Agro Presentation_2012_e.ppt

- Количество слайдов: 48

Welcome

Welcome

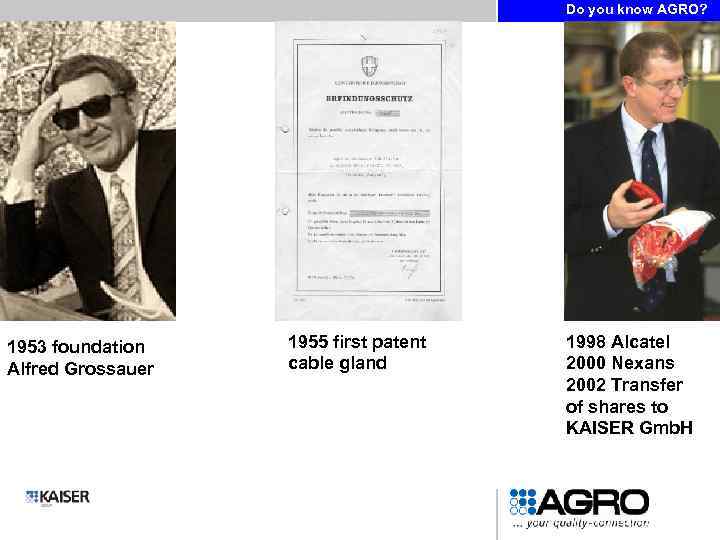

Do you know AGRO? 1953 foundation Alfred Grossauer 1955 first patent cable gland 1998 Alcatel 2000 Nexans 2002 Transfer of shares to KAISER Gmb. H

Do you know AGRO? 1953 foundation Alfred Grossauer 1955 first patent cable gland 1998 Alcatel 2000 Nexans 2002 Transfer of shares to KAISER Gmb. H

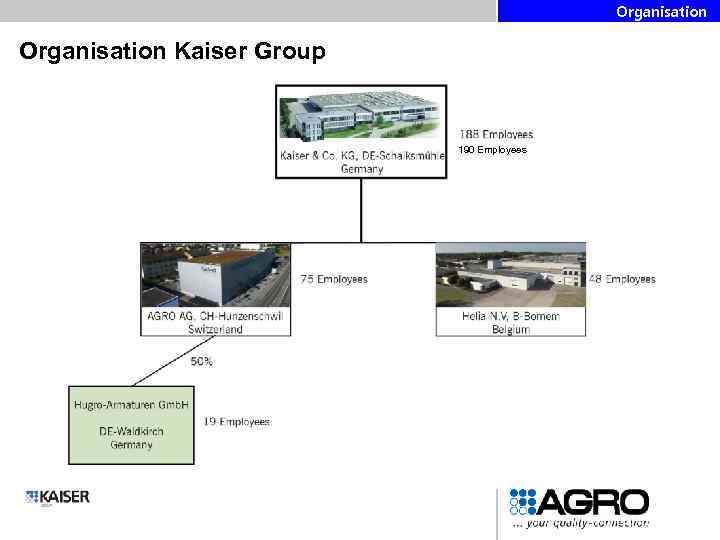

Organisation Kaiser Group 190 Employees

Organisation Kaiser Group 190 Employees

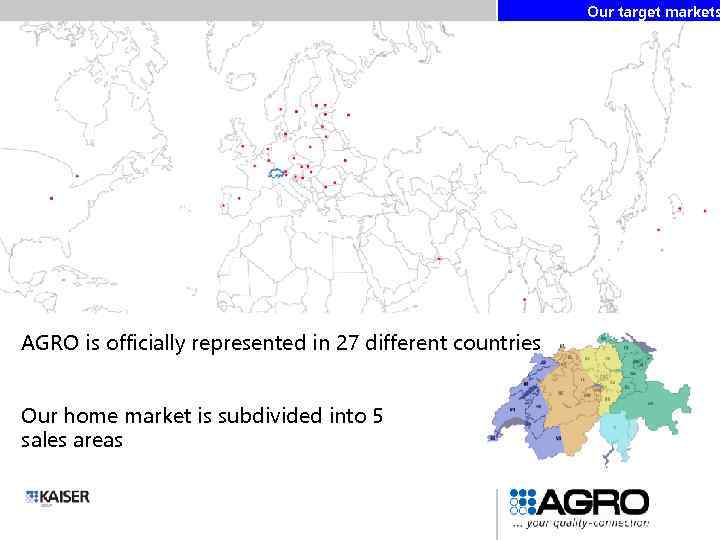

Our target markets AGRO is officially represented in 27 different countries Our home market is subdivided into 5 sales areas

Our target markets AGRO is officially represented in 27 different countries Our home market is subdivided into 5 sales areas

Our target markets Shares of Sales We achieve about 70% of the volume of sales in our home market Switzerland Every other cable gland that AGRO produces is sold abroad

Our target markets Shares of Sales We achieve about 70% of the volume of sales in our home market Switzerland Every other cable gland that AGRO produces is sold abroad

Our target groups Our Target Groups in the International Field § Global Players § Industrial enterprises § Distributors

Our target groups Our Target Groups in the International Field § Global Players § Industrial enterprises § Distributors

Products and Services – Cable Glands AGRO offers solution-oriented products for cable entries in industrial applications. The basis assortment for the industrial customer segment includes standard cable glands as well as cable glands for Ex and EMC applications and corresponding accessories. With customised products we cover individual requirements.

Products and Services – Cable Glands AGRO offers solution-oriented products for cable entries in industrial applications. The basis assortment for the industrial customer segment includes standard cable glands as well as cable glands for Ex and EMC applications and corresponding accessories. With customised products we cover individual requirements.

Products and Services – Protective Conduits for Cables Cable protecting conduits in plastic material and metal as well as corresponding conduit glands complete the assortment of cable glands. Typical applications areas: rolling stock and transportation systems, machinery and automation industry, power engineering

Products and Services – Protective Conduits for Cables Cable protecting conduits in plastic material and metal as well as corresponding conduit glands complete the assortment of cable glands. Typical applications areas: rolling stock and transportation systems, machinery and automation industry, power engineering

Products and Services – Braided Sleeves and glass fibre sle Braided sleeves are used to bundle cables or to separate data cables from energy cables, installation in in cabinets, rolling stock, machinery and automation industry. Glass fibre sleeves are ideally suited for use in applications where both good dielectric values and high temperature resistance are vital.

