9a1d6e3bd690752063dc807894d3f5f5.ppt

- Количество слайдов: 33

WASTEWATER MINIMIZATION FOR A FIVE STAGE IRON PHOSPHATE SPRAY WASH SYSTEM Colin Kiefer, P 2 AD Engineer and Project Manager Mary Beth Schwefel, Metcam EH&S and Finishing Manager

WASTEWATER MINIMIZATION FOR A FIVE STAGE IRON PHOSPHATE SPRAY WASH SYSTEM Colin Kiefer, P 2 AD Engineer and Project Manager Mary Beth Schwefel, Metcam EH&S and Finishing Manager

Discussion Outline Ø What is P 2 AD? Ø P 2 AD’s Metal Finishing Initiative Ø Who is Metcam? Ø Metcam - P 2 AD Partnership Ø Phase I Discussion & Results ü Project Background ü Determining the Full Wastewater Cost ü Choosing a P 2 Technology

Discussion Outline Ø What is P 2 AD? Ø P 2 AD’s Metal Finishing Initiative Ø Who is Metcam? Ø Metcam - P 2 AD Partnership Ø Phase I Discussion & Results ü Project Background ü Determining the Full Wastewater Cost ü Choosing a P 2 Technology

Discussion Outline Ø Phase I Discussion & Results ü Crossflow Membrane Filtration Technical Principles ü P 2 System Conceptual Design ü P 2 System Footprint ü Pilot Project Results ü Long-Term Results ü Lessons Learned

Discussion Outline Ø Phase I Discussion & Results ü Crossflow Membrane Filtration Technical Principles ü P 2 System Conceptual Design ü P 2 System Footprint ü Pilot Project Results ü Long-Term Results ü Lessons Learned

What is P 2 AD ? A non-regulatory division of the Georgia Department of Natural Resources P 2 AD provides FREE, confidential assistance to help clients reduce waste and conserve resources Services available to any Georgia business, government agency, or institution Customized assistance to meet clients’ needs

What is P 2 AD ? A non-regulatory division of the Georgia Department of Natural Resources P 2 AD provides FREE, confidential assistance to help clients reduce waste and conserve resources Services available to any Georgia business, government agency, or institution Customized assistance to meet clients’ needs

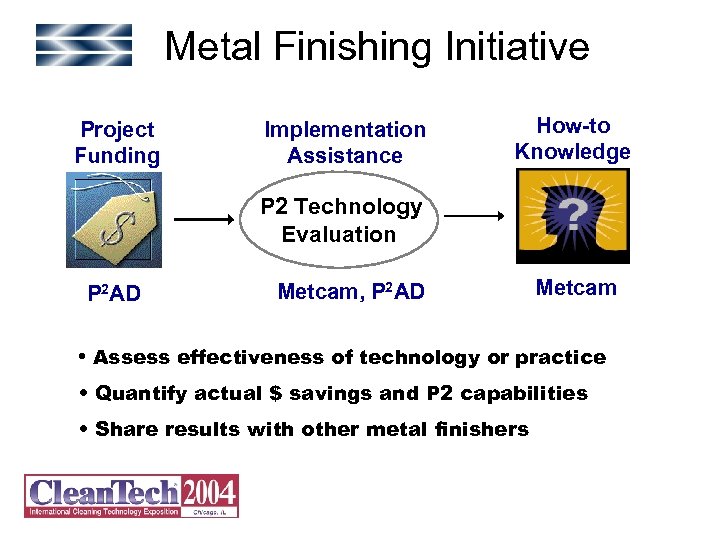

Metal Finishing Initiative Project Funding Implementation Assistance How-to Knowledge P 2 Technology Evaluation P 2 AD Metcam, P 2 AD Metcam • Assess effectiveness of technology or practice • Quantify actual $ savings and P 2 capabilities • Share results with other metal finishers

Metal Finishing Initiative Project Funding Implementation Assistance How-to Knowledge P 2 Technology Evaluation P 2 AD Metcam, P 2 AD Metcam • Assess effectiveness of technology or practice • Quantify actual $ savings and P 2 capabilities • Share results with other metal finishers

Who is Metcam? • Alpharetta, GA • 100, 000 ft 2 Facility • Precision Metal Fabrication • Metal Finishing • Light Assembly • ISO 9001 Registered • ISO 14001 (Coming Soon) • 2002 Honorable Mention v Governor’s Award for Pollution Prevention

