Well Stimulation on Tengiz Field Dombaeva Anar RMG

Well Stimulation on Tengiz Field Dombaeva Anar RMG Trainee July, 2007 TCO

Content Stimulation Goals Diverters Coiled Tubing Job Procedure VDA Summary

Stimulation Goals Removal of buildup from tubing walls and perforations. Removal of partial plugging up of well bottom-hole with fragments of drilled formation, oil-based drill mud and plugging material. Reducing of Skin factor during perforation at pressure higher than the hydrostatical pressure. Improve hydrodynamic bond between the well and formation. Increase depth of perforating penetration.

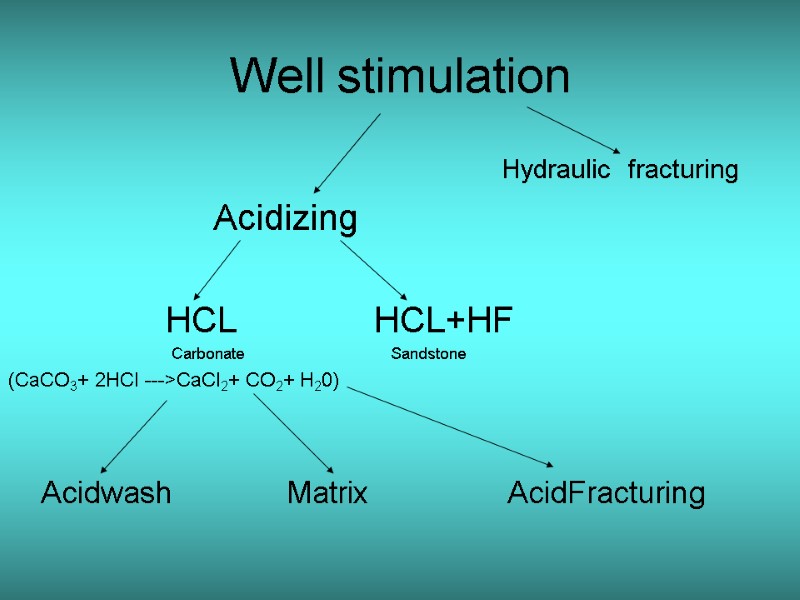

Well stimulation Hydraulic fracturing Acidizing HCL HCL+HF Carbonate Sandstone (CaCO3+ 2HCl --->CaCl2+ CO2+ H20) Acidwash Matrix AcidFracturing

Diverters Viscous fluid (ex. VDA) Balls Particles Foam CT Packer (Demands cased hole completion and workover rig)

Coiled Tubing Job procedure CT pickling Crude oil displacement stage Preflush Acid stage Overflash stage Diverter stage Repeat steps (4-6 as necessary) Final displacement stage

VDA Based on Shlumberger technology of using viscoelastic mud surfactant Improves variation during acid treatment of carbonate formations at pressure lower than hydraulic fracturing the variation is based on change of acid viscosity in formation acid density is low during injection. it increases as far as injection goes Corrosion monitoring

VDA Applications •Stimulation carbonate formations •Oil producers or water injection wells •Multilayered reservoirs and reservoirs with long production intervals •Reservoirs with variations in permeability •Horizontal and vertical wells •Bullheading or pumping through coiled tubing

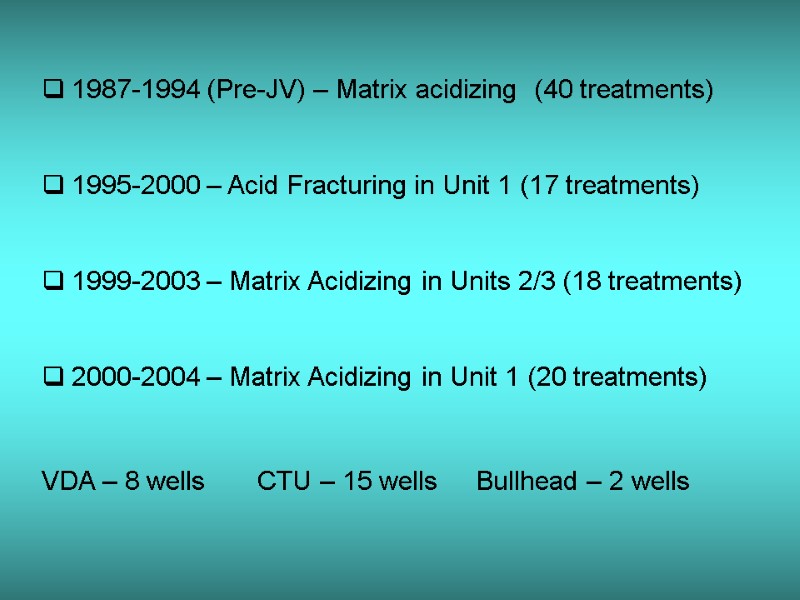

1987-1994 (Pre-JV) – Matrix acidizing (40 treatments) 1995-2000 – Acid Fracturing in Unit 1 (17 treatments) 1999-2003 – Matrix Acidizing in Units 2/3 (18 treatments) 2000-2004 – Matrix Acidizing in Unit 1 (20 treatments) VDA – 8 wells CTU – 15 wells Bullhead – 2 wells