Products and Services – Braided Sleeves and glass fibre sle Braided sleeves are used to bundle cables or to separate data cables from energy cables, installation in in cabinets, rolling stock, machinery and automation industry. Glass fibre sleeves are ideally suited for use in applications where both good dielectric values and high temperature resistance are vital.

Products and Services – Installation Material AGRO offers a wide range of products for the electric installation for structural work to the electric installer. Experts find professional products for the installation in concrete, in cavity walls and ceilings, for energy-efficient installation, for fire and sound protection as well as for buried wiring or surface mounted installations. AGRO as Swiss market leader frequently is the driver of new trends.

Products and Services – Installation Material AGRO offers a wide range of products for the electric installation for structural work to the electric installer. Experts find professional products for the installation in concrete, in cavity walls and ceilings, for energy-efficient installation, for fire and sound protection as well as for buried wiring or surface mounted installations. AGRO as Swiss market leader frequently is the driver of new trends.

Why AGRO ? All our Products are Certified! All our cable and conduit glands do have several certificates. The same applies to cable protective conduits and braided sleeves. AGRO’s installation products strictly follow the normative guidelines for electric installation. That‘s what makes you feel safe !

Why AGRO ? All our Products are Certified! All our cable and conduit glands do have several certificates. The same applies to cable protective conduits and braided sleeves. AGRO’s installation products strictly follow the normative guidelines for electric installation. That‘s what makes you feel safe !

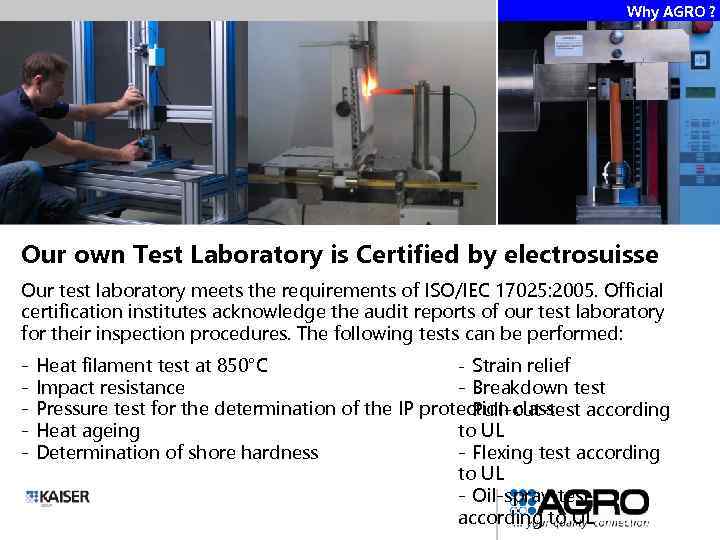

Why AGRO ? Our own Test Laboratory is Certified by electrosuisse Our test laboratory meets the requirements of ISO/IEC 17025: 2005. Official certification institutes acknowledge the audit reports of our test laboratory for their inspection procedures. The following tests can be performed: - Heat filament test at 850°C - Strain relief Impact resistance - Breakdown test Pressure test for the determination of the IP protection class - Pull-out-test according Heat ageing to UL Determination of shore hardness - Flexing test according to UL - Oil-spray-test according to UL

Why AGRO ? Our own Test Laboratory is Certified by electrosuisse Our test laboratory meets the requirements of ISO/IEC 17025: 2005. Official certification institutes acknowledge the audit reports of our test laboratory for their inspection procedures. The following tests can be performed: - Heat filament test at 850°C - Strain relief Impact resistance - Breakdown test Pressure test for the determination of the IP protection class - Pull-out-test according Heat ageing to UL Determination of shore hardness - Flexing test according to UL - Oil-spray-test according to UL

Why AGRO ? High Product Availability More than 99% of all our products are available off the shelf. We consider this one of our main strengths and a service to the customer. Our delivery capacity improves your liquidity. Our logistics make sure that our customers get the desired product in good time.

Why AGRO ? High Product Availability More than 99% of all our products are available off the shelf. We consider this one of our main strengths and a service to the customer. Our delivery capacity improves your liquidity. Our logistics make sure that our customers get the desired product in good time.

Why AGRO ? Our Concept for Success – our Employees Our committed, motivated and well trained employees turned AGRO AG to what it is today. We rely on the ideas, the manpower, the care and the skills of our staff members.

Why AGRO ? Our Concept for Success – our Employees Our committed, motivated and well trained employees turned AGRO AG to what it is today. We rely on the ideas, the manpower, the care and the skills of our staff members.

Why AGRO ? Our Webpage • Product finding tool • Technical datasheet • 3 D CAD download • Certificates • Catalogues / leaflets • Assembly instructions www. agro. ch

Why AGRO ? Our Webpage • Product finding tool • Technical datasheet • 3 D CAD download • Certificates • Catalogues / leaflets • Assembly instructions www. agro. ch

Technical Introduction

Technical Introduction

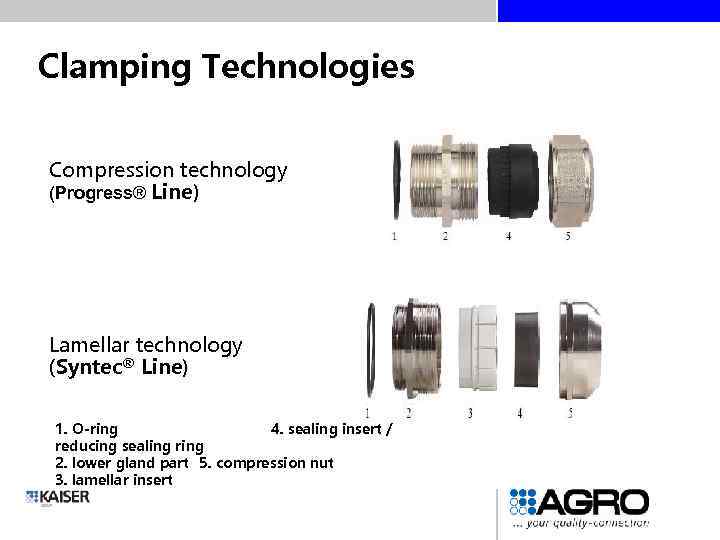

Clamping Technologies Compression technology (Progress® Line) Lamellar technology (Syntec® Line) 1. O-ring 4. sealing insert / reducing sealing ring 2. lower gland part 5. compression nut 3. lamellar insert

