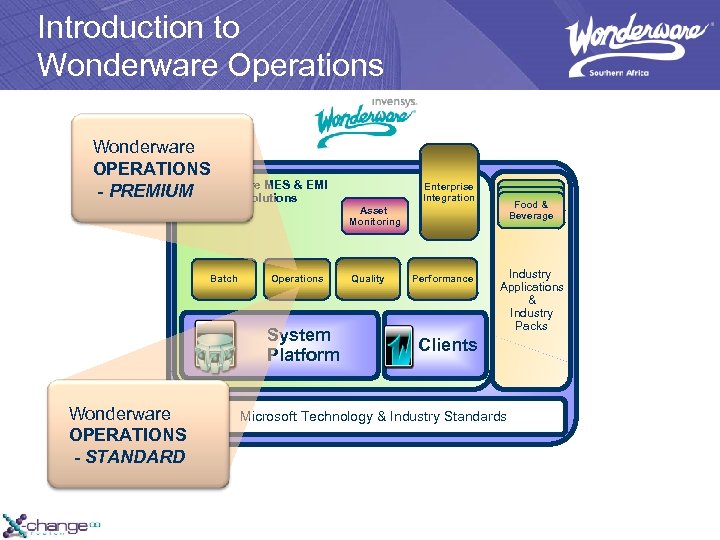

Introduction to Wonderware Operations Wonderware OPERATIONS Wonderware MES & EMI - PREMIUM Software Solutions Enterprise Integration Food & Beverage Asset Monitoring Batch Operations System Platform Wonderware OPERATIONS - STANDARD Quality Performance Industry Applications & Industry Packs Clients Microsoft Technology & Industry Standards

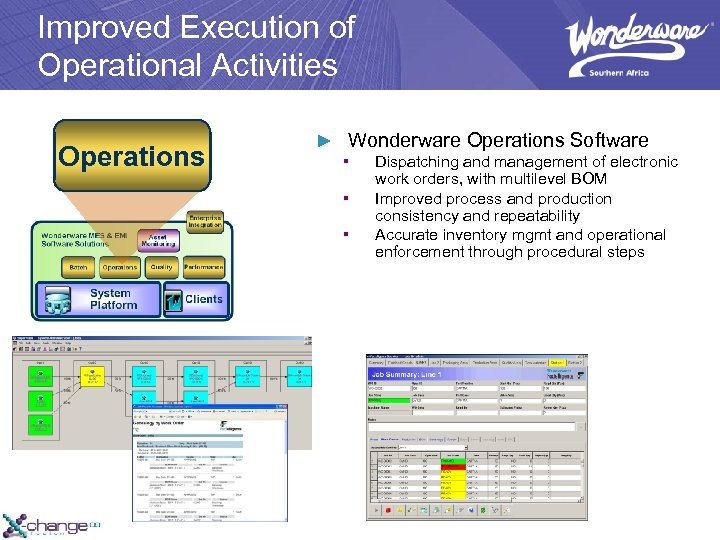

Improved Execution of Operational Activities Operations ► Wonderware Operations Software ▪ ▪ ▪ Dispatching and management of electronic work orders, with multilevel BOM Improved process and production consistency and repeatability Accurate inventory mgmt and operational enforcement through procedural steps

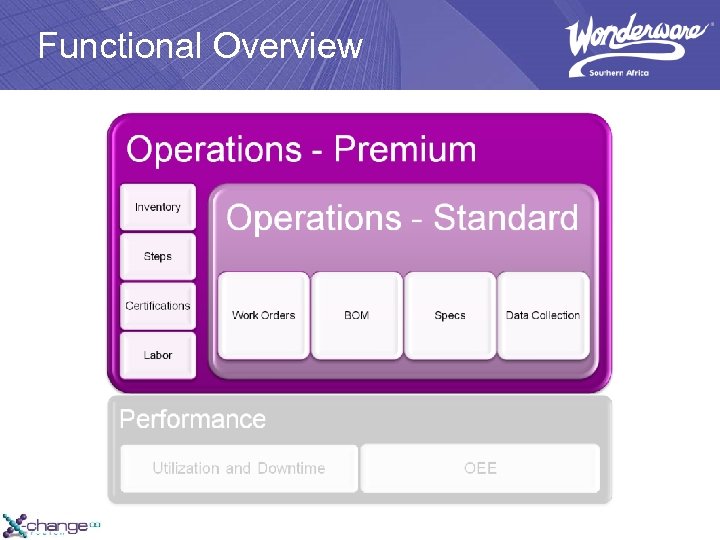

Functional Overview

Agenda The many faces of MES Introduction to Wonderware Operations Modeling the Process Leveraging configurable business rules in defining entities, items and process Typical MES applications & Key Capabilities Integration with System Platform S u mma ry

