6d2ac1fe1ce3cadaddadb57f7b21a65e.ppt

- Количество слайдов: 53

Welcome to Marquette University’s Hazardous Waste and Emergency Procedures Awareness Training NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Welcome to Marquette University’s Hazardous Waste and Emergency Procedures Awareness Training NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Why am I here? • Handle or generate hazardous materials • Formal personnel training program is a requirement for large quantity generators (49 CFR 265. 16) • To be trained on the proper procedures of accumulating and storing hazardous materials to ensure compliance with the law • To prevent personal injury, property damage, or a major spill NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Why am I here? • Handle or generate hazardous materials • Formal personnel training program is a requirement for large quantity generators (49 CFR 265. 16) • To be trained on the proper procedures of accumulating and storing hazardous materials to ensure compliance with the law • To prevent personal injury, property damage, or a major spill NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Agenda • Marquette’s Generator Classification • Hazardous Waste Characteristics • Globally Harmonized System (GHS) Classification and Labeling of Chemicals • Handling Hazardous Materials & Proper Personal Protective Equipment • Satellite Accumulation Procedures • Spill Response, Clean-Up, Emergency Response and Preparedness NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Agenda • Marquette’s Generator Classification • Hazardous Waste Characteristics • Globally Harmonized System (GHS) Classification and Labeling of Chemicals • Handling Hazardous Materials & Proper Personal Protective Equipment • Satellite Accumulation Procedures • Spill Response, Clean-Up, Emergency Response and Preparedness NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Acronyms • EPA = Environmental Protection Agency » Determines what is a hazardous waste » Governs hazardous waste regulations • DOT = Department of Transportation » Regulates transportation of hazardous materials • RCRA = Resource Conservation & Recovery Act » Standard for the disposal of solid and hazardous wastes • DNR = Department of Natural Resources » Governs over the generators of hazardous waste at the state level • OSHA = Occupational Safety and Health Administration » Regulates hazardous materials in the workplace • PPE = Personal Protective Equipment » Last line of defense against hazardous materials NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Acronyms • EPA = Environmental Protection Agency » Determines what is a hazardous waste » Governs hazardous waste regulations • DOT = Department of Transportation » Regulates transportation of hazardous materials • RCRA = Resource Conservation & Recovery Act » Standard for the disposal of solid and hazardous wastes • DNR = Department of Natural Resources » Governs over the generators of hazardous waste at the state level • OSHA = Occupational Safety and Health Administration » Regulates hazardous materials in the workplace • PPE = Personal Protective Equipment » Last line of defense against hazardous materials NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Marquette’s Classification NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Marquette’s Classification NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

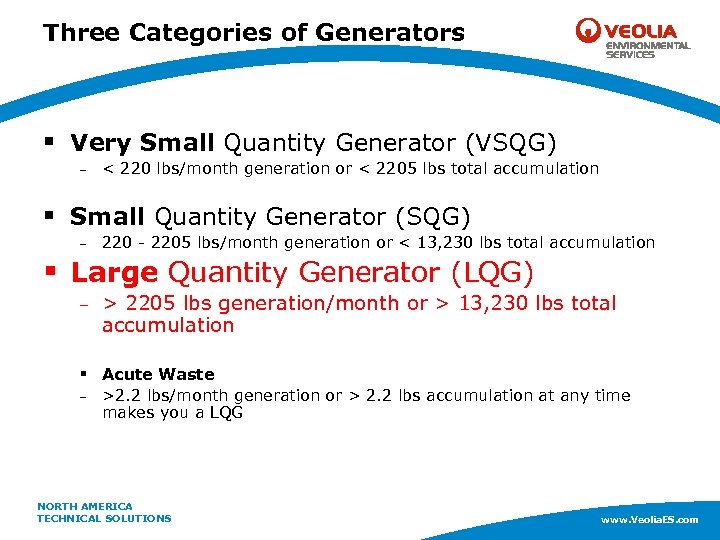

Three Categories of Generators § Very Small Quantity Generator (VSQG) – < 220 lbs/month generation or < 2205 lbs total accumulation § Small Quantity Generator (SQG) – 220 - 2205 lbs/month generation or < 13, 230 lbs total accumulation § Large Quantity Generator (LQG) – > 2205 lbs generation/month or > 13, 230 lbs total accumulation § Acute Waste – >2. 2 lbs/month generation or > 2. 2 lbs accumulation at any time makes you a LQG NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Three Categories of Generators § Very Small Quantity Generator (VSQG) – < 220 lbs/month generation or < 2205 lbs total accumulation § Small Quantity Generator (SQG) – 220 - 2205 lbs/month generation or < 13, 230 lbs total accumulation § Large Quantity Generator (LQG) – > 2205 lbs generation/month or > 13, 230 lbs total accumulation § Acute Waste – >2. 2 lbs/month generation or > 2. 2 lbs accumulation at any time makes you a LQG NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

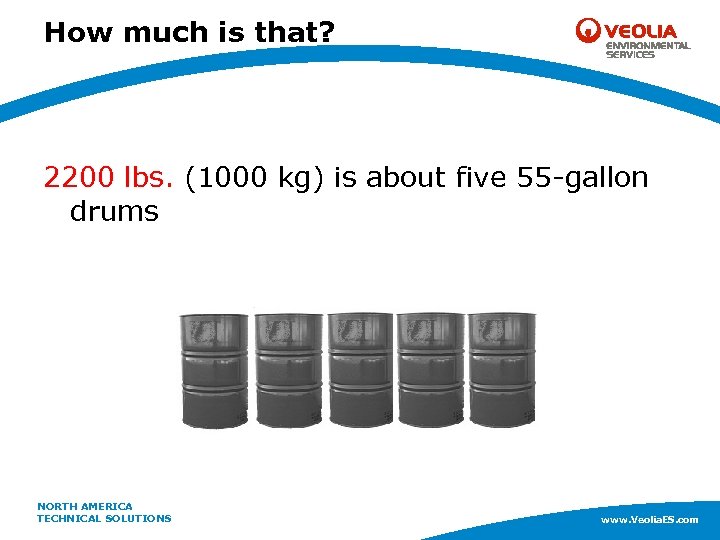

How much is that? 2200 lbs. (1000 kg) is about five 55 -gallon drums NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

How much is that? 2200 lbs. (1000 kg) is about five 55 -gallon drums NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Hazardous Waste Determination Characteristic versus Listed Wastes NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Hazardous Waste Determination Characteristic versus Listed Wastes NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