Clamping Technologies Compression technology (Progress® Line) Lamellar technology (Syntec® Line) 1. O-ring 4. sealing insert / reducing sealing ring 2. lower gland part 5. compression nut 3. lamellar insert

Comparison clamping technology Compression technology • Excellent aging behaviours • Smooth pressure around cable, large pressing area • Ideal for application with movement between cable and gland vibration e. g. rolling stock and transportation systems • Heavy duty outdoor applications • Best possible sealing behaviour (e. g. underwater application)

Comparison clamping technology Compression technology • Excellent aging behaviours • Smooth pressure around cable, large pressing area • Ideal for application with movement between cable and gland vibration e. g. rolling stock and transportation systems • Heavy duty outdoor applications • Best possible sealing behaviour (e. g. underwater application)

Comparison clamping technology Lamellar technology • Large clamping range • AGRO lamellar: hexagonal compression avoids a torsion of the cable • AGRO lamellar: pre-fixing of compression nut facilitates over-the-head mounting • AGRO lamellar: large wrench flats for easy installation

Comparison clamping technology Lamellar technology • Large clamping range • AGRO lamellar: hexagonal compression avoids a torsion of the cable • AGRO lamellar: pre-fixing of compression nut facilitates over-the-head mounting • AGRO lamellar: large wrench flats for easy installation

Technical features of Syntec® cable glands

Technical features of Syntec® cable glands

Materials of cable glands Synthetic • Polyamide PA 6 • Polyamide PA 6 GF 30 (glass-fibre reinforced Polyamide) • AGROMID Polyamide PA 6 GF 30 (glass-fibre reinforced, impactresistant, heat aging, special modified) Metal • Nickel –plated brass (Cu. Zn 39 Pb 3) • Stainless steel A 2 A (AISI 303) • Rustproof and acid-resistant stainless steel A 4 (AISI 316 L)

Materials of cable glands Synthetic • Polyamide PA 6 • Polyamide PA 6 GF 30 (glass-fibre reinforced Polyamide) • AGROMID Polyamide PA 6 GF 30 (glass-fibre reinforced, impactresistant, heat aging, special modified) Metal • Nickel –plated brass (Cu. Zn 39 Pb 3) • Stainless steel A 2 A (AISI 303) • Rustproof and acid-resistant stainless steel A 4 (AISI 316 L)

Materials of the Sealing Inserts • TPE (Thermoplastic elastomere) Temperature range: *-40°/+100°C • NBR (Acrylyonitrile-butadiene-rubber) Temperature range: *-40°/+100°C ideal for hole drilling for multiple cables • FPM (Fluorine-rubber) (Viton®) Temperature range: *-40°/+200°C • CR (Chloroprene-rubber) Temperature range: -30°/+100°C * TPE / NBR / FPM: -60°C if: no dynamic load; no relative movement between cable and cable gland; not suitable for Ex glands

Materials of the Sealing Inserts • TPE (Thermoplastic elastomere) Temperature range: *-40°/+100°C • NBR (Acrylyonitrile-butadiene-rubber) Temperature range: *-40°/+100°C ideal for hole drilling for multiple cables • FPM (Fluorine-rubber) (Viton®) Temperature range: *-40°/+200°C • CR (Chloroprene-rubber) Temperature range: -30°/+100°C * TPE / NBR / FPM: -60°C if: no dynamic load; no relative movement between cable and cable gland; not suitable for Ex glands

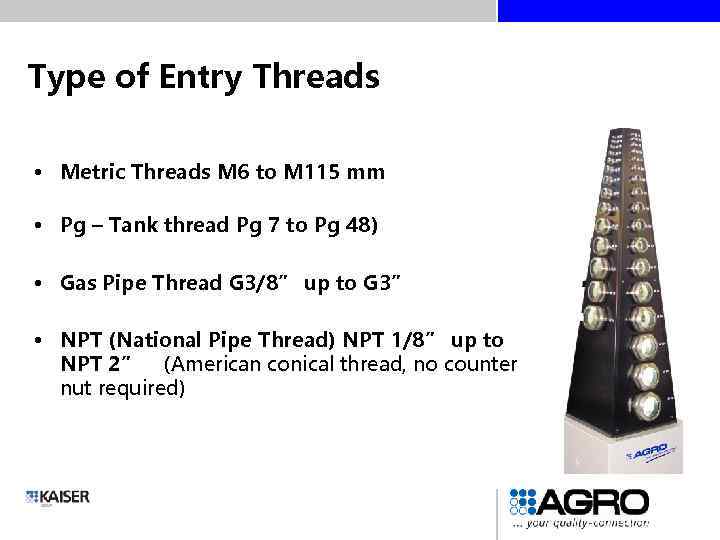

Type of Entry Threads • Metric Threads M 6 to M 115 mm • Pg – Tank thread Pg 7 to Pg 48) • Gas Pipe Thread G 3/8” up to G 3” • NPT (National Pipe Thread) NPT 1/8” up to NPT 2” (American conical thread, no counter nut required)

Type of Entry Threads • Metric Threads M 6 to M 115 mm • Pg – Tank thread Pg 7 to Pg 48) • Gas Pipe Thread G 3/8” up to G 3” • NPT (National Pipe Thread) NPT 1/8” up to NPT 2” (American conical thread, no counter nut required)

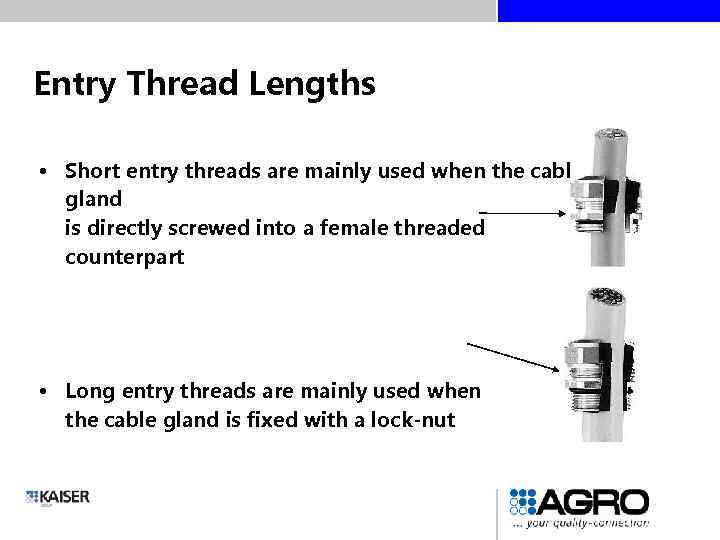

Entry Thread Lengths • Short entry threads are mainly used when the cable gland is directly screwed into a female threaded counterpart • Long entry threads are mainly used when the cable gland is fixed with a lock-nut

