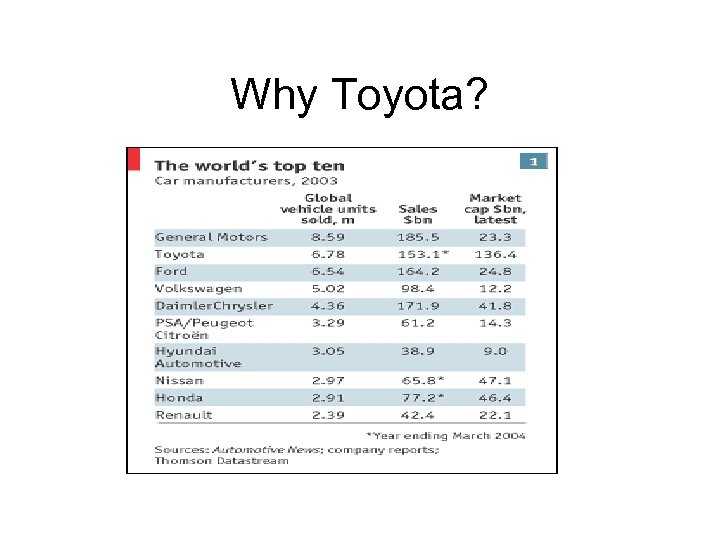

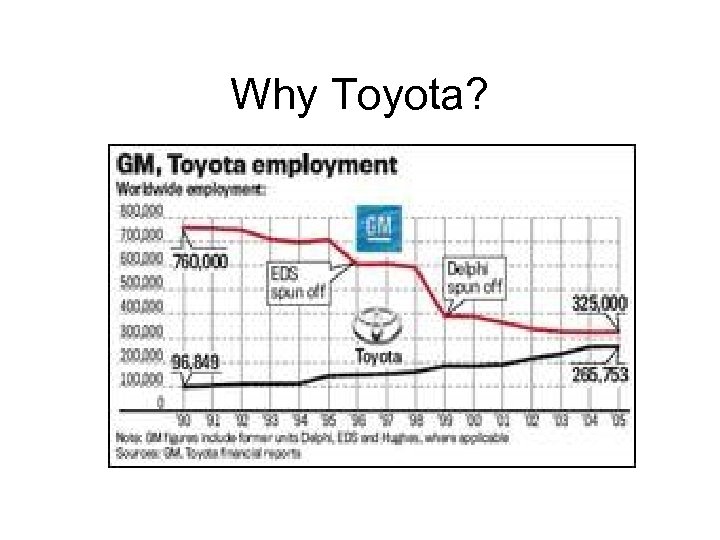

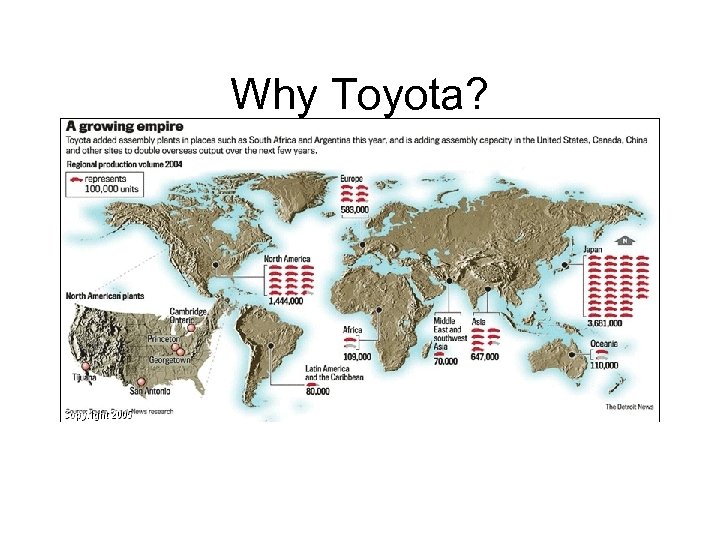

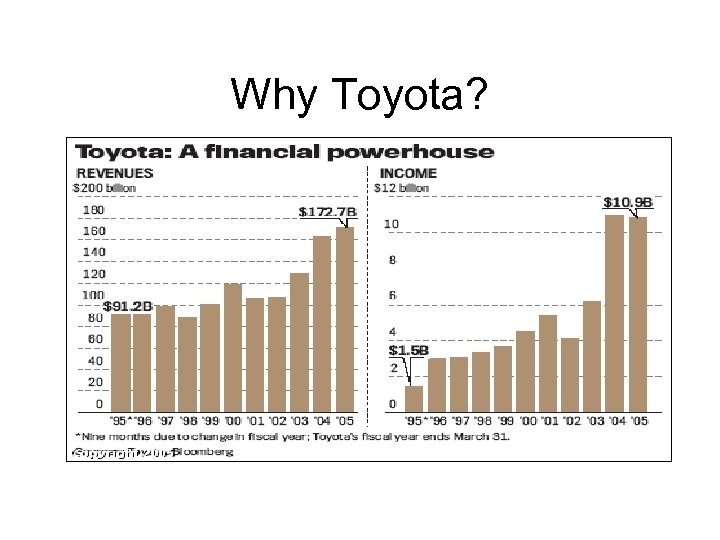

Why Toyota?

