acc6a4cad45d20f74c7fddd90dc20675.ppt

- Количество слайдов: 38

Warehousing Chapter 1: Introduction Warehouse • part of a firm’s logistics system that stores products (raw material, parts, goods-in-process, finished goods) at and between point of origin and point of consumption and provides information to management on the status, condition and disposition of items being stored. • The term distribution center (DC) is sometimes used, but the terms are not identical. Warehouse is the more generic term.

Warehousing Chapter 1: Introduction Warehouse • part of a firm’s logistics system that stores products (raw material, parts, goods-in-process, finished goods) at and between point of origin and point of consumption and provides information to management on the status, condition and disposition of items being stored. • The term distribution center (DC) is sometimes used, but the terms are not identical. Warehouse is the more generic term.

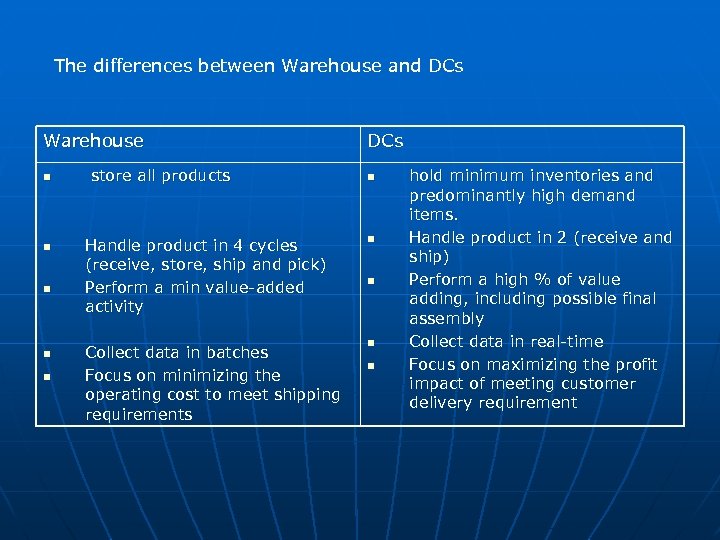

The differences between Warehouse and DCs Warehouse n n n store all products DCs n Handle product in 4 cycles (receive, store, ship and pick) Perform a min value-added activity n Collect data in batches Focus on minimizing the operating cost to meet shipping requirements n n n hold minimum inventories and predominantly high demand items. Handle product in 2 (receive and ship) Perform a high % of value adding, including possible final assembly Collect data in real-time Focus on maximizing the profit impact of meeting customer delivery requirement

The differences between Warehouse and DCs Warehouse n n n store all products DCs n Handle product in 4 cycles (receive, store, ship and pick) Perform a min value-added activity n Collect data in batches Focus on minimizing the operating cost to meet shipping requirements n n n hold minimum inventories and predominantly high demand items. Handle product in 2 (receive and ship) Perform a high % of value adding, including possible final assembly Collect data in real-time Focus on maximizing the profit impact of meeting customer delivery requirement

Strategic versus Operational Warehousing Decisions Warehousing decisions may be strategic or operational ü Strategic decision deal with the allocation of logistic resources over an extended time in a manner consistent and supportive of overall enterprise policies and objectives. • Should warehousing be owned, leased, rented or some combination of these? • Should the warehousing functions be ‘spun off’, that is contracted out to a third party provider? • Should the company install new materials handling equipment or continue to hire more labor? ü Operational decisions are used to manage or control logistics performance. For example, a warehouse manager would be concerned with how the best utilize labor in the shipping department.

Strategic versus Operational Warehousing Decisions Warehousing decisions may be strategic or operational ü Strategic decision deal with the allocation of logistic resources over an extended time in a manner consistent and supportive of overall enterprise policies and objectives. • Should warehousing be owned, leased, rented or some combination of these? • Should the warehousing functions be ‘spun off’, that is contracted out to a third party provider? • Should the company install new materials handling equipment or continue to hire more labor? ü Operational decisions are used to manage or control logistics performance. For example, a warehouse manager would be concerned with how the best utilize labor in the shipping department.

a) Nature and Importance of Warehousing has traditionally provided storage of products (referred to as inventory) during all phase of the logistics process. Two basic type of inventories can be place into storage: 1. raw materials, components, and part (physical supply); 2. finished goods (physical distribution). Why do companies hold inventories in storage? a) Achieve transportation economies b) Achieve production economies c) Maintain a source of supply d) Support the just-in-time programs of suppliers and customers

a) Nature and Importance of Warehousing has traditionally provided storage of products (referred to as inventory) during all phase of the logistics process. Two basic type of inventories can be place into storage: 1. raw materials, components, and part (physical supply); 2. finished goods (physical distribution). Why do companies hold inventories in storage? a) Achieve transportation economies b) Achieve production economies c) Maintain a source of supply d) Support the just-in-time programs of suppliers and customers