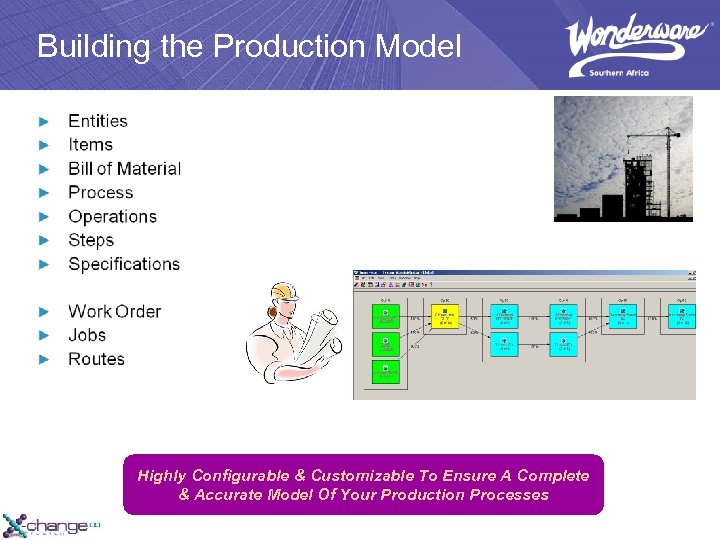

Building the Production Model Highly Configurable & Customizable To Ensure A Complete & Accurate Model Of Your Production Processes

