d60217a8342eacc775bc353a0e3400b9.ppt

- Количество слайдов: 41

Welcome to the Plymouth Resource Efficiency Club Plymouth Manufacturers Group Adding value through environmental management

The Team Gary Nelson: Project Director Joe Reynolds: Senior Consultant Tim Ashmore: Senior Consultant Companies: Plymouth Resource Efficiency Club Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Introduction to Resource Efficiency Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club What Is Resource Efficiency ? Ø Awareness has taught us that the world’s resources are finite. Every year we try to improve our performance against increased restrictions, and the costs to business go up. Ø Don’t think of it as just saving the environment – it’s about making savings for your business. Welcome to the world of Resource Efficiency. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Why Bother ? Ø Resource efficiency is about maximising output from a given level of materials and energy. Ø For many cost is the main driver, many regard resource efficiency as a way of improving competitiveness. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Ø Greater Profitability. Ø Political Pressure. Ø Legislation & Taxation. Ø Customers. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Getting the basics right Ø A good starting point for any company looking to become more resource efficient is an exercise known as process mapping. Ø Process mapping helps you to fully understand your business operation and is important step towards identifying inefficiencies and potential cost savings. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Process Mapping Ø Breaking the Organisation down into its individual processes. Ø Breaking each process down into its separate elements. Ø Taking each process element & identify all its inputs and outputs. Plymouth Manufacturers Group Adding value through environmental management

Inputs: What are we talking about? Ø Materials Ø Water Ø Energy Plymouth Manufacturers Group Adding value through environmental management

What are we talking about? Outputs: Ø Air, Ø Water, Ø Land, Ø Product Plymouth Manufacturers Group Adding value through environmental management

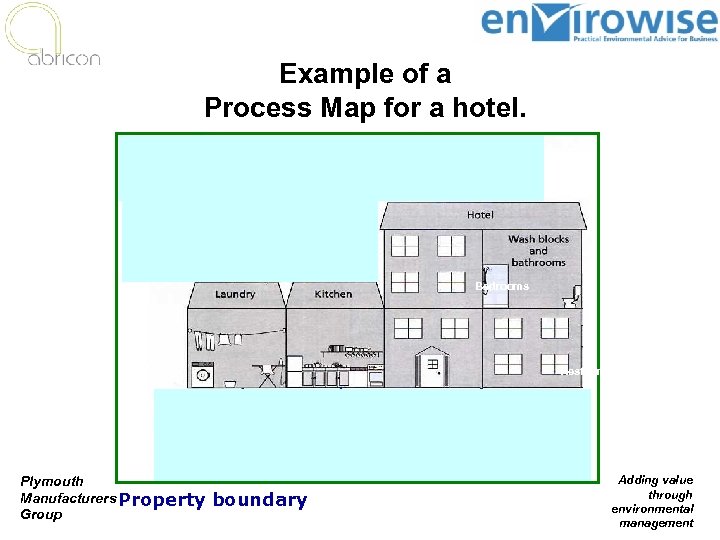

Example of a Process Map for a hotel. Bedrooms Restaurant/bar Plymouth Manufacturers Property Group boundary Adding value through environmental management

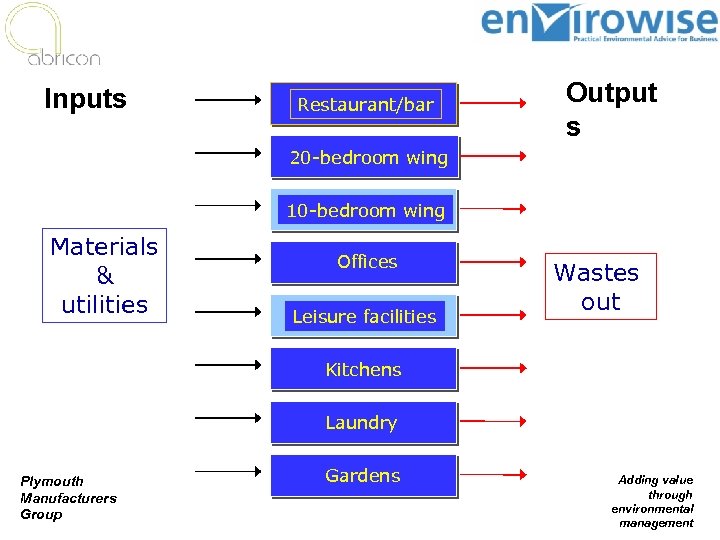

Inputs Restaurant/bar Output s 20 -bedroom wing 10 -bedroom wing Materials & utilities Offices Leisure facilities Wastes out Kitchens Laundry Plymouth Manufacturers Group Gardens Adding value through environmental management

