56d529e29ab0db21405023ab6868c5b9.ppt

- Количество слайдов: 81

With support from Go through Skip instructions and start (recommended)

With support from Go through Skip instructions and start (recommended)

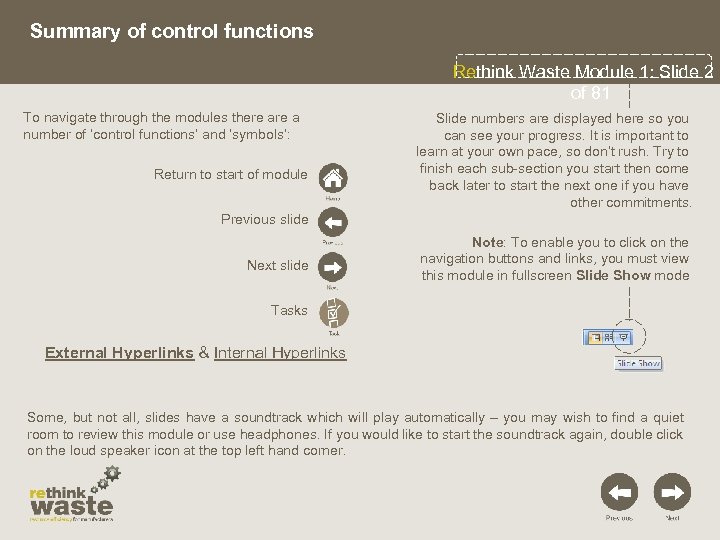

Summary of control functions Rethink Waste Module 1: Slide 2 of 81 To navigate through the modules there a number of ‘control functions’ and ‘symbols’: Return to start of module Slide numbers are displayed here so you can see your progress. It is important to learn at your own pace, so don’t rush. Try to finish each sub-section you start then come back later to start the next one if you have other commitments. Previous slide Next slide Note: To enable you to click on the navigation buttons and links, you must view this module in fullscreen Slide Show mode Tasks External Hyperlinks & Internal Hyperlinks Some, but not all, slides have a soundtrack which will play automatically – you may wish to find a quiet room to review this module or use headphones. If you would like to start the soundtrack again, double click on the loud speaker icon at the top left hand corner.

Summary of control functions Rethink Waste Module 1: Slide 2 of 81 To navigate through the modules there a number of ‘control functions’ and ‘symbols’: Return to start of module Slide numbers are displayed here so you can see your progress. It is important to learn at your own pace, so don’t rush. Try to finish each sub-section you start then come back later to start the next one if you have other commitments. Previous slide Next slide Note: To enable you to click on the navigation buttons and links, you must view this module in fullscreen Slide Show mode Tasks External Hyperlinks & Internal Hyperlinks Some, but not all, slides have a soundtrack which will play automatically – you may wish to find a quiet room to review this module or use headphones. If you would like to start the soundtrack again, double click on the loud speaker icon at the top left hand corner.

Objectives of Rethink Waste Module 1: Slide 3 of 81 After working through the three modules in this package you will: • Be familiar with the principles of resource efficiency • Appreciate the importance of prioritising resource efficiency improvements • Have learnt the key drivers for business resource efficiency and the importance of these to different people within your company • Be able to use a range of tried and tested techniques to identify business resource efficiency opportunities • Be capable of developing an Action Plan summarising key resource efficiency opportunities for your site • Be able to prioritise this Action Plan to help you achieve quick wins and continual improvement • Know where to go for further help/information/advice

Objectives of Rethink Waste Module 1: Slide 3 of 81 After working through the three modules in this package you will: • Be familiar with the principles of resource efficiency • Appreciate the importance of prioritising resource efficiency improvements • Have learnt the key drivers for business resource efficiency and the importance of these to different people within your company • Be able to use a range of tried and tested techniques to identify business resource efficiency opportunities • Be capable of developing an Action Plan summarising key resource efficiency opportunities for your site • Be able to prioritise this Action Plan to help you achieve quick wins and continual improvement • Know where to go for further help/information/advice

Rethink Waste modules Chapter 1 - Introduction Rethink Waste Module 1: Slide 4 of 81 In order to help you achieve these objectives, we have broken the training materials into : Module 1: Understanding Resource Efficiency & Establishing Your Baseline Module 2: Identifying cost and resource saving improvements & developing an Action Plan Module 3: How to prioritise your Action Plan and start implementing key measures You will also: • • Receive regular e-mails from the Rethink Waste team Be signposted to key publications and tools to help you apply what you learn Have access to a broad range of further information and tools via the Rethink webpage Have the opportunity to ask questions through the resource efficiency advice line --------------------------------------------------------------------------------Note: Throughout this initiative there will be references to Envirowise in the downloadable materials. Rethink Waste was run by Envirowise last year, but now WRAP are delivering this initiative as part of the single body on resource efficiency.

Rethink Waste modules Chapter 1 - Introduction Rethink Waste Module 1: Slide 4 of 81 In order to help you achieve these objectives, we have broken the training materials into : Module 1: Understanding Resource Efficiency & Establishing Your Baseline Module 2: Identifying cost and resource saving improvements & developing an Action Plan Module 3: How to prioritise your Action Plan and start implementing key measures You will also: • • Receive regular e-mails from the Rethink Waste team Be signposted to key publications and tools to help you apply what you learn Have access to a broad range of further information and tools via the Rethink webpage Have the opportunity to ask questions through the resource efficiency advice line --------------------------------------------------------------------------------Note: Throughout this initiative there will be references to Envirowise in the downloadable materials. Rethink Waste was run by Envirowise last year, but now WRAP are delivering this initiative as part of the single body on resource efficiency.

Rethink Waste is designed to help you improve the resource efficiency of your business Rethink Waste Module 1: Slide 5 of 81 Consider the following steps as the way to get started: • Identify resources you use and waste (Module 1) • Establish your baseline (Module 1) • Identify what resource efficiency options are available to you (Module 2) • Prepare an Action Plan (Module 2) • Prioritise your Action Plan (Module 3) • Measure, monitor and manage the implementation of your Action Plan (Module 3)

Rethink Waste is designed to help you improve the resource efficiency of your business Rethink Waste Module 1: Slide 5 of 81 Consider the following steps as the way to get started: • Identify resources you use and waste (Module 1) • Establish your baseline (Module 1) • Identify what resource efficiency options are available to you (Module 2) • Prepare an Action Plan (Module 2) • Prioritise your Action Plan (Module 3) • Measure, monitor and manage the implementation of your Action Plan (Module 3)

Rethink Waste Module 1: Establishing your Baseline Rethink Waste Module 1: Slide 6 of 81 This module will cover the following subjects: 1. Introduction 2. Drivers For Resource Efficiency 3. Establishing Your Baseline 4. Finding Data 5. Using your data effectively 6. Summary & Next Steps Use hyperlinks to move to a particular section. Otherwise click ‘Next’…. You can return to this page at any time by clicking ‘Home’

Rethink Waste Module 1: Establishing your Baseline Rethink Waste Module 1: Slide 6 of 81 This module will cover the following subjects: 1. Introduction 2. Drivers For Resource Efficiency 3. Establishing Your Baseline 4. Finding Data 5. Using your data effectively 6. Summary & Next Steps Use hyperlinks to move to a particular section. Otherwise click ‘Next’…. You can return to this page at any time by clicking ‘Home’

Rethink Waste Module 1: Slide 7 of 81 Introduction WASTE & RESOURCE EFFICIENCY

Rethink Waste Module 1: Slide 7 of 81 Introduction WASTE & RESOURCE EFFICIENCY

A quick introduction to waste – the facts Rethink Waste Module 1: Slide 8 of 81 WASTE FACTS • 600 million tonnes raw resources used by industry per year. • On average 93% production materials are never used in the final product. • 75 million tonnes of solid waste goes to landfill each year. • Cost £ 15 billion per year. • This is unsustainable, it’s uneconomic – we need to do something.

A quick introduction to waste – the facts Rethink Waste Module 1: Slide 8 of 81 WASTE FACTS • 600 million tonnes raw resources used by industry per year. • On average 93% production materials are never used in the final product. • 75 million tonnes of solid waste goes to landfill each year. • Cost £ 15 billion per year. • This is unsustainable, it’s uneconomic – we need to do something.

What is ‘resource efficiency’? Rethink Waste Module 1: Slide 9 of 81 Looking at eliminating or reducing the use of materials or utilities (energy and water) to make a process more efficient or eliminating/reducing or recycling waste from that process. Energy Materials Water

What is ‘resource efficiency’? Rethink Waste Module 1: Slide 9 of 81 Looking at eliminating or reducing the use of materials or utilities (energy and water) to make a process more efficient or eliminating/reducing or recycling waste from that process. Energy Materials Water

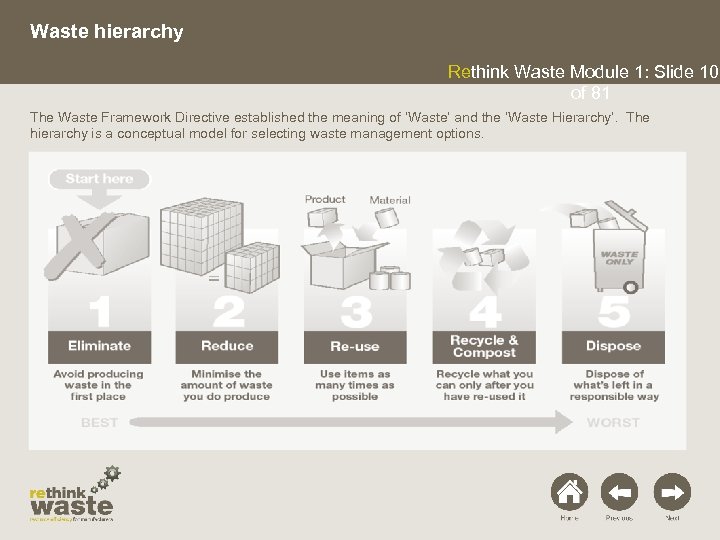

Waste hierarchy Rethink Waste Module 1: Slide 10 of 81 The Waste Framework Directive established the meaning of ‘Waste’ and the ‘Waste Hierarchy’. The hierarchy is a conceptual model for selecting waste management options.

Waste hierarchy Rethink Waste Module 1: Slide 10 of 81 The Waste Framework Directive established the meaning of ‘Waste’ and the ‘Waste Hierarchy’. The hierarchy is a conceptual model for selecting waste management options.

What does it mean? Rethink Waste Module 1: Slide 11 of 81 It is easy to gloss over the waste hierarchy without appreciating the meaning of ‘Eliminate’ ‘Reduce’ ‘Re-use’ ‘Recycle’ ‘Dispose’ Some examples of improvement options for each of the above for simple paper waste are highlighted in the next few slides together with details of the hidden costs you may incur if you do not apply these options…. .

What does it mean? Rethink Waste Module 1: Slide 11 of 81 It is easy to gloss over the waste hierarchy without appreciating the meaning of ‘Eliminate’ ‘Reduce’ ‘Re-use’ ‘Recycle’ ‘Dispose’ Some examples of improvement options for each of the above for simple paper waste are highlighted in the next few slides together with details of the hidden costs you may incur if you do not apply these options…. .

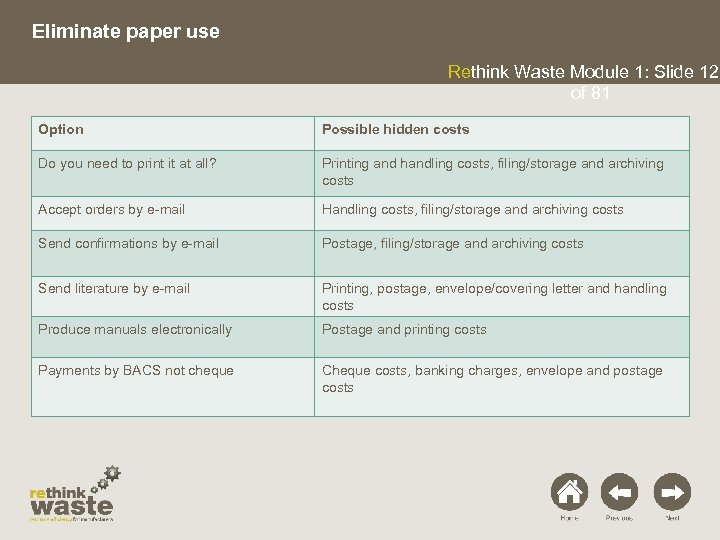

Eliminate paper use Rethink Waste Module 1: Slide 12 of 81 Option Possible hidden costs Do you need to print it at all? Printing and handling costs, filing/storage and archiving costs Accept orders by e-mail Handling costs, filing/storage and archiving costs Send confirmations by e-mail Postage, filing/storage and archiving costs Send literature by e-mail Printing, postage, envelope/covering letter and handling costs Produce manuals electronically Postage and printing costs Payments by BACS not cheque Cheque costs, banking charges, envelope and postage costs

Eliminate paper use Rethink Waste Module 1: Slide 12 of 81 Option Possible hidden costs Do you need to print it at all? Printing and handling costs, filing/storage and archiving costs Accept orders by e-mail Handling costs, filing/storage and archiving costs Send confirmations by e-mail Postage, filing/storage and archiving costs Send literature by e-mail Printing, postage, envelope/covering letter and handling costs Produce manuals electronically Postage and printing costs Payments by BACS not cheque Cheque costs, banking charges, envelope and postage costs

