15d16fa8f567814dd670e2daa99b0490.ppt

- Количество слайдов: 42

Wireless Solutions Product Launch August 2008

Wireless Solutions Product Launch August 2008

Agenda Ø Introduction to Wireless Ø Products and applications Ø Opportunity Ø Resources Ø Next steps 2

Agenda Ø Introduction to Wireless Ø Products and applications Ø Opportunity Ø Resources Ø Next steps 2

Introduction to wireless Ø Imagine 3

Introduction to wireless Ø Imagine 3

Introduction to wireless Ø Imagine 4

Introduction to wireless Ø Imagine 4

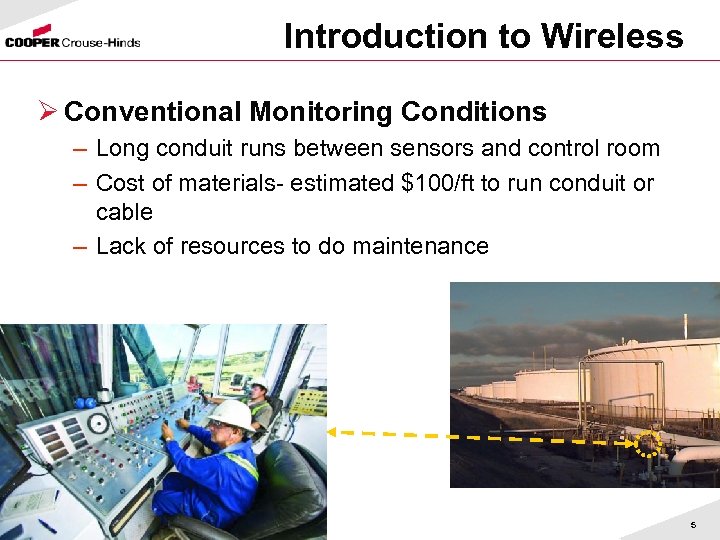

Introduction to Wireless Ø Conventional Monitoring Conditions – Long conduit runs between sensors and control room – Cost of materials- estimated $100/ft to run conduit or cable – Lack of resources to do maintenance 5

Introduction to Wireless Ø Conventional Monitoring Conditions – Long conduit runs between sensors and control room – Cost of materials- estimated $100/ft to run conduit or cable – Lack of resources to do maintenance 5

Introduction to Wireless Ø The reality with wired solutions – Long distances from critical monitoring – Large obstructions can make wiring impractical or impossible – Processes or equipment need monitoring in use – No power available in remote applications – Expense 6

Introduction to Wireless Ø The reality with wired solutions – Long distances from critical monitoring – Large obstructions can make wiring impractical or impossible – Processes or equipment need monitoring in use – No power available in remote applications – Expense 6

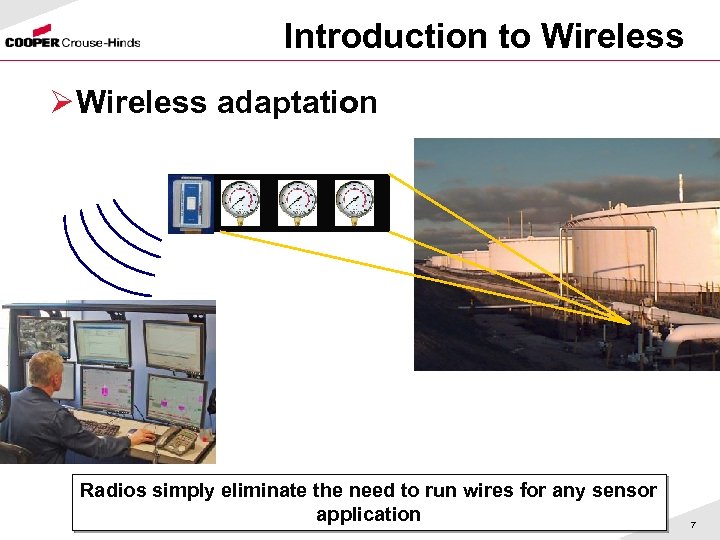

Introduction to Wireless Ø Wireless adaptation Radios simply eliminate the need to run wires for any sensor application 7

Introduction to Wireless Ø Wireless adaptation Radios simply eliminate the need to run wires for any sensor application 7

