warehouse system.pptx

- Количество слайдов: 7

Warehouse Management System The system is completely integrated with online customer ordering capabilities. This gives any business the ability to take orders and requisitions from their customers. It is a system to coordinate these processes whether they are internal or external. The warehouse system will track inventory levels and valuations. They can now give you (and your customer) the ability to see the amount of product available at the time the order is placed. Customers who save money on food by ordering in bulk and use an external warehouse for storage can ensure their inventories are in the right place at the right time with this Warehouse Management System. Suppliers can use the system as well for a seamless ordering process.

Warehouse Management System The system is completely integrated with online customer ordering capabilities. This gives any business the ability to take orders and requisitions from their customers. It is a system to coordinate these processes whether they are internal or external. The warehouse system will track inventory levels and valuations. They can now give you (and your customer) the ability to see the amount of product available at the time the order is placed. Customers who save money on food by ordering in bulk and use an external warehouse for storage can ensure their inventories are in the right place at the right time with this Warehouse Management System. Suppliers can use the system as well for a seamless ordering process.

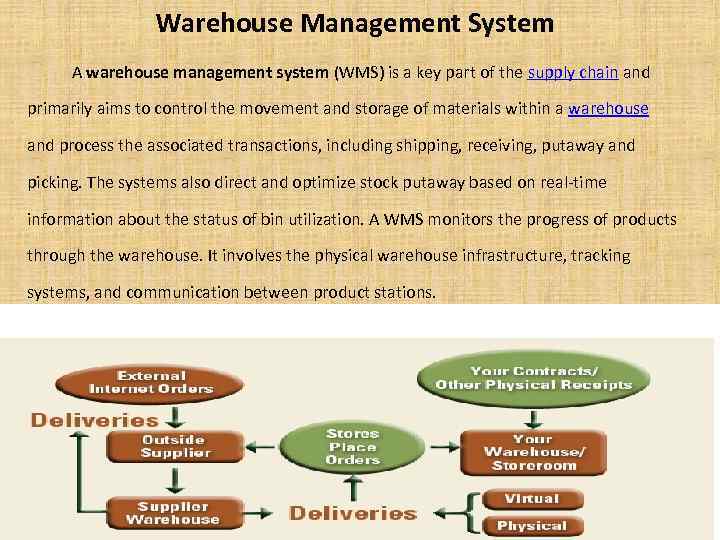

Warehouse Management System A warehouse management system (WMS) is a key part of the supply chain and primarily aims to control the movement and storage of materials within a warehouse and process the associated transactions, including shipping, receiving, putaway and picking. The systems also direct and optimize stock putaway based on real-time information about the status of bin utilization. A WMS monitors the progress of products through the warehouse. It involves the physical warehouse infrastructure, tracking systems, and communication between product stations.

Warehouse Management System A warehouse management system (WMS) is a key part of the supply chain and primarily aims to control the movement and storage of materials within a warehouse and process the associated transactions, including shipping, receiving, putaway and picking. The systems also direct and optimize stock putaway based on real-time information about the status of bin utilization. A WMS monitors the progress of products through the warehouse. It involves the physical warehouse infrastructure, tracking systems, and communication between product stations.

The Purposes of the Stores / Warehouse The stores is self-evidently a major company service department. Service is provided on behalf of the following functions: Service to Purchasing & Quality: The stores receives raw materials and bought-out parts on behalf of Purchasing. The receipts must therefore be counted accurately and the material checked or sampled as to quality. Information about receipts must be promptly notified to the central database. Service to Production: The stores must marshal and issue all works orders on behalf of production, and perhaps any tools and fittings needed. The stores also accepts material from production, whether completed work or scrap. The nature of production is such that emergency issues of material are always likely to be required. It would follow from this for a factory stores that the facility should provide a service during all times that production takes place. . . including second and third shifts. Service to Production Planning: The planning of production and the correct maintenance of stocks are essential services as the company progresses manufacture, but these tasks simply cannot sensibly proceed unless the stores/warehouse correctly maintain stock records at a very high level of accuracy. Service to Distribution (Logistics): The stores or warehouse must prepare goods for despatch to external customers within a turnaround time that has been agreed between its manager, the distribution manager and transport supervision. The function of despatch includes packaging and, perhaps, making ready all documentation.

The Purposes of the Stores / Warehouse The stores is self-evidently a major company service department. Service is provided on behalf of the following functions: Service to Purchasing & Quality: The stores receives raw materials and bought-out parts on behalf of Purchasing. The receipts must therefore be counted accurately and the material checked or sampled as to quality. Information about receipts must be promptly notified to the central database. Service to Production: The stores must marshal and issue all works orders on behalf of production, and perhaps any tools and fittings needed. The stores also accepts material from production, whether completed work or scrap. The nature of production is such that emergency issues of material are always likely to be required. It would follow from this for a factory stores that the facility should provide a service during all times that production takes place. . . including second and third shifts. Service to Production Planning: The planning of production and the correct maintenance of stocks are essential services as the company progresses manufacture, but these tasks simply cannot sensibly proceed unless the stores/warehouse correctly maintain stock records at a very high level of accuracy. Service to Distribution (Logistics): The stores or warehouse must prepare goods for despatch to external customers within a turnaround time that has been agreed between its manager, the distribution manager and transport supervision. The function of despatch includes packaging and, perhaps, making ready all documentation.

