7c4d0290e85d286baded53fbbbf9845b.ppt

- Количество слайдов: 23

WARM ASPHALT MIXTURES Necessity for a thermal approach The case of LEA Y. Martineau LEA-CO USIRF 31 th MAY 2007

WARM ASPHALT MIXTURES Necessity for a thermal approach The case of LEA Y. Martineau LEA-CO USIRF 31 th MAY 2007

Change in coating practice Warm Mix n Warm or Half-Warm Mixtures ? Warm above 100°C Half-Warm under 100°C n What is the right choice ?

Change in coating practice Warm Mix n Warm or Half-Warm Mixtures ? Warm above 100°C Half-Warm under 100°C n What is the right choice ?

Energy conditions the characterisrics and performances of asphalt mixtures An happy influence on environment q The reduction of heating energy produce the same level of reduction on Green House Gas emission Influence of a full or partial, water elimination A possible non happy influence on the mixture characteristics q Properties for production and placing mixtures q Mechanical performances

Energy conditions the characterisrics and performances of asphalt mixtures An happy influence on environment q The reduction of heating energy produce the same level of reduction on Green House Gas emission Influence of a full or partial, water elimination A possible non happy influence on the mixture characteristics q Properties for production and placing mixtures q Mechanical performances

Warm mixtures : a global approach including, thermal, mechanical and chemical concepts. Use the different physical state of asphalt binder. Chemical additives to minimize the influence of water During mixing, inter-action between physical characteristic, temperature, existing water and mechanical effect Analysis of thermal content and thermal transfer between components.

Warm mixtures : a global approach including, thermal, mechanical and chemical concepts. Use the different physical state of asphalt binder. Chemical additives to minimize the influence of water During mixing, inter-action between physical characteristic, temperature, existing water and mechanical effect Analysis of thermal content and thermal transfer between components.

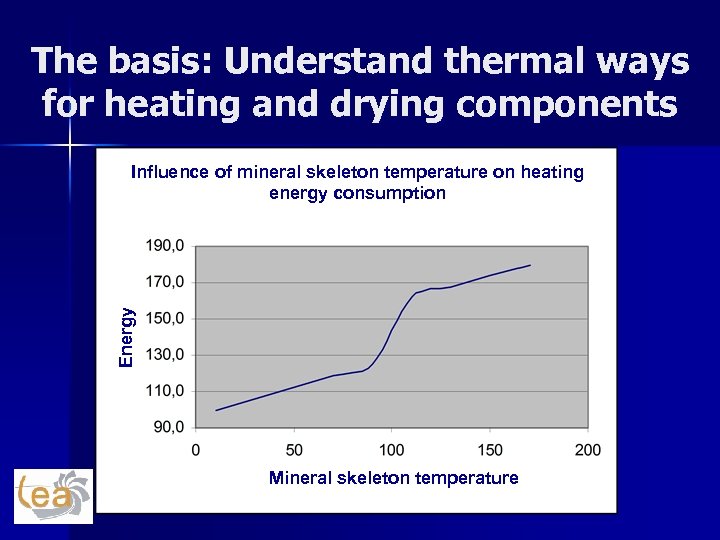

The basis: Understand thermal ways for heating and drying components Energy Influence of mineral skeleton temperature on heating energy consumption Mineral skeleton temperature

The basis: Understand thermal ways for heating and drying components Energy Influence of mineral skeleton temperature on heating energy consumption Mineral skeleton temperature

