1326bc46480d3eb3075b58f015e9f372.ppt

- Количество слайдов: 35

Weir PW Critical Dimension & Process Window Analysis Weir PW is a new generation of lithography process analysis software providing: • critical element analysis, • control calculation, • yield estimation, • behavioral visualization and • automated modeling for process optimization. TEA Systems Corp. Overview Weir PW 65 Schlossburg St. Alburtis, PA 18011 610 682 4146 www. TEAsystems. com

Weir PW Critical Dimension & Process Window Analysis Weir PW is a new generation of lithography process analysis software providing: • critical element analysis, • control calculation, • yield estimation, • behavioral visualization and • automated modeling for process optimization. TEA Systems Corp. Overview Weir PW 65 Schlossburg St. Alburtis, PA 18011 610 682 4146 www. TEAsystems. com

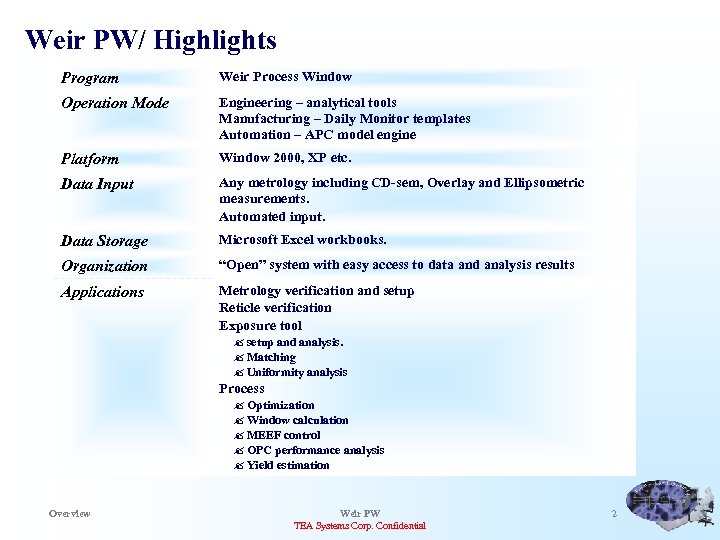

Weir PW/ Highlights Program Weir Process Window Operation Mode Engineering – analytical tools Manufacturing – Daily Monitor templates Automation – APC model engine Platform Window 2000, XP etc. Data Input Any metrology including CD-sem, Overlay and Ellipsometric measurements. Automated input. Data Storage Microsoft Excel workbooks. Organization “Open” system with easy access to data and analysis results Applications Metrology verification and setup Reticle verification Exposure tool ? setup and analysis. ? Matching ? Uniformity analysis Process ? Optimization ? Window calculation ? MEEF control ? OPC performance analysis ? Yield estimation Overview Weir PW TEA Systems Corp. Confidential 2

Weir PW/ Highlights Program Weir Process Window Operation Mode Engineering – analytical tools Manufacturing – Daily Monitor templates Automation – APC model engine Platform Window 2000, XP etc. Data Input Any metrology including CD-sem, Overlay and Ellipsometric measurements. Automated input. Data Storage Microsoft Excel workbooks. Organization “Open” system with easy access to data and analysis results Applications Metrology verification and setup Reticle verification Exposure tool ? setup and analysis. ? Matching ? Uniformity analysis Process ? Optimization ? Window calculation ? MEEF control ? OPC performance analysis ? Yield estimation Overview Weir PW TEA Systems Corp. Confidential 2

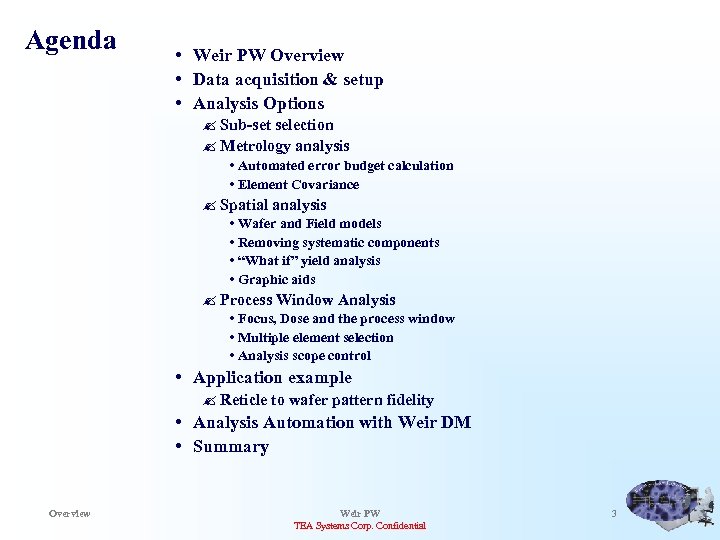

Agenda • Weir PW Overview • Data acquisition & setup • Analysis Options ? Sub-set selection ? Metrology analysis • Automated error budget calculation • Element Covariance ? Spatial analysis • Wafer and Field models • Removing systematic components • “What if” yield analysis • Graphic aids ? Process Window Analysis • Focus, Dose and the process window • Multiple element selection • Analysis scope control • Application example ? Reticle to wafer pattern fidelity • Analysis Automation with Weir DM • Summary Overview Weir PW TEA Systems Corp. Confidential 3

Agenda • Weir PW Overview • Data acquisition & setup • Analysis Options ? Sub-set selection ? Metrology analysis • Automated error budget calculation • Element Covariance ? Spatial analysis • Wafer and Field models • Removing systematic components • “What if” yield analysis • Graphic aids ? Process Window Analysis • Focus, Dose and the process window • Multiple element selection • Analysis scope control • Application example ? Reticle to wafer pattern fidelity • Analysis Automation with Weir DM • Summary Overview Weir PW TEA Systems Corp. Confidential 3

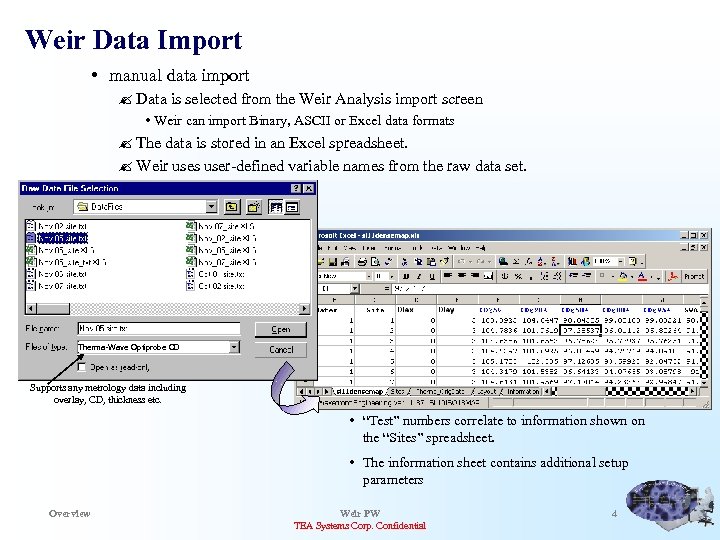

Weir Data Import • manual data import ? Data is selected from the Weir Analysis import screen • Weir can import Binary, ASCII or Excel data formats ? The data is stored in an Excel spreadsheet. ? Weir uses user-defined variable names from the raw data set. Therma-Wave Optiprobe CD Supports any metrology data including overlay, CD, thickness etc. • “Test” numbers correlate to information shown on the “Sites” spreadsheet. • The information sheet contains additional setup parameters Overview Weir PW TEA Systems Corp. Confidential 4

Weir Data Import • manual data import ? Data is selected from the Weir Analysis import screen • Weir can import Binary, ASCII or Excel data formats ? The data is stored in an Excel spreadsheet. ? Weir uses user-defined variable names from the raw data set. Therma-Wave Optiprobe CD Supports any metrology data including overlay, CD, thickness etc. • “Test” numbers correlate to information shown on the “Sites” spreadsheet. • The information sheet contains additional setup parameters Overview Weir PW TEA Systems Corp. Confidential 4

