1d984c119f85fb98fa3f4befabbf7758.ppt

- Количество слайдов: 23

Water, Wastewater 2017 REVIEW 2018 PLAN

Water, Wastewater 2017 REVIEW 2018 PLAN

OCWA / KL Partnership • 18 employees in Kirkland Lake area – Central location for cluster • 6 have moved into KL • Parts, contractors, vehicles, fuel

OCWA / KL Partnership • 18 employees in Kirkland Lake area – Central location for cluster • 6 have moved into KL • Parts, contractors, vehicles, fuel

Partnership • • Town of Kirkland Lake Owns the facilities Seeks to minimize operational costs Invests in the infrastructure to ensure system longevity, safety and quality for community Prove compliance with Provincial and Federal regulations • • OCWA Operates and maintains the facilities Provides a valuable service at a competitive rate Manage the infrastructure to extend equipment life and reduce capital costs Provide training, systems, and people to ensure

Partnership • • Town of Kirkland Lake Owns the facilities Seeks to minimize operational costs Invests in the infrastructure to ensure system longevity, safety and quality for community Prove compliance with Provincial and Federal regulations • • OCWA Operates and maintains the facilities Provides a valuable service at a competitive rate Manage the infrastructure to extend equipment life and reduce capital costs Provide training, systems, and people to ensure

One Water • OCWA program to help raise awareness of water and wastewater treatment and challenges. • Part of Northern college advisory committee to enhance that course. Attracts students from around the globe. • Secures our future • Don’t Flush campaign

One Water • OCWA program to help raise awareness of water and wastewater treatment and challenges. • Part of Northern college advisory committee to enhance that course. Attracts students from around the globe. • Secures our future • Don’t Flush campaign

Improvements • • Automated Valve turner CCTV Camera - video Smoke Testing Emergency Preparedness and Response (OERT)

Improvements • • Automated Valve turner CCTV Camera - video Smoke Testing Emergency Preparedness and Response (OERT)

Health & Safety • • • NEO region had zero lost time accidents in 2017 Kirkland Lake cluster had one near miss Monthly safety meetings and plant inspections Daily morning safety huddle Non-routine hazardous tasks assessments and tailgate meetings

Health & Safety • • • NEO region had zero lost time accidents in 2017 Kirkland Lake cluster had one near miss Monthly safety meetings and plant inspections Daily morning safety huddle Non-routine hazardous tasks assessments and tailgate meetings

Health and Safety • 2017 Safety Initiatives – Tailgate forms and meetings for Non-routine Work • Chlorine work, Chlorine Dioxide, Tower work, Decanting modifications – Near Miss Reporting • Safety triangle of incidents

Health and Safety • 2017 Safety Initiatives – Tailgate forms and meetings for Non-routine Work • Chlorine work, Chlorine Dioxide, Tower work, Decanting modifications – Near Miss Reporting • Safety triangle of incidents

Health and Safety • Weekly Health and Safety Meetings • Each employee received 29 hours of OJT • Each employee received 31 hours of Ministry approved training • 12 cluster safety meetings – WHMIS, Lock&Tag, SCBA, Electrical, Confined Space, Near Miss reporting, Fall protection, Tailgate meetings, Lifting techniques, Heat stress, Slips and Trips, Winter driving, Asbestos • Zero LTA • 1 Near Miss

Health and Safety • Weekly Health and Safety Meetings • Each employee received 29 hours of OJT • Each employee received 31 hours of Ministry approved training • 12 cluster safety meetings – WHMIS, Lock&Tag, SCBA, Electrical, Confined Space, Near Miss reporting, Fall protection, Tailgate meetings, Lifting techniques, Heat stress, Slips and Trips, Winter driving, Asbestos • Zero LTA • 1 Near Miss

