06df24cf1ecfdab1ebe45d1da53b78d2.ppt

- Количество слайдов: 28

WONDER = PGBA 6 + PTIM Integration Review Integration / Design Review Phase 1 Contract April – September 2003 PTIM Integration into PGBA Bio. Serve Space Technologies University of Colorado and The Bionetics Corporation, Space Life Sciences Lab (SLSL), NASA KSC 09 October 2003 Footer 1

Acronyms: • • • • PGBA Plant Generic Bio. Processing Apparatus PTIM Porous Tube Insert Module WONDER Water Offset Nutrient Delivery Experiment EMI Electromagnetic Interference EXPRESS Expedite the Processing of Experiments to the Space Station ISS International Space Station JSC Johnson Space Center KSC Kennedy Space Center MDL Middeck Locker NDS Nutrient Delivery System PI Principal Investigator PGBA Plant Generic Bio. Processing Apparatus PTNDS Porous Tube Nutrient Delivery System PTIM Porous Tube Insert Module STS Space Transportation System WONDER Water Offset Nutrient Delivery Experiment WONDER = PGBA + PTIM Integration Review 2

References: • • WONDER-White Paper: Water Offset Nutrient Delivery Experiment (WONDER) Feasibility Study for Flight on the International Space Station (ISS) PGBA-WONDER-ICD: Water Offset Nutrient Delivery Experiment (WONDER) PGBA to PTIM Interface Control Document (draft). LSSC-WONDER-EIS: Porous Tube Insert Module (PTIM) End Item Specification, 08/04/03 LSSC-WONDER-ERD: Water Offset Nutrient Delivery Experiment (WONDER) Experiment Requirements Document IDD: NSTS-21000 -IDD-MDK Rev. B and SSP 52000 -IDD-ERP Safety: NSTS 1700. 7 B / NSTS 1700. 7 B ISS Addendum / KHB 1700. 7 Electric: MSFC-HDBK-527 E Links: • Bio. Serve Automation and Operations Server: http: //bioserve-boulder. colorado. edu WONDER = PGBA + PTIM Integration Review 3

Personnel Bio. Serve Space Technologies: • • Jon Genova, Mechanical design. Kevin Gifford, Automation lead. Alex Hoehn, Systems. Seb Kuzminski, Automation. Jim Russel, Project management. Shea Williams, Automation / Test / Verification. Peter Journey-Kahler, atmosphere control. Chris Madsen, fluids. Bionetics: • • April Boody, WONDER Project Engineer Kevin Burtness, WONDER Hardware/Software Engineer Trevor Murdoch, WONDER Electrical Bill Wells, Flight Experiment Development/Management PI: • Howard Levine, Dynamac, NASA KSC LSLS WONDER = PGBA + PTIM Integration Review 4

Agenda for CDR • • 11: 30/13: 30 Alex Hoehn (Chris Madsen, Jim Russel, Peter Journey-Kahler) » » » Introduction, tasks of SOW, schedule hydraulic design electric design remote site GSE enhancements (mech. , CO 2) (Alex Hoehn) documentation exchange 12: 30/14: 30 Kevin Gifford / Shea Williams » » automation, incl. user new interfaces (Kevin Gifford, Shea Williams) remote site GSE enhancements (automation) (Shea Williams) 13: 30/15: 30 All: » » Questions / open items / tasks / test schedule Phase 2 target accomplishments (PGBA deploy, remote site ops. ) 14: 30/16: 30 Adjourn WONDER = PGBA + PTIM Integration Review 5

Background • • After Columbia accident, no flights assigned. Previously working in parallel on: » » PGBA-5: PGBA + Pine trees, STS-118 / ISS. 13 A. 1 PGBA-6: PGBA + PTIM, STS-120 Sortie Science Only Potential use conflicts for PGBAs unknown » » » Currently use both PGBAs for testing, development, software upgrades 1. one PGBA to be deployed to KSC for WONDER testing. 2. one PGBA to be deployed to Ames for PINE testing. Maintain, whenever possible / especially initially, at CU for trouble shooting. Currently no plans to develop 3 rd PGBA. Other / General PGBA Work in preparation: » » » Updated heat exchangers (corrosion, backpressure) Updated dehumidifier (seal life time, serviceability) Updated chamber lid (seal life time, seal verifications) Software / Automation – lessons learned ISS. 9 A / usability enhancements Operations – web plots incl. online performance analysis, PDH payload data historian WONDER = PGBA + PTIM Integration Review 6