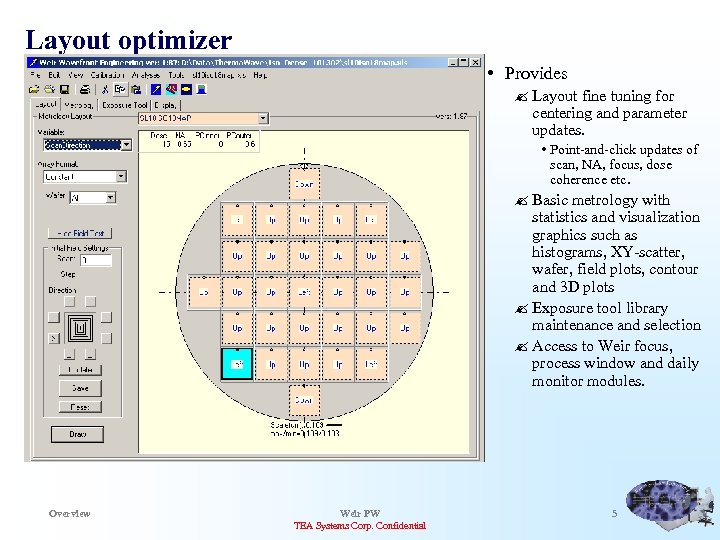

Layout optimizer • Provides ? Layout fine tuning for centering and parameter updates. • Point-and-click updates of scan, NA, focus, dose coherence etc. ? Basic metrology with statistics and visualization graphics such as histograms, XY-scatter, wafer, field plots, contour and 3 D plots ? Exposure tool library maintenance and selection ? Access to Weir focus, process window and daily monitor modules. Overview Weir PW TEA Systems Corp. Confidential 5

Layout optimizer • Provides ? Layout fine tuning for centering and parameter updates. • Point-and-click updates of scan, NA, focus, dose coherence etc. ? Basic metrology with statistics and visualization graphics such as histograms, XY-scatter, wafer, field plots, contour and 3 D plots ? Exposure tool library maintenance and selection ? Access to Weir focus, process window and daily monitor modules. Overview Weir PW TEA Systems Corp. Confidential 5

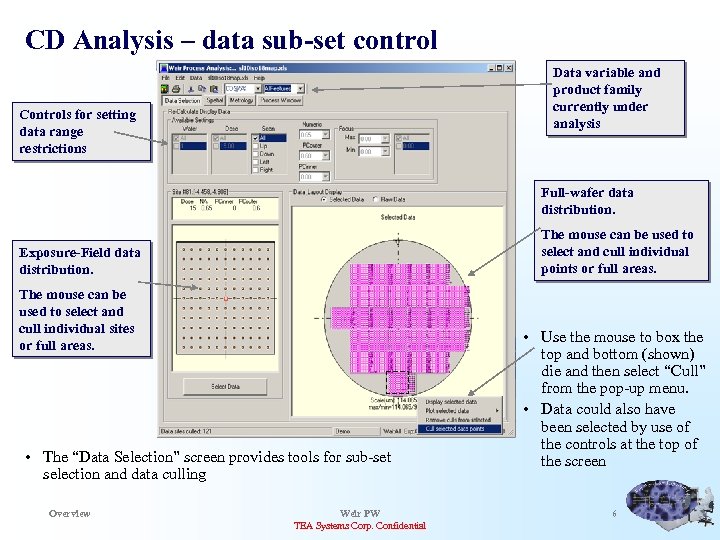

CD Analysis – data sub-set control Data variable and product family currently under analysis Controls for setting data range restrictions Full-wafer data distribution. The mouse can be used to select and cull individual points or full areas. Exposure-Field data distribution. The mouse can be used to select and cull individual sites or full areas. • The “Data Selection” screen provides tools for sub-set selection and data culling Overview Weir PW TEA Systems Corp. Confidential • Use the mouse to box the top and bottom (shown) die and then select “Cull” from the pop-up menu. • Data could also have been selected by use of the controls at the top of the screen 6

CD Analysis – data sub-set control Data variable and product family currently under analysis Controls for setting data range restrictions Full-wafer data distribution. The mouse can be used to select and cull individual points or full areas. Exposure-Field data distribution. The mouse can be used to select and cull individual sites or full areas. • The “Data Selection” screen provides tools for sub-set selection and data culling Overview Weir PW TEA Systems Corp. Confidential • Use the mouse to box the top and bottom (shown) die and then select “Cull” from the pop-up menu. • Data could also have been selected by use of the controls at the top of the screen 6

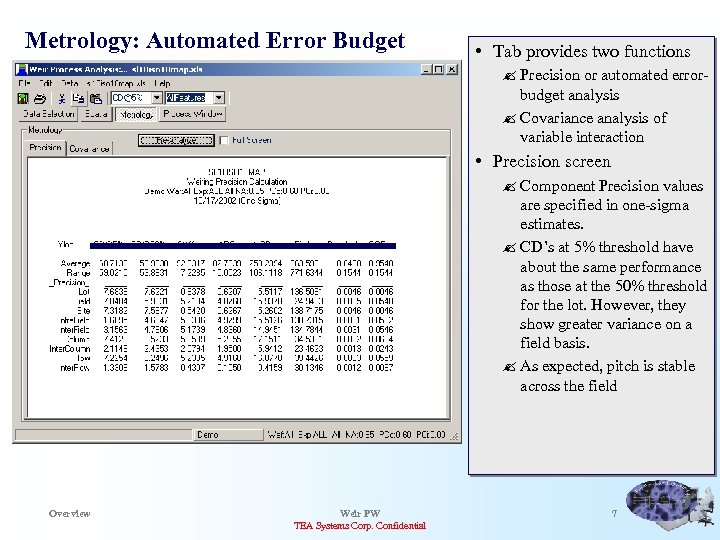

Metrology: Automated Error Budget Variable names derived from data import file • Tab provides two functions ? Precision or automated errorbudget analysis ? Covariance analysis of variable interaction • Precision screen ? Component Precision values are specified in one-sigma estimates. ? CD’s at 5% threshold have about the same performance as those at the 50% threshold for the lot. However, they show greater variance on a field basis. ? As expected, pitch is stable across the field Overview Weir PW TEA Systems Corp. Confidential 7

Metrology: Automated Error Budget Variable names derived from data import file • Tab provides two functions ? Precision or automated errorbudget analysis ? Covariance analysis of variable interaction • Precision screen ? Component Precision values are specified in one-sigma estimates. ? CD’s at 5% threshold have about the same performance as those at the 50% threshold for the lot. However, they show greater variance on a field basis. ? As expected, pitch is stable across the field Overview Weir PW TEA Systems Corp. Confidential 7

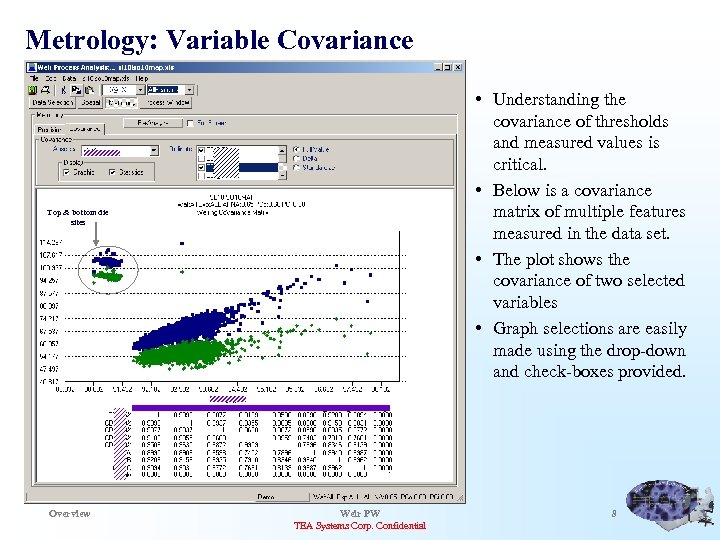

Metrology: Variable Covariance • Understanding the covariance of thresholds and measured values is critical. • Below is a covariance matrix of multiple features measured in the data set. • The plot shows the covariance of two selected variables • Graph selections are easily made using the drop-down and check-boxes provided. Top & bottom die sites Overview Weir PW TEA Systems Corp. Confidential 8

Metrology: Variable Covariance • Understanding the covariance of thresholds and measured values is critical. • Below is a covariance matrix of multiple features measured in the data set. • The plot shows the covariance of two selected variables • Graph selections are easily made using the drop-down and check-boxes provided. Top & bottom die sites Overview Weir PW TEA Systems Corp. Confidential 8

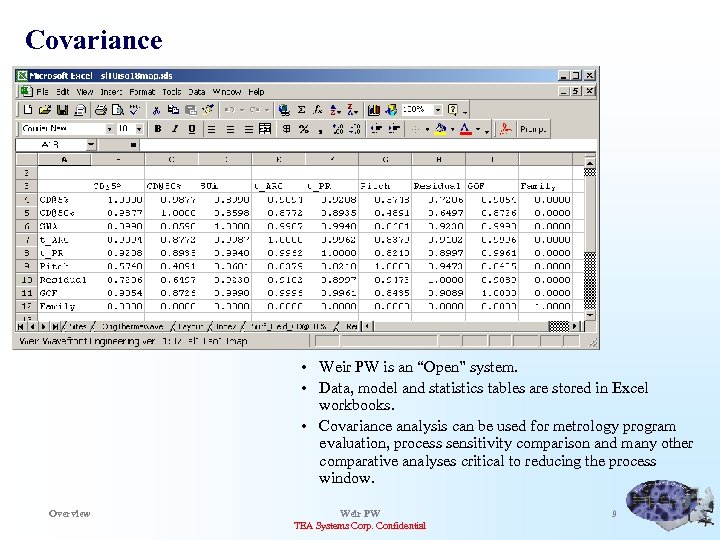

Covariance • Weir PW is an “Open” system. • Data, model and statistics tables are stored in Excel workbooks. • Covariance analysis can be used for metrology program evaluation, process sensitivity comparison and many other comparative analyses critical to reducing the process window. Overview Weir PW TEA Systems Corp. Confidential 9

