WBS 1. 1. 1. 5 (& W. B. S. 1. 1. 1. 6. 2 & Services) Pixel Module Assembly & Test 1. Technical Status 2. Goals for 2004 3. Service Panels July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 1

Technical Status • • Thinning and dicing Module Assembly Pigtails are gone Adhesives Sector loading Production testing Burn-in setup July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 2

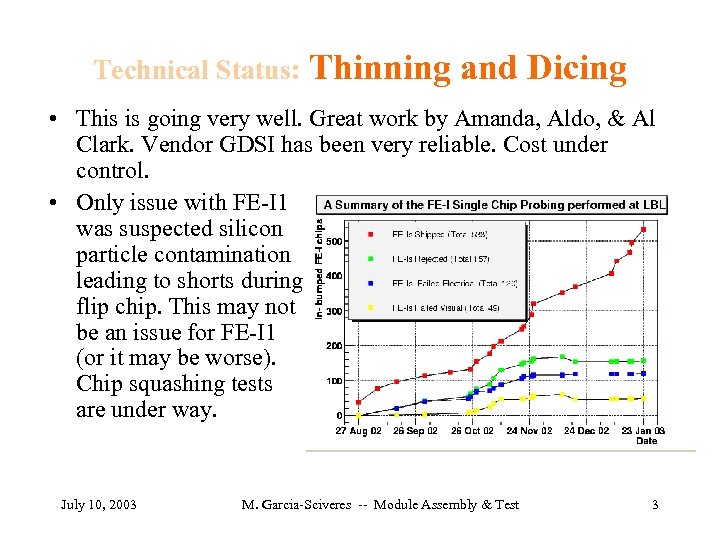

Technical Status: Thinning and Dicing • This is going very well. Great work by Amanda, Aldo, & Al Clark. Vendor GDSI has been very reliable. Cost under control. • Only issue with FE-I 1 was suspected silicon particle contamination leading to shorts during flip chip. This may not be an issue for FE-I 1 (or it may be worse). Chip squashing tests are under way. July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 3

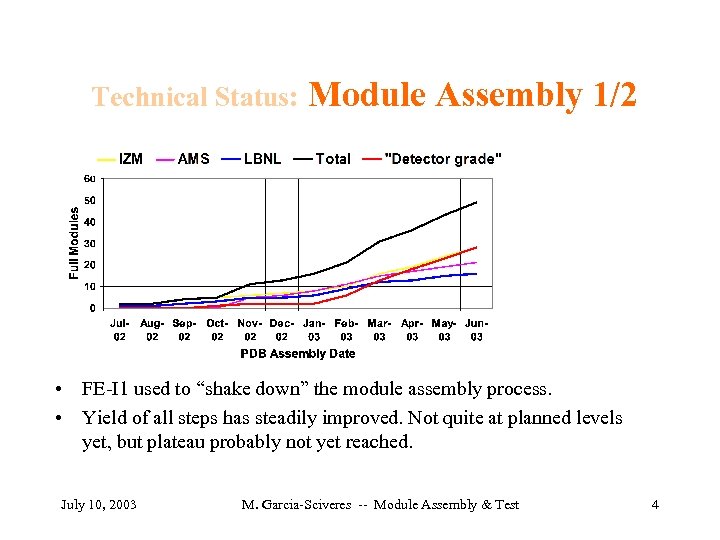

Technical Status: Module Assembly 1/2 • FE-I 1 used to “shake down” the module assembly process. • Yield of all steps has steadily improved. Not quite at planned levels yet, but plateau probably not yet reached. July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 4