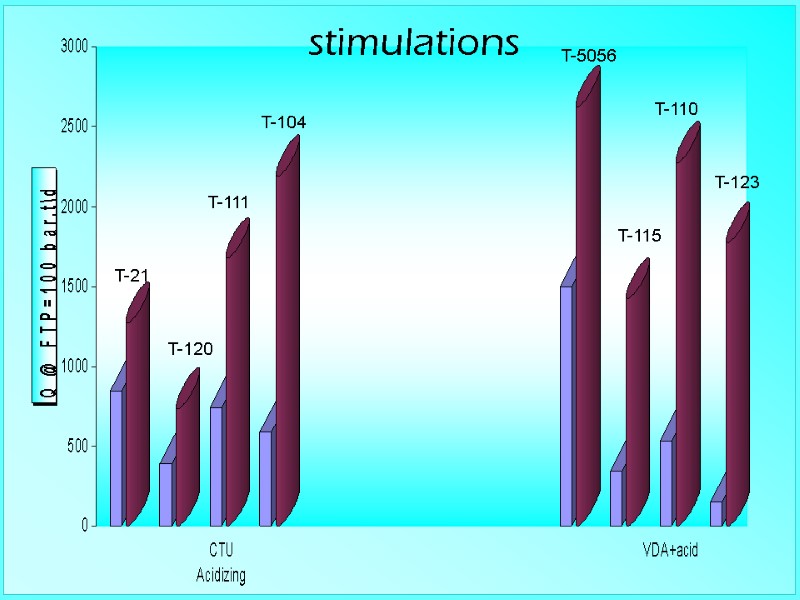

stimulations T-123 T-110 T-115 T-5056 T-104 T-111 T-120 T-21

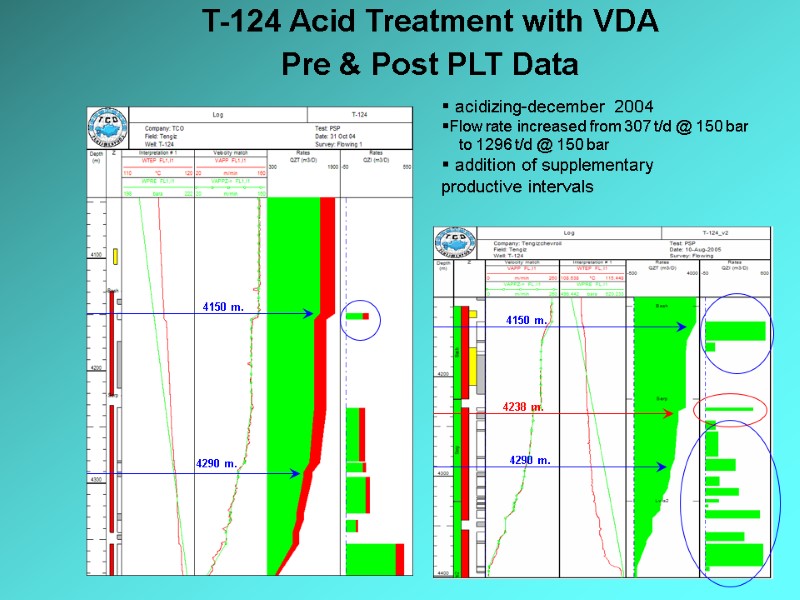

T-124 Acid Treatment with VDA Pre & Post PLT Data 4150 m. 4290 m. 4150 m. 4290 m. 4238 m. acidizing-december 2004 Flow rate increased from 307 t/d @ 150 bar to 1296 t/d @ 150 bar addition of supplementary productive intervals

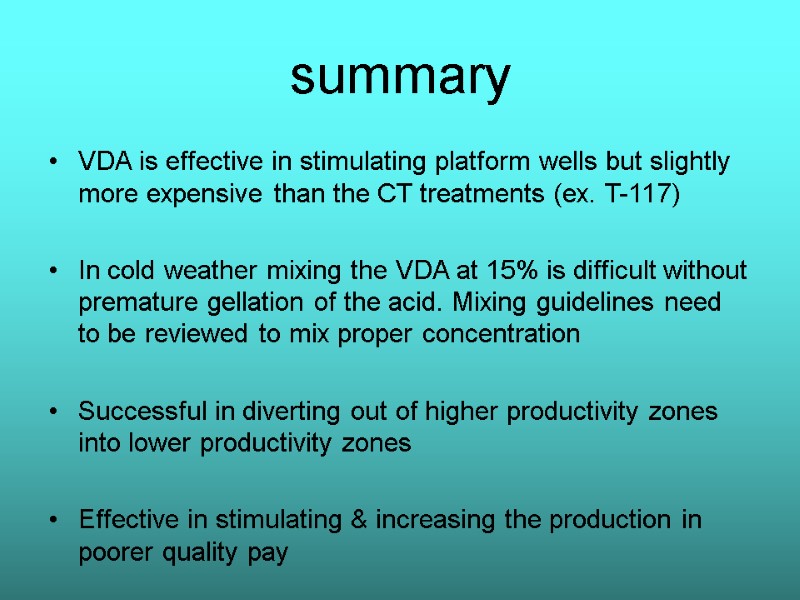

summary VDA is effective in stimulating platform wells but slightly more expensive than the CT treatments (ex. T-117) In cold weather mixing the VDA at 15% is difficult without premature gellation of the acid. Mixing guidelines need to be reviewed to mix proper concentration Successful in diverting out of higher productivity zones into lower productivity zones Effective in stimulating & increasing the production in poorer quality pay

Thanks For Attention

7650-lekciya8_well_stimulation_.ppt

- Количество слайдов: 13