Plymouth Resource Efficiency Club Identify source/ quantities/cost of: Ø Ø Ø Raw materials Energy Waste Water Effluent Air emissions Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Gathering information Ø Walk around your site Ø check your facts Ø compare theoretical/actual operations Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Gathering information Raw Materials / Packaging Ø Bills of materials and receipts Ø Suppliers’ information Ø Purchase and sales information Ø Packaging specifications Ø Packaging waste regulations data Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Gathering information Ø Water/Utility Ø Existing site plans – drainage details – waste disposal areas Ø Bills and invoices – water, effluent, energy – waste consignments Plymouth Manufacturers Group Adding value through environmental management

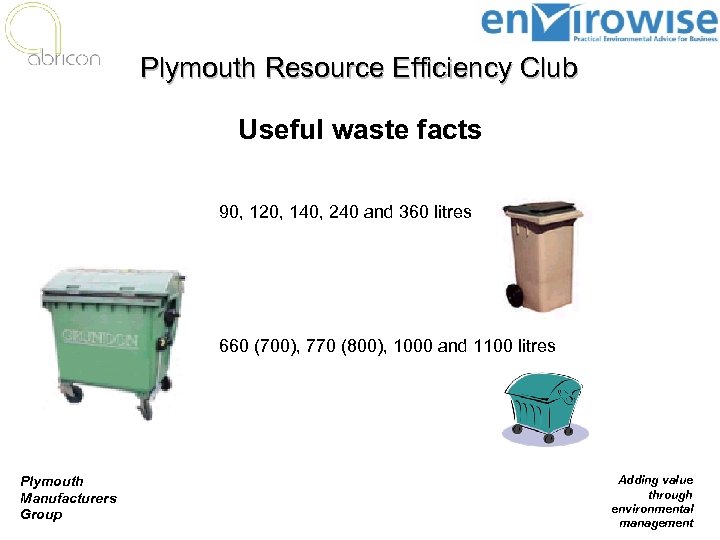

Plymouth Resource Efficiency Club Useful waste facts 90, 120, 140, 240 and 360 litres 660 (700), 770 (800), 1000 and 1100 litres Plymouth Manufacturers Group Adding value through environmental management

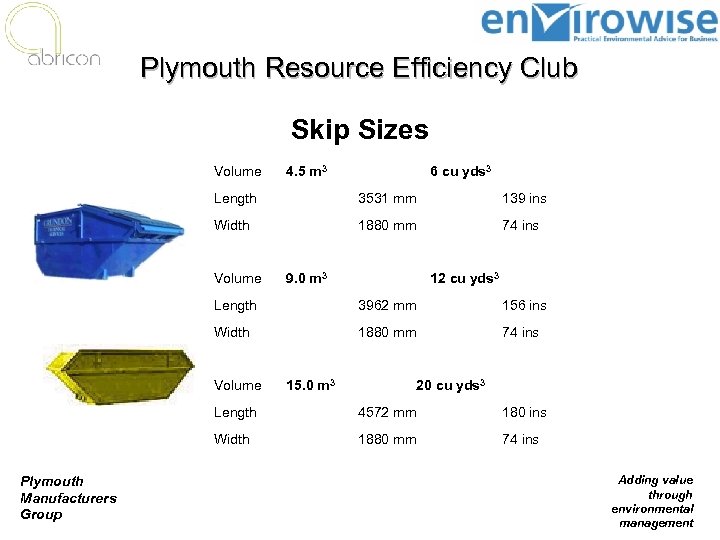

Plymouth Resource Efficiency Club Skip Sizes Volume 4. 5 m 3 6 cu yds 3 Length 3531 mm 139 ins Width 1880 mm 74 ins Volume 9. 0 m 3 12 cu yds 3 Length 3962 mm 156 ins Width 1880 mm 74 ins Volume 15. 0 m 3 20 cu yds 3 Length 180 ins Width Plymouth Manufacturers Group 4572 mm 1880 mm 74 ins Adding value through environmental management

