824ea02deb30cd7a546122f4ab6ea9ca.ppt

- Количество слайдов: 55

Waste reduction of returnable packaging: A case study of reverse logistics in an auto parts company Issued by Nophanut Katephap Sunpasit Limnararat Faculty of Engineering King Mongkut’s Institute of Technology Ladkrabang

Summary of topics I. Introduction II. Methodology III. Results IV. Conclusion V. Further study 2

I. Introduction Environmental problems have been hotly discussed among the government, businesses and society. Thus, companies should develop their image by changing their process. A suitable method to reach the environmental development in reverse logistics has received increasing consideration due to competitiveness reasons, environmental requirements and marketing. 3

I. Introduction Nowadays industrial packaging has still been considered on disposable packaging which big and varied quantities of waste but returnable packaging can reduce wastes, resource consumption and save cost. Based on current demand, studies on reverse logistics with focus on the industrial packaging activity stand out. 4

I. Introduction Examples of relevant publications on reverse logistics with emphasis on industrial packaging : D. J. Adlmaier & M. A. Sellitto suggested the benefits from replacement of disposable packaging with a returnable packaging by reducing resource consumption and operational costs. 5

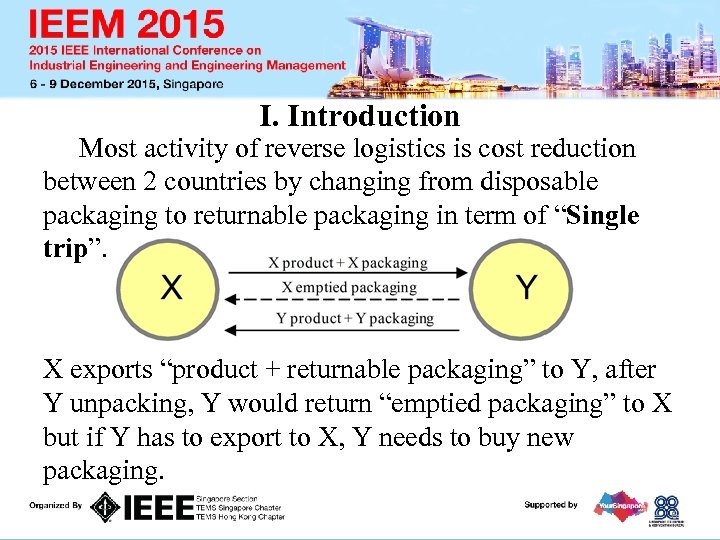

I. Introduction Most activity of reverse logistics is cost reduction between 2 countries by changing from disposable packaging to returnable packaging in term of “Single trip”. X exports “product + returnable packaging” to Y, after Y unpacking, Y would return “emptied packaging” to X but if Y has to export to X, Y needs to buy new packaging. 6

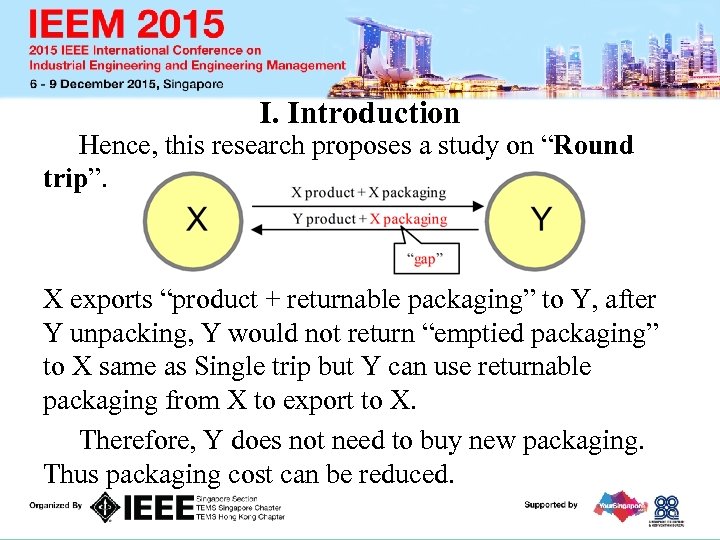

I. Introduction Hence, this research proposes a study on “Round trip”. X exports “product + returnable packaging” to Y, after Y unpacking, Y would not return “emptied packaging” to X same as Single trip but Y can use returnable packaging from X to export to X. Therefore, Y does not need to buy new packaging. Thus packaging cost can be reduced. 7

I. Introduction This research presents a case study of reverse logistics of returnable packaging used to transport auto parts among 3 countries located in Thailand, Vietnam and the Philippines in replacement for its usual disposable packaging including Single trip and Round trip. Therefore, a cost reducing analysis was conducted expecting to prove that the reverse logistics with returnable packaging can get benefits that contribute to the sustainable development of the company. 8

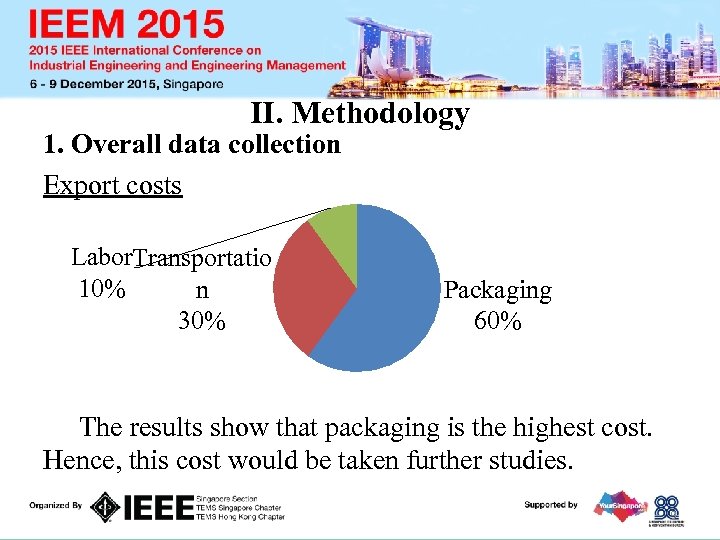

II. Methodology 1. Overall data collection Export costs Labor. Transportatio 10% n 30% Packaging 60% The results show that packaging is the highest cost. Hence, this cost would be taken further studies. 9

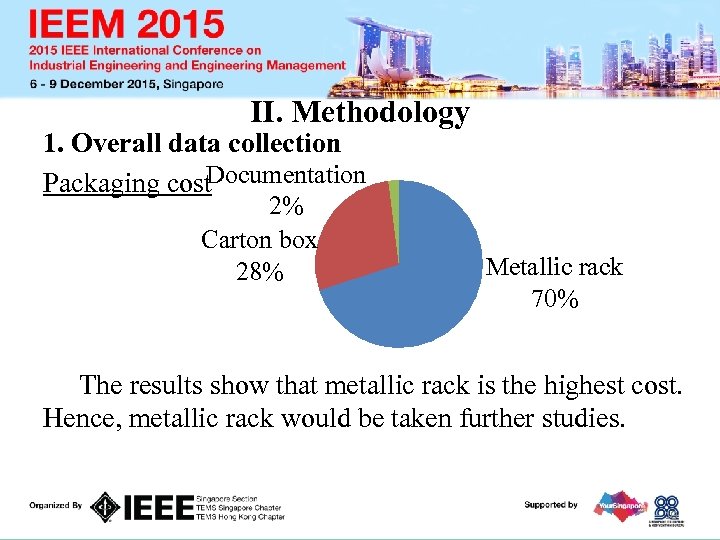

II. Methodology 1. Overall data collection Documentation Packaging cost 2% Carton box 28% Metallic rack 70% The results show that metallic rack is the highest cost. Hence, metallic rack would be taken further studies. 10