“What, no fittings? ” 8

“What, no fittings? ” 8

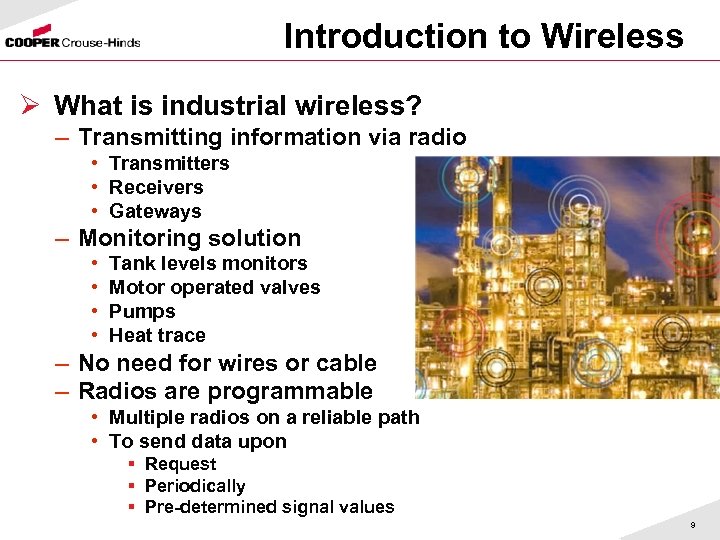

Introduction to Wireless Ø What is industrial wireless? – Transmitting information via radio • Transmitters • Receivers • Gateways – Monitoring solution • • Tank levels monitors Motor operated valves Pumps Heat trace – No need for wires or cable – Radios are programmable • Multiple radios on a reliable path • To send data upon § Request § Periodically § Pre-determined signal values 9

Introduction to Wireless Ø What is industrial wireless? – Transmitting information via radio • Transmitters • Receivers • Gateways – Monitoring solution • • Tank levels monitors Motor operated valves Pumps Heat trace – No need for wires or cable – Radios are programmable • Multiple radios on a reliable path • To send data upon § Request § Periodically § Pre-determined signal values 9

Introduction to Wireless Ø Applications considerations – Monitoring (90+%) • Requirements § Pipelines – Pressure monitoring, heat tracing monitoring § Motor operated valves – Feedback needed to confirm valve position 10

Introduction to Wireless Ø Applications considerations – Monitoring (90+%) • Requirements § Pipelines – Pressure monitoring, heat tracing monitoring § Motor operated valves – Feedback needed to confirm valve position 10

Introduction to Wireless Ø Applications considerations – Control • Requirements § Process control – Automated and manual process control for various industries § Alarms – Monitor conditions and automate alarms when needed 11

Introduction to Wireless Ø Applications considerations – Control • Requirements § Process control – Automated and manual process control for various industries § Alarms – Monitor conditions and automate alarms when needed 11

Introduction to Wireless Ø Why go wireless? – Cost effective solution • Avoiding long wire or conduit runs • Eliminating trenching and cable trays • Facilitating solutions for applications hindered by physical obstruction – Added value • Increased operational safety by continuous monitoring • Mobile and flexible monitoring • Easy to upgrade as you grow • Low cost per access point • Easy to install 12

Introduction to Wireless Ø Why go wireless? – Cost effective solution • Avoiding long wire or conduit runs • Eliminating trenching and cable trays • Facilitating solutions for applications hindered by physical obstruction – Added value • Increased operational safety by continuous monitoring • Mobile and flexible monitoring • Easy to upgrade as you grow • Low cost per access point • Easy to install 12

