3ce328952c4871251e03a72a207eb2e1.ppt

- Количество слайдов: 33

Why Benchmark? + + + + Identify opportunities Set realistic but aggressive goals Challenge internal paradigms on what is possible Understand methods for improved processes Uncover strengths within your organization Learn from the leaders’ experiences Better prioritize and allocate resources Performance Improvement

E&S Tucson - November 1999 Evaluating Targets • • • Is this process important to our customers? Would improvements in this process support our business goals and objectives? Is the process owner committed to making changes in this process?

E&S Tucson - November 1999 Keys to Successful Benchmarking What You Need to Make Benchmarking Effective • • Focus on the processes that are critical to your business Willingness to admit that you’re not the best Openness to new ideas from potentially unexpected sources Commitment to provide resources and to overcome resistance to change • Recognition given to successful benchmarking teams • Understanding of the benchmarking process • Communication to the organization about the objectives of the benchmarking project

E&S Tucson - November 1999 When You Shouldn’t Benchmark • • • it isn’t critical to the business You don’t know what your customers require from your process Key stakeholders aren’t involved in the benchmarking project Inadequate resources have been committed You have an unreasonable fear of sharing information with benchmarking partners There are no up-front plans for implementing your findings You haven’t done your “homework” before contacting benchmarking partners You’re benchmarking an organization rather than a process There is a strong resistance to change When you are expecting results instantaneously

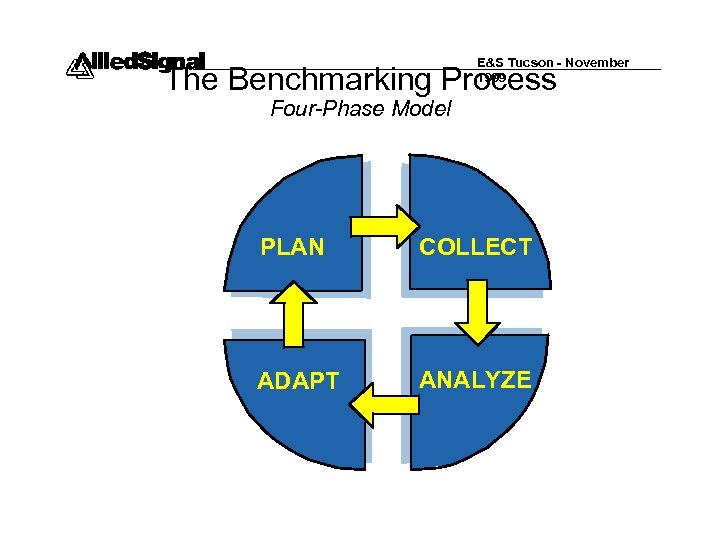

E&S Tucson - November 1999 The Benchmarking Process Four-Phase Model PLAN COLLECT ADAPT ANALYZE

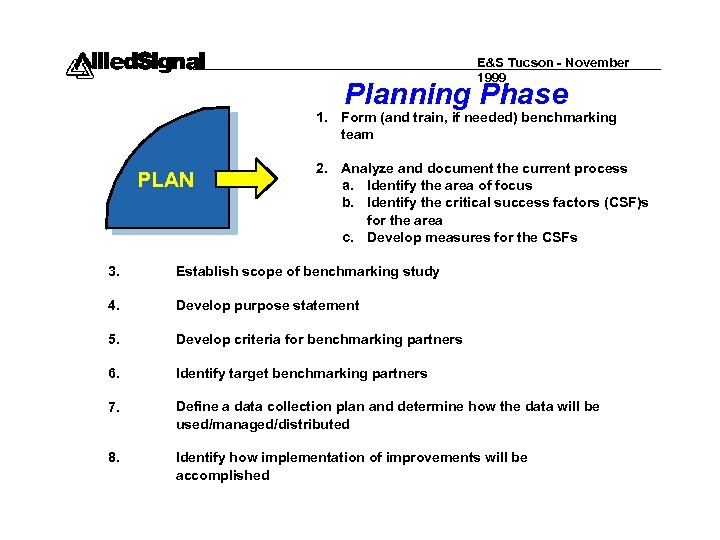

E&S Tucson - November 1999 Planning Phase 1. Form (and train, if needed) benchmarking team PLAN 2. Analyze and document the current process a. Identify the area of focus b. Identify the critical success factors (CSF)s for the area c. Develop measures for the CSFs 3. Establish scope of benchmarking study 4. Develop purpose statement 5. Develop criteria for benchmarking partners 6. Identify target benchmarking partners 7. Define a data collection plan and determine how the data will be used/managed/distributed 8. Identify how implementation of improvements will be accomplished