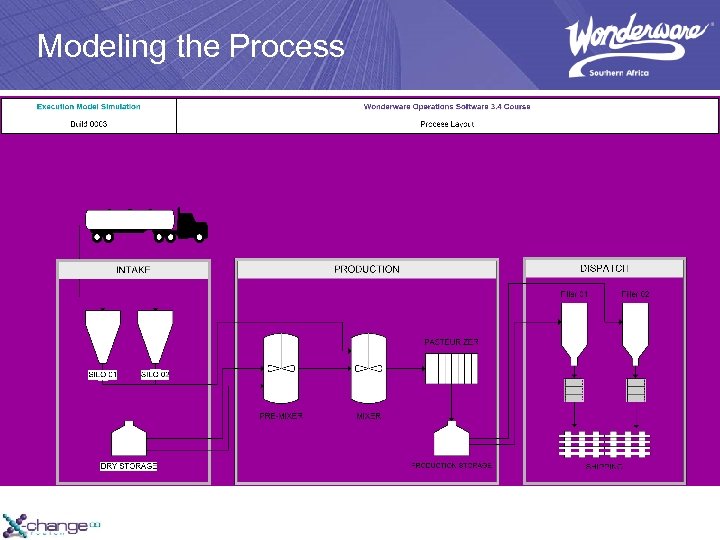

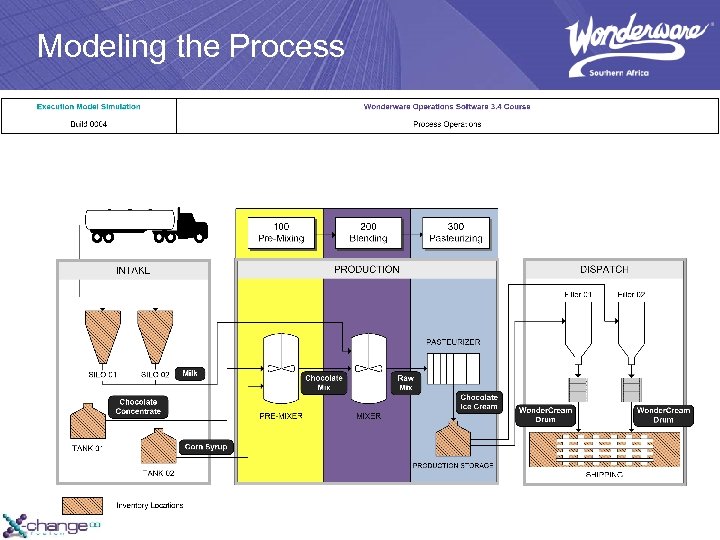

Modeling the Process

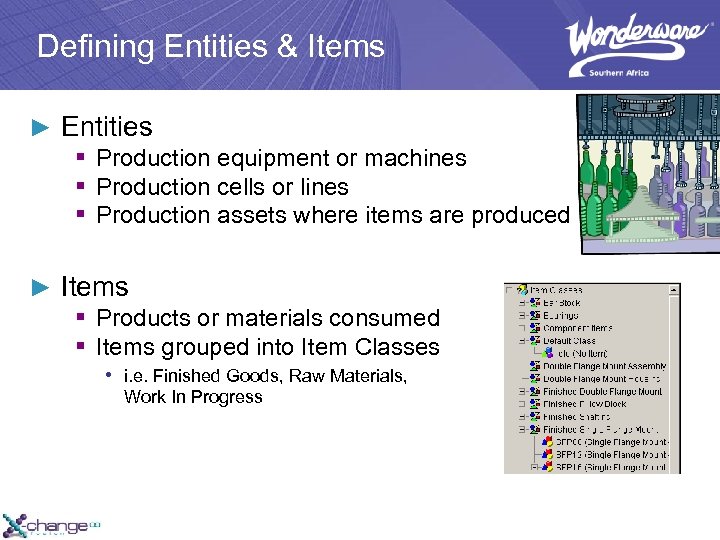

Defining Entities & Items ► Entities ▪ Production equipment or machines ▪ Production cells or lines ▪ Production assets where items are produced ► Items ▪ Products or materials consumed ▪ Items grouped into Item Classes • i. e. Finished Goods, Raw Materials, Work In Progress

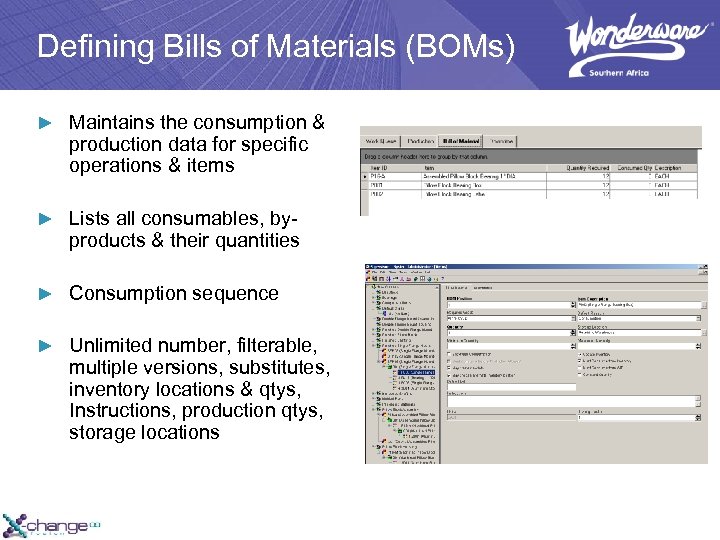

Defining Bills of Materials (BOMs) ► Maintains the consumption & production data for specific operations & items ► Lists all consumables, by- products & their quantities ► Consumption sequence ► Unlimited number, filterable, multiple versions, substitutes, inventory locations & qtys, Instructions, production qtys, storage locations