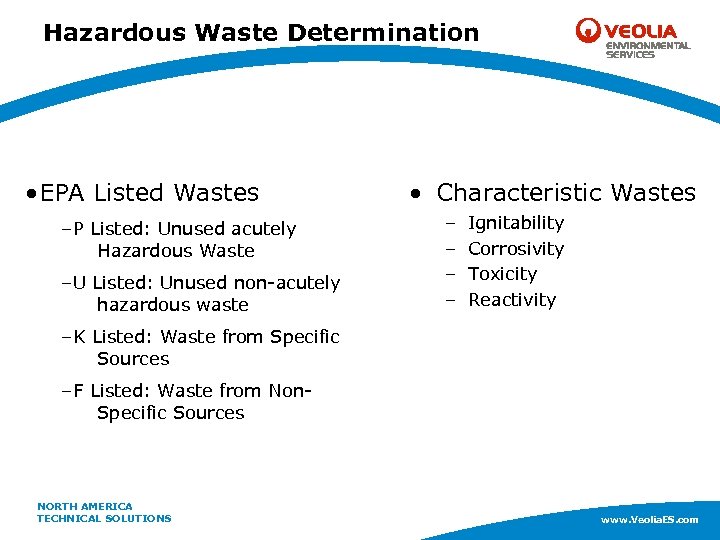

Hazardous Waste Determination • EPA Listed Wastes –P Listed: Unused acutely Hazardous Waste –U Listed: Unused non-acutely hazardous waste • Characteristic Wastes – – Ignitability Corrosivity Toxicity Reactivity –K Listed: Waste from Specific Sources –F Listed: Waste from Non. Specific Sources NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Hazardous Waste Determination • EPA Listed Wastes –P Listed: Unused acutely Hazardous Waste –U Listed: Unused non-acutely hazardous waste • Characteristic Wastes – – Ignitability Corrosivity Toxicity Reactivity –K Listed: Waste from Specific Sources –F Listed: Waste from Non. Specific Sources NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

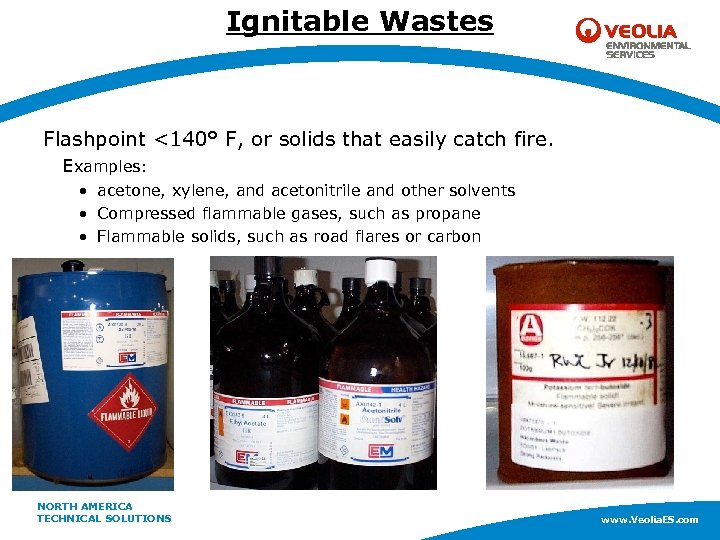

Ignitable Wastes Flashpoint <140° F, or solids that easily catch fire. Examples: • acetone, xylene, and acetonitrile and other solvents • Compressed flammable gases, such as propane • Flammable solids, such as road flares or carbon . NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Ignitable Wastes Flashpoint <140° F, or solids that easily catch fire. Examples: • acetone, xylene, and acetonitrile and other solvents • Compressed flammable gases, such as propane • Flammable solids, such as road flares or carbon . NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

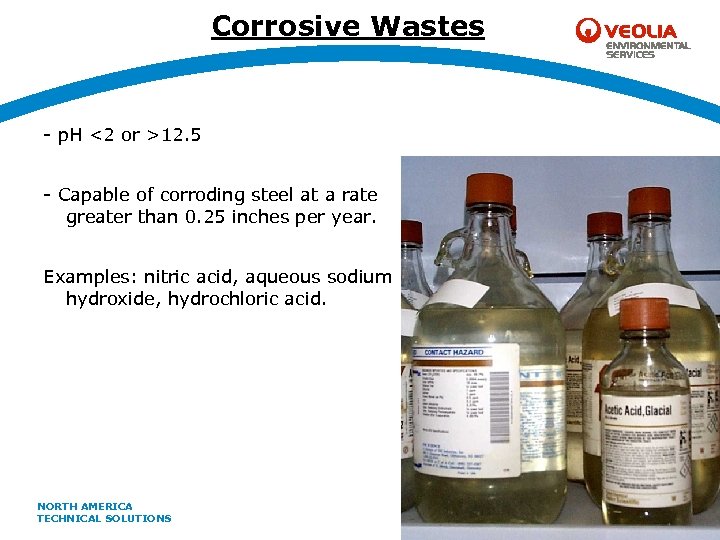

Corrosive Wastes - p. H <2 or >12. 5 - Capable of corroding steel at a rate greater than 0. 25 inches per year. Examples: nitric acid, aqueous sodium hydroxide, hydrochloric acid. Potassium Tert-butoxide, a flammable solid NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Corrosive Wastes - p. H <2 or >12. 5 - Capable of corroding steel at a rate greater than 0. 25 inches per year. Examples: nitric acid, aqueous sodium hydroxide, hydrochloric acid. Potassium Tert-butoxide, a flammable solid NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

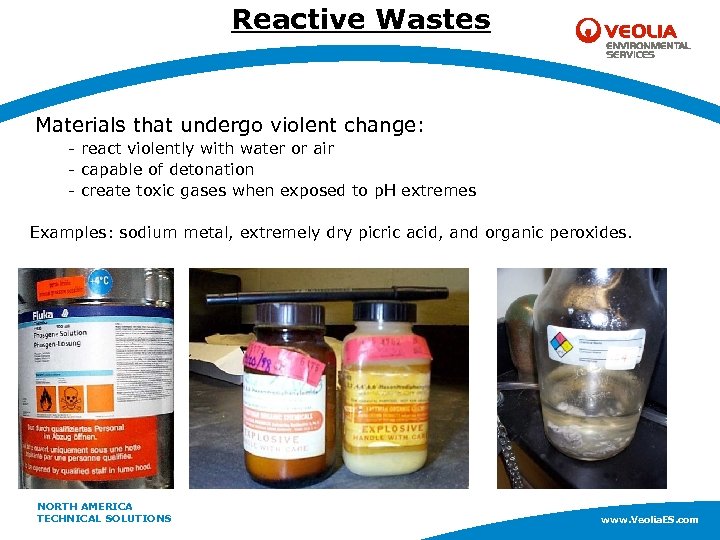

Reactive Wastes Materials that undergo violent change: - react violently with water or air - capable of detonation - create toxic gases when exposed to p. H extremes Examples: sodium metal, extremely dry picric acid, and organic peroxides. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Reactive Wastes Materials that undergo violent change: - react violently with water or air - capable of detonation - create toxic gases when exposed to p. H extremes Examples: sodium metal, extremely dry picric acid, and organic peroxides. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