Covariance • Weir PW is an “Open” system. • Data, model and statistics tables are stored in Excel workbooks. • Covariance analysis can be used for metrology program evaluation, process sensitivity comparison and many other comparative analyses critical to reducing the process window. Overview Weir PW TEA Systems Corp. Confidential 9

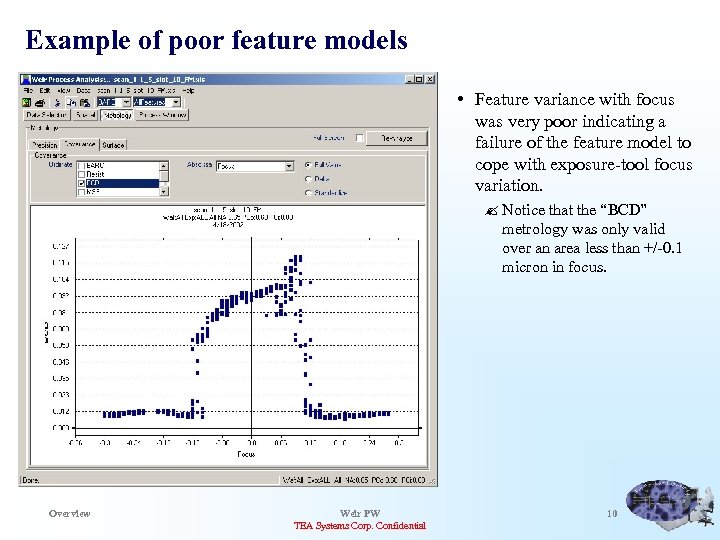

Example of poor feature models • Feature variance with focus was very poor indicating a failure of the feature model to cope with exposure-tool focus variation. ? Notice that the “BCD” metrology was only valid over an area less than +/-0. 1 micron in focus. Overview Weir PW TEA Systems Corp. Confidential 10

Example of poor feature models • Feature variance with focus was very poor indicating a failure of the feature model to cope with exposure-tool focus variation. ? Notice that the “BCD” metrology was only valid over an area less than +/-0. 1 micron in focus. Overview Weir PW TEA Systems Corp. Confidential 10

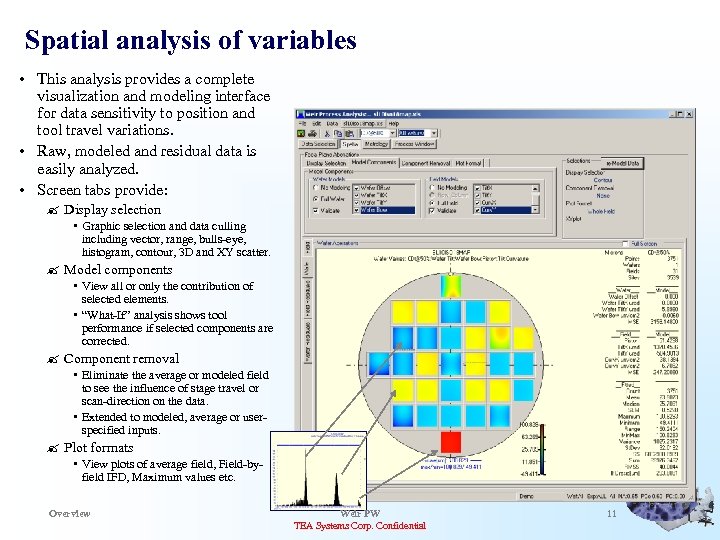

Spatial analysis of variables • This analysis provides a complete visualization and modeling interface for data sensitivity to position and tool travel variations. • Raw, modeled and residual data is easily analyzed. • Screen tabs provide: ? Display selection • Graphic selection and data culling including vector, range, bulls-eye, histogram, contour, 3 D and XY scatter. ? Model components • View all or only the contribution of selected elements. • “What-If” analysis shows tool performance if selected components are corrected. ? Component removal • Eliminate the average or modeled field to see the influence of stage travel or scan-direction on the data. • Extended to modeled, average or userspecified inputs. ? Plot formats • View plots of average field, Field-byfield IFD, Maximum values etc. Overview Weir PW TEA Systems Corp. Confidential 11

Spatial analysis of variables • This analysis provides a complete visualization and modeling interface for data sensitivity to position and tool travel variations. • Raw, modeled and residual data is easily analyzed. • Screen tabs provide: ? Display selection • Graphic selection and data culling including vector, range, bulls-eye, histogram, contour, 3 D and XY scatter. ? Model components • View all or only the contribution of selected elements. • “What-If” analysis shows tool performance if selected components are corrected. ? Component removal • Eliminate the average or modeled field to see the influence of stage travel or scan-direction on the data. • Extended to modeled, average or userspecified inputs. ? Plot formats • View plots of average field, Field-byfield IFD, Maximum values etc. Overview Weir PW TEA Systems Corp. Confidential 11

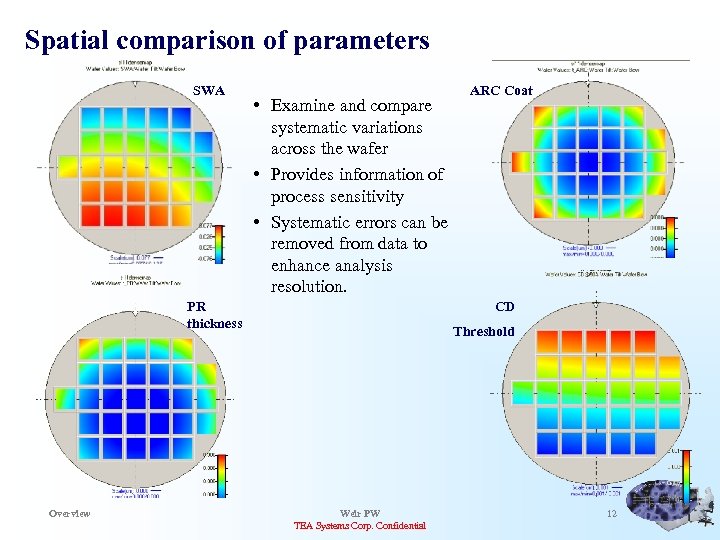

Spatial comparison of parameters SWA • Examine and compare systematic variations across the wafer • Provides information of process sensitivity • Systematic errors can be removed from data to enhance analysis resolution. PR thickness Overview ARC Coat CD Threshold Weir PW TEA Systems Corp. Confidential 12

Spatial comparison of parameters SWA • Examine and compare systematic variations across the wafer • Provides information of process sensitivity • Systematic errors can be removed from data to enhance analysis resolution. PR thickness Overview ARC Coat CD Threshold Weir PW TEA Systems Corp. Confidential 12

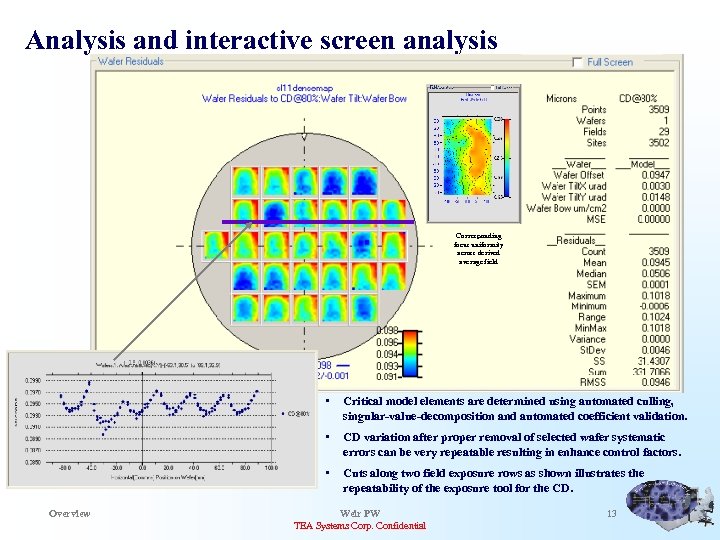

Analysis and interactive screen analysis Corresponding focus uniformity across derived average field • • CD variation after proper removal of selected wafer systematic errors can be very repeatable resulting in enhance control factors. • Overview Critical model elements are determined using automated culling, singular-value-decomposition and automated coefficient validation. Cuts along two field exposure rows as shown illustrates the repeatability of the exposure tool for the CD. Weir PW TEA Systems Corp. Confidential 13