Entry Thread Lengths • Short entry threads are mainly used when the cable gland is directly screwed into a female threaded counterpart • Long entry threads are mainly used when the cable gland is fixed with a lock-nut

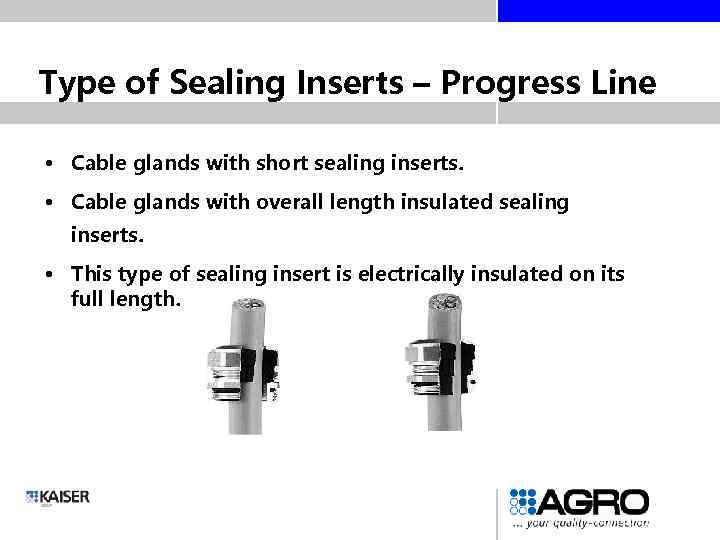

Type of Sealing Inserts – Progress Line • Cable glands with short sealing inserts. • Cable glands with overall length insulated sealing inserts. • This type of sealing insert is electrically insulated on its full length.

Type of Sealing Inserts – Progress Line • Cable glands with short sealing inserts. • Cable glands with overall length insulated sealing inserts. • This type of sealing insert is electrically insulated on its full length.

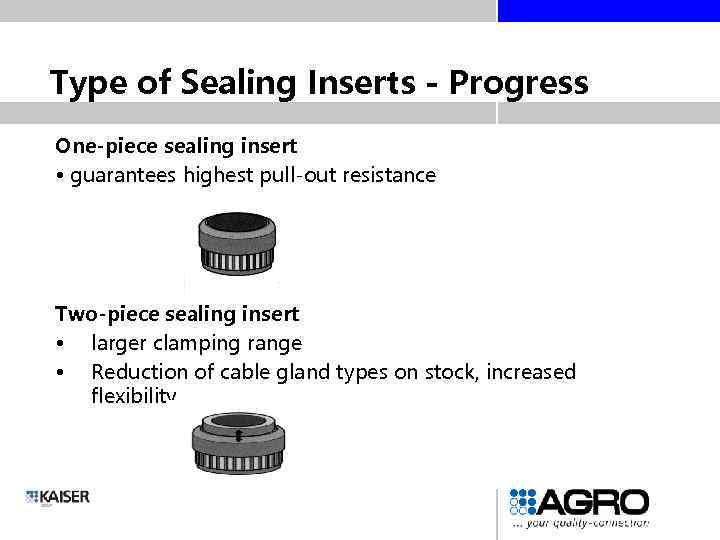

Type of Sealing Inserts - Progress One-piece sealing insert • guarantees highest pull-out resistance Two-piece sealing insert • larger clamping range • Reduction of cable gland types on stock, increased flexibility

Type of Sealing Inserts - Progress One-piece sealing insert • guarantees highest pull-out resistance Two-piece sealing insert • larger clamping range • Reduction of cable gland types on stock, increased flexibility

Type of Sealing Inserts Progress® Other Sealing Insert versions:

Type of Sealing Inserts Progress® Other Sealing Insert versions:

Our modular system Progress®

Our modular system Progress®

EN 50262 • • Testing retaining forces Tests made on calibre gauges with elastomeric lagging Tests correspond to min. / max. cable dia Pullout force (N) 5 min without interruption, movement max. 3 mm • • Testing strain relief and anti twisting behaviour Retaining forces 50 movements axial without jerking, each for 1 sec Max slipping distance 2 mm Twisting force: radial slip less than 45° • • Further requirements Resistance to impact force Min. electrical effects (EMC) and min. insulation behaviours Directions for marking and documentation

EN 50262 • • Testing retaining forces Tests made on calibre gauges with elastomeric lagging Tests correspond to min. / max. cable dia Pullout force (N) 5 min without interruption, movement max. 3 mm • • Testing strain relief and anti twisting behaviour Retaining forces 50 movements axial without jerking, each for 1 sec Max slipping distance 2 mm Twisting force: radial slip less than 45° • • Further requirements Resistance to impact force Min. electrical effects (EMC) and min. insulation behaviours Directions for marking and documentation

AGRO EMC Cable Glands

AGRO EMC Cable Glands

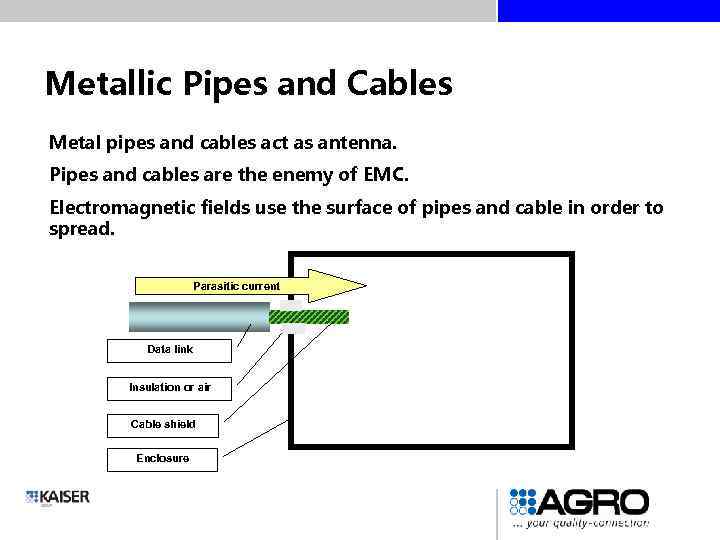

Metallic Pipes and Cables Metal pipes and cables act as antenna. Pipes and cables are the enemy of EMC. Electromagnetic fields use the surface of pipes and cable in order to spread. Parasitic current Data link Insulation or air Cable shield Enclosure