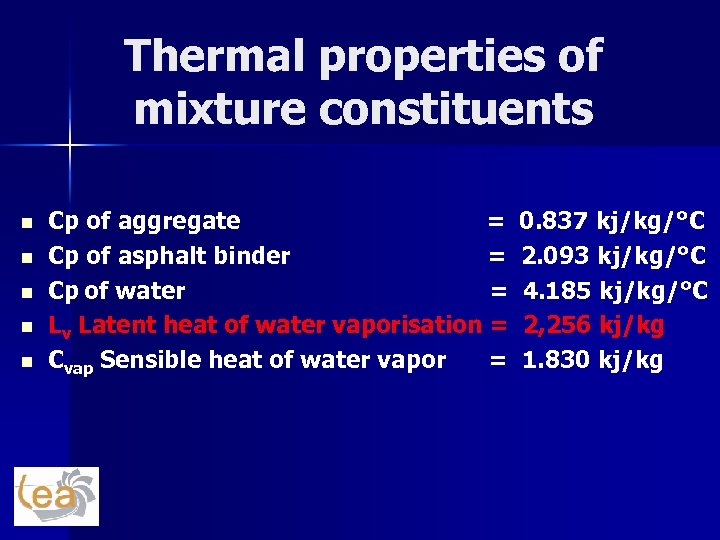

Thermal properties of mixture constituents n n n Cp of aggregate = Cp of asphalt binder = Cp of water = Lv Latent heat of water vaporisation = Cvap Sensible heat of water vapor = 0. 837 kj/kg/°C 2. 093 kj/kg/°C 4. 185 kj/kg/°C 2, 256 kj/kg 1. 830 kj/kg

Thermal properties of mixture constituents n n n Cp of aggregate = Cp of asphalt binder = Cp of water = Lv Latent heat of water vaporisation = Cvap Sensible heat of water vapor = 0. 837 kj/kg/°C 2. 093 kj/kg/°C 4. 185 kj/kg/°C 2, 256 kj/kg 1. 830 kj/kg

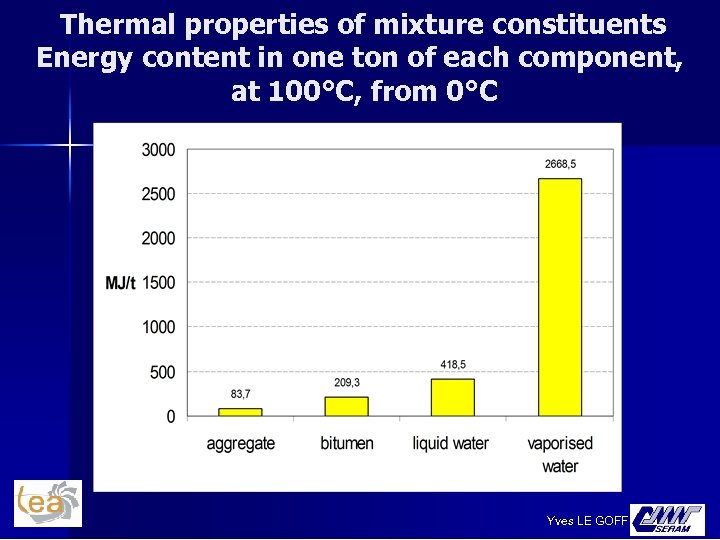

Thermal properties of mixture constituents Energy content in one ton of each component, at 100°C, from 0°C Yves LE GOFF

Thermal properties of mixture constituents Energy content in one ton of each component, at 100°C, from 0°C Yves LE GOFF

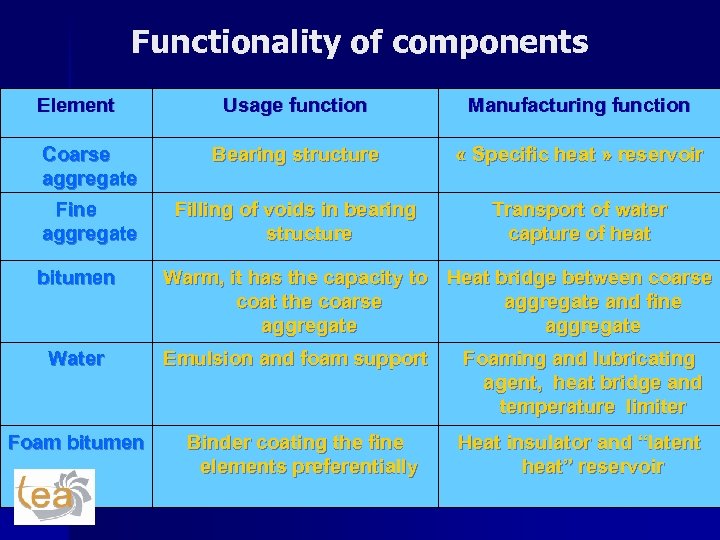

Functionality of components Element Usage function Manufacturing function Coarse aggregate Bearing structure « Specific heat » reservoir Fine aggregate Filling of voids in bearing structure Transport of water capture of heat bitumen Water Foam bitumen Warm, it has the capacity to Heat bridge between coarse coat the coarse aggregate and fine aggregate Emulsion and foam support Foaming and lubricating agent, heat bridge and temperature limiter Binder coating the fine elements preferentially Heat insulator and “latent heat” reservoir