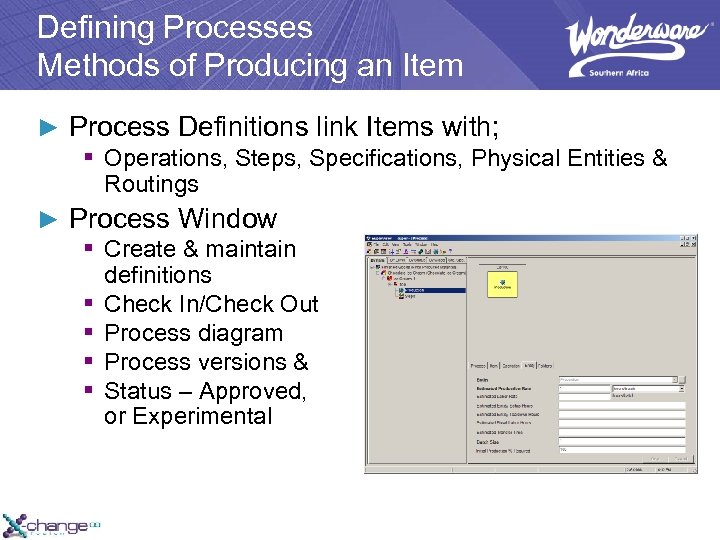

Defining Processes Methods of Producing an Item ► Process Definitions link Items with; ▪ Operations, Steps, Specifications, Physical Entities & Routings ► Process Window ▪ Create & maintain process definitions ▪ Check In/Check Out ▪ Process diagram ▪ Process versions & templates ▪ Status – Approved, or Experimental

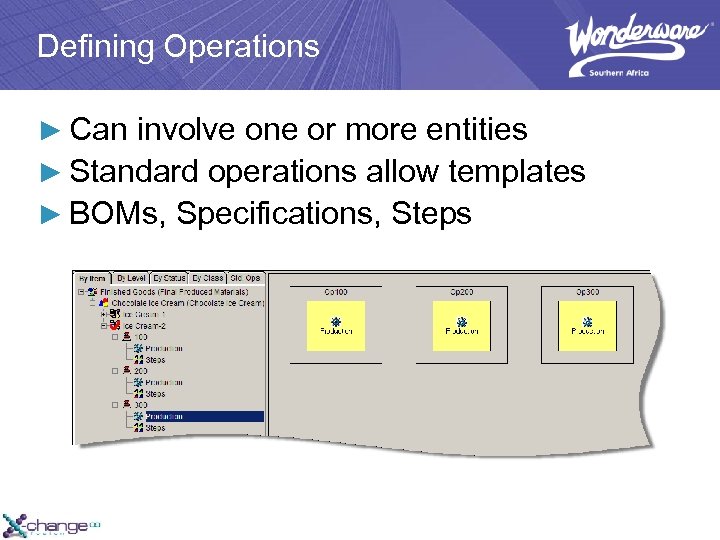

Defining Operations ► Can involve one or more entities ► Standard operations allow templates ► BOMs, Specifications, Steps

Modeling the Process

Agenda The many faces of MES Introduction to Wonderware Operations Modeling the Process Leveraging configurable business rules in defining entities, items and process Typical MES applications & Key Capabilities Integration with System Platform S u mma ry

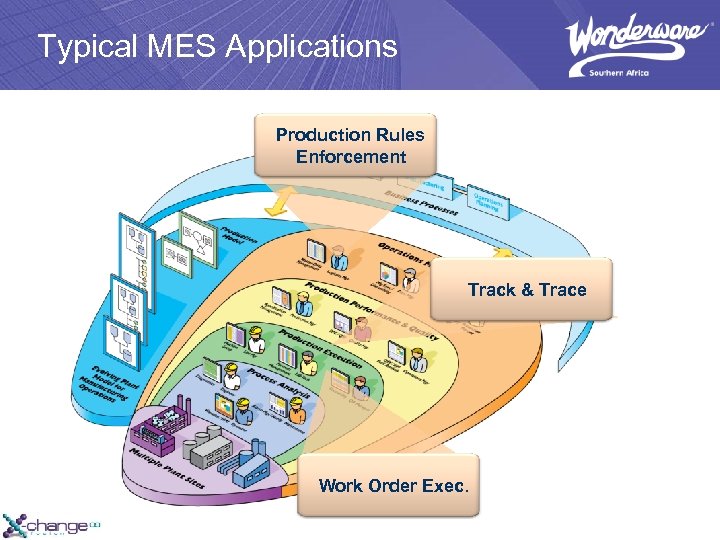

Typical MES Applications Production Rules Enforcement Track & Trace Work Order Exec.