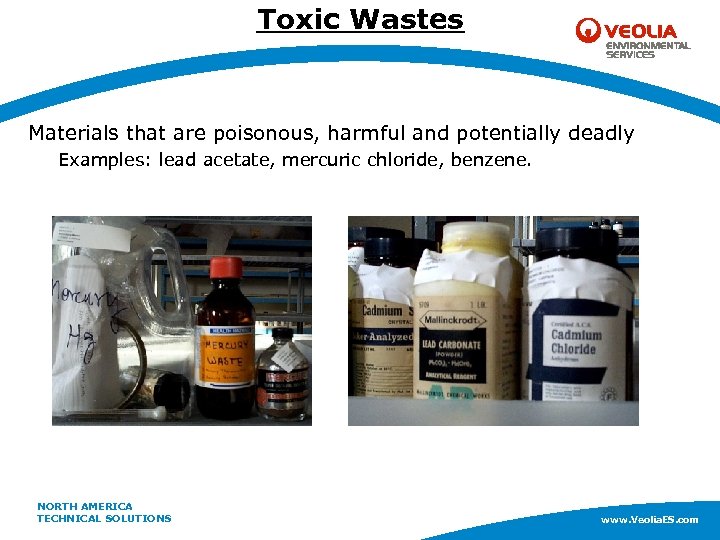

Toxic Wastes Materials that are poisonous, harmful and potentially deadly Examples: lead acetate, mercuric chloride, benzene. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Toxic Wastes Materials that are poisonous, harmful and potentially deadly Examples: lead acetate, mercuric chloride, benzene. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

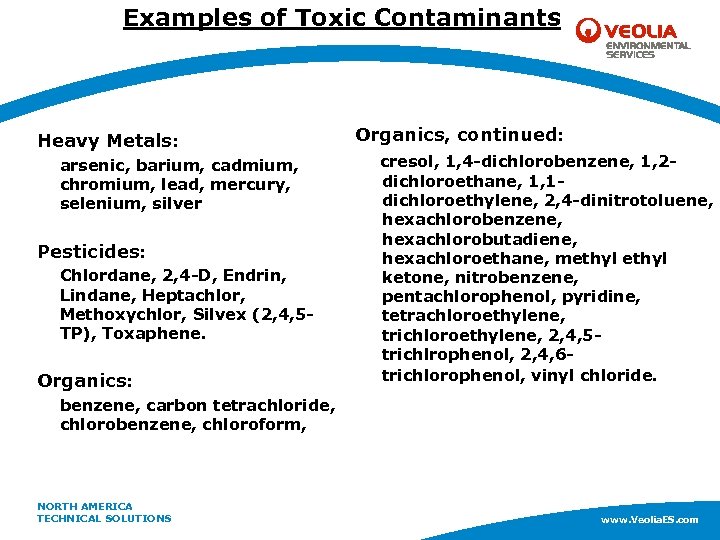

Examples of Toxic Contaminants Heavy Metals: arsenic, barium, cadmium, chromium, lead, mercury, selenium, silver Pesticides: Chlordane, 2, 4 -D, Endrin, Lindane, Heptachlor, Methoxychlor, Silvex (2, 4, 5 TP), Toxaphene. Organics: Organics, continued: cresol, 1, 4 -dichlorobenzene, 1, 2 dichloroethane, 1, 1 dichloroethylene, 2, 4 -dinitrotoluene, hexachlorobenzene, hexachlorobutadiene, hexachloroethane, methyl ketone, nitrobenzene, pentachlorophenol, pyridine, tetrachloroethylene, trichloroethylene, 2, 4, 5 trichlrophenol, 2, 4, 6 trichlorophenol, vinyl chloride. benzene, carbon tetrachloride, chlorobenzene, chloroform, NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Examples of Toxic Contaminants Heavy Metals: arsenic, barium, cadmium, chromium, lead, mercury, selenium, silver Pesticides: Chlordane, 2, 4 -D, Endrin, Lindane, Heptachlor, Methoxychlor, Silvex (2, 4, 5 TP), Toxaphene. Organics: Organics, continued: cresol, 1, 4 -dichlorobenzene, 1, 2 dichloroethane, 1, 1 dichloroethylene, 2, 4 -dinitrotoluene, hexachlorobenzene, hexachlorobutadiene, hexachloroethane, methyl ketone, nitrobenzene, pentachlorophenol, pyridine, tetrachloroethylene, trichloroethylene, 2, 4, 5 trichlrophenol, 2, 4, 6 trichlorophenol, vinyl chloride. benzene, carbon tetrachloride, chlorobenzene, chloroform, NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Contact Dennis Daye (414) 288 -8411 if you have questions about the status of your waste. Hazardous Waste Management can be very confusing and we are here to help you! Steve Sprung, Veolia Environmental Services On campus Wednesday from 1 -4 PM NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Contact Dennis Daye (414) 288 -8411 if you have questions about the status of your waste. Hazardous Waste Management can be very confusing and we are here to help you! Steve Sprung, Veolia Environmental Services On campus Wednesday from 1 -4 PM NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Globally Harmonized System (GHS) & Recognizing Hazardous Materials NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Globally Harmonized System (GHS) & Recognizing Hazardous Materials NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

What is the GHS? A common and coherent approach to defining and classifying hazards, and communicating information on labels and safety data sheets. (Revision to OSHA’s Hazard Communication Standard 1910. 1200) NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

What is the GHS? A common and coherent approach to defining and classifying hazards, and communicating information on labels and safety data sheets. (Revision to OSHA’s Hazard Communication Standard 1910. 1200) NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