Analysis and interactive screen analysis Corresponding focus uniformity across derived average field • • CD variation after proper removal of selected wafer systematic errors can be very repeatable resulting in enhance control factors. • Overview Critical model elements are determined using automated culling, singular-value-decomposition and automated coefficient validation. Cuts along two field exposure rows as shown illustrates the repeatability of the exposure tool for the CD. Weir PW TEA Systems Corp. Confidential 13

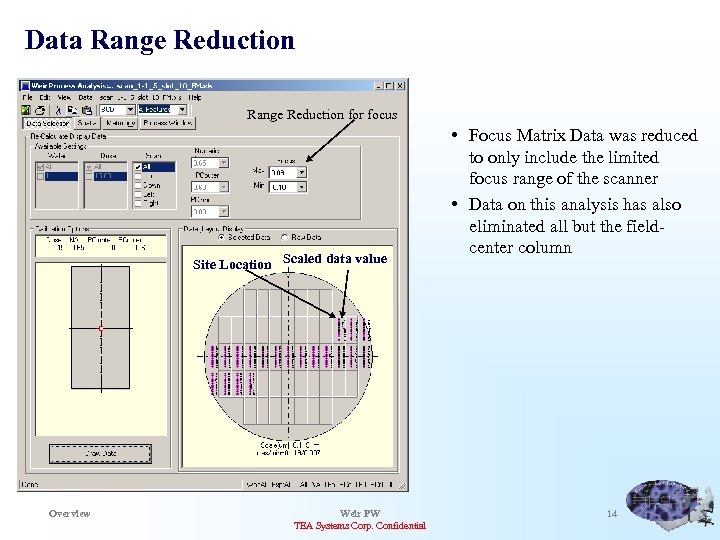

Data Range Reduction for focus Site Location Scaled data value Overview Weir PW TEA Systems Corp. Confidential • Focus Matrix Data was reduced to only include the limited focus range of the scanner • Data on this analysis has also eliminated all but the fieldcenter column 14

Data Range Reduction for focus Site Location Scaled data value Overview Weir PW TEA Systems Corp. Confidential • Focus Matrix Data was reduced to only include the limited focus range of the scanner • Data on this analysis has also eliminated all but the fieldcenter column 14

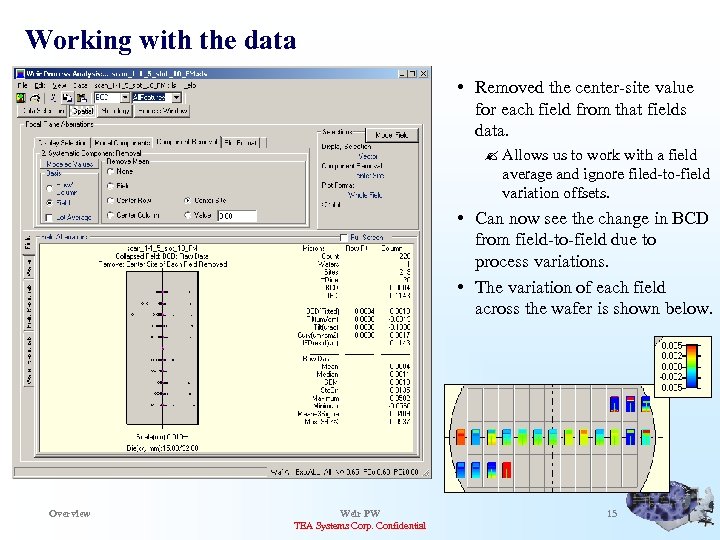

Working with the data • Removed the center-site value for each field from that fields data. ? Allows us to work with a field average and ignore filed-to-field variation offsets. • Can now see the change in BCD from field-to-field due to process variations. • The variation of each field across the wafer is shown below. Overview Weir PW TEA Systems Corp. Confidential 15

Working with the data • Removed the center-site value for each field from that fields data. ? Allows us to work with a field average and ignore filed-to-field variation offsets. • Can now see the change in BCD from field-to-field due to process variations. • The variation of each field across the wafer is shown below. Overview Weir PW TEA Systems Corp. Confidential 15

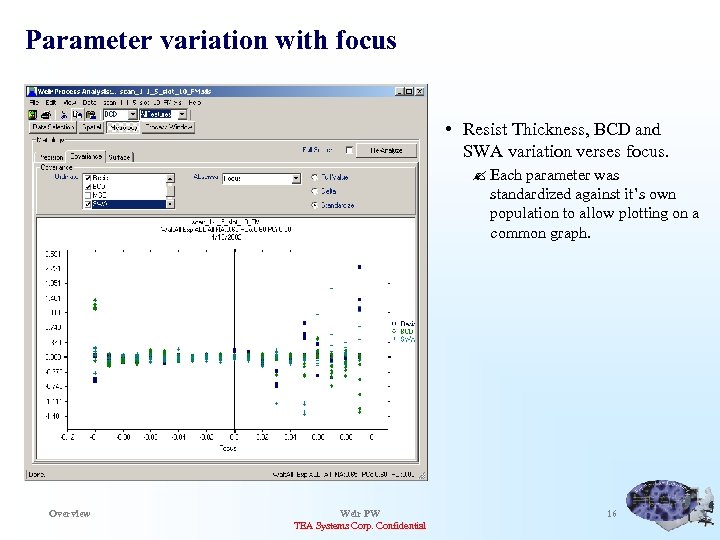

Parameter variation with focus • Resist Thickness, BCD and SWA variation verses focus. ? Each parameter was standardized against it’s own population to allow plotting on a common graph. Overview Weir PW TEA Systems Corp. Confidential 16

Parameter variation with focus • Resist Thickness, BCD and SWA variation verses focus. ? Each parameter was standardized against it’s own population to allow plotting on a common graph. Overview Weir PW TEA Systems Corp. Confidential 16

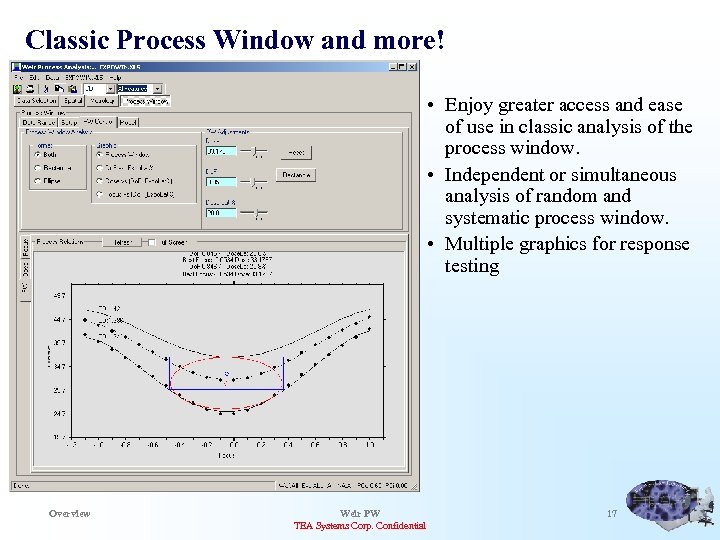

Classic Process Window and more! • Enjoy greater access and ease of use in classic analysis of the process window. • Independent or simultaneous analysis of random and systematic process window. • Multiple graphics for response testing Overview Weir PW TEA Systems Corp. Confidential 17

Classic Process Window and more! • Enjoy greater access and ease of use in classic analysis of the process window. • Independent or simultaneous analysis of random and systematic process window. • Multiple graphics for response testing Overview Weir PW TEA Systems Corp. Confidential 17

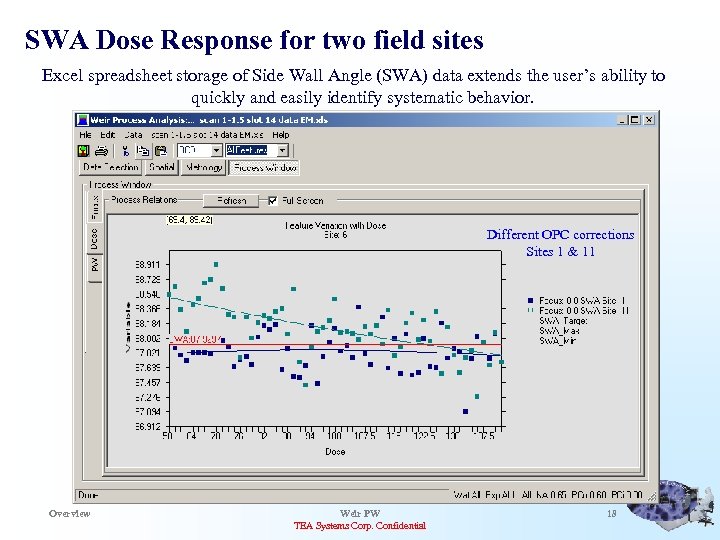

SWA Dose Response for two field sites Excel spreadsheet storage of Side Wall Angle (SWA) data extends the user’s ability to quickly and easily identify systematic behavior. Different OPC corrections Sites 1 & 11 Overview Weir PW TEA Systems Corp. Confidential 18

