64590a630f5dbf8291abd86b9f2c2158.ppt

- Количество слайдов: 17

Welcome Water-Lubricated Bearings

Lignum Vitae Described Lignum Vitae is the hardest heaviest wood in the world @ (84. 4 lbs. /ft. 3), it is most commonly used for bearings and wear surfaces. Due to the hardness and lubricity it is the most durable bearing material in salt water and unfiltered run of the river applications. • Combination of enormous compression strength unmatched lubricity with tremendous shock absorption qualities. • When warmed, the wood’s resin comes to the surface, creating a lubricating glaze impervious to water that does not migrate off the surface of the bearing. • Zero clearance providing a solution for vibration and instability typically found in older equipment –Increases the longevity • Is the most steel friendly material known to man (no smearing or wiping to shaft) • Only 100% natural renewable industrial bearings available.

A History of Firsts • 1852 - First successful stern tube bearing for ship rotating shafts patented by John Penn. • 1856 - Lignum Vitae bearings were used by the SS Great Eastern to lay the first transatlantic cable. • 1856 - Lignum Vitae Stern Tube Bearings were the first to make a transatlantic voyage. • 1882 - Lignum Vitae bearings were the first hydro bearings specified by Thomas Edison at the Appleton Wisconsin plant still using Lignum Vitae bearings. • 1952 - The SS United States broke the transatlantic speed record averaging 39. 71 miles per hour from Cornwall U. K. to New York City using Lignum Vitae bearings. The record still stands today. • Lignum Vitae was considered a competitive advantage and classified for 50 years after WW 11 making all relevant information a secret until recent times. • Lignum Vitae bearings were used in the first nuclear submarine the USS Nautilus. • Polar class icebreakers, the Polar Star and the Polar Sea, the largest non-nuclear ships were designed to operated on Lignum Vitae bearings.

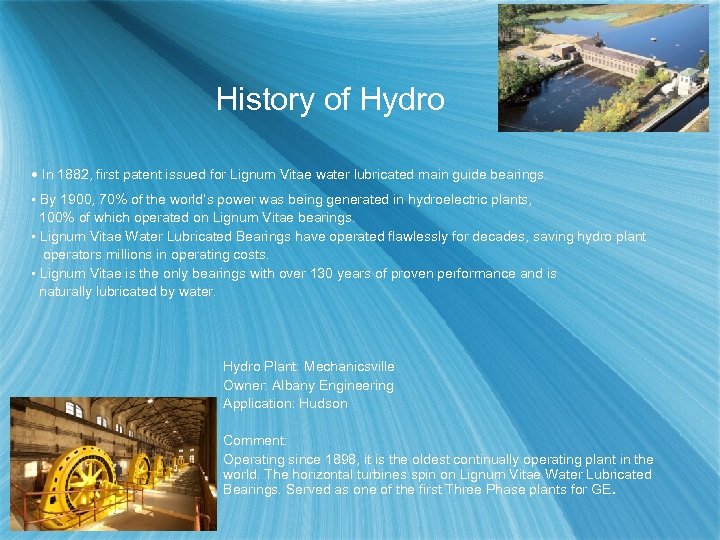

History of Hydro • In 1882, first patent issued for Lignum Vitae water lubricated main guide bearings. • By 1900, 70% of the world’s power was being generated in hydroelectric plants, 100% of which operated on Lignum Vitae bearings. • Lignum Vitae Water Lubricated Bearings have operated flawlessly for decades, saving hydro plant operators millions in operating costs. • Lignum Vitae is the only bearings with over 130 years of proven performance and is naturally lubricated by water. Hydro Plant: Mechanicsville Owner: Albany Engineering Application: Hudson Comment: Operating since 1898, it is the oldest continually operating plant in the world. The horizontal turbines spin on Lignum Vitae Water Lubricated Bearings. Served as one of the first Three Phase plants for GE.

Lignum Vitae Supply WWII put pressure on the supply of Lignum Vitae when the U. S. , Japan, and Germany replaced all brass & lead bearings in the stern tubes of their destroyers, submarines, and aircraft carriers. Due to this interruption in supply composites and plastics began experimenting with various substitutes. Lignum Vitae North America subscribes to a harvest schedule that has been endorsed by CITES after issuing a “non detriment harvest of Lignum Vitae” statement. With a sustainable harvesting program in place, Lignum Vitae North America has a sustainable supply of Lignum Vitae that will last into perpetuity. Lignum Vitae North America currently stocks 200 tons of Lignum Vitae, prime bearing material in inventory.