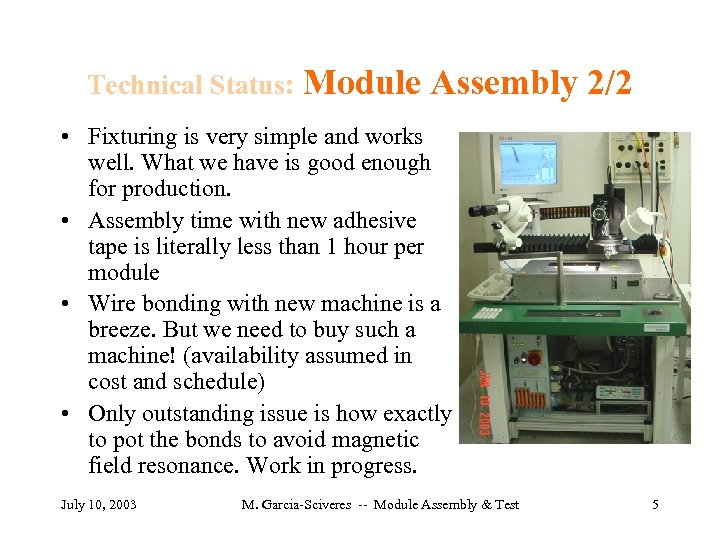

Technical Status: Module Assembly 2/2 • Fixturing is very simple and works well. What we have is good enough for production. • Assembly time with new adhesive tape is literally less than 1 hour per module • Wire bonding with new machine is a breeze. But we need to buy such a machine! (availability assumed in cost and schedule) • Only outstanding issue is how exactly to pot the bonds to avoid magnetic field resonance. Work in progress. July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 5

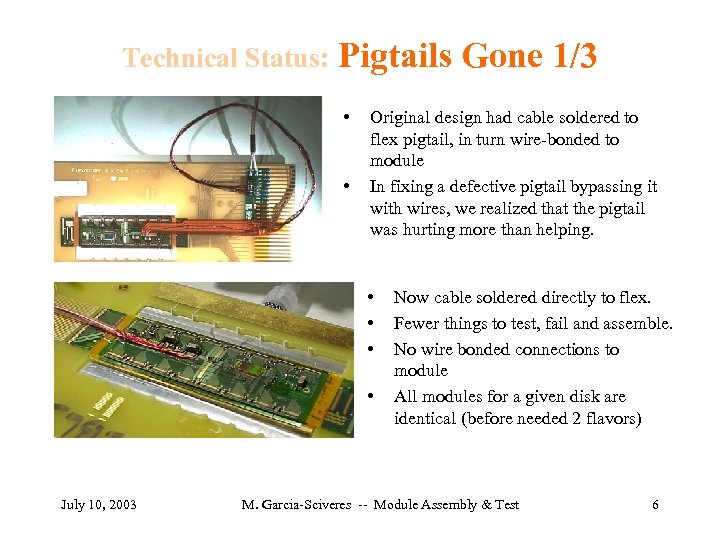

Technical Status: Pigtails Gone 1/3 • • Original design had cable soldered to flex pigtail, in turn wire-bonded to module In fixing a defective pigtail bypassing it with wires, we realized that the pigtail was hurting more than helping. • • July 10, 2003 Now cable soldered directly to flex. Fewer things to test, fail and assemble. No wire bonded connections to module All modules for a given disk are identical (before needed 2 flavors) M. Garcia-Sciveres -- Module Assembly & Test 6

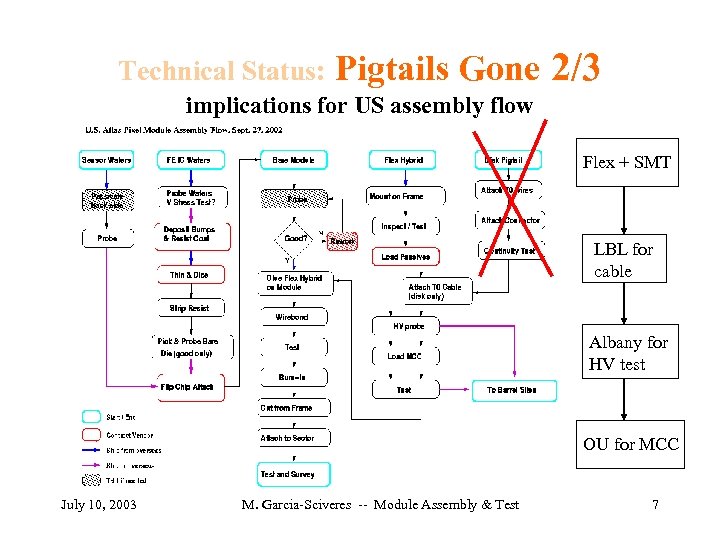

Technical Status: Pigtails Gone 2/3 implications for US assembly flow Flex + SMT LBL for cable Albany for HV test OU for MCC July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 7