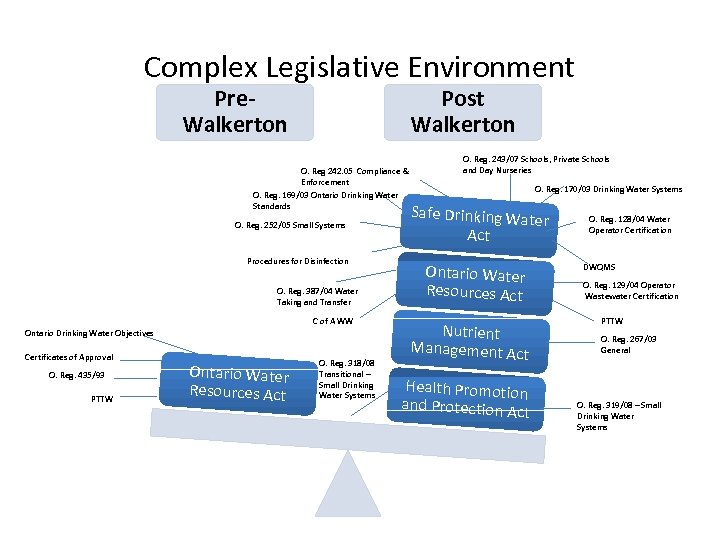

Complex Legislative Environment Pre. Walkerton Post Walkerton O. Reg 242. 05 Compliance & Enforcement O. Reg. 169/03 Ontario Drinking Water Standards O. Reg. 252/05 Small Systems Procedures for Disinfection O. Reg. 387/04 Water Taking and Transfer C of A WW Ontario Drinking Water Objectives Certificates of Approval O. Reg. 435/93 PTTW Ontario Water Resources Act O. Reg. 318/08 Transitional – Small Drinking Water Systems O. Reg. 243/07 Schools, Private Schools and Day Nurseries O. Reg. 170/03 Drinking Water Systems Safe Drinking Wate r Act Ontario Water Resources Act Nutrient Management Act Health Promotion and Protection Ac t O. Reg. 128/04 Water Operator Certification DWQMS O. Reg. 129/04 Operator Wastewater Certification PTTW O. Reg. 267/03 General O. Reg. 319/08 – Small Drinking Water Systems

Complex Legislative Environment Pre. Walkerton Post Walkerton O. Reg 242. 05 Compliance & Enforcement O. Reg. 169/03 Ontario Drinking Water Standards O. Reg. 252/05 Small Systems Procedures for Disinfection O. Reg. 387/04 Water Taking and Transfer C of A WW Ontario Drinking Water Objectives Certificates of Approval O. Reg. 435/93 PTTW Ontario Water Resources Act O. Reg. 318/08 Transitional – Small Drinking Water Systems O. Reg. 243/07 Schools, Private Schools and Day Nurseries O. Reg. 170/03 Drinking Water Systems Safe Drinking Wate r Act Ontario Water Resources Act Nutrient Management Act Health Promotion and Protection Ac t O. Reg. 128/04 Water Operator Certification DWQMS O. Reg. 129/04 Operator Wastewater Certification PTTW O. Reg. 267/03 General O. Reg. 319/08 – Small Drinking Water Systems

Compliance • KLWTP – 2016 MOECC inspection report 100% • Suggest to begin water reduction strategy – Latest Inspection January 9, 2018 – One resample at Federal School August 13 th – Background count

Compliance • KLWTP – 2016 MOECC inspection report 100% • Suggest to begin water reduction strategy – Latest Inspection January 9, 2018 – One resample at Federal School August 13 th – Background count

Compliance • KLWWTP –MOECC inspection was late 2014 with zero noncompliance issues noted • In 2017: – 2 UV system unit bypasses due to heavy rainfall (May and October) – Exploring operational options to avoid rainfall unit bypasses in the future • SSTP – most recent MOECC inspection March 2014 – Plant bypass in April 2017 due to spring melt