Environmentally Friendly • • • NSF-61 Certified for Water treatment plants Oil and grease free Lead and toxic metal free in manufacturing No EPA, hazmat compliance and DEQ issues Self/Water lubricated bearing No oil lines to maintain, no inspections for leaks, no seals required. No plastic or composite to smear or wipe onto shaft. No moving parts, low coefficient of friction, 100% reliable. 100% renewable bearing.

Our Mission Provide a reliable long term water lubricated bearing solution to industry employing underwater rotating shafts currently using oil, grease or composites by eliminating all threat of accidental leaks into the water.

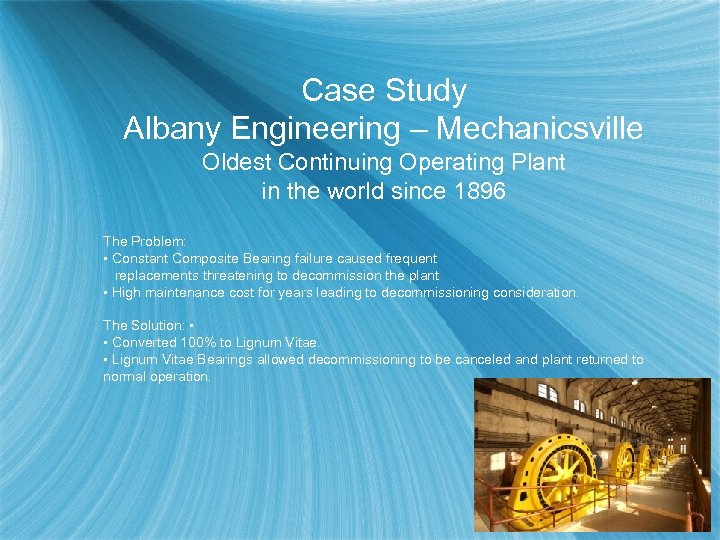

Case Study Albany Engineering – Mechanicsville Oldest Continuing Operating Plant in the world since 1896 The Problem: • Constant Composite Bearing failure caused frequent replacements threatening to decommission the plant • High maintenance cost for years leading to decommissioning consideration. The Solution: • • Converted 100% to Lignum Vitae. • Lignum Vitae Bearings allowed decommissioning to be canceled and plant returned to normal operation.

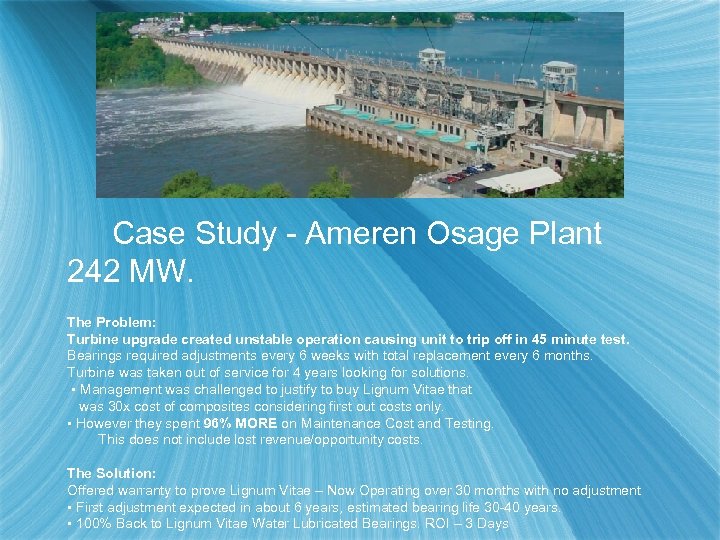

Case Study - Ameren Osage Plant 242 MW. The Problem: Turbine upgrade created unstable operation causing unit to trip off in 45 minute test. Bearings required adjustments every 6 weeks with total replacement every 6 months. Turbine was taken out of service for 4 years looking for solutions. • Management was challenged to justify to buy Lignum Vitae that was 30 x cost of composites considering first out costs only. • However they spent 96% MORE on Maintenance Cost and Testing. This does not include lost revenue/opportunity costs. The Solution: Offered warranty to prove Lignum Vitae – Now Operating over 30 months with no adjustment • First adjustment expected in about 6 years, estimated bearing life 30 -40 years. • 100% Back to Lignum Vitae Water Lubricated Bearings. ROI – 3 Days