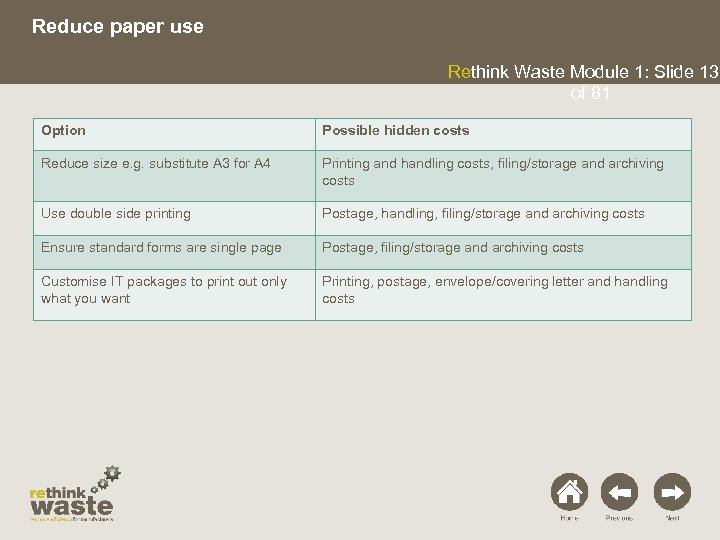

Reduce paper use Rethink Waste Module 1: Slide 13 of 81 Option Possible hidden costs Reduce size e. g. substitute A 3 for A 4 Printing and handling costs, filing/storage and archiving costs Use double side printing Postage, handling, filing/storage and archiving costs Ensure standard forms are single page Postage, filing/storage and archiving costs Customise IT packages to print out only what you want Printing, postage, envelope/covering letter and handling costs

Reduce paper use Rethink Waste Module 1: Slide 13 of 81 Option Possible hidden costs Reduce size e. g. substitute A 3 for A 4 Printing and handling costs, filing/storage and archiving costs Use double side printing Postage, handling, filing/storage and archiving costs Ensure standard forms are single page Postage, filing/storage and archiving costs Customise IT packages to print out only what you want Printing, postage, envelope/covering letter and handling costs

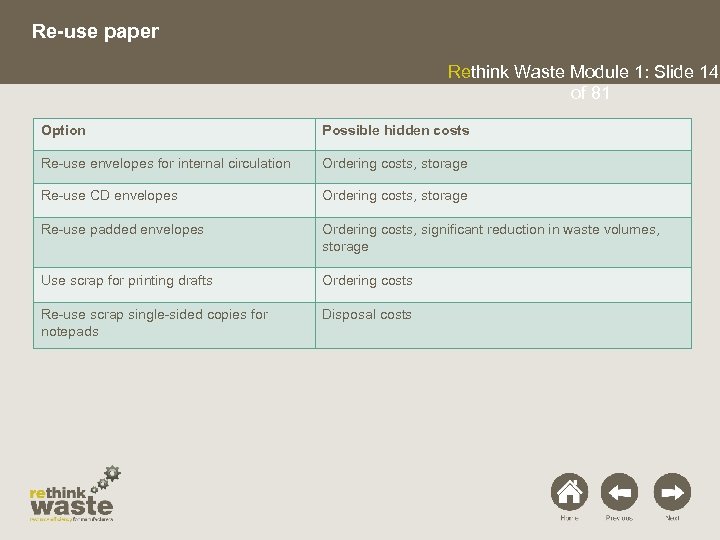

Re-use paper Rethink Waste Module 1: Slide 14 of 81 Option Possible hidden costs Re-use envelopes for internal circulation Ordering costs, storage Re-use CD envelopes Ordering costs, storage Re-use padded envelopes Ordering costs, significant reduction in waste volumes, storage Use scrap for printing drafts Ordering costs Re-use scrap single-sided copies for notepads Disposal costs

Re-use paper Rethink Waste Module 1: Slide 14 of 81 Option Possible hidden costs Re-use envelopes for internal circulation Ordering costs, storage Re-use CD envelopes Ordering costs, storage Re-use padded envelopes Ordering costs, significant reduction in waste volumes, storage Use scrap for printing drafts Ordering costs Re-use scrap single-sided copies for notepads Disposal costs

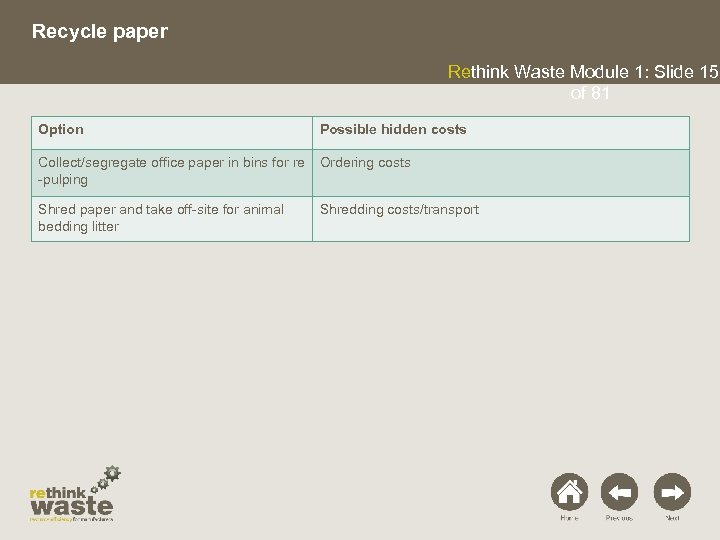

Recycle paper Rethink Waste Module 1: Slide 15 of 81 Option Possible hidden costs Collect/segregate office paper in bins for re -pulping Ordering costs Shred paper and take off-site for animal bedding litter Shredding costs/transport

Recycle paper Rethink Waste Module 1: Slide 15 of 81 Option Possible hidden costs Collect/segregate office paper in bins for re -pulping Ordering costs Shred paper and take off-site for animal bedding litter Shredding costs/transport

Become more resource efficient Rethink Waste Module 1: Slide 16 of 81 All companies should aim to eliminate waste from the outset, but if this is not practical or possible, then consider reducing, re-using or recycling waste. If none of these options can apply, then dispose of waste in a responsible manner. Envirowise has produced the guidance leaflet ‘Become More Resource Efficient’ to enable businesses to progress up the ‘waste hierarchy’ to reduce their waste and potentially achieve significant cost savings.

Become more resource efficient Rethink Waste Module 1: Slide 16 of 81 All companies should aim to eliminate waste from the outset, but if this is not practical or possible, then consider reducing, re-using or recycling waste. If none of these options can apply, then dispose of waste in a responsible manner. Envirowise has produced the guidance leaflet ‘Become More Resource Efficient’ to enable businesses to progress up the ‘waste hierarchy’ to reduce their waste and potentially achieve significant cost savings.

Denso video Case Study Rethink Waste Module 1: Slide 17 of 81 It’s fashionable and easy to say ‘improve resource efficiency’ – but what does it really mean? Envirowise has published a resource efficiency “Making More From Less” video case study for DENSO Manufacturing UK Limited. By applying a variety of waste reduction and re-use techniques to its manufacturing plant DENSO realised significant cost and environmental benefits including: • • • £ 172, 000 savings through energy efficiency improvements; £ 100, 000 savings by introducing a pallet reuse/re-sale scheme; £ 5, 000 reduction in hazardous waste disposal costs; 50% costs savings by amending lube oil supply method; 20% less hazardous waste generated.

Denso video Case Study Rethink Waste Module 1: Slide 17 of 81 It’s fashionable and easy to say ‘improve resource efficiency’ – but what does it really mean? Envirowise has published a resource efficiency “Making More From Less” video case study for DENSO Manufacturing UK Limited. By applying a variety of waste reduction and re-use techniques to its manufacturing plant DENSO realised significant cost and environmental benefits including: • • • £ 172, 000 savings through energy efficiency improvements; £ 100, 000 savings by introducing a pallet reuse/re-sale scheme; £ 5, 000 reduction in hazardous waste disposal costs; 50% costs savings by amending lube oil supply method; 20% less hazardous waste generated.

Rethink Waste Module 1: Slide 18 of 81 Drivers for Resource Efficiency WHY IT IS IMPORTANT FOR YOUR BUSINESS?

Rethink Waste Module 1: Slide 18 of 81 Drivers for Resource Efficiency WHY IT IS IMPORTANT FOR YOUR BUSINESS?

Why improve ‘resource efficiency’? Rethink Waste Module 1: Slide 19 of 81 Looking at ‘resource efficiency’ will help you to: • reduce the true cost of waste to your company; • determine the baseline against which to judge the progress of your resource efficiency improvements; • identify cost-effective opportunities to prevent and reduce waste; • control your services/processes more effectively; • set improvement objectives and targets; • measure progress towards your targets and set new ones.

Why improve ‘resource efficiency’? Rethink Waste Module 1: Slide 19 of 81 Looking at ‘resource efficiency’ will help you to: • reduce the true cost of waste to your company; • determine the baseline against which to judge the progress of your resource efficiency improvements; • identify cost-effective opportunities to prevent and reduce waste; • control your services/processes more effectively; • set improvement objectives and targets; • measure progress towards your targets and set new ones.

What are the drivers? Rethink Waste Module 1: Slide 20 of 81 Reducing waste is not the only incentive to using resources efficiently. The points below should also be considered: 1. company internal goals; It is also a 2. legislation; O P G P O 3. costs; L 4. reduce company’s environmental impact. D E Let’s just have a quick look at each of these …. N R T U N I T Y

What are the drivers? Rethink Waste Module 1: Slide 20 of 81 Reducing waste is not the only incentive to using resources efficiently. The points below should also be considered: 1. company internal goals; It is also a 2. legislation; O P G P O 3. costs; L 4. reduce company’s environmental impact. D E Let’s just have a quick look at each of these …. N R T U N I T Y

Company internal goals Rethink Waste Module 1: Slide 21 of 81 Implementing good environmental practice used to be considered a ‘fringe’ idea - now, most major FTSE 100 companies have environmental issues at the core of their business strategy because of: • image; • Corporate Social Responsibility; • Environmental Management Systems (ISO 14001, Eco-Management and Audit Scheme [EMAS], BS 8555 – Acorn/ Green Dragon/STEMS); • pressure groups; • marketing.

Company internal goals Rethink Waste Module 1: Slide 21 of 81 Implementing good environmental practice used to be considered a ‘fringe’ idea - now, most major FTSE 100 companies have environmental issues at the core of their business strategy because of: • image; • Corporate Social Responsibility; • Environmental Management Systems (ISO 14001, Eco-Management and Audit Scheme [EMAS], BS 8555 – Acorn/ Green Dragon/STEMS); • pressure groups; • marketing.

Legislation Rethink Waste Module 1: Slide 22 of 81 The main pieces of legislation directly affecting the way companies use resources and dispose of wastes are: Environmental Protection Act/Environmental Protection (Duty of Care) Regulations Integrated Pollution Prevention and Control Directive (Environmental/PPC Permitting) Producer Responsibility Obligations (Packaging Waste) Regulations/Packaging (Essential Requirements) Regulations Hazardous/Special Waste Regulations The Waste Electrical and Electronic Equipment Regulations Batteries Directive

Legislation Rethink Waste Module 1: Slide 22 of 81 The main pieces of legislation directly affecting the way companies use resources and dispose of wastes are: Environmental Protection Act/Environmental Protection (Duty of Care) Regulations Integrated Pollution Prevention and Control Directive (Environmental/PPC Permitting) Producer Responsibility Obligations (Packaging Waste) Regulations/Packaging (Essential Requirements) Regulations Hazardous/Special Waste Regulations The Waste Electrical and Electronic Equipment Regulations Batteries Directive

Costs Rethink Waste Module 1: Slide 23 of 81 ‘Resource Efficiency’ is not just an environmental initiative but an important business process that could potentially save your organisation a lot of money. Waste also costs money and by finding ways to reduce waste, your company could become more profitable. Did you know: – that waste and badly used resources can account for over 4% of business turnover? – that companies can save up to £ 1, 000 per employee by tackling their use of resources? – that most waste minimisation actions are simple low cost/no cost solutions?

Costs Rethink Waste Module 1: Slide 23 of 81 ‘Resource Efficiency’ is not just an environmental initiative but an important business process that could potentially save your organisation a lot of money. Waste also costs money and by finding ways to reduce waste, your company could become more profitable. Did you know: – that waste and badly used resources can account for over 4% of business turnover? – that companies can save up to £ 1, 000 per employee by tackling their use of resources? – that most waste minimisation actions are simple low cost/no cost solutions?