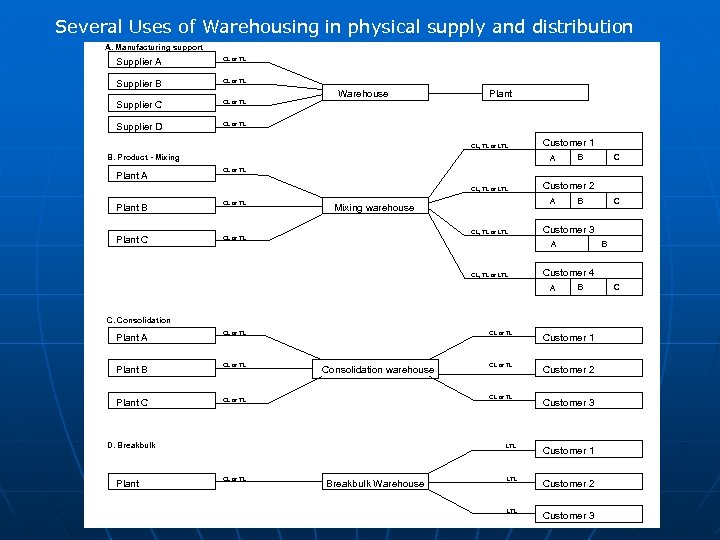

Several Uses of Warehousing in physical supply and distribution A. Manufacturing support Supplier A CL or TL Supplier B CL or TL Supplier C CL or TL Supplier D CL or TL Warehouse Plant CL, TL or LTL B. Product - Mixing Plant A Customer 1 A B CL, TL or LTL Plant B CL or TL Plant C CL or TL Customer 2 A Mixing warehouse CL, TL or LTL B B Customer 4 A B C. Consolidation Plant A CL or TL Plant B CL or TL Plant C CL or TL D. Breakbulk Customer 1 CL or TL Customer 2 CL or TL Consolidation warehouse Customer 3 LTL CL or TL Breakbulk Warehouse C Customer 3 A CL, TL or LTL Plant C CL or TL Customer 1 LTL Customer 2 LTL Customer 3 C

Several Uses of Warehousing in physical supply and distribution A. Manufacturing support Supplier A CL or TL Supplier B CL or TL Supplier C CL or TL Supplier D CL or TL Warehouse Plant CL, TL or LTL B. Product - Mixing Plant A Customer 1 A B CL, TL or LTL Plant B CL or TL Plant C CL or TL Customer 2 A Mixing warehouse CL, TL or LTL B B Customer 4 A B C. Consolidation Plant A CL or TL Plant B CL or TL Plant C CL or TL D. Breakbulk Customer 1 CL or TL Customer 2 CL or TL Consolidation warehouse Customer 3 LTL CL or TL Breakbulk Warehouse C Customer 3 A CL, TL or LTL Plant C CL or TL Customer 1 LTL Customer 2 LTL Customer 3 C

Manufacturing support • • A firm order raw materials, parts, components or supplier from various suppliers, who ship truckload (TL) or carload (CL) quantities to a warehouse Items are transferred from the warehouse to the manufacturing plant Product Mixing • • Often involves multiple plant location (e. g. plant A, B and C) to a central warehouse. Shipment are usually make in large quantities (TL or CL) to the central warehouse, where customer orders for multiple product are combined or mixed for shipment Outbound Consolidation • • TL and CL shipments are made to a central facility from a number of manufacturing locations The warehouse consolidates or combines product from the various plants into a single higher volume shipment to the customer Break-bulk Warehouse • • • Facilities that receive large shipments of product manufacturing plants Several customer orders are combined into a single shipment from the plants to the break-bulk warehouse. When the shipment is received at the warehouse, it is broken down into smaller LTL shipments which are sent to customers.

Manufacturing support • • A firm order raw materials, parts, components or supplier from various suppliers, who ship truckload (TL) or carload (CL) quantities to a warehouse Items are transferred from the warehouse to the manufacturing plant Product Mixing • • Often involves multiple plant location (e. g. plant A, B and C) to a central warehouse. Shipment are usually make in large quantities (TL or CL) to the central warehouse, where customer orders for multiple product are combined or mixed for shipment Outbound Consolidation • • TL and CL shipments are made to a central facility from a number of manufacturing locations The warehouse consolidates or combines product from the various plants into a single higher volume shipment to the customer Break-bulk Warehouse • • • Facilities that receive large shipments of product manufacturing plants Several customer orders are combined into a single shipment from the plants to the break-bulk warehouse. When the shipment is received at the warehouse, it is broken down into smaller LTL shipments which are sent to customers.