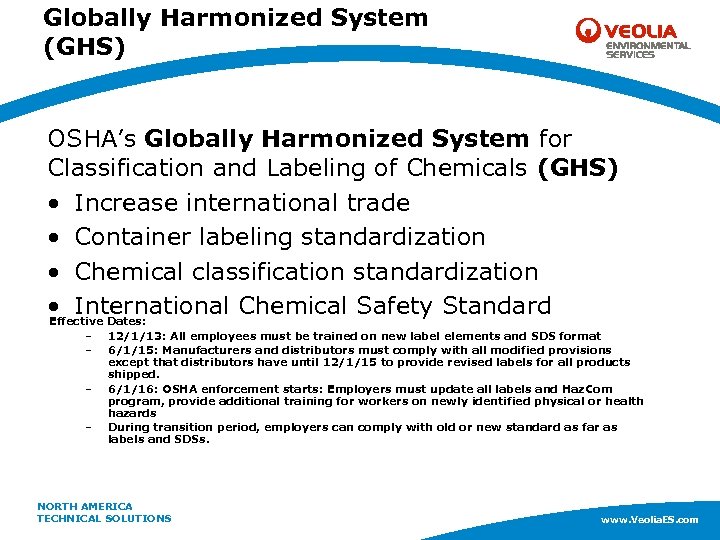

Globally Harmonized System (GHS) OSHA’s Globally Harmonized System for Classification and Labeling of Chemicals (GHS) • Increase international trade • Container labeling standardization • Chemical classification standardization • International Chemical Safety Standard Effective Dates: – – 12/1/13: All employees must be trained on new label elements and SDS format 6/1/15: Manufacturers and distributors must comply with all modified provisions except that distributors have until 12/1/15 to provide revised labels for all products shipped. 6/1/16: OSHA enforcement starts: Employers must update all labels and Haz. Com program, provide additional training for workers on newly identified physical or health hazards During transition period, employers can comply with old or new standard as far as labels and SDSs. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Globally Harmonized System (GHS) OSHA’s Globally Harmonized System for Classification and Labeling of Chemicals (GHS) • Increase international trade • Container labeling standardization • Chemical classification standardization • International Chemical Safety Standard Effective Dates: – – 12/1/13: All employees must be trained on new label elements and SDS format 6/1/15: Manufacturers and distributors must comply with all modified provisions except that distributors have until 12/1/15 to provide revised labels for all products shipped. 6/1/16: OSHA enforcement starts: Employers must update all labels and Haz. Com program, provide additional training for workers on newly identified physical or health hazards During transition period, employers can comply with old or new standard as far as labels and SDSs. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

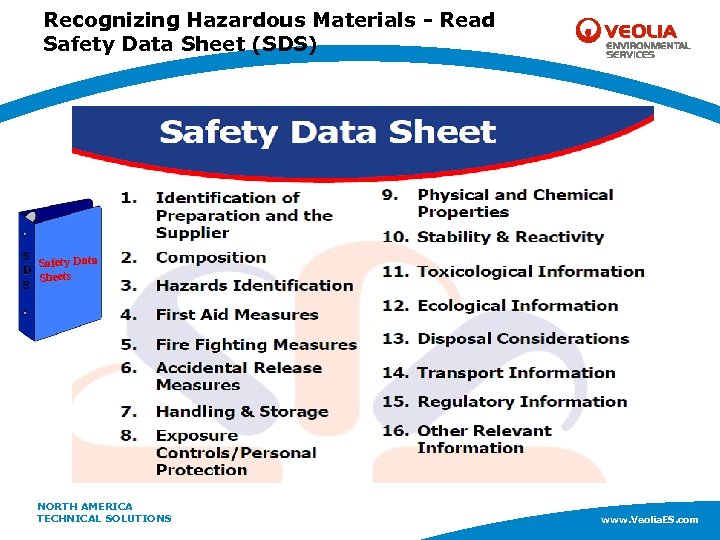

Recognizing Hazardous Materials - Read Safety Data Sheet (SDS) S Safety Data D Sheets S NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Recognizing Hazardous Materials - Read Safety Data Sheet (SDS) S Safety Data D Sheets S NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

http: //cispro. mu. edu/ NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

http: //cispro. mu. edu/ NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Container Labeling NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Container Labeling NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

National Fire Protection Association (NFPA) Label • NFPA –Colors and numbers are used to communicate the potential hazards of a material. Flammability Hazard Health Hazard Reactivity Hazard Specific Hazards NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

National Fire Protection Association (NFPA) Label • NFPA –Colors and numbers are used to communicate the potential hazards of a material. Flammability Hazard Health Hazard Reactivity Hazard Specific Hazards NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

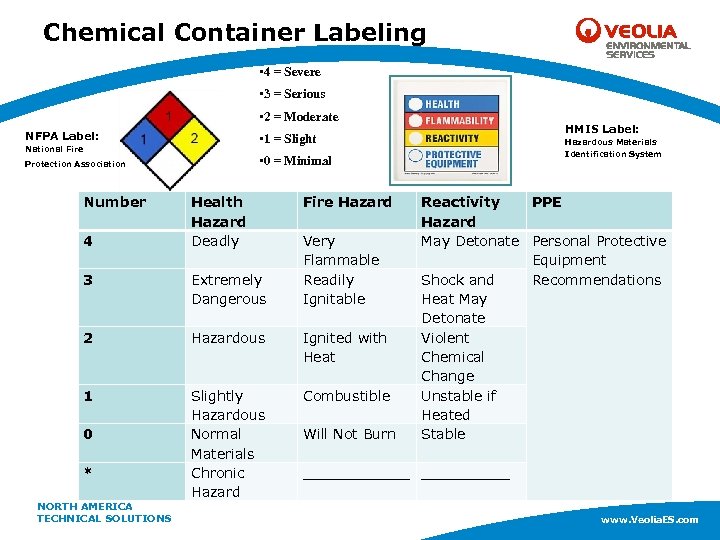

Chemical Container Labeling • 4 = Severe • 3 = Serious • 2 = Moderate NFPA Label: National Fire 4 Health Hazard Deadly Fire Hazard Very Flammable Readily Ignitable 3 Extremely Dangerous 2 Hazardous Ignited with Heat 1 Slightly Hazardous Normal Materials Chronic Hazard Combustible 0 * NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS Hazardous Materials Identification System • 0 = Minimal Protection Association Number HMIS Label: • 1 = Slight Will Not Burn Reactivity PPE Hazard May Detonate Personal Protective Equipment Shock and Recommendations Heat May Detonate Violent Chemical Change Unstable if Heated Stable ______ www. Veolia. ES. com

Chemical Container Labeling • 4 = Severe • 3 = Serious • 2 = Moderate NFPA Label: National Fire 4 Health Hazard Deadly Fire Hazard Very Flammable Readily Ignitable 3 Extremely Dangerous 2 Hazardous Ignited with Heat 1 Slightly Hazardous Normal Materials Chronic Hazard Combustible 0 * NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS Hazardous Materials Identification System • 0 = Minimal Protection Association Number HMIS Label: • 1 = Slight Will Not Burn Reactivity PPE Hazard May Detonate Personal Protective Equipment Shock and Recommendations Heat May Detonate Violent Chemical Change Unstable if Heated Stable ______ www. Veolia. ES. com

New Label Requirements GHS Label Workplace Label • Updated OSHA GHS Standard • Current OSHA Standard – – Material identity Hazard warnings PPE Supplier information NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS – – – – Product identifier Signal word Hazard statements Precautionary statements Pictograms Supplier information Supplemental information www. Veolia. ES. com

New Label Requirements GHS Label Workplace Label • Updated OSHA GHS Standard • Current OSHA Standard – – Material identity Hazard warnings PPE Supplier information NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS – – – – Product identifier Signal word Hazard statements Precautionary statements Pictograms Supplier information Supplemental information www. Veolia. ES. com

