35f3774dd54e64f1603804612510158e.ppt

- Количество слайдов: 62

Warehouse Management System

Warehouse Management System

Company Profile

Company Profile

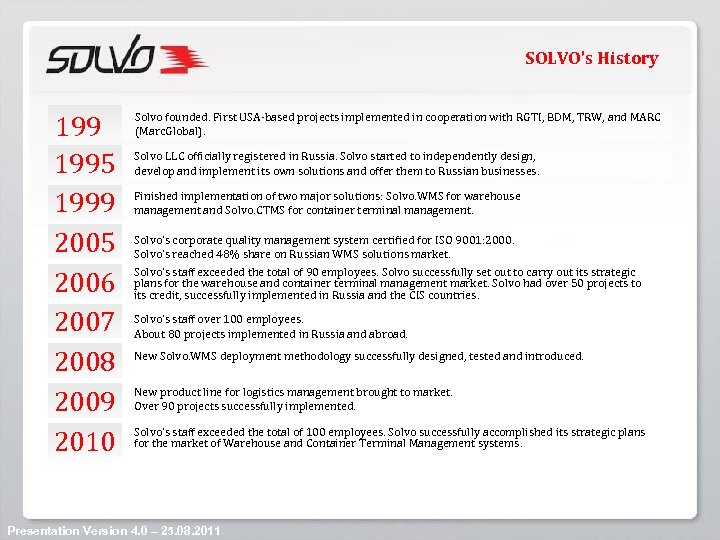

SOLVO’s History 199 2 1995 1999 2005 2006 2007 2008 2009 2010 Solvo founded. First USA-based projects implemented in cooperation with RGTI, BDM, TRW, and MARC (Marc. Global). Solvo LLC officially registered in Russia. Solvo started to independently design, develop and implement its own solutions and offer them to Russian businesses. Finished implementation of two major solutions: Solvo. WMS for warehouse management and Solvo. CTMS for container terminal management. Solvo’s corporate quality management system certified for ISO 9001: 2000. Solvo’s reached 48% share on Russian WMS solutions market. Solvo’s staff exceeded the total of 90 employees. Solvo successfully set out to carry out its strategic plans for the warehouse and container terminal management market. Solvo had over 50 projects to its credit, successfully implemented in Russia and the CIS countries. Solvo’s staff over 100 employees. About 80 projects implemented in Russia and abroad. New Solvo. WMS deployment methodology successfully designed, tested and introduced. New product line for logistics management brought to market. Over 90 projects successfully implemented. Solvo’s staff exceeded the total of 100 employees. Solvo successfully accomplished its strategic plans for the market of Warehouse and Container Terminal Management systems. Presentation Version 4. 0 – 25. 08. 2011

SOLVO’s History 199 2 1995 1999 2005 2006 2007 2008 2009 2010 Solvo founded. First USA-based projects implemented in cooperation with RGTI, BDM, TRW, and MARC (Marc. Global). Solvo LLC officially registered in Russia. Solvo started to independently design, develop and implement its own solutions and offer them to Russian businesses. Finished implementation of two major solutions: Solvo. WMS for warehouse management and Solvo. CTMS for container terminal management. Solvo’s corporate quality management system certified for ISO 9001: 2000. Solvo’s reached 48% share on Russian WMS solutions market. Solvo’s staff exceeded the total of 90 employees. Solvo successfully set out to carry out its strategic plans for the warehouse and container terminal management market. Solvo had over 50 projects to its credit, successfully implemented in Russia and the CIS countries. Solvo’s staff over 100 employees. About 80 projects implemented in Russia and abroad. New Solvo. WMS deployment methodology successfully designed, tested and introduced. New product line for logistics management brought to market. Over 90 projects successfully implemented. Solvo’s staff exceeded the total of 100 employees. Solvo successfully accomplished its strategic plans for the market of Warehouse and Container Terminal Management systems. Presentation Version 4. 0 – 25. 08. 2011

Our Customers in Russia, the CIS and the Baltic Countries 100 Over projects successfully implemented in Russia and near countries

Our Customers in Russia, the CIS and the Baltic Countries 100 Over projects successfully implemented in Russia and near countries