Why Toyota?

Why Toyota?

Why Toyota?

Why Toyota?

Why Toyota?

Why not Toyota?

Why not Toyota?

Why Toyota?

Why Toyota?

History

History

History (cont. )

History (cont. )

Toyota Production System (TPS)

Toyota Production System (TPS)

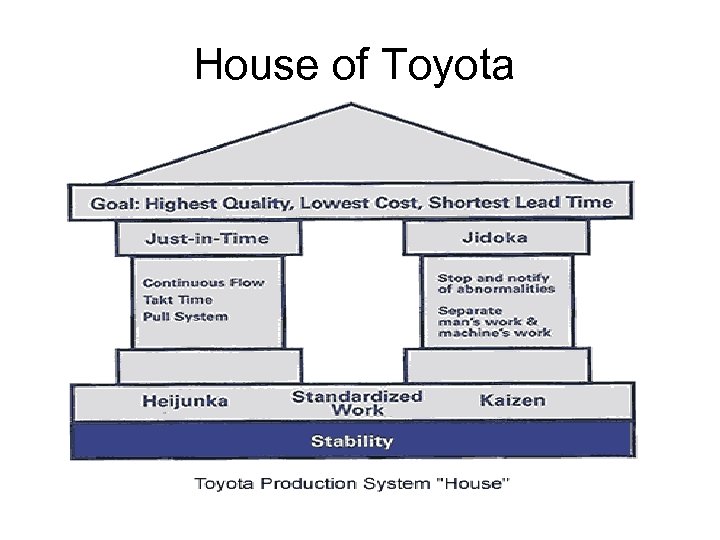

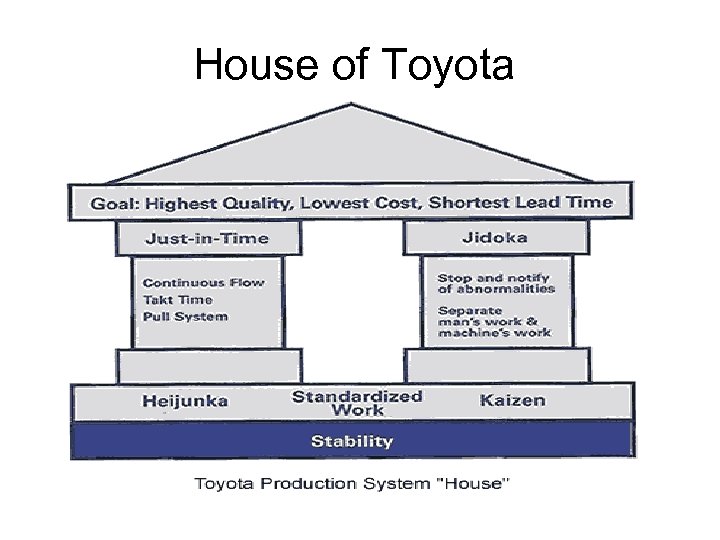

House of Toyota

House of Toyota

How to make money?

How to make money?

Toyota’s philosophy

Toyota’s philosophy

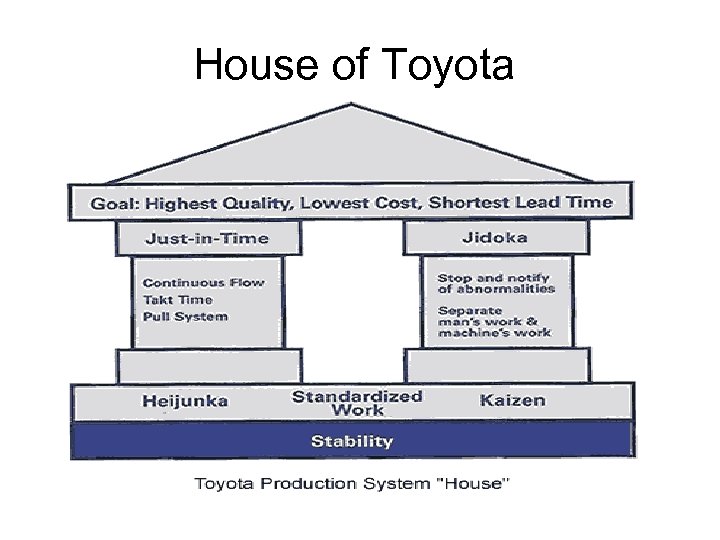

House of Toyota

House of Toyota

What Does Just-in-Time Do?

What Does Just-in-Time Do?