Who is Metcam? • Alpharetta, GA • 100, 000 ft 2 Facility • Precision Metal Fabrication • Metal Finishing • Light Assembly • ISO 9001 Registered • ISO 14001 (Coming Soon) • 2002 Honorable Mention v Governor’s Award for Pollution Prevention

Metcam - P 2 AD Partnership • Phase I - Alkaline Spray Cleaner & Rinse Bath Life Extension • Phase II - Non-Chrome Substitute Aluminum Treatment/Coating • Phase III – Join P 2 AD Partnership Program (Implement Environmental Management System)

Metcam - P 2 AD Partnership • Phase I - Alkaline Spray Cleaner & Rinse Bath Life Extension • Phase II - Non-Chrome Substitute Aluminum Treatment/Coating • Phase III – Join P 2 AD Partnership Program (Implement Environmental Management System)

Phase I – Project Background Metcam, Inc. • No sewer line; cannot overflow process rinse tanks • Using atmospheric evaporators for non-haz. wastewater • Five stage iron phosphate washer ü Oil levels in Stage 2 rinse cannot exceed 10 ml/liter. ü Stage 2 rinse dumped twice per week (75, 000 gal. /year). ü Production increases causing Stage 2 to deteriorate faster! What Should Be Done? 1) Dump Stage 2 daily and purchase another evaporator? 2) Dump Stage 2 daily and ship wastewater offsite? 3) Reduce oil loading rate to Stage 2 rinse?

Phase I – Project Background Metcam, Inc. • No sewer line; cannot overflow process rinse tanks • Using atmospheric evaporators for non-haz. wastewater • Five stage iron phosphate washer ü Oil levels in Stage 2 rinse cannot exceed 10 ml/liter. ü Stage 2 rinse dumped twice per week (75, 000 gal. /year). ü Production increases causing Stage 2 to deteriorate faster! What Should Be Done? 1) Dump Stage 2 daily and purchase another evaporator? 2) Dump Stage 2 daily and ship wastewater offsite? 3) Reduce oil loading rate to Stage 2 rinse?

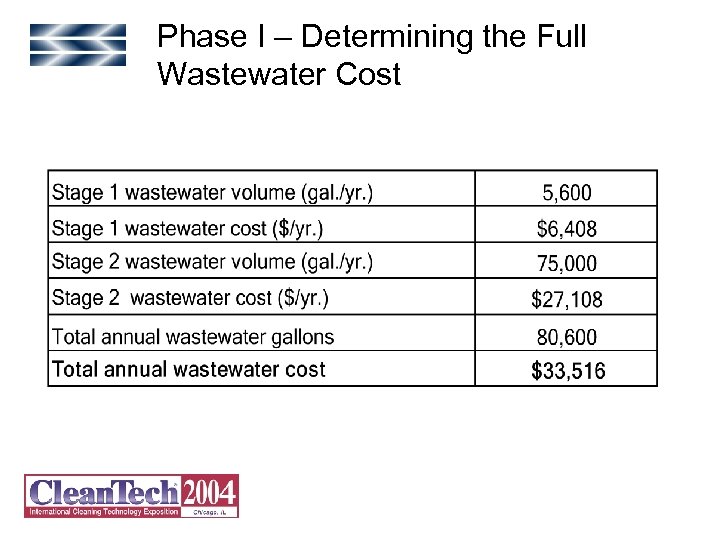

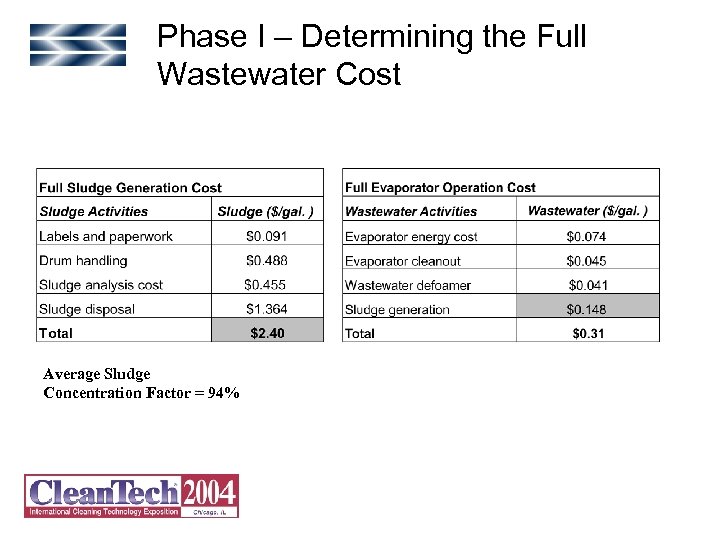

Phase I – Determining the Full Wastewater Cost

Phase I – Determining the Full Wastewater Cost

Phase I – Determining the Full Wastewater Cost Average Sludge Concentration Factor = 94%