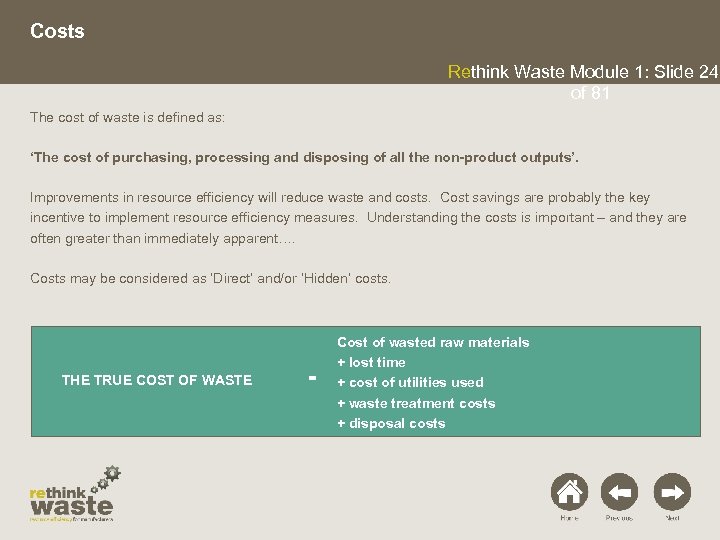

Costs Rethink Waste Module 1: Slide 24 of 81 The cost of waste is defined as: ‘The cost of purchasing, processing and disposing of all the non-product outputs’. Improvements in resource efficiency will reduce waste and costs. Cost savings are probably the key incentive to implement resource efficiency measures. Understanding the costs is important – and they are often greater than immediately apparent…. Costs may be considered as ‘Direct’ and/or ‘Hidden’ costs. THE TRUE COST OF WASTE = Cost of wasted raw materials + lost time + cost of utilities used + waste treatment costs + disposal costs

Costs Rethink Waste Module 1: Slide 24 of 81 The cost of waste is defined as: ‘The cost of purchasing, processing and disposing of all the non-product outputs’. Improvements in resource efficiency will reduce waste and costs. Cost savings are probably the key incentive to implement resource efficiency measures. Understanding the costs is important – and they are often greater than immediately apparent…. Costs may be considered as ‘Direct’ and/or ‘Hidden’ costs. THE TRUE COST OF WASTE = Cost of wasted raw materials + lost time + cost of utilities used + waste treatment costs + disposal costs

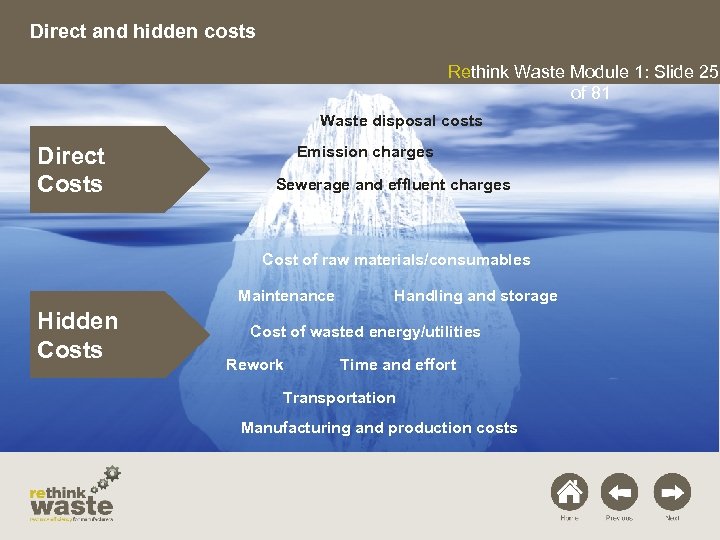

Direct and hidden costs Rethink Waste Module 1: Slide 25 of 81 Waste disposal costs Direct Costs Emission charges Sewerage and effluent charges Cost of raw materials/consumables Maintenance Hidden Costs Handling and storage Cost of wasted energy/utilities Rework Time and effort Transportation Manufacturing and production costs

Direct and hidden costs Rethink Waste Module 1: Slide 25 of 81 Waste disposal costs Direct Costs Emission charges Sewerage and effluent charges Cost of raw materials/consumables Maintenance Hidden Costs Handling and storage Cost of wasted energy/utilities Rework Time and effort Transportation Manufacturing and production costs

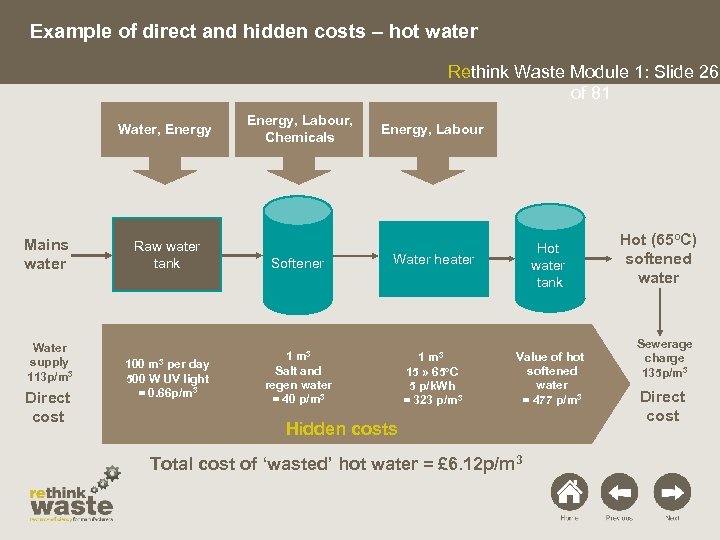

Example of direct and hidden costs – hot water Rethink Waste Module 1: Slide 26 of 81 Water, Energy Mains water Water supply 113 p/m 3 Direct cost Raw water tank 100 m 3 per day 500 W UV light = 0. 66 p/m 3 Energy, Labour, Chemicals Energy, Labour Softener Water heater Hot water tank 1 m 3 Salt and regen water = 40 p/m 3 15 » 65 o. C 5 p/k. Wh = 323 p/m 3 Value of hot softened water = 477 p/m 3 Hidden costs Total cost of ‘wasted’ hot water = £ 6. 12 p/m 3 Hot (65 o. C) softened water Sewerage charge 135 p/m 3 Direct cost

Example of direct and hidden costs – hot water Rethink Waste Module 1: Slide 26 of 81 Water, Energy Mains water Water supply 113 p/m 3 Direct cost Raw water tank 100 m 3 per day 500 W UV light = 0. 66 p/m 3 Energy, Labour, Chemicals Energy, Labour Softener Water heater Hot water tank 1 m 3 Salt and regen water = 40 p/m 3 15 » 65 o. C 5 p/k. Wh = 323 p/m 3 Value of hot softened water = 477 p/m 3 Hidden costs Total cost of ‘wasted’ hot water = £ 6. 12 p/m 3 Hot (65 o. C) softened water Sewerage charge 135 p/m 3 Direct cost

Direct costs Rethink Waste Module 1: Slide 27 of 81 Examples of ‘direct’ costs include: • waste handling storage and disposal costs; • utilities cost; • landfill Tax (currently 2009/10): • £ 2. 50/tonne (inert/inactive wastes); • £ 40/tonne (all other wastes). Together with actual disposal costs (eg transport, landfill charges etc) direct disposal costs can easily amount to £ 100 -120/tonne.

Direct costs Rethink Waste Module 1: Slide 27 of 81 Examples of ‘direct’ costs include: • waste handling storage and disposal costs; • utilities cost; • landfill Tax (currently 2009/10): • £ 2. 50/tonne (inert/inactive wastes); • £ 40/tonne (all other wastes). Together with actual disposal costs (eg transport, landfill charges etc) direct disposal costs can easily amount to £ 100 -120/tonne.

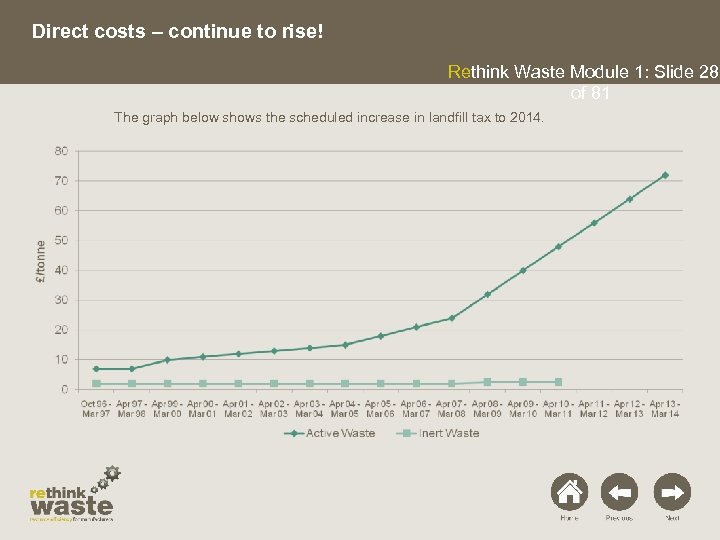

Direct costs – continue to rise! Rethink Waste Module 1: Slide 28 of 81 The graph below shows the scheduled increase in landfill tax to 2014.

Direct costs – continue to rise! Rethink Waste Module 1: Slide 28 of 81 The graph below shows the scheduled increase in landfill tax to 2014.

Hidden costs Rethink Waste Module 1: Slide 29 of 81 Examples of ‘hidden’ or ‘indirect’ costs include: • materials/energy; • effort; • added value – waste is not just the cost of discarded materials. It includes the cost of: – – – – wasted raw materials; rework; lost production time; excessive use of energy and water; loss of materials to atmosphere and to drain; waste treatment costs; wasted labour.

Hidden costs Rethink Waste Module 1: Slide 29 of 81 Examples of ‘hidden’ or ‘indirect’ costs include: • materials/energy; • effort; • added value – waste is not just the cost of discarded materials. It includes the cost of: – – – – wasted raw materials; rework; lost production time; excessive use of energy and water; loss of materials to atmosphere and to drain; waste treatment costs; wasted labour.

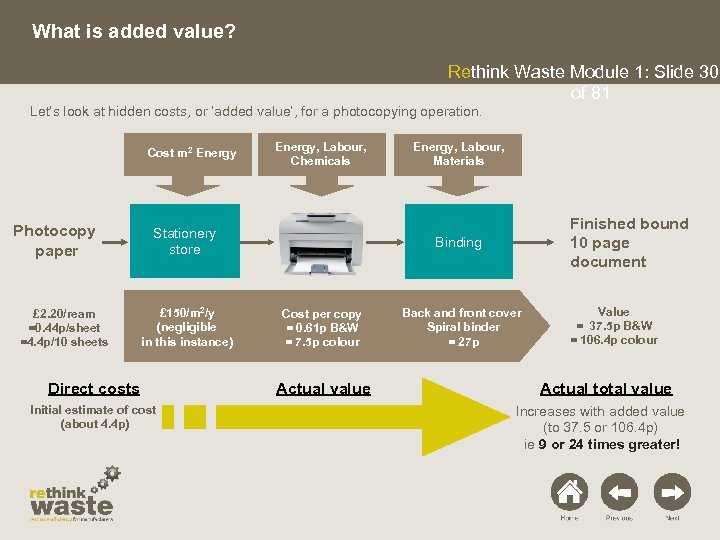

What is added value? Rethink Waste Module 1: Slide 30 of 81 Let’s look at hidden costs, or ‘added value’, for a photocopying operation. Cost m 2 Energy Photocopy paper £ 2. 20/ream =0. 44 p/sheet =4. 4 p/10 sheets Energy, Labour, Chemicals Stationery store £ 150/m 2/y (negligible in this instance) Direct costs Initial estimate of cost (about 4. 4 p) Energy, Labour, Materials Finished bound 10 page document Binding Cost per copy = 0. 61 p B&W = 7. 5 p colour Actual value Back and front cover Spiral binder = 27 p Value = 37. 5 p B&W = 106. 4 p colour Actual total value Increases with added value (to 37. 5 or 106. 4 p) ie 9 or 24 times greater!

What is added value? Rethink Waste Module 1: Slide 30 of 81 Let’s look at hidden costs, or ‘added value’, for a photocopying operation. Cost m 2 Energy Photocopy paper £ 2. 20/ream =0. 44 p/sheet =4. 4 p/10 sheets Energy, Labour, Chemicals Stationery store £ 150/m 2/y (negligible in this instance) Direct costs Initial estimate of cost (about 4. 4 p) Energy, Labour, Materials Finished bound 10 page document Binding Cost per copy = 0. 61 p B&W = 7. 5 p colour Actual value Back and front cover Spiral binder = 27 p Value = 37. 5 p B&W = 106. 4 p colour Actual total value Increases with added value (to 37. 5 or 106. 4 p) ie 9 or 24 times greater!

Reduce environmental impact Rethink Waste Module 1: Slide 31 of 81 Pressure may come from internal or external sources to reduce environmental impact. • • Staff Pressure groups (e. g. Greenpeace/Friends of the Earth) Local residents Local authorities and planning The Envirowise Indicator is an interactive webbased tool designed to allow all UK businesses, irrespective of their size or industry sector, to gain a useful indication of their company’s environmental impact and the financial savings that can be made by addressing it.

Reduce environmental impact Rethink Waste Module 1: Slide 31 of 81 Pressure may come from internal or external sources to reduce environmental impact. • • Staff Pressure groups (e. g. Greenpeace/Friends of the Earth) Local residents Local authorities and planning The Envirowise Indicator is an interactive webbased tool designed to allow all UK businesses, irrespective of their size or industry sector, to gain a useful indication of their company’s environmental impact and the financial savings that can be made by addressing it.

Rethink Waste Module 1: Slide 32 of 81 Establishing Your Baseline WASTE MAPPING

Rethink Waste Module 1: Slide 32 of 81 Establishing Your Baseline WASTE MAPPING

Understanding your site Rethink Waste Module 1: Slide 33 of 81 Whether your site is large or small, it is often difficult to grasp the true ‘picture’ of waste – particularly when considering ‘waste’ in the wider context. An initial review to develop a ‘waste map’ can help in gathering basic information and understanding: • • Walk around your site looking for areas of waste and potential improvement; Take photographs; Talk to key people in all departments; Gather information on amounts and costs for raw materials, utilities and wastes; Estimate the potential savings associated with a few of the more promising opportunities to reduce resource use; Identify gaps in your data; and Start thinking about how to address them. The following slides will take you through the process of developing a waste map. However, more detailed guidance is available in the Envirowise Guide ‘Waste Mapping: Your Route To More Profit’.

