72a7de3a9923ce9c397fb3c3d799cdd2.ppt

- Количество слайдов: 26

Welcome To Crony Group

Abanti Colour Tex Limited. A world class composite unit since 1994. Abanti Colour Tex Limited (ACTL) is a specialized plant with state of the art technologies for manufacture and export of Knitwear. As a vendor to the largest chain stores in throughout the world, we have established ourselves as a very competitive, reliable, and quality source of knit apparel. Our reputation is based on the simple philosophy that “Price, Quality and On-time delivery is the essence of long term relationship in export business”.

ACHIEVEMENT Abanti Colour Tex Limited (ACTL) achieved the International Star for Leadership in Quality Award in the Gold Category, awarded by International B. I. D Quality Convention, Paris-2009. ACTL is an ISO 9001: 2000 standard business organization attained certification from the accreditation body of ANSHRAB and it has permission to put OEKO Tex label on all its fabrics. Our Associate Company in textile apparels is S. S Cotton Fabrics Ltd, Crony Apparels Ltd, Crony Fashion Ltd, Crony Knitwear Ltd, Crony Printing & Embroidery Ltd and BD Packaging Limited. In collaboration with all these member concerns we work as CRONY GROUP.

PRODUCT Abanti Colour Tex Limited has an enviable reputation as an international garment manufacturer based on a simple but unwavering philosophy of producing high quality products. ACTL is 100% export oriented, vertically integrated knitting, dyeing, finishing and garment manufacturing company with production capacity of about 10 million pieces of garments per year. ACTL exports to EU countries, Canada, North America. The products of the Company include Pique Polo-shirts, Jersey Polo-shirts, Double knit Polo-shirts, Golf shirts, Sweat shirts, Hooded Sweat shirts, Polo shirts, Sweat Pants, Basic Tee-shirts, Track suits, Tank Tops, Big Tee-shirts, Heavy Tee-shirts, Jogging Suits, Turtle Neck Tee-shirts, Jackets, Underwear, Children wear, men wear, babies wear etc.

QUALITY We believe that only by after providing our Customers with the Services and Products specified at the requested time, and in the stated manner, we can claim to be a Quality Conscious Company, and expect our Customer's continued patronage. All the knitted fabric is subjected to 100% inspection in accordance with our in house established quality inspection standards, which are part of our Internal Quality Management System. During our fabric processing, we work in compliance with international standard and we also follow OEKO Tex – 100 Standard. During our stitching & packing In -Line Inspecting as well as Final Inspection is carried out according to stated AQL (Acceptable Quality Level). Besides that we also comply with customers supplied specifications reports.

COMPLIANCE, WORKERS BENIFITS & LABOR LAWS Crony Group fully complies with the laws on workers wages. The workforce is our strength. We abide by all the labor and industrial laws of the country, which are based on the recommendation of International Labor Organization (ILO). The factory never had any child labor and strictly follows the minimum wage guideline. Workers welfare, Child care, Medical facility, safety and working conditions are maintained as per international standards.

ENVIRONMENTAL STANDARDS All the solid waste and effluent generated by the factory are disposed off in an environmentally safe manner. Our commitment: Ø Installation of an Effluent Treatment Plant (ETP) is going on & it will be accomplished by December 2009. Ø Meet relative environmental safety standards. Ø Continual waste reduction, recycle and reuse. Ø Improve work environment and work safety.

MARKETING & MERCHANDISING The Marketing & Merchandising Department is governed by the General Manager and runs by a well organized merchandising team. Marketing & merchandising division's main function is to introduce Abanti Colour Tex/Crony Group to new buyers whenever the opportunity arises. Some of the other tasks maintained by this department are to provide marketing samples, analyze prices and preserve regular communication with existing buyers about their requirements. They also provide development samples & prices for both old and prospective customers of Crony Group. The merchandising team is also responsible for allocating production blocks to existing buyers and follow up on the fulfillment of the allocated space. This team is also the intermediary correspondent between the buyers and the factory production team.

PLANNING CELL Planning cell is the central organ for operations and management of Abanti Colour Tex Limited. The planning cell formed by carefully chosen individuals who are able to delegate responsibilities to different divisions, departments and sections for the respective functions. This team is also responsible for on-time delivery of orders and inspection as per buyer's requirement.

TECHNICAL STRENGTH Lab Section All fabrics produced in ACTL's own factory are tested in its own laboratory for wet & dry rub fastness, wash fastness, dimensional stability, required fabric density, yarn count and composition before making finished garments.

TECHNICAL STRENGTH RND & CAD Section (9 th Floor) A Research and Development as well as CAD section is fully equipped with advanced machinery and operated by a team of well-experienced technicians. We are confident enough to develop any sort of style within seven days only.

TECHNICAL STRENGTH Conference & Display Room (9 th Floor) We have pleasant interior furnished conference room with well organized display both in our factory & corporate office.

TECHNICAL STRENGTH Power Plant (Gas Generator) Electricity generating capacity 1125 KVA/900 KW with uninterrupted power supply.