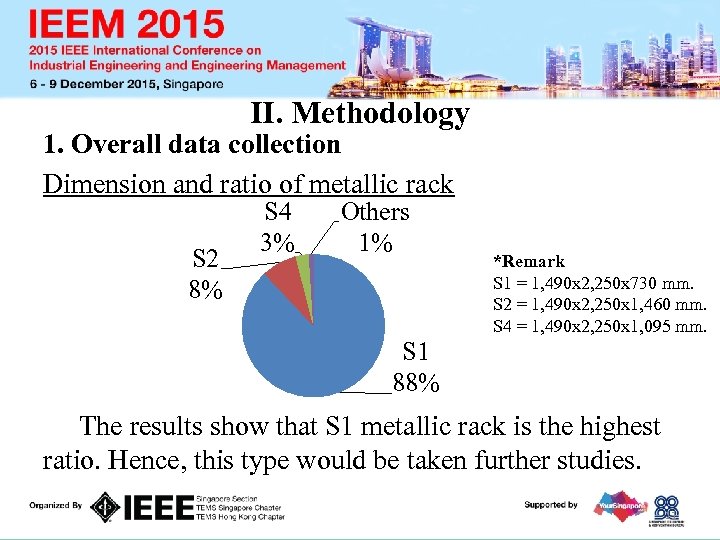

II. Methodology 1. Overall data collection Dimension and ratio of metallic rack S 2 8% S 4 3% Others 1% *Remark S 1 = 1, 490 x 2, 250 x 730 mm. S 2 = 1, 490 x 2, 250 x 1, 460 mm. S 4 = 1, 490 x 2, 250 x 1, 095 mm. S 1 88% The results show that S 1 metallic rack is the highest ratio. Hence, this type would be taken further studies. 11

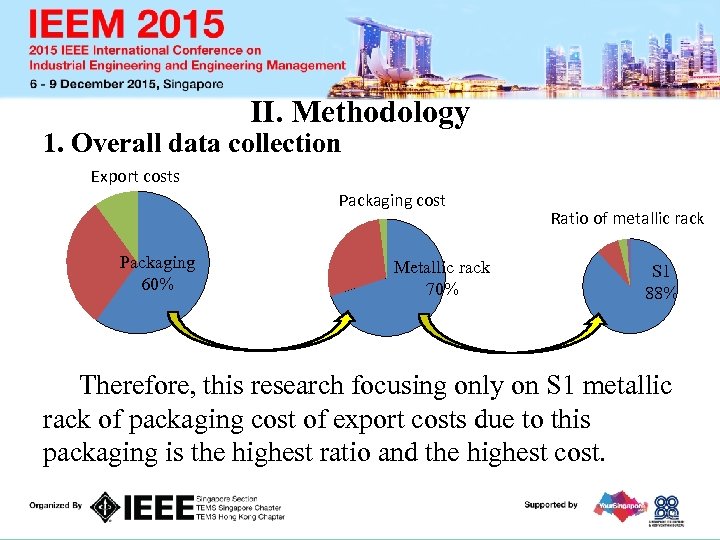

II. Methodology 1. Overall data collection Export costs Packaging cost Packaging 60% Metallic rack 70% Ratio of metallic rack S 1 88% Therefore, this research focusing only on S 1 metallic rack of packaging cost of export costs due to this packaging is the highest ratio and the highest cost. 12

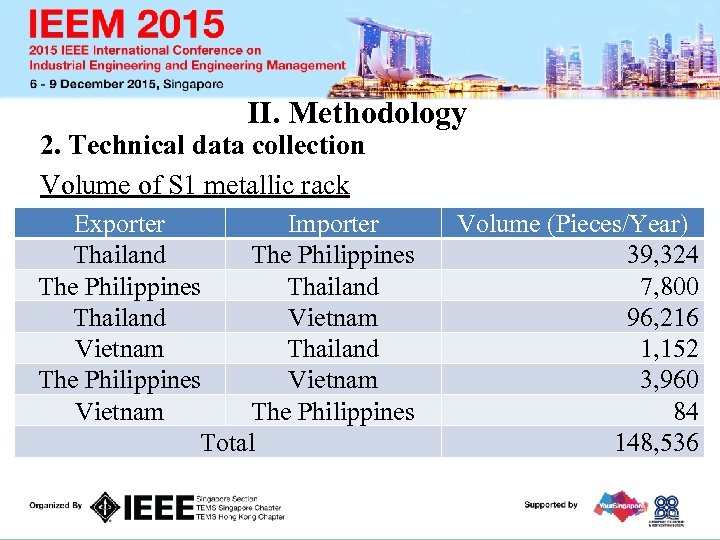

II. Methodology 2. Technical data collection Volume of S 1 metallic rack Exporter Importer Thailand The Philippines Thailand Vietnam Thailand The Philippines Vietnam The Philippines Total Volume (Pieces/Year) 39, 324 7, 800 96, 216 1, 152 3, 960 84 148, 536 13

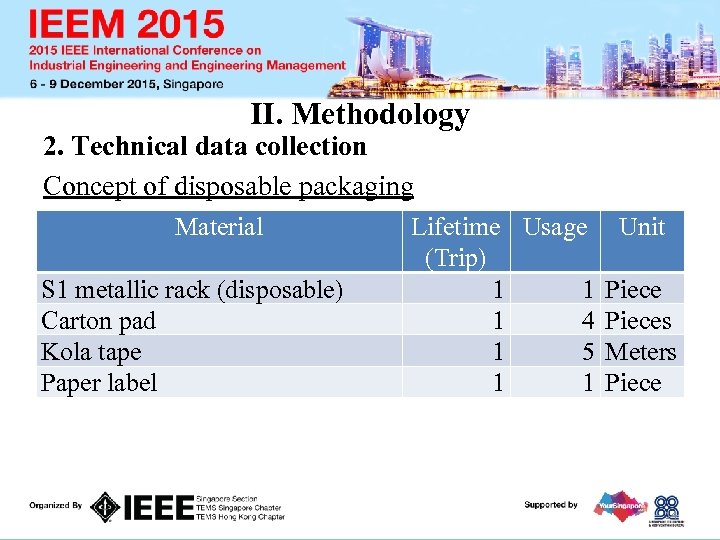

II. Methodology 2. Technical data collection Concept of disposable packaging Material Lifetime Usage Materials used in the disposable packaging. Unit (Trip) S 1 metallic rack (disposable) Carton pad Kola tape Paper label 1 1 1 4 5 1 Pieces Meters Piece 14

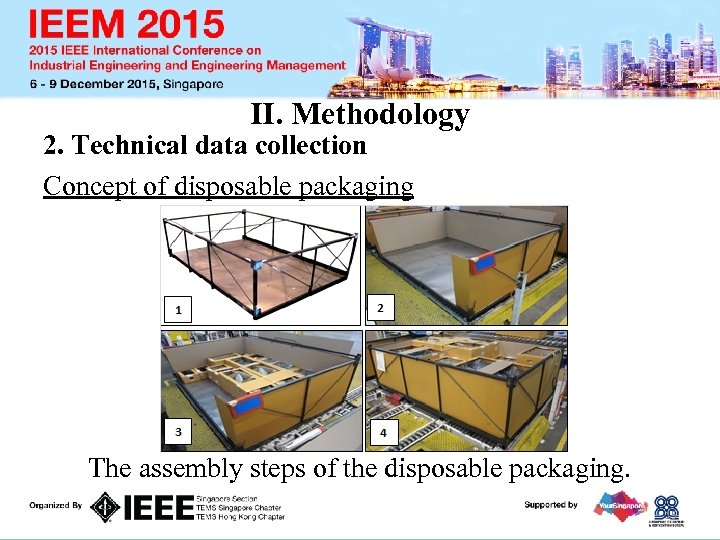

II. Methodology 2. Technical data collection Concept of disposable packaging The assembly steps of the disposable packaging. 15