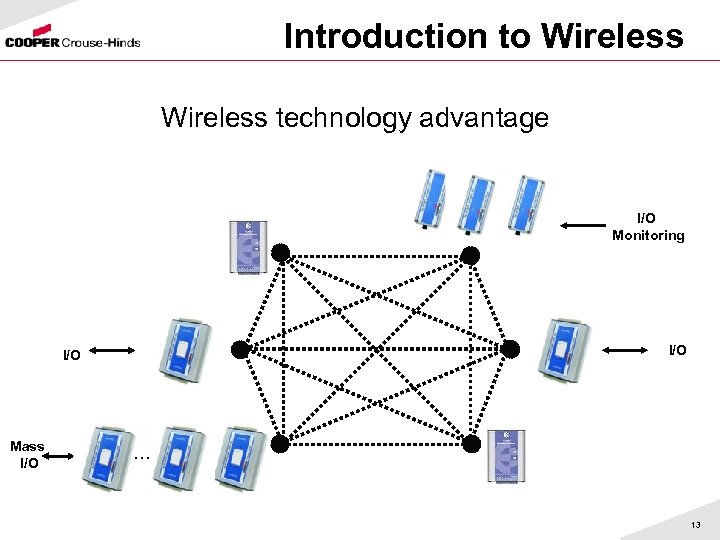

Introduction to Wireless technology advantage I/O Monitoring I/O Mass I/O … 13

Introduction to Wireless technology advantage I/O Monitoring I/O Mass I/O … 13

Introduction to Wireless Ø Application: Oil & Gas – Well-head and pump monitoring system – Pipeline pressure, flow and valve monitoring – Protection system monitoring – Leak detection monitoring – Underground gas storage monitoring – Pump/compressor station control systems 14

Introduction to Wireless Ø Application: Oil & Gas – Well-head and pump monitoring system – Pipeline pressure, flow and valve monitoring – Protection system monitoring – Leak detection monitoring – Underground gas storage monitoring – Pump/compressor station control systems 14

Introduction to Wireless Ø Application: Process Industries Eg Chemical plants, Pulp & paper, steel mills, power gen, glass manufacturing – Flow monitoring – Tank level monitoring – Condition monitoring of equipment – Utility plant alarms – Effluent treatment plants – Security and access-control – Remote water pumps – Monitoring of fire-fighting and safety systems – Gas detection systems 15

Introduction to Wireless Ø Application: Process Industries Eg Chemical plants, Pulp & paper, steel mills, power gen, glass manufacturing – Flow monitoring – Tank level monitoring – Condition monitoring of equipment – Utility plant alarms – Effluent treatment plants – Security and access-control – Remote water pumps – Monitoring of fire-fighting and safety systems – Gas detection systems 15

Introduction to Wireless Ø Application: Factory Automation Eg. Assembly plants, component manufacturers, Pharmaceutical, food & beverage, packaging • Detection of moving machinery • Power network monitoring • PLC interconnection • Alarm monitoring of portable machinery • Utility plant alarms • Effluent treatment plants • Security and access-control • Rotating and moving machinery • Alert and Evacuation alarm systems 16

Introduction to Wireless Ø Application: Factory Automation Eg. Assembly plants, component manufacturers, Pharmaceutical, food & beverage, packaging • Detection of moving machinery • Power network monitoring • PLC interconnection • Alarm monitoring of portable machinery • Utility plant alarms • Effluent treatment plants • Security and access-control • Rotating and moving machinery • Alert and Evacuation alarm systems 16

Introduction to Wireless Ø Application: Utilities & Municipal – Water management • • Pump station control Tank monitoring, level and security Flow metering systems Irrigation monitoring and control Water quality monitoring Large network SCADA systems Treatment plant monitoring Early flood-warning systems – Electricity distribution • Monitoring of power poles • HV Feeder alarm fault monitoring – Gas reticulation • Valve stations • Pressure monitoring 17

Introduction to Wireless Ø Application: Utilities & Municipal – Water management • • Pump station control Tank monitoring, level and security Flow metering systems Irrigation monitoring and control Water quality monitoring Large network SCADA systems Treatment plant monitoring Early flood-warning systems – Electricity distribution • Monitoring of power poles • HV Feeder alarm fault monitoring – Gas reticulation • Valve stations • Pressure monitoring 17

The products

The products

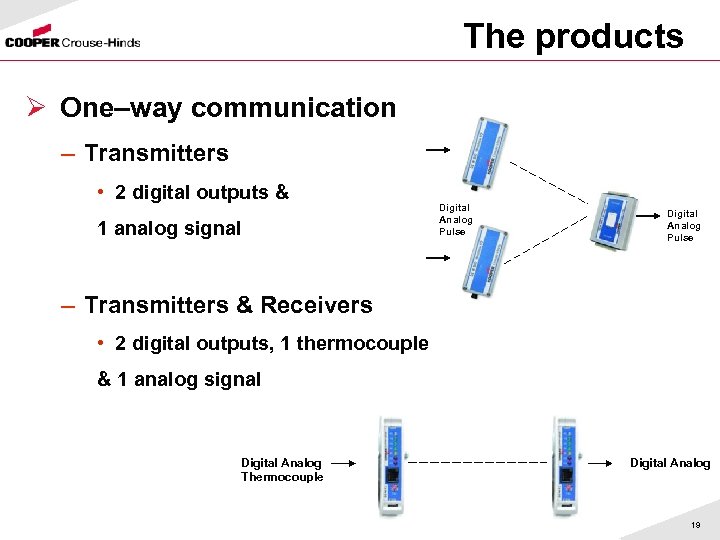

The products Ø One–way communication – Transmitters • 2 digital outputs & 1 analog signal Digital Analog Pulse – Transmitters & Receivers • 2 digital outputs, 1 thermocouple & 1 analog signal Digital Analog Thermocouple Digital Analog 19

