171544e8ada73592a3d999c8e2e0c72f.ppt

- Количество слайдов: 9

Winter. Wind 2011 CC Conference - Review 2011 International Wind Diesel Conference, Cold Climate Concerns Per Lundsager Senior Consultant, Darup Associates Inc. Advisor to Wi. DAC

Winter. Wind 2011 CC Conference - Review 2011 International Wind Diesel Conference, Cold Climate Concerns Per Lundsager Senior Consultant, Darup Associates Inc. Advisor to Wi. DAC

My Cold Climate (CC) background (not very extensive) • 1993 Project manager for a DK project on the possible application of • • WE in Greenland. The main issues were not so much CC related as WD and extreme wind related. Project pointed towards RE potential in both townships and remote communities (settlements). Recommendations were not followed, Greenland today relies on hydropower (about 80% of electricity production) Distant offspring of that project: In 2010 a 6 k. W Proven wind turbine was installed and connected to the diesel grid in the settlement Sarfannguaq. Independently of each other we put the cross where the WT should be erected on the precise same spot, 2001 One of the founding fathers (parents) of the IEA Annex 19, Wind Energy in Cold Climates. DK eventually left the annex by reason of lack of interest in CC issues by DK manufacturers (!) due to alleged limited market International Wind Diesel Conference, March 8 -11, 2011, Girdwood, Alaska 2

My Cold Climate (CC) background (not very extensive) • 1993 Project manager for a DK project on the possible application of • • WE in Greenland. The main issues were not so much CC related as WD and extreme wind related. Project pointed towards RE potential in both townships and remote communities (settlements). Recommendations were not followed, Greenland today relies on hydropower (about 80% of electricity production) Distant offspring of that project: In 2010 a 6 k. W Proven wind turbine was installed and connected to the diesel grid in the settlement Sarfannguaq. Independently of each other we put the cross where the WT should be erected on the precise same spot, 2001 One of the founding fathers (parents) of the IEA Annex 19, Wind Energy in Cold Climates. DK eventually left the annex by reason of lack of interest in CC issues by DK manufacturers (!) due to alleged limited market International Wind Diesel Conference, March 8 -11, 2011, Girdwood, Alaska 2

Winter. Wind 2011 in brief I • ”Since the 2008 Conference we have seen a growing interest in wind • • power on cold climate and icing conditions. Many companies now offer technical solutions for this big and upcoming market - - - We are proud to see delegates from over 15 countries at the 2011 Conference” 40 Presentations in English, similar number in Swedish in a parallel session 30 posters 25 exhibitors (equipment and service providers) 270 delegates Majority of presentations were on icing forecast and mitigation Not very many papers were on mechanical design and materials But a very interesting final round table had presentations by and discussion with major wind turbine manufacturers International Wind Diesel Conference, March 8 -11, 2011, Girdwood, Alaska 3

Winter. Wind 2011 in brief I • ”Since the 2008 Conference we have seen a growing interest in wind • • power on cold climate and icing conditions. Many companies now offer technical solutions for this big and upcoming market - - - We are proud to see delegates from over 15 countries at the 2011 Conference” 40 Presentations in English, similar number in Swedish in a parallel session 30 posters 25 exhibitors (equipment and service providers) 270 delegates Majority of presentations were on icing forecast and mitigation Not very many papers were on mechanical design and materials But a very interesting final round table had presentations by and discussion with major wind turbine manufacturers International Wind Diesel Conference, March 8 -11, 2011, Girdwood, Alaska 3

Winter. Wind 2011 in brief II • Jos Beurskens (old Dutch WE and WD warrior) conclusions @ end of Conference: Priorities at the Conference (with an eye on CC R&D needs): 1. 2. 3. 4. 5. Anti icing & de-icing Conditions for icing, icing probability, cc resistant equipment Hidden energy losses (icing, ice loads & aerodynamics, OM&R) Feed back from real operating experience to designers Update of market potential (only 3 presentations on the grid!!) You can see his complete presentation on the Winterwind 2011 home page www. winterwind 2011. se 4

Winter. Wind 2011 in brief II • Jos Beurskens (old Dutch WE and WD warrior) conclusions @ end of Conference: Priorities at the Conference (with an eye on CC R&D needs): 1. 2. 3. 4. 5. Anti icing & de-icing Conditions for icing, icing probability, cc resistant equipment Hidden energy losses (icing, ice loads & aerodynamics, OM&R) Feed back from real operating experience to designers Update of market potential (only 3 presentations on the grid!!) You can see his complete presentation on the Winterwind 2011 home page www. winterwind 2011. se 4