SWA Dose Response for two field sites Excel spreadsheet storage of Side Wall Angle (SWA) data extends the user’s ability to quickly and easily identify systematic behavior. Different OPC corrections Sites 1 & 11 Overview Weir PW TEA Systems Corp. Confidential 18

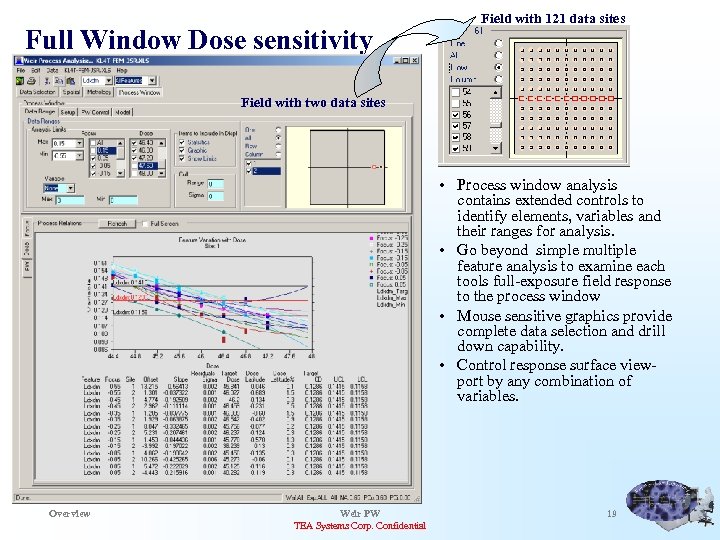

Full Window Dose sensitivity Field with 121 data sites Field with two data sites • Process window analysis contains extended controls to identify elements, variables and their ranges for analysis. • Go beyond simple multiple feature analysis to examine each tools full-exposure field response to the process window • Mouse sensitive graphics provide complete data selection and drill down capability. • Control response surface viewport by any combination of variables. Overview Weir PW TEA Systems Corp. Confidential 19

Full Window Dose sensitivity Field with 121 data sites Field with two data sites • Process window analysis contains extended controls to identify elements, variables and their ranges for analysis. • Go beyond simple multiple feature analysis to examine each tools full-exposure field response to the process window • Mouse sensitive graphics provide complete data selection and drill down capability. • Control response surface viewport by any combination of variables. Overview Weir PW TEA Systems Corp. Confidential 19

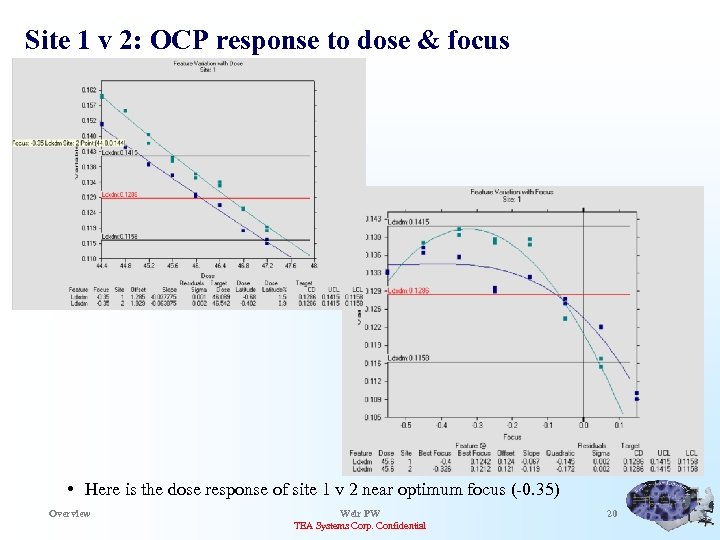

Site 1 v 2: OCP response to dose & focus • Here is the dose response of site 1 v 2 near optimum focus (-0. 35) Overview Weir PW TEA Systems Corp. Confidential 20

Site 1 v 2: OCP response to dose & focus • Here is the dose response of site 1 v 2 near optimum focus (-0. 35) Overview Weir PW TEA Systems Corp. Confidential 20

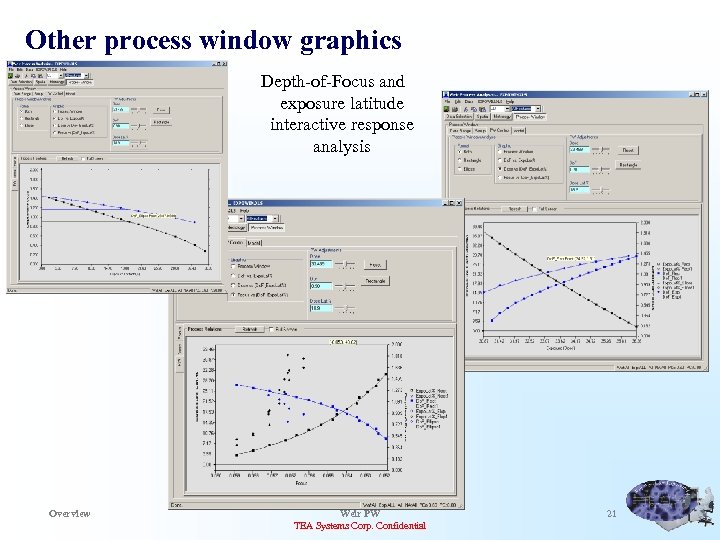

Other process window graphics Depth-of-Focus and exposure latitude interactive response analysis Overview Weir PW TEA Systems Corp. Confidential 21

Other process window graphics Depth-of-Focus and exposure latitude interactive response analysis Overview Weir PW TEA Systems Corp. Confidential 21

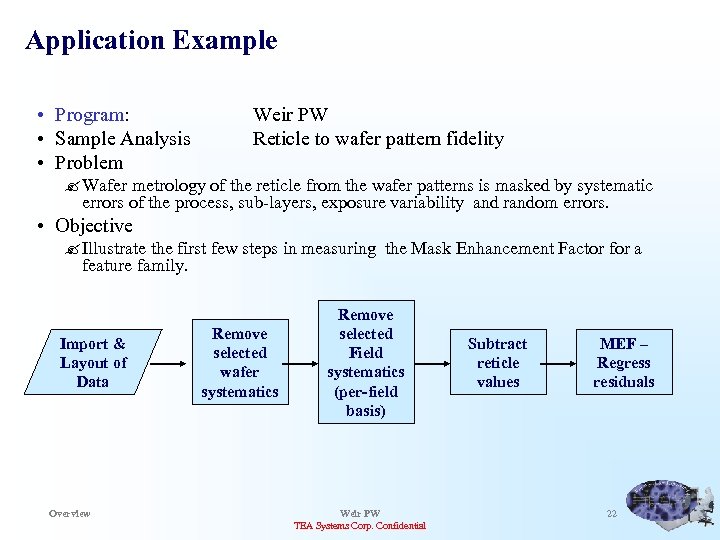

Application Example • Program: • Sample Analysis • Problem Weir PW Reticle to wafer pattern fidelity ? Wafer metrology of the reticle from the wafer patterns is masked by systematic errors of the process, sub-layers, exposure variability and random errors. • Objective ? Illustrate the first few steps in measuring the Mask Enhancement Factor for a feature family. Import & Layout of Data Overview Remove selected wafer systematics Remove selected Field systematics (per-field basis) Weir PW TEA Systems Corp. Confidential Subtract reticle values MEF – Regress residuals 22

Application Example • Program: • Sample Analysis • Problem Weir PW Reticle to wafer pattern fidelity ? Wafer metrology of the reticle from the wafer patterns is masked by systematic errors of the process, sub-layers, exposure variability and random errors. • Objective ? Illustrate the first few steps in measuring the Mask Enhancement Factor for a feature family. Import & Layout of Data Overview Remove selected wafer systematics Remove selected Field systematics (per-field basis) Weir PW TEA Systems Corp. Confidential Subtract reticle values MEF – Regress residuals 22