Understanding your site Rethink Waste Module 1: Slide 33 of 81 Whether your site is large or small, it is often difficult to grasp the true ‘picture’ of waste – particularly when considering ‘waste’ in the wider context. An initial review to develop a ‘waste map’ can help in gathering basic information and understanding: • • Walk around your site looking for areas of waste and potential improvement; Take photographs; Talk to key people in all departments; Gather information on amounts and costs for raw materials, utilities and wastes; Estimate the potential savings associated with a few of the more promising opportunities to reduce resource use; Identify gaps in your data; and Start thinking about how to address them. The following slides will take you through the process of developing a waste map. However, more detailed guidance is available in the Envirowise Guide ‘Waste Mapping: Your Route To More Profit’.

Who should I involve? Rethink Waste Module 1: Slide 34 of 81 Where practicable, it is best to consult a team that includes: 1. the environmental, quality, health and safety manager(s); 2. the manufacturing and product development manager(s); 3. appropriate shop-floor staff (who often know the process best); 4. the procurement and purchasing manager(s); 5. suppliers and customers.

Who should I involve? Rethink Waste Module 1: Slide 34 of 81 Where practicable, it is best to consult a team that includes: 1. the environmental, quality, health and safety manager(s); 2. the manufacturing and product development manager(s); 3. appropriate shop-floor staff (who often know the process best); 4. the procurement and purchasing manager(s); 5. suppliers and customers.

Getting staff involved Rethink Waste Module 1: Slide 35 of 81 Key to getting peer buy-in to your ‘resource efficiency’ improvement is involvement and empowerment. The points below are things you should consider: • Involvement – eg brainstorming sessions. • Create a positive climate to identify opportunities. • Develop new performance measures. • Encourage thoughts about environmental effects. • Important message to get across is ‘How will they benefit? ’.

Getting staff involved Rethink Waste Module 1: Slide 35 of 81 Key to getting peer buy-in to your ‘resource efficiency’ improvement is involvement and empowerment. The points below are things you should consider: • Involvement – eg brainstorming sessions. • Create a positive climate to identify opportunities. • Develop new performance measures. • Encourage thoughts about environmental effects. • Important message to get across is ‘How will they benefit? ’.

Brainstorming Rethink Waste Module 1: Slide 36 of 81 Often brainstorming descends into a situation where only the extrovert (or thick-skinned!) get to put forward their ideas. During your brainstorming sessions establish rules such as: • • No criticism or debate/editing; Be creative (encourage wild or exaggerated ideas); Quantity rather than quality; Build on and combine ideas. To ensure you obtain all contributions (whatever they may be and from whomever) make sure: • • everyone has a chance to participate; everyone is thinking about the same problem; all ideas are encouraged; all ideas are recorded. Otherwise it’s not brainstorming!

Brainstorming Rethink Waste Module 1: Slide 36 of 81 Often brainstorming descends into a situation where only the extrovert (or thick-skinned!) get to put forward their ideas. During your brainstorming sessions establish rules such as: • • No criticism or debate/editing; Be creative (encourage wild or exaggerated ideas); Quantity rather than quality; Build on and combine ideas. To ensure you obtain all contributions (whatever they may be and from whomever) make sure: • • everyone has a chance to participate; everyone is thinking about the same problem; all ideas are encouraged; all ideas are recorded. Otherwise it’s not brainstorming!

What should I look out for? Rethink Waste Module 1: Slide 37 of 81 Particularly wasteful processes, such as: • off-cuts or discarded packaging; • water running down the drains; • unnecessary heating or lighting. Start by noting the obvious. Look into less obvious wastes later. A checklist is available to help you Waste Checklist

What should I look out for? Rethink Waste Module 1: Slide 37 of 81 Particularly wasteful processes, such as: • off-cuts or discarded packaging; • water running down the drains; • unnecessary heating or lighting. Start by noting the obvious. Look into less obvious wastes later. A checklist is available to help you Waste Checklist

What do I do with all this information? Rethink Waste Module 1: Slide 38 of 81 Develop a ‘waste map’! It’s not complicated and a waste map will allow you to manage the majority of the information you gather in a clear and explanatory way. The only exception may be costs. Costs may not ‘fit’ exactly on a waste map – they may apply to a collection of wastes or be a bill for site wide supply. If costs cannot be entered on a waste map keep the information available elsewhere – perhaps start a cost file. Download a copy of the waste map template To develop a waste map we recommend that you initially produce a flow chart representing your site activities so you can assign all the information you find to the relevant area or department. Process Map

What do I do with all this information? Rethink Waste Module 1: Slide 38 of 81 Develop a ‘waste map’! It’s not complicated and a waste map will allow you to manage the majority of the information you gather in a clear and explanatory way. The only exception may be costs. Costs may not ‘fit’ exactly on a waste map – they may apply to a collection of wastes or be a bill for site wide supply. If costs cannot be entered on a waste map keep the information available elsewhere – perhaps start a cost file. Download a copy of the waste map template To develop a waste map we recommend that you initially produce a flow chart representing your site activities so you can assign all the information you find to the relevant area or department. Process Map

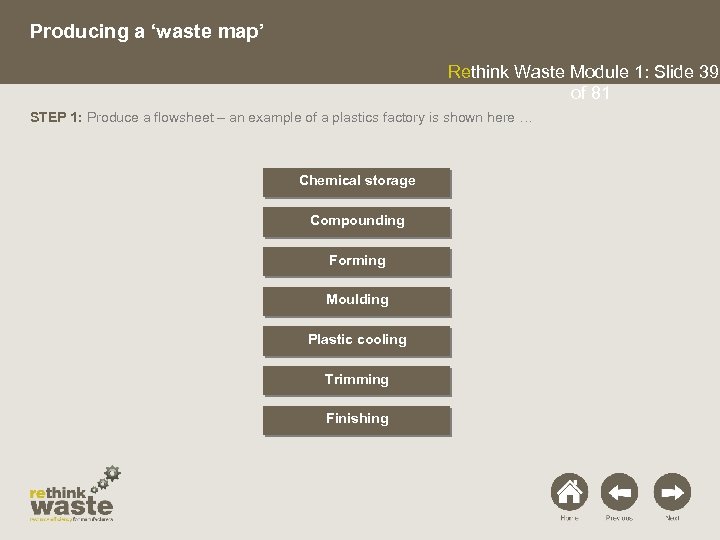

Producing a ‘waste map’ Rethink Waste Module 1: Slide 39 of 81 STEP 1: Produce a flowsheet – an example of a plastics factory is shown here … Chemical storage Compounding Forming Moulding Plastic cooling Trimming Finishing

Producing a ‘waste map’ Rethink Waste Module 1: Slide 39 of 81 STEP 1: Produce a flowsheet – an example of a plastics factory is shown here … Chemical storage Compounding Forming Moulding Plastic cooling Trimming Finishing

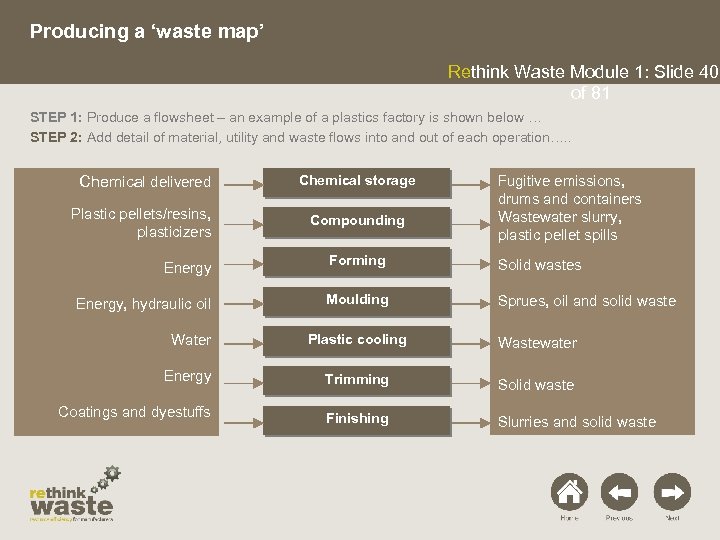

Producing a ‘waste map’ Rethink Waste Module 1: Slide 40 of 81 STEP 1: Produce a flowsheet – an example of a plastics factory is shown below … STEP 2: Add detail of material, utility and waste flows into and out of each operation…. . Chemical delivered Chemical storage Plastic pellets/resins, plasticizers Compounding Energy, hydraulic oil Fugitive emissions, drums and containers Wastewater slurry, plastic pellet spills Forming Solid wastes Moulding Sprues, oil and solid waste Water Plastic cooling Wastewater Energy Trimming Solid waste Coatings and dyestuffs Finishing Slurries and solid waste

Producing a ‘waste map’ Rethink Waste Module 1: Slide 40 of 81 STEP 1: Produce a flowsheet – an example of a plastics factory is shown below … STEP 2: Add detail of material, utility and waste flows into and out of each operation…. . Chemical delivered Chemical storage Plastic pellets/resins, plasticizers Compounding Energy, hydraulic oil Fugitive emissions, drums and containers Wastewater slurry, plastic pellet spills Forming Solid wastes Moulding Sprues, oil and solid waste Water Plastic cooling Wastewater Energy Trimming Solid waste Coatings and dyestuffs Finishing Slurries and solid waste

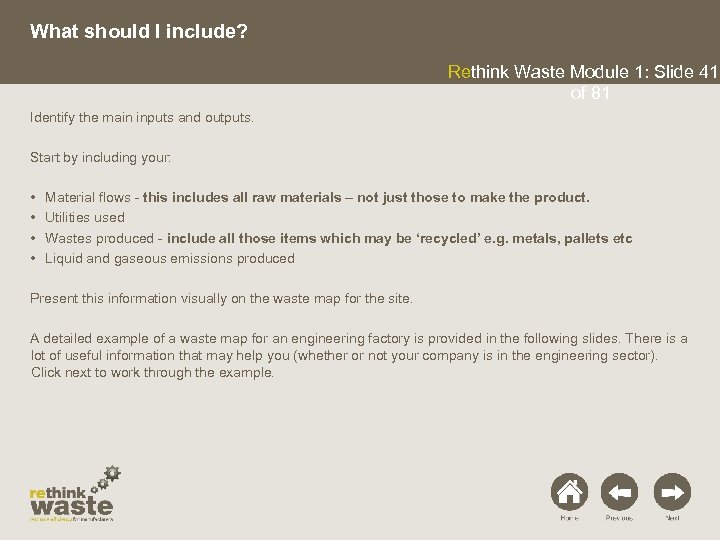

What should I include? Rethink Waste Module 1: Slide 41 of 81 Identify the main inputs and outputs. Start by including your: • • Material flows - this includes all raw materials – not just those to make the product. Utilities used Wastes produced - include all those items which may be ‘recycled’ e. g. metals, pallets etc Liquid and gaseous emissions produced Present this information visually on the waste map for the site. A detailed example of a waste map for an engineering factory is provided in the following slides. There is a lot of useful information that may help you (whether or not your company is in the engineering sector). Click next to work through the example.

What should I include? Rethink Waste Module 1: Slide 41 of 81 Identify the main inputs and outputs. Start by including your: • • Material flows - this includes all raw materials – not just those to make the product. Utilities used Wastes produced - include all those items which may be ‘recycled’ e. g. metals, pallets etc Liquid and gaseous emissions produced Present this information visually on the waste map for the site. A detailed example of a waste map for an engineering factory is provided in the following slides. There is a lot of useful information that may help you (whether or not your company is in the engineering sector). Click next to work through the example.

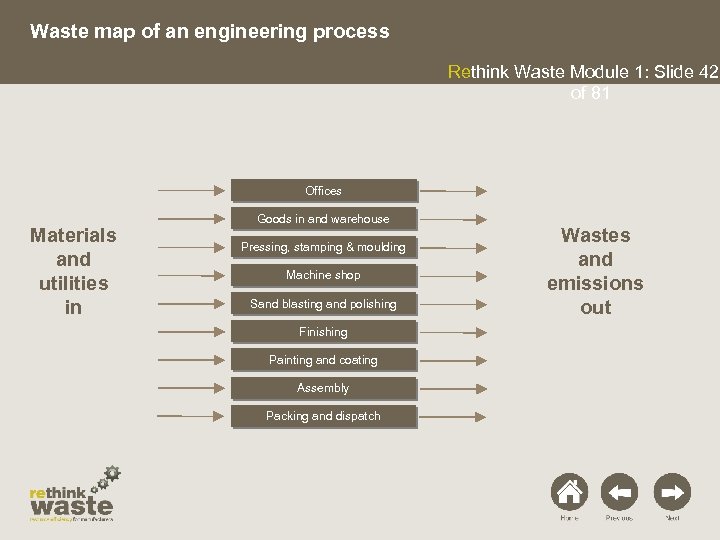

Waste map of an engineering process Rethink Waste Module 1: Slide 42 of 81 Offices Materials and utilities in Goods in and warehouse Pressing, stamping & moulding Machine shop Sand blasting and polishing Finishing Painting and coating Assembly Packing and dispatch Wastes and emissions out

Waste map of an engineering process Rethink Waste Module 1: Slide 42 of 81 Offices Materials and utilities in Goods in and warehouse Pressing, stamping & moulding Machine shop Sand blasting and polishing Finishing Painting and coating Assembly Packing and dispatch Wastes and emissions out