Phase 1 Tasks Design, test, and (as necessary for testing) implementation of: • PGBA Integration documentation delivery: • • » Safety, verification, electrical, mechanical, operations documentation. Electrical interfaces for PTIM: » » » Power (5 V, 12 V) – switched and fused. Data (RS 485). Video (2 channels analog color video). Mechanical interfaces for PTIM: » » PTIM alignment structure. PTIM water/fluid replenishment and PGBA interface. PGBA GSE support: » PGBA CO 2 GSE, Stand, video interface box, power supply Automation interfaces for PTIM: » » » Updated S/W architecture for PTIM. Updated touch-screens. Updated remote user interfaces (webplots, EGSE documentation/interfaces) WONDER = PGBA + PTIM Integration Review 7

Electrical Interface • Single Interface Connector to PGBA Chamber » 27 pins, share power, analog data, digital signal, digital communication WONDER = PGBA + PTIM Integration Review 8

Electrical Interface - Schematic WONDER = PGBA + PTIM Integration Review 9

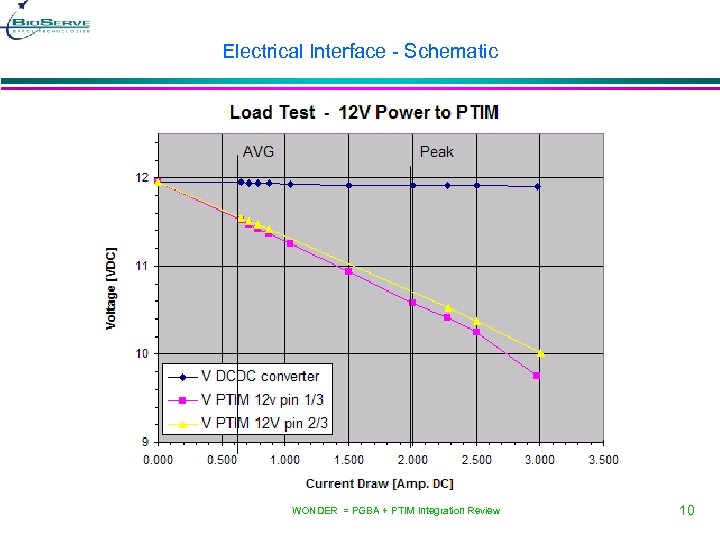

Electrical Interface - Schematic WONDER = PGBA + PTIM Integration Review 10

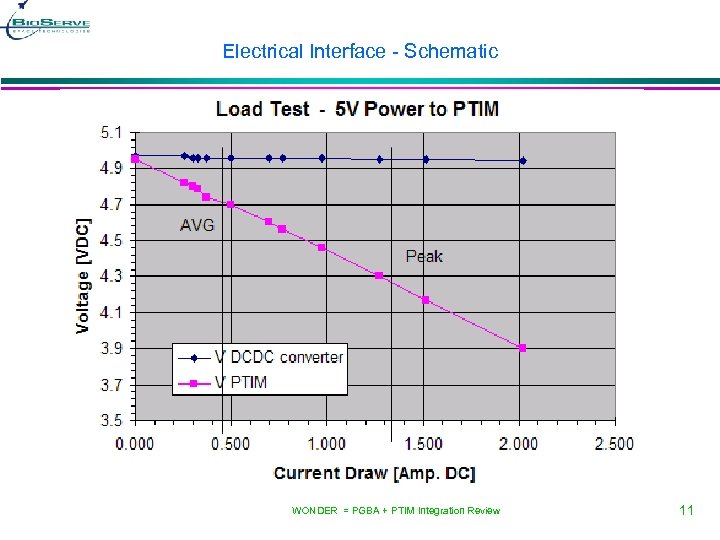

Electrical Interface - Schematic WONDER = PGBA + PTIM Integration Review 11

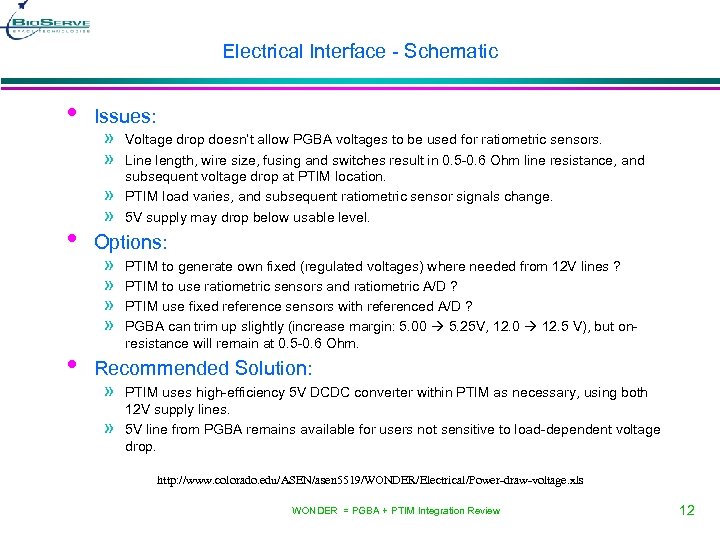

Electrical Interface - Schematic • • • Issues: » » Voltage drop doesn’t allow PGBA voltages to be used for ratiometric sensors. Line length, wire size, fusing and switches result in 0. 5 -0. 6 Ohm line resistance, and subsequent voltage drop at PTIM location. PTIM load varies, and subsequent ratiometric sensor signals change. 