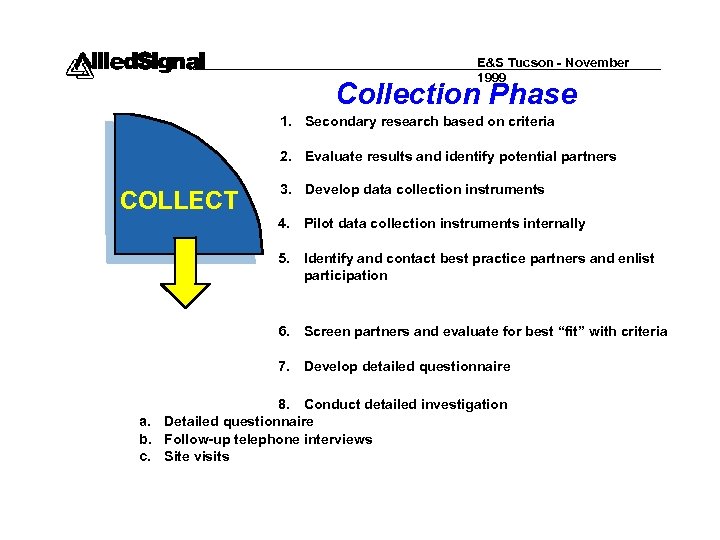

E&S Tucson - November 1999 Collection Phase 1. Secondary research based on criteria 2. Evaluate results and identify potential partners COLLECT 3. Develop data collection instruments 4. Pilot data collection instruments internally 5. Identify and contact best practice partners and enlist participation 6. Screen partners and evaluate for best “fit” with criteria 7. Develop detailed questionnaire 8. Conduct detailed investigation a. Detailed questionnaire b. Follow-up telephone interviews c. Site visits

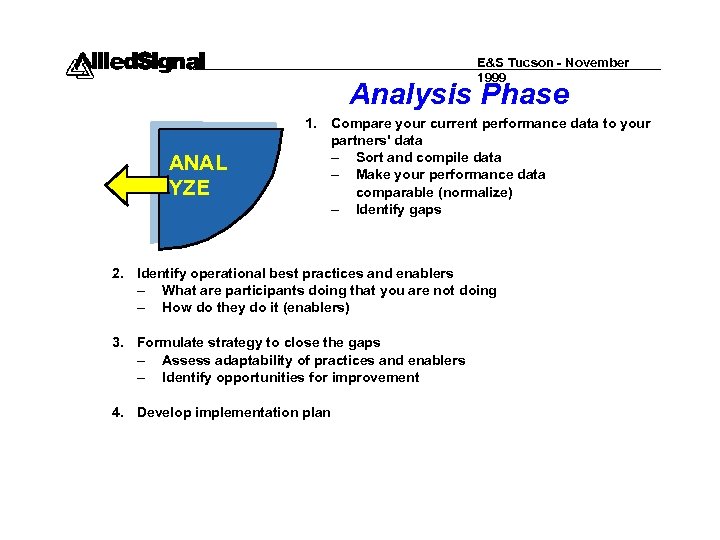

E&S Tucson - November 1999 Analysis Phase ANAL YZE 1. Compare your current performance data to your partners' data – Sort and compile data – Make your performance data comparable (normalize) – Identify gaps 2. Identify operational best practices and enablers – What are participants doing that you are not doing – How do they do it (enablers) 3. Formulate strategy to close the gaps – Assess adaptability of practices and enablers – Identify opportunities for improvement 4. Develop implementation plan