What did I especially notice I • GL Technical Note for CC: Normal operating temperature (certification) • Mean annual temperature 15 deg C • One year min / max survival temperature -20 to + 50 deg C • One year min / max operating temperature -10 to +40 deg C • Standard air density 1. 225 kg /m 3 • GL Technical Note for CC: Cold Climate ambient temperatures (certification) • Minimum 9 days of -20 deg C • Operation of turbines below -15 deg C • Manufacturers define the above 3 temperatures and the air density • To put it in perspective: If I remember correctly the 65 k. W Bonus WTG in Kuujuaq Canada was • Specified / Designed / Certified (? ) for -45 deg C • Operated the first two weeks in -65 deg C (operated !!) GL = Germanischer Lloyd 5

What did I especially notice I • GL Technical Note for CC: Normal operating temperature (certification) • Mean annual temperature 15 deg C • One year min / max survival temperature -20 to + 50 deg C • One year min / max operating temperature -10 to +40 deg C • Standard air density 1. 225 kg /m 3 • GL Technical Note for CC: Cold Climate ambient temperatures (certification) • Minimum 9 days of -20 deg C • Operation of turbines below -15 deg C • Manufacturers define the above 3 temperatures and the air density • To put it in perspective: If I remember correctly the 65 k. W Bonus WTG in Kuujuaq Canada was • Specified / Designed / Certified (? ) for -45 deg C • Operated the first two weeks in -65 deg C (operated !!) GL = Germanischer Lloyd 5

What did I especially notice II • Typical annual icing downtime 10 – 28 % (Finland) • International CC market 2010 - 2014 estimated to 4 -5. 000 MW, i. e. similar to • estimated offshore market (!). (IEA Annex 19). Maybe that’s why big WE industry is now interested. Blade heating, does it pay? Enercon is presently the only manuf. that offers blade heating incl. Warranty. 2 Enercon E 82 tested in Switzerland: • WTGs stop for 3 h blade heating when ice is detected. WTGs restart automatically after blade heating • Meteorological vs. Instrumental icing 10 vs. 40 days • Annual production loss w/o blade heating about 10 % • Blade heating allowed about 7 % more production than w/o heating • Energy needed for blade heating about 0. 4% of annual production • Production loss of about 3 % remains b/c WTGs stop for heating • Results are very site specific 6

What did I especially notice II • Typical annual icing downtime 10 – 28 % (Finland) • International CC market 2010 - 2014 estimated to 4 -5. 000 MW, i. e. similar to • estimated offshore market (!). (IEA Annex 19). Maybe that’s why big WE industry is now interested. Blade heating, does it pay? Enercon is presently the only manuf. that offers blade heating incl. Warranty. 2 Enercon E 82 tested in Switzerland: • WTGs stop for 3 h blade heating when ice is detected. WTGs restart automatically after blade heating • Meteorological vs. Instrumental icing 10 vs. 40 days • Annual production loss w/o blade heating about 10 % • Blade heating allowed about 7 % more production than w/o heating • Energy needed for blade heating about 0. 4% of annual production • Production loss of about 3 % remains b/c WTGs stop for heating • Results are very site specific 6

What did I especially notice III • Very little talk about isolated / WD systems and related WTG sizes. • Mostly utility grade & offshore machinery For those WTGs the manufacturers promised to develop and offer blade heating systems during the final round table (but they were not happy to provide us and their competitors with technical details): • Wind (Finland): Estimated 1, 95% of power production needed for blade heating. • Nordex Scandinavia: System developed with Skellefteå Power installed Nov 2010. ”Heating is easy, control is difficult” • Vestas: Working on de-icing techniques, will eventually provide as an option • Siemens: Ice is more of a problem than low temperatures (refers to Kuujuaq). Blade heating system will be integrated @ the factory. 2 nd generation expected to be ready in 2012 7

What did I especially notice III • Very little talk about isolated / WD systems and related WTG sizes. • Mostly utility grade & offshore machinery For those WTGs the manufacturers promised to develop and offer blade heating systems during the final round table (but they were not happy to provide us and their competitors with technical details): • Wind (Finland): Estimated 1, 95% of power production needed for blade heating. • Nordex Scandinavia: System developed with Skellefteå Power installed Nov 2010. ”Heating is easy, control is difficult” • Vestas: Working on de-icing techniques, will eventually provide as an option • Siemens: Ice is more of a problem than low temperatures (refers to Kuujuaq). Blade heating system will be integrated @ the factory. 2 nd generation expected to be ready in 2012 7