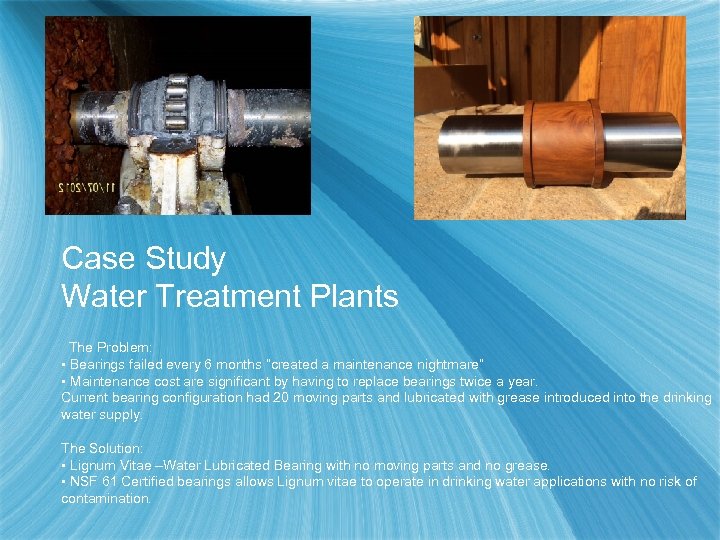

Case Study Water Treatment Plants The Problem: • Bearings failed every 6 months “created a maintenance nightmare” • Maintenance cost are significant by having to replace bearings twice a year. Current bearing configuration had 20 moving parts and lubricated with grease introduced into the drinking water supply. The Solution: • Lignum Vitae –Water Lubricated Bearing with no moving parts and no grease. • NSF 61 Certified bearings allows Lignum vitae to operate in drinking water applications with no risk of contamination.

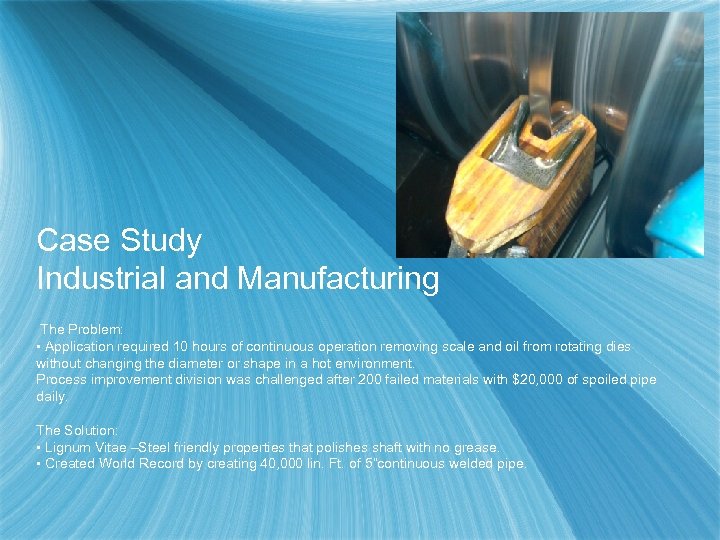

Case Study Industrial and Manufacturing The Problem: • Application required 10 hours of continuous operation removing scale and oil from rotating dies without changing the diameter or shape in a hot environment. Process improvement division was challenged after 200 failed materials with $20, 000 of spoiled pipe daily. The Solution: • Lignum Vitae –Steel friendly properties that polishes shaft with no grease. • Created World Record by creating 40, 000 lin. Ft. of 5”continuous welded pipe.

Case Study Steady Rest The Problem: • When manufacturing a crankshaft you need to do precise finish work and a product was needed to hold the shaft in place without damaging the shaft. The Solution: • Lignum Vitae –Steel Friendly- Self-Lubricating with no moving parts and no grease. • Polishes steel – Does not: Score, Wipe, or smear steel.