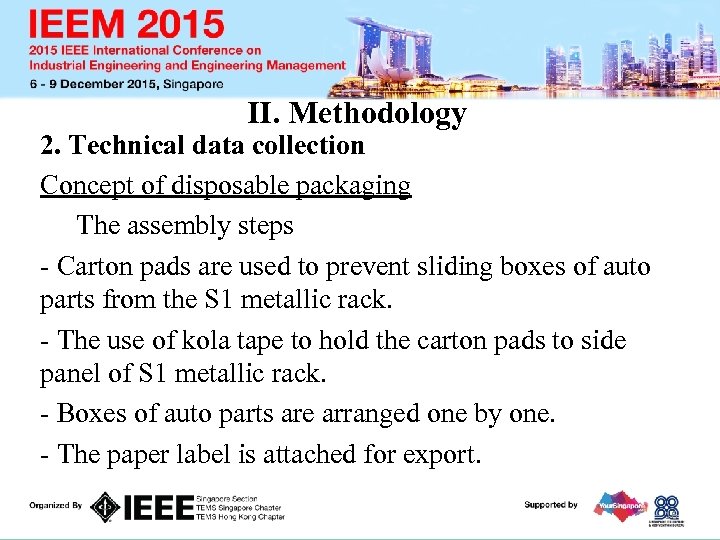

II. Methodology 2. Technical data collection Concept of disposable packaging The assembly steps - Carton pads are used to prevent sliding boxes of auto parts from the S 1 metallic rack. - The use of kola tape to hold the carton pads to side panel of S 1 metallic rack. - Boxes of auto parts are arranged one by one. - The paper label is attached for export. 16

II. Methodology 2. Technical data collection Concept of returnable packaging Only S 1 metallic rack was developed from disposable to returnable packaging in order to reduce inventory management of various types of packaging, the concept was described as follows: - Dimension was same as current disposable packaging to hold all of auto parts in a 40 foot export container. 17

II. Methodology 2. Technical data collection Concept of returnable packaging - The strength of structure was improved to extend lifetime of packaging. - Steel plates were added at the side panel of S 1 metallic rack instead of carton pads to prevent sliding boxes of auto parts. - Carton pads and kola tape were not required. - The packaging was painted to prevent rust. 18

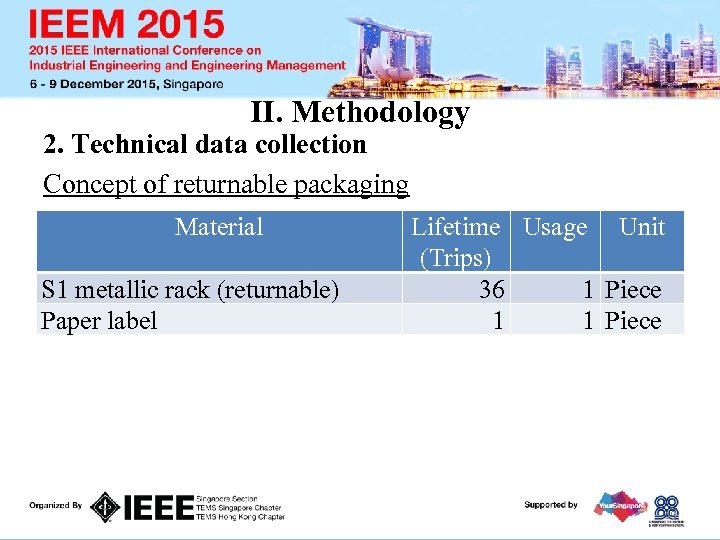

II. Methodology 2. Technical data collection Concept of returnable packaging Materials used in the returnable packaging. Material Lifetime Usage S 1 metallic rack (returnable) Paper label (Trips) 36 1 Unit 1 Piece 19

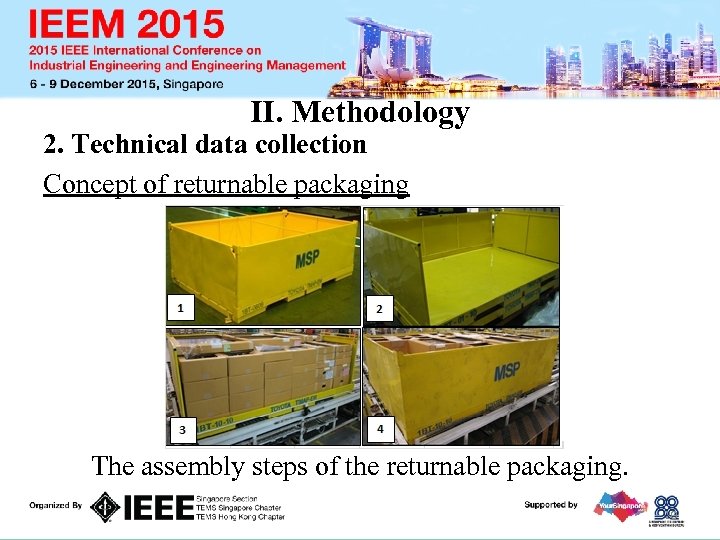

II. Methodology 2. Technical data collection Concept of returnable packaging The assembly steps of the returnable packaging. 20

II. Methodology 2. Technical data collection Concept of returnable packaging The assembly steps - Boxes of auto parts are arranged one by one. - The paper label is attached for export. 21

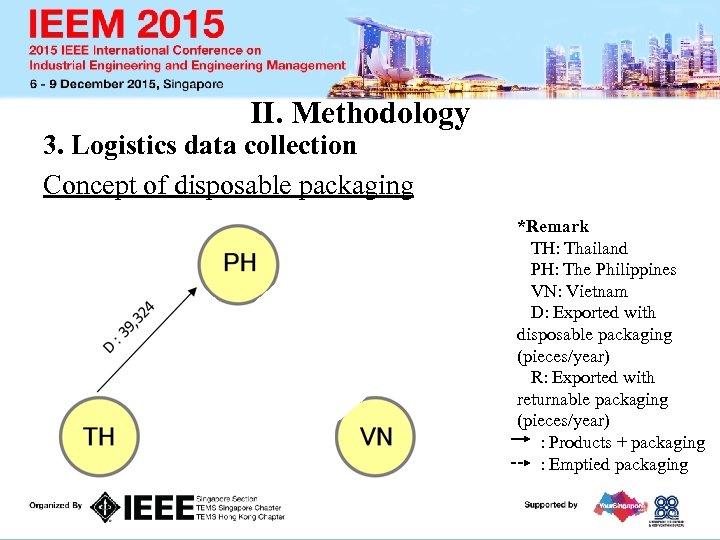

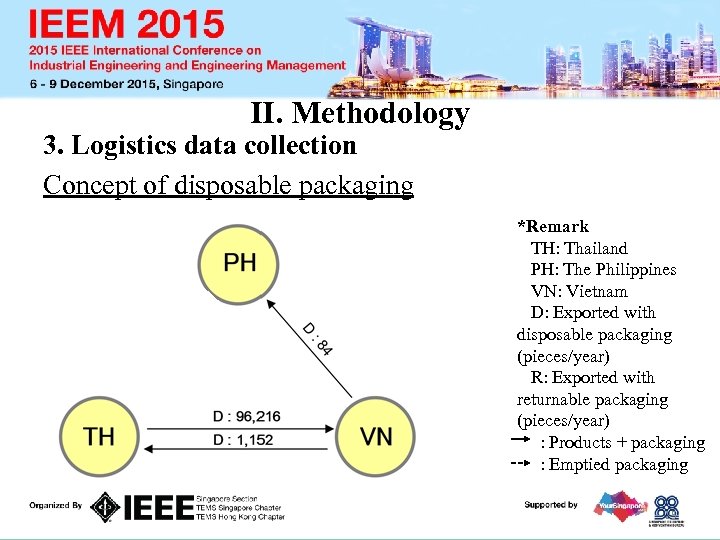

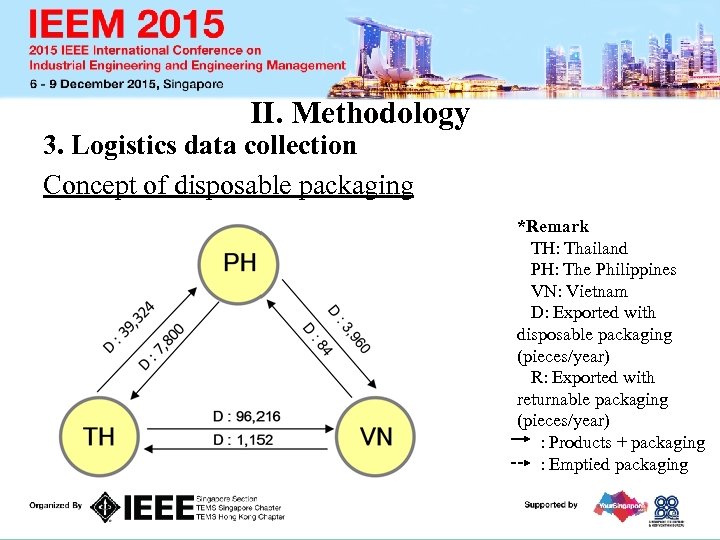

II. Methodology 3. Logistics data collection Concept of disposable packaging *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 22