Functionality of components Element Usage function Manufacturing function Coarse aggregate Bearing structure « Specific heat » reservoir Fine aggregate Filling of voids in bearing structure Transport of water capture of heat bitumen Water Foam bitumen Warm, it has the capacity to Heat bridge between coarse coat the coarse aggregate and fine aggregate Emulsion and foam support Foaming and lubricating agent, heat bridge and temperature limiter Binder coating the fine elements preferentially Heat insulator and “latent heat” reservoir

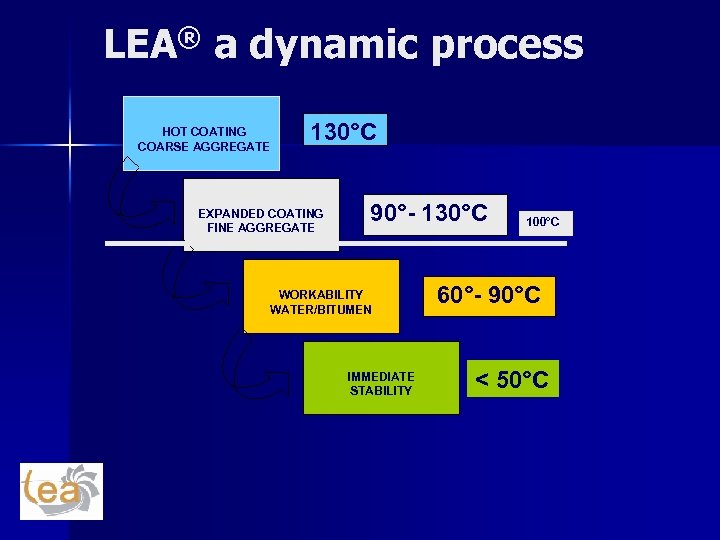

LEA® a dynamic process HOT COATING COARSE AGGREGATE 130°C EXPANDED COATING FINE AGGREGATE 90°- 130°C WORKABILITY WATER/BITUMEN IMMEDIATE STABILITY 100°C 60°- 90°C < 50°C

LEA® a dynamic process HOT COATING COARSE AGGREGATE 130°C EXPANDED COATING FINE AGGREGATE 90°- 130°C WORKABILITY WATER/BITUMEN IMMEDIATE STABILITY 100°C 60°- 90°C < 50°C

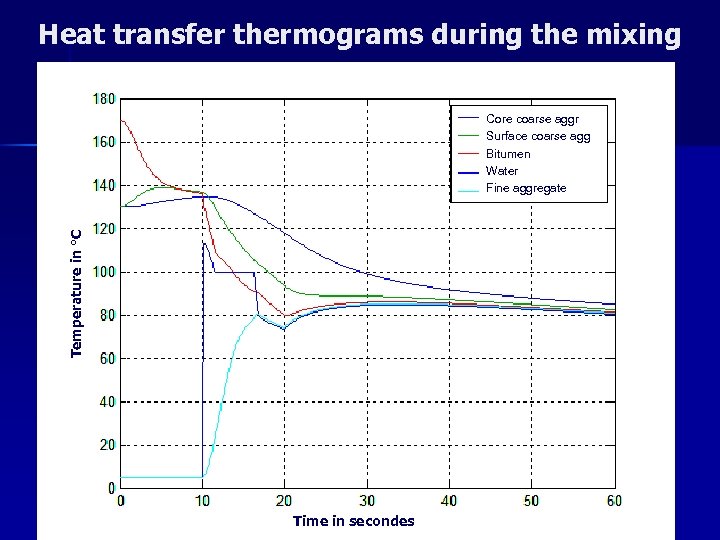

Heat transfer thermograms during the mixing Temperature in °C Core coarse aggr Surface coarse agg Bitumen Water Fine aggregate Time in secondes