Pull versus Push Systems in Warehousing Push Systems 1. The traditional method of distribution 2. Productions plans are based on capabilities and capacities of the plant 3. The product is produced in the expectation that it will sell 4. When it is produced faster than it can be sold, it is stockpiled at the plant warehouse 5. If sales cannot be accelerated, then the plant will be slowed down until supply moves into balance with demand. 6. Warehouse serves to absorb excess production Pull Systems 1. Depends on information 2. It is based on a constant monitoring of demand 3. There is no need for a reservoir 4. The warehouse serves as a flow-through center offering improved service by positioning inventory closer to the customer

Pull versus Push Systems in Warehousing Push Systems 1. The traditional method of distribution 2. Productions plans are based on capabilities and capacities of the plant 3. The product is produced in the expectation that it will sell 4. When it is produced faster than it can be sold, it is stockpiled at the plant warehouse 5. If sales cannot be accelerated, then the plant will be slowed down until supply moves into balance with demand. 6. Warehouse serves to absorb excess production Pull Systems 1. Depends on information 2. It is based on a constant monitoring of demand 3. There is no need for a reservoir 4. The warehouse serves as a flow-through center offering improved service by positioning inventory closer to the customer

Relationship between Warehouse and Transportation economies are possible for both the physical supply and physical distribution systems. • Physical supply, ü the warehouse is located near the sources of supply so that the LTL rates apply only to a short haul ü the volume rate is used for the long haul from the warehouse to the plant. • Physical distribution; ü Shipments from plants to field warehouses are frequently made by rail in full carload quantities of the product manufactured at each plant. ü The use of field warehouses result in lower transportation costs than direct shipments to customer

Relationship between Warehouse and Transportation economies are possible for both the physical supply and physical distribution systems. • Physical supply, ü the warehouse is located near the sources of supply so that the LTL rates apply only to a short haul ü the volume rate is used for the long haul from the warehouse to the plant. • Physical distribution; ü Shipments from plants to field warehouses are frequently made by rail in full carload quantities of the product manufactured at each plant. ü The use of field warehouses result in lower transportation costs than direct shipments to customer

Warehousing and Production • Short production runs minimize the amount of inventory held throughout the logistic system by producing quantities near to current demand • Long production runs lead to larger inventories and increased warehouse requirements. • Warehousing was necessary if the company was to take advantage of quantity purchase discounts on raw materials or other products. Not only is the per unit price lower as a result of the discount, but if the company pays the freight, transportation costs will be less on a volume purchase because of the transportation economies. • Increasingly, companies operating with a JIT manufacturing philosophy are negotiating with their suppliers to receive cumulative quantity discounts. Thus, they receive the lower rate base on total yearly order volume rather than individual order size.

Warehousing and Production • Short production runs minimize the amount of inventory held throughout the logistic system by producing quantities near to current demand • Long production runs lead to larger inventories and increased warehouse requirements. • Warehousing was necessary if the company was to take advantage of quantity purchase discounts on raw materials or other products. Not only is the per unit price lower as a result of the discount, but if the company pays the freight, transportation costs will be less on a volume purchase because of the transportation economies. • Increasingly, companies operating with a JIT manufacturing philosophy are negotiating with their suppliers to receive cumulative quantity discounts. Thus, they receive the lower rate base on total yearly order volume rather than individual order size.

Warehouse and Customer Service • Customer service policies, such as a 24 -hour delivery standard, may require a number of field warehouses in order to minimize total costs while achieving the standard. • Changing the market condition may make it necessary to warehouse product in the field, primarily because companies are unable to accurately predict consumer demand the time of retailer or wholesaler order. By keeping some excess inventory in field warehouse location, companies can response quickly to meet unexpected demand. • Excess inventory allows manufacturers to fill customer order when shipments to restock the field a warehouse arrive late

Warehouse and Customer Service • Customer service policies, such as a 24 -hour delivery standard, may require a number of field warehouses in order to minimize total costs while achieving the standard. • Changing the market condition may make it necessary to warehouse product in the field, primarily because companies are unable to accurately predict consumer demand the time of retailer or wholesaler order. By keeping some excess inventory in field warehouse location, companies can response quickly to meet unexpected demand. • Excess inventory allows manufacturers to fill customer order when shipments to restock the field a warehouse arrive late

b) Types of Warehousing i. Cross-docking • the warehouses serve primarily as “distribution mixing centers. ” • Product arrive in bulk and is immediately broken down and mixed in the proper range and quantity of product for customer shipment. • In essence, the product never enters the warehouse. • Cross-docking is becoming popular among retailers, who can order TL, then remix and immediately ship to individual store locations. • When a firm decides to store product in the field, it faces two warehousing options: rented facilities, called public warehousing, or owned or leased facilities, called private warehousing

b) Types of Warehousing i. Cross-docking • the warehouses serve primarily as “distribution mixing centers. ” • Product arrive in bulk and is immediately broken down and mixed in the proper range and quantity of product for customer shipment. • In essence, the product never enters the warehouse. • Cross-docking is becoming popular among retailers, who can order TL, then remix and immediately ship to individual store locations. • When a firm decides to store product in the field, it faces two warehousing options: rented facilities, called public warehousing, or owned or leased facilities, called private warehousing