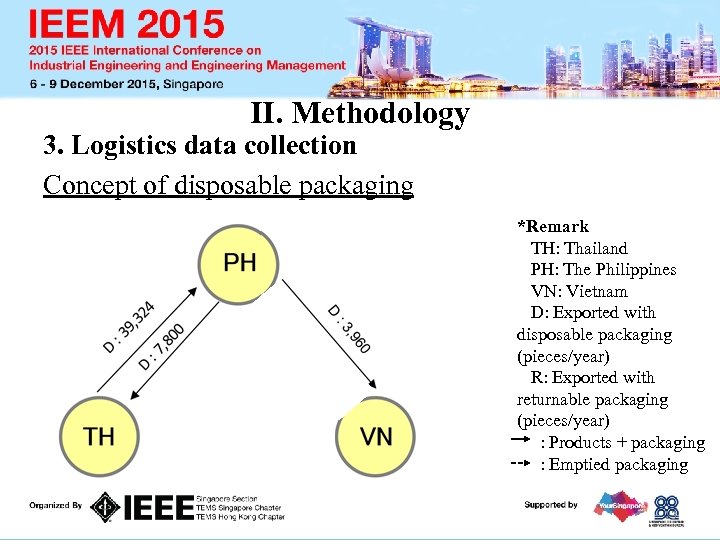

II. Methodology 3. Logistics data collection Concept of disposable packaging *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 23

II. Methodology 3. Logistics data collection Concept of disposable packaging *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 24

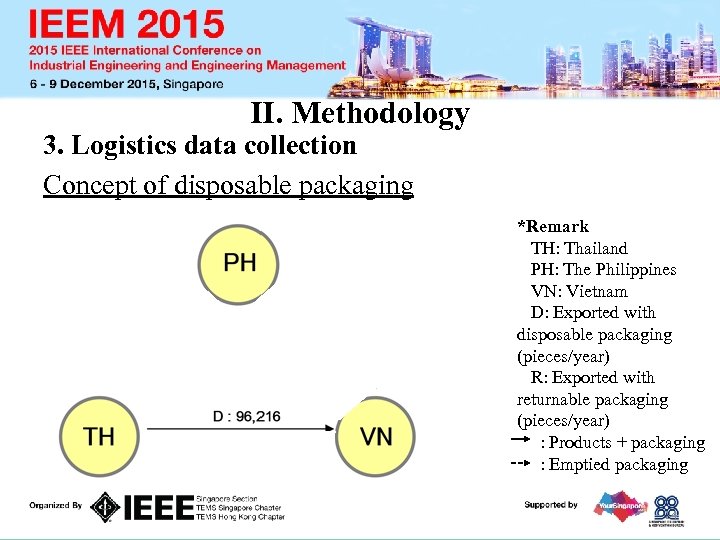

II. Methodology 3. Logistics data collection Concept of disposable packaging *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 25

II. Methodology 3. Logistics data collection Concept of disposable packaging *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 26

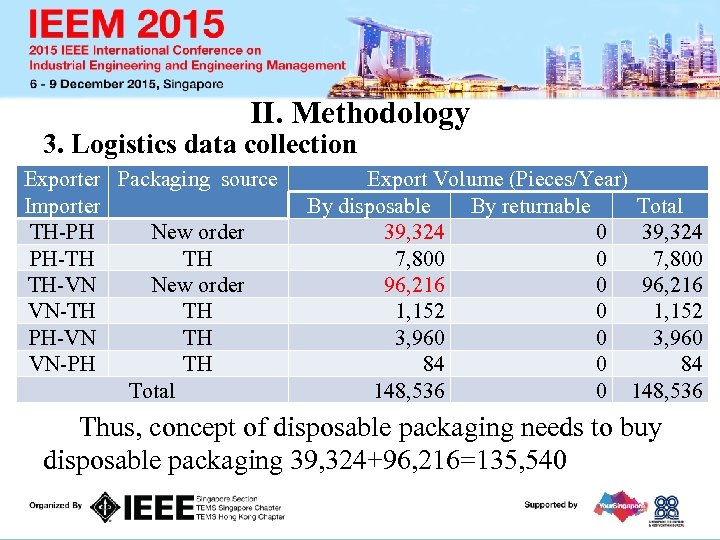

II. Methodology 3. Logistics data collection Exporter Packaging source packaging Volume (Pieces/Year) Export Concept of disposable Importer TH-PH PH-TH TH-VN VN-TH PH-VN VN-PH New order TH TH TH Total By disposable 39, 324 7, 800 96, 216 1, 152 3, 960 84 148, 536 By returnable 0 0 0 0 Total 39, 324 7, 800 96, 216 1, 152 3, 960 84 148, 536 Thus, concept of disposable packaging needs to buy disposable packaging 39, 324+96, 216=135, 540 27