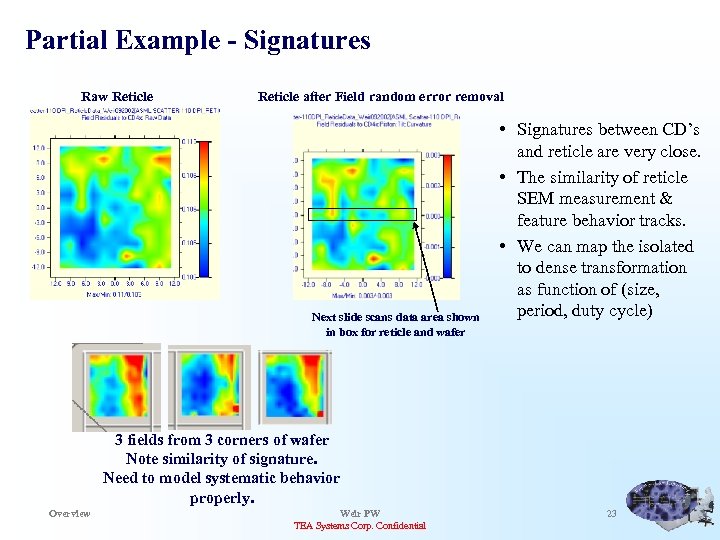

Partial Example - Signatures Raw Reticle after Field random error removal Next slide scans data area shown in box for reticle and wafer • Signatures between CD’s and reticle are very close. • The similarity of reticle SEM measurement & feature behavior tracks. • We can map the isolated to dense transformation as function of (size, period, duty cycle) 3 fields from 3 corners of wafer Note similarity of signature. Need to model systematic behavior properly. Overview Weir PW TEA Systems Corp. Confidential 23

Partial Example - Signatures Raw Reticle after Field random error removal Next slide scans data area shown in box for reticle and wafer • Signatures between CD’s and reticle are very close. • The similarity of reticle SEM measurement & feature behavior tracks. • We can map the isolated to dense transformation as function of (size, period, duty cycle) 3 fields from 3 corners of wafer Note similarity of signature. Need to model systematic behavior properly. Overview Weir PW TEA Systems Corp. Confidential 23

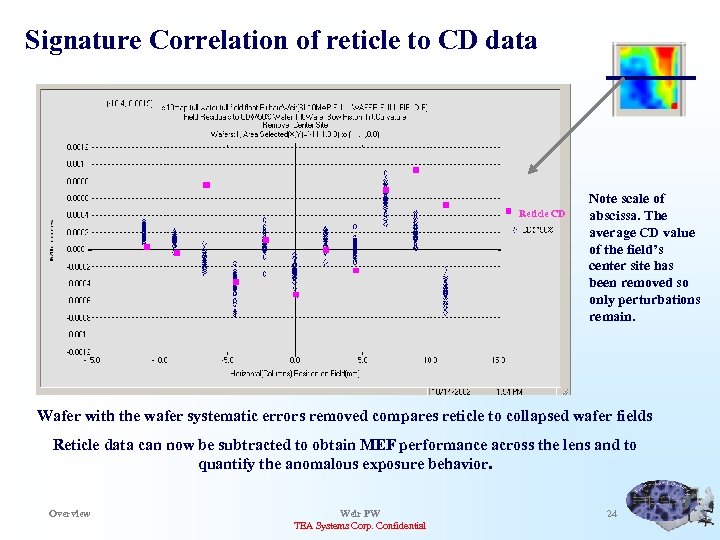

Signature Correlation of reticle to CD data Reticle CD Note scale of abscissa. The average CD value of the field’s center site has been removed so only perturbations remain. Wafer with the wafer systematic errors removed compares reticle to collapsed wafer fields Reticle data can now be subtracted to obtain MEF performance across the lens and to quantify the anomalous exposure behavior. Overview Weir PW TEA Systems Corp. Confidential 24

Signature Correlation of reticle to CD data Reticle CD Note scale of abscissa. The average CD value of the field’s center site has been removed so only perturbations remain. Wafer with the wafer systematic errors removed compares reticle to collapsed wafer fields Reticle data can now be subtracted to obtain MEF performance across the lens and to quantify the anomalous exposure behavior. Overview Weir PW TEA Systems Corp. Confidential 24

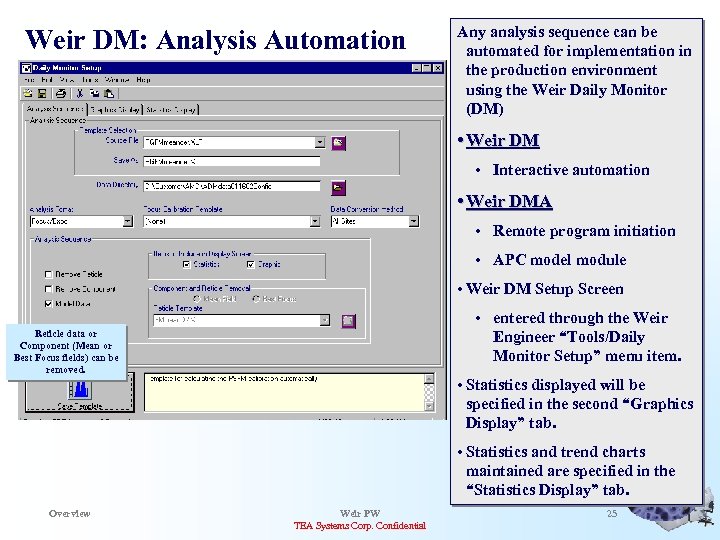

Weir DM: Analysis Automation Any analysis sequence can be automated for implementation in the production environment using the Weir Daily Monitor (DM) • Weir DM • Interactive automation • Weir DMA • Remote program initiation • APC model module • Weir DM Setup Screen • entered through the Weir Engineer “Tools/Daily Monitor Setup” menu item. Reticle data or Component (Mean or Best Focus fields) can be removed. • Statistics displayed will be specified in the second “Graphics Display” tab. • Statistics and trend charts maintained are specified in the “Statistics Display” tab. Overview Weir PW TEA Systems Corp. Confidential 25

Weir DM: Analysis Automation Any analysis sequence can be automated for implementation in the production environment using the Weir Daily Monitor (DM) • Weir DM • Interactive automation • Weir DMA • Remote program initiation • APC model module • Weir DM Setup Screen • entered through the Weir Engineer “Tools/Daily Monitor Setup” menu item. Reticle data or Component (Mean or Best Focus fields) can be removed. • Statistics displayed will be specified in the second “Graphics Display” tab. • Statistics and trend charts maintained are specified in the “Statistics Display” tab. Overview Weir PW TEA Systems Corp. Confidential 25

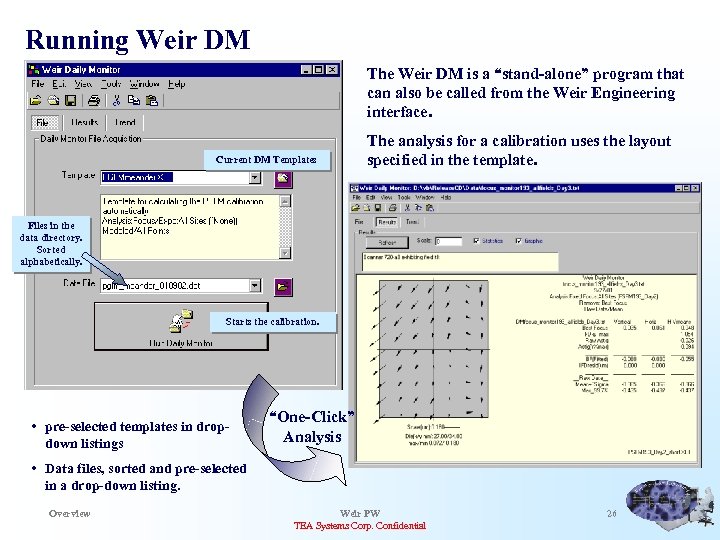

Running Weir DM The Weir DM is a “stand-alone” program that can also be called from the Weir Engineering interface. Current DM Templates The analysis for a calibration uses the layout specified in the template. Files in the data directory. Sorted alphabetically. Starts the calibration. • pre-selected templates in dropdown listings “One-Click” Analysis • Data files, sorted and pre-selected in a drop-down listing. Overview Weir PW TEA Systems Corp. Confidential 26

Running Weir DM The Weir DM is a “stand-alone” program that can also be called from the Weir Engineering interface. Current DM Templates The analysis for a calibration uses the layout specified in the template. Files in the data directory. Sorted alphabetically. Starts the calibration. • pre-selected templates in dropdown listings “One-Click” Analysis • Data files, sorted and pre-selected in a drop-down listing. Overview Weir PW TEA Systems Corp. Confidential 26