The products Ø One–way communication – Transmitters • 2 digital outputs & 1 analog signal Digital Analog Pulse – Transmitters & Receivers • 2 digital outputs, 1 thermocouple & 1 analog signal Digital Analog Thermocouple Digital Analog 19

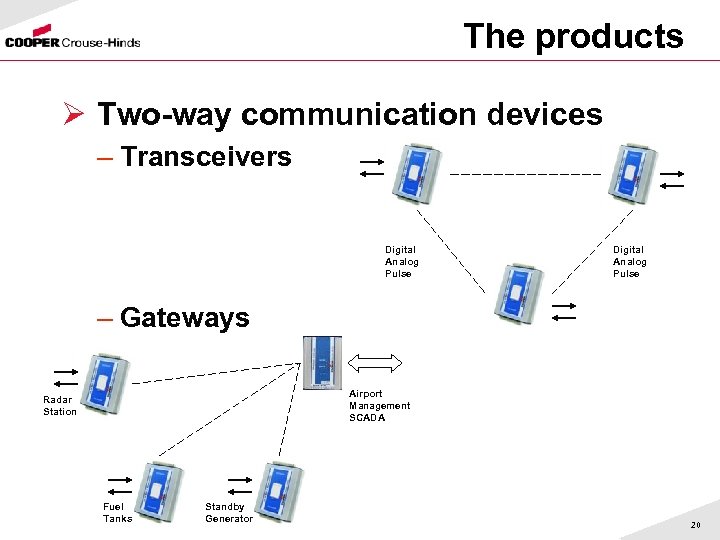

The products Ø Two-way communication devices – Transceivers Digital Analog Pulse – Gateways Airport Management SCADA Radar Station Fuel Tanks Standby Generator 20

The products Ø Two-way communication devices – Transceivers Digital Analog Pulse – Gateways Airport Management SCADA Radar Station Fuel Tanks Standby Generator 20