E&S Tucson - November 1999 Adapting Improvements 1. Implement the plan 2. Monitor and report progress 4 4 4 Celebrate ! ! ! 4 4 4 (Acknowledge the benchmarking team) ADAPT 3. Document the study Communicate the results (internally and to benchmarking partners) Assist in the internal transfer of best practices 4. – – Plan for continuous improvement Identify new benchmarking opportunities Set new goals

Benchmarking • A control process. – Involving employees in the process of evaluation and change. – Philosophy one of self control rather than imposed control, where the person most closely associated with the task is involved in the cross measurement and assessment of practice. – Places personnel in a position where their unquestioned beliefs (paradigm) may be challenged , creating opportunities for innovation and learning. 10

Benchmarking Ø Ø Benchmarking is the process of continually searching for the best methods, practices and processes, and either adopting or adapting their good features and implementing them to become the “best of the best. ” Measuring your performance against that of the best-in-class companies, determining how the best-in-class achieve those performance levels, and using the information as a basis for your own company’s targets, strategies, and implementation. • Compare performance of an existing process against other companies’ best-in-class practices • Determine how those companies achieve their performance levels • Improve internal performance levels Total Quality Management - Spring 2010 - IUG 11

Xerox 12 -Step Benchmarking Process v Phase 1: Planning Ø 1. Identify what to benchmark; Ø 2. Identify comparative companies; Ø 3. Determine data collection method & collect data. v Phase 2: Analysis Ø 4. Determine current performance gap; Ø 5. Project future performance levels. v Phase 3: Integration Ø 6. Communicate finding and gain acceptance; Ø 7. Establish functional goals. Total Quality Management - Spring 2010 - IUG 12

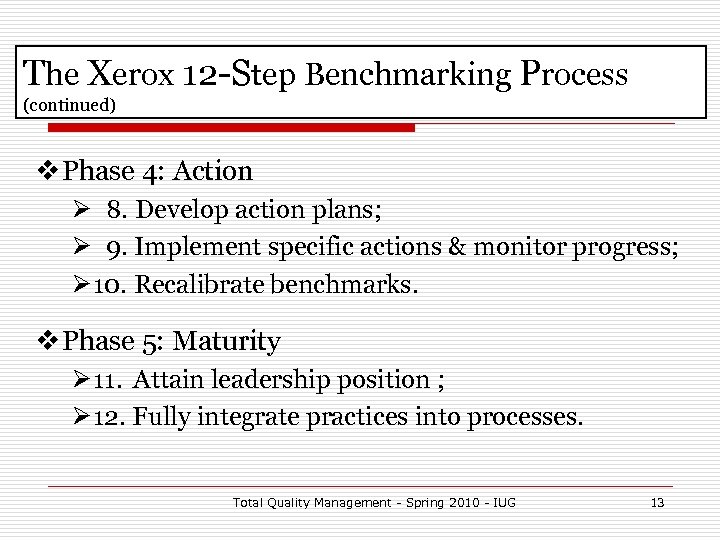

The Xerox 12 -Step Benchmarking Process (continued) v Phase 4: Action Ø 8. Develop action plans; Ø 9. Implement specific actions & monitor progress; Ø 10. Recalibrate benchmarks. v Phase 5: Maturity Ø 11. Attain leadership position ; Ø 12. Fully integrate practices into processes. Total Quality Management - Spring 2010 - IUG 13

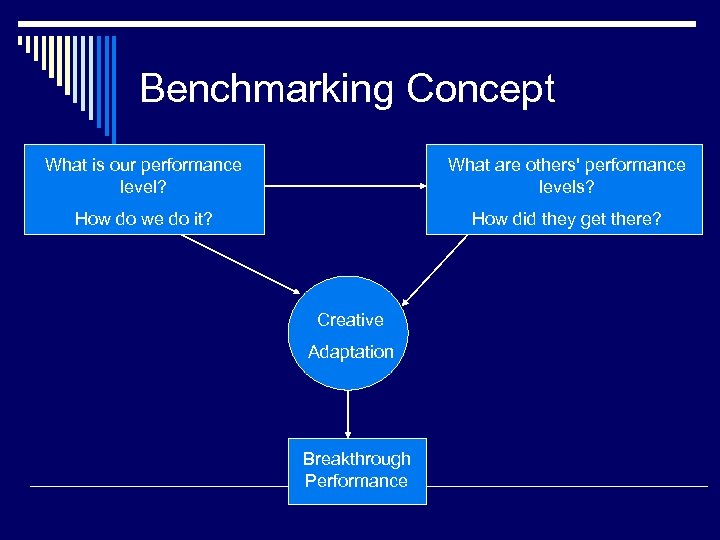

Benchmarking Concept What is our performance level? What are others' performance levels? How do we do it? How did they get there? Creative Adaptation Breakthrough Performance