Compliance • KLWWTP –MOECC inspection was late 2014 with zero noncompliance issues noted • In 2017: – 2 UV system unit bypasses due to heavy rainfall (May and October) – Exploring operational options to avoid rainfall unit bypasses in the future • SSTP – most recent MOECC inspection March 2014 – Plant bypass in April 2017 due to spring melt

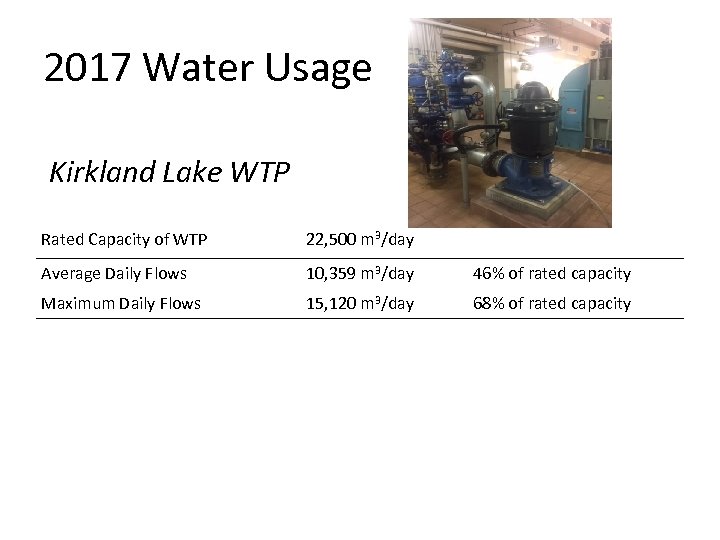

2017 Water Usage Kirkland Lake WTP Rated Capacity of WTP 22, 500 m 3/day Average Daily Flows 10, 359 m 3/day 46% of rated capacity Maximum Daily Flows 15, 120 m 3/day 68% of rated capacity

2017 Water Usage Kirkland Lake WTP Rated Capacity of WTP 22, 500 m 3/day Average Daily Flows 10, 359 m 3/day 46% of rated capacity Maximum Daily Flows 15, 120 m 3/day 68% of rated capacity

SSTP Project • Started with plant assessment of Swastika STP in 2014 • KL was presented with plant assessment report indicating that significant costs would be incurred in order to bring plant up to current standards • Followed by feasibility study in 2015 to explore option of pumping material back to KLWWTP • Presented to CWF and was funded on this option

SSTP Project • Started with plant assessment of Swastika STP in 2014 • KL was presented with plant assessment report indicating that significant costs would be incurred in order to bring plant up to current standards • Followed by feasibility study in 2015 to explore option of pumping material back to KLWWTP • Presented to CWF and was funded on this option

Benefits of Swastika Project • Eliminate any environmental effect on Otto Lake through regional treatment • Reduce long term operating costs • Reduce long term electrical costs • Reduce RISK

Benefits of Swastika Project • Eliminate any environmental effect on Otto Lake through regional treatment • Reduce long term operating costs • Reduce long term electrical costs • Reduce RISK

