Watermelon Ripeness Sensor Melon Inc. In Search of Perfect Melons. Jason L. Firko Allan Cohen Matt Behr Dave Bartoski

Watermelon Ripeness Sensor Melon Inc. In Search of Perfect Melons. Jason L. Firko Allan Cohen Matt Behr Dave Bartoski

Watermelon Ripeness Sensor Team #2 Members: Jason Firko Allan Cohen Matt Behr Dave Bartoski Customer: Ed Kee Advisor: Dr. James Glancey Mission: Develop a non-destructive method and apparatus for accurately determining the ripeness of watermelons. Approach: Research and develop the best solution to the problem in accordance with customer wants, constraints and the engineering method. The solution will be developed using an iterative process to insure compliance with derived metrics.

Watermelon Ripeness Sensor Team #2 Members: Jason Firko Allan Cohen Matt Behr Dave Bartoski Customer: Ed Kee Advisor: Dr. James Glancey Mission: Develop a non-destructive method and apparatus for accurately determining the ripeness of watermelons. Approach: Research and develop the best solution to the problem in accordance with customer wants, constraints and the engineering method. The solution will be developed using an iterative process to insure compliance with derived metrics.

Background w Watermelon Industry Key Facts: w w w Grown in 90 countries on 5 continents Worldwide production: More than 50 Billion lbs. /year The U. S. is the fourth largest producer of watermelons 70% of households in the U. S. buy watermelons each year 33% of these buy at least 7 times per year 75% of all watermelons are purchased whole

Background w Watermelon Industry Key Facts: w w w Grown in 90 countries on 5 continents Worldwide production: More than 50 Billion lbs. /year The U. S. is the fourth largest producer of watermelons 70% of households in the U. S. buy watermelons each year 33% of these buy at least 7 times per year 75% of all watermelons are purchased whole

Problem Description l Present problems due to inaccurate testing: • Unneeded destruction of melons for inspection • Loss of money • Poor quality of product l Potential benefits of solution: • • • Minimize waste Reduce shipping costs Prevent rejection of shipments Improve overall quality of the product Marketing advantage

Problem Description l Present problems due to inaccurate testing: • Unneeded destruction of melons for inspection • Loss of money • Poor quality of product l Potential benefits of solution: • • • Minimize waste Reduce shipping costs Prevent rejection of shipments Improve overall quality of the product Marketing advantage

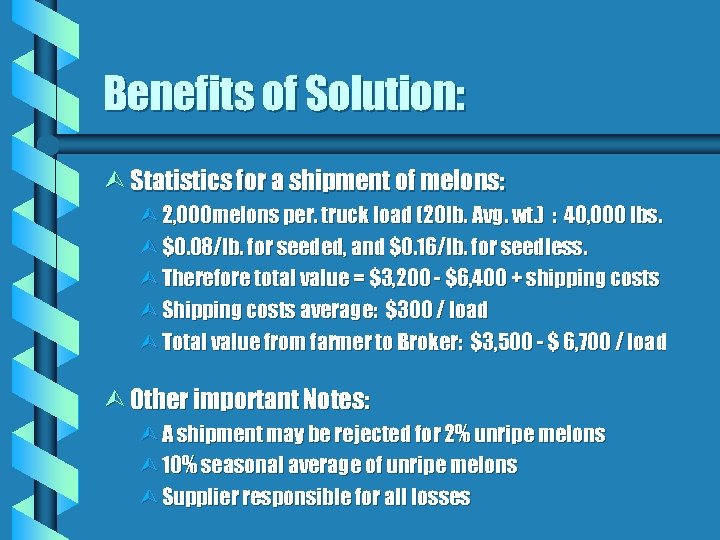

Benefits of Solution: Ù Statistics for a shipment of melons: Ù 2, 000 melons per. truck load (20 lb. Avg. wt. ) : 40, 000 lbs. Ù $0. 08/lb. for seeded, and $0. 16/lb. for seedless. Ù Therefore total value = $3, 200 - $6, 400 + shipping costs Ù Shipping costs average: $300 / load Ù Total value from farmer to Broker: $3, 500 - $ 6, 700 / load Ù Other important Notes: Ù A shipment may be rejected for 2% unripe melons Ù 10% seasonal average of unripe melons Ù Supplier responsible for all losses

Benefits of Solution: Ù Statistics for a shipment of melons: Ù 2, 000 melons per. truck load (20 lb. Avg. wt. ) : 40, 000 lbs. Ù $0. 08/lb. for seeded, and $0. 16/lb. for seedless. Ù Therefore total value = $3, 200 - $6, 400 + shipping costs Ù Shipping costs average: $300 / load Ù Total value from farmer to Broker: $3, 500 - $ 6, 700 / load Ù Other important Notes: Ù A shipment may be rejected for 2% unripe melons Ù 10% seasonal average of unripe melons Ù Supplier responsible for all losses

Project Mission êDevelop a non-destructive method and apparatus for accurately determining the ripeness of watermelons.

Project Mission êDevelop a non-destructive method and apparatus for accurately determining the ripeness of watermelons.