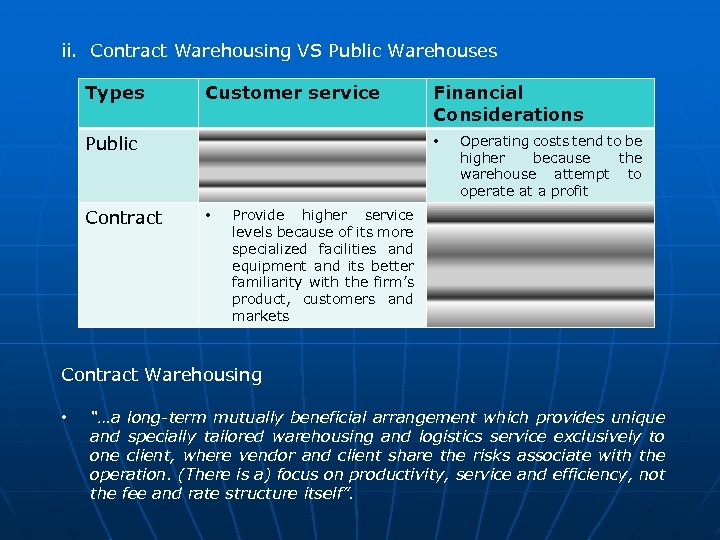

ii. Contract Warehousing VS Public Warehouses Types Customer service Public Contract Financial Considerations • • Operating costs tend to be higher because the warehouse attempt to operate at a profit Provide higher service levels because of its more specialized facilities and equipment and its better familiarity with the firm’s product, customers and markets Contract Warehousing • “…a long-term mutually beneficial arrangement which provides unique and specially tailored warehousing and logistics service exclusively to one client, where vendor and client share the risks associate with the operation. (There is a) focus on productivity, service and efficiency, not the fee and rate structure itself”.

ii. Contract Warehousing VS Public Warehouses Types Customer service Public Contract Financial Considerations • • Operating costs tend to be higher because the warehouse attempt to operate at a profit Provide higher service levels because of its more specialized facilities and equipment and its better familiarity with the firm’s product, customers and markets Contract Warehousing • “…a long-term mutually beneficial arrangement which provides unique and specially tailored warehousing and logistics service exclusively to one client, where vendor and client share the risks associate with the operation. (There is a) focus on productivity, service and efficiency, not the fee and rate structure itself”.

Types of Public Warehouses 1. General Merchandise Warehouse • The most common form storing almost any kind of product 2. Refrigerated Warehouse • Provide a temperature controlled storage environment • Used for preserving perishable items such as fruits and vegetables 3. Bonded Warehouse • These warehouses undertake surety bonds and place their premises under the custody of an agent of the Treasury. • Goods such as imported tobacco and alcoholic beverages are stored in this type of warehouse, although the government retains control of the goods until they are distributed to the market. • The importers must pay customs duties

Types of Public Warehouses 1. General Merchandise Warehouse • The most common form storing almost any kind of product 2. Refrigerated Warehouse • Provide a temperature controlled storage environment • Used for preserving perishable items such as fruits and vegetables 3. Bonded Warehouse • These warehouses undertake surety bonds and place their premises under the custody of an agent of the Treasury. • Goods such as imported tobacco and alcoholic beverages are stored in this type of warehouse, although the government retains control of the goods until they are distributed to the market. • The importers must pay customs duties

4. Household Goods Warehouse • Used for storage of personal property rather than merchandise 5. Special Commodity Warehouse • Used for particular agricultural such as wool, grains and cotton. • Ordinarily, handles one kind of product and offers special services specific to that product 6. Bulk Storage Warehouses • Provide tank storage of liquids and open or sheltered storage of dry products such as coal, sand chemicals. • Provide services such as filling drums from bulk or mixing various types of chemical with others to produce new compound or mixtures.

4. Household Goods Warehouse • Used for storage of personal property rather than merchandise 5. Special Commodity Warehouse • Used for particular agricultural such as wool, grains and cotton. • Ordinarily, handles one kind of product and offers special services specific to that product 6. Bulk Storage Warehouses • Provide tank storage of liquids and open or sheltered storage of dry products such as coal, sand chemicals. • Provide services such as filling drums from bulk or mixing various types of chemical with others to produce new compound or mixtures.