Metallic Pipes and Cables Metal pipes and cables act as antenna. Pipes and cables are the enemy of EMC. Electromagnetic fields use the surface of pipes and cable in order to spread. Parasitic current Data link Insulation or air Cable shield Enclosure

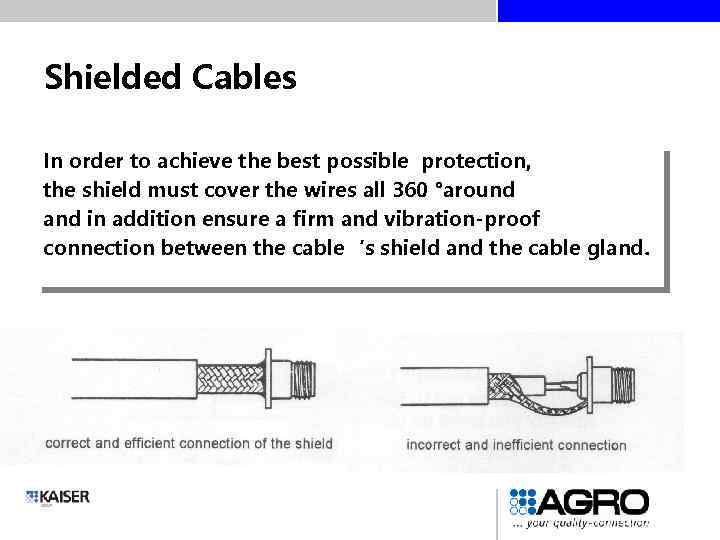

Shielded Cables In order to achieve the best possible protection, the shield must cover the wires all 360 °around and in addition ensure a firm and vibration-proof connection between the cable‘s shield and the cable gland.

Shielded Cables In order to achieve the best possible protection, the shield must cover the wires all 360 °around and in addition ensure a firm and vibration-proof connection between the cable‘s shield and the cable gland.

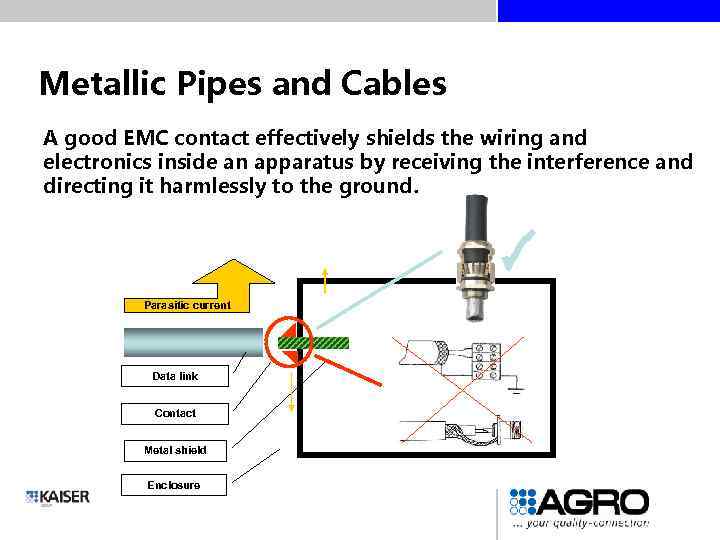

Metallic Pipes and Cables A good EMC contact effectively shields the wiring and electronics inside an apparatus by receiving the interference and directing it harmlessly to the ground. Parasitic current Data link Contact Metal shield Enclosure

Metallic Pipes and Cables A good EMC contact effectively shields the wiring and electronics inside an apparatus by receiving the interference and directing it harmlessly to the ground. Parasitic current Data link Contact Metal shield Enclosure

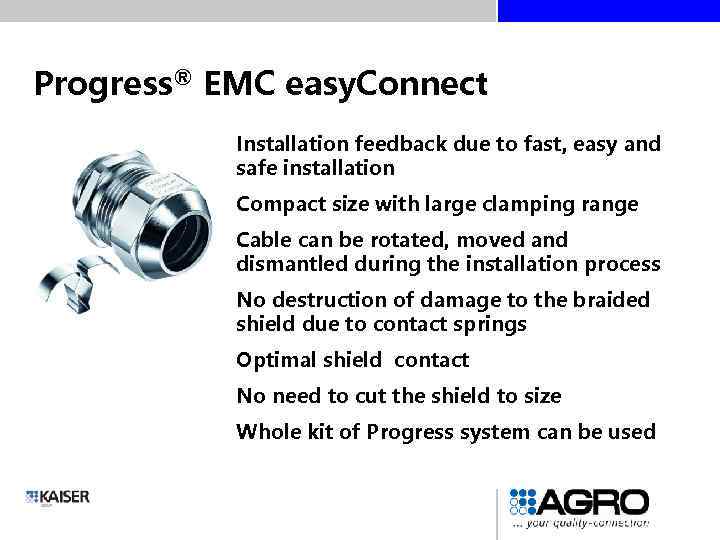

Progress® EMC easy. Connect Installation feedback due to fast, easy and safe installation Compact size with large clamping range Cable can be rotated, moved and dismantled during the installation process No destruction of damage to the braided shield due to contact springs Optimal shield contact No need to cut the shield to size Whole kit of Progress system can be used

Progress® EMC easy. Connect Installation feedback due to fast, easy and safe installation Compact size with large clamping range Cable can be rotated, moved and dismantled during the installation process No destruction of damage to the braided shield due to contact springs Optimal shield contact No need to cut the shield to size Whole kit of Progress system can be used