Phase I – Determining the Full Wastewater Cost Average Sludge Concentration Factor = 94%

Choosing a P 2 Technology • Ozone/Electrolysis v Convert oil and grease into usable surfactants • Biological Cleaning v Biodegrade oil and grease to CO 2 and H 2 O • Crossflow Membrane Filtration v Physically separate cleaner from oil and grease

Choosing a P 2 Technology • Ozone/Electrolysis v Convert oil and grease into usable surfactants • Biological Cleaning v Biodegrade oil and grease to CO 2 and H 2 O • Crossflow Membrane Filtration v Physically separate cleaner from oil and grease

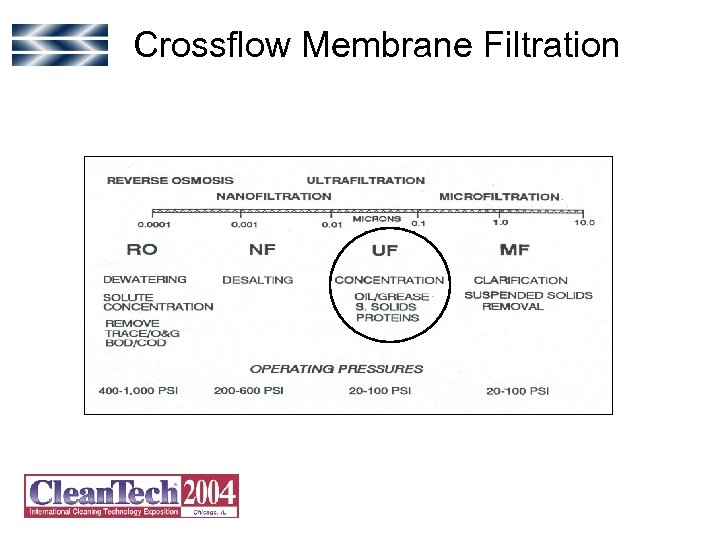

Crossflow Membrane Filtration

Crossflow Membrane Filtration

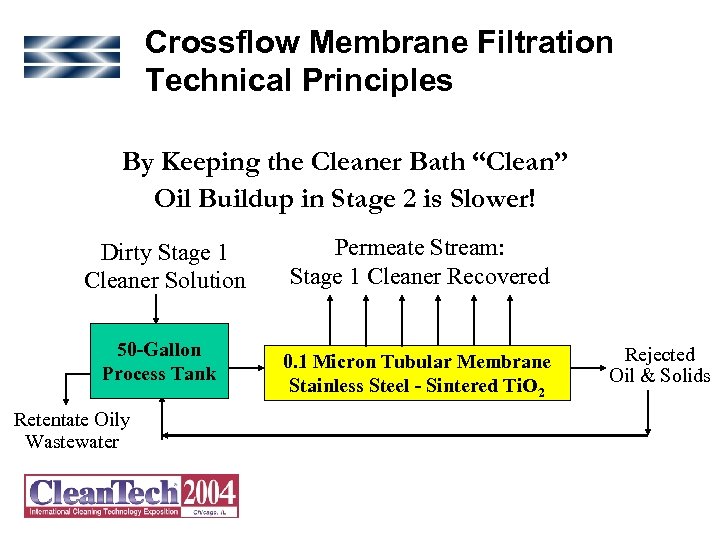

Crossflow Membrane Filtration Technical Principles By Keeping the Cleaner Bath “Clean” Oil Buildup in Stage 2 is Slower! Dirty Stage 1 Cleaner Solution 50 -Gallon Process Tank Retentate Oily Wastewater Permeate Stream: Stage 1 Cleaner Recovered 0. 1 Micron Tubular Membrane Stainless Steel - Sintered Ti. O 2 Rejected Oil & Solids