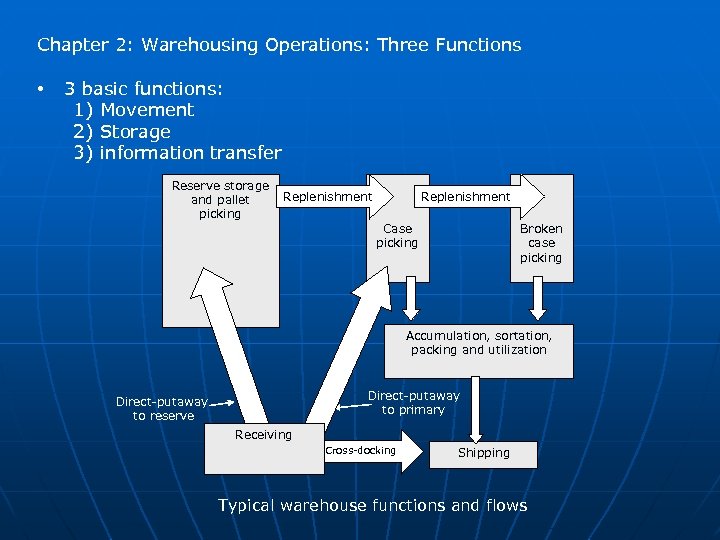

Chapter 2: Warehousing Operations: Three Functions • 3 basic functions: 1) Movement 2) Storage 3) information transfer Reserve storage and pallet picking Replenishment Case picking Broken case picking Accumulation, sortation, packing and utilization Direct-putaway to primary Direct-putaway to reserve Receiving Cross-docking Shipping Typical warehouse functions and flows

Chapter 2: Warehousing Operations: Three Functions • 3 basic functions: 1) Movement 2) Storage 3) information transfer Reserve storage and pallet picking Replenishment Case picking Broken case picking Accumulation, sortation, packing and utilization Direct-putaway to primary Direct-putaway to reserve Receiving Cross-docking Shipping Typical warehouse functions and flows

• Movement Divided into several activities a) Receiving - unloading of products from the transportation carrier, the updating of warehouse inventory records, inspection of damage and verification of the merchandise count against order and shipping records b) Transfer or put-away – the physical movement of the product into the warehouse for storage, movement to areas for specialized services such as consolidation and movement to outbound shipment. c) Order picking / selection – is the major movement activity and involves regrouping products into the assortments customers desire. Packing slip are made up at this point. d) Cross docking – bypasses the storage activity by transferring items directly from the receiving dock to the shipping dock. e) Shipping – consists of product staging and physically moving the assembled orders onto carrier equipment, adjusting inventory and checking orders to be shipped.

• Movement Divided into several activities a) Receiving - unloading of products from the transportation carrier, the updating of warehouse inventory records, inspection of damage and verification of the merchandise count against order and shipping records b) Transfer or put-away – the physical movement of the product into the warehouse for storage, movement to areas for specialized services such as consolidation and movement to outbound shipment. c) Order picking / selection – is the major movement activity and involves regrouping products into the assortments customers desire. Packing slip are made up at this point. d) Cross docking – bypasses the storage activity by transferring items directly from the receiving dock to the shipping dock. e) Shipping – consists of product staging and physically moving the assembled orders onto carrier equipment, adjusting inventory and checking orders to be shipped.

• Storage Can be performed on a temporary or a semi-permanent basis a) Temporary storage Ø Emphasizes the movement function of the warehouse and includes only the storage of product necessary for basic inventory replenishment. b) Semi-permanent storage Ø Is the storage of inventory in excess of that required for normal replenishment -> this inventory referred as buffer of safety stock Ø The most conditions leading to semi-permanent storage; 1) Seasonal demand 2) Erratic demand 3) Speculation or forward buying 4) Special deals such as quantity discount

• Storage Can be performed on a temporary or a semi-permanent basis a) Temporary storage Ø Emphasizes the movement function of the warehouse and includes only the storage of product necessary for basic inventory replenishment. b) Semi-permanent storage Ø Is the storage of inventory in excess of that required for normal replenishment -> this inventory referred as buffer of safety stock Ø The most conditions leading to semi-permanent storage; 1) Seasonal demand 2) Erratic demand 3) Speculation or forward buying 4) Special deals such as quantity discount

• Information Transfer Ø Occurs simultaneously with the movement and storage function Ø Management needs timely and accurate information as it attempts to administer the warehouse activity. Ø Examples of information that is vital to the successful operation of a warehouse; ü Inventory levels ü Throughput levels (i. e. , the amount of product moving through the warehouse) ü Stock keeping locations ü Inbound and outbound shipment ü Customer data ü Facility space utilization Ø Organizations are relying on computerized information transfer utilizing electronic data interchange (EDI) and bar coding to improve both the speed and accuracy of information transfer.

• Information Transfer Ø Occurs simultaneously with the movement and storage function Ø Management needs timely and accurate information as it attempts to administer the warehouse activity. Ø Examples of information that is vital to the successful operation of a warehouse; ü Inventory levels ü Throughput levels (i. e. , the amount of product moving through the warehouse) ü Stock keeping locations ü Inbound and outbound shipment ü Customer data ü Facility space utilization Ø Organizations are relying on computerized information transfer utilizing electronic data interchange (EDI) and bar coding to improve both the speed and accuracy of information transfer.