5 V supply may drop below usable level. Options: » » PTIM to generate own fixed (regulated voltages) where needed from 12 V lines ? PTIM to use ratiometric sensors and ratiometric A/D ? PTIM use fixed reference sensors with referenced A/D ? PGBA can trim up slightly (increase margin: 5. 00 5. 25 V, 12. 0 12. 5 V), but onresistance will remain at 0. 5 -0. 6 Ohm. Recommended Solution: » » PTIM uses high-efficiency 5 V DCDC converter within PTIM as necessary, using both 12 V supply lines. 5 V line from PGBA remains available for users not sensitive to load-dependent voltage drop. http: //www. colorado. edu/ASEN/asen 5519/WONDER/Electrical/Power-draw-voltage. xls WONDER = PGBA + PTIM Integration Review 12

Electrical Interface - Other • • • Replace PGBA ‘Switcher’ for flight: » Current switcher PCB (fused – Polyswitch - Photo. MOS switches) has been ‘modified’ for evaluation and testing, and requires replacement with ‘clean’ PCB for flight. Usable for ground usage. PGBA DCDC Converters: » Voltages tightly controlled at PGBA computer only. Testing if trim-up will provide enhanced performance for distributed users at extreme ends of distribution (inside chamber, …). Video Transmission Quality: » » To date not tested. ODU connector requires twisted pair feed-through with other users. Quality impact unknown. Testing necessary. New video lines installed for testing, but never tested. http: //www. colorado. edu/ASEN/asen 5519/WONDER/Electrical/Power-draw-voltage. xls WONDER = PGBA + PTIM Integration Review 13