Crossflow Membrane Filtration Technical Principles By Keeping the Cleaner Bath “Clean” Oil Buildup in Stage 2 is Slower! Dirty Stage 1 Cleaner Solution 50 -Gallon Process Tank Retentate Oily Wastewater Permeate Stream: Stage 1 Cleaner Recovered 0. 1 Micron Tubular Membrane Stainless Steel - Sintered Ti. O 2 Rejected Oil & Solids

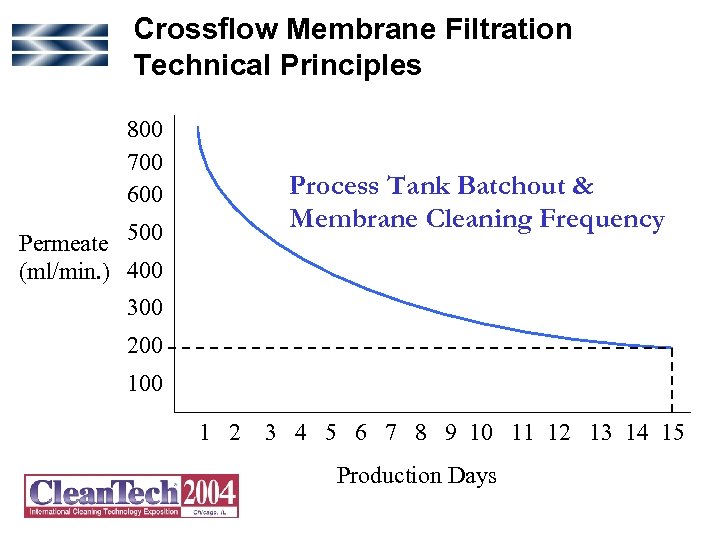

Crossflow Membrane Filtration Technical Principles 800 700 600 Process Tank Batchout & Membrane Cleaning Frequency Permeate 500 (ml/min. ) 400 300 200 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Production Days

Crossflow Membrane Filtration Technical Principles 800 700 600 Process Tank Batchout & Membrane Cleaning Frequency Permeate 500 (ml/min. ) 400 300 200 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 Production Days

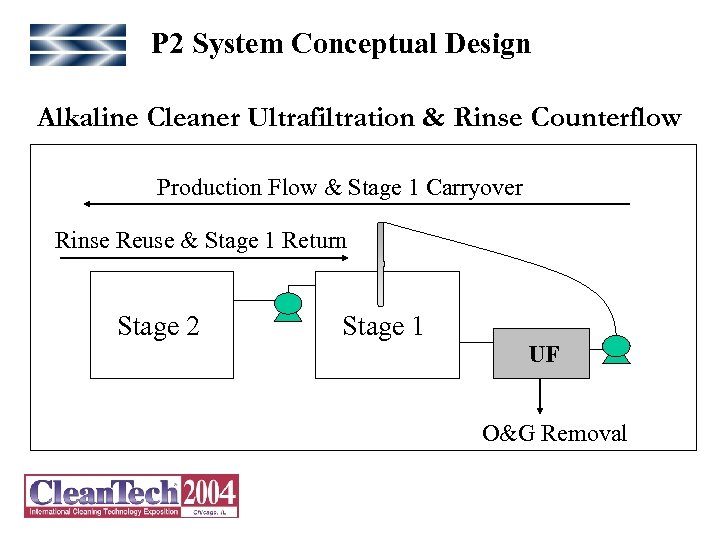

P 2 System Conceptual Design Alkaline Cleaner Ultrafiltration & Rinse Counterflow Production Flow & Stage 1 Carryover Rinse Reuse & Stage 1 Return Stage 2 Stage 1 UF O&G Removal

P 2 System Conceptual Design Alkaline Cleaner Ultrafiltration & Rinse Counterflow Production Flow & Stage 1 Carryover Rinse Reuse & Stage 1 Return Stage 2 Stage 1 UF O&G Removal