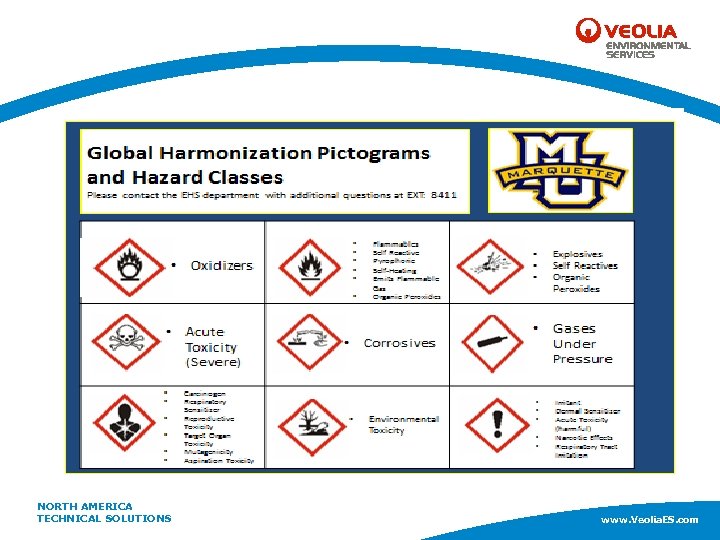

NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

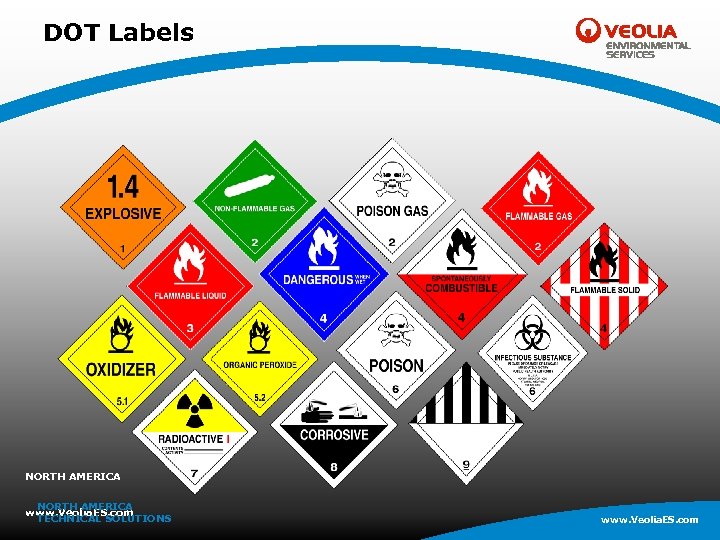

DOT Labels NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

DOT Labels NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

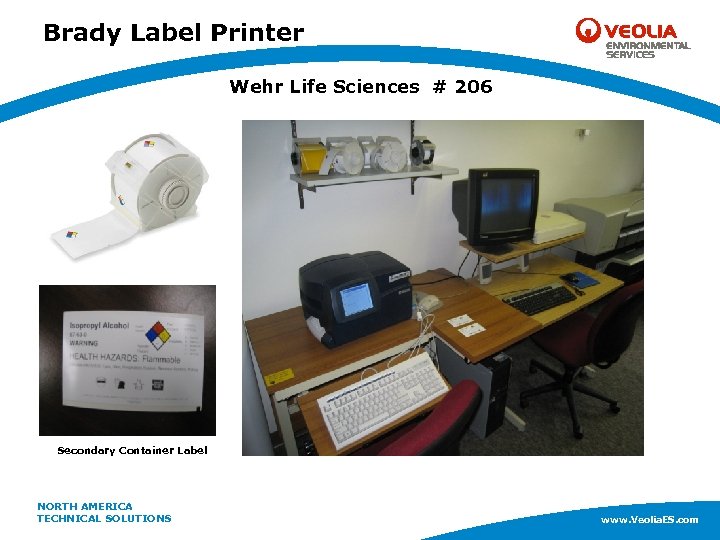

Brady Label Printer Wehr Life Sciences # 206 Secondary Container Label NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Brady Label Printer Wehr Life Sciences # 206 Secondary Container Label NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Hazardous Material Handling and Proper Personal Protective Equipment NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Hazardous Material Handling and Proper Personal Protective Equipment NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Considerations when Handling Hazardous Materials • Use common sense! • Think before you act • Follow good housekeeping procedures – Clean-up after yourself • Always wear the proper PPE • Know the hazards of the materials you are working with! • Create and use chemical specific SOP’s (Safe Operating Procedures) NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Considerations when Handling Hazardous Materials • Use common sense! • Think before you act • Follow good housekeeping procedures – Clean-up after yourself • Always wear the proper PPE • Know the hazards of the materials you are working with! • Create and use chemical specific SOP’s (Safe Operating Procedures) NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Material Handling and Proper PPE Controlling Hazards (Hierarchy of Controls) 1. Elimination 2. Substitution 3. Engineering Controls • Remove the hazard or place a barrier between the worker and the hazard 2. Administrative Controls • Limit worker contact with the hazard • Training/Procedures, Good Housekeeping 3. PPE • LAST RESORT NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Material Handling and Proper PPE Controlling Hazards (Hierarchy of Controls) 1. Elimination 2. Substitution 3. Engineering Controls • Remove the hazard or place a barrier between the worker and the hazard 2. Administrative Controls • Limit worker contact with the hazard • Training/Procedures, Good Housekeeping 3. PPE • LAST RESORT NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

PPE = Last Resort • When PPE is the primary control measure, the hazard is still present in the environment • Failure of the PPE or improper usage can expose the worker to the full effect of the hazards present in the environment NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

PPE = Last Resort • When PPE is the primary control measure, the hazard is still present in the environment • Failure of the PPE or improper usage can expose the worker to the full effect of the hazards present in the environment NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