Heat transfer thermograms during the mixing Temperature in °C Core coarse aggr Surface coarse agg Bitumen Water Fine aggregate Time in secondes

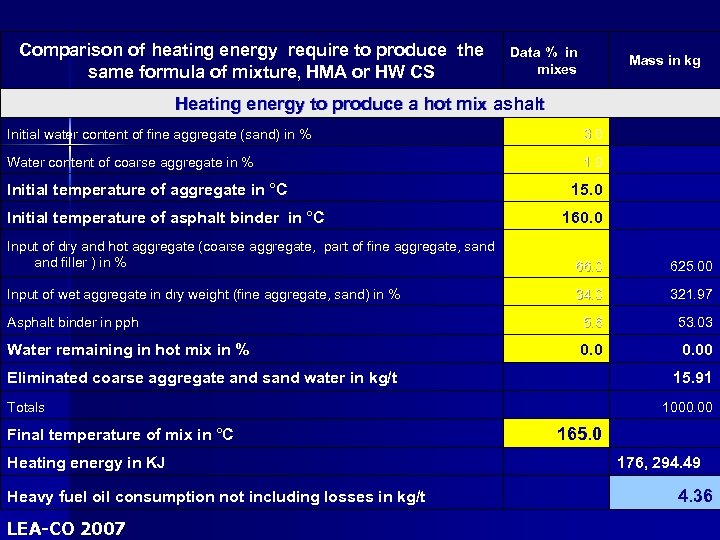

Comparison of heating energy require to produce the same formula of mixture, HMA or HW CS Data % in mixes Mass in kg Heating energy to produce a hot mix ashalt Initial water content of fine aggregate (sand) in % 3. 0 Water content of coarse aggregate in % 1. 0 Initial temperature of aggregate in °C 15. 0 Initial temperature of asphalt binder in °C 160. 0 Input of dry and hot aggregate (coarse aggregate, part of fine aggregate, sand filler ) in % 66. 0 625. 00 Input of wet aggregate in dry weight (fine aggregate, sand) in % 34. 0 321. 97 Asphalt binder in pph 5. 6 53. 03 Water remaining in hot mix in % 0. 00 Eliminated coarse aggregate and sand water in kg/t 15. 91 Totals 1000. 00 165. 0 Final temperature of mix in °C Heating energy in KJ Heavy fuel oil consumption not including losses in kg/t LEA-CO 2007 176, 294. 49 4. 36

Comparison of heating energy require to produce the same formula of mixture, HMA or HW CS Data % in mixes Mass in kg Heating energy to produce a hot mix ashalt Initial water content of fine aggregate (sand) in % 3. 0 Water content of coarse aggregate in % 1. 0 Initial temperature of aggregate in °C 15. 0 Initial temperature of asphalt binder in °C 160. 0 Input of dry and hot aggregate (coarse aggregate, part of fine aggregate, sand filler ) in % 66. 0 625. 00 Input of wet aggregate in dry weight (fine aggregate, sand) in % 34. 0 321. 97 Asphalt binder in pph 5. 6 53. 03 Water remaining in hot mix in % 0. 00 Eliminated coarse aggregate and sand water in kg/t 15. 91 Totals 1000. 00 165. 0 Final temperature of mix in °C Heating energy in KJ Heavy fuel oil consumption not including losses in kg/t LEA-CO 2007 176, 294. 49 4. 36