P 2 System Footprint Stage 2 Rinse Counterflow Stage 1 Ultrafiltration System

P 2 System Footprint Stage 2 Rinse Counterflow Stage 1 Ultrafiltration System

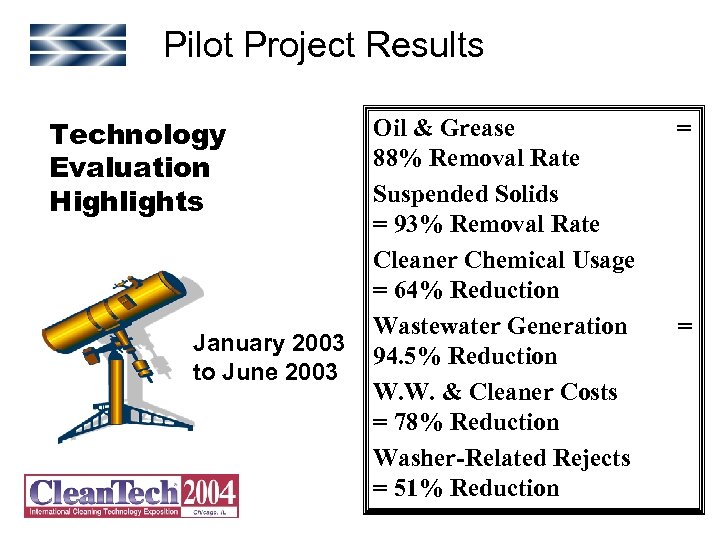

Pilot Project Results Technology Evaluation Highlights January 2003 to June 2003 Oil & Grease 88% Removal Rate Suspended Solids = 93% Removal Rate Cleaner Chemical Usage = 64% Reduction Wastewater Generation 94. 5% Reduction W. W. & Cleaner Costs = 78% Reduction Washer-Related Rejects = 51% Reduction = =

Pilot Project Results Technology Evaluation Highlights January 2003 to June 2003 Oil & Grease 88% Removal Rate Suspended Solids = 93% Removal Rate Cleaner Chemical Usage = 64% Reduction Wastewater Generation 94. 5% Reduction W. W. & Cleaner Costs = 78% Reduction Washer-Related Rejects = 51% Reduction = =

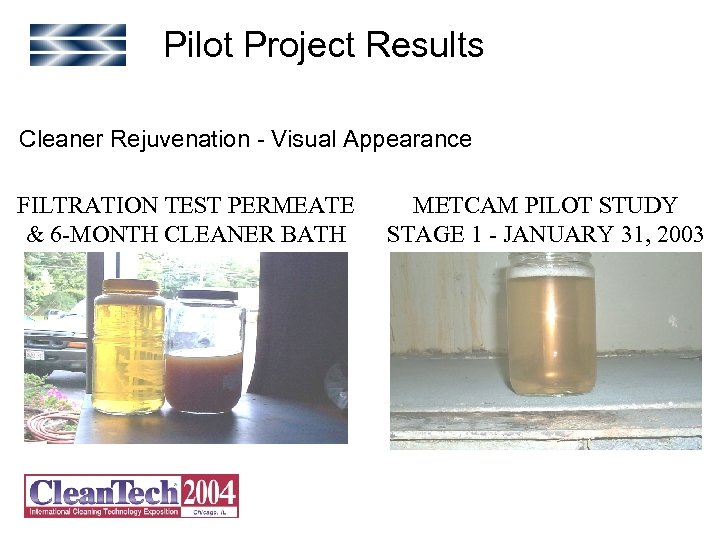

Pilot Project Results Cleaner Rejuvenation - Visual Appearance FILTRATION TEST PERMEATE & 6 -MONTH CLEANER BATH METCAM PILOT STUDY STAGE 1 - JANUARY 31, 2003

Pilot Project Results Cleaner Rejuvenation - Visual Appearance FILTRATION TEST PERMEATE & 6 -MONTH CLEANER BATH METCAM PILOT STUDY STAGE 1 - JANUARY 31, 2003