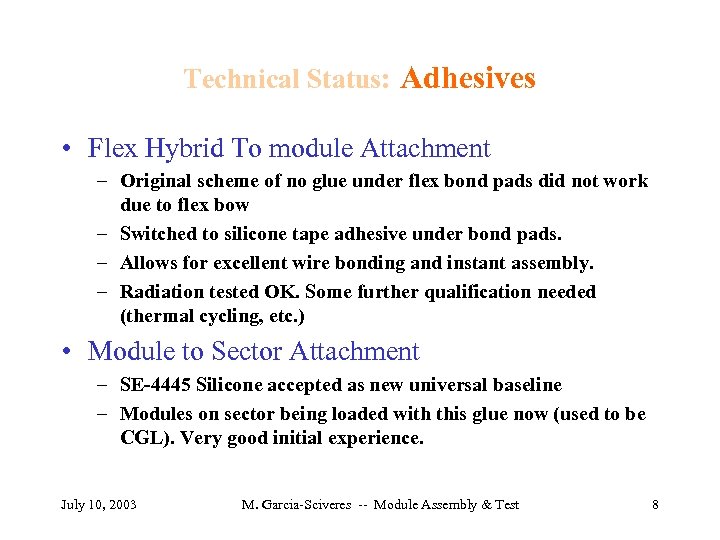

Technical Status: Adhesives • Flex Hybrid To module Attachment – Original scheme of no glue under flex bond pads did not work due to flex bow – Switched to silicone tape adhesive under bond pads. – Allows for excellent wire bonding and instant assembly. – Radiation tested OK. Some further qualification needed (thermal cycling, etc. ) • Module to Sector Attachment – SE-4445 Silicone accepted as new universal baseline – Modules on sector being loaded with this glue now (used to be CGL). Very good initial experience. July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 8

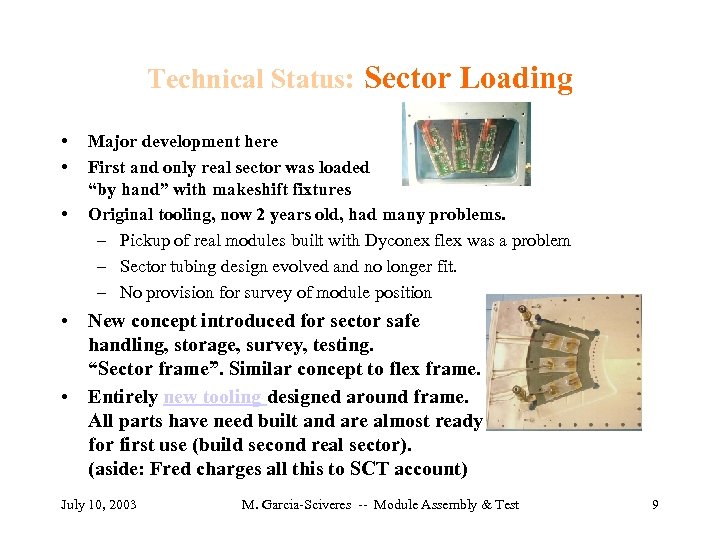

Technical Status: Sector Loading • • • Major development here First and only real sector was loaded “by hand” with makeshift fixtures Original tooling, now 2 years old, had many problems. – Pickup of real modules built with Dyconex flex was a problem – Sector tubing design evolved and no longer fit. – No provision for survey of module position • New concept introduced for sector safe handling, storage, survey, testing. “Sector frame”. Similar concept to flex frame. • Entirely new tooling designed around frame. All parts have need built and are almost ready for first use (build second real sector). (aside: Fred charges all this to SCT account) July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 9