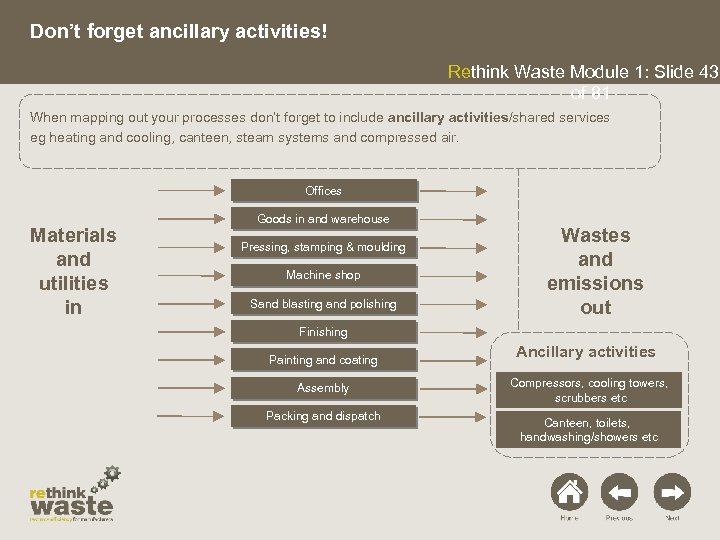

Don’t forget ancillary activities! Rethink Waste Module 1: Slide 43 of 81 When mapping out your processes don’t forget to include ancillary activities/shared services eg heating and cooling, canteen, steam systems and compressed air. Offices Materials and utilities in Goods in and warehouse Pressing, stamping & moulding Machine shop Sand blasting and polishing Wastes and emissions out Finishing Painting and coating Assembly Packing and dispatch Ancillary activities Compressors, cooling towers, scrubbers etc Canteen, toilets, handwashing/showers etc

Don’t forget ancillary activities! Rethink Waste Module 1: Slide 43 of 81 When mapping out your processes don’t forget to include ancillary activities/shared services eg heating and cooling, canteen, steam systems and compressed air. Offices Materials and utilities in Goods in and warehouse Pressing, stamping & moulding Machine shop Sand blasting and polishing Wastes and emissions out Finishing Painting and coating Assembly Packing and dispatch Ancillary activities Compressors, cooling towers, scrubbers etc Canteen, toilets, handwashing/showers etc

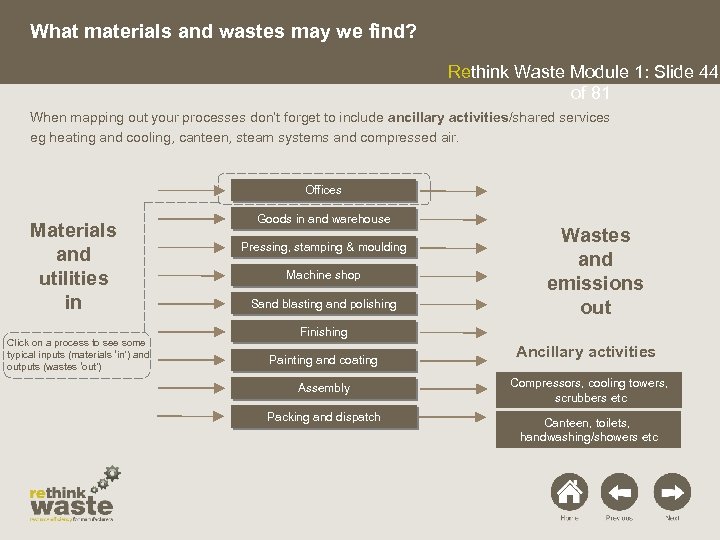

What materials and wastes may we find? Rethink Waste Module 1: Slide 44 of 81 When mapping out your processes don’t forget to include ancillary activities/shared services eg heating and cooling, canteen, steam systems and compressed air. Offices Materials and utilities in Click on a process to see some typical inputs (materials ‘in’) and outputs (wastes ‘out’) Goods in and warehouse Pressing, stamping & moulding Machine shop Sand blasting and polishing Wastes and emissions out Finishing Painting and coating Assembly Packing and dispatch Ancillary activities Compressors, cooling towers, scrubbers etc Canteen, toilets, handwashing/showers etc

What materials and wastes may we find? Rethink Waste Module 1: Slide 44 of 81 When mapping out your processes don’t forget to include ancillary activities/shared services eg heating and cooling, canteen, steam systems and compressed air. Offices Materials and utilities in Click on a process to see some typical inputs (materials ‘in’) and outputs (wastes ‘out’) Goods in and warehouse Pressing, stamping & moulding Machine shop Sand blasting and polishing Wastes and emissions out Finishing Painting and coating Assembly Packing and dispatch Ancillary activities Compressors, cooling towers, scrubbers etc Canteen, toilets, handwashing/showers etc

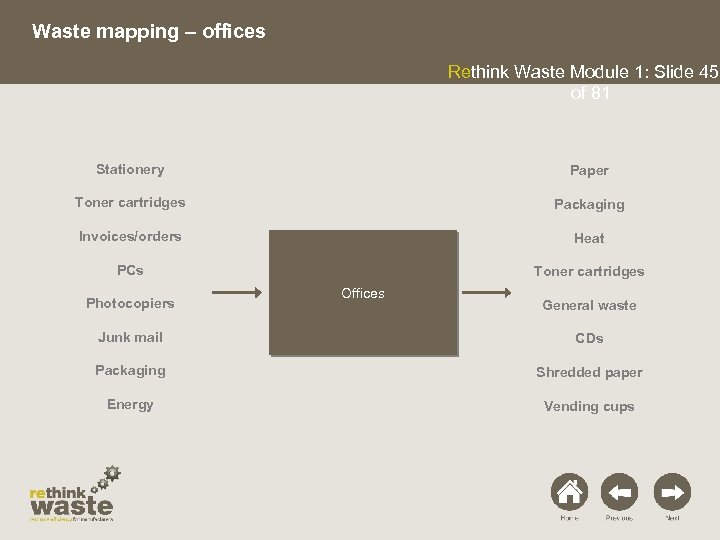

Waste mapping – offices Rethink Waste Module 1: Slide 45 of 81 Stationery Paper Toner cartridges Packaging Invoices/orders Heat PCs Toner cartridges Photocopiers Offices General waste Junk mail CDs Packaging Shredded paper Energy Vending cups

Waste mapping – offices Rethink Waste Module 1: Slide 45 of 81 Stationery Paper Toner cartridges Packaging Invoices/orders Heat PCs Toner cartridges Photocopiers Offices General waste Junk mail CDs Packaging Shredded paper Energy Vending cups

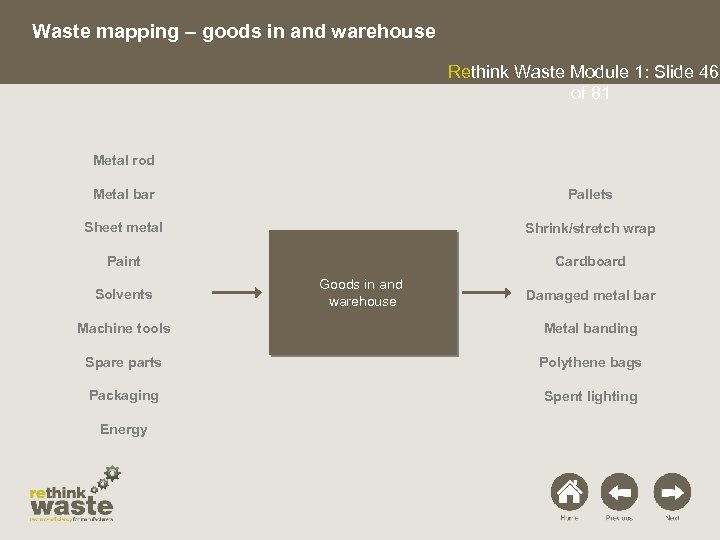

Waste mapping – goods in and warehouse Rethink Waste Module 1: Slide 46 of 81 Metal rod Metal bar Pallets Sheet metal Shrink/stretch wrap Paint Cardboard Solvents Goods in and warehouse Damaged metal bar Machine tools Metal banding Spare parts Polythene bags Packaging Spent lighting Energy

Waste mapping – goods in and warehouse Rethink Waste Module 1: Slide 46 of 81 Metal rod Metal bar Pallets Sheet metal Shrink/stretch wrap Paint Cardboard Solvents Goods in and warehouse Damaged metal bar Machine tools Metal banding Spare parts Polythene bags Packaging Spent lighting Energy

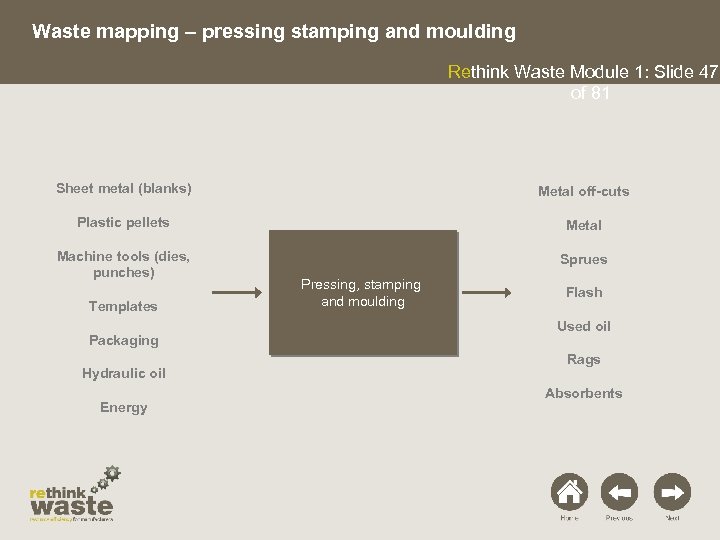

Waste mapping – pressing stamping and moulding Rethink Waste Module 1: Slide 47 of 81 Sheet metal (blanks) Metal off-cuts Plastic pellets Metal Machine tools (dies, punches) Sprues Templates Packaging Hydraulic oil Energy Pressing, stamping and moulding Flash Used oil Rags Absorbents

Waste mapping – pressing stamping and moulding Rethink Waste Module 1: Slide 47 of 81 Sheet metal (blanks) Metal off-cuts Plastic pellets Metal Machine tools (dies, punches) Sprues Templates Packaging Hydraulic oil Energy Pressing, stamping and moulding Flash Used oil Rags Absorbents

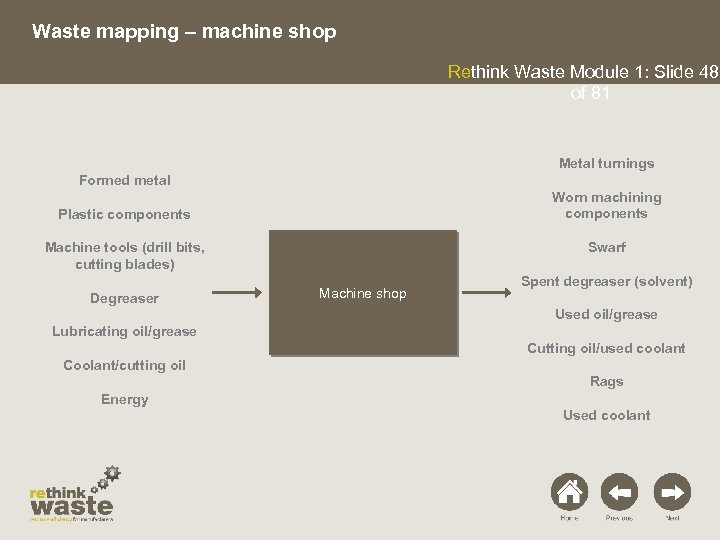

Waste mapping – machine shop Rethink Waste Module 1: Slide 48 of 81 Metal turnings Formed metal Worn machining components Plastic components Swarf Machine tools (drill bits, cutting blades) Degreaser Machine shop Spent degreaser (solvent) Used oil/grease Lubricating oil/grease Cutting oil/used coolant Coolant/cutting oil Rags Energy Used coolant

Waste mapping – machine shop Rethink Waste Module 1: Slide 48 of 81 Metal turnings Formed metal Worn machining components Plastic components Swarf Machine tools (drill bits, cutting blades) Degreaser Machine shop Spent degreaser (solvent) Used oil/grease Lubricating oil/grease Cutting oil/used coolant Coolant/cutting oil Rags Energy Used coolant

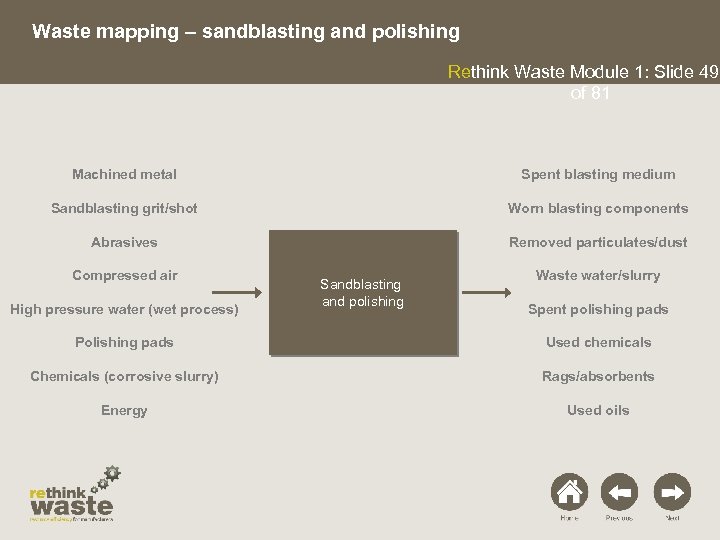

Waste mapping – sandblasting and polishing Rethink Waste Module 1: Slide 49 of 81 Machined metal Spent blasting medium Sandblasting grit/shot Worn blasting components Abrasives Removed particulates/dust Compressed air High pressure water (wet process) Sandblasting and polishing Waste water/slurry Spent polishing pads Polishing pads Used chemicals Chemicals (corrosive slurry) Rags/absorbents Energy Used oils