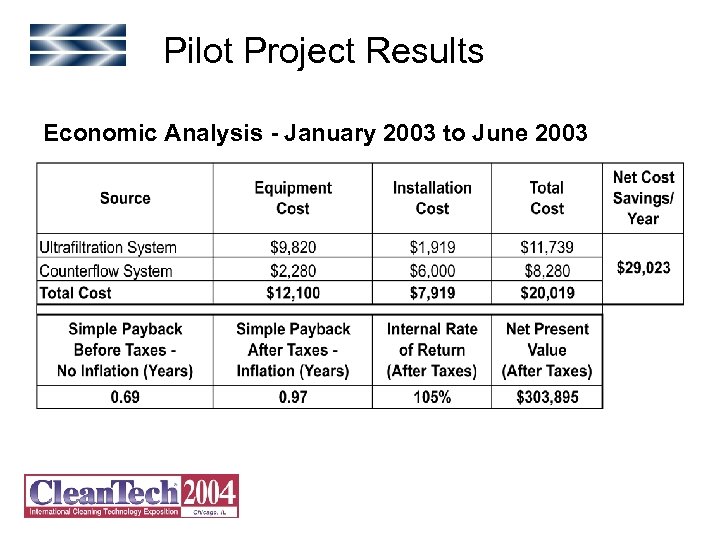

Pilot Project Results Economic Analysis - January 2003 to June 2003

Pilot Project Results Economic Analysis - January 2003 to June 2003

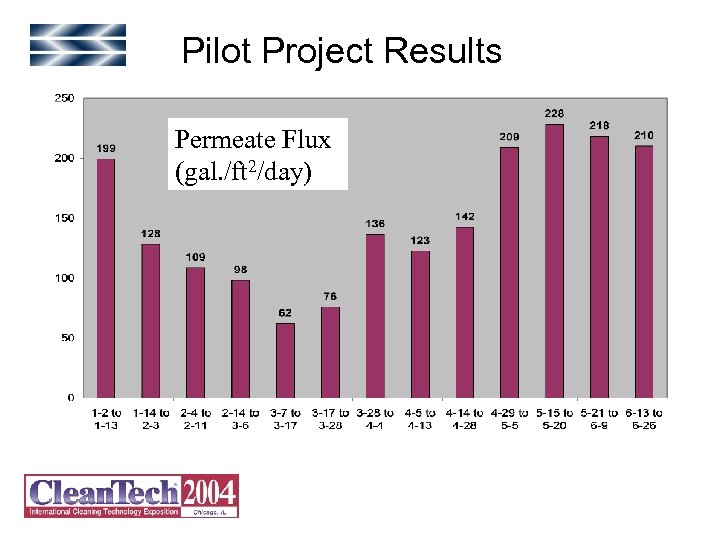

Pilot Project Results Permeate Flux (gal. /ft 2/day)

Pilot Project Results Permeate Flux (gal. /ft 2/day)

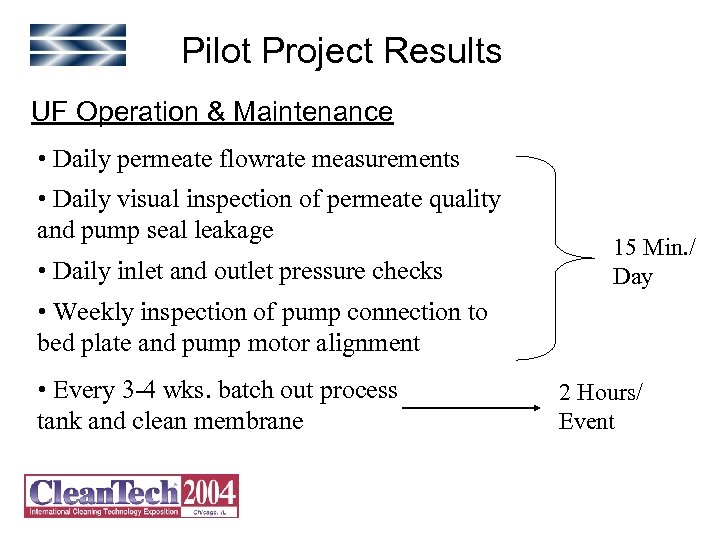

Pilot Project Results UF Operation & Maintenance • Daily permeate flowrate measurements • Daily visual inspection of permeate quality and pump seal leakage • Daily inlet and outlet pressure checks 15 Min. / Day • Weekly inspection of pump connection to bed plate and pump motor alignment • Every 3 -4 wks. batch out process tank and clean membrane 2 Hours/ Event

Pilot Project Results UF Operation & Maintenance • Daily permeate flowrate measurements • Daily visual inspection of permeate quality and pump seal leakage • Daily inlet and outlet pressure checks 15 Min. / Day • Weekly inspection of pump connection to bed plate and pump motor alignment • Every 3 -4 wks. batch out process tank and clean membrane 2 Hours/ Event