Technical Status: Production Testing • Have been pushing for a documented module, sector and stave QA plan. Collaboration has been slow to respond. • Nevertheless, a fairly clear picture is emerging of the resources needed. • Basically: – Characterize each module with PC test setup – Burn-in and thermal cycle each module (new burn-in setup needed) – Burn-in, survey, thermal cycle, and IR image each sector (same burn-in setup as module) – Undecided: test each sector with ROD. July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 10

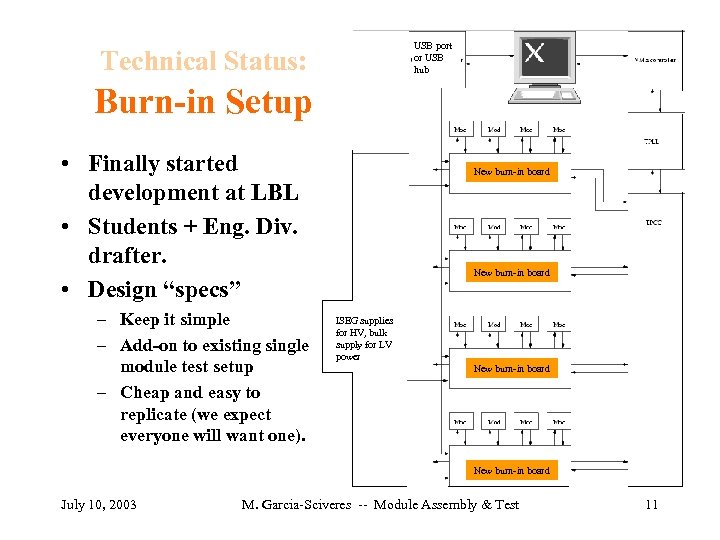

USB port or USB hub Technical Status: Burn-in Setup • Finally started development at LBL • Students + Eng. Div. drafter. • Design “specs” – Keep it simple – Add-on to existing single module test setup – Cheap and easy to replicate (we expect everyone will want one). New burn-in board ISEG supplies for HV, bulk supply for LV power New burn-in board July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 11

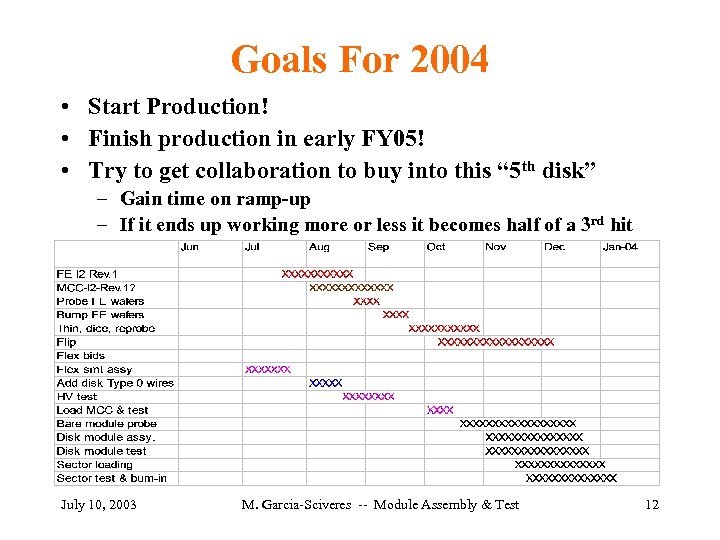

Goals For 2004 • Start Production! • Finish production in early FY 05! • Try to get collaboration to buy into this “ 5 th disk” – Gain time on ramp-up – If it ends up working more or less it becomes half of a 3 rd hit July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 12