Waste mapping – sandblasting and polishing Rethink Waste Module 1: Slide 49 of 81 Machined metal Spent blasting medium Sandblasting grit/shot Worn blasting components Abrasives Removed particulates/dust Compressed air High pressure water (wet process) Sandblasting and polishing Waste water/slurry Spent polishing pads Polishing pads Used chemicals Chemicals (corrosive slurry) Rags/absorbents Energy Used oils

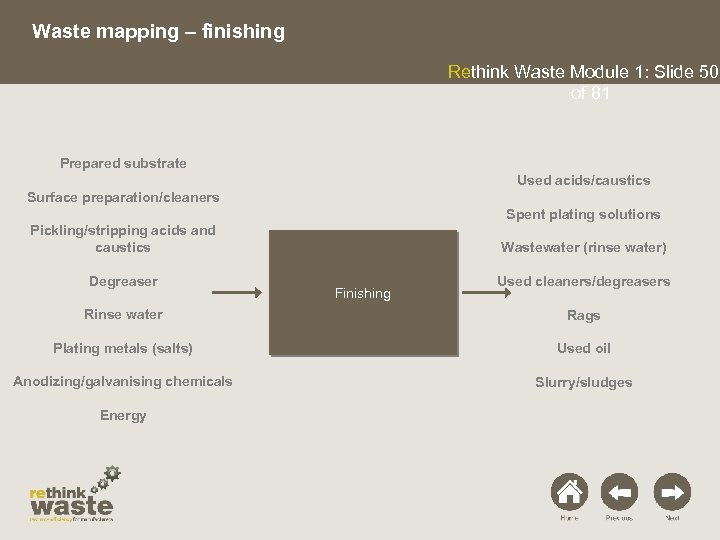

Waste mapping – finishing Rethink Waste Module 1: Slide 50 of 81 Prepared substrate Used acids/caustics Surface preparation/cleaners Spent plating solutions Pickling/stripping acids and caustics Degreaser Wastewater (rinse water) Finishing Used cleaners/degreasers Rinse water Rags Plating metals (salts) Used oil Anodizing/galvanising chemicals Slurry/sludges Energy

Waste mapping – finishing Rethink Waste Module 1: Slide 50 of 81 Prepared substrate Used acids/caustics Surface preparation/cleaners Spent plating solutions Pickling/stripping acids and caustics Degreaser Wastewater (rinse water) Finishing Used cleaners/degreasers Rinse water Rags Plating metals (salts) Used oil Anodizing/galvanising chemicals Slurry/sludges Energy

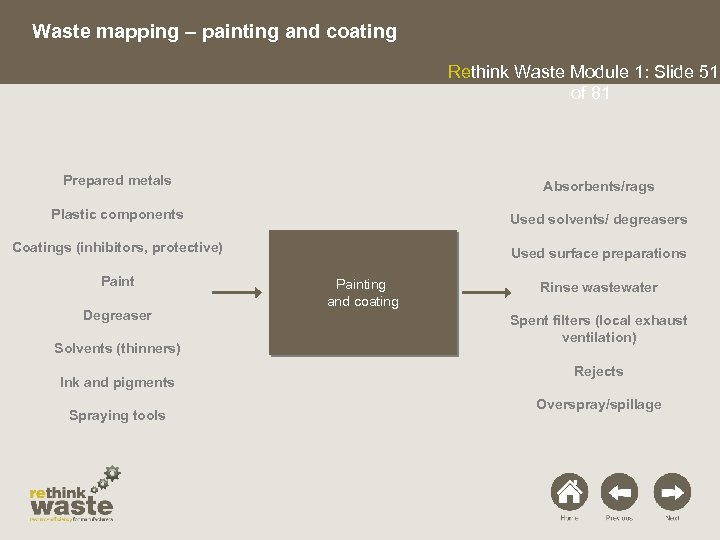

Waste mapping – painting and coating Rethink Waste Module 1: Slide 51 of 81 Prepared metals Absorbents/rags Plastic components Used solvents/ degreasers Coatings (inhibitors, protective) Used surface preparations Paint Degreaser Solvents (thinners) Ink and pigments Spraying tools Painting and coating Rinse wastewater Spent filters (local exhaust ventilation) Rejects Overspray/spillage

Waste mapping – painting and coating Rethink Waste Module 1: Slide 51 of 81 Prepared metals Absorbents/rags Plastic components Used solvents/ degreasers Coatings (inhibitors, protective) Used surface preparations Paint Degreaser Solvents (thinners) Ink and pigments Spraying tools Painting and coating Rinse wastewater Spent filters (local exhaust ventilation) Rejects Overspray/spillage

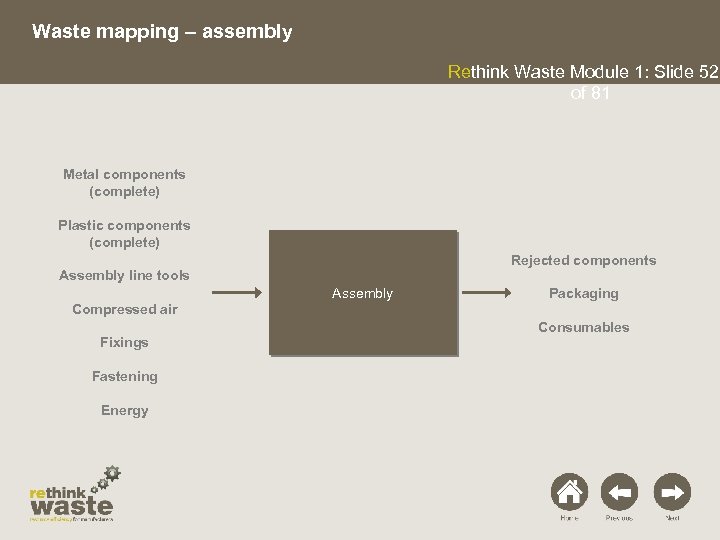

Waste mapping – assembly Rethink Waste Module 1: Slide 52 of 81 Metal components (complete) Plastic components (complete) Rejected components Assembly line tools Assembly Packaging Compressed air Consumables Fixings Fastening Energy

Waste mapping – assembly Rethink Waste Module 1: Slide 52 of 81 Metal components (complete) Plastic components (complete) Rejected components Assembly line tools Assembly Packaging Compressed air Consumables Fixings Fastening Energy

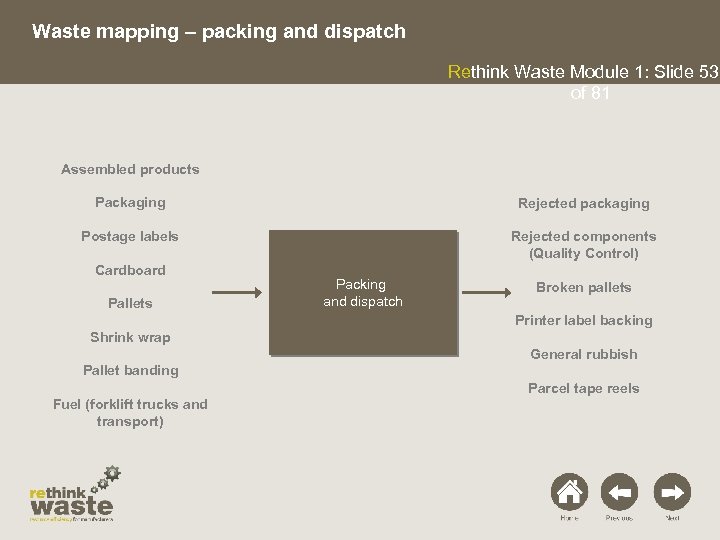

Waste mapping – packing and dispatch Rethink Waste Module 1: Slide 53 of 81 Assembled products Packaging Rejected packaging Postage labels Rejected components (Quality Control) Cardboard Pallets Packing and dispatch Broken pallets Printer label backing Shrink wrap General rubbish Pallet banding Parcel tape reels Fuel (forklift trucks and transport)

Waste mapping – packing and dispatch Rethink Waste Module 1: Slide 53 of 81 Assembled products Packaging Rejected packaging Postage labels Rejected components (Quality Control) Cardboard Pallets Packing and dispatch Broken pallets Printer label backing Shrink wrap General rubbish Pallet banding Parcel tape reels Fuel (forklift trucks and transport)

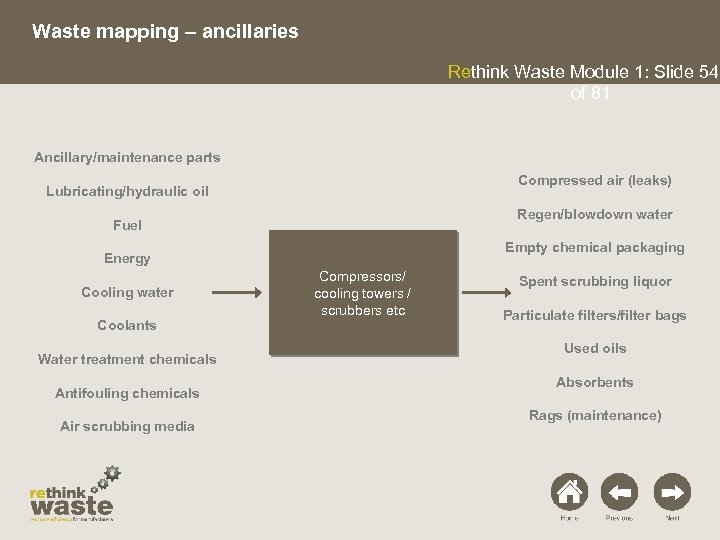

Waste mapping – ancillaries Rethink Waste Module 1: Slide 54 of 81 Ancillary/maintenance parts Compressed air (leaks) Lubricating/hydraulic oil Regen/blowdown water Fuel Empty chemical packaging Energy Cooling water Coolants Water treatment chemicals Antifouling chemicals Air scrubbing media Compressors/ cooling towers / scrubbers etc Spent scrubbing liquor Particulate filters/filter bags Used oils Absorbents Rags (maintenance)

Waste mapping – ancillaries Rethink Waste Module 1: Slide 54 of 81 Ancillary/maintenance parts Compressed air (leaks) Lubricating/hydraulic oil Regen/blowdown water Fuel Empty chemical packaging Energy Cooling water Coolants Water treatment chemicals Antifouling chemicals Air scrubbing media Compressors/ cooling towers / scrubbers etc Spent scrubbing liquor Particulate filters/filter bags Used oils Absorbents Rags (maintenance)

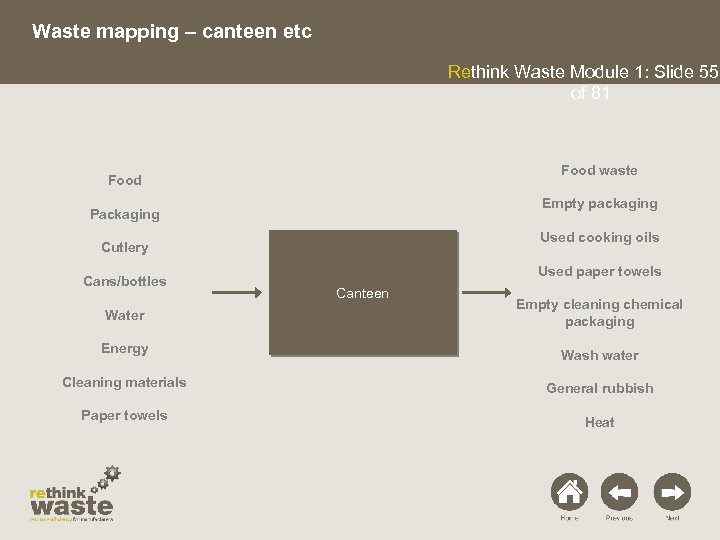

Waste mapping – canteen etc Rethink Waste Module 1: Slide 55 of 81 Food waste Food Empty packaging Packaging Used cooking oils Cutlery Cans/bottles Used paper towels Canteen Water Empty cleaning chemical packaging Energy Wash water Cleaning materials General rubbish Paper towels Heat

Waste mapping – canteen etc Rethink Waste Module 1: Slide 55 of 81 Food waste Food Empty packaging Packaging Used cooking oils Cutlery Cans/bottles Used paper towels Canteen Water Empty cleaning chemical packaging Energy Wash water Cleaning materials General rubbish Paper towels Heat