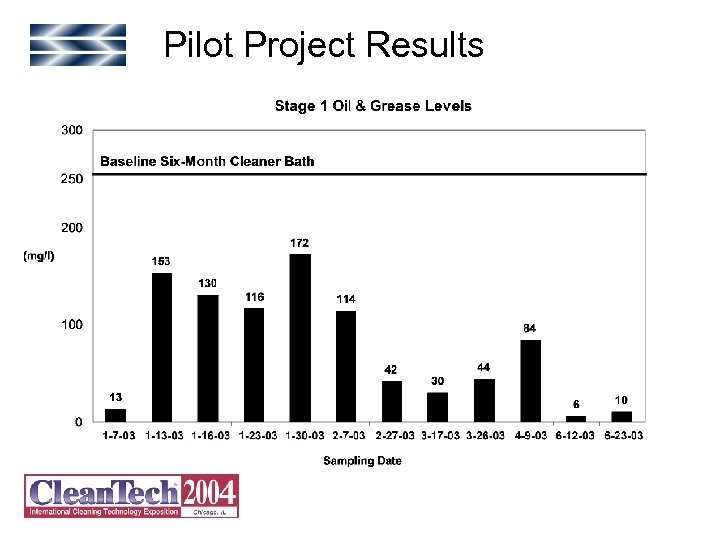

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Pilot Project Results

Long-Term Results Before Project During Project After Project Stage 2 Wastewater Generation

Long-Term Results Before Project During Project After Project Stage 2 Wastewater Generation

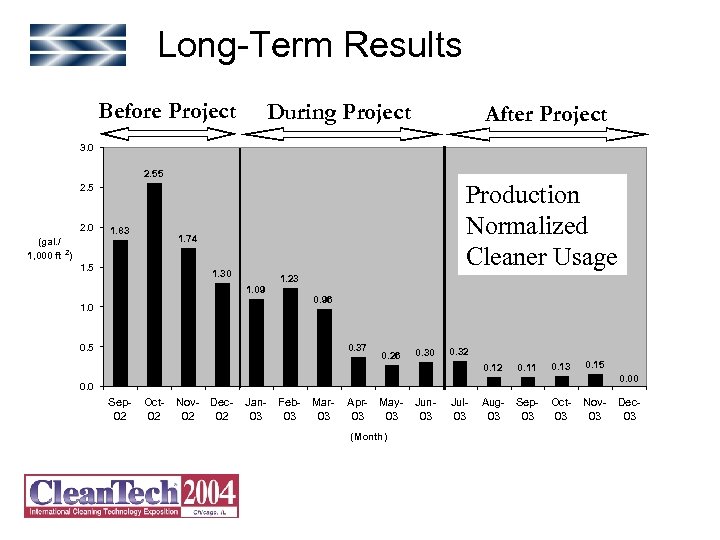

Long-Term Results Before Project During Project After Project 3. 0 2. 55 Production Normalized Cleaner Usage 2. 5 2. 0 (gal. / 1, 000 ft 2) 1. 83 1. 74 1. 5 1. 30 1. 09 1. 23 0. 96 1. 0 0. 5 0. 37 0. 26 0. 30 0. 32 0. 11 0. 13 0. 15 0. 00 0. 0 Sep 02 Oct 02 Nov- Dec 02 02 Jan 03 Feb 03 Mar 03 Apr 03 May 03 (Month) Jun 03 Jul 03 Aug- Sep 03 03 Oct 03 Nov 03 Dec 03

Long-Term Results Before Project During Project After Project 3. 0 2. 55 Production Normalized Cleaner Usage 2. 5 2. 0 (gal. / 1, 000 ft 2) 1. 83 1. 74 1. 5 1. 30 1. 09 1. 23 0. 96 1. 0 0. 5 0. 37 0. 26 0. 30 0. 32 0. 11 0. 13 0. 15 0. 00 0. 0 Sep 02 Oct 02 Nov- Dec 02 02 Jan 03 Feb 03 Mar 03 Apr 03 May 03 (Month) Jun 03 Jul 03 Aug- Sep 03 03 Oct 03 Nov 03 Dec 03