Organization of containerboard Appropriate inventory management equipment and supplies can help ease the struggle of proper inventory maintenance. From lift vehicles, to pallets to the warehouses themselves, business inventory equipment can be a complicated list of buildings, hardware and software.

Organization of containerboard Appropriate inventory management equipment and supplies can help ease the struggle of proper inventory maintenance. From lift vehicles, to pallets to the warehouses themselves, business inventory equipment can be a complicated list of buildings, hardware and software.

The Package The development of a company's packaging is a well- established, dedicated function in larger warehouses, often entailing the appointment of a packaging manager. His role is to ensure that the company's packages meet the standards specified, and to develop new packages in order to increase the competitive edge and reduce costs. Complaints about split packages or damaged goods must be evaluated carefully to establish the precise reason. The job clearly involves liaison with package manufacturers to identify possible applications of new package types. Proposed changes to packages must be evaluated carefully by the entire material handing chain as discussed below - by manufacturing (to test handling and filling), by distribution (for transport and handling) and by the customer.

The Package The development of a company's packaging is a well- established, dedicated function in larger warehouses, often entailing the appointment of a packaging manager. His role is to ensure that the company's packages meet the standards specified, and to develop new packages in order to increase the competitive edge and reduce costs. Complaints about split packages or damaged goods must be evaluated carefully to establish the precise reason. The job clearly involves liaison with package manufacturers to identify possible applications of new package types. Proposed changes to packages must be evaluated carefully by the entire material handing chain as discussed below - by manufacturing (to test handling and filling), by distribution (for transport and handling) and by the customer.

Packaging Waste The packaging waste regulations became law in 1997 and were forced on the UK by the hated European Union. They were intended to reduce the effect of packaging waste on the environment. The targets set are as follows: recovery (including energy recovery and compost), 50% - 65%; and recycling: 25% - 45% (at least 15% by weight of each individual package material to be recycled. Five terms should first be defined, as follows. *Primary packaging - the package that constitutes the sales unit sold to the ultimate customer. *Secondary, or grouped, packaging - the package used to contain the primary packages *Tertiary packaging - the package containing the secondary packages. *Recovery or reprocessing - (including recycling and incineration with energy recovery). *Recycling - use of the packaging to make new packaging.

Packaging Waste The packaging waste regulations became law in 1997 and were forced on the UK by the hated European Union. They were intended to reduce the effect of packaging waste on the environment. The targets set are as follows: recovery (including energy recovery and compost), 50% - 65%; and recycling: 25% - 45% (at least 15% by weight of each individual package material to be recycled. Five terms should first be defined, as follows. *Primary packaging - the package that constitutes the sales unit sold to the ultimate customer. *Secondary, or grouped, packaging - the package used to contain the primary packages *Tertiary packaging - the package containing the secondary packages. *Recovery or reprocessing - (including recycling and incineration with energy recovery). *Recycling - use of the packaging to make new packaging.

Equipment for Seizing and Lifting Devices include multiple tines with hydraulic pads for bricks and concrete blocks, tipper forks and many others. Clamps constitute the largest family. Examples of such equipment include: rotating paper reel clamps; mechanical clamps for drums; hydraulic squeeze clamp; an hydraulic clamp for a drum; mechanically operated overhead concrete block clamps; and hydraulic bale clamps to squeeze soft loads such as wool. Hand Operated Equipment The humble wheelbarrow is an example of hand-operated equipment, perhaps modified specially to carry sacks or other particular loads. Selector trucks contain numerous bins for components and might be wheeled round a factory floor to dispense materials. Stillage trucks are wheeled platforms pulled by a drawbar, and are sometimes fitted with a hydraulic lifting facility. Other hand-operated devices include hand stackers, pulley blocks, chutes, and monorails. Also encountered are pallet trucks, similar to stillage trucks, but with forks instead of a platform, and roller conveyors.

Equipment for Seizing and Lifting Devices include multiple tines with hydraulic pads for bricks and concrete blocks, tipper forks and many others. Clamps constitute the largest family. Examples of such equipment include: rotating paper reel clamps; mechanical clamps for drums; hydraulic squeeze clamp; an hydraulic clamp for a drum; mechanically operated overhead concrete block clamps; and hydraulic bale clamps to squeeze soft loads such as wool. Hand Operated Equipment The humble wheelbarrow is an example of hand-operated equipment, perhaps modified specially to carry sacks or other particular loads. Selector trucks contain numerous bins for components and might be wheeled round a factory floor to dispense materials. Stillage trucks are wheeled platforms pulled by a drawbar, and are sometimes fitted with a hydraulic lifting facility. Other hand-operated devices include hand stackers, pulley blocks, chutes, and monorails. Also encountered are pallet trucks, similar to stillage trucks, but with forks instead of a platform, and roller conveyors.