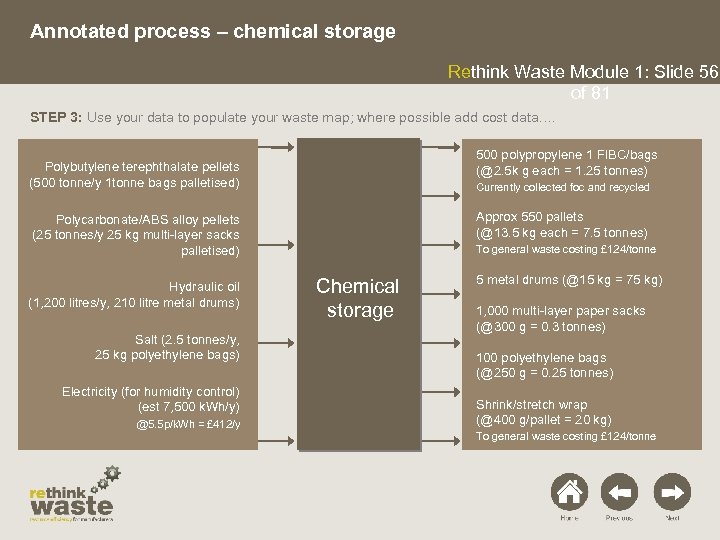

Annotated process – chemical storage Rethink Waste Module 1: Slide 56 of 81 STEP 3: Use your data to populate your waste map; where possible add cost data…. 500 polypropylene 1 FIBC/bags (@2. 5 k g each = 1. 25 tonnes) Polybutylene terephthalate pellets (500 tonne/y 1 tonne bags palletised) Currently collected foc and recycled Approx 550 pallets (@13. 5 kg each = 7. 5 tonnes) Polycarbonate/ABS alloy pellets (25 tonnes/y 25 kg multi-layer sacks palletised) Hydraulic oil (1, 200 litres/y, 210 litre metal drums) Salt (2. 5 tonnes/y, 25 kg polyethylene bags) Electricity (for humidity control) (est 7, 500 k. Wh/y) @5. 5 p/k. Wh = £ 412/y To general waste costing £ 124/tonne Chemical storage 5 metal drums (@15 kg = 75 kg) 1, 000 multi-layer paper sacks (@300 g = 0. 3 tonnes) 100 polyethylene bags (@250 g = 0. 25 tonnes) Shrink/stretch wrap (@400 g/pallet = 20 kg) To general waste costing £ 124/tonne

Annotated process – chemical storage Rethink Waste Module 1: Slide 56 of 81 STEP 3: Use your data to populate your waste map; where possible add cost data…. 500 polypropylene 1 FIBC/bags (@2. 5 k g each = 1. 25 tonnes) Polybutylene terephthalate pellets (500 tonne/y 1 tonne bags palletised) Currently collected foc and recycled Approx 550 pallets (@13. 5 kg each = 7. 5 tonnes) Polycarbonate/ABS alloy pellets (25 tonnes/y 25 kg multi-layer sacks palletised) Hydraulic oil (1, 200 litres/y, 210 litre metal drums) Salt (2. 5 tonnes/y, 25 kg polyethylene bags) Electricity (for humidity control) (est 7, 500 k. Wh/y) @5. 5 p/k. Wh = £ 412/y To general waste costing £ 124/tonne Chemical storage 5 metal drums (@15 kg = 75 kg) 1, 000 multi-layer paper sacks (@300 g = 0. 3 tonnes) 100 polyethylene bags (@250 g = 0. 25 tonnes) Shrink/stretch wrap (@400 g/pallet = 20 kg) To general waste costing £ 124/tonne

Additional information to collect Rethink Waste Module 1: Slide 57 of 81 When gathering information about the site and the processes which may benefit from improved resource efficiency you may also wish to consider the following: • Take photos of what you see (it will act as an aide memoir later on). • Talk to staff to identify the cause of wastes if it is not obvious and record a summary of your discussions. • Record any unusual occurrences of wastes. • Estimate quantities and costs - don’t worry if you can’t be accurate. • Use common units and time frames to record inputs, outputs and wastes - It may be easier to annualise. Don’t get distracted too much at this stage!

Additional information to collect Rethink Waste Module 1: Slide 57 of 81 When gathering information about the site and the processes which may benefit from improved resource efficiency you may also wish to consider the following: • Take photos of what you see (it will act as an aide memoir later on). • Talk to staff to identify the cause of wastes if it is not obvious and record a summary of your discussions. • Record any unusual occurrences of wastes. • Estimate quantities and costs - don’t worry if you can’t be accurate. • Use common units and time frames to record inputs, outputs and wastes - It may be easier to annualise. Don’t get distracted too much at this stage!

Rethink Waste Module 1: Slide 58 of 81 Using Your Data Effectively FINDING, RECORDING AND USING YOUR DATA

Rethink Waste Module 1: Slide 58 of 81 Using Your Data Effectively FINDING, RECORDING AND USING YOUR DATA

OK – so what do I do then? Rethink Waste Module 1: Slide 59 of 81 Once you have a waste map you can then populate your waste map with data: • quantities of materials used; • utilities consumed (gas/water/electricity); • quantities of wastes generated; • costs (if possible). Remember this information is important – What you cannot measure you cannot manage!

OK – so what do I do then? Rethink Waste Module 1: Slide 59 of 81 Once you have a waste map you can then populate your waste map with data: • quantities of materials used; • utilities consumed (gas/water/electricity); • quantities of wastes generated; • costs (if possible). Remember this information is important – What you cannot measure you cannot manage!

Tip - How to express data Rethink Waste Module 1: Slide 60 of 81 So that you can make comparisons and make it easy to understand the data you obtain, it is recommended that you use common units of measurement and quantification. Common examples include: Raw materials (tonnes/year) Water use and effluent (m 3/year) Gas and electricity (k. Wh/year) Fuel use (litres/year) Solid waste (tonnes/year) Solvent use and emissions (tonnes/year) Rejects (number/year, % of produced)

Tip - How to express data Rethink Waste Module 1: Slide 60 of 81 So that you can make comparisons and make it easy to understand the data you obtain, it is recommended that you use common units of measurement and quantification. Common examples include: Raw materials (tonnes/year) Water use and effluent (m 3/year) Gas and electricity (k. Wh/year) Fuel use (litres/year) Solid waste (tonnes/year) Solvent use and emissions (tonnes/year) Rejects (number/year, % of produced)

Data collection Rethink Waste Module 1: Slide 61 of 81 Where can you get the data to quantify the inputs and outputs for your waste map? Possibly from one or more of the following: • Bills from suppliers of materials/utilities; • Material use reports; • Production statistics; • By-product and waste disposal records; • Actual measurements; • Empirical calculations − If the weight of waste is not known the size of the container multiplied by the density will suffice; • Plant rated capacities etc; • Customers and suppliers.

Data collection Rethink Waste Module 1: Slide 61 of 81 Where can you get the data to quantify the inputs and outputs for your waste map? Possibly from one or more of the following: • Bills from suppliers of materials/utilities; • Material use reports; • Production statistics; • By-product and waste disposal records; • Actual measurements; • Empirical calculations − If the weight of waste is not known the size of the container multiplied by the density will suffice; • Plant rated capacities etc; • Customers and suppliers.

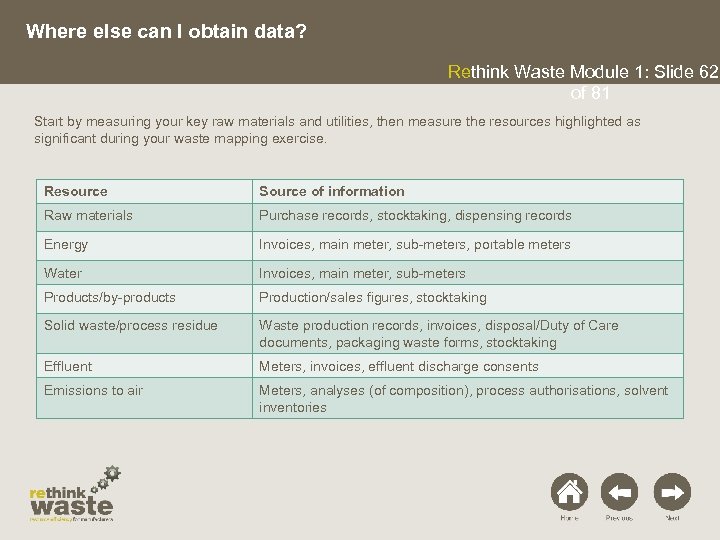

Where else can I obtain data? Rethink Waste Module 1: Slide 62 of 81 Start by measuring your key raw materials and utilities, then measure the resources highlighted as significant during your waste mapping exercise. Resource Source of information Raw materials Purchase records, stocktaking, dispensing records Energy Invoices, main meter, sub-meters, portable meters Water Invoices, main meter, sub-meters Products/by-products Production/sales figures, stocktaking Solid waste/process residue Waste production records, invoices, disposal/Duty of Care documents, packaging waste forms, stocktaking Effluent Meters, invoices, effluent discharge consents Emissions to air Meters, analyses (of composition), process authorisations, solvent inventories

Where else can I obtain data? Rethink Waste Module 1: Slide 62 of 81 Start by measuring your key raw materials and utilities, then measure the resources highlighted as significant during your waste mapping exercise. Resource Source of information Raw materials Purchase records, stocktaking, dispensing records Energy Invoices, main meter, sub-meters, portable meters Water Invoices, main meter, sub-meters Products/by-products Production/sales figures, stocktaking Solid waste/process residue Waste production records, invoices, disposal/Duty of Care documents, packaging waste forms, stocktaking Effluent Meters, invoices, effluent discharge consents Emissions to air Meters, analyses (of composition), process authorisations, solvent inventories

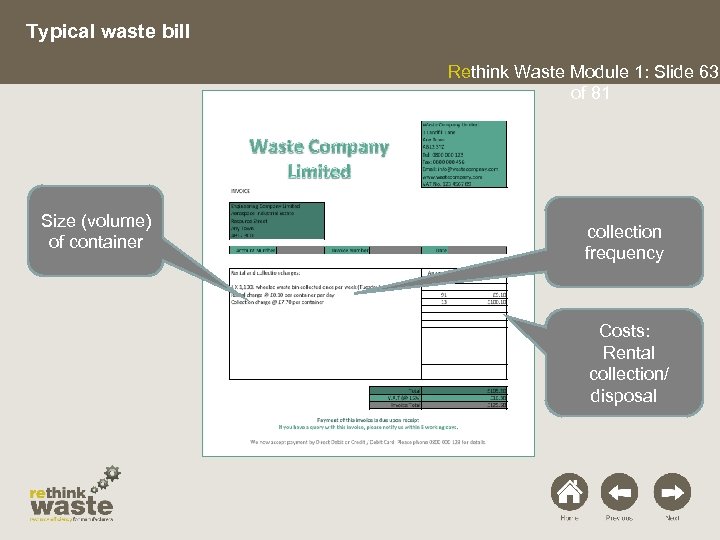

Typical waste bill Rethink Waste Module 1: Slide 63 of 81 Size (volume) of container collection frequency Costs: Rental collection/ disposal

Typical waste bill Rethink Waste Module 1: Slide 63 of 81 Size (volume) of container collection frequency Costs: Rental collection/ disposal

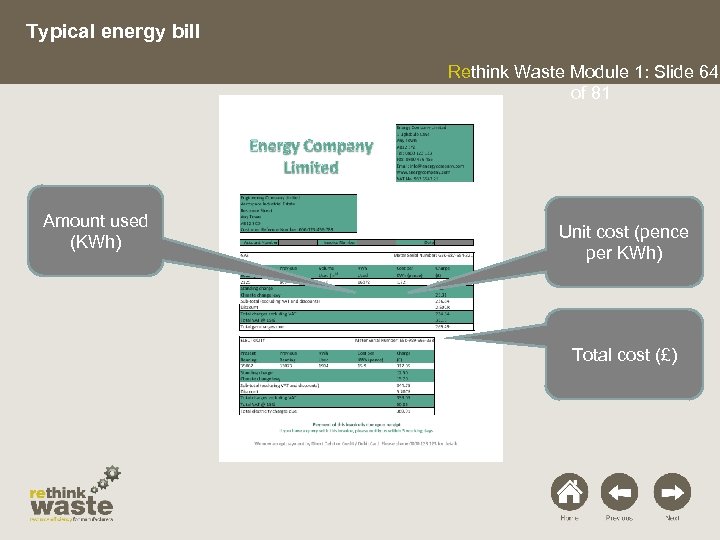

Typical energy bill Rethink Waste Module 1: Slide 64 of 81 Amount used (KWh) Unit cost (pence per KWh) Total cost (£)

Typical energy bill Rethink Waste Module 1: Slide 64 of 81 Amount used (KWh) Unit cost (pence per KWh) Total cost (£)

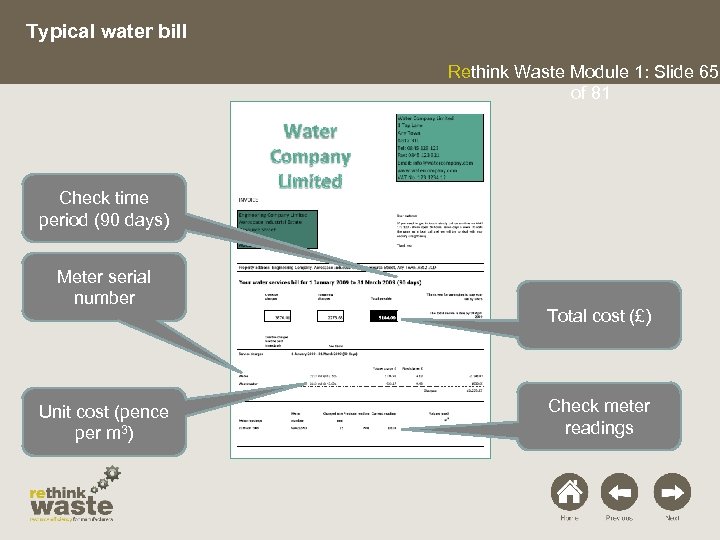

Typical water bill Rethink Waste Module 1: Slide 65 of 81 Check time period (90 days) Meter serial number Unit cost (pence per m 3) Total cost (£) Check meter readings

Typical water bill Rethink Waste Module 1: Slide 65 of 81 Check time period (90 days) Meter serial number Unit cost (pence per m 3) Total cost (£) Check meter readings

Typical bin sizes Rethink Waste Module 1: Slide 66 of 81 90, 120, 140, 240 and 360 litres Commonly encountered sizes 660 (700), 770 (800), 1, 000 and 1, 100 litres