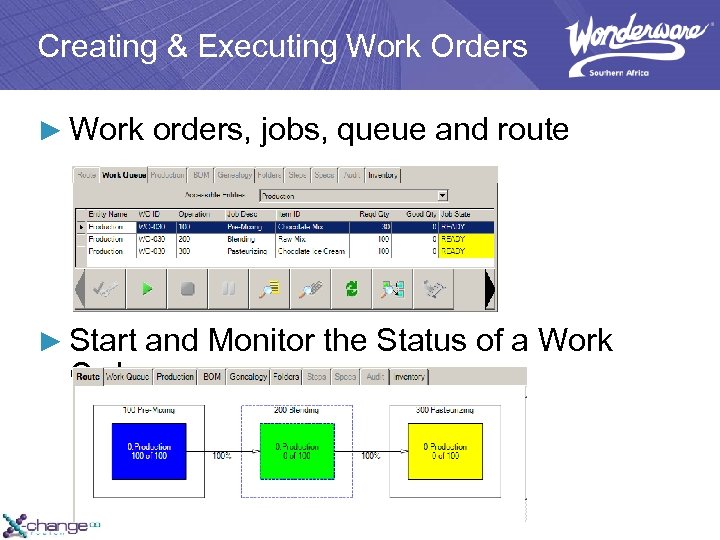

Creating & Executing Work Orders ► Work orders, jobs, queue and route ► Start and Monitor the Status of a Work Order

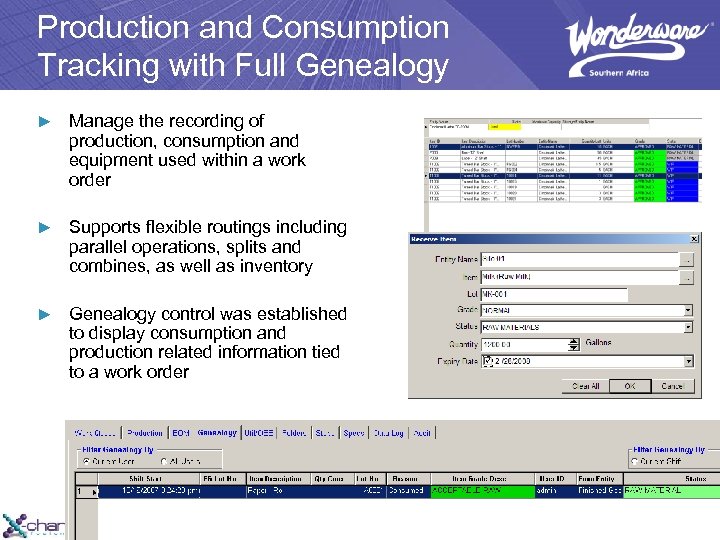

Production and Consumption Tracking with Full Genealogy ► Manage the recording of production, consumption and equipment used within a work order ► Supports flexible routings including parallel operations, splits and combines, as well as inventory ► Genealogy control was established to display consumption and production related information tied to a work order

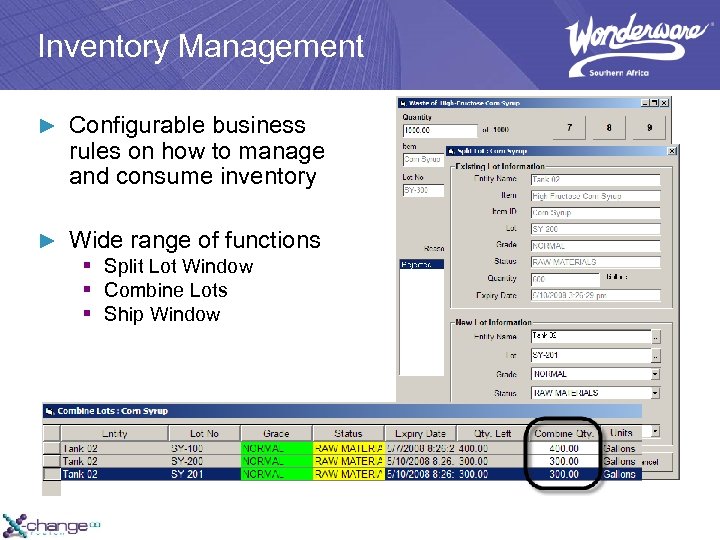

Inventory Management ► Configurable business rules on how to manage and consume inventory ► Wide range of functions ▪ Split Lot Window ▪ Combine Lots ▪ Ship Window