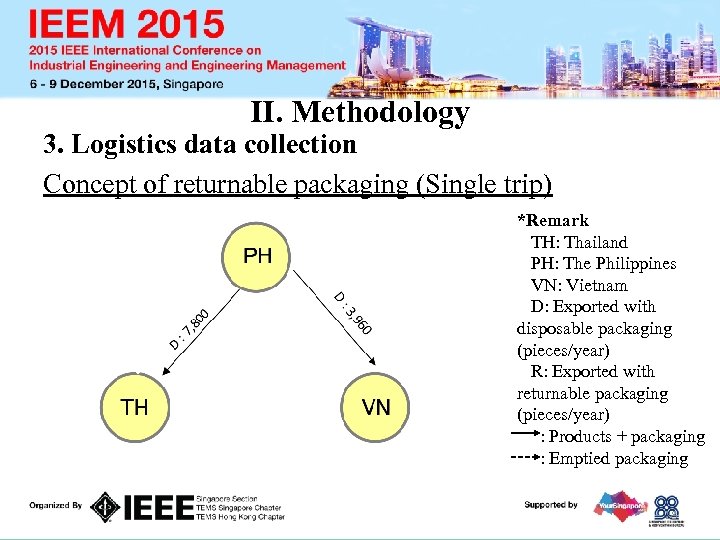

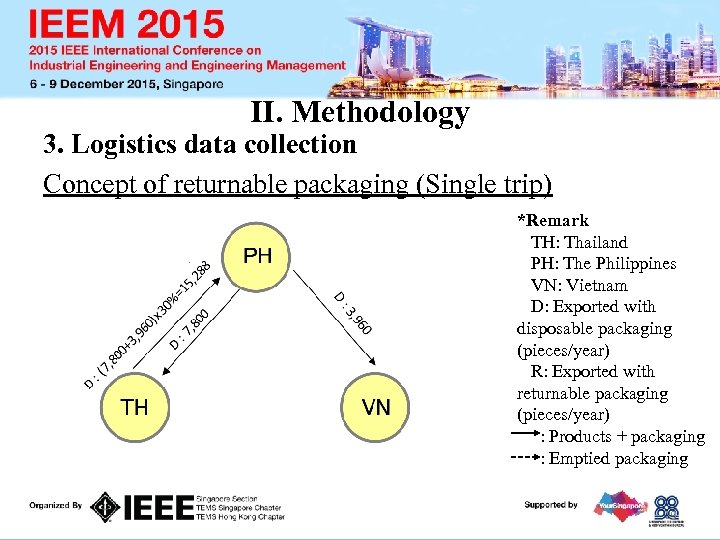

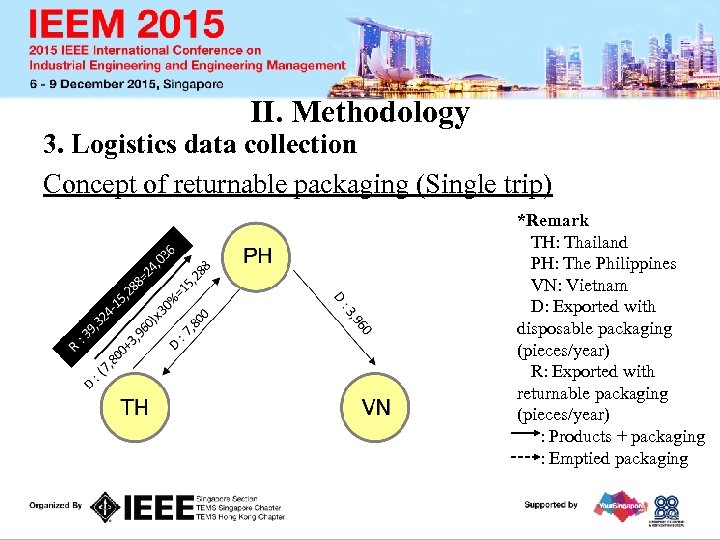

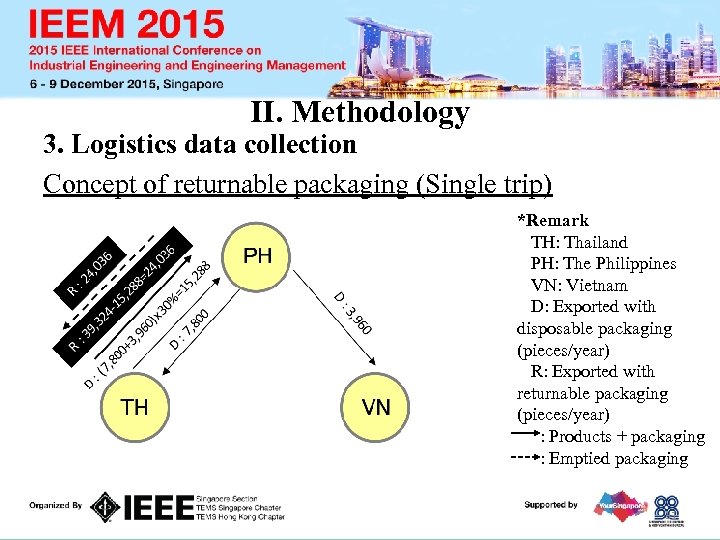

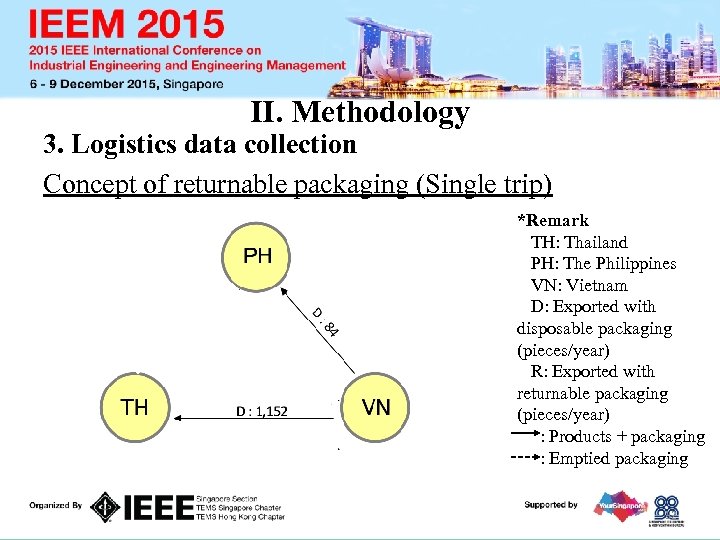

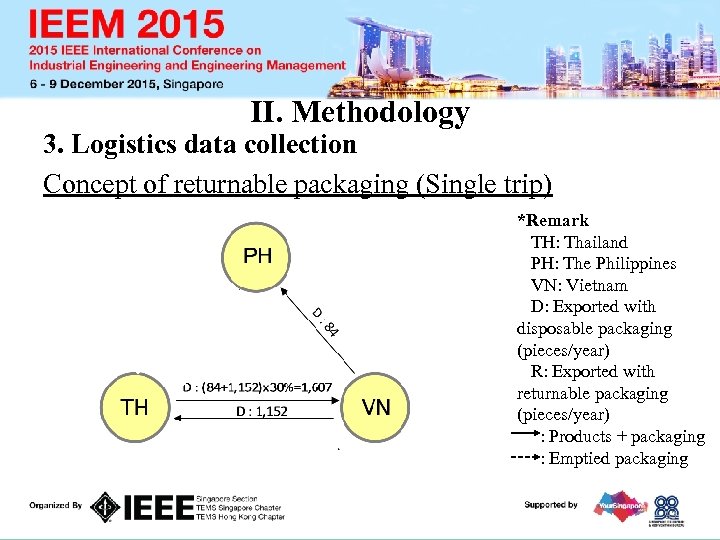

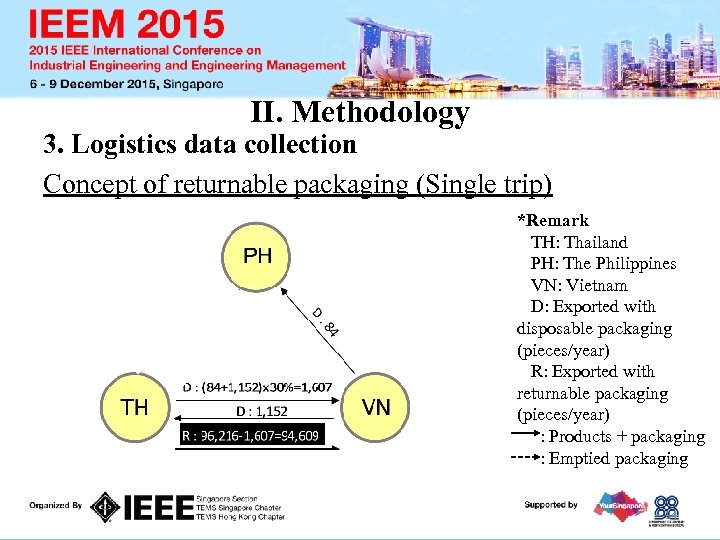

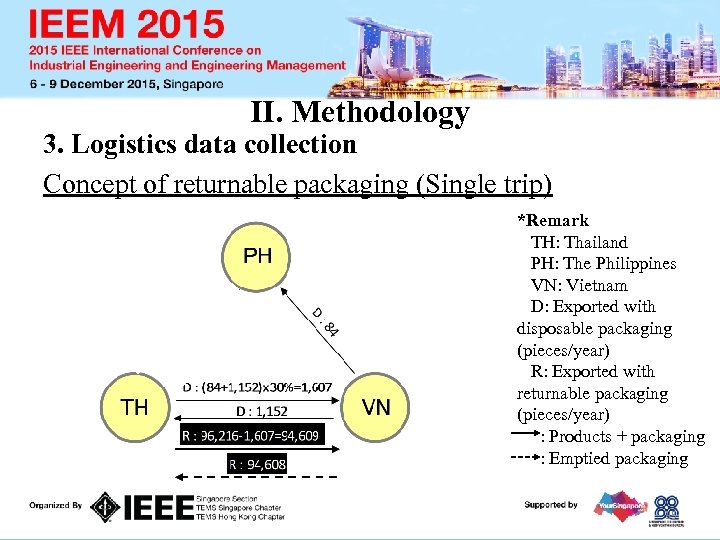

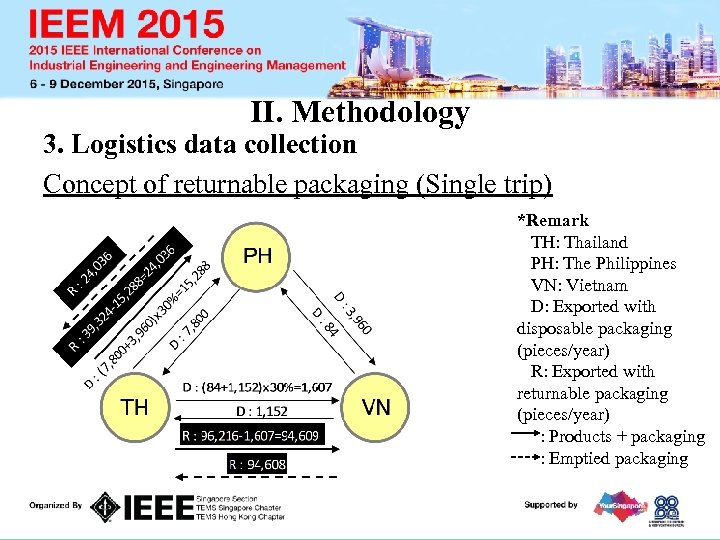

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 28

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 29

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 30

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 31

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 32

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 33

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 34

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 35

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 36

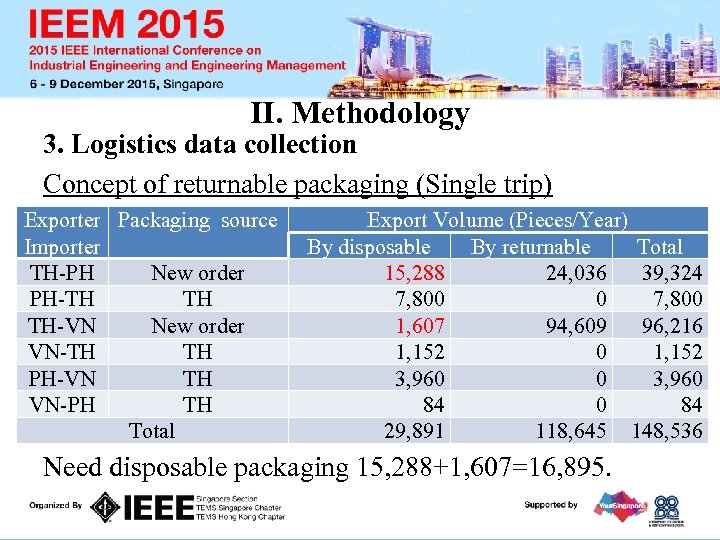

II. Methodology 3. Logistics data collection Concept of returnable packaging (Single trip) Exporter Packaging source Importer TH-PH New order PH-TH TH TH-VN New order VN-TH TH PH-VN TH VN-PH TH Total Export Volume (Pieces/Year) By disposable By returnable Total 15, 288 24, 036 39, 324 7, 800 0 7, 800 1, 607 94, 609 96, 216 1, 152 0 1, 152 3, 960 0 3, 960 84 29, 891 118, 645 148, 536 Need disposable packaging 15, 288+1, 607=16, 895. 37