Introductory Quotation

Introductory Quotation

Variability Occurs Because

Variability Occurs Because

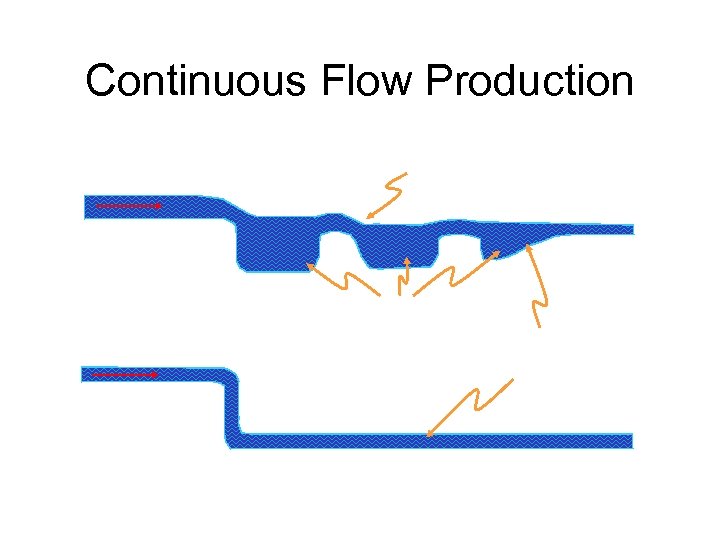

Continuous Flow Production

Continuous Flow Production

Push versus Pull

Push versus Pull

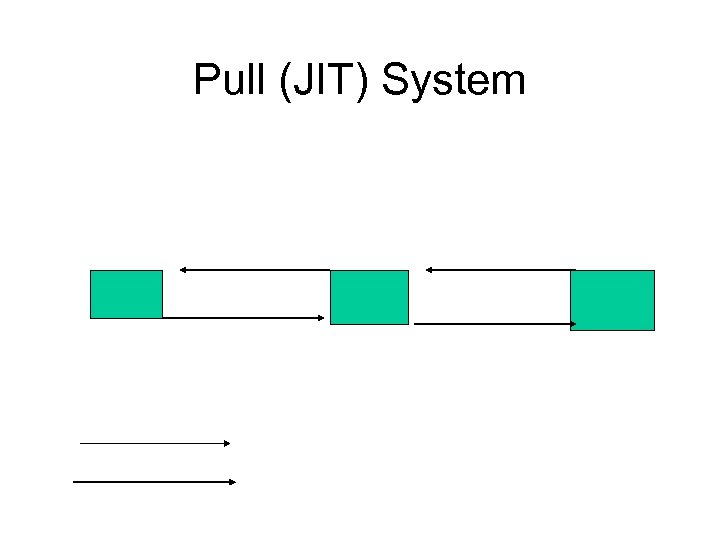

Pull (JIT) System

Pull (JIT) System

Kanban

Kanban

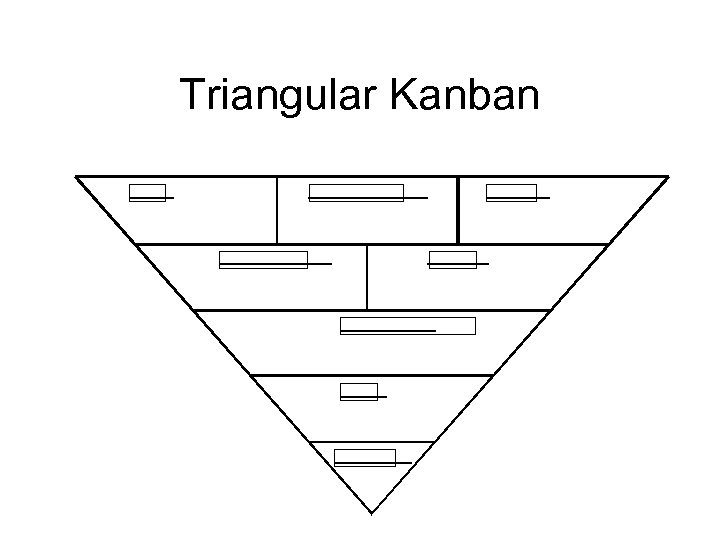

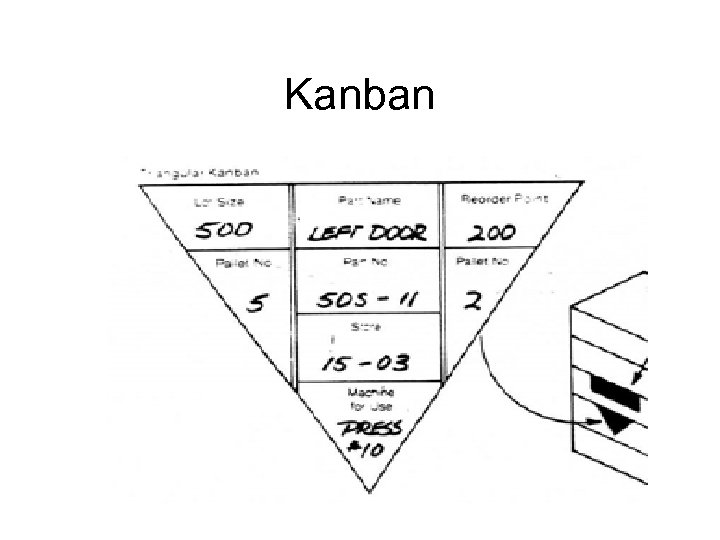

Triangular Kanban

Triangular Kanban

Kanban

Kanban

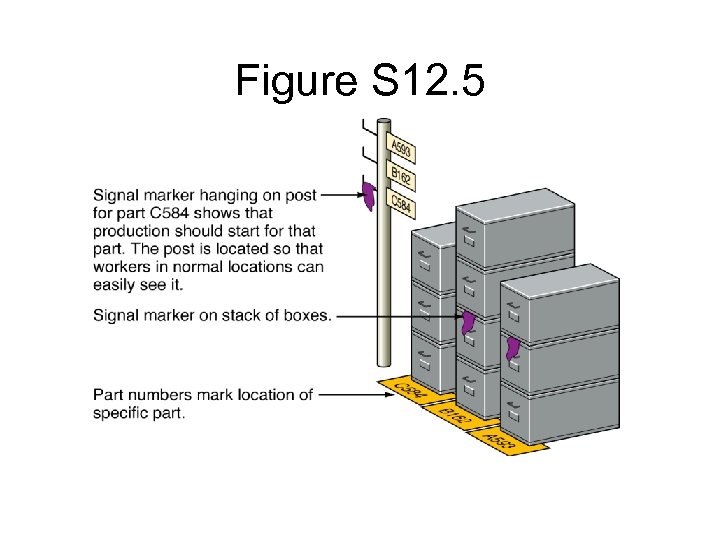