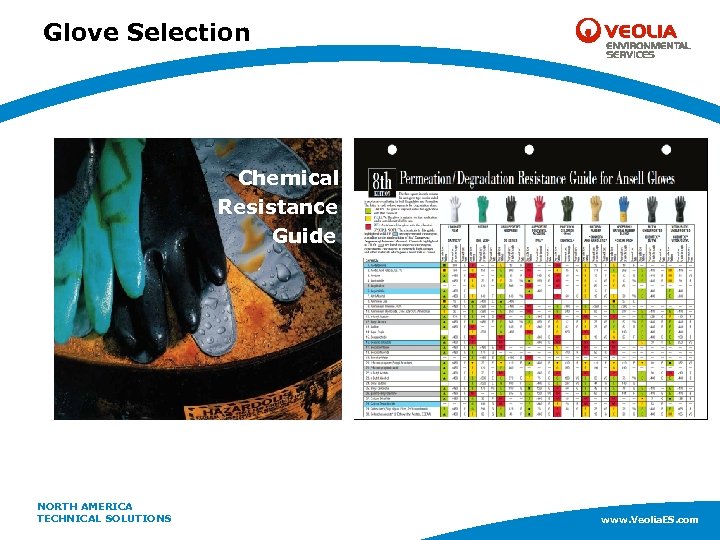

Glove Selection Chemical Resistance Guide NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Glove Selection Chemical Resistance Guide NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Satellite Accumulation Procedures NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Satellite Accumulation Procedures NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Satellite Accumulation • “A generator may accumulate as much as 55 gallons of hazardous waste…in containers at or near any point of generation…which is under the control of the operator…” • Up to 1 quart of acutely hazardous waste (P-coded) can be collected in a satellite accumulation area • Your research labs, student labs or other rooms where materials are collected and accumulated are considered to be Satellite Accumulation Areas NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Satellite Accumulation • “A generator may accumulate as much as 55 gallons of hazardous waste…in containers at or near any point of generation…which is under the control of the operator…” • Up to 1 quart of acutely hazardous waste (P-coded) can be collected in a satellite accumulation area • Your research labs, student labs or other rooms where materials are collected and accumulated are considered to be Satellite Accumulation Areas NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

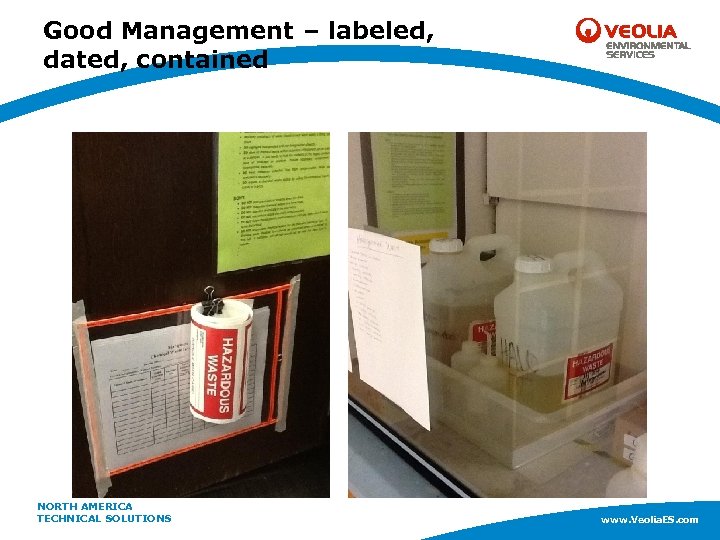

Good Management – labeled, dated, contained NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Good Management – labeled, dated, contained NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

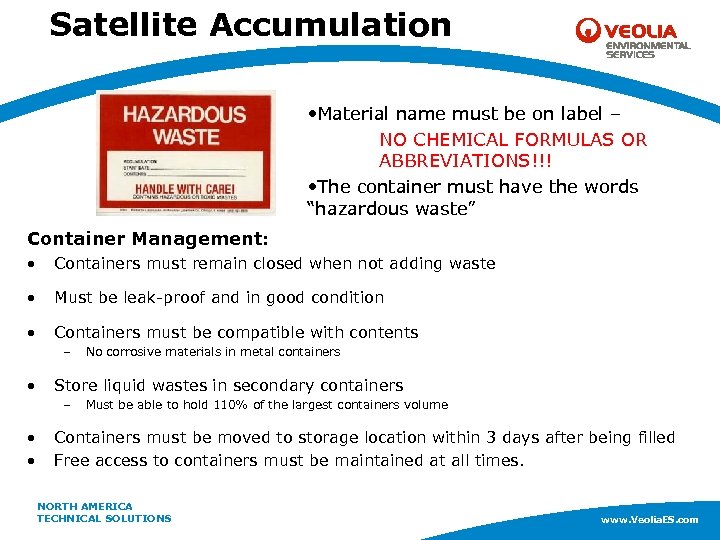

Satellite Accumulation • Material name must be on label – NO CHEMICAL FORMULAS OR ABBREVIATIONS!!! • The container must have the words “hazardous waste” Container Management: • Containers must remain closed when not adding waste • Must be leak-proof and in good condition • Containers must be compatible with contents – • Store liquid wastes in secondary containers – • • No corrosive materials in metal containers Must be able to hold 110% of the largest containers volume Containers must be moved to storage location within 3 days after being filled Free access to containers must be maintained at all times. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Satellite Accumulation • Material name must be on label – NO CHEMICAL FORMULAS OR ABBREVIATIONS!!! • The container must have the words “hazardous waste” Container Management: • Containers must remain closed when not adding waste • Must be leak-proof and in good condition • Containers must be compatible with contents – • Store liquid wastes in secondary containers – • • No corrosive materials in metal containers Must be able to hold 110% of the largest containers volume Containers must be moved to storage location within 3 days after being filled Free access to containers must be maintained at all times. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

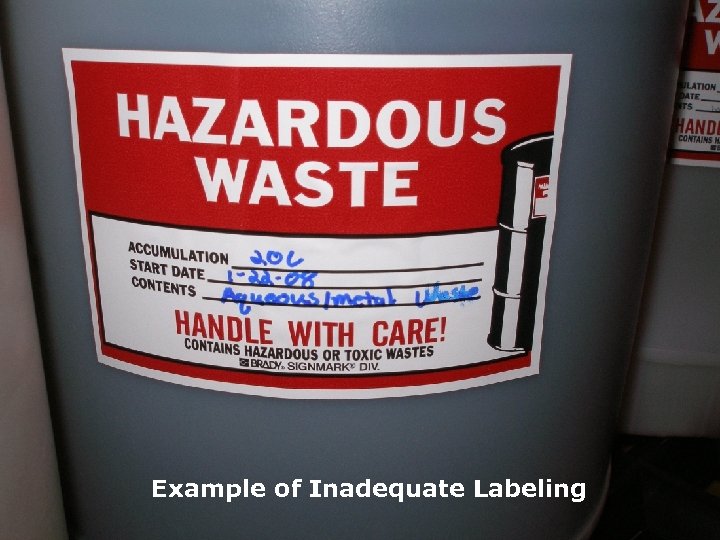

NORTH AMERICA Example of Inadequate Labeling NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

NORTH AMERICA Example of Inadequate Labeling NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