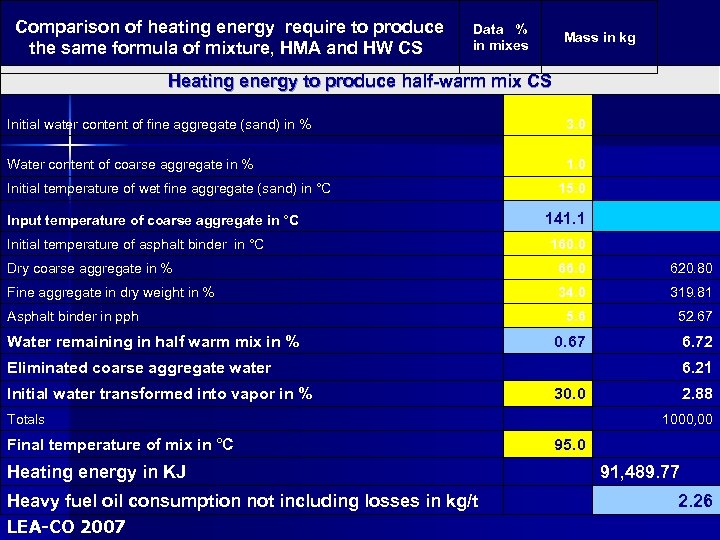

Comparison of heating energy require to produce the same formula of mixture, HMA and HW CS Data % in mixes Mass in kg Heating energy to produce half-warm mix CS Initial water content of fine aggregate (sand) in % 3. 0 Water content of coarse aggregate in % 1. 0 Initial temperature of wet fine aggregate (sand) in °C 15. 0 141. 1 Input temperature of coarse aggregate in °C Initial temperature of asphalt binder in °C 160. 0 Dry coarse aggregate in % 66. 0 620. 80 Fine aggregate in dry weight in % 34. 0 319. 81 5. 6 52. 67 0. 67 6. 72 Asphalt binder in pph Water remaining in half warm mix in % Eliminated coarse aggregate water Initial water transformed into vapor in % Totals 6. 21 30. 0 2. 88 Final temperature of mix in °C 1000, 00 95. 0 Heating energy in KJ Heavy fuel oil consumption not including losses in kg/t LEA-CO 2007 91, 489. 77 2. 26

Comparison of heating energy require to produce the same formula of mixture, HMA and HW CS Data % in mixes Mass in kg Heating energy to produce half-warm mix CS Initial water content of fine aggregate (sand) in % 3. 0 Water content of coarse aggregate in % 1. 0 Initial temperature of wet fine aggregate (sand) in °C 15. 0 141. 1 Input temperature of coarse aggregate in °C Initial temperature of asphalt binder in °C 160. 0 Dry coarse aggregate in % 66. 0 620. 80 Fine aggregate in dry weight in % 34. 0 319. 81 5. 6 52. 67 0. 67 6. 72 Asphalt binder in pph Water remaining in half warm mix in % Eliminated coarse aggregate water Initial water transformed into vapor in % Totals 6. 21 30. 0 2. 88 Final temperature of mix in °C 1000, 00 95. 0 Heating energy in KJ Heavy fuel oil consumption not including losses in kg/t LEA-CO 2007 91, 489. 77 2. 26

The model can be applied to: Laboratory mix design, Industrial production, Industrial quality control, for any type of warm or half-warm mix and hot mix

The model can be applied to: Laboratory mix design, Industrial production, Industrial quality control, for any type of warm or half-warm mix and hot mix

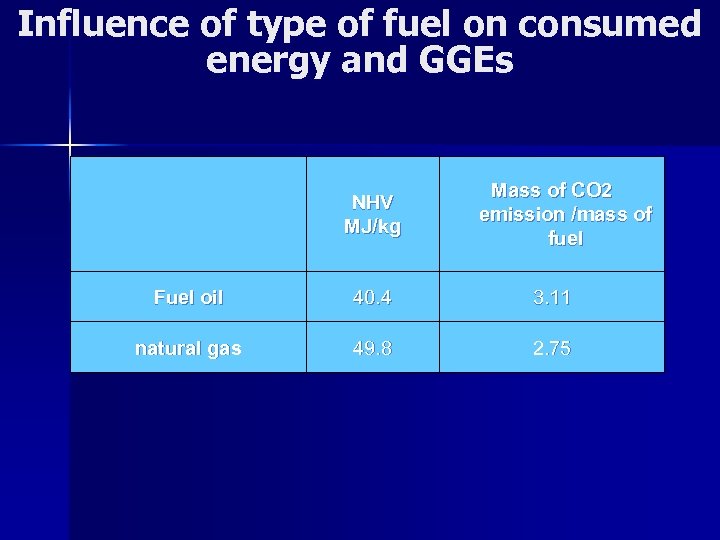

Influence of type of fuel on consumed energy and GGEs NHV MJ/kg Mass of CO 2 emission /mass of fuel Fuel oil 40. 4 3. 11 natural gas 49. 8 2. 75