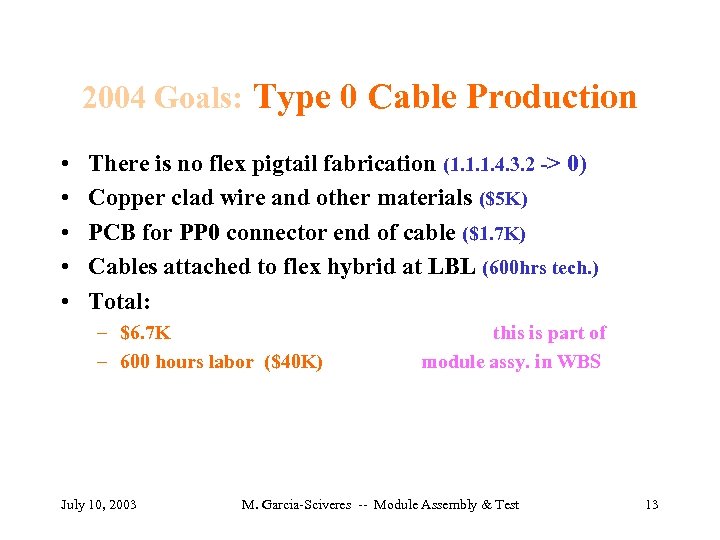

2004 Goals: Type 0 Cable Production • • • There is no flex pigtail fabrication (1. 1. 1. 4. 3. 2 -> 0) Copper clad wire and other materials ($5 K) PCB for PP 0 connector end of cable ($1. 7 K) Cables attached to flex hybrid at LBL (600 hrs tech. ) Total: – $6. 7 K – 600 hours labor ($40 K) July 10, 2003 this is part of module assy. in WBS M. Garcia-Sciveres -- Module Assembly & Test 13

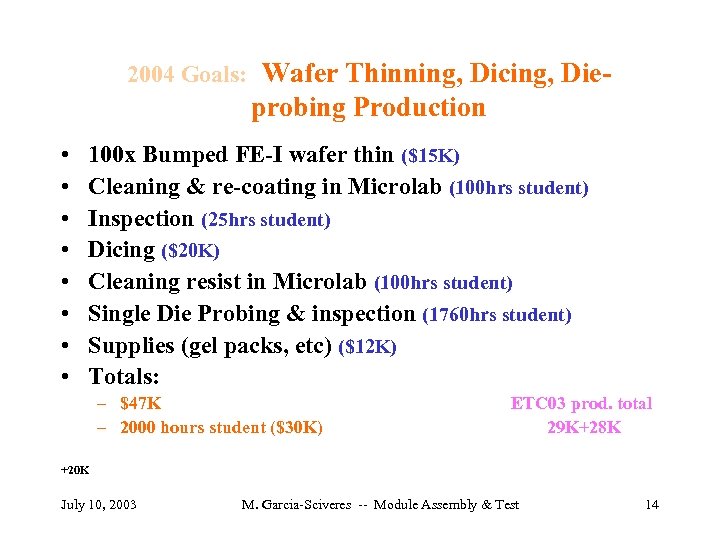

2004 Goals: Wafer Thinning, Dicing, Die- probing Production • • 100 x Bumped FE-I wafer thin ($15 K) Cleaning & re-coating in Microlab (100 hrs student) Inspection (25 hrs student) Dicing ($20 K) Cleaning resist in Microlab (100 hrs student) Single Die Probing & inspection (1760 hrs student) Supplies (gel packs, etc) ($12 K) Totals: – $47 K – 2000 hours student ($30 K) ETC 03 prod. total 29 K+28 K +20 K July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 14