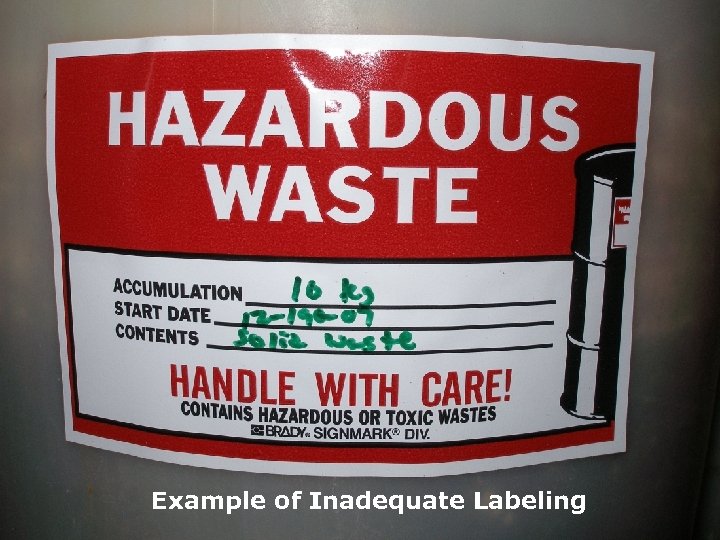

Example of Inadequate Labeling NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Example of Inadequate Labeling NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

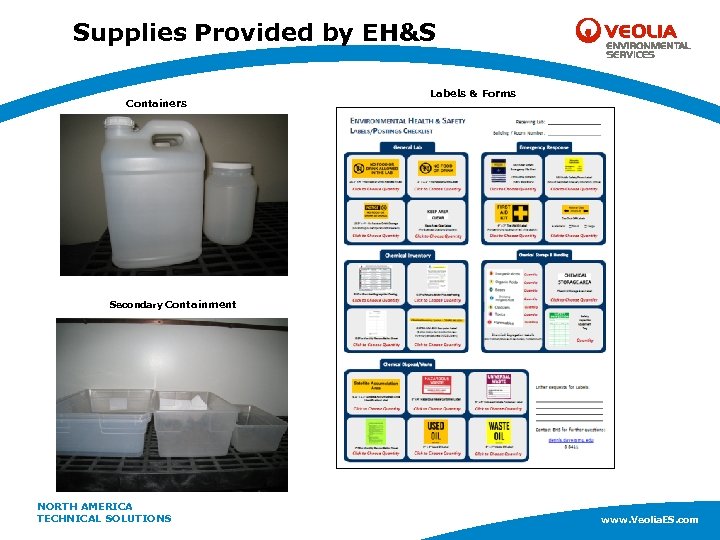

Supplies Provided by EH&S Containers Labels & Forms Secondary Containment NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Supplies Provided by EH&S Containers Labels & Forms Secondary Containment NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

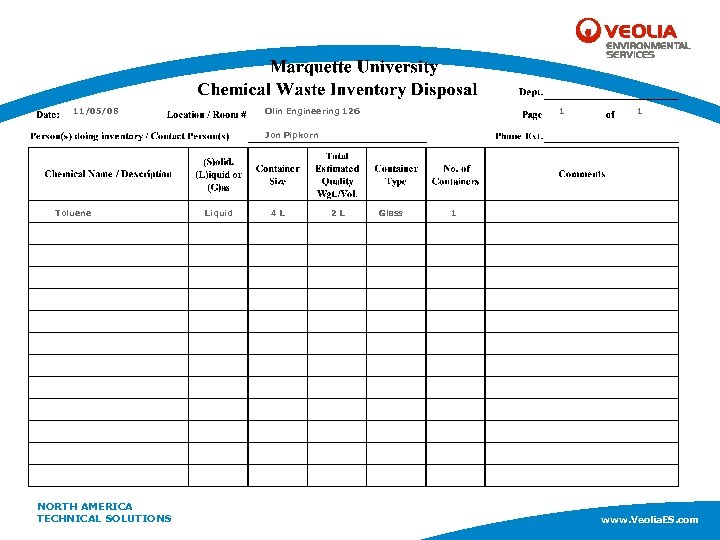

11/05/08 Olin Engineering 126 1 1 Jon Pipkorn Toluene Liquid 4 L 2 L Glass 1 NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

11/05/08 Olin Engineering 126 1 1 Jon Pipkorn Toluene Liquid 4 L 2 L Glass 1 NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