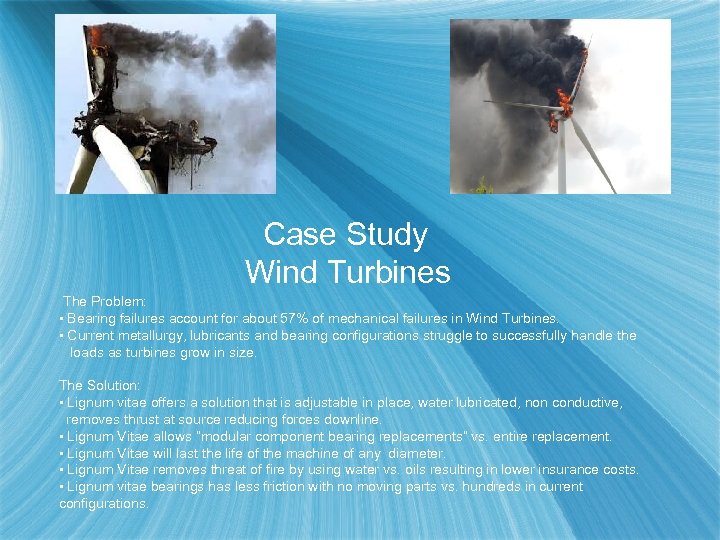

Case Study Wind Turbines The Problem: • Bearing failures account for about 57% of mechanical failures in Wind Turbines. • Current metallurgy, lubricants and bearing configurations struggle to successfully handle the loads as turbines grow in size. The Solution: • Lignum vitae offers a solution that is adjustable in place, water lubricated, non conductive, removes thrust at source reducing forces downline. • Lignum Vitae allows “modular component bearing replacements” vs. entire replacement. • Lignum Vitae will last the life of the machine of any diameter. • Lignum Vitae removes threat of fire by using water vs. oils resulting in lower insurance costs. • Lignum vitae bearings has less friction with no moving parts vs. hundreds in current configurations.

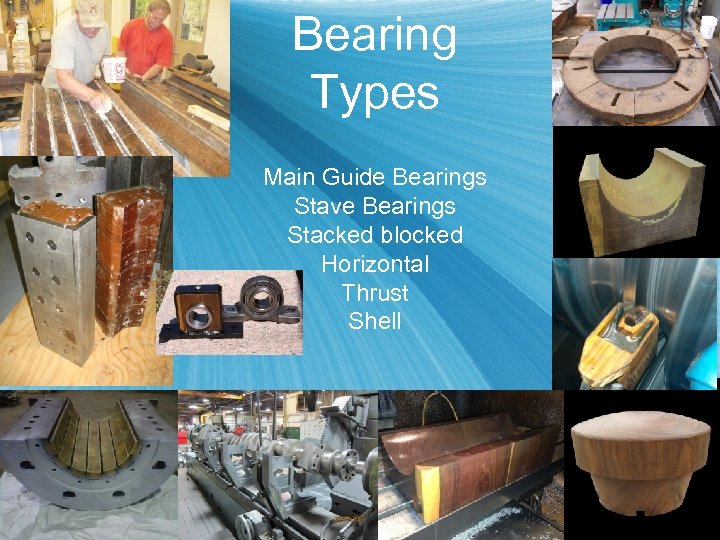

Bearing Types Main Guide Bearings Stave Bearings Stacked blocked Horizontal Thrust Shell

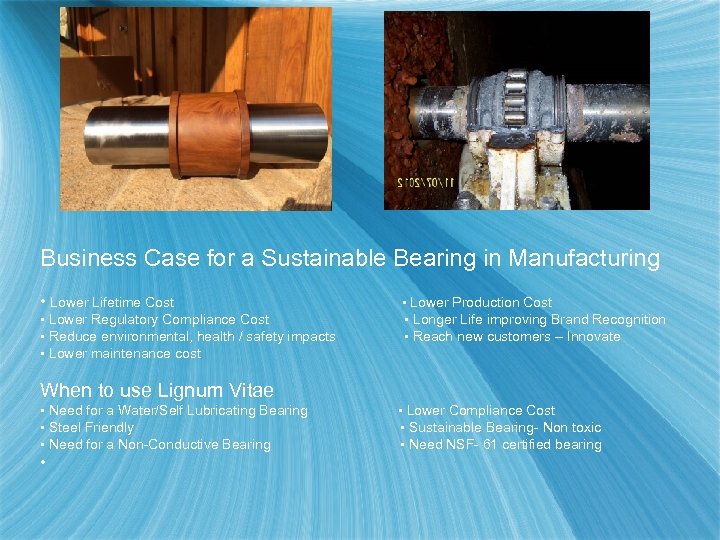

Business Case for a Sustainable Bearing in Manufacturing • Lower Lifetime Cost • Lower Production Cost • Lower Regulatory Compliance Cost • Longer Life improving Brand Recognition • Reduce environmental, health / safety impacts • Reach new customers – Innovate • Lower maintenance cost When to use Lignum Vitae • Need for a Water/Self Lubricating Bearing • Steel Friendly • Need for a Non-Conductive Bearing • Lower Compliance Cost • Sustainable Bearing- Non toxic • Need NSF- 61 certified bearing

Why Water Lubricated Bearings are important to the future of water applications: Environmental issues will eventually dictate removal of all oil and greased materials that threaten leaking into the water supply. Lawsuits filed in various watersheds will accelerate conversions to environmentally friendly materials. Risk adverse operators will require a reliable water lubricated bearing to replace all sealed oiled bearings. It is our hope not one penny is spent defending outdated environmentally damaging bearings when a reliable alternative exists. “Restlessness and discontent are the first necessity of progress. ”

Lignum-Vitae Water-Lubricated Bearings Bob Shortridge bshortridge@lignum-vitae. com www. lignum-vitae-bearings. com

64590a630f5dbf8291abd86b9f2c2158.ppt