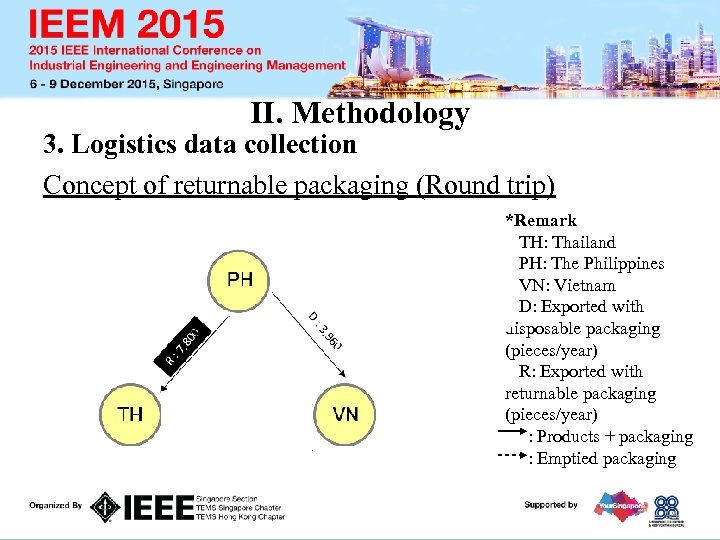

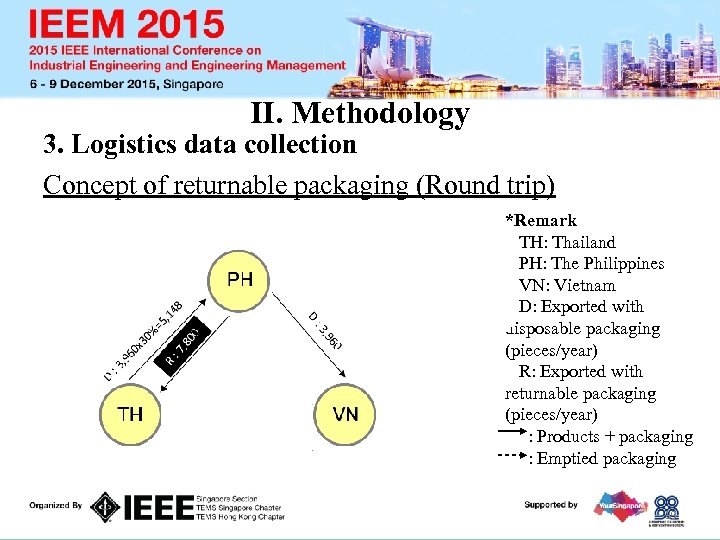

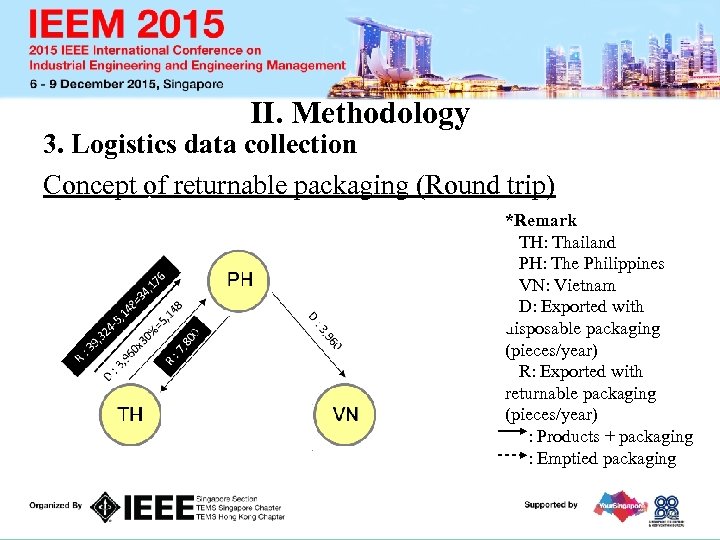

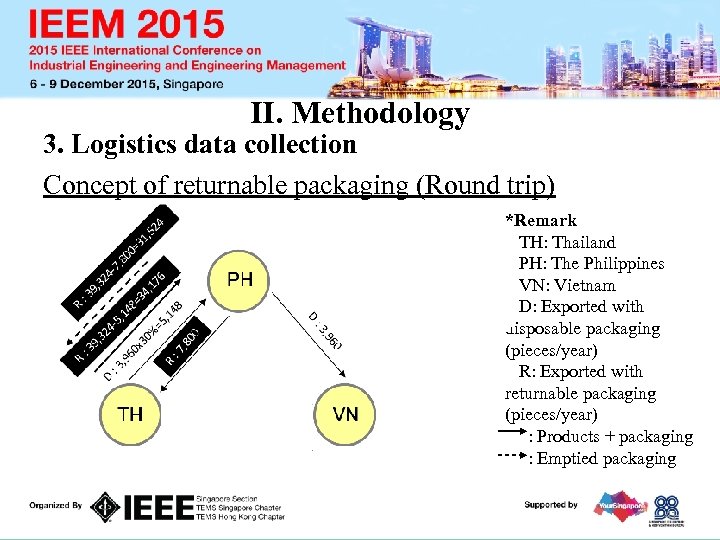

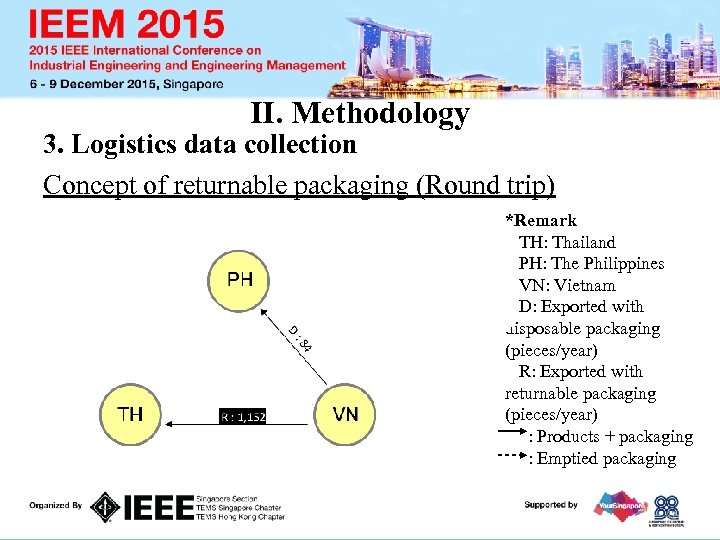

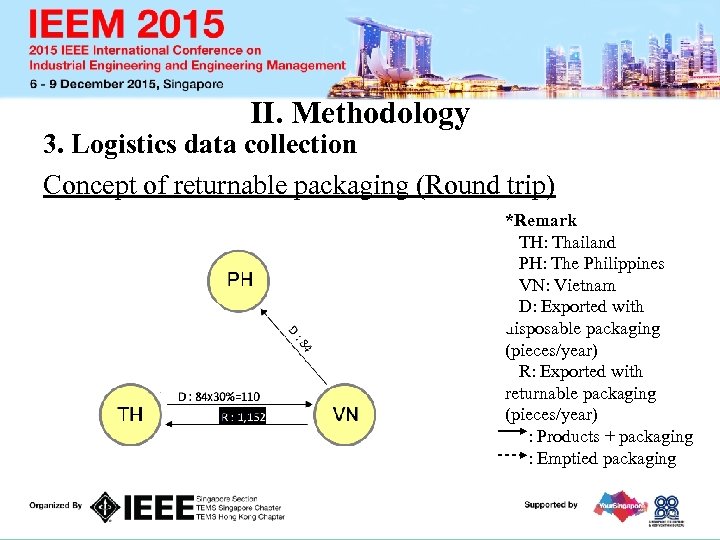

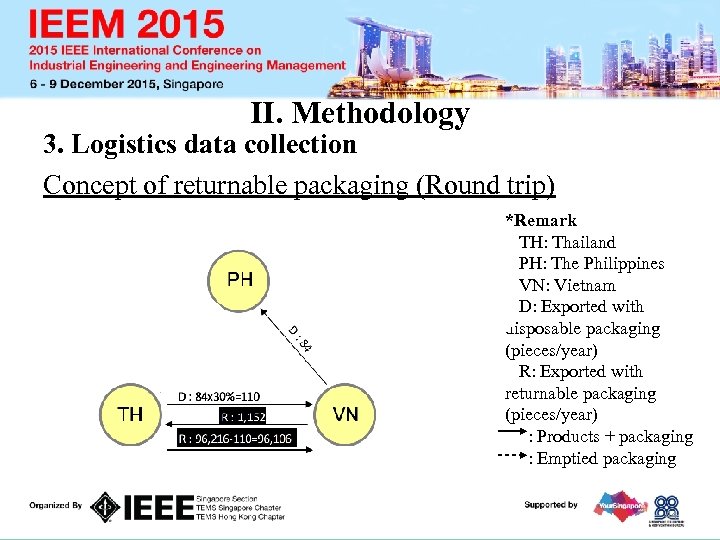

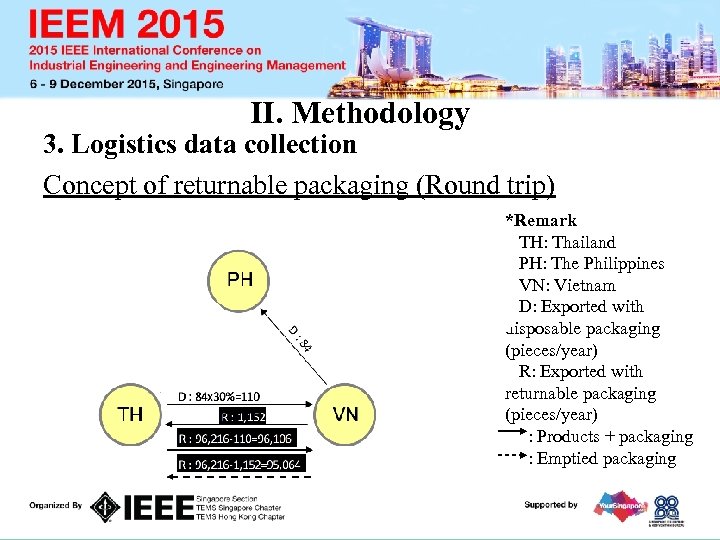

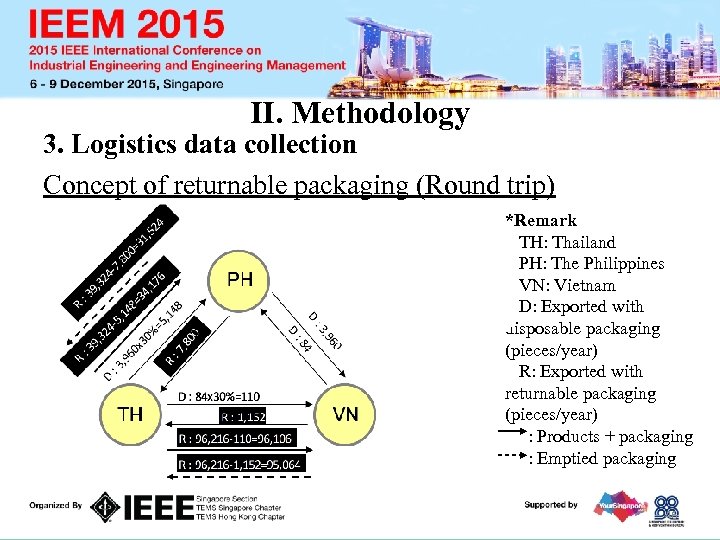

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 38

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 39

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 40

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 41

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 42

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 43

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 44