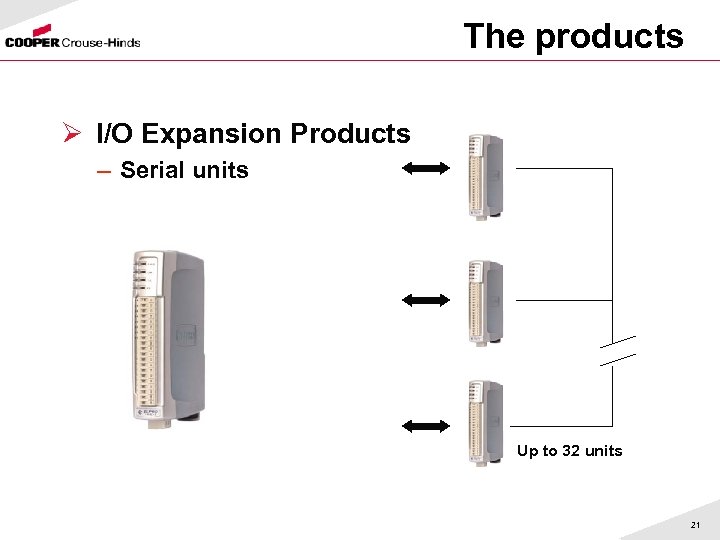

The products Ø I/O Expansion Products – Serial units Up to 32 units 21

The products Ø I/O Expansion Products – Serial units Up to 32 units 21

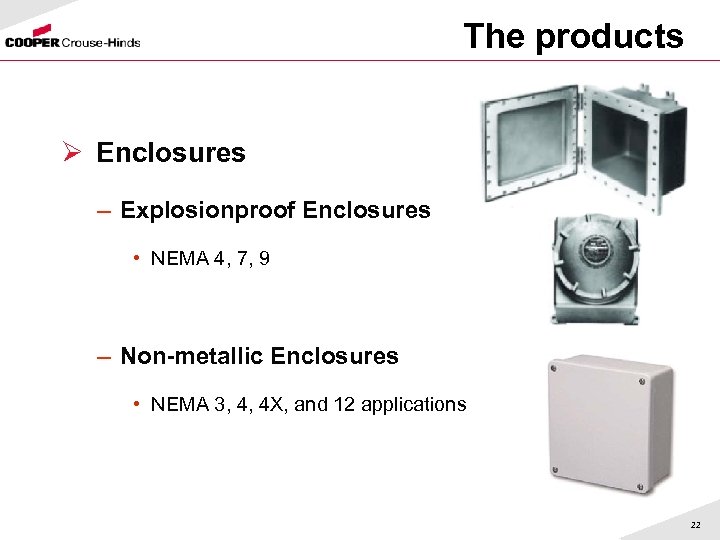

The products Ø Enclosures – Explosionproof Enclosures • NEMA 4, 7, 9 – Non-metallic Enclosures • NEMA 3, 4, 4 X, and 12 applications 22

The products Ø Enclosures – Explosionproof Enclosures • NEMA 4, 7, 9 – Non-metallic Enclosures • NEMA 3, 4, 4 X, and 12 applications 22

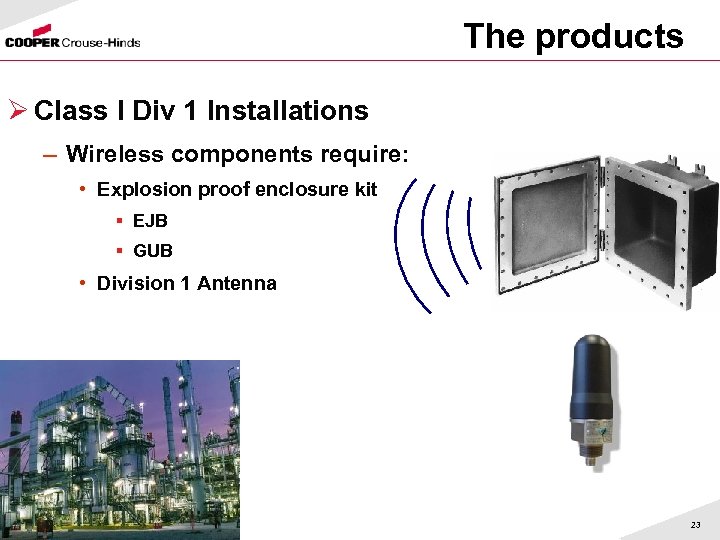

The products Ø Class I Div 1 Installations – Wireless components require: • Explosion proof enclosure kit § EJB § GUB • Division 1 Antenna 23

The products Ø Class I Div 1 Installations – Wireless components require: • Explosion proof enclosure kit § EJB § GUB • Division 1 Antenna 23

The products Ø Industrial and Class I Div 2 – Wireless components require: • “Enclosure suitable for the environment” • Non-metallic Enclosure § NEMA 4 X § Fiberglass Reinforced Polyester 24

The products Ø Industrial and Class I Div 2 – Wireless components require: • “Enclosure suitable for the environment” • Non-metallic Enclosure § NEMA 4 X § Fiberglass Reinforced Polyester 24

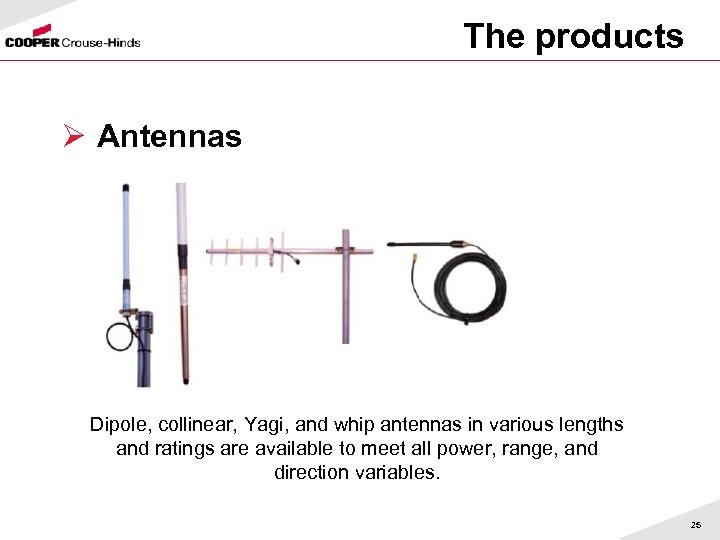

The products Ø Antennas Dipole, collinear, Yagi, and whip antennas in various lengths and ratings are available to meet all power, range, and direction variables. 25