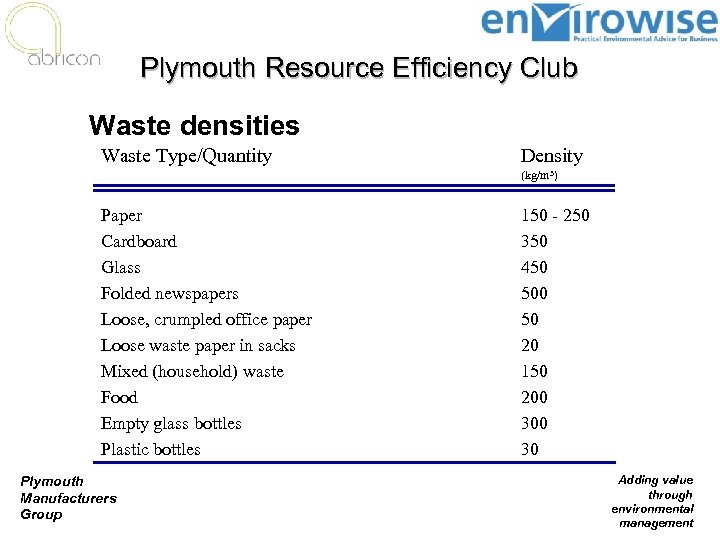

Plymouth Resource Efficiency Club Waste densities Waste Type/Quantity Density (kg/m 3) Paper Cardboard Glass Folded newspapers Loose, crumpled office paper Loose waste paper in sacks Mixed (household) waste Food Empty glass bottles Plastic bottles Plymouth Manufacturers Group 150 - 250 350 450 50 20 150 200 30 Adding value through environmental management

Plymouth Resource Efficiency Club Raw Materials Ø A considerable proportion of manufacturing costs are directly related to the raw materials necessary for production. Ø The relationship between production and raw materials is crucial. By fine tuning that relationship and making it more efficient, the savings can be considerable. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Waste amounts Waste Type/Quantity 1 x sack paper Laser printer toner cartridge 1 Box A 4 paper (5 reams) 50, 000 drinks cans 250, 000 plastic vending cups Plymouth Manufacturers Group Weight Approx. 10 kg Approx. 2 kg Approx 12. 5 kg 1 tonne Adding value through environmental management

Plymouth Resource Efficiency Club Water Ø No sooner does the sun shine for more than a weekend than there is a hose pipe ban and empty reservoirs. Ø Charges for water consumption and for the discharge of effluent are only going up as the utilities seek to recover the true cost of the service they provide. Plymouth Manufacturers Group Adding value through environmental management

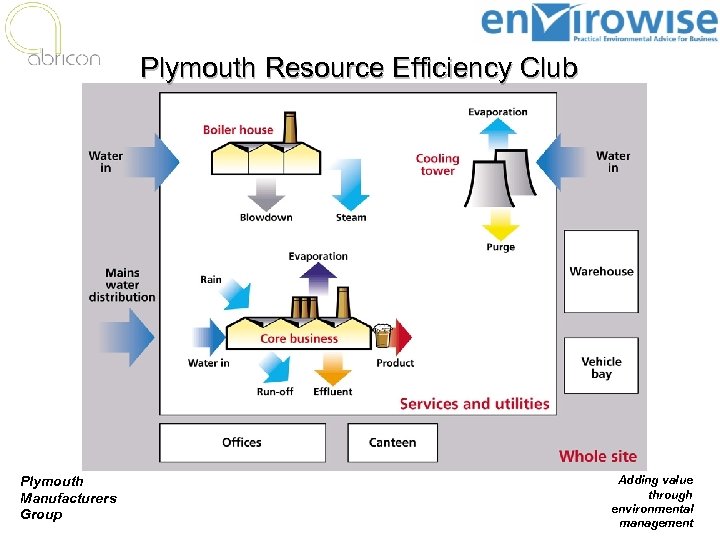

Plymouth Resource Efficiency Club Plymouth Manufacturers Group Adding value through environmental management