Figure S 12. 5

Figure S 12. 5

Kanban

Kanban

Kanban System

Kanban System

Inventory

Inventory

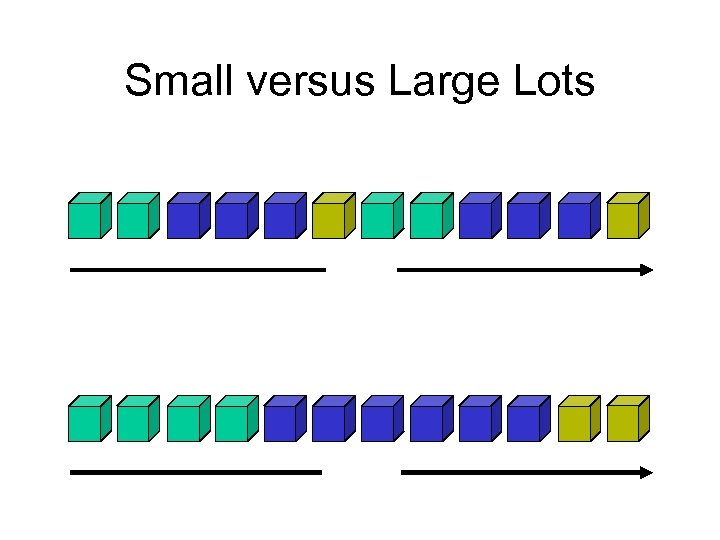

Small versus Large Lots

Small versus Large Lots

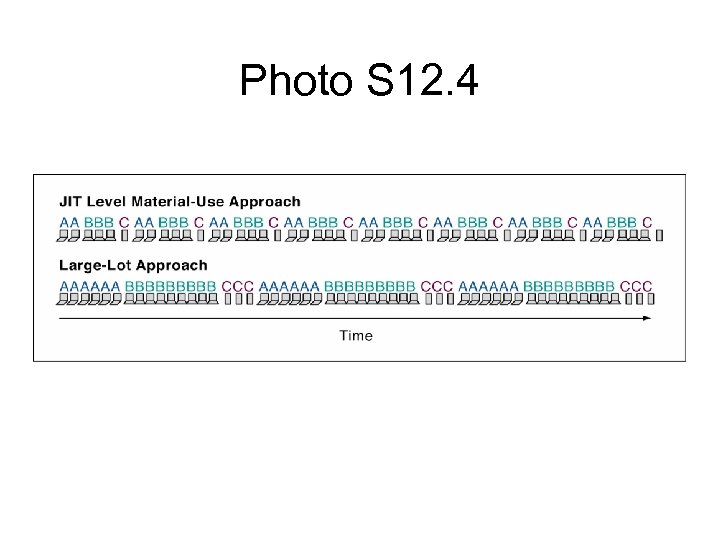

Photo S 12. 4

Photo S 12. 4

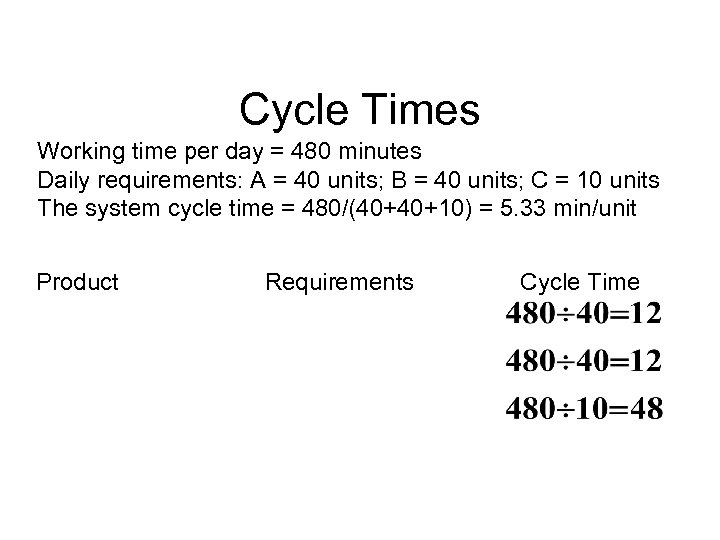

Cycle Times Working time per day = 480 minutes Daily requirements: A = 40 units; B = 40 units; C = 10 units The system cycle time = 480/(40+40+10) = 5. 33 min/unit Product Requirements Cycle Time