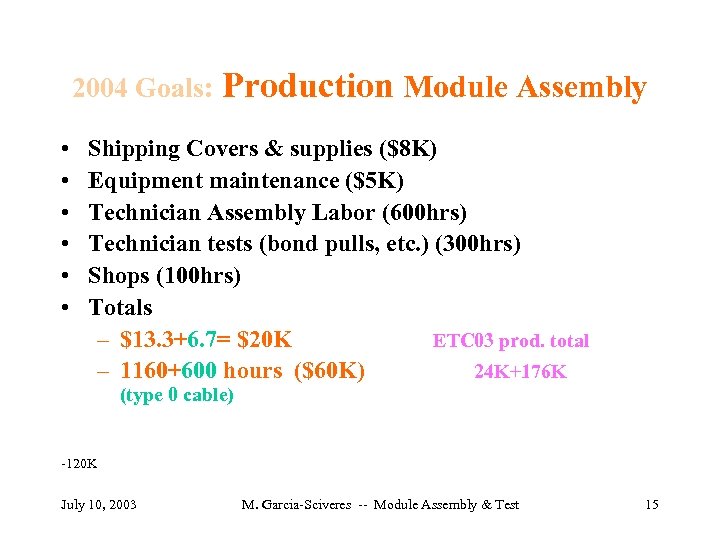

2004 Goals: • • • Production Module Assembly Shipping Covers & supplies ($8 K) Equipment maintenance ($5 K) Technician Assembly Labor (600 hrs) Technician tests (bond pulls, etc. ) (300 hrs) Shops (100 hrs) Totals – $13. 3+6. 7= $20 K ETC 03 prod. total – 1160+600 hours ($60 K) 24 K+176 K (type 0 cable) -120 K July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 15

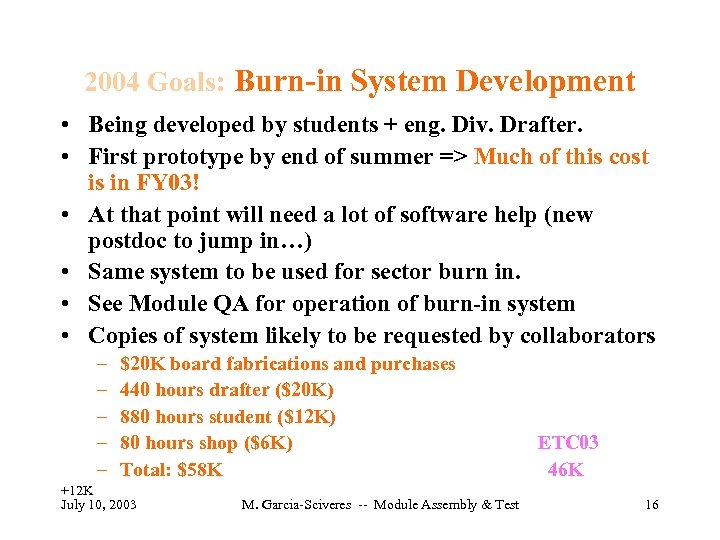

2004 Goals: Burn-in System Development • Being developed by students + eng. Div. Drafter. • First prototype by end of summer => Much of this cost is in FY 03! • At that point will need a lot of software help (new postdoc to jump in…) • Same system to be used for sector burn in. • See Module QA for operation of burn-in system • Copies of system likely to be requested by collaborators – – – $20 K board fabrications and purchases 440 hours drafter ($20 K) 880 hours student ($12 K) 80 hours shop ($6 K) Total: $58 K +12 K July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test ETC 03 46 K 16