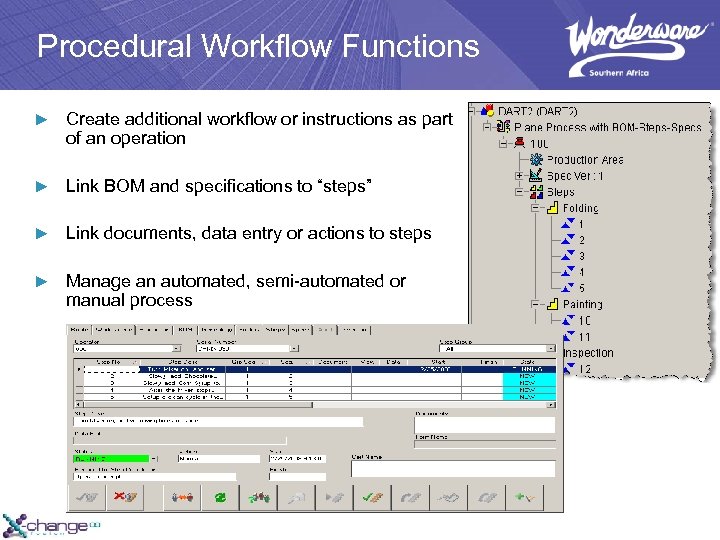

Procedural Workflow Functions ► Create additional workflow or instructions as part of an operation ► Link BOM and specifications to “steps” ► Link documents, data entry or actions to steps ► Manage an automated, semi-automated or manual process

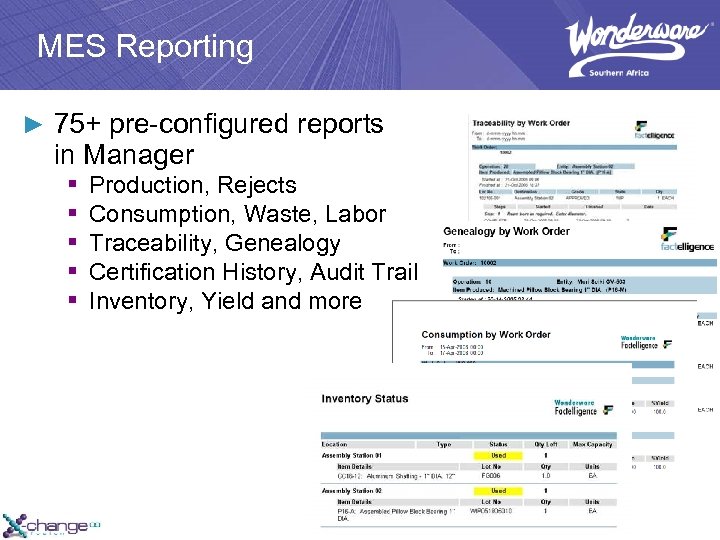

MES Reporting ► 75+ pre-configured reports in Manager ▪ Production, Rejects ▪ Consumption, Waste, Labor ▪ Traceability, Genealogy ▪ Certification History, Audit Trail ▪ Inventory, Yield and more

Agenda The many faces of MES Introduction to Wonderware Operations Modeling the Process Leveraging configurable business rules in defining entities, items and process Typical MES applications & Key Capabilities Integration with System Platform S u mma ry

Enhanced Economy of Scale and Economy of Scope ► System Platform as Reproducible Platform & Logic Engine ▪ Repeatability / consistency / min. customization ▪ Standards based ▪ Concept of templates and deployment ► Different Elements of Integration ▪ Business logic ▪ User interfaces ► Different Approaches to Integration ▪ Scripting to API/middleware ▪ Intelligent. net controls for visualization

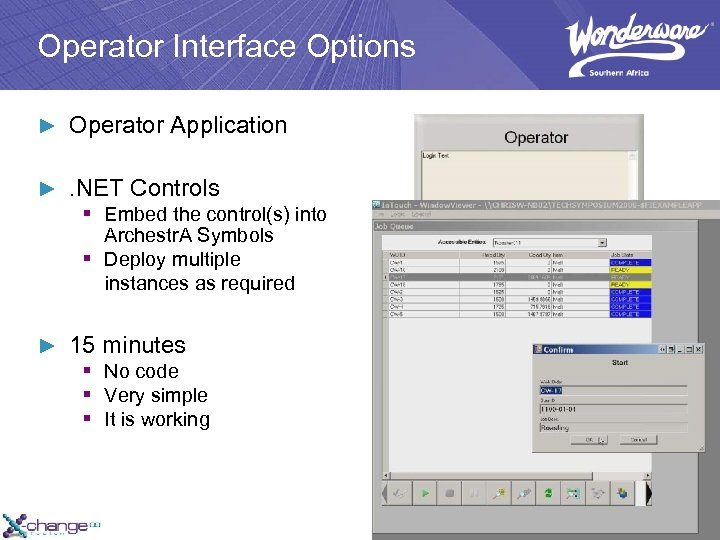

Operator Interface Options ► Operator Application ►. NET Controls ▪ Embed the control(s) into Archestr. A Symbols ▪ Deploy multiple instances as required ► 15 minutes ▪ No code ▪ Very simple ▪ It is working