Reasons to Benchmark o Promotes continuous improvement o Makes companies search for the best practices, innovative ideas, and highly effective operating procedures o Can notify a company if it has fallen behind the competition o Inspires managers to compete o Allows goals to be set objectively

6 General Steps to Benchmarking 1) Decide what to benchmark 2) Understand current performance 3) Plan 4) Study others 5) Learn from the data 6) Use the findings

Questions for Discussion o Explain how an organization might benefit from benchmarking organizations in a completely different industry…

Gaining Insight Through Benchmarking • Benchmarking is the sharing of information between companies, so that both can improve. • The first step a benchmarking firm must take is to document current performance. • If the managers in firm are unsure that they are pursuing a useful plan of action, benchmarking can help them understand how what they are doing stacks up against the master. © 2001 Prentice-Hall Transparency 6 -18

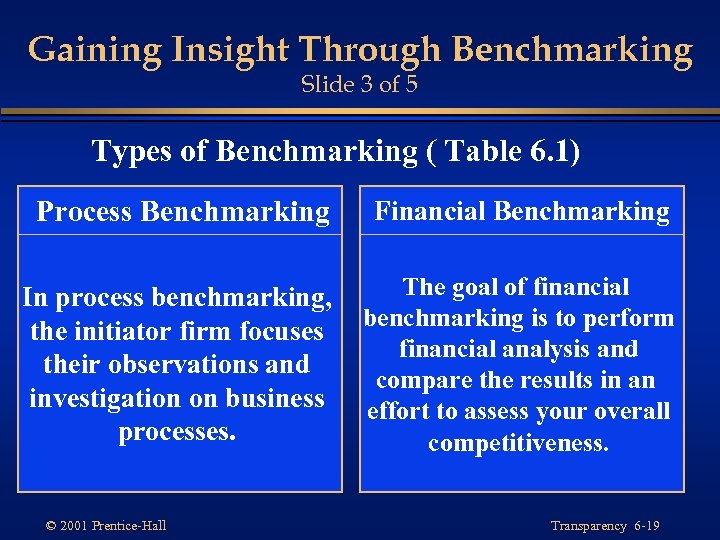

Gaining Insight Through Benchmarking Slide 3 of 5 Types of Benchmarking ( Table 6. 1) Process Benchmarking Financial Benchmarking In process benchmarking, the initiator firm focuses their observations and investigation on business processes. The goal of financial benchmarking is to perform financial analysis and compare the results in an effort to assess your overall competitiveness. © 2001 Prentice-Hall Transparency 6 -19

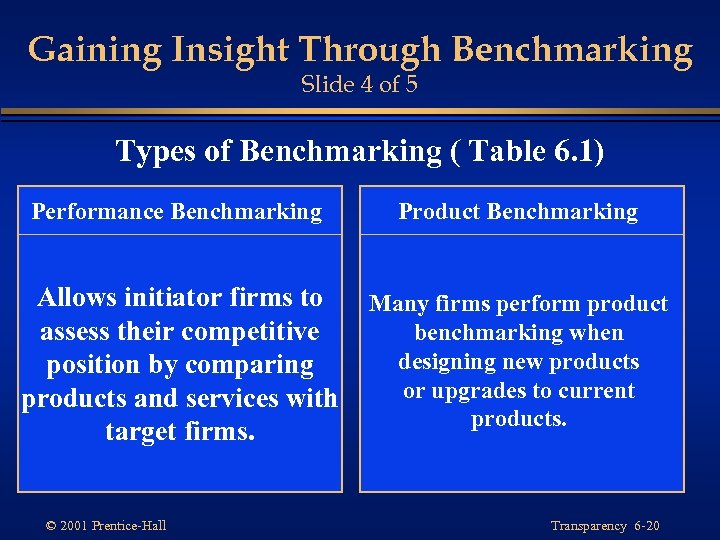

Gaining Insight Through Benchmarking Slide 4 of 5 Types of Benchmarking ( Table 6. 1) Performance Benchmarking Product Benchmarking Allows initiator firms to assess their competitive position by comparing products and services with target firms. Many firms perform product benchmarking when designing new products or upgrades to current products. © 2001 Prentice-Hall Transparency 6 -20