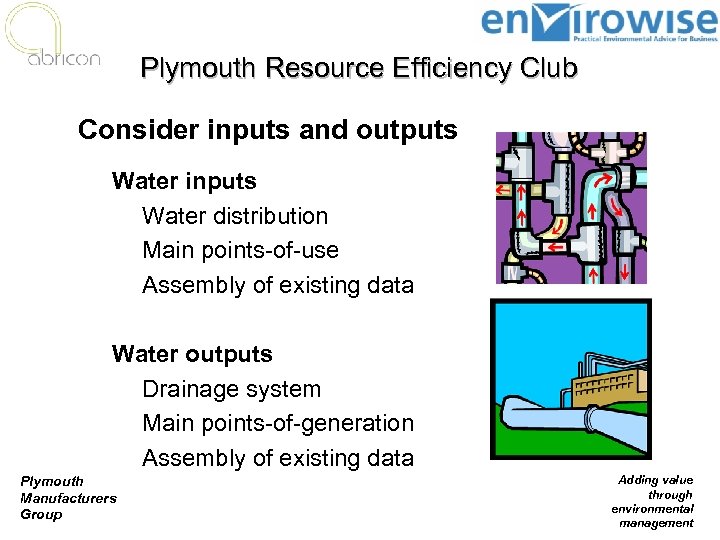

Plymouth Resource Efficiency Club Consider inputs and outputs Water inputs n Water distribution n Main points-of-use n Assembly of existing data Water outputs n Drainage system n Main points-of-generation n Assembly of existing data Plymouth Manufacturers Group Adding value through environmental management

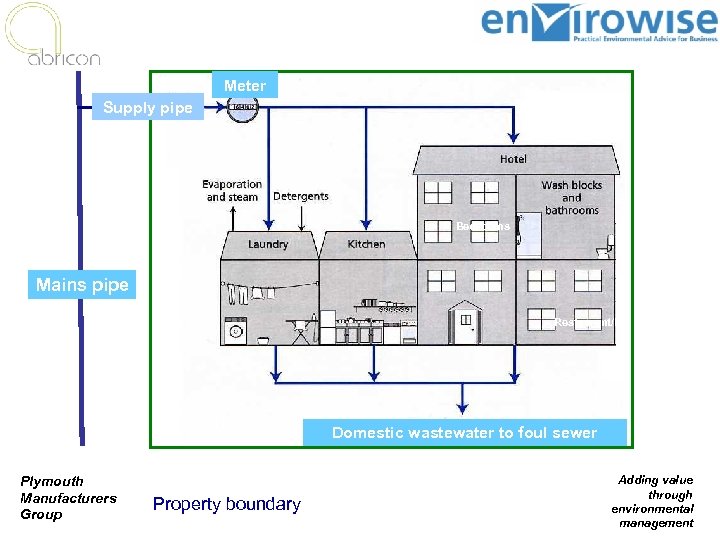

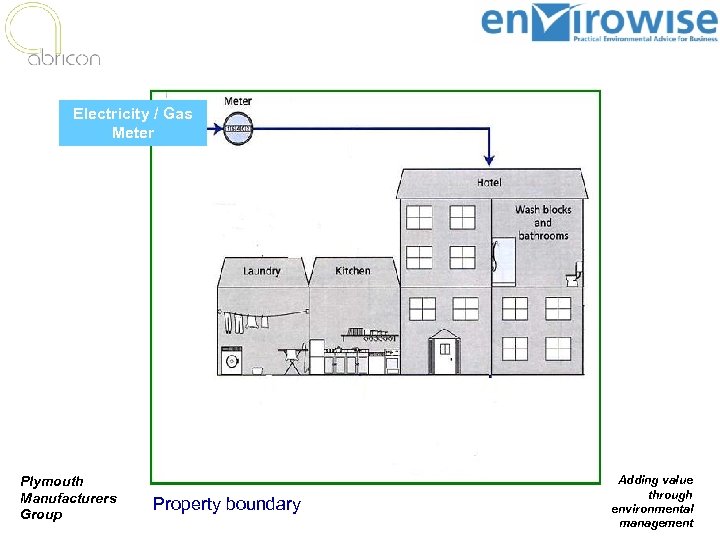

Meter Supply pipe Bedrooms Mains pipe Restaurant/bar Domestic wastewater to foul sewer Plymouth Manufacturers Group Property boundary Adding value through environmental management