Typical bin sizes Rethink Waste Module 1: Slide 66 of 81 90, 120, 140, 240 and 360 litres Commonly encountered sizes 660 (700), 770 (800), 1, 000 and 1, 100 litres

Typical waste weights Rethink Waste Module 1: Slide 67 of 81 Waste Type/Quantity 1 x sack paper Laser printer toner cartridge 1 box A 4 paper (5 reams) 50, 000 drinks cans 170, 000 plastic vending cups 1 sack of vending cups Weight Approx. 10 kg Approx. 2 kg Approx. 12. 5 kg 1 tonne 3 kg (510 cups)

Typical waste weights Rethink Waste Module 1: Slide 67 of 81 Waste Type/Quantity 1 x sack paper Laser printer toner cartridge 1 box A 4 paper (5 reams) 50, 000 drinks cans 170, 000 plastic vending cups 1 sack of vending cups Weight Approx. 10 kg Approx. 2 kg Approx. 12. 5 kg 1 tonne 3 kg (510 cups)

Typical skip sizes Rethink Waste Module 1: Slide 68 of 81 Volume Length Width 4. 5 m 3 3, 531 mm 1, 880 mm 6 cu yds 139 ins 74 ins Volume Length Width 9. 0 m 3 3, 962 mm 1, 880 mm 12 cu yds 156 ins 74 ins Volume Length Width 15. 0 m 3 4, 572 mm 1, 880 mm 20 cu yds 180 ins 74 ins

Typical skip sizes Rethink Waste Module 1: Slide 68 of 81 Volume Length Width 4. 5 m 3 3, 531 mm 1, 880 mm 6 cu yds 139 ins 74 ins Volume Length Width 9. 0 m 3 3, 962 mm 1, 880 mm 12 cu yds 156 ins 74 ins Volume Length Width 15. 0 m 3 4, 572 mm 1, 880 mm 20 cu yds 180 ins 74 ins

Typical waste densities Rethink Waste Module 1: Slide 69 of 81 Waste Type/Quantity Density (kg/m 3) Mixed domestic 150 - 250 Cardboard 350 Glass 450 Folded newspapers 500 Loose, crumpled office paper 50 Loose waste paper in sacks 20 Food 200 Empty glass bottles 300

Typical waste densities Rethink Waste Module 1: Slide 69 of 81 Waste Type/Quantity Density (kg/m 3) Mixed domestic 150 - 250 Cardboard 350 Glass 450 Folded newspapers 500 Loose, crumpled office paper 50 Loose waste paper in sacks 20 Food 200 Empty glass bottles 300

Watch out for data errors! Rethink Waste Module 1: Slide 70 of 81 As well as indicating the material and waste flows you need to measure, your waste map will help you to identify: • Weigh/count delivery quantities • Standard conversion factors which are often incorporated into process descriptions eg 10 kg of raw material ‘X’ always gives 50 m 2 of product ‘Y’ • Hidden materials eg consumables used for Health & Safety purposes, materials used during maintenance etc • Use of financial data that are not necessarily linked to consumption You may find that some of the historical assumptions that have been made are wrong!

Watch out for data errors! Rethink Waste Module 1: Slide 70 of 81 As well as indicating the material and waste flows you need to measure, your waste map will help you to identify: • Weigh/count delivery quantities • Standard conversion factors which are often incorporated into process descriptions eg 10 kg of raw material ‘X’ always gives 50 m 2 of product ‘Y’ • Hidden materials eg consumables used for Health & Safety purposes, materials used during maintenance etc • Use of financial data that are not necessarily linked to consumption You may find that some of the historical assumptions that have been made are wrong!

Use of data – baseline and benchmarking Rethink Waste Module 1: Slide 71 of 81 Once obtained, the data in your ‘waste map’ provides you with your baseline. This will enable you to establish your baseline and benchmark your site: Baseline = Where you are now and a point from where improvements (or otherwise!) can be gauged Benchmark = Where you are compared to your peers – usually compared against the same manufacturing sector Both parameters are important in undertaking any ‘Measuring to Manage’ activity. Looking back at your baseline helps you to see how you are progressing and benchmarking your performance helps you to see how you fare compared to others. Envirowise has produced some guides which provide further information on ‘Measuring to Manage’ Measuring to Manage : How reducing waste can unlock hidden profits Measuring to Manage : A ‘How To’ Guide Measuring to Manage: The key to reducing waste costs Further information on baseline and benchmarking is given in Module 3.

Use of data – baseline and benchmarking Rethink Waste Module 1: Slide 71 of 81 Once obtained, the data in your ‘waste map’ provides you with your baseline. This will enable you to establish your baseline and benchmark your site: Baseline = Where you are now and a point from where improvements (or otherwise!) can be gauged Benchmark = Where you are compared to your peers – usually compared against the same manufacturing sector Both parameters are important in undertaking any ‘Measuring to Manage’ activity. Looking back at your baseline helps you to see how you are progressing and benchmarking your performance helps you to see how you fare compared to others. Envirowise has produced some guides which provide further information on ‘Measuring to Manage’ Measuring to Manage : How reducing waste can unlock hidden profits Measuring to Manage : A ‘How To’ Guide Measuring to Manage: The key to reducing waste costs Further information on baseline and benchmarking is given in Module 3.

Rethink Waste Module 1: Slide 72 of 81 Summary & Next Steps WHAT YOU KNOW & WHAT YOU SHOULD DO NEXT

Rethink Waste Module 1: Slide 72 of 81 Summary & Next Steps WHAT YOU KNOW & WHAT YOU SHOULD DO NEXT

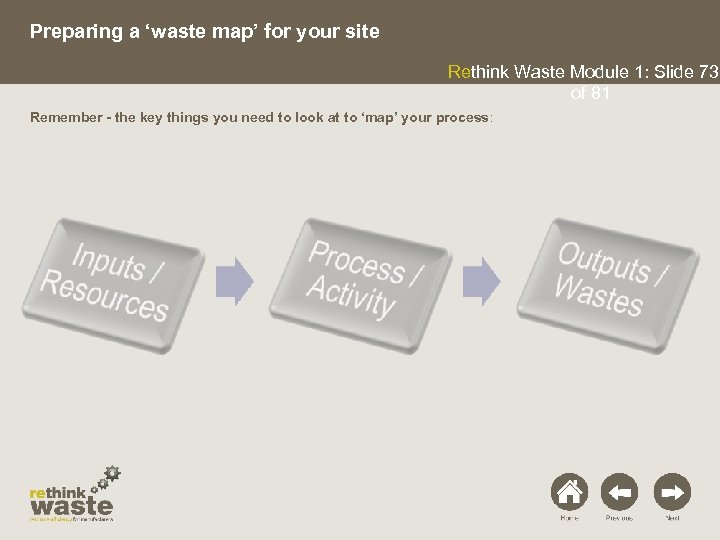

Preparing a ‘waste map’ for your site Rethink Waste Module 1: Slide 73 of 81 Remember - the key things you need to look at to ‘map’ your process:

Preparing a ‘waste map’ for your site Rethink Waste Module 1: Slide 73 of 81 Remember - the key things you need to look at to ‘map’ your process:

What have you learnt so far? Rethink Waste Module 1: Slide 74 of 81 By getting this far into rethink waste you should: • Have an awareness of materials and utilities used; • Know how to complete a waste map; • Be aware of the information needed to populate your waste map including: - Main materials and utilities used for each process; Wastes leaving the process; Ideally, some of above quantified and costed.

What have you learnt so far? Rethink Waste Module 1: Slide 74 of 81 By getting this far into rethink waste you should: • Have an awareness of materials and utilities used; • Know how to complete a waste map; • Be aware of the information needed to populate your waste map including: - Main materials and utilities used for each process; Wastes leaving the process; Ideally, some of above quantified and costed.

Suggested next steps… Rethink Waste Module 1: Slide 75 of 81 From the information in Module 1, consider the following points as your next key steps towards ‘Rethinking waste’: • Quickly think about your site, complete a review • Sketch down the individual process areas that would compose a ‘waste map’ • Jot down where information on materials and utilities in, and wastes out, may be available from within your organisation • Prepare your first ‘waste map’.

Suggested next steps… Rethink Waste Module 1: Slide 75 of 81 From the information in Module 1, consider the following points as your next key steps towards ‘Rethinking waste’: • Quickly think about your site, complete a review • Sketch down the individual process areas that would compose a ‘waste map’ • Jot down where information on materials and utilities in, and wastes out, may be available from within your organisation • Prepare your first ‘waste map’.

Gaining support and commitment Rethink Waste Module 1: Slide 76 of 81 To undertake resource efficiency improvements usually requires commitment from senior management to facilitate the availability of resources and to get support from colleagues. It is often difficult to get management commitment without being ‘armed with some knowledge’ – particularly details of the potential savings that can be made. • Try to explain that the initial review is not just paperwork and that it will probably identify and bring about realistic changes that will save both resources and money. • If you can, during the review gain some facts and figures on some ‘quick wins’ you may be able to achieve. Further information on gaining support and commitment is provided in Module 3 - after the initial review has been undertaken.

Gaining support and commitment Rethink Waste Module 1: Slide 76 of 81 To undertake resource efficiency improvements usually requires commitment from senior management to facilitate the availability of resources and to get support from colleagues. It is often difficult to get management commitment without being ‘armed with some knowledge’ – particularly details of the potential savings that can be made. • Try to explain that the initial review is not just paperwork and that it will probably identify and bring about realistic changes that will save both resources and money. • If you can, during the review gain some facts and figures on some ‘quick wins’ you may be able to achieve. Further information on gaining support and commitment is provided in Module 3 - after the initial review has been undertaken.

What you should have achieved… Rethink Waste Module 1: Slide 77 of 81 Module 1 has introduced you to the important concepts of data collection and waste mapping. Through this module we hope you have achieved an awareness of the … • Principles of resource efficiency; • Likely benefits resource efficiency can bring; • Type of data required to establish your baseline; • Importance of true costs (particularly added value); • Concept of presenting data in a ‘waste map’ format. Completed task documents: Two key templates are provided to help you. If you have not used them, download them now and complete both templates before module 2. If you are short of time, focus on one area of your business. Waste checklist Process map template

What you should have achieved… Rethink Waste Module 1: Slide 77 of 81 Module 1 has introduced you to the important concepts of data collection and waste mapping. Through this module we hope you have achieved an awareness of the … • Principles of resource efficiency; • Likely benefits resource efficiency can bring; • Type of data required to establish your baseline; • Importance of true costs (particularly added value); • Concept of presenting data in a ‘waste map’ format. Completed task documents: Two key templates are provided to help you. If you have not used them, download them now and complete both templates before module 2. If you are short of time, focus on one area of your business. Waste checklist Process map template

Organisations that can provide further help Rethink Waste Module 1: Slide 78 of 81 Where can you go for further help and guidance? • WRAP’s Resource Efficiency website (www. envirowise. gov. uk) or Advice Line (0808 100 2040) • EEF’s website www. eef. org. uk and EEF Environment pages • The Carbon Trust ‘s (for energy) website www. carbontrust. co. uk or helpline (0800 0852005) • The Net. Regs website www. environment-agency. gov. uk/netregs/

Organisations that can provide further help Rethink Waste Module 1: Slide 78 of 81 Where can you go for further help and guidance? • WRAP’s Resource Efficiency website (www. envirowise. gov. uk) or Advice Line (0808 100 2040) • EEF’s website www. eef. org. uk and EEF Environment pages • The Carbon Trust ‘s (for energy) website www. carbontrust. co. uk or helpline (0800 0852005) • The Net. Regs website www. environment-agency. gov. uk/netregs/

Further Reading Rethink Waste Module 1: Slide 79 of 81 Defra has produced ‘The environment in your pocket 2008’, which focuses strongly on theme of climate change. ‘The Environment in your Pocket’ is a handy, free of charge, pocket-sized distillation of around 60 key data series largely from the ‘e-Digest of Environmental Statistics’ website. Its aim is to make environmental statistics accessible to wider and different audiences.

Further Reading Rethink Waste Module 1: Slide 79 of 81 Defra has produced ‘The environment in your pocket 2008’, which focuses strongly on theme of climate change. ‘The Environment in your Pocket’ is a handy, free of charge, pocket-sized distillation of around 60 key data series largely from the ‘e-Digest of Environmental Statistics’ website. Its aim is to make environmental statistics accessible to wider and different audiences.

Further Reading Rethink Waste Module 1: Slide 80 of 81 There is growing international recognition that current patterns of consumption and production are unsustainable. The EEF, with support from Barclays Commercial, has produced a 'Sustainable Resource Management’ publication to support manufacturers in moving forward on resource efficiency. The document provides an overview of the key issues and questions as well as highlighting examples of best practice.

Further Reading Rethink Waste Module 1: Slide 80 of 81 There is growing international recognition that current patterns of consumption and production are unsustainable. The EEF, with support from Barclays Commercial, has produced a 'Sustainable Resource Management’ publication to support manufacturers in moving forward on resource efficiency. The document provides an overview of the key issues and questions as well as highlighting examples of best practice.

Thank you for completing Rethink Waste module 1 Rethink Waste Module 1: Slide 81 of 81 Thank you for completing Rethink Waste module 1 Join us for module 2 – Identifying Opportunities & Developing An Action Plan WRAP’s vision is a world without waste, where resources are used sustainably END & EXIT

Thank you for completing Rethink Waste module 1 Rethink Waste Module 1: Slide 81 of 81 Thank you for completing Rethink Waste module 1 Join us for module 2 – Identifying Opportunities & Developing An Action Plan WRAP’s vision is a world without waste, where resources are used sustainably END & EXIT