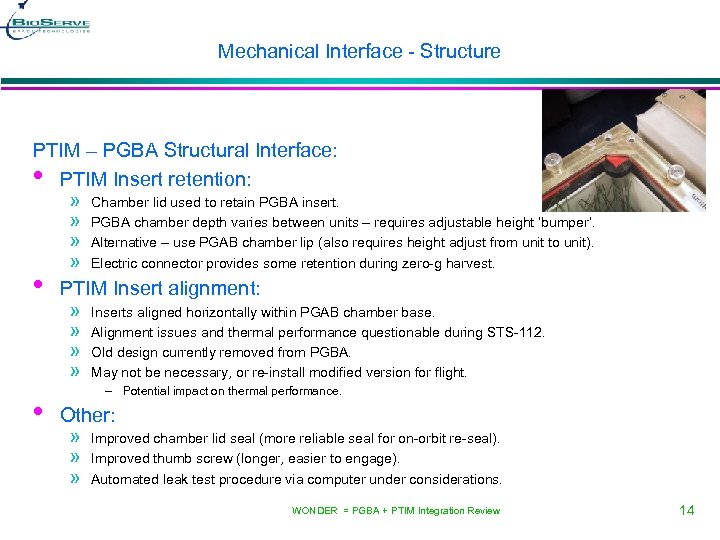

Mechanical Interface - Structure PTIM – PGBA Structural Interface: • PTIM Insert retention: • • » » Chamber lid used to retain PGBA insert. PGBA chamber depth varies between units – requires adjustable height ‘bumper’. Alternative – use PGAB chamber lip (also requires height adjust from unit to unit). Electric connector provides some retention during zero-g harvest. PTIM Insert alignment: » » Inserts aligned horizontally within PGAB chamber base. Alignment issues and thermal performance questionable during STS-112. Old design currently removed from PGBA. May not be necessary, or re-install modified version for flight. – Potential impact on thermal performance. Other: » » » Improved chamber lid seal (more reliable seal for on-orbit re-seal). Improved thumb screw (longer, easier to engage). Automated leak test procedure via computer under considerations. WONDER = PGBA + PTIM Integration Review 14

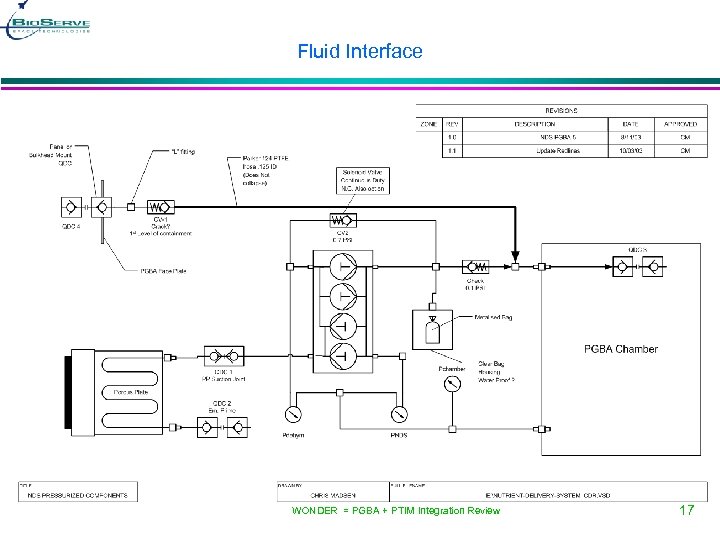

Mechanical Interface - Hydraulics Hydraulic Design – NDS Refill: • Science requires crew-assisted nutrient solution concentrate refill: » » • Water content expected almost constant (excluding plant fresh matter and some atmospheric moisture loss) during mission, but nutrients depleted. Based on concentration (salinity) and p. H (<4, >10), may be hazard level 2 fluid (Bionetics to clarify). Assume hazard level 1. Requirements: » » » » Connect at faceplate (syringe / QD). Route injected nutrient solution to PTIM. Contain fluids with adequate factors of safety (1 level). Protects PGBA humidity condensate control and return system (over-pressurization, salt-solution vs. distilled water). Seamless interface to PGBA condensate return system. Crew-applied loads. Tethered (req. ) and sealed (desire) cap when not used. WONDER = PGBA + PTIM Integration Review 15

Mechanical Interface – Hydraulics 2 • • Risk – Over-pressurization: » » Solenoid pumps (Lee 50 ul/stroke piston pump) max. pressure = 2 psi. Crew injection (20 lbm force, 20 ml/sec, brute force) = 15 psi MDP. – Note: PTIM tank may not be able to withstand that pressure – limit at astronaut end. Constraint: » » Provide water make-up during crew harvest to porous plate – requires additional PGBA water tank / cannot use PTIM water due to salinity. add new bladder tank. Minimize / avoid changes to PGBA. WONDER = PGBA + PTIM Integration Review 16