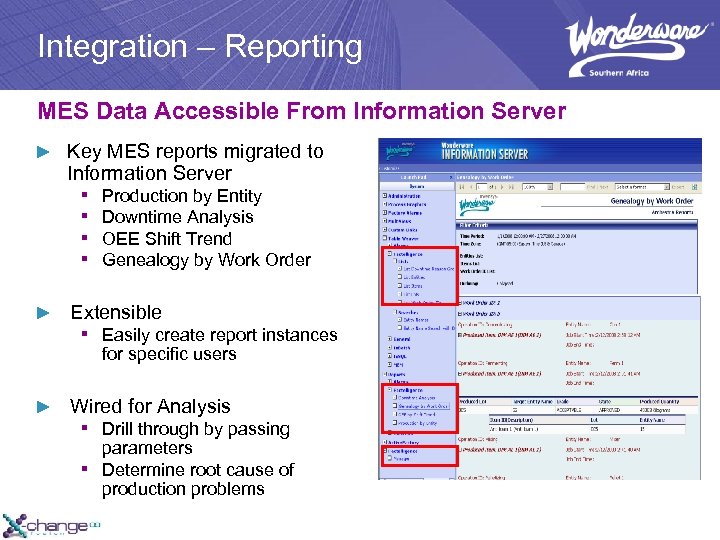

Integration – Reporting MES Data Accessible From Information Server ► Key MES reports migrated to Information Server ▪ ▪ ► Production by Entity Downtime Analysis OEE Shift Trend Genealogy by Work Order Extensible ▪ Easily create report instances for specific users ► Wired for Analysis ▪ Drill through by passing ▪ parameters Determine root cause of production problems

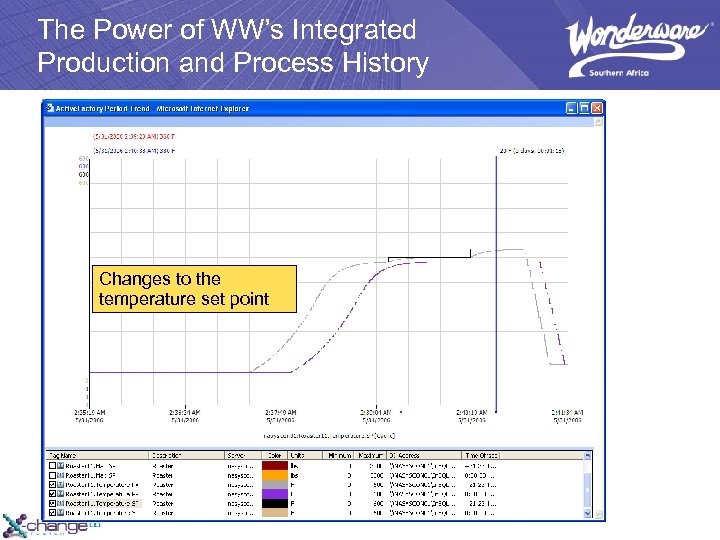

The Power of WW’s Integrated Production and Process History Changes to the temperature set point

In Summary: Wonderware Provides Unique Value with Incremental Approach ► Increased Business Agility and Performance through Improved Manufacturing Operations ► Wonderware MES & EMI Software Solutions enable: ▪ Productivity Increase from Existing Resources ▪ Lead Time Reduction ▪ Production Throughput and Efficiency Increase ▪ Manufacturing Costs Reduction ▪ Regulatory Compliance ► Underlying System Platform and adoption of market standards dramatically reduces total cost of ownership and enables a flexible approach to evolve as you require

Software Solutions for Real-Time Success SM

1d181b2fdd3ae3156c01747de34cade1.ppt