Winterwind conclusion • Was it well organized and well operated? Yes, definitely • Was it worthwhile attending? I think so • Was it relevant for WD in Alaska and other CC places? • With respect to meteorological & instrumental icing issues: Yes, • • absolutely. • With respect to WD and related machinery. Not a lot, although developments in blade heating (round table) and certification (GL) may eventually become relevant. The Conference program and all presentations can be downloaded from the home page http: //winterwind 2011. se/programme. html There is a lot of good info there. But beware!: There were two sessions in parallel, one in English and one in Swedish. Most of you won’t understand the Swedish presentations, but they are there anyway. Some of the pictures are nice to watch. 8

Winterwind conclusion • Was it well organized and well operated? Yes, definitely • Was it worthwhile attending? I think so • Was it relevant for WD in Alaska and other CC places? • With respect to meteorological & instrumental icing issues: Yes, • • absolutely. • With respect to WD and related machinery. Not a lot, although developments in blade heating (round table) and certification (GL) may eventually become relevant. The Conference program and all presentations can be downloaded from the home page http: //winterwind 2011. se/programme. html There is a lot of good info there. But beware!: There were two sessions in parallel, one in English and one in Swedish. Most of you won’t understand the Swedish presentations, but they are there anyway. Some of the pictures are nice to watch. 8

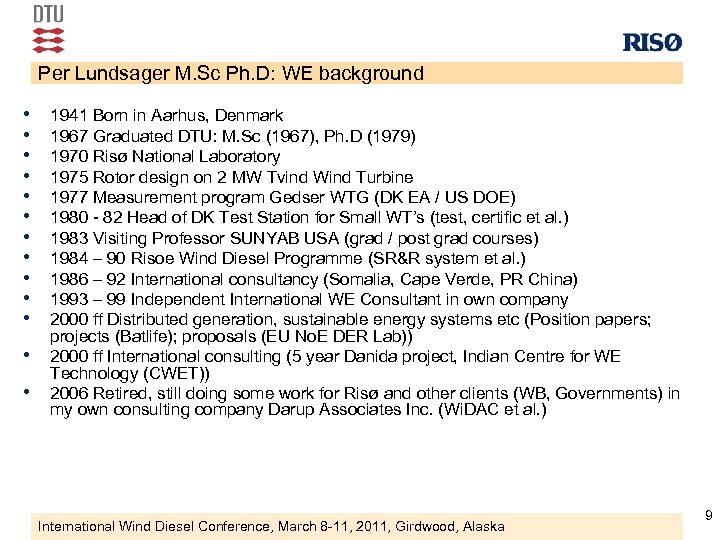

Per Lundsager M. Sc Ph. D: WE background • • • • 1941 Born in Aarhus, Denmark 1967 Graduated DTU: M. Sc (1967), Ph. D (1979) 1970 Risø National Laboratory 1975 Rotor design on 2 MW Tvind Wind Turbine 1977 Measurement program Gedser WTG (DK EA / US DOE) 1980 - 82 Head of DK Test Station for Small WT’s (test, certific et al. ) 1983 Visiting Professor SUNYAB USA (grad / post grad courses) 1984 – 90 Risoe Wind Diesel Programme (SR&R system et al. ) 1986 – 92 International consultancy (Somalia, Cape Verde, PR China) 1993 – 99 Independent International WE Consultant in own company 2000 ff Distributed generation, sustainable energy systems etc (Position papers; projects (Batlife); proposals (EU No. E DER Lab)) 2000 ff International consulting (5 year Danida project, Indian Centre for WE Technology (CWET)) 2006 Retired, still doing some work for Risø and other clients (WB, Governments) in my own consulting company Darup Associates Inc. (Wi. DAC et al. ) International Wind Diesel Conference, March 8 -11, 2011, Girdwood, Alaska 9

Per Lundsager M. Sc Ph. D: WE background • • • • 1941 Born in Aarhus, Denmark 1967 Graduated DTU: M. Sc (1967), Ph. D (1979) 1970 Risø National Laboratory 1975 Rotor design on 2 MW Tvind Wind Turbine 1977 Measurement program Gedser WTG (DK EA / US DOE) 1980 - 82 Head of DK Test Station for Small WT’s (test, certific et al. ) 1983 Visiting Professor SUNYAB USA (grad / post grad courses) 1984 – 90 Risoe Wind Diesel Programme (SR&R system et al. ) 1986 – 92 International consultancy (Somalia, Cape Verde, PR China) 1993 – 99 Independent International WE Consultant in own company 2000 ff Distributed generation, sustainable energy systems etc (Position papers; projects (Batlife); proposals (EU No. E DER Lab)) 2000 ff International consulting (5 year Danida project, Indian Centre for WE Technology (CWET)) 2006 Retired, still doing some work for Risø and other clients (WB, Governments) in my own consulting company Darup Associates Inc. (Wi. DAC et al. ) International Wind Diesel Conference, March 8 -11, 2011, Girdwood, Alaska 9