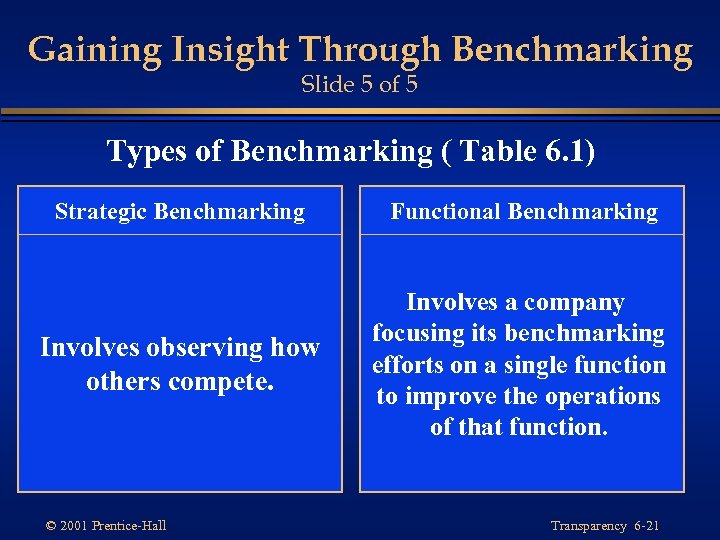

Gaining Insight Through Benchmarking Slide 5 of 5 Types of Benchmarking ( Table 6. 1) Strategic Benchmarking Functional Benchmarking Involves observing how others compete. Involves a company focusing its benchmarking efforts on a single function to improve the operations of that function. © 2001 Prentice-Hall Transparency 6 -21

Problems With Benchmarking Slide 1 of 2 • 1. There is an enormous difficulty obtaining cooperation from other firms in your own industry. © 2001 Prentice-Hall Transparency 6 -22

Problems With Benchmarking Slide 2 of 2 • 2. Your efforts will be wasted unless you fully understand your own processes before you benchmark against someone else. • 3. Benchmarking is time consuming and costly. © 2001 Prentice-Hall Transparency 6 -23

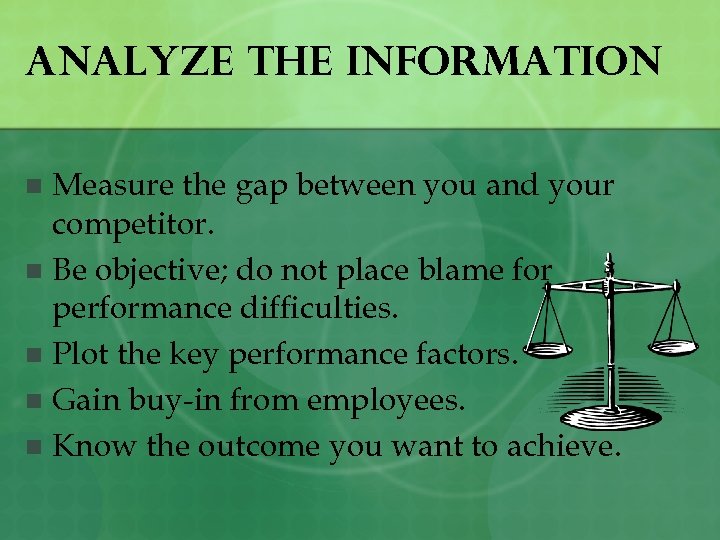

Analyze the Information Measure the gap between you and your competitor. n Be objective; do not place blame for performance difficulties. n Plot the key performance factors. n Gain buy-in from employees. n Know the outcome you want to achieve. n

Self Notes! Benchmark - against the best & try to beat them!. Competitive benchmarking – study from distance – no contact Cooperative benchmarking It is not cheating, illegal, immoral, unethical. In bm, two companies agree to cooperate. And the companies need not be competitor! Best in class not willing to partner. Far away (geography).