Services CONSULTING ADAPTATION AND IMPLEMENTATION TRAINING SUPPORT RADIO-EQUIPMENT IMPLEMENTATION AND SERVICES

Services CONSULTING ADAPTATION AND IMPLEMENTATION TRAINING SUPPORT RADIO-EQUIPMENT IMPLEMENTATION AND SERVICES

System Description

System Description

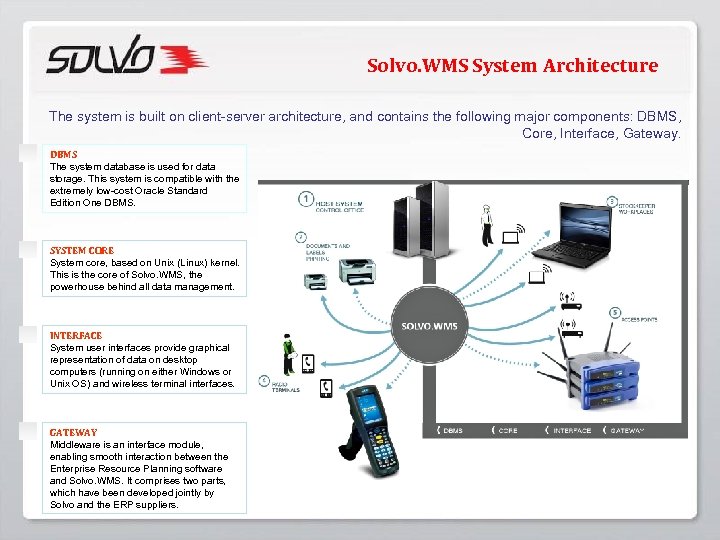

Solvo. WMS System Architecture The system is built on client-server architecture, and contains the following major components: DBMS, Core, Interface, Gateway. DBMS The system database is used for data storage. This system is compatible with the extremely low-cost Oracle Standard Edition One DBMS. SYSTEM CORE System core, based on Unix (Linux) kernel. This is the core of Solvo. WMS, the powerhouse behind all data management. INTERFACE System user interfaces provide graphical representation of data on desktop computers (running on either Windows or Unix OS) and wireless terminal interfaces. GATEWAY Middleware is an interface module, enabling smooth interaction between the Enterprise Resource Planning software and Solvo. WMS. It comprises two parts, which have been developed jointly by Solvo and the ERP suppliers.

Solvo. WMS System Architecture The system is built on client-server architecture, and contains the following major components: DBMS, Core, Interface, Gateway. DBMS The system database is used for data storage. This system is compatible with the extremely low-cost Oracle Standard Edition One DBMS. SYSTEM CORE System core, based on Unix (Linux) kernel. This is the core of Solvo. WMS, the powerhouse behind all data management. INTERFACE System user interfaces provide graphical representation of data on desktop computers (running on either Windows or Unix OS) and wireless terminal interfaces. GATEWAY Middleware is an interface module, enabling smooth interaction between the Enterprise Resource Planning software and Solvo. WMS. It comprises two parts, which have been developed jointly by Solvo and the ERP suppliers.

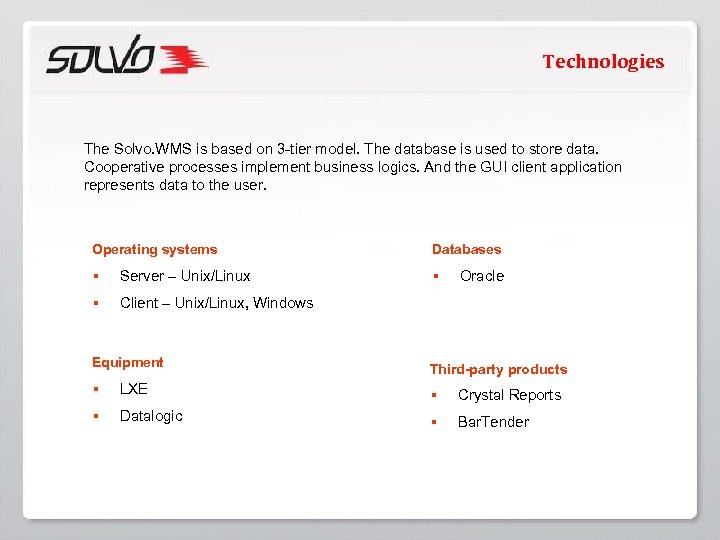

Technologies The Solvo. WMS is based on 3 -tier model. The database is used to store data. Cooperative processes implement business logics. And the GUI client application represents data to the user. Operating systems Databases § Server – Unix/Linux § § Client – Unix/Linux, Windows Oracle Equipment Third-party products § LXE § Crystal Reports § Datalogic § Bar. Tender