Influence of type of fuel on consumed energy and GGEs NHV MJ/kg Mass of CO 2 emission /mass of fuel Fuel oil 40. 4 3. 11 natural gas 49. 8 2. 75

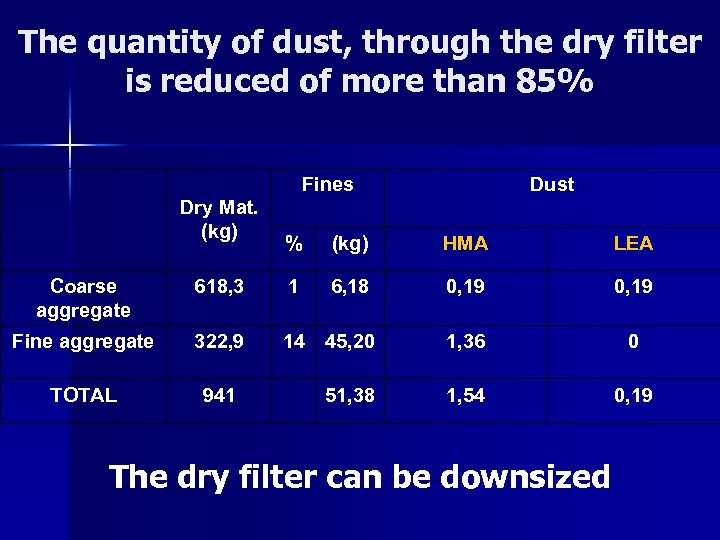

The quantity of dust, through the dry filter is reduced of more than 85% Fines Dry Mat. (kg) Dust % (kg) HMA LEA Coarse aggregate 618, 3 1 6, 18 0, 19 Fine aggregate 322, 9 14 45, 20 1, 36 0 TOTAL 941 51, 38 1, 54 0, 19 The dry filter can be downsized

The quantity of dust, through the dry filter is reduced of more than 85% Fines Dry Mat. (kg) Dust % (kg) HMA LEA Coarse aggregate 618, 3 1 6, 18 0, 19 Fine aggregate 322, 9 14 45, 20 1, 36 0 TOTAL 941 51, 38 1, 54 0, 19 The dry filter can be downsized

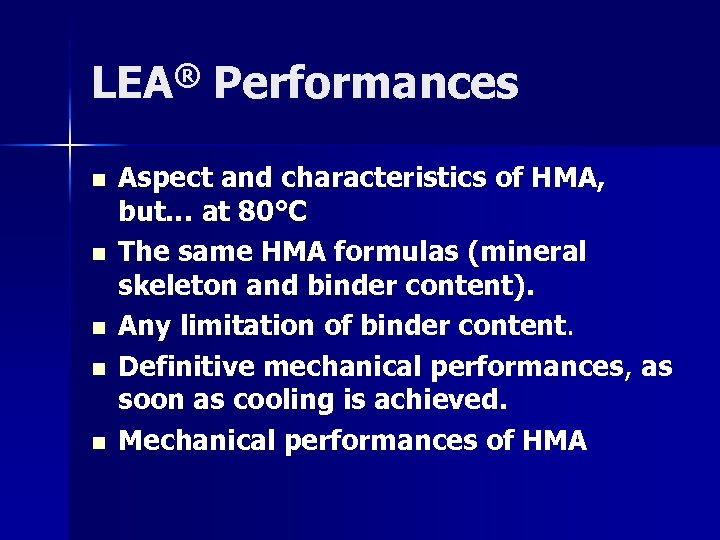

LEA® Performances n n n Aspect and characteristics of HMA, but… at 80°C The same HMA formulas (mineral skeleton and binder content). Any limitation of binder content. Definitive mechanical performances, as soon as cooling is achieved. Mechanical performances of HMA

LEA® Performances n n n Aspect and characteristics of HMA, but… at 80°C The same HMA formulas (mineral skeleton and binder content). Any limitation of binder content. Definitive mechanical performances, as soon as cooling is achieved. Mechanical performances of HMA