Chapter 3: Public (rented) versus Private Warehousing (owned or leased) Advantages and Disadvantages of Public Warehousing The benefits of uses public warehouses rather than private warehousing 1. Conservation of capital • • Require no capital investment from the user The user avoids the investment in buildings, land material handling equipment 2. The ability to increase warehouse space to cover peak requirement • If a firm’s operations are subjected to seasonality, the public warehouse allows the user to rent as much storage space as needed to meet peak requirement

Chapter 3: Public (rented) versus Private Warehousing (owned or leased) Advantages and Disadvantages of Public Warehousing The benefits of uses public warehouses rather than private warehousing 1. Conservation of capital • • Require no capital investment from the user The user avoids the investment in buildings, land material handling equipment 2. The ability to increase warehouse space to cover peak requirement • If a firm’s operations are subjected to seasonality, the public warehouse allows the user to rent as much storage space as needed to meet peak requirement

3. Reduced risk • The user firm can switch to another facility in a short period of time, often within 30 days. 4. Economies of scale • • Since public warehouse handle the requirements of a number of firms, their volume allows the employment of a full-time warehousing staff Can offer a number of specialized services more economically than a private warehouse; Ø Packaging of manufacturers product for shipping Ø Consolidation of damaged and recalled product for shipment to the manufacturer in CL or TL quantities. Ø Can performed the reworking of damaged product.

3. Reduced risk • The user firm can switch to another facility in a short period of time, often within 30 days. 4. Economies of scale • • Since public warehouse handle the requirements of a number of firms, their volume allows the employment of a full-time warehousing staff Can offer a number of specialized services more economically than a private warehouse; Ø Packaging of manufacturers product for shipping Ø Consolidation of damaged and recalled product for shipment to the manufacturer in CL or TL quantities. Ø Can performed the reworking of damaged product.

5. Greater Flexibility • • • Require only a short term contract and thus short term commitments. Short term contract make it is easy for firms to change warehouse locations A firm that uses public warehouses does not have to hire or lay off employees as the volume of business changes 6. Tax advantages • • If the company does not currently own property in a state, it may find it advantageous to use a public warehouse Some states do not charge property taxes on inventories in public warehouse this tax shelter applies to both regular warehouse inventories and storage-in-transit inventories.

5. Greater Flexibility • • • Require only a short term contract and thus short term commitments. Short term contract make it is easy for firms to change warehouse locations A firm that uses public warehouses does not have to hire or lay off employees as the volume of business changes 6. Tax advantages • • If the company does not currently own property in a state, it may find it advantageous to use a public warehouse Some states do not charge property taxes on inventories in public warehouse this tax shelter applies to both regular warehouse inventories and storage-in-transit inventories.

7. Knows Exact Warehousing Costs • • know the exact storage and handling costs because we receives a bill each month The user can forecast costs for different levels of activity because the costs are known in advance. 8. Can Minimize Labor Disputes • The court has ruled that a labor union does not have the right to picket a public warehouse when the union is involved in a labor dispute with one of the customers of that warehouse.

7. Knows Exact Warehousing Costs • • know the exact storage and handling costs because we receives a bill each month The user can forecast costs for different levels of activity because the costs are known in advance. 8. Can Minimize Labor Disputes • The court has ruled that a labor union does not have the right to picket a public warehouse when the union is involved in a labor dispute with one of the customers of that warehouse.

Public (rented) versus Private Warehousing (owned or leased) Advantages and Disadvantages of Public Warehousing The disadvantages of uses public warehouses 1. Communication Problems § § § Not all computer terminals and system are compatible A warehouse operator may hesitate to add another terminal for only one customer In addition, the lack of standardization in contractual agreements makes communication regarding contractual obligations difficult

Public (rented) versus Private Warehousing (owned or leased) Advantages and Disadvantages of Public Warehousing The disadvantages of uses public warehouses 1. Communication Problems § § § Not all computer terminals and system are compatible A warehouse operator may hesitate to add another terminal for only one customer In addition, the lack of standardization in contractual agreements makes communication regarding contractual obligations difficult

2. Lack of Specialized Services § § Many public warehouse facilities provide only local service A manufacturer that wants to use public warehouses for national distribution may find it necessary to deal with several different operators and monitors several contractual agreements 3. Space May Not Be Available § § Public warehousing space may not be available when and where a firm wants it. Shortage of space do occur periodically in selected markets, which can have an adverse affect on the logistics and marketing strategies of a firm.

2. Lack of Specialized Services § § Many public warehouse facilities provide only local service A manufacturer that wants to use public warehouses for national distribution may find it necessary to deal with several different operators and monitors several contractual agreements 3. Space May Not Be Available § § Public warehousing space may not be available when and where a firm wants it. Shortage of space do occur periodically in selected markets, which can have an adverse affect on the logistics and marketing strategies of a firm.