Cycle Times Working time per day = 480 minutes Daily requirements: A = 40 units; B = 40 units; C = 10 units The system cycle time = 480/(40+40+10) = 5. 33 min/unit Product Requirements Cycle Time

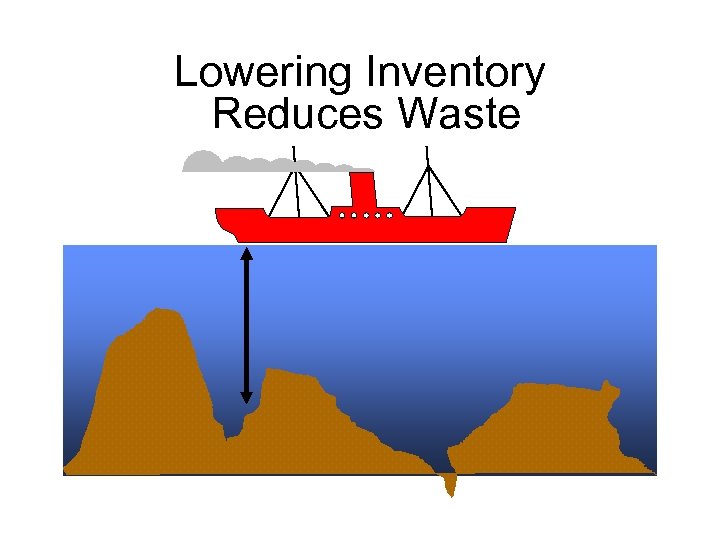

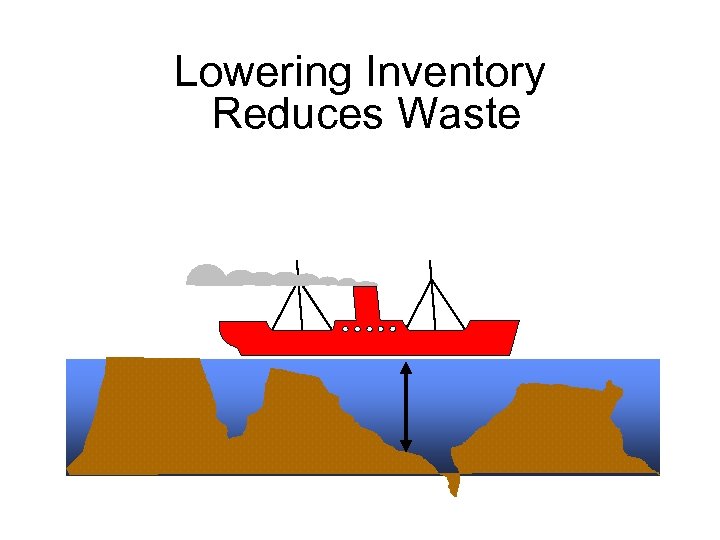

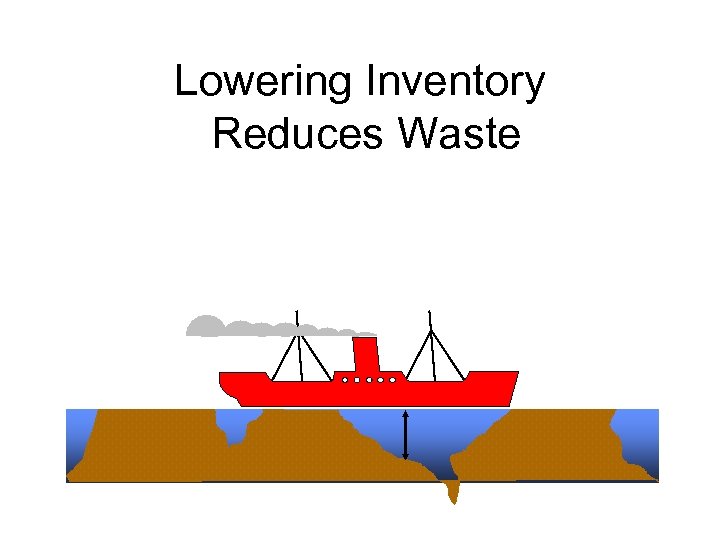

Lowering Inventory Reduces Waste

Lowering Inventory Reduces Waste

Lowering Inventory Reduces Waste

Lowering Inventory Reduces Waste

Lowering Inventory Reduces Waste