Technologies The Solvo. WMS is based on 3 -tier model. The database is used to store data. Cooperative processes implement business logics. And the GUI client application represents data to the user. Operating systems Databases § Server – Unix/Linux § § Client – Unix/Linux, Windows Oracle Equipment Third-party products § LXE § Crystal Reports § Datalogic § Bar. Tender

Technologies AUTOMATED IDENTIFICATION ADDRESS-BASED STORAGE REMOTE MANAGEMENT OF PERSONNEL

Technologies AUTOMATED IDENTIFICATION ADDRESS-BASED STORAGE REMOTE MANAGEMENT OF PERSONNEL

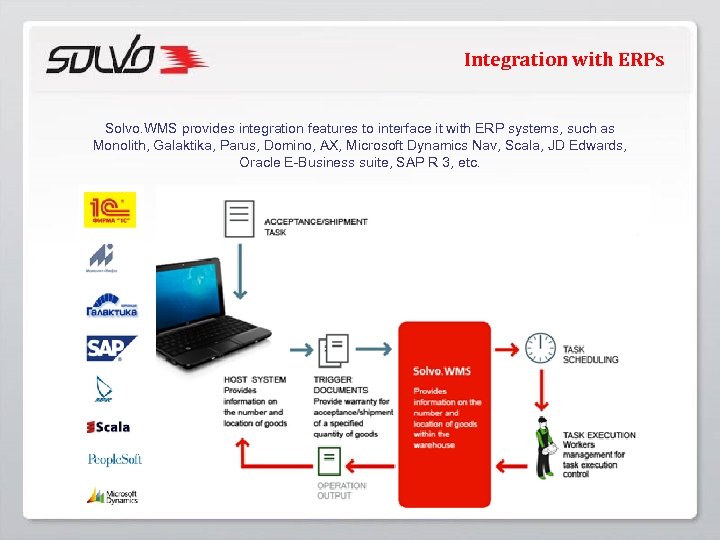

Integration with ERPs Solvo. WMS provides integration features to interface it with ERP systems, such as Monolith, Galaktika, Parus, Domino, AX, Microsoft Dynamics Nav, Scala, JD Edwards, Oracle E-Business suite, SAP R 3, etc.

Integration with ERPs Solvo. WMS provides integration features to interface it with ERP systems, such as Monolith, Galaktika, Parus, Domino, AX, Microsoft Dynamics Nav, Scala, JD Edwards, Oracle E-Business suite, SAP R 3, etc.

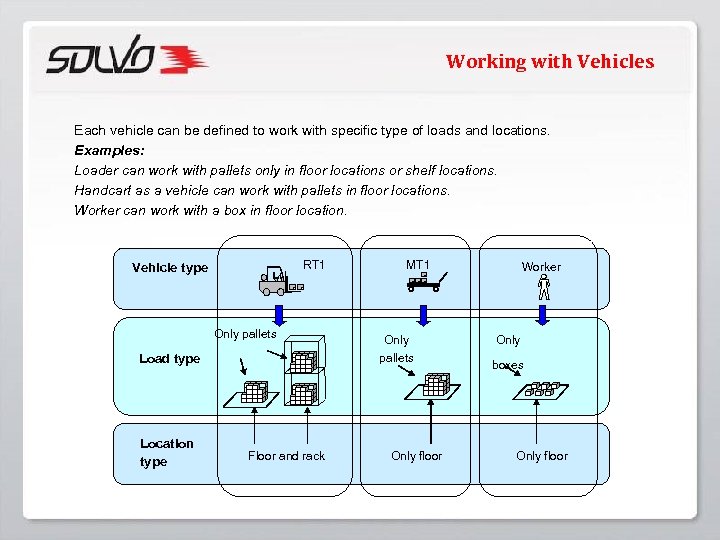

Working with Vehicles Each vehicle can be defined to work with specific type of loads and locations. Examples: Loader can work with pallets only in floor locations or shelf locations. Handcart as a vehicle can work with pallets in floor locations. Worker can work with a box in floor location. RT 1 Vehicle type Only pallets Load type Location type Floor and rack MT 1 Only pallets Only floor Worker Only boxes Only floor

Working with Vehicles Each vehicle can be defined to work with specific type of loads and locations. Examples: Loader can work with pallets only in floor locations or shelf locations. Handcart as a vehicle can work with pallets in floor locations. Worker can work with a box in floor location. RT 1 Vehicle type Only pallets Load type Location type Floor and rack MT 1 Only pallets Only floor Worker Only boxes Only floor