Public (rented) versus Private Warehousing (owned or leased) Advantages and Disadvantages of Public Warehousing The Benefits of uses Private Warehousing 1. Degree of Control § The firm has direct control of and responsibility for the product until the customer takes possession or delivery 2. Flexibility § With warehouse control comes a greater degree of flexibility to design and operate the warehouse to fit the needs of customers and the characteristics of the product. § The warehouse can be modified through expansion or renovation to facilitate product changes or it can be converted to manufacturing plant or branch office location. 3. Less Costly Over the Long Term § Private warehousing can be less costly over the long term

Public (rented) versus Private Warehousing (owned or leased) Advantages and Disadvantages of Public Warehousing The Benefits of uses Private Warehousing 1. Degree of Control § The firm has direct control of and responsibility for the product until the customer takes possession or delivery 2. Flexibility § With warehouse control comes a greater degree of flexibility to design and operate the warehouse to fit the needs of customers and the characteristics of the product. § The warehouse can be modified through expansion or renovation to facilitate product changes or it can be converted to manufacturing plant or branch office location. 3. Less Costly Over the Long Term § Private warehousing can be less costly over the long term

3. Better Use of Human Resources • There is greater care in handling and storage when the firm’s own workforce operates the warehouse 4. Tax Benefits • Depreciation allowances on buildings and equipment reduce taxes payable 5. Intangible Benefits • When a firm distributes its product through a private warehouse, it can give the customer a sense of permanence and continuity of business operation • The customers sees the company as a stable, dependable and lasting supplier of product

3. Better Use of Human Resources • There is greater care in handling and storage when the firm’s own workforce operates the warehouse 4. Tax Benefits • Depreciation allowances on buildings and equipment reduce taxes payable 5. Intangible Benefits • When a firm distributes its product through a private warehouse, it can give the customer a sense of permanence and continuity of business operation • The customers sees the company as a stable, dependable and lasting supplier of product

Public (rented) VS Private Warehousing (owned or leased) Advantages and Disadvantages of Private Warehousing The disadvantages of uses Private Warehousing 1. Lack of Flexibility § Many experts feel that the major drawback of private warehousing is the same as one its main advantages Flexibility § May be too costly because of its fixed size and costs § A private facility cannot expand contract to meet increases or decreases in demand § When demand is low, the firm must still assume the fixed costs as well as the lower productivity linked to unused warehouse space.

Public (rented) VS Private Warehousing (owned or leased) Advantages and Disadvantages of Private Warehousing The disadvantages of uses Private Warehousing 1. Lack of Flexibility § Many experts feel that the major drawback of private warehousing is the same as one its main advantages Flexibility § May be too costly because of its fixed size and costs § A private facility cannot expand contract to meet increases or decreases in demand § When demand is low, the firm must still assume the fixed costs as well as the lower productivity linked to unused warehouse space.

2. Financial Constraints § high costs involved, many firms are simply unable to build or buy a warehouse § A warehouse is a long-term, often risky investment which later may be difficult to sell because of its customized design § The hiring and training employees, the purchase of material handling equipment makes start up a costly and time consuming process 3. Rate of Return § At a minimum, the investment in a corporate warehouse should generate the same rate of returns as the firm’s other investments.

2. Financial Constraints § high costs involved, many firms are simply unable to build or buy a warehouse § A warehouse is a long-term, often risky investment which later may be difficult to sell because of its customized design § The hiring and training employees, the purchase of material handling equipment makes start up a costly and time consuming process 3. Rate of Return § At a minimum, the investment in a corporate warehouse should generate the same rate of returns as the firm’s other investments.

Chapter 4: Facility Development 1. Size and Number of Warehouse • • Size can be defined in terms of square footage or cubic space Cubic space refer to the total volume of space available within a facility Greater space required when product are large, production lead time is long, manual material handling are used and demand is erratic and unpredictable 4 factors are significantly in deciding the number of warehousing facilities a) Cost of Lost Sales ↑, no. warehouse ↓ b) Inventory Costs ↑, no. warehouse ↑ c) Warehousing Costs ↑, no. warehouse ↑ d) Transportation Costs ↑, no. warehouse ↓

Chapter 4: Facility Development 1. Size and Number of Warehouse • • Size can be defined in terms of square footage or cubic space Cubic space refer to the total volume of space available within a facility Greater space required when product are large, production lead time is long, manual material handling are used and demand is erratic and unpredictable 4 factors are significantly in deciding the number of warehousing facilities a) Cost of Lost Sales ↑, no. warehouse ↓ b) Inventory Costs ↑, no. warehouse ↑ c) Warehousing Costs ↑, no. warehouse ↑ d) Transportation Costs ↑, no. warehouse ↓

Facility Development 2. Location Analysis • Macro Approaches; Ø Market Positioned ü Locates warehouses nearest to the final customer ü Maximize CSL and enables to utilize transportation economies

Facility Development 2. Location Analysis • Macro Approaches; Ø Market Positioned ü Locates warehouses nearest to the final customer ü Maximize CSL and enables to utilize transportation economies

Facility Development Ø Production Positioned ü Locates warehouses in close proximity to sources of supply or production facilities ü The factors influence the placement are perishability of raw materials, no. of product in the firm’s mix, assortment of products ordered by customer and transportation consolidation rates Ø Intermediately Positioned ü Strategy that places warehouses at a midpoint location between the final customer and the producer ü If it must offer high customer service level and if it has a varied product offering manufactured at several plant location