Progress® EMC Series 85 The Cable Gland Series 85 is the flagship of Agro EMC Cable glands. Excellent shield contact: A perfect shield contact over a wide surface area is granted with the collets. As a result of this excellent damping characteristics are achieved. Highest leakage currents: The massive collets guarantees a concentric, low –impedance screened tap connection and handles leakage currents of up to 1. 6 k. A continuous – and short term to 3 k. A

Progress® EMC Series 85 The Cable Gland Series 85 is the flagship of Agro EMC Cable glands. Excellent shield contact: A perfect shield contact over a wide surface area is granted with the collets. As a result of this excellent damping characteristics are achieved. Highest leakage currents: The massive collets guarantees a concentric, low –impedance screened tap connection and handles leakage currents of up to 1. 6 k. A continuous – and short term to 3 k. A

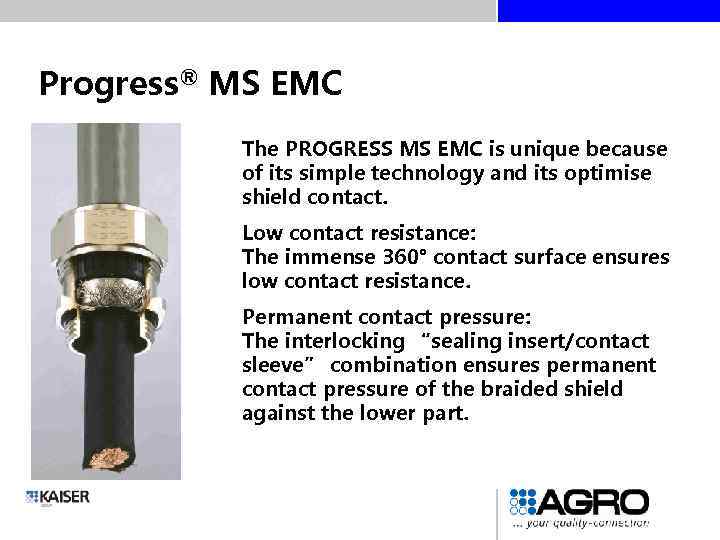

Progress® MS EMC The PROGRESS MS EMC is unique because of its simple technology and its optimise shield contact. Low contact resistance: The immense 360° contact surface ensures low contact resistance. Permanent contact pressure: The interlocking “sealing insert/contact sleeve” combination ensures permanent contact pressure of the braided shield against the lower part.

Progress® MS EMC The PROGRESS MS EMC is unique because of its simple technology and its optimise shield contact. Low contact resistance: The immense 360° contact surface ensures low contact resistance. Permanent contact pressure: The interlocking “sealing insert/contact sleeve” combination ensures permanent contact pressure of the braided shield against the lower part.

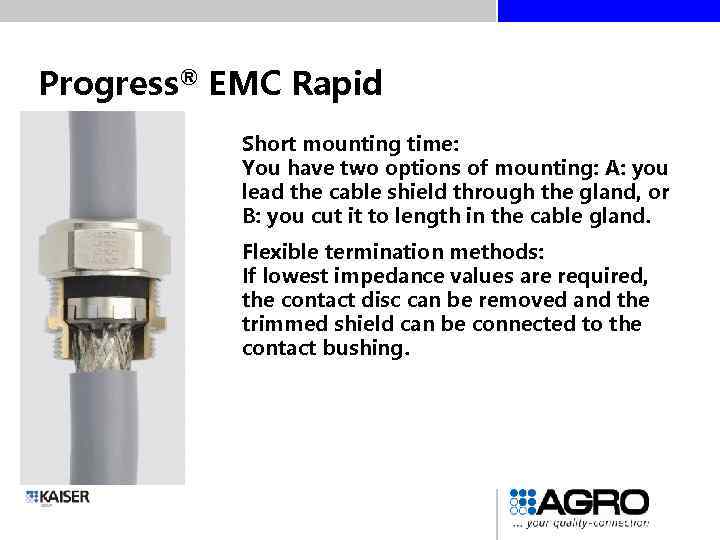

Progress® EMC Rapid Short mounting time: You have two options of mounting: A: you lead the cable shield through the gland, or B: you cut it to length in the cable gland. Flexible termination methods: If lowest impedance values are required, the contact disc can be removed and the trimmed shield can be connected to the contact bushing.

Progress® EMC Rapid Short mounting time: You have two options of mounting: A: you lead the cable shield through the gland, or B: you cut it to length in the cable gland. Flexible termination methods: If lowest impedance values are required, the contact disc can be removed and the trimmed shield can be connected to the contact bushing.

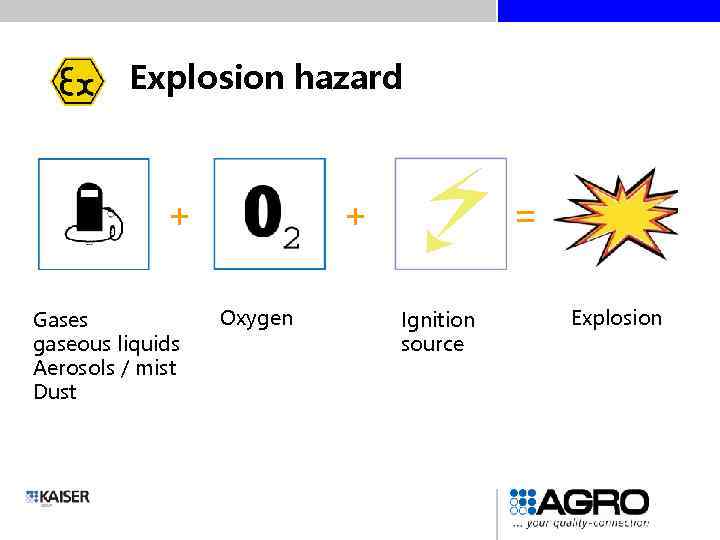

Explosion hazard + Gases gaseous liquids Aerosols / mist Dust + Oxygen = Ignition source Explosion

Explosion hazard + Gases gaseous liquids Aerosols / mist Dust + Oxygen = Ignition source Explosion

Directives & Regulations ATEX 95 (atmosphère explosible) regulates the explosion protection in electrical installations in the EU. The operator company has to make a risk analysis based on the Directive 1999/92/EG (ATEX 137). He has to define the ignition protection categories and the zone category.