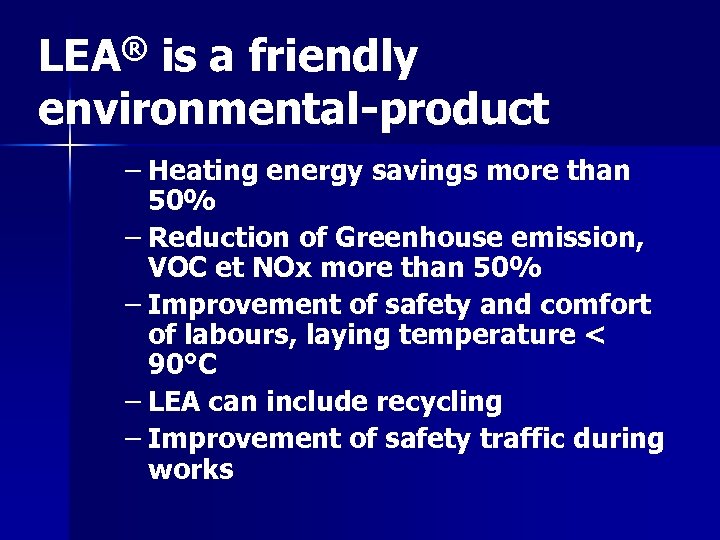

LEA® is a friendly environmental-product – Heating energy savings more than 50% – Reduction of Greenhouse emission, VOC et NOx more than 50% – Improvement of safety and comfort of labours, laying temperature < 90°C – LEA can include recycling – Improvement of safety traffic during works

LEA® is a friendly environmental-product – Heating energy savings more than 50% – Reduction of Greenhouse emission, VOC et NOx more than 50% – Improvement of safety and comfort of labours, laying temperature < 90°C – LEA can include recycling – Improvement of safety traffic during works

Half-Warm Mix in industrial practices Use existing Hot Mix Asphalt plants, with complementary equipment n Apply existing standards from Hot Mix Asphalt specs n WMA Quality = HMA Quality Quantity of energy Mix temperature Water content of the mix n

Half-Warm Mix in industrial practices Use existing Hot Mix Asphalt plants, with complementary equipment n Apply existing standards from Hot Mix Asphalt specs n WMA Quality = HMA Quality Quantity of energy Mix temperature Water content of the mix n

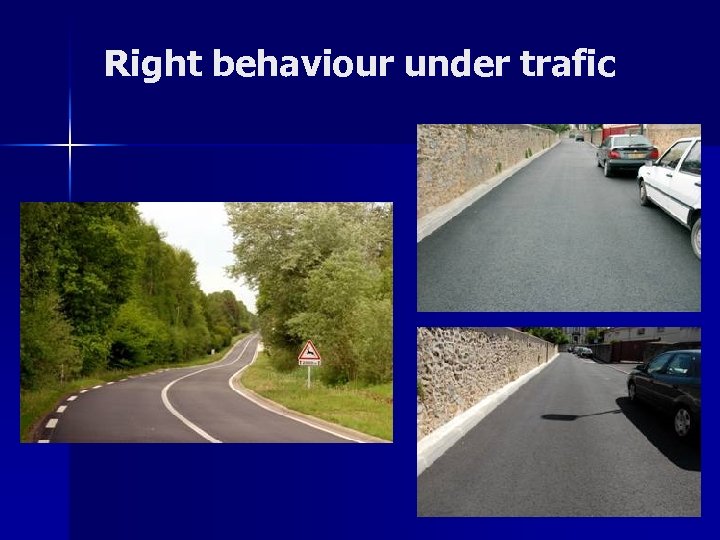

Right behaviour under trafic

Right behaviour under trafic

Cortland, DOT NY STATE, 09/09/2006

Cortland, DOT NY STATE, 09/09/2006

Cortland, DOT NY State, 09/09/2006

Cortland, DOT NY State, 09/09/2006

Cortland, DOT NY, 09/09/2006

Cortland, DOT NY, 09/09/2006

Thank you for your attention LEA-co France leaco@fairco. fr 17 rue GUTENBERG 91 620 NOZAY Tel. +33 (0)1 69 63 28 44 Fax. +33 (0)1 69 63 90 52

Thank you for your attention LEA-co France leaco@fairco. fr 17 rue GUTENBERG 91 620 NOZAY Tel. +33 (0)1 69 63 28 44 Fax. +33 (0)1 69 63 90 52