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 45

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) *Remark TH: Thailand PH: The Philippines VN: Vietnam D: Exported with disposable packaging (pieces/year) R: Exported with returnable packaging (pieces/year) : Products + packaging : Emptied packaging 46

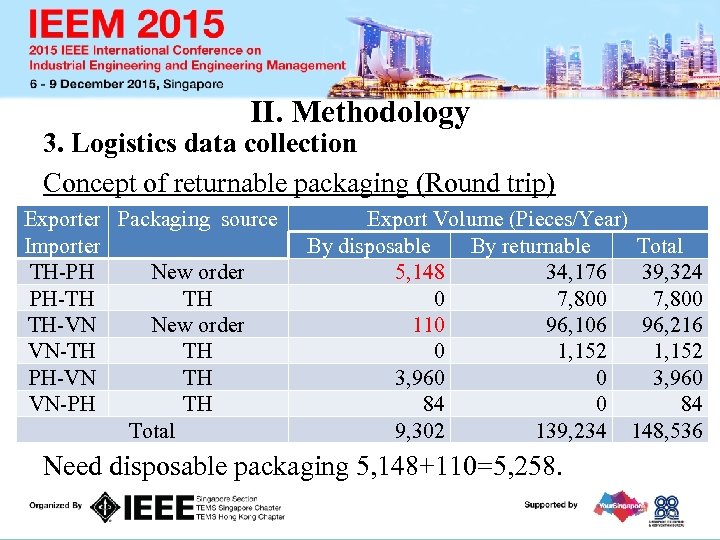

II. Methodology 3. Logistics data collection Concept of returnable packaging (Round trip) Exporter Packaging source Importer TH-PH New order PH-TH TH TH-VN New order VN-TH TH PH-VN TH VN-PH TH Total Export Volume (Pieces/Year) By disposable By returnable Total 5, 148 34, 176 39, 324 0 7, 800 110 96, 106 96, 216 0 1, 152 3, 960 0 3, 960 84 9, 302 139, 234 148, 536 Need disposable packaging 5, 148+110=5, 258. 47