Continued! Evaluating where you are – determining where you are going How much water you use – how much coffee. Benchmark it No need of spending time in lab for what you can learn from others. In area where you lag far behind, world do not have time to give you for ci. Look far and wide – thief @ warehouse – look how casinos stop theft.

Prerequisite to benchmarking: Before getting involved in BM Will & commitment: Top management – process owner. BM objective linked with strategic objective: Goal is to become the best – not simply improved. It is not about incremental improvement, unless you are far below from world class. Openness to new ideas: essence of bm to capitalize on the ideas of others! Thorough understanding of own processes, products, services, practices, customer requirements so we can know what needs to be benchmarked. Processes must be completely documented too. So everyone working have similar understanding of the process. Process analysis skills – self and partner. Research (identify best in class process owners), communication and team-building skills (to carry out bm activity).

Obstacles to successful BM – why it can fail Internally focused – not looking outside. Just improving from past. BM objective too broad. Narrow it for example, invoicing issue. Unrealistic timetable. It can take some time. 6 -8 months. Evaluate if time is a year. Poor team composition. Process users must be involved. They can pick subtle difference in our vs “their” process. Engineers and supervisors yes but process owners who use it are important. Settling for “ok in class”: benchmarking best in class. Insensitivity to partner: you are disrupting their routine. Taking valuable time from their key people. Observe common courtesy + protocol. Limited support from top leadership.

Role of management in benchmarking: Commitment to change – improve – becoming world class – learning from others – money & time can get wasted. Funding – authorized by management. E. g you might have to travel to best in class. HR available to benchmark. How much process info to disclose. Involvement. Which process to benchmark & who is target.

Benchmarking sequence – number of variations are possible but Obtain management commitment – money available – key people available – they will need information in exchange which can be only authorized by management. You are looking for major changes. No management approval, stop! Baseline your own processes – understand process – capability. Cant have lcl and ucl without understanding process. Identify your strong (your partner will need info) and weak processes and document them. Working on weakest link. Select processes to be benchmarked. – don’t benchmark what you don’t wish to change! It is not about satisfying curiosity. Form benchmarking teams. Management representation – radical changes. Research the best in class – who is willing. Process is account receivable – look for credit card company. Select candidate best in class benchmarking partners. Competitor? U will share info? Form agreements with benchmarking partners. Visit arrangements. Point of contact. Limits of disclosure.

Benchmarking sequence (continued) Collect data. Observe, collect, document everything about target process. Try to understand underlying factors. They apply TPM, statistics, employee involvement. You are in different plant culture. Be open to why they do better. When you leave you should know how to adopt/adapt/implement that process, if not, more work required. Analyse data and establish the gap. Cost of applying. Can we afford. Your plan is to be best in class, not just replicate the process. Plan action to close the gap or surpass. Implement change. Monitor. SPC invaluable tool here. Update benchmarks: continue cycle. … … … Competition and u on same level – no – surpass it! Bm is not about zero gap. Added information you observed while observing the process. Study atmosphere & environment play a big role on productivity. Try to bring good elements in your culture. Never ending process. Knowledge you gain through bm (the process itself).

Stealing shamelessly – BM No with permission – adapting, adopting ideas BM Expensive – would it be relevant in the future BM + Understanding what is the future! How old is BM Concept – first time someone thought, learn from each other Cheaper (cost), faster (time), better (quality) Industry safeguard their secrets BM – Neither quick nor easy Best in class is a moving target! Productivity/quality race has no end point. What makes BM Success! Is organization ready? Process manager ready? KPI!

Attributes for the airline service quality Proper baggage handling Competitive airfare On-time arrival/departure Alterative flight arrangement for a missing flight Smooth connecting flight Airplane cleanliness Availability of non-stop flights Short wait at the ticket counter Complimentary drinks/snacks Complimentary pillows/blankets Frequent flier program

3ce328952c4871251e03a72a207eb2e1.ppt