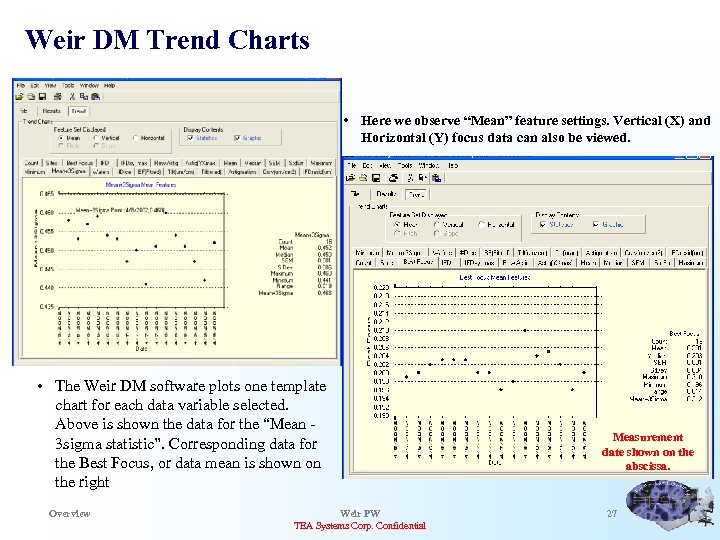

Weir DM Trend Charts • Here we observe “Mean” feature settings. Vertical (X) and Horizontal (Y) focus data can also be viewed. • The Weir DM software plots one template chart for each data variable selected. Above is shown the data for the “Mean 3 sigma statistic”. Corresponding data for the Best Focus, or data mean is shown on the right Overview Weir PW TEA Systems Corp. Confidential Measurement date shown on the abscissa. 27

Weir DM Trend Charts • Here we observe “Mean” feature settings. Vertical (X) and Horizontal (Y) focus data can also be viewed. • The Weir DM software plots one template chart for each data variable selected. Above is shown the data for the “Mean 3 sigma statistic”. Corresponding data for the Best Focus, or data mean is shown on the right Overview Weir PW TEA Systems Corp. Confidential Measurement date shown on the abscissa. 27

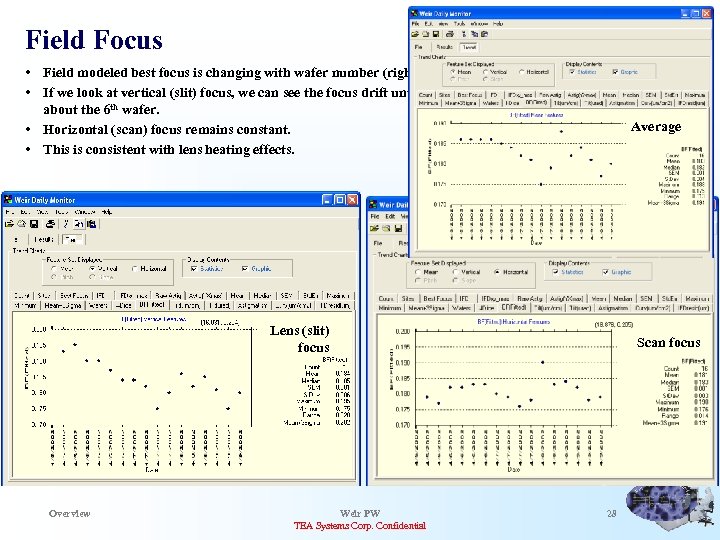

Field Focus • Field modeled best focus is changing with wafer number (right). • If we look at vertical (slit) focus, we can see the focus drift until about the 6 th wafer. • Horizontal (scan) focus remains constant. • This is consistent with lens heating effects. Average Lens (slit) focus Overview Weir PW TEA Systems Corp. Confidential Scan focus 28

Field Focus • Field modeled best focus is changing with wafer number (right). • If we look at vertical (slit) focus, we can see the focus drift until about the 6 th wafer. • Horizontal (scan) focus remains constant. • This is consistent with lens heating effects. Average Lens (slit) focus Overview Weir PW TEA Systems Corp. Confidential Scan focus 28

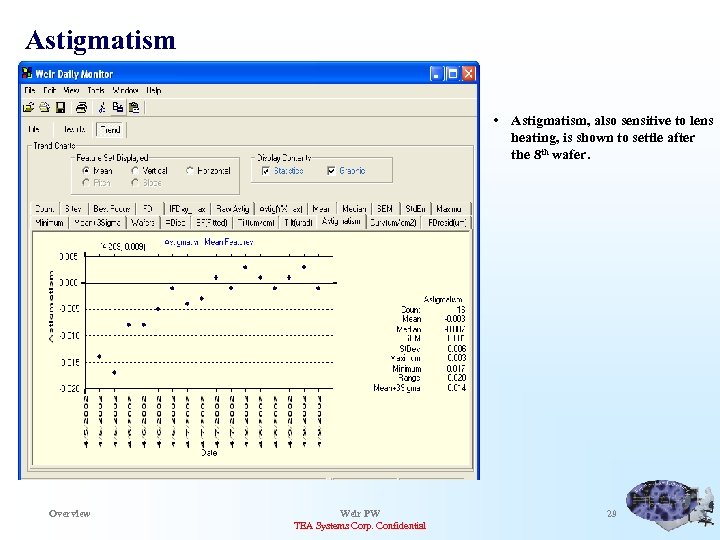

Astigmatism • Astigmatism, also sensitive to lens heating, is shown to settle after the 8 th wafer. Overview Weir PW TEA Systems Corp. Confidential 29

Astigmatism • Astigmatism, also sensitive to lens heating, is shown to settle after the 8 th wafer. Overview Weir PW TEA Systems Corp. Confidential 29

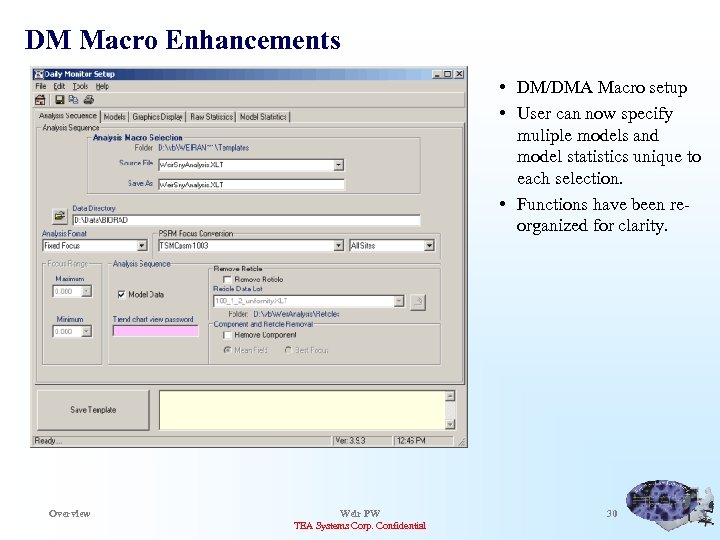

DM Macro Enhancements • DM/DMA Macro setup • User can now specify muliple models and model statistics unique to each selection. • Functions have been reorganized for clarity. Overview Weir PW TEA Systems Corp. Confidential 30

DM Macro Enhancements • DM/DMA Macro setup • User can now specify muliple models and model statistics unique to each selection. • Functions have been reorganized for clarity. Overview Weir PW TEA Systems Corp. Confidential 30

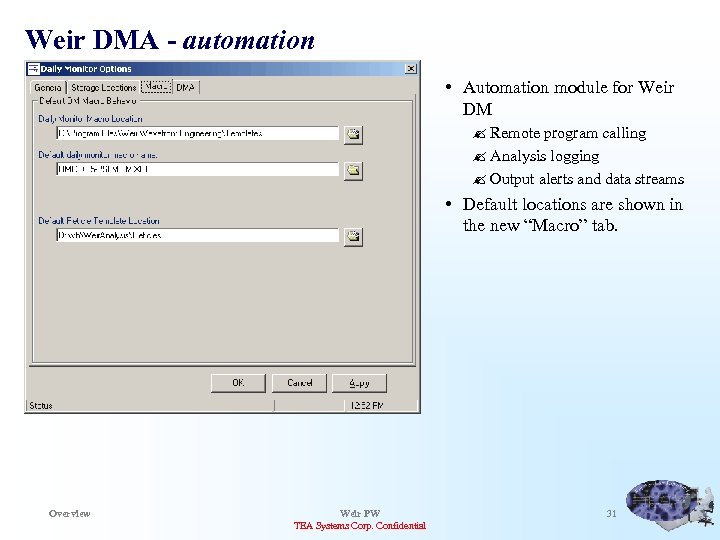

Weir DMA - automation • Automation module for Weir DM ? Remote program calling ? Analysis logging ? Output alerts and data streams • Default locations are shown in the new “Macro” tab. Overview Weir PW TEA Systems Corp. Confidential 31