Facility Development Ø Production Positioned ü Locates warehouses in close proximity to sources of supply or production facilities ü The factors influence the placement are perishability of raw materials, no. of product in the firm’s mix, assortment of products ordered by customer and transportation consolidation rates Ø Intermediately Positioned ü Strategy that places warehouses at a midpoint location between the final customer and the producer ü If it must offer high customer service level and if it has a varied product offering manufactured at several plant location

Facility Development • Micro Approaches; Ø Quality and variety of transportation carriers serving the site Ø Quality and quantity of available labor Ø Labor rates Ø Cost and quality of industrial land Ø Potential for expansion Ø Cost of construction Ø Cost and availability of utilities Ø Tax structure Ø Nature of the community environment

Facility Development • Micro Approaches; Ø Quality and variety of transportation carriers serving the site Ø Quality and quantity of available labor Ø Labor rates Ø Cost and quality of industrial land Ø Potential for expansion Ø Cost of construction Ø Cost and availability of utilities Ø Tax structure Ø Nature of the community environment

Facility Development 3. Warehouse Layout and Design • Good warehouse layout can: 1. Increase output 2. Improve product flow 3. Reduce costs 4. Improve service to customer 5. Provide better employee working conditions

Facility Development 3. Warehouse Layout and Design • Good warehouse layout can: 1. Increase output 2. Improve product flow 3. Reduce costs 4. Improve service to customer 5. Provide better employee working conditions

Facility Development 3. Warehouse Layout and Design • 2 example of how product can be located and arranged; 1. Randomized Storage a) Places items in the closets available slot, bin or rack b) The items are retrieved on a first in, first out (FIFO) basis c) Employ a computerized automatic storage and retrieval system (AS/RS) d) Maximizes space utilization, minimizes labor and handling costs

Facility Development 3. Warehouse Layout and Design • 2 example of how product can be located and arranged; 1. Randomized Storage a) Places items in the closets available slot, bin or rack b) The items are retrieved on a first in, first out (FIFO) basis c) Employ a computerized automatic storage and retrieval system (AS/RS) d) Maximizes space utilization, minimizes labor and handling costs

Facility Development 3. Warehouse Layout and Design 2. Dedicated Storage (fixed-slot storage) a) Products are stored in permanent locations within the warehouse b) 3 methods to implement the dedicated storage; • Part number sequence • Usage rates • Activity levels (how fast products move in and out)

Facility Development 3. Warehouse Layout and Design 2. Dedicated Storage (fixed-slot storage) a) Products are stored in permanent locations within the warehouse b) 3 methods to implement the dedicated storage; • Part number sequence • Usage rates • Activity levels (how fast products move in and out)

Facility Development c) Product may be grouped according to; • Compatibility – refers to whether products can be stored together harmoniously • Complementarity – refers to how often products are ordered together and therefore stored together. Example: pens, pencils, desk and chairs • Popularity – relates to the different inventory turnover rates or demand rates of product. Example: greatest demand stored closest to shipping and receiving docks, slow moving items stored elsewhere

Facility Development c) Product may be grouped according to; • Compatibility – refers to whether products can be stored together harmoniously • Complementarity – refers to how often products are ordered together and therefore stored together. Example: pens, pencils, desk and chairs • Popularity – relates to the different inventory turnover rates or demand rates of product. Example: greatest demand stored closest to shipping and receiving docks, slow moving items stored elsewhere

Chapter 5: Improving Warehouse Productivity 1. Method-Related Programs • • Consider alternative processes for achieving desired result Warehouse cube utilization, warehouse layout and design, method and procedures analysis, batch picking of small order, wrap packaging and standardized packaging 2. Equipment-Related Programs • The use of new technology such as optical scanners, automatic labeling devices, automated handling equipment, communication devices, computer and automated storage/ retrieval systems (AS/RS) and conveyors

Chapter 5: Improving Warehouse Productivity 1. Method-Related Programs • • Consider alternative processes for achieving desired result Warehouse cube utilization, warehouse layout and design, method and procedures analysis, batch picking of small order, wrap packaging and standardized packaging 2. Equipment-Related Programs • The use of new technology such as optical scanners, automatic labeling devices, automated handling equipment, communication devices, computer and automated storage/ retrieval systems (AS/RS) and conveyors

Chapter 5: Improving Warehouse Productivity 3. Systems-Related Programs • Include the use of router/location systems, geographic or zone picking and random location of products in the warehouse 4. Training/ Motivation-Related Programs • Include employee training, management development programs, work teams, incentive systems and awards recognition

Chapter 5: Improving Warehouse Productivity 3. Systems-Related Programs • Include the use of router/location systems, geographic or zone picking and random location of products in the warehouse 4. Training/ Motivation-Related Programs • Include employee training, management development programs, work teams, incentive systems and awards recognition