Lowering Inventory Reduces Waste

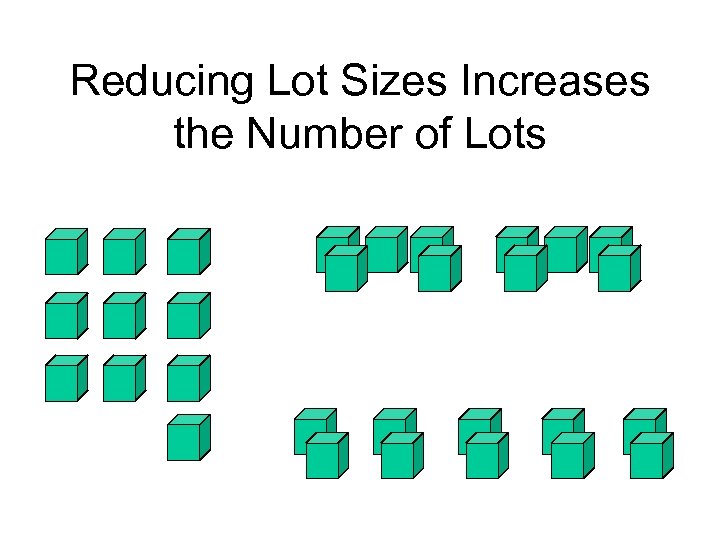

Reducing Lot Sizes Increases the Number of Lots

Reducing Lot Sizes Increases the Number of Lots

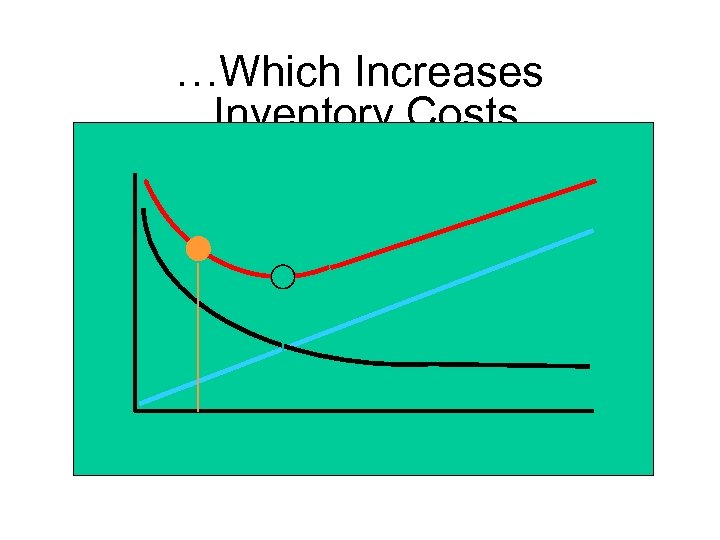

…Which Increases Inventory Costs

…Which Increases Inventory Costs

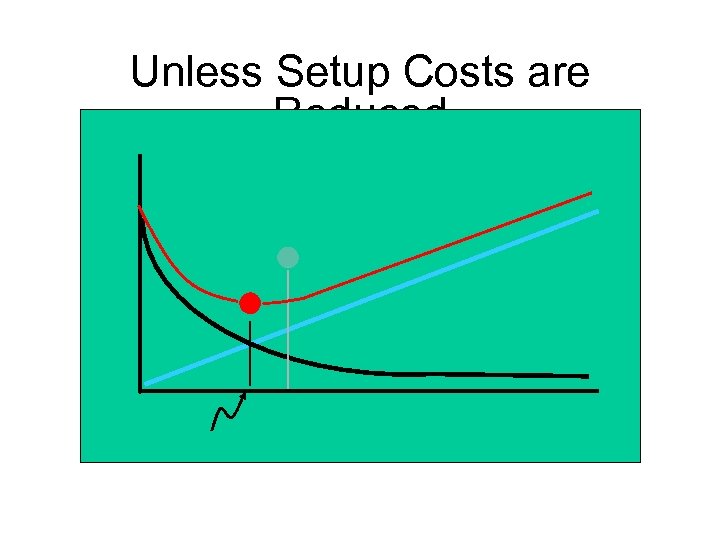

Unless Setup Costs are Reduced

Unless Setup Costs are Reduced

Quick setup = Quick changeover

Quick setup = Quick changeover

Setup Components

Setup Components