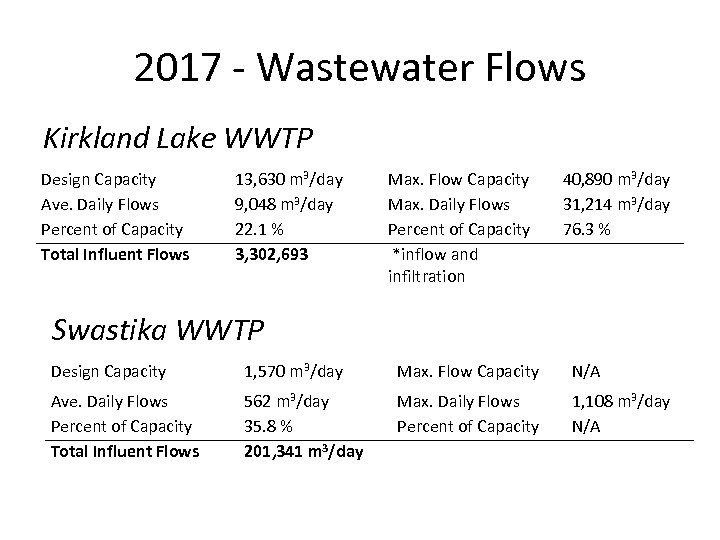

2017 - Wastewater Flows Kirkland Lake WWTP Design Capacity Ave. Daily Flows Percent of Capacity Total Influent Flows 13, 630 m 3/day 9, 048 m 3/day 22. 1 % 3, 302, 693 Max. Flow Capacity Max. Daily Flows Percent of Capacity *inflow and infiltration 40, 890 m 3/day 31, 214 m 3/day 76. 3 % Swastika WWTP Design Capacity 1, 570 m 3/day Max. Flow Capacity N/A Ave. Daily Flows Percent of Capacity Total Influent Flows 562 m 3/day 35. 8 % 201, 341 m 3/day Max. Daily Flows Percent of Capacity 1, 108 m 3/day N/A

2017 - Wastewater Flows Kirkland Lake WWTP Design Capacity Ave. Daily Flows Percent of Capacity Total Influent Flows 13, 630 m 3/day 9, 048 m 3/day 22. 1 % 3, 302, 693 Max. Flow Capacity Max. Daily Flows Percent of Capacity *inflow and infiltration 40, 890 m 3/day 31, 214 m 3/day 76. 3 % Swastika WWTP Design Capacity 1, 570 m 3/day Max. Flow Capacity N/A Ave. Daily Flows Percent of Capacity Total Influent Flows 562 m 3/day 35. 8 % 201, 341 m 3/day Max. Daily Flows Percent of Capacity 1, 108 m 3/day N/A

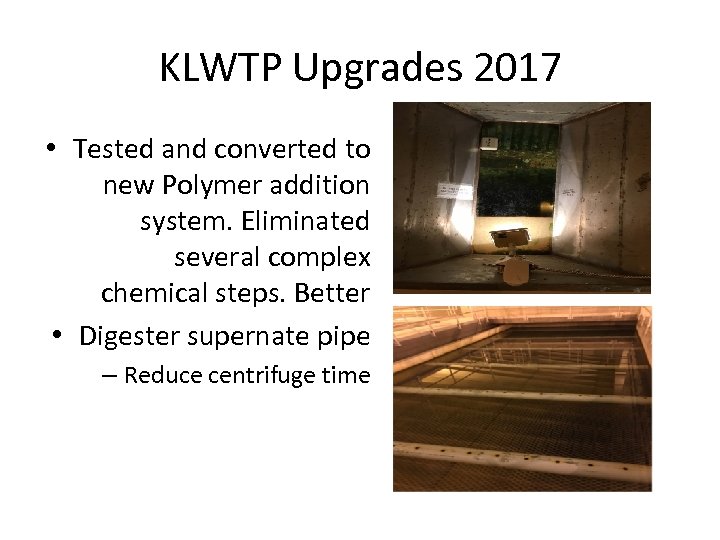

KLWTP Upgrades 2017 • Tested and converted to new Polymer addition system. Eliminated several complex chemical steps. Better • Digester supernate pipe – Reduce centrifuge time

KLWTP Upgrades 2017 • Tested and converted to new Polymer addition system. Eliminated several complex chemical steps. Better • Digester supernate pipe – Reduce centrifuge time