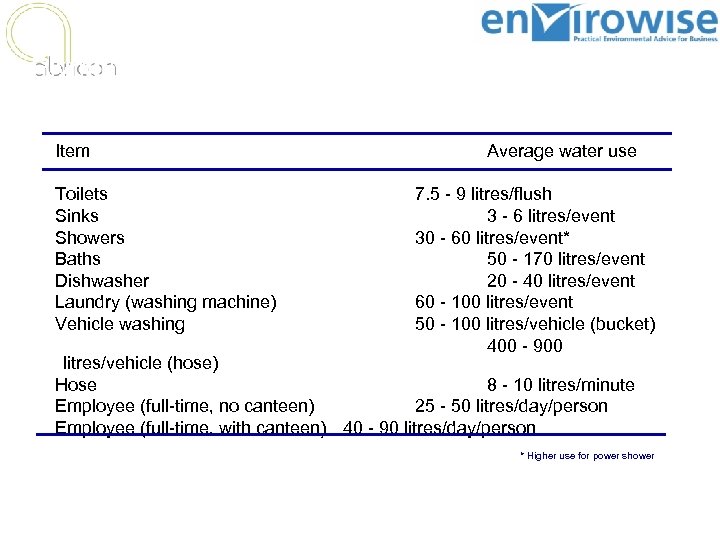

Plymouth Resource Efficiency Club Water Consumption Item Toilets Sinks Showers Baths Dishwasher Laundry (washing machine) Vehicle washing Average water use 7. 5 - 9 litres/flush 3 - 6 litres/event 30 - 60 litres/event* 50 - 170 litres/event 20 - 40 litres/event 60 - 100 litres/event 50 - 100 litres/vehicle (bucket) 400 - 900 litres/vehicle (hose) Hose 8 - 10 litres/minute Employee (full-time, no canteen) 25 - 50 litres/day/person Employee (full-time, with canteen) 40 - 90 litres/day/person * Higher use for power shower

Plymouth Resource Efficiency Club Estimate daily water use (employee) Estimate how many people are on site per day Rule of thumb: 25 - 35 litres/person/day 40 - 50 litres/person/day no canteen Daily water use = 10 x 35 = 350 l/day Plymouth Manufacturers Group Adding value through environmental management

Measuring water flows/losses 0. 1 L/min 4 L/min £ 58/yr £ 2312 /yr 14 L/min 66 L/min £ 8094 /yr Plymouth Manufacturers Group £ 38, 158 /yr Source: GG 067 Adding value through environmental management

Plymouth Resource Efficiency Club Energy Ø All companies use energy whether gas, electricity or fuel oil and it is now one of the key business costs. Ø Heating bills can be reduced by up to 10% simply by reducing room temperatures by one degree which is barely noticeable. Plymouth Manufacturers Group Adding value through environmental management

Electricity / Gas Meter Bedrooms Plymouth Manufacturers Group Property boundary Adding value through environmental management

Plymouth Resource Efficiency Club Energy Monitoring Ø Read meters Ø Obtain data from supplier Ø E. g. half hour data Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Reporting Ø Compare usage / production to influencing factor Ø Energy k. Wh/m 2 or k. Wh/tonne Ø Waste kg/ tonne Ø Water use m 3 / tonne Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club If you don’t measure it, you can’t manage it Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club People Ø It’s an often quoted maxim, but people are the most valuable resource of any business and resource efficiency relates to people as much as to any other resource. Ø Management needs to be receptive to employee ideas and encourage suggestions for change perhaps implementing incentive schemes to rewards efficient employees. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Waste a resource in the wrong place Ø British industry produced 430 million tonnes of waste in 2003, costing companies over £ 15 billion. Ø The true cost of waste is five to twenty times higher than the disposal costs. Therefore the cost to UK industry is between £ 75 billion and £ 300 billion p. a. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Monitoring and measuring Ø Resource efficiency initiatives need to be monitored, measured and managed if they are to be successful. Ø Companies who have joined a resource efficiency club have access to a unique programme designed to enable resource efficiency opportunities to be recorded mapped and progressed. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Conclusion Ø Reducing the impact your company is having on the environment is one of the best methods of reducing costs Ø Waste is currently costing UK business £ 50 billion each year. Ø On Average a company could make savings of amounting over £ 1, 000 per employ by taking simple steps. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Members Ø Algram Ø Arjo Wiggins Ø BEA Systems Ø Bandvulc* Ø Barden Ø Becton Dickinson* ØDML ØFine Tubes ØGleason ØHellerman Tyton ØKawasaki ØPrincess Yachts ØRittal * Companies to present Success Stories Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Opportunities Identified To Date Ø Number Identified - over 50 Ø Potential Savings identified - £ 1. 8 million Ø Savings Implemented in 1 st Year – over £ 0. 5 m Ø Average payback 1 year Ø Estimated capital expenditure £ 0. 6 million Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Opportunities Implemented To Date Ø 25% already implemented Ø 20% within 6 months Ø 40% within 1 year Ø 10% within 2 years Ø 5% within 3 years. Plymouth Manufacturers Group Adding value through environmental management

Plymouth Resource Efficiency Club Ø Case Studies ØBandvulc* ØMatteo Litera, ØBecton Dickinson* ØEva Espanol, Plymouth Manufacturers Group Adding value through environmental management

d60217a8342eacc775bc353a0e3400b9.ppt