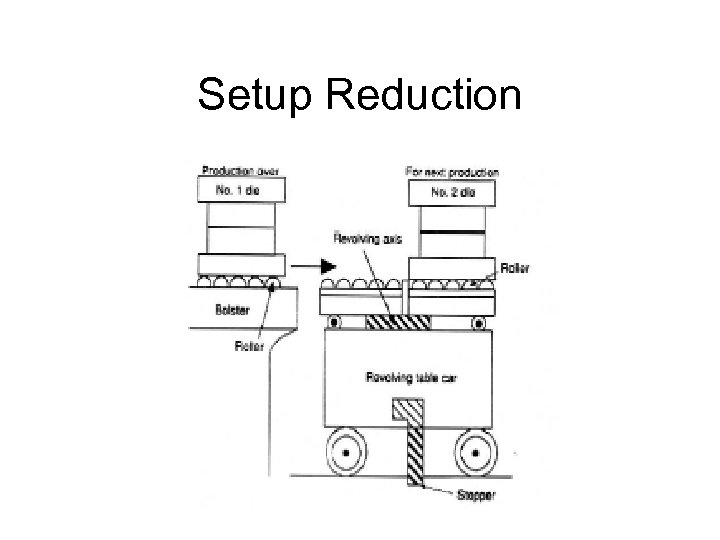

Setup Reduction

Setup Reduction

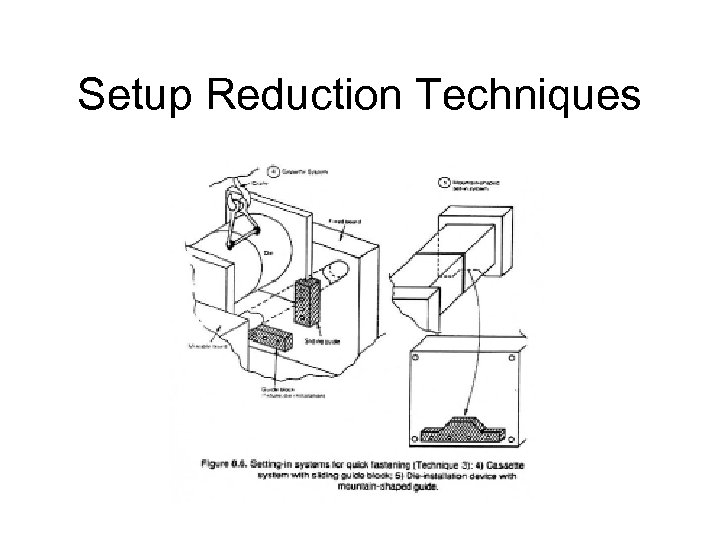

Setup Reduction Techniques

Setup Reduction Techniques

Quality At The Source

Quality At The Source

House of Toyota

House of Toyota

Jidoka

Jidoka

Jidoka Techniques

Jidoka Techniques

Kaizen

Kaizen

GEMBA

GEMBA

5 S

5 S

5 S in a Factory

5 S in a Factory

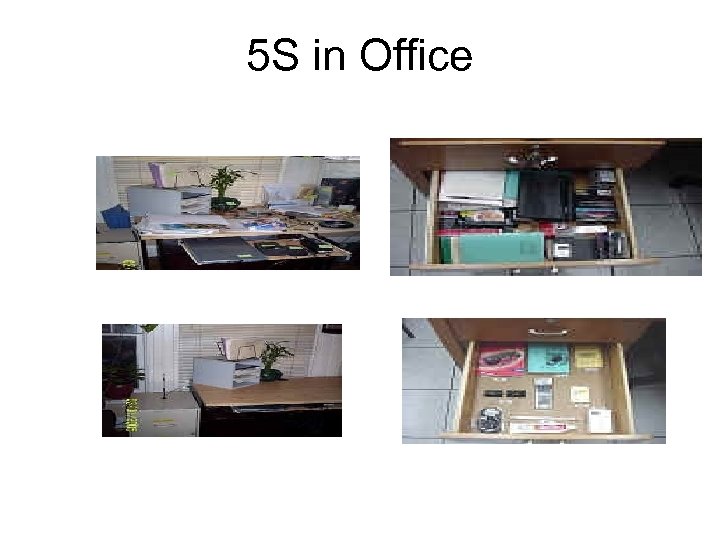

5 S in Office

5 S in Office

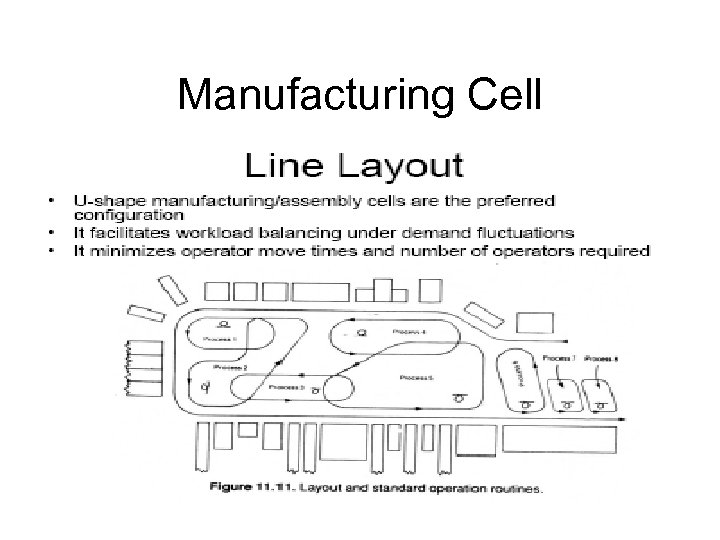