Fluid Interface WONDER = PGBA + PTIM Integration Review 17

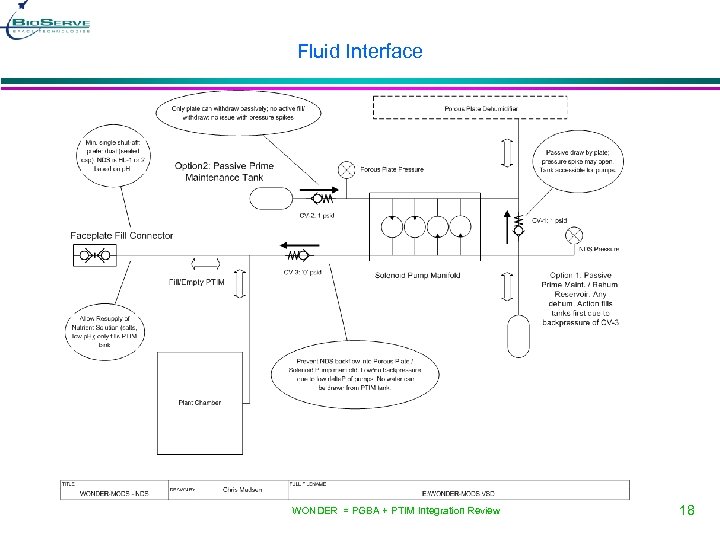

Fluid Interface WONDER = PGBA + PTIM Integration Review 18

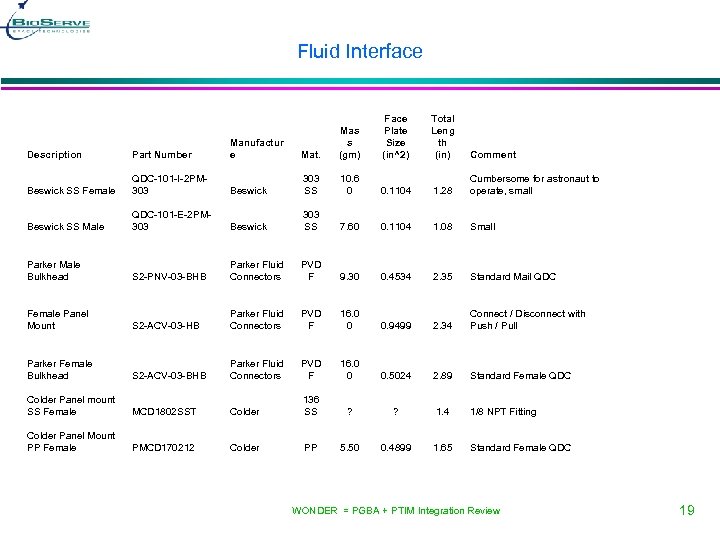

Fluid Interface Face Plate Size (in^2) Total Leng th (in) Comment Description Part Number Manufactur e Mat. Mas s (gm) Beswick SS Female QDC-101 -I-2 PM 303 Beswick 303 SS 10. 6 0 0. 1104 1. 28 Cumbersome for astronaut to operate, small Beswick SS Male QDC-101 -E-2 PM 303 Beswick 303 SS 7. 60 0. 1104 1. 08 Small Parker Male Bulkhead S 2 -PNV-03 -BHB Parker Fluid Connectors PVD F 9. 30 0. 4534 2. 35 Standard Mail QDC Female Panel Mount S 2 -ACV-03 -HB Parker Fluid Connectors PVD F 16. 0 0 0. 9499 2. 34 Connect / Disconnect with Push / Pull Parker Female Bulkhead S 2 -ACV-03 -BHB Parker Fluid Connectors PVD F 16. 0 0 0. 5024 2. 89 Standard Female QDC Colder Panel mount SS Female MCD 1802 SST Colder 136 SS ? ? 1. 4 1/8 NPT Fitting Colder Panel Mount PP Female PMCD 170212 Colder PP 5. 50 0. 4899 1. 65 Standard Female QDC WONDER = PGBA + PTIM Integration Review 19