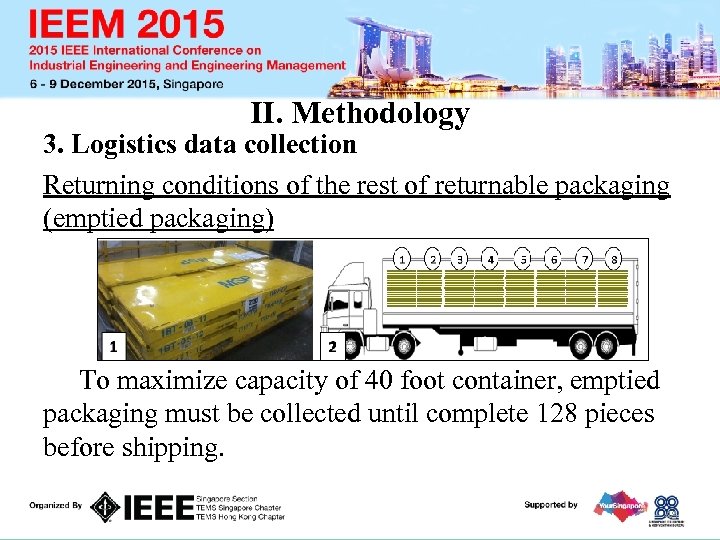

II. Methodology 3. Logistics data collection Returning conditions of the rest of returnable packaging (emptied packaging) To maximize capacity of 40 foot container, emptied packaging must be collected until complete 128 pieces before shipping. 48

II. Methodology 4. Packaging waste calculation Before improvement - Exported with disposable packaging. After improvement - Exported with returnable packaging (Single trip) - Exported with returnable packaging (Round trip) 49

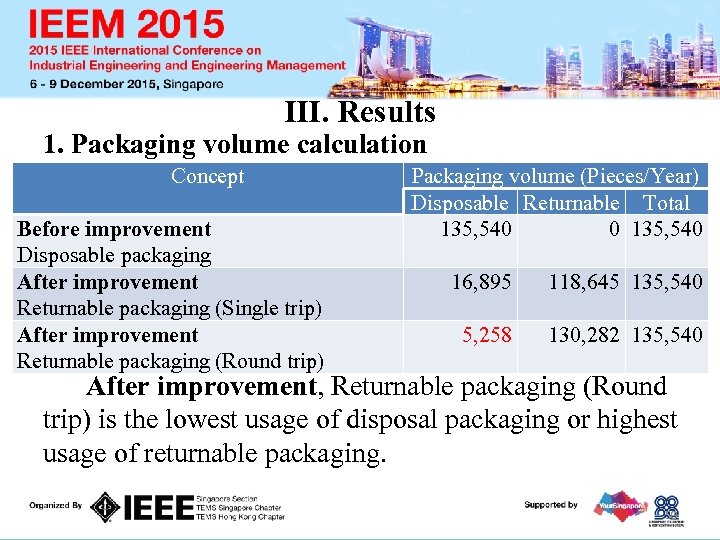

III. Results 1. Packaging volume calculation Concept Before improvement Disposable packaging After improvement Returnable packaging (Single trip) After improvement Returnable packaging (Round trip) Packaging volume (Pieces/Year) Disposable Returnable Total 135, 540 0 135, 540 16, 895 118, 645 135, 540 5, 258 130, 282 135, 540 After improvement, Returnable packaging (Round trip) is the lowest usage of disposal packaging or highest usage of returnable packaging. 50

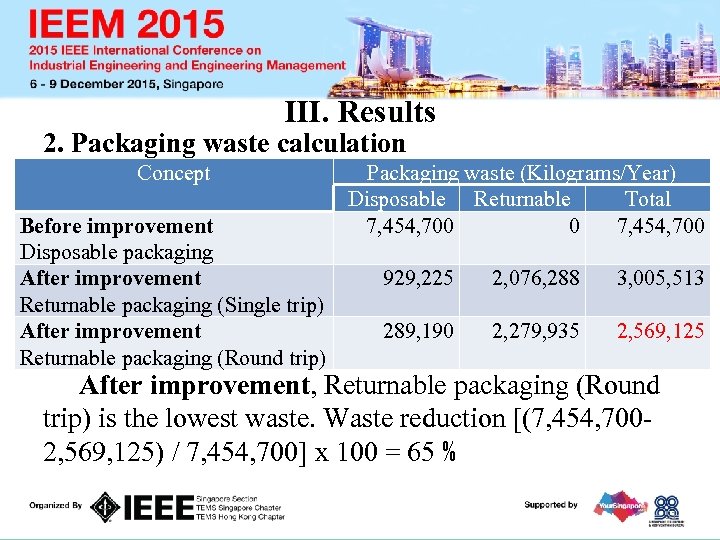

III. Results 2. Packaging waste calculation Concept Before improvement Disposable packaging After improvement Returnable packaging (Single trip) After improvement Returnable packaging (Round trip) Packaging waste (Kilograms/Year) Disposable Returnable Total 7, 454, 700 0 7, 454, 700 929, 225 2, 076, 288 3, 005, 513 289, 190 2, 279, 935 2, 569, 125 After improvement, Returnable packaging (Round trip) is the lowest waste. Waste reduction [(7, 454, 7002, 569, 125) / 7, 454, 700] x 100 = 65 % 51

IV. Conclusion We presents a case study of reverse logistics of returnable packaging used to transport auto parts among 3 countries in replacement for its usual disposable packaging including concept of Single trip and Round trip. Therefore, a waste reducing analysis was calculated, the result shows that returnable packaging by concept of Round trip is the best option, can reduce waste 65% that contribute to the sustainable development of the company. 52

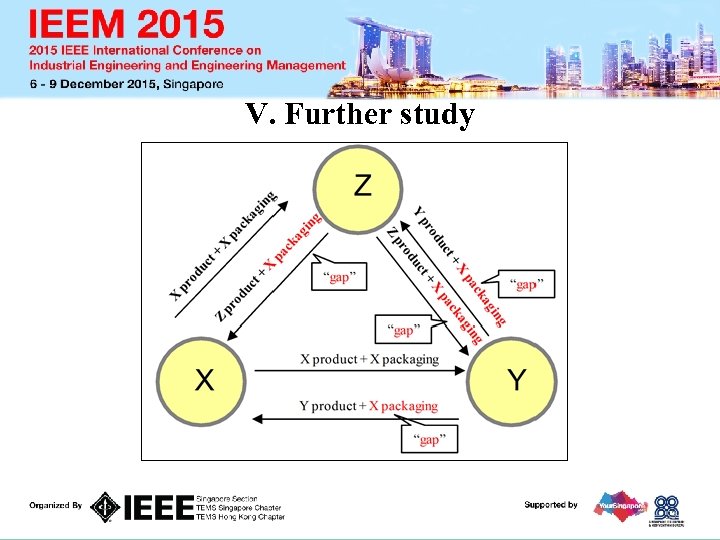

V. Further study 53

V. Further study discusses a study on “Multi trip”. Multi trip is X export “product + returnable packaging” to Y & Z, after Y & Z unpacking, Y & Z would not return “emptied packaging” to X same as Single trip but Y can use returnable packaging from X to export to X & Z, Z can use returnable packaging from X to export to X & Y. 54

Thank you 55

824ea02deb30cd7a546122f4ab6ea9ca.ppt