Directives & Regulations ATEX 95 (atmosphère explosible) regulates the explosion protection in electrical installations in the EU. The operator company has to make a risk analysis based on the Directive 1999/92/EG (ATEX 137). He has to define the ignition protection categories and the zone category.

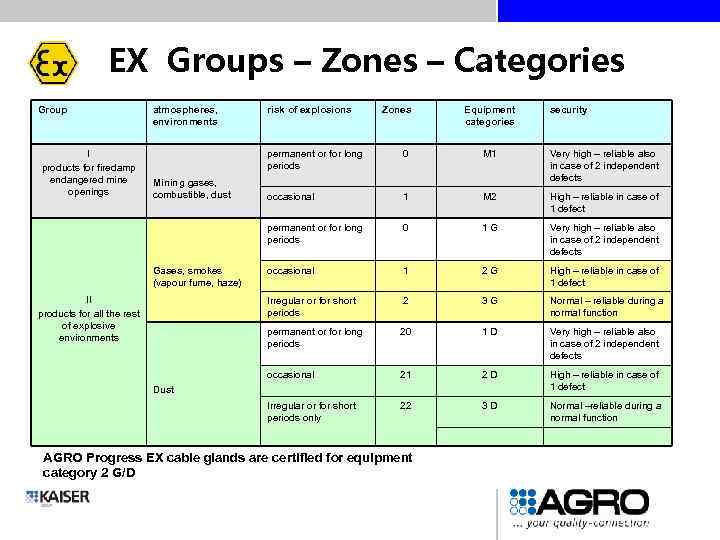

EX Groups – Zones – Categories Group I products for firedamp endangered mine openings atmospheres, environments risk of explosions Zones Equipment categories security permanent or for long periods occasional 1 M 2 High – reliable in case of 1 defect 0 1 G Very high – reliable also in case of 2 independent defects occasional 1 2 G High – reliable in case of 1 defect 2 3 G Normal – reliable during a normal function permanent or for long periods 20 1 D Very high – reliable also in case of 2 independent defects occasional 21 2 D High – reliable in case of 1 defect Irregular or for short periods only II products for all the rest of explosive environments Very high – reliable also in case of 2 independent defects Irregular or for short periods Gases, smokes (vapour fume, haze) M 1 permanent or for long periods Mining gases, combustible, dust 0 22 3 D Normal –reliable during a normal function Dust AGRO Progress EX cable glands are certified for equipment category 2 G/D

EX Groups – Zones – Categories Group I products for firedamp endangered mine openings atmospheres, environments risk of explosions Zones Equipment categories security permanent or for long periods occasional 1 M 2 High – reliable in case of 1 defect 0 1 G Very high – reliable also in case of 2 independent defects occasional 1 2 G High – reliable in case of 1 defect 2 3 G Normal – reliable during a normal function permanent or for long periods 20 1 D Very high – reliable also in case of 2 independent defects occasional 21 2 D High – reliable in case of 1 defect Irregular or for short periods only II products for all the rest of explosive environments Very high – reliable also in case of 2 independent defects Irregular or for short periods Gases, smokes (vapour fume, haze) M 1 permanent or for long periods Mining gases, combustible, dust 0 22 3 D Normal –reliable during a normal function Dust AGRO Progress EX cable glands are certified for equipment category 2 G/D

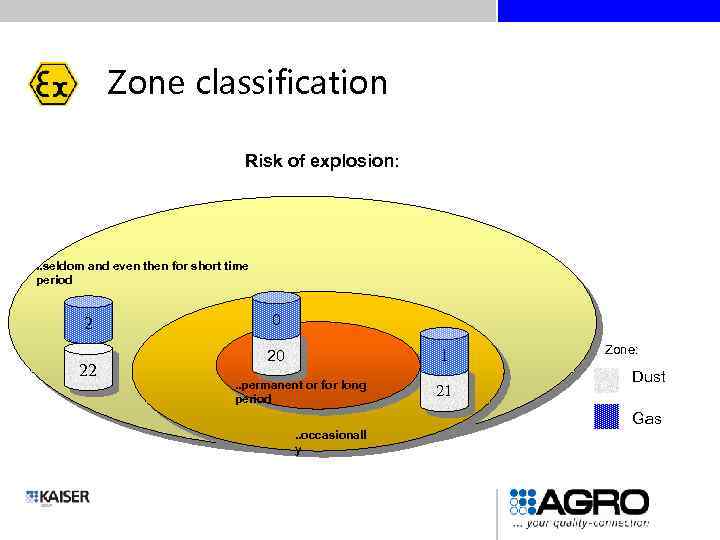

Zone classification Risk of explosion: . . seldom and even then for short time period 2 22 0 1 20. . permanent or for long period 21 Zone: Dust Gas . . occasionall y

Zone classification Risk of explosion: . . seldom and even then for short time period 2 22 0 1 20. . permanent or for long period 21 Zone: Dust Gas . . occasionall y