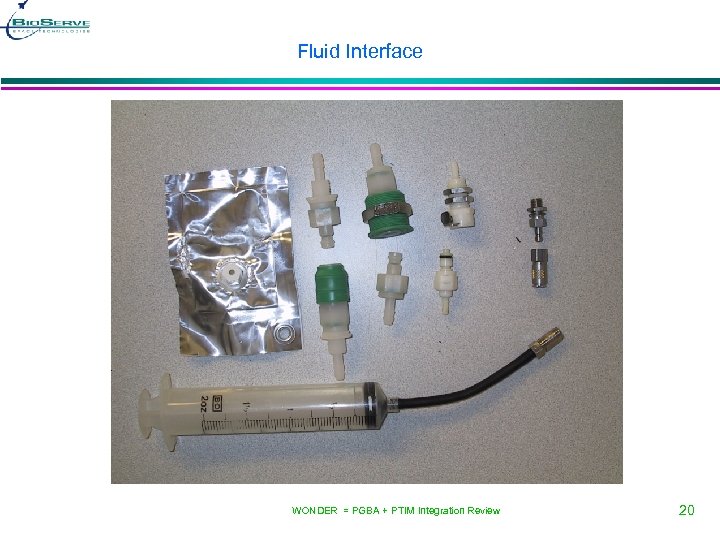

Fluid Interface WONDER = PGBA + PTIM Integration Review 20

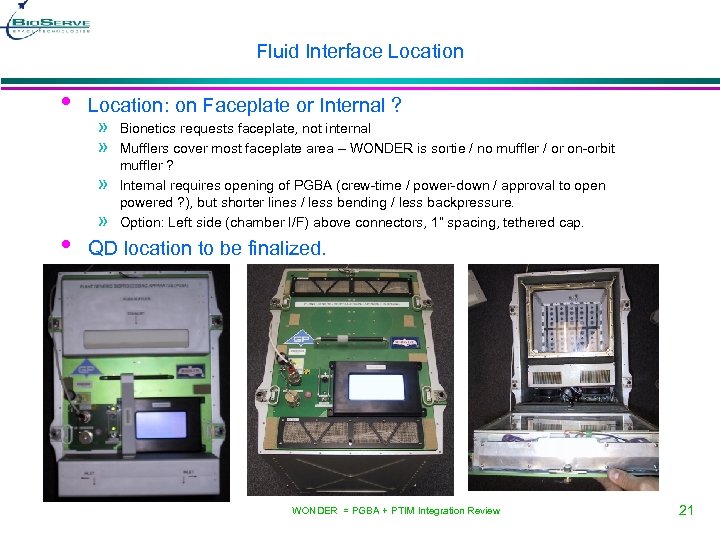

Fluid Interface Location • Location: on Faceplate or Internal ? » » » • » Bionetics requests faceplate, not internal Mufflers cover most faceplate area – WONDER is sortie / no muffler / or on-orbit muffler ? Internal requires opening of PGBA (crew-time / power-down / approval to open powered ? ), but shorter lines / less bending / less backpressure. Option: Left side (chamber I/F) above connectors, 1” spacing, tethered cap. QD location to be finalized. WONDER = PGBA + PTIM Integration Review 21

Fluid Interface Remaining Tasks: • QD Selection: » » • • Tubing Selection: » » » Tbd – materials compatibility / permeability \PhoebehardwarePGBAPressurized-SystemsTubing-Selection. doc \Phoebetransfertomtubing_writeup. doc Water Tank Installation: » » • Beswick (smallest, SS), Colter CPC (larger, PP). \PhoebehardwarePGBA 6 -WONDERPressurized. SystemsQDC_Comparison. xls Metallized bladder tank, 15 -25 psi ultimate, low water loss / diffusion. (APPLIED RESEARCH PRODUCTS LTD). \PhoebehardwarePGBA 6 -WONDERPressurized. SystemsSample_Bag_Options. doc Check Valve Selection: » \PhoebehardwarePGBA 6 -WONDERPressurized. SystemsCheck_Valve_Selection. doc WONDER = PGBA + PTIM Integration Review 22

GSE Updates for Remote Operations Operation of PGBA at Bionetics w/o Bio. Serve presence required updates and enhancements of PGBA mechanical, automation and operations GSE equipment, as well as improved procedures / training material: • Updated stand (mechanical interface, power supply). • Updated CO 2 supply (ISS/NSTS atmosphere simulation / enriched CO 2 supply, humidity control). • Updated operations, setup and checkout procedures. • Additional training and user manuals in preparation. • EGSE documentation and updates in progress (remote operation, commanding via KSC firewall, Bio. Serve/Bionetics dual login, …. • Webplots at: http: //bioserve-boulder. colorado. edu WONDER = PGBA + PTIM Integration Review 23