Manufacturing Cell

Manufacturing Cell

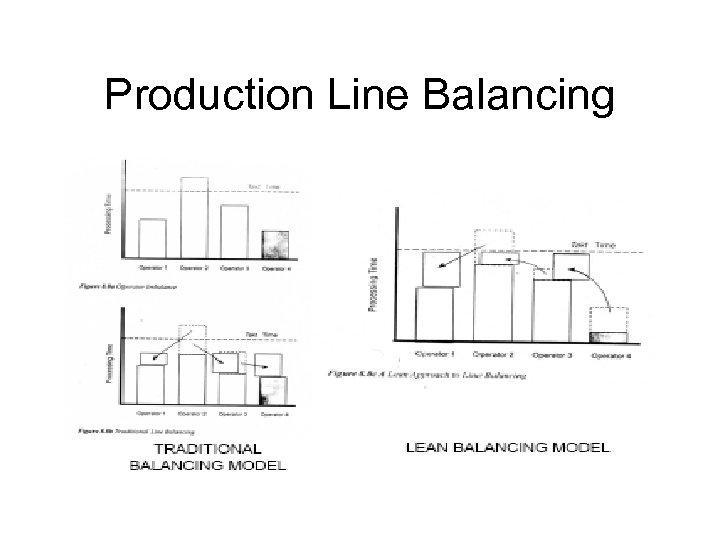

Production Line Balancing

Production Line Balancing

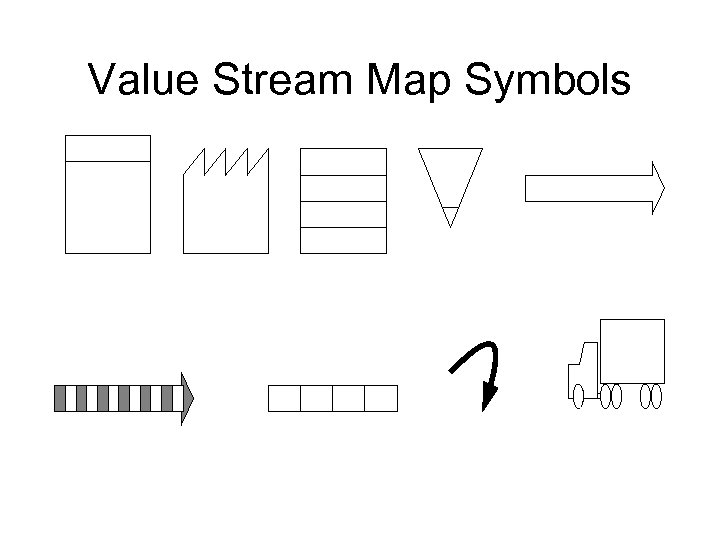

Value Stream Map Symbols

Value Stream Map Symbols

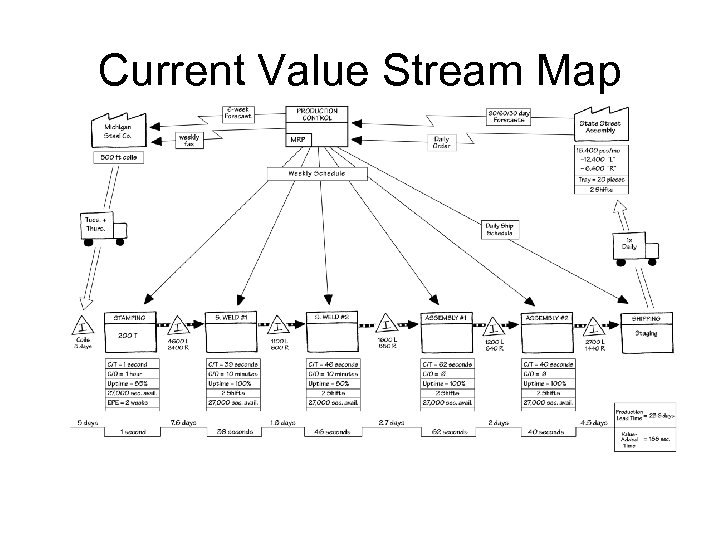

Current Value Stream Map

Current Value Stream Map

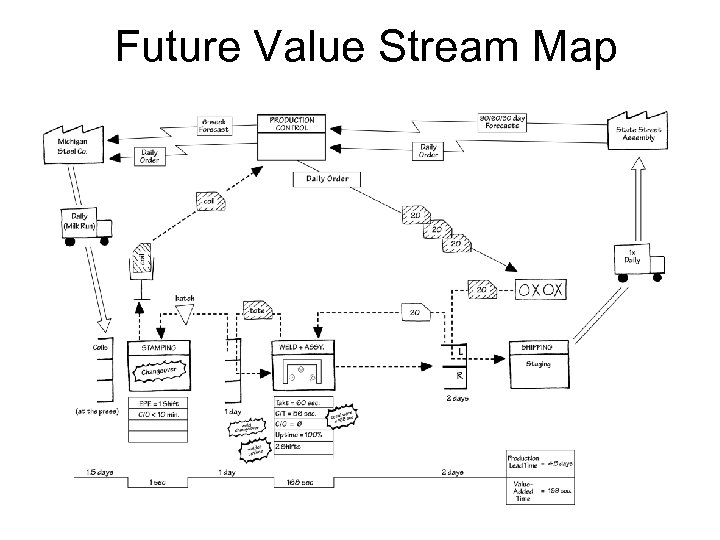

Future Value Stream Map

Future Value Stream Map

Attributes of Lean Producers they

Attributes of Lean Producers they