Personnel Two categories of employees work with the system: managers and operators. Manager has management functions and works with WMS using PC. Operator works with inventory according to tasks from WMS and using radio terminal screen. The system allows to control which functions and commands are available for each operator. In addition, allowed working areas can be defined. Manager Operator

Personnel Two categories of employees work with the system: managers and operators. Manager has management functions and works with WMS using PC. Operator works with inventory according to tasks from WMS and using radio terminal screen. The system allows to control which functions and commands are available for each operator. In addition, allowed working areas can be defined. Manager Operator

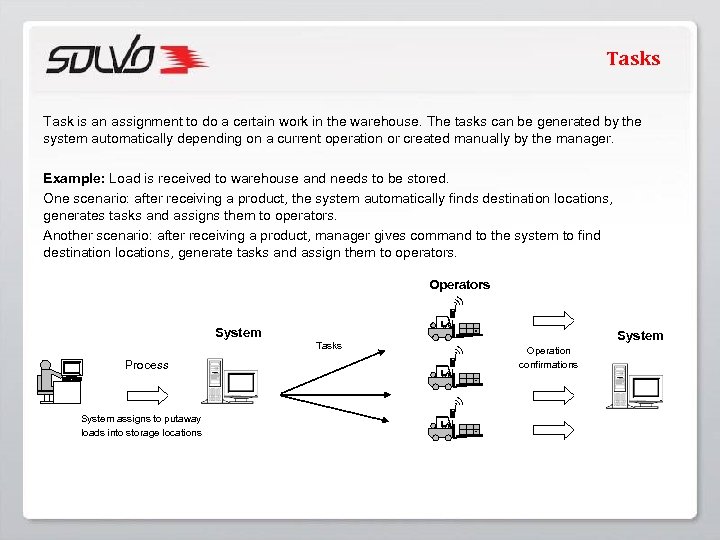

Tasks Task is an assignment to do a certain work in the warehouse. The tasks can be generated by the system automatically depending on a current operation or created manually by the manager. Example: Load is received to warehouse and needs to be stored. One scenario: after receiving a product, the system automatically finds destination locations, generates tasks and assigns them to operators. Another scenario: after receiving a product, manager gives command to the system to find destination locations, generate tasks and assign them to operators. Operators System Tasks Process System assigns to putaway loads into storage locations System Operation confirmations

Tasks Task is an assignment to do a certain work in the warehouse. The tasks can be generated by the system automatically depending on a current operation or created manually by the manager. Example: Load is received to warehouse and needs to be stored. One scenario: after receiving a product, the system automatically finds destination locations, generates tasks and assigns them to operators. Another scenario: after receiving a product, manager gives command to the system to find destination locations, generate tasks and assign them to operators. Operators System Tasks Process System assigns to putaway loads into storage locations System Operation confirmations

Task Dispatching The operator receives task assignments via a radio terminal and confirms them by scanning the cargo’s or location’s barcode. If RFID technology is deployed, task assignments are confirmed by scanning the RF mark.

Task Dispatching The operator receives task assignments via a radio terminal and confirms them by scanning the cargo’s or location’s barcode. If RFID technology is deployed, task assignments are confirmed by scanning the RF mark.

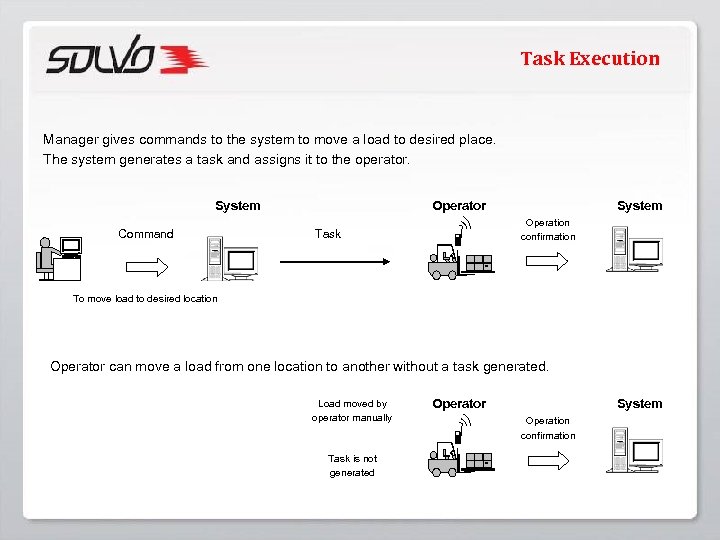

Task Execution Manager gives commands to the system to move a load to desired place. The system generates a task and assigns it to the operator. System Command Operator System Operation confirmation Task To move load to desired location Operator can move a load from one location to another without a task generated. Load moved by operator manually Task is not generated Operator System Operation confirmation