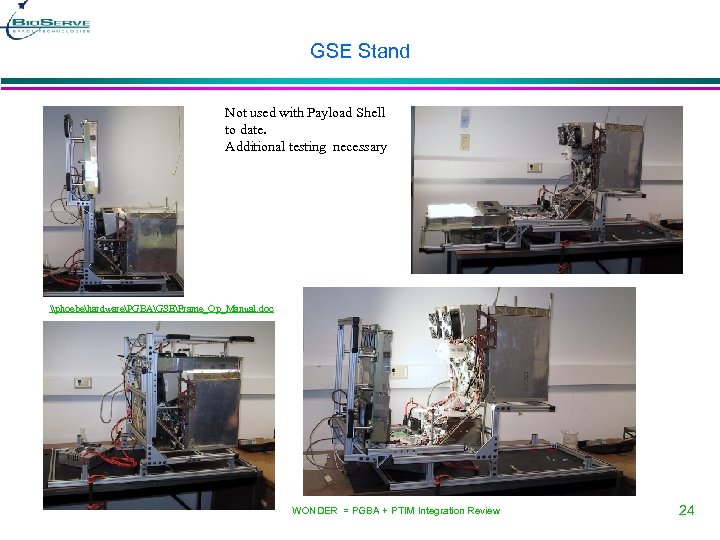

GSE Stand Not used with Payload Shell to date. Additional testing necessary \phoebehardwarePGBAGSEFrame_Op_Manual. doc WONDER = PGBA + PTIM Integration Review 24

Documentation Support • • Existing electronic documentation provided to Bionetics: » » » Includes PGBA 4: – Safety and Interface documentation and verifications. – Operational documents (crew and ground procedures, test procedures). Not all files are available electronically. Mechanical drawing package not provided. Need to Update (with PGBA delivery): » » » Updated electrical documentation. Updated plumbing documentation. Updated hazard reports (? ) – Plumbing / crew interface: Bionetics or Bio. Serve ? WONDER = PGBA + PTIM Integration Review 25

WONDER-Independent Upgrades Under Considerations • • • Install updated heat exchangers (enhanced corrosion protection). Install updated porous plate frame (enhanced thermal and seal performance). Investigate science data analysis enhancements » Rate of photosynthesis/respiration via draw-down and PWM flow rate. Investigate payload automation robustness enhancements: » Actuator failure detection (porous plate / NDS flow / pressure) » Fire detection updates via parameter monitoring as necessary. Update Atmosphere Treatment Performance Tests: » New GC testing. » Re-verified CO 2 scrubbing selection. » Re-verifying activated carbon selection. » Re-verifying ethylene scrubbing via UV-Ti. O 2 vs. KMn. O 4 / Purafil. WONDER = PGBA + PTIM Integration Review 26

Open Action Items – Phase 1 Bionetics Docs: Updates/Modifications to LSSC-WONDER-EIS: • Update new 5 V/12 V wiring (PTIM internal 5 V) (2. 2. 5, 2. 2. 6) • Update average and peak current draw numbers (3. 2. 1) • Update Connector P 1 Wire List (3. 2. 2) Bio. Serve Docs: Update PGBA-PTIM ICD: • Structures I/F (mass, C. G) • Mechanical I/F • Electrical Interface • Thermal Interface • S/W Interface Bio. Serve: Update Payload Schedule: • Project timeline. • Phase 2 Contract. WONDER = PGBA + PTIM Integration Review 27

Phase 2 Action Items • • • NDS Hydraulics Implementation. Electric Verification and checkout incl. video transmission. » Flight preparation: new switcher. Thermal testing with simulated PTIM load. Automation implementation incl. remote ops. support. HW handover preparation » » Replace limited life items as necessary for successful testing. Complete procedures and Bionetics training (test, setup, operate). WONDER = PGBA + PTIM Integration Review 28

06df24cf1ecfdab1ebe45d1da53b78d2.ppt