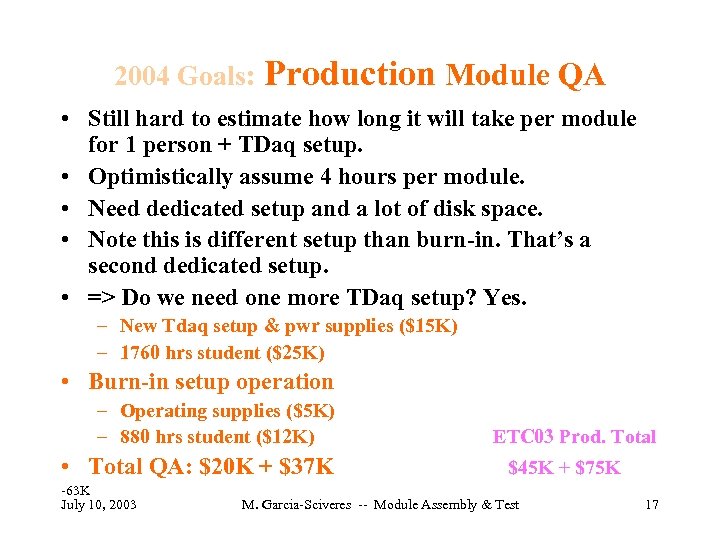

2004 Goals: Production Module QA • Still hard to estimate how long it will take per module for 1 person + TDaq setup. • Optimistically assume 4 hours per module. • Need dedicated setup and a lot of disk space. • Note this is different setup than burn-in. That’s a second dedicated setup. • => Do we need one more TDaq setup? Yes. – New Tdaq setup & pwr supplies ($15 K) – 1760 hrs student ($25 K) • Burn-in setup operation – Operating supplies ($5 K) – 880 hrs student ($12 K) • Total QA: $20 K + $37 K -63 K July 10, 2003 ETC 03 Prod. Total $45 K + $75 K M. Garcia-Sciveres -- Module Assembly & Test 17

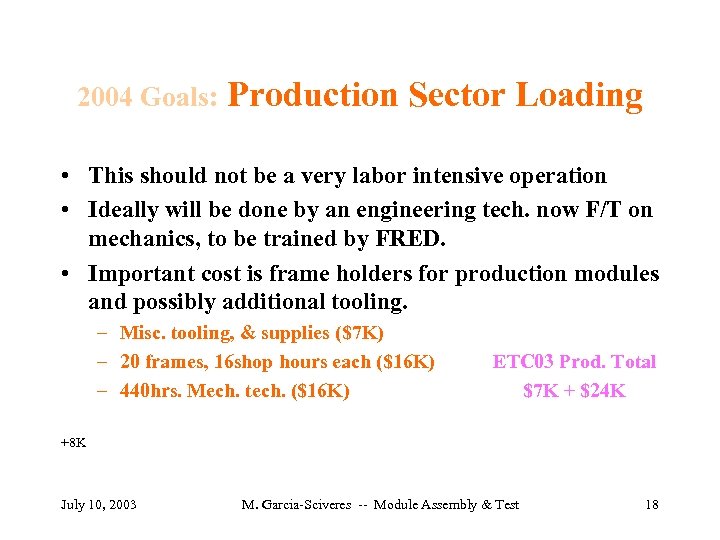

2004 Goals: Production Sector Loading • This should not be a very labor intensive operation • Ideally will be done by an engineering tech. now F/T on mechanics, to be trained by FRED. • Important cost is frame holders for production modules and possibly additional tooling. – Misc. tooling, & supplies ($7 K) – 20 frames, 16 shop hours each ($16 K) – 440 hrs. Mech. tech. ($16 K) ETC 03 Prod. Total $7 K + $24 K +8 K July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 18

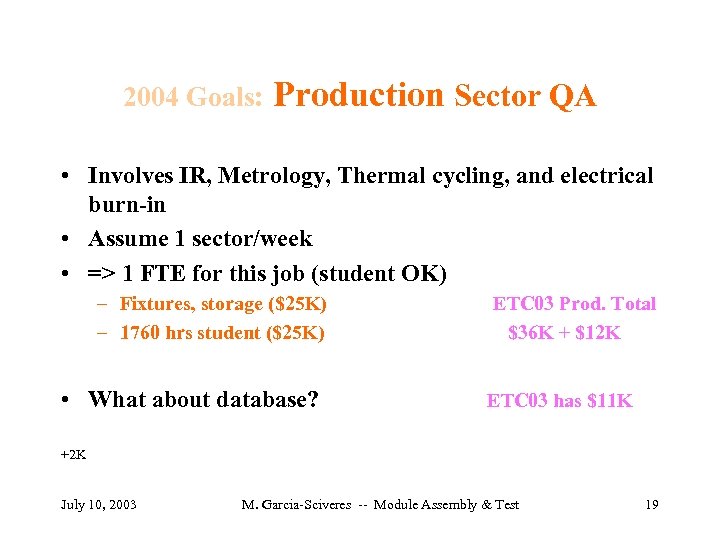

2004 Goals: Production Sector QA • Involves IR, Metrology, Thermal cycling, and electrical burn-in • Assume 1 sector/week • => 1 FTE for this job (student OK) – Fixtures, storage ($25 K) – 1760 hrs student ($25 K) • What about database? ETC 03 Prod. Total $36 K + $12 K ETC 03 has $11 K +2 K July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 19