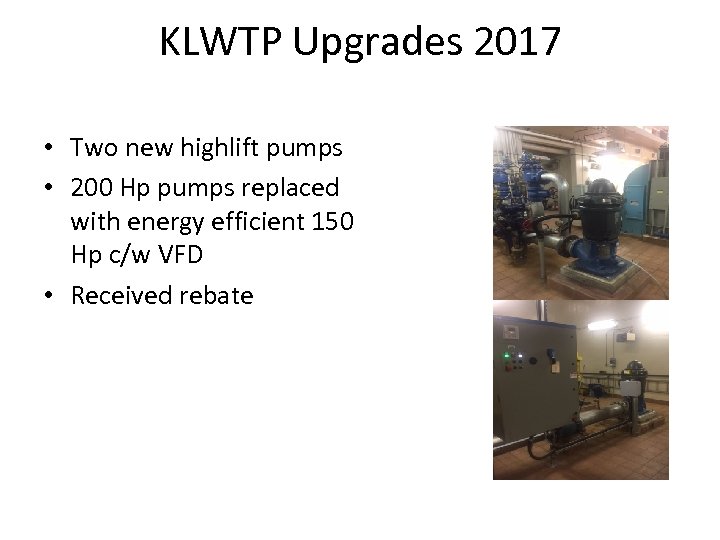

KLWTP Upgrades 2017 • Two new highlift pumps • 200 Hp pumps replaced with energy efficient 150 Hp c/w VFD • Received rebate

KLWTP Upgrades 2017 • Two new highlift pumps • 200 Hp pumps replaced with energy efficient 150 Hp c/w VFD • Received rebate

Preventative Maintenance - 170 Completed work orders for KL Facilities • Preventative Maintenance Work Orders: – – Maintenance Programs based on Manufacture Recommendations Applied to all mechanical pieces including valves Greasing, Oil Changes, Detailed Inspections of equipment Equipment performance and maximize equipment efficiency • Emergency Work Orders – Work orders created to reflect equipment failure – Immediate Attention Required – Investigative - why such failure • Corrective Work Orders – – Work done to prevent Emergency failures/ ‘call back’ work orders Reflects Operational and PM Inspections Replace/Refurbish old (end of service life) equipment or pieces of Includes Annual Work such Standpipe cleaning/Inspection etc.

Preventative Maintenance - 170 Completed work orders for KL Facilities • Preventative Maintenance Work Orders: – – Maintenance Programs based on Manufacture Recommendations Applied to all mechanical pieces including valves Greasing, Oil Changes, Detailed Inspections of equipment Equipment performance and maximize equipment efficiency • Emergency Work Orders – Work orders created to reflect equipment failure – Immediate Attention Required – Investigative - why such failure • Corrective Work Orders – – Work done to prevent Emergency failures/ ‘call back’ work orders Reflects Operational and PM Inspections Replace/Refurbish old (end of service life) equipment or pieces of Includes Annual Work such Standpipe cleaning/Inspection etc.

2018 > Improvement Plan • Rate Assessment Study • MOECC report suggestions to reduce water use throughout the municipality – Average 890 L/person/day – Env Can 300 L/person/day • • • Conservation program Meter program Leak detection Operating modifications Awareness

2018 > Improvement Plan • Rate Assessment Study • MOECC report suggestions to reduce water use throughout the municipality – Average 890 L/person/day – Env Can 300 L/person/day • • • Conservation program Meter program Leak detection Operating modifications Awareness