The products Ø Antennas Dipole, collinear, Yagi, and whip antennas in various lengths and ratings are available to meet all power, range, and direction variables. 25

The products Ø Accessories Cooper Crouse-Hinds also provides other accessories needed for your application (including cables, brackets, power supplies, and surge diverters). 26

The products Ø Accessories Cooper Crouse-Hinds also provides other accessories needed for your application (including cables, brackets, power supplies, and surge diverters). 26

The products Ø Product certifications – All radio components: • CSA (N American ) Class 1 Div 2 • FCC – Enclosures and accessories • UL and CSA • Ingress protection 27

The products Ø Product certifications – All radio components: • CSA (N American ) Class 1 Div 2 • FCC – Enclosures and accessories • UL and CSA • Ingress protection 27

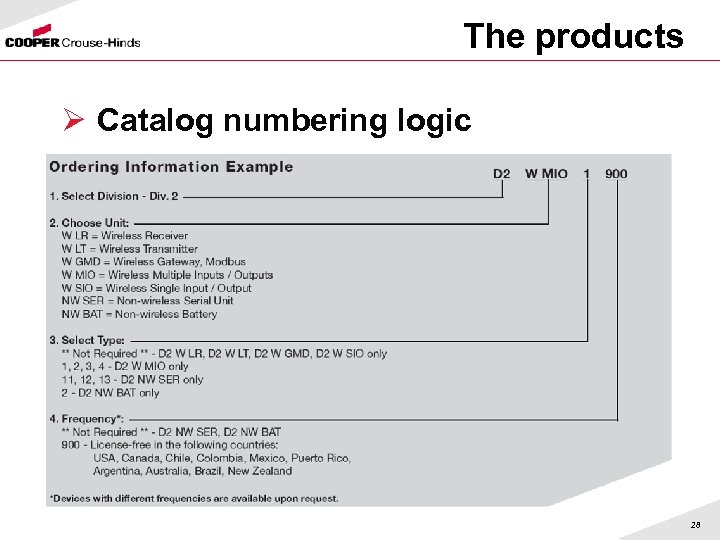

The products Ø Catalog numbering logic 28

The products Ø Catalog numbering logic 28

The Applications Ø Tank Farm – Remote tank monitoring Ø Power plant – Stack gas monitoring 29

The Applications Ø Tank Farm – Remote tank monitoring Ø Power plant – Stack gas monitoring 29