PRODUCTION FACILITIES Knitting Division (1 st Floor) Production Capacity: 09 tons per day, Total Machine: 34

PRODUCTION FACILITIES Knitting Division (Contd……. ) Fabrics Structures Single Jersey All Rib fabrics Waffle Pique Lacoste Honey comb Lycra Jersey French Terry Fleece Stripe Fabrics Inter lock Fabrics

PRODUCTION FACILITIES Our In-house Production facilities include the following: Dyeing Division (Ground Floor) Production Capacity: 12 tons per day.

PRODUCTION FACILITIES Cutting Section (6 th Floor) Production capacity of our cutting section is 75, 000 Pcs per day.

PRODUCTION FACILITIES Garments Division Production Capacity: 60000 Pcs, Total Sewing Line: 31

PRODUCTION FACILITIES Finishing Section Production Capacity: 61000 Pcs

PRODUCTION FACILITIES Printing Section (7 th floor) We have our own printing factory in the 7 th floor of this complex. Production capacity of this printing factory is 25, 000 Pcs per day.

PRODUCTION FACILITIES Embroidery Section Capacity: 10, 000 Pcs

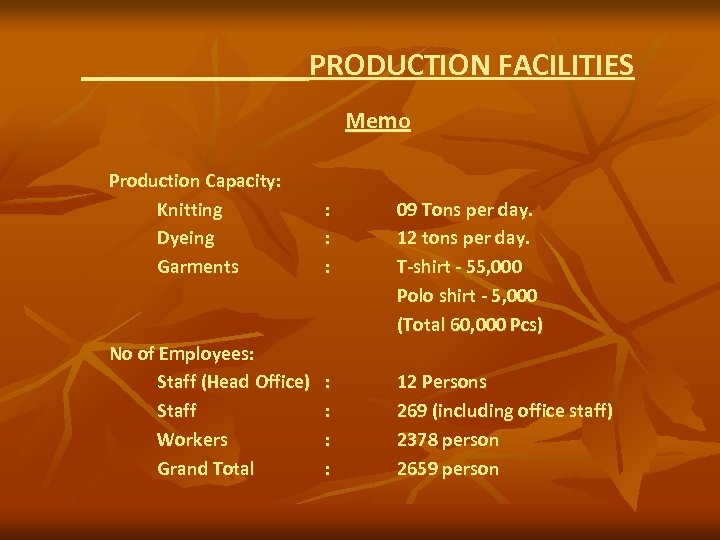

PRODUCTION FACILITIES Memo Production Capacity: Knitting Dyeing Garments : : : 09 Tons per day. 12 tons per day. T-shirt - 55, 000 Polo shirt - 5, 000 (Total 60, 000 Pcs) No of Employees: Staff (Head Office) Staff Workers Grand Total : : 12 Persons 269 (including office staff) 2378 person 2659 person

PRODUCTION FACILITIES Expansion Plan: We have an expansion plan to extend our production capacity, where our facilities will be upgraded to another Six Storied Building each floor having the space of 25000 square feet including Open Width Dyeing & Yarn Dyeing project with world class finishing machineries in Ground Floor, Complete Garments Divisions in 1 st, 2 nd, 3 rd , 4 th and 5 th floor. In implementation of this extension plan by mid of 2010 our production capacity will be increased by another 40, 000 Pcs per day.

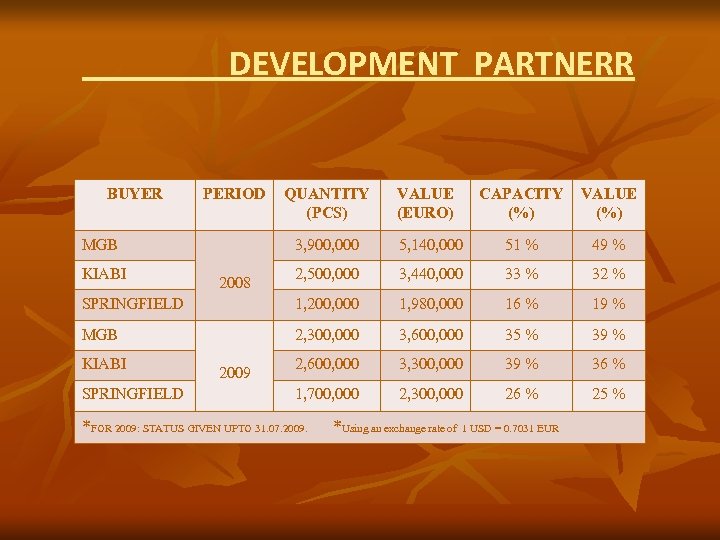

DEVELOPMENT PARTNERR BUYER PERIOD QUANTITY (PCS) VALUE (EURO) 3, 900, 000 5, 140, 000 51 % 49 % 2, 500, 000 3, 440, 000 33 % 32 % SPRINGFIELD 1, 200, 000 1, 980, 000 16 % 19 % MGB 2, 300, 000 3, 600, 000 35 % 39 % 2, 600, 000 3, 300, 000 39 % 36 % 1, 700, 000 2, 300, 000 26 % 25 % MGB KIABI SPRINGFIELD 2008 2009 *FOR 2009: STATUS GIVEN UPTO 31. 07. 2009. *Using an exchange rate of CAPACITY VALUE (%) 1 USD = 0. 7031 EUR

Thanks a million for your continuous patronage……….

72a7de3a9923ce9c397fb3c3d799cdd2.ppt