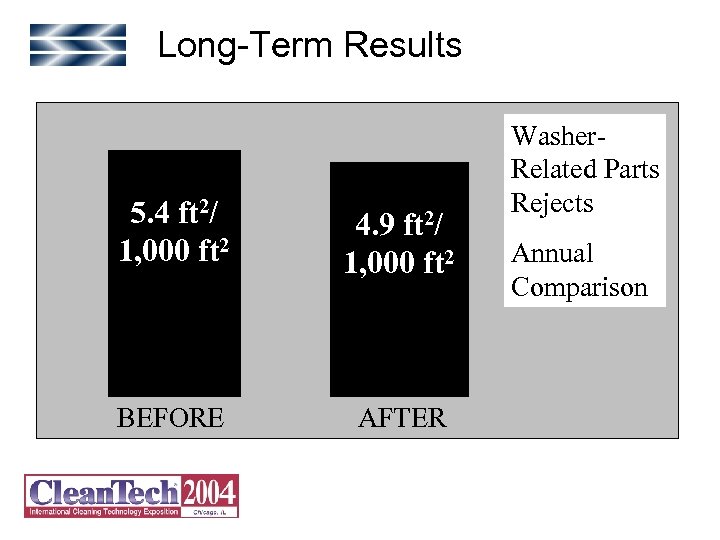

Long-Term Results 5. 4 ft 2/ 1, 000 ft 2 4. 9 ft 2/ 1, 000 ft 2 BEFORE AFTER Washer. Related Parts Rejects Annual Comparison

Long-Term Results 5. 4 ft 2/ 1, 000 ft 2 4. 9 ft 2/ 1, 000 ft 2 BEFORE AFTER Washer. Related Parts Rejects Annual Comparison

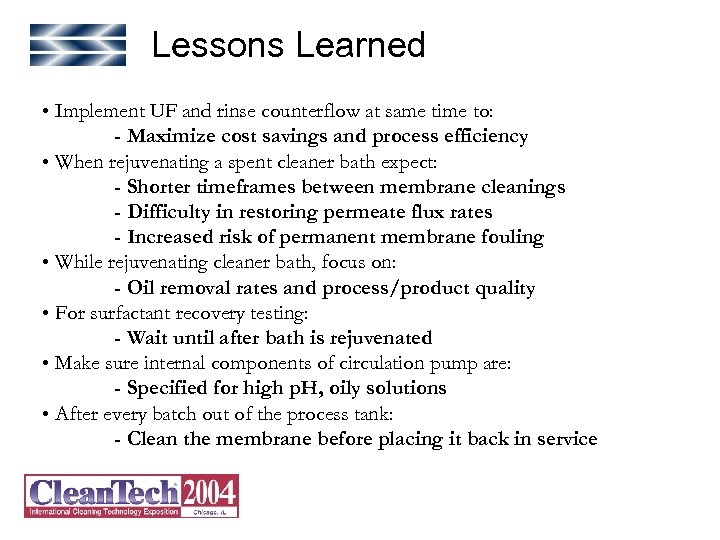

Lessons Learned • Implement UF and rinse counterflow at same time to: - Maximize cost savings and process efficiency • When rejuvenating a spent cleaner bath expect: - Shorter timeframes between membrane cleanings - Difficulty in restoring permeate flux rates - Increased risk of permanent membrane fouling • While rejuvenating cleaner bath, focus on: - Oil removal rates and process/product quality • For surfactant recovery testing: - Wait until after bath is rejuvenated • Make sure internal components of circulation pump are: - Specified for high p. H, oily solutions • After every batch out of the process tank: - Clean the membrane before placing it back in service

Lessons Learned • Implement UF and rinse counterflow at same time to: - Maximize cost savings and process efficiency • When rejuvenating a spent cleaner bath expect: - Shorter timeframes between membrane cleanings - Difficulty in restoring permeate flux rates - Increased risk of permanent membrane fouling • While rejuvenating cleaner bath, focus on: - Oil removal rates and process/product quality • For surfactant recovery testing: - Wait until after bath is rejuvenated • Make sure internal components of circulation pump are: - Specified for high p. H, oily solutions • After every batch out of the process tank: - Clean the membrane before placing it back in service

For More Information… Colin Kiefer - P 2 AD (404) 651 -5128 Colin_Kiefer@p 2 ad. org Mary Beth Schwefel – Metcam (770) 475 -9633 Mary. Beth@metcam. com Raymond Graffia - Arbortech (815) 385 -0001 sales@arbortech. com Final Project Report www. p 2 ad. org/pdfs/Metcam. Report. Final. pdf

For More Information… Colin Kiefer - P 2 AD (404) 651 -5128 Colin_Kiefer@p 2 ad. org Mary Beth Schwefel – Metcam (770) 475 -9633 Mary. Beth@metcam. com Raymond Graffia - Arbortech (815) 385 -0001 sales@arbortech. com Final Project Report www. p 2 ad. org/pdfs/Metcam. Report. Final. pdf