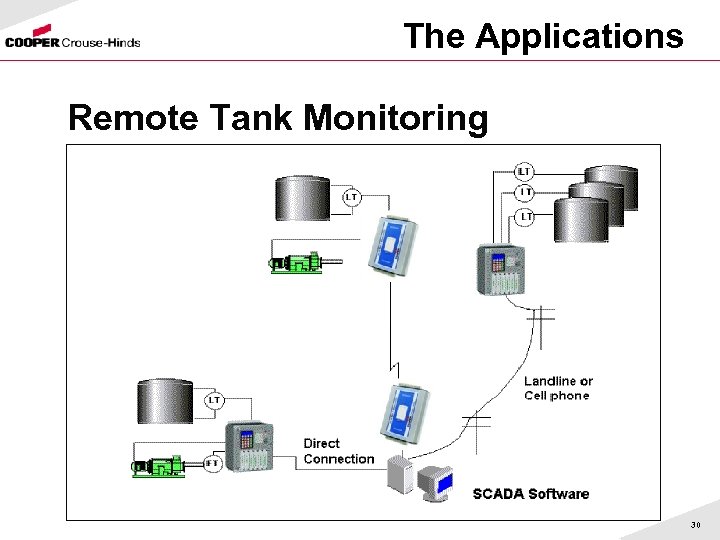

The Applications Remote Tank Monitoring 30

The Applications Remote Tank Monitoring 30

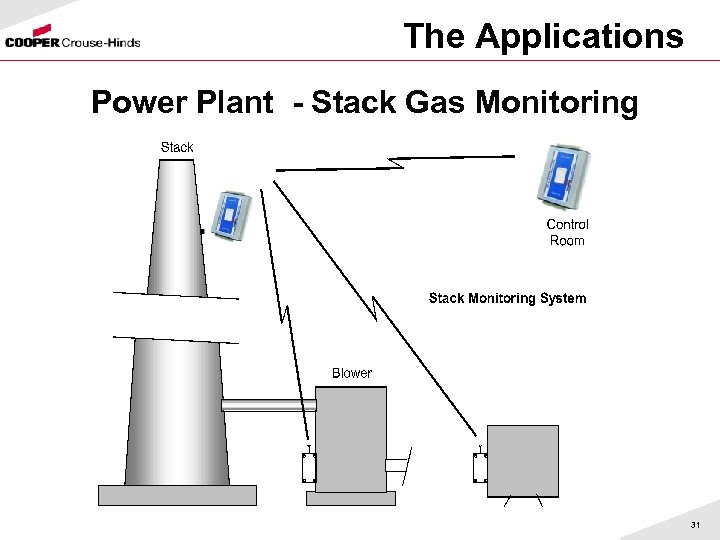

The Applications Power Plant - Stack Gas Monitoring 31

The Applications Power Plant - Stack Gas Monitoring 31

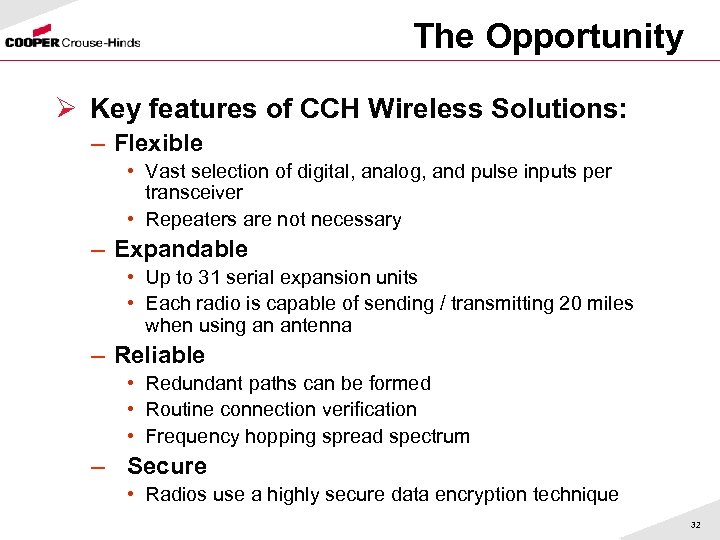

The Opportunity Ø Key features of CCH Wireless Solutions: – Flexible • Vast selection of digital, analog, and pulse inputs per transceiver • Repeaters are not necessary – Expandable • Up to 31 serial expansion units • Each radio is capable of sending / transmitting 20 miles when using an antenna – Reliable • Redundant paths can be formed • Routine connection verification • Frequency hopping spread spectrum – Secure • Radios use a highly secure data encryption technique 32

The Opportunity Ø Key features of CCH Wireless Solutions: – Flexible • Vast selection of digital, analog, and pulse inputs per transceiver • Repeaters are not necessary – Expandable • Up to 31 serial expansion units • Each radio is capable of sending / transmitting 20 miles when using an antenna – Reliable • Redundant paths can be formed • Routine connection verification • Frequency hopping spread spectrum – Secure • Radios use a highly secure data encryption technique 32

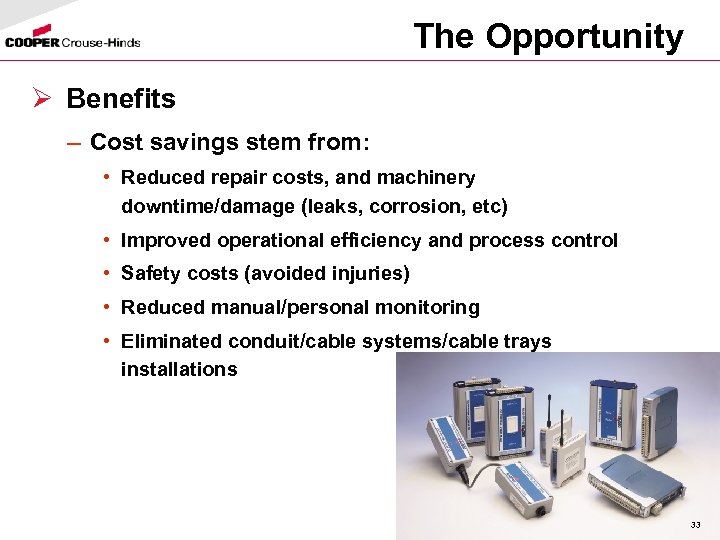

The Opportunity Ø Benefits – Cost savings stem from: • Reduced repair costs, and machinery downtime/damage (leaks, corrosion, etc) • Improved operational efficiency and process control • Safety costs (avoided injuries) • Reduced manual/personal monitoring • Eliminated conduit/cable systems/cable trays installations 33