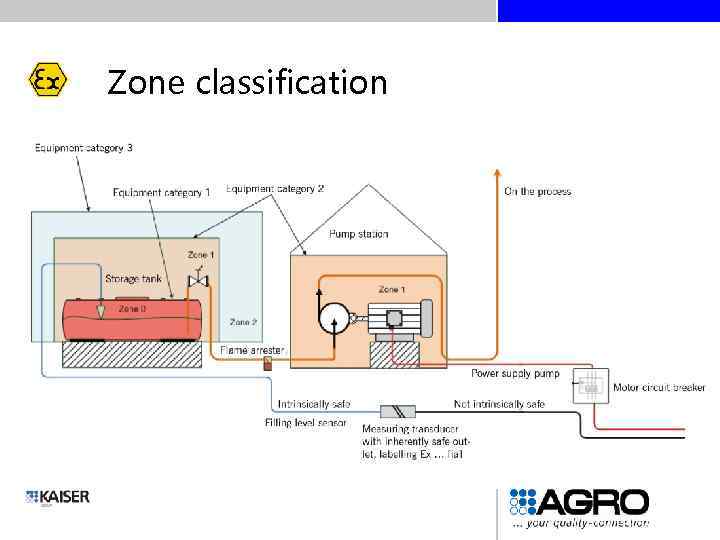

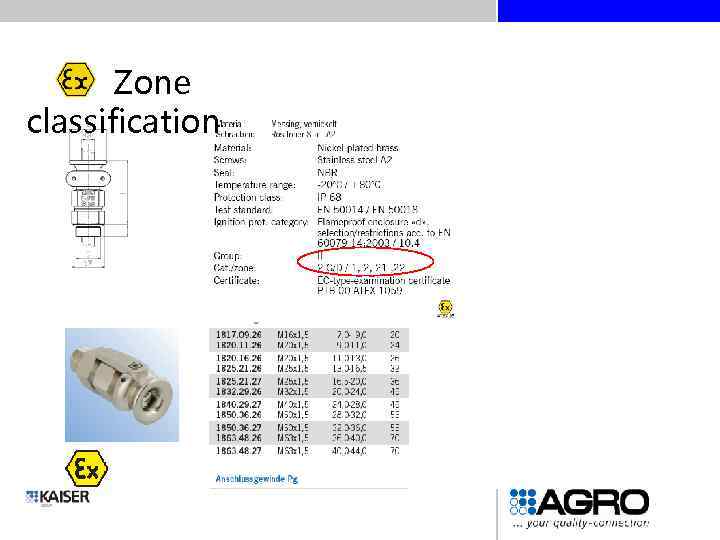

Zone classification

Zone classification

Zone classification

Zone classification

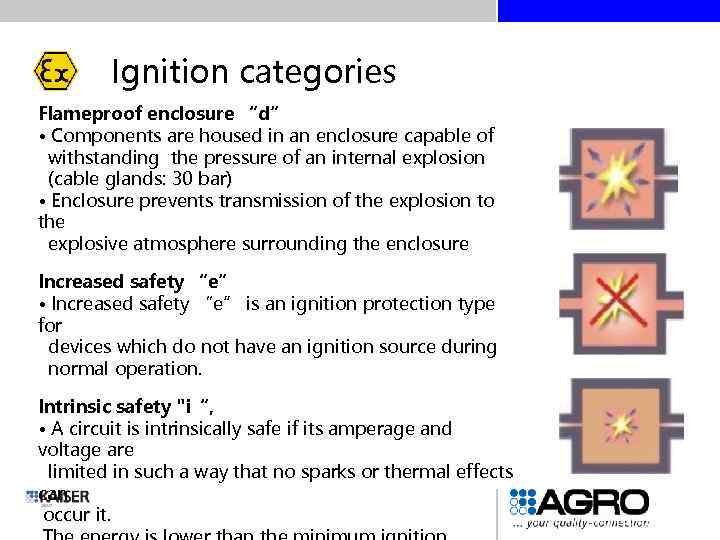

Ignition categories Flameproof enclosure “d” • Components are housed in an enclosure capable of withstanding the pressure of an internal explosion (cable glands: 30 bar) • Enclosure prevents transmission of the explosion to the explosive atmosphere surrounding the enclosure Increased safety “e” • Increased safety “e” is an ignition protection type for devices which do not have an ignition source during normal operation. Intrinsic safety "i“, • A circuit is intrinsically safe if its amperage and voltage are limited in such a way that no sparks or thermal effects can occur it.

Ignition categories Flameproof enclosure “d” • Components are housed in an enclosure capable of withstanding the pressure of an internal explosion (cable glands: 30 bar) • Enclosure prevents transmission of the explosion to the explosive atmosphere surrounding the enclosure Increased safety “e” • Increased safety “e” is an ignition protection type for devices which do not have an ignition source during normal operation. Intrinsic safety "i“, • A circuit is intrinsically safe if its amperage and voltage are limited in such a way that no sparks or thermal effects can occur it.

Thank you for your attention!

Thank you for your attention!

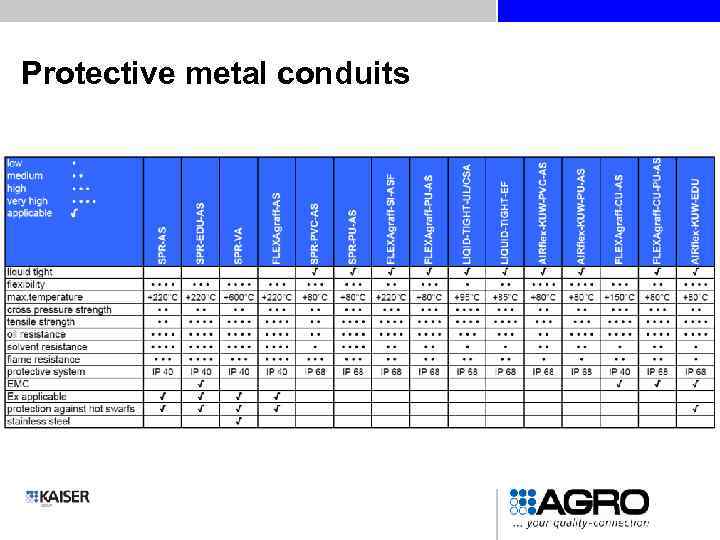

Protective metal conduits

Protective metal conduits

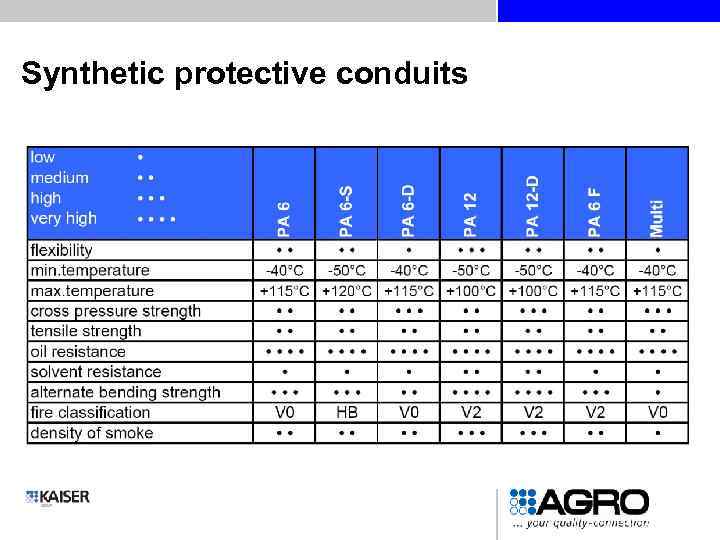

Synthetic protective conduits

Synthetic protective conduits