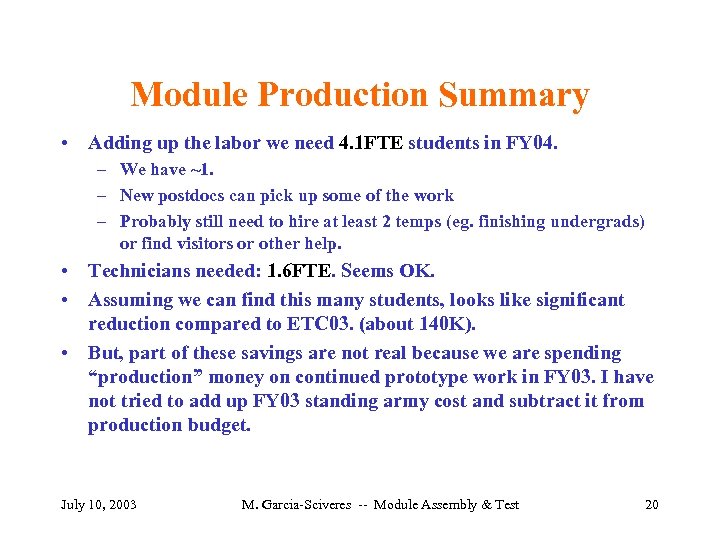

Module Production Summary • Adding up the labor we need 4. 1 FTE students in FY 04. – We have ~1. – New postdocs can pick up some of the work – Probably still need to hire at least 2 temps (eg. finishing undergrads) or find visitors or other help. • Technicians needed: 1. 6 FTE. Seems OK. • Assuming we can find this many students, looks like significant reduction compared to ETC 03. (about 140 K). • But, part of these savings are not real because we are spending “production” money on continued prototype work in FY 03. I have not tried to add up FY 03 standing army cost and subtract it from production budget. July 10, 2003 M. Garcia-Sciveres -- Module Assembly & Test 20

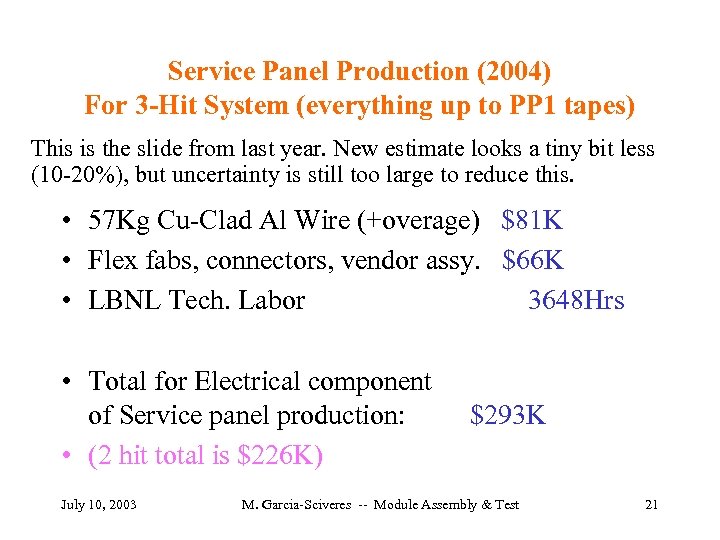

Service Panel Production (2004) For 3 -Hit System (everything up to PP 1 tapes) This is the slide from last year. New estimate looks a tiny bit less (10 -20%), but uncertainty is still too large to reduce this. • 57 Kg Cu-Clad Al Wire (+overage) $81 K • Flex fabs, connectors, vendor assy. $66 K • LBNL Tech. Labor 3648 Hrs • Total for Electrical component of Service panel production: • (2 hit total is $226 K) July 10, 2003 $293 K M. Garcia-Sciveres -- Module Assembly & Test 21