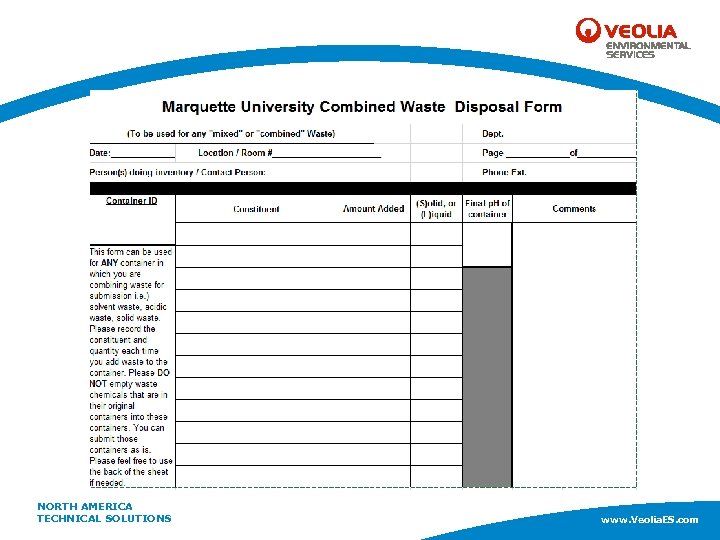

NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

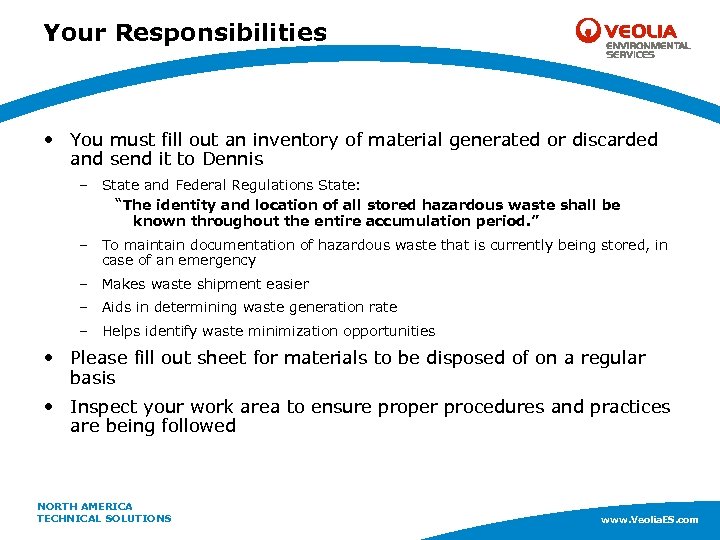

Your Responsibilities • You must fill out an inventory of material generated or discarded and send it to Dennis – State and Federal Regulations State: “The identity and location of all stored hazardous waste shall be known throughout the entire accumulation period. ” – To maintain documentation of hazardous waste that is currently being stored, in case of an emergency – Makes waste shipment easier – Aids in determining waste generation rate – Helps identify waste minimization opportunities • Please fill out sheet for materials to be disposed of on a regular basis • Inspect your work area to ensure proper procedures and practices are being followed NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Your Responsibilities • You must fill out an inventory of material generated or discarded and send it to Dennis – State and Federal Regulations State: “The identity and location of all stored hazardous waste shall be known throughout the entire accumulation period. ” – To maintain documentation of hazardous waste that is currently being stored, in case of an emergency – Makes waste shipment easier – Aids in determining waste generation rate – Helps identify waste minimization opportunities • Please fill out sheet for materials to be disposed of on a regular basis • Inspect your work area to ensure proper procedures and practices are being followed NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Spill Response, Clean-Up, and Emergency Response NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Spill Response, Clean-Up, and Emergency Response NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Please reference the Marquette University Emergency Procedures Guide and Contingency Plan for further details on what to do in case of an emergency. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Please reference the Marquette University Emergency Procedures Guide and Contingency Plan for further details on what to do in case of an emergency. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Causes of a Spill Causes of chemical spills are as follows: • Inappropriate handling techniques; • Inappropriate storage containers; • Damaged storage containers; • Uncontrolled access to chemical storage; • Lack of chemical-related training; and • Lack of supervision. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Causes of a Spill Causes of chemical spills are as follows: • Inappropriate handling techniques; • Inappropriate storage containers; • Damaged storage containers; • Uncontrolled access to chemical storage; • Lack of chemical-related training; and • Lack of supervision. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Spill Prevention Planning • Only buy and store amount of material needed • Buy the least hazardous materials possible • Use non-hazardous materials when possible • Minimize traffic in the area • Store liquid wastes in secondary containers • Regularly inspect containers to ensure their integrity • Be aware of evacuation routes and emergency equipment NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Spill Prevention Planning • Only buy and store amount of material needed • Buy the least hazardous materials possible • Use non-hazardous materials when possible • Minimize traffic in the area • Store liquid wastes in secondary containers • Regularly inspect containers to ensure their integrity • Be aware of evacuation routes and emergency equipment NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Managing A Spill What type and size of spills am I capable of managing? You should only be cleaning up small spills (less than 1 gallon) of known materials that you work with on a regular basis after you have had attended a training session given by the EHS department. Small spill clean-up kits are located in the 90 -day storage area and in “all” laboratories. Notify the Marquette Police Department (x 8 -1911) for larger spills, or spills containing reactive or highly toxic materials. Marquette Police will notify the proper authorities. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Managing A Spill What type and size of spills am I capable of managing? You should only be cleaning up small spills (less than 1 gallon) of known materials that you work with on a regular basis after you have had attended a training session given by the EHS department. Small spill clean-up kits are located in the 90 -day storage area and in “all” laboratories. Notify the Marquette Police Department (x 8 -1911) for larger spills, or spills containing reactive or highly toxic materials. Marquette Police will notify the proper authorities. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Spill Kits These spill kits contain everything you need to properly manage a small spill in your labs. These are available from EH&S. Please contact Dennis Daye to place an order. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Spill Kits These spill kits contain everything you need to properly manage a small spill in your labs. These are available from EH&S. Please contact Dennis Daye to place an order. NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

What to do when an emergency occurs… • TAKE CARE OF THE SAFETY OF YOURSELF AND OTHERS! • Activate the building’s fire alarm system. • If you have bodily contact with material: – immediately remove any contaminated clothing – flush the area with copious amounts of water • Call Marquette Police at 288 -1911 – – Identify yourself and why you are calling the exact location and nature of the emergency any injuries of symptoms involved all hazardous materials involved (if known) NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

What to do when an emergency occurs… • TAKE CARE OF THE SAFETY OF YOURSELF AND OTHERS! • Activate the building’s fire alarm system. • If you have bodily contact with material: – immediately remove any contaminated clothing – flush the area with copious amounts of water • Call Marquette Police at 288 -1911 – – Identify yourself and why you are calling the exact location and nature of the emergency any injuries of symptoms involved all hazardous materials involved (if known) NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

This is a general awareness training. You are not trained as an emergency responder and should not attempt to manage emergencies. Emergency agencies such as the Fire Department, Police Department and Haz Mat Response Teams will be responsible for situations other than easily contained spills or incidental situations. ALWAYS CALL 288 -1911 ON CAMPUS TO REPORT AN EMERGENCY NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

This is a general awareness training. You are not trained as an emergency responder and should not attempt to manage emergencies. Emergency agencies such as the Fire Department, Police Department and Haz Mat Response Teams will be responsible for situations other than easily contained spills or incidental situations. ALWAYS CALL 288 -1911 ON CAMPUS TO REPORT AN EMERGENCY NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

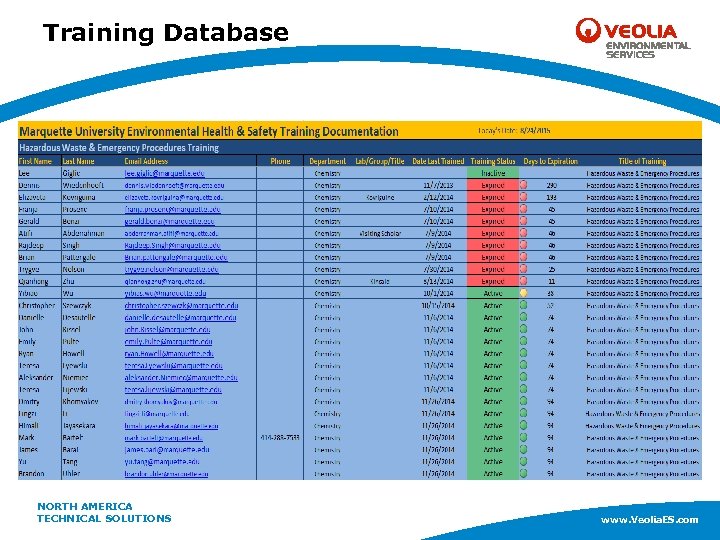

Training Database NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Training Database NORTH AMERICA www. Veolia. ES. com TECHNICAL SOLUTIONS www. Veolia. ES. com

Questions or Suggestions? Feel free to contact Dennis Daye (414) 288 -8411 or Steve Sprung steve. sprung@Veolia. com with questions, concerns, or suggestions. NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Questions or Suggestions? Feel free to contact Dennis Daye (414) 288 -8411 or Steve Sprung steve. sprung@Veolia. com with questions, concerns, or suggestions. NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Thank you for participating in Hazardous Waste Generator Requirements Training NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com

Thank you for participating in Hazardous Waste Generator Requirements Training NORTH AMERICA TECHNICAL SOLUTIONS www. Veolia. ES. com