Weir DMA - automation • Automation module for Weir DM ? Remote program calling ? Analysis logging ? Output alerts and data streams • Default locations are shown in the new “Macro” tab. Overview Weir PW TEA Systems Corp. Confidential 31

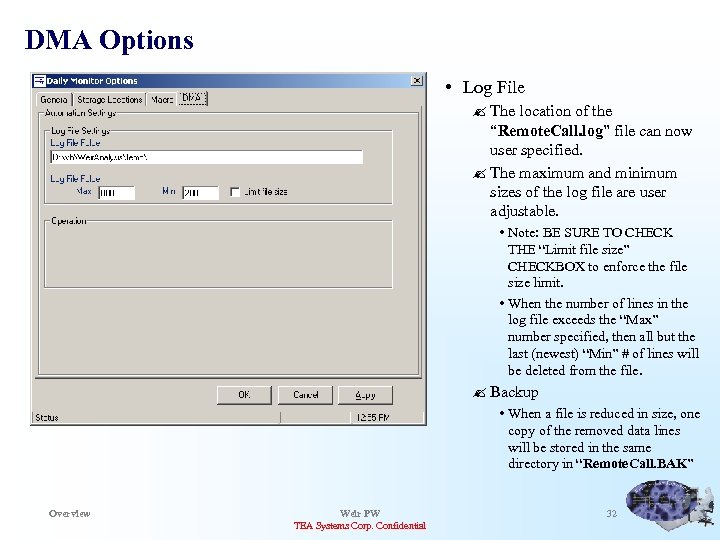

DMA Options • Log File ? The location of the “Remote. Call. log” file can now user specified. ? The maximum and minimum sizes of the log file are user adjustable. • Note: BE SURE TO CHECK THE “Limit file size” CHECKBOX to enforce the file size limit. • When the number of lines in the log file exceeds the “Max” number specified, then all but the last (newest) “Min” # of lines will be deleted from the file. ? Backup • When a file is reduced in size, one copy of the removed data lines will be stored in the same directory in “Remote. Call. BAK” Overview Weir PW TEA Systems Corp. Confidential 32

DMA Options • Log File ? The location of the “Remote. Call. log” file can now user specified. ? The maximum and minimum sizes of the log file are user adjustable. • Note: BE SURE TO CHECK THE “Limit file size” CHECKBOX to enforce the file size limit. • When the number of lines in the log file exceeds the “Max” number specified, then all but the last (newest) “Min” # of lines will be deleted from the file. ? Backup • When a file is reduced in size, one copy of the removed data lines will be stored in the same directory in “Remote. Call. BAK” Overview Weir PW TEA Systems Corp. Confidential 32

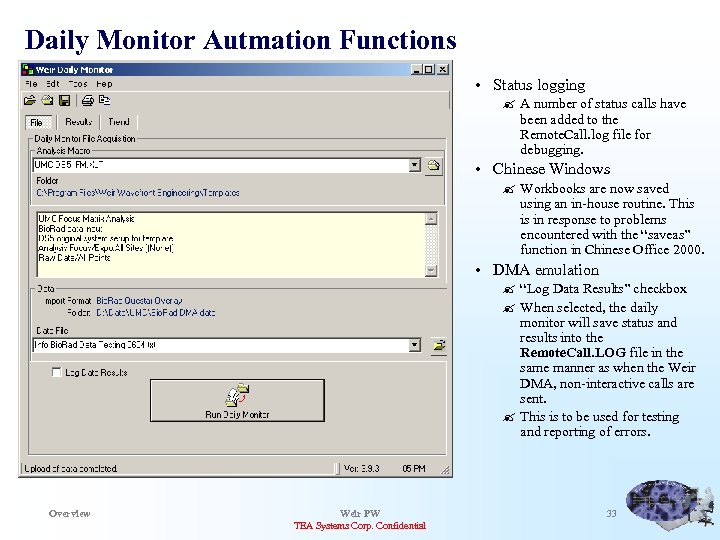

Daily Monitor Autmation Functions • Status logging ? A number of status calls have been added to the Remote. Call. log file for debugging. • Chinese Windows ? Workbooks are now saved using an in-house routine. This is in response to problems encountered with the “saveas” function in Chinese Office 2000. • DMA emulation ? “Log Data Results” checkbox ? When selected, the daily monitor will save status and results into the Remote. Call. LOG file in the same manner as when the Weir DMA, non-interactive calls are sent. ? This is to be used for testing and reporting of errors. Overview Weir PW TEA Systems Corp. Confidential 33

Daily Monitor Autmation Functions • Status logging ? A number of status calls have been added to the Remote. Call. log file for debugging. • Chinese Windows ? Workbooks are now saved using an in-house routine. This is in response to problems encountered with the “saveas” function in Chinese Office 2000. • DMA emulation ? “Log Data Results” checkbox ? When selected, the daily monitor will save status and results into the Remote. Call. LOG file in the same manner as when the Weir DMA, non-interactive calls are sent. ? This is to be used for testing and reporting of errors. Overview Weir PW TEA Systems Corp. Confidential 33

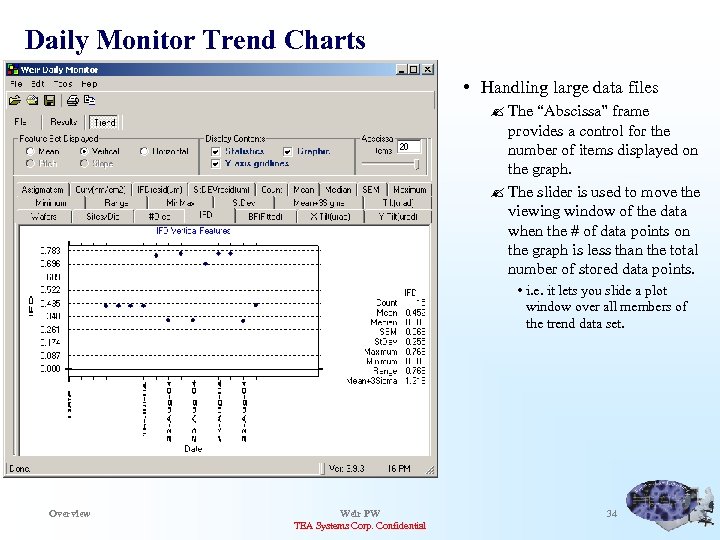

Daily Monitor Trend Charts • Handling large data files ? The “Abscissa” frame provides a control for the number of items displayed on the graph. ? The slider is used to move the viewing window of the data when the # of data points on the graph is less than the total number of stored data points. • i. e. it lets you slide a plot window over all members of the trend data set. Overview Weir PW TEA Systems Corp. Confidential 34

Daily Monitor Trend Charts • Handling large data files ? The “Abscissa” frame provides a control for the number of items displayed on the graph. ? The slider is used to move the viewing window of the data when the # of data points on the graph is less than the total number of stored data points. • i. e. it lets you slide a plot window over all members of the trend data set. Overview Weir PW TEA Systems Corp. Confidential 34

Summary of Weir PW • Any metrology data can be imported ? Weir PW contains a layout optimizer and basic metrology analysis capabilities ? Any user-defined variable names may be used ? Data is stored in Microsoft Excel® worksheet and workbooks • Multiple data sets can be combined and data sub-sets selected for analysis ? Point-and-click mouse interaction for data viewing and culling • “Metrology” analysis ? Automated metrology covariance ? Automated error-budget analysis. • Spatial analysis of variables ? Provides information on variation with scan direction and film thickness variation ? Point-and-click drill down capability for sub-field graphics, data viewing and analysis ? Remove critical systematic components to see the true exposure performance • Process Window analysis and more! ? Extend beyond the single feature/family analysis. ? Examine process window performance variation across the full field of exposure. • Automation ? Weir DM can be used to automate process-monitor points for any variable series. Overview Weir PW TEA Systems Corp. Confidential 35

Summary of Weir PW • Any metrology data can be imported ? Weir PW contains a layout optimizer and basic metrology analysis capabilities ? Any user-defined variable names may be used ? Data is stored in Microsoft Excel® worksheet and workbooks • Multiple data sets can be combined and data sub-sets selected for analysis ? Point-and-click mouse interaction for data viewing and culling • “Metrology” analysis ? Automated metrology covariance ? Automated error-budget analysis. • Spatial analysis of variables ? Provides information on variation with scan direction and film thickness variation ? Point-and-click drill down capability for sub-field graphics, data viewing and analysis ? Remove critical systematic components to see the true exposure performance • Process Window analysis and more! ? Extend beyond the single feature/family analysis. ? Examine process window performance variation across the full field of exposure. • Automation ? Weir DM can be used to automate process-monitor points for any variable series. Overview Weir PW TEA Systems Corp. Confidential 35