The Opportunity Ø Benefits – Cost savings stem from: • Reduced repair costs, and machinery downtime/damage (leaks, corrosion, etc) • Improved operational efficiency and process control • Safety costs (avoided injuries) • Reduced manual/personal monitoring • Eliminated conduit/cable systems/cable trays installations 33

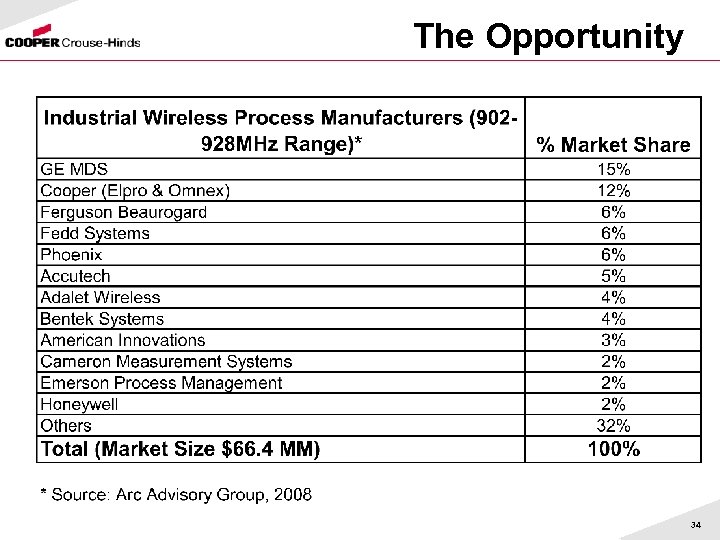

The Opportunity 34

The Opportunity 34

Your resources

Your resources

Resources Ø Field Experts – Field Sales Regions • Mid-West- Chuck Marcis • Gulf Coast- Matt Debray • Northeast- John Kwiecinski • Canada- Alan Campbell • West Coast- Ken Blanco Ø Inside Experts – Syracuse: Joe Geswaldo, John Ponto – ICI, Houston: Jose Hernandez Ø 24/5 Global Customer Support – Toll-free (866) 764 -5454 – (866) 713 -4409 36

Resources Ø Field Experts – Field Sales Regions • Mid-West- Chuck Marcis • Gulf Coast- Matt Debray • Northeast- John Kwiecinski • Canada- Alan Campbell • West Coast- Ken Blanco Ø Inside Experts – Syracuse: Joe Geswaldo, John Ponto – ICI, Houston: Jose Hernandez Ø 24/5 Global Customer Support – Toll-free (866) 764 -5454 – (866) 713 -4409 36

Resources Ø Customized launch package – Overview Brochure – Product Catalog – Product Line – Customer survey questions, selling tips – Complete sub-Website with Wireless technology references Ø Demonstration and site assessment kits 37

Resources Ø Customized launch package – Overview Brochure – Product Catalog – Product Line – Customer survey questions, selling tips – Complete sub-Website with Wireless technology references Ø Demonstration and site assessment kits 37

Resources Ø Dedicated Web Site – Wireless Products and Technology Portal 38

Resources Ø Dedicated Web Site – Wireless Products and Technology Portal 38

Resources Ø Pricing – Distributor price books – Discounting Ø Lead time – Radio components: 4 weeks – Accessories: stock to 4 weeks – Site assessments as needed 39

Resources Ø Pricing – Distributor price books – Discounting Ø Lead time – Radio components: 4 weeks – Accessories: stock to 4 weeks – Site assessments as needed 39

Next steps “Start to think in Wireless”

Next steps “Start to think in Wireless”

Next steps Ø What you need to do – Review all materials – Attend training and info sessions – Identify 5 viable accounts – Give us feedback on sales and opportunities 41

Next steps Ø What you need to do – Review all materials – Attend training and info sessions – Identify 5 viable accounts – Give us feedback on sales and opportunities 41

“Any questions? ” One great offering…and please include the enclosures. 42

“Any questions? ” One great offering…and please include the enclosures. 42