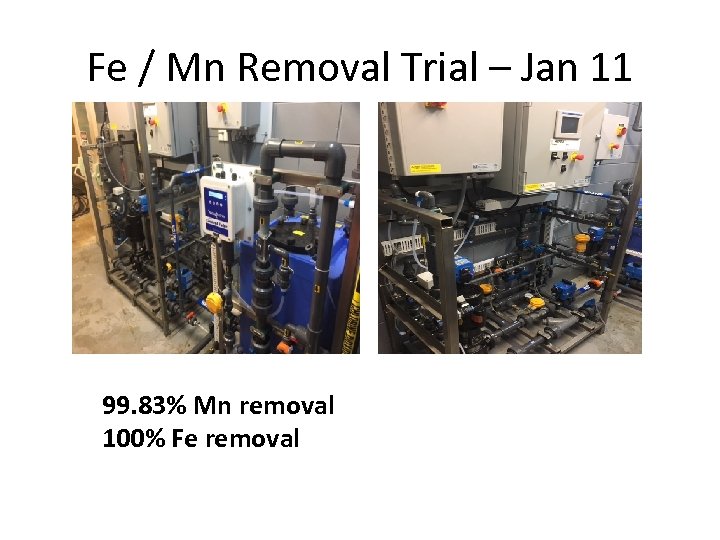

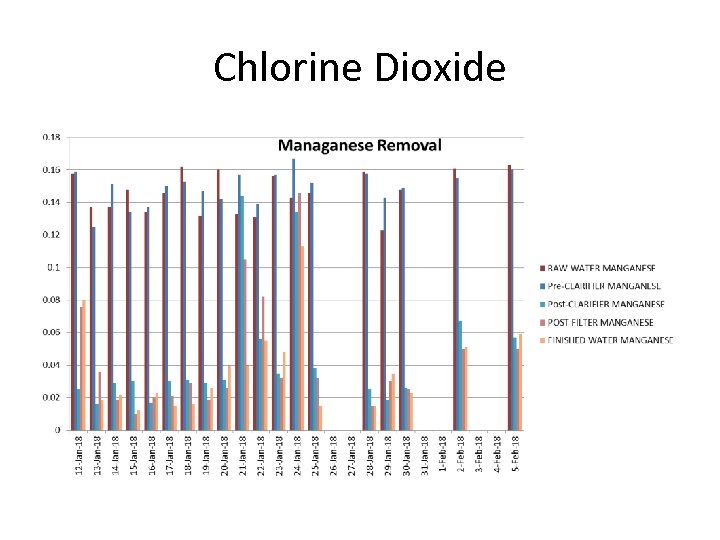

Fe / Mn Removal Trial – Jan 11 99. 83% Mn removal 100% Fe removal

Fe / Mn Removal Trial – Jan 11 99. 83% Mn removal 100% Fe removal

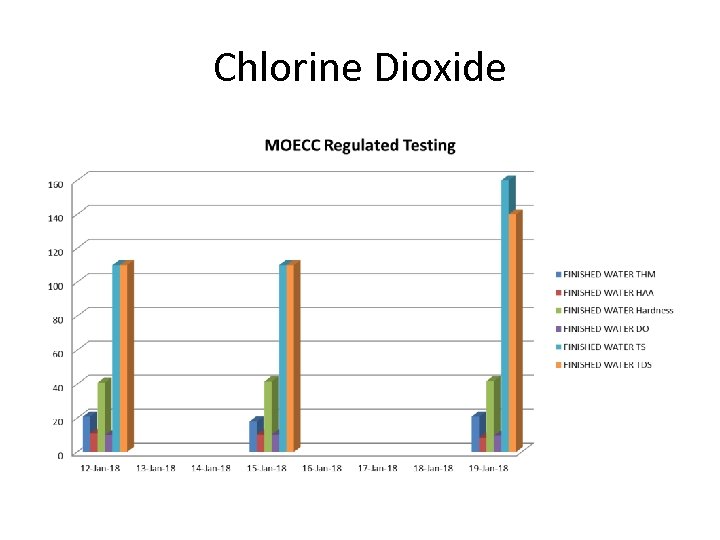

Chlorine Dioxide

Chlorine Dioxide

Chlorine Dioxide

Chlorine Dioxide

Testing Phase • Some taste and odour complaints upon start-up – Chlorite solution will also clean pipe bio-film – Mixing with old water – Older pipes have more tuberculation • Dosing efficiency and charting • Fine-tune process (pre-p. H and alkalinity)

Testing Phase • Some taste and odour complaints upon start-up – Chlorite solution will also clean pipe bio-film – Mixing with old water – Older pipes have more tuberculation • Dosing efficiency and charting • Fine-tune process (pre-p. H and alkalinity)