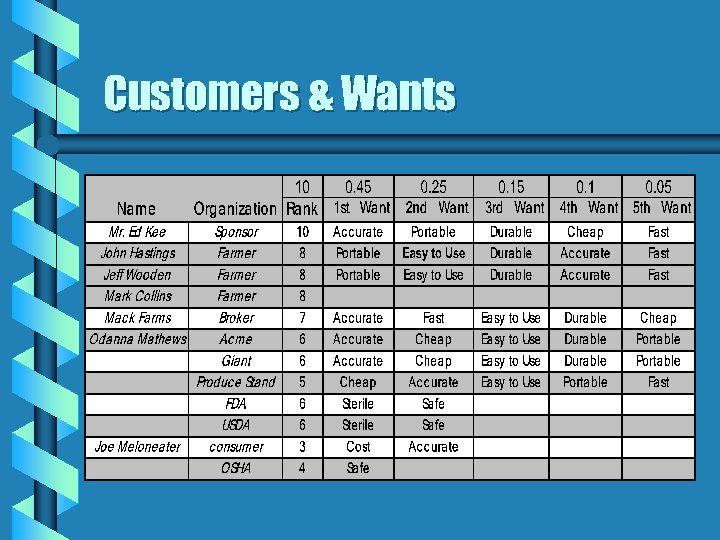

Customers & Wants

Customers & Wants

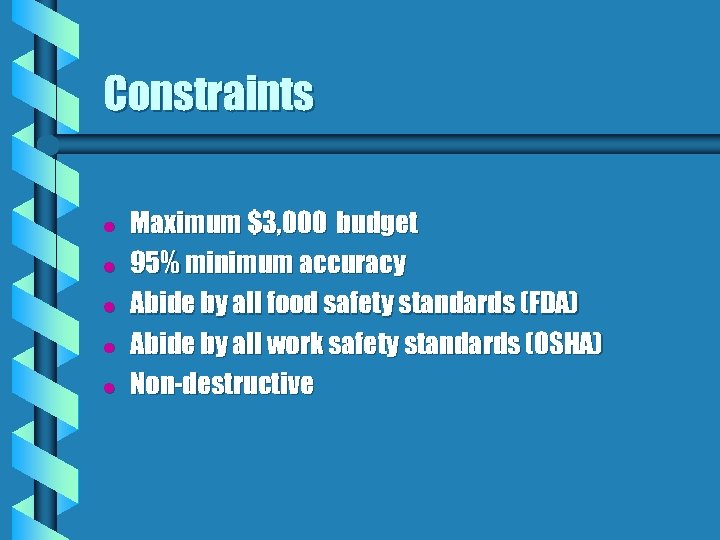

Constraints l l l Maximum $3, 000 budget 95% minimum accuracy Abide by all food safety standards (FDA) Abide by all work safety standards (OSHA) Non-destructive

Constraints l l l Maximum $3, 000 budget 95% minimum accuracy Abide by all food safety standards (FDA) Abide by all work safety standards (OSHA) Non-destructive

Benchmarking ò Benchmarking Strategy ò Traditional methods ò Broad spectrum search of related methods ò Narrowing of search to feasible techniques

Benchmarking ò Benchmarking Strategy ò Traditional methods ò Broad spectrum search of related methods ò Narrowing of search to feasible techniques

Benchmarking Cont. ò Traditional Methods ò Thumping ò Stem color ò Skin color ò Germination period (35 days)

Benchmarking Cont. ò Traditional Methods ò Thumping ò Stem color ò Skin color ò Germination period (35 days)

Benchmarking Cont. ò Related Procedures Thumping/Resonance Acoustic testing Ultrasonic testing Optoelectrics Intrusive testing Nuclear magnetic resonance Electronic sensing of aromatic volatiles

Benchmarking Cont. ò Related Procedures Thumping/Resonance Acoustic testing Ultrasonic testing Optoelectrics Intrusive testing Nuclear magnetic resonance Electronic sensing of aromatic volatiles

Estimated Budget l l l u u Testing equipment: $1, 000 (depending on availability of equipment) Produce for testing: $0 Prototype construction: $1, 000 Allowable Budget: $3, 000 Reserve Budget: $1, 000

Estimated Budget l l l u u Testing equipment: $1, 000 (depending on availability of equipment) Produce for testing: $0 Prototype construction: $1, 000 Allowable Budget: $3, 000 Reserve Budget: $1, 000

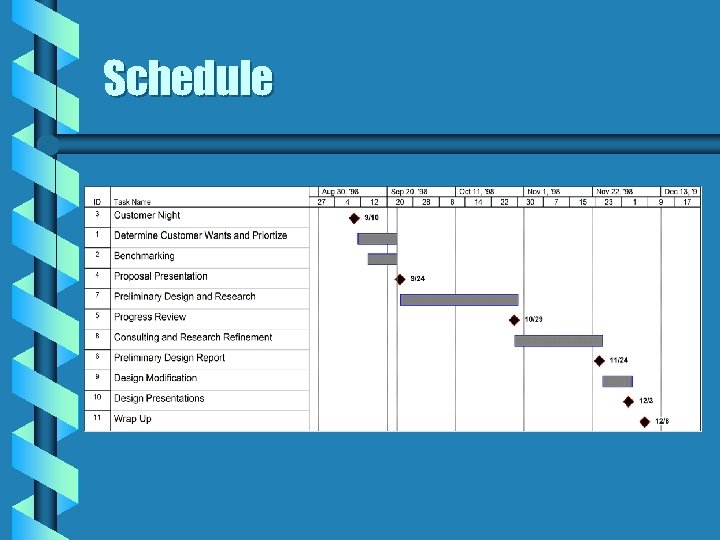

Schedule

Schedule

Conclusion b Large market for watermelons b Definite need for non-destructive test b Numerous possible testing options b Currently contacting experts in each testing area

Conclusion b Large market for watermelons b Definite need for non-destructive test b Numerous possible testing options b Currently contacting experts in each testing area