Task Execution Manager gives commands to the system to move a load to desired place. The system generates a task and assigns it to the operator. System Command Operator System Operation confirmation Task To move load to desired location Operator can move a load from one location to another without a task generated. Load moved by operator manually Task is not generated Operator System Operation confirmation

System Functions

System Functions

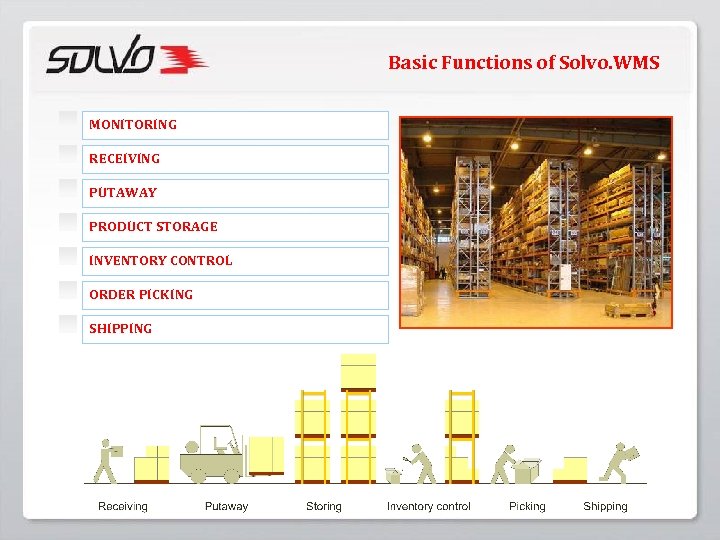

Basic Functions of Solvo. WMS MONITORING RECEIVING PUTAWAY PRODUCT STORAGE INVENTORY CONTROL ORDER PICKING SHIPPING

Basic Functions of Solvo. WMS MONITORING RECEIVING PUTAWAY PRODUCT STORAGE INVENTORY CONTROL ORDER PICKING SHIPPING

Receiving Expected receipts ASN receiving EXPECTED RECEIPTS REPACKING AND LABELING OVERSIZED GOODS RECEIVING CROSS-DOCKING WEIGHT CONTROL QC GOODS CERTIFICATION GOODS LABELING Receiving from product lines Receiving from the branches

Receiving Expected receipts ASN receiving EXPECTED RECEIPTS REPACKING AND LABELING OVERSIZED GOODS RECEIVING CROSS-DOCKING WEIGHT CONTROL QC GOODS CERTIFICATION GOODS LABELING Receiving from product lines Receiving from the branches

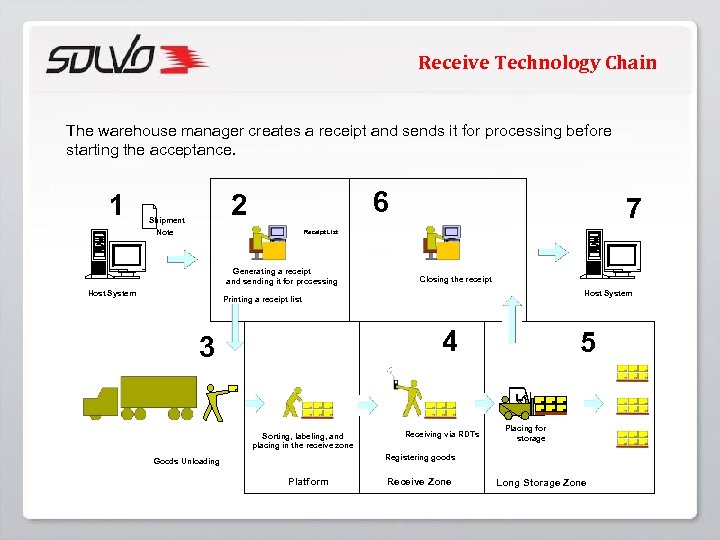

Receive Technology Chain The warehouse manager creates a receipt and sends it for processing before starting the acceptance. 1 6 2 Shipment Note 7 Receipt List Generating a receipt and sending it for processing Host System Closing the receipt Host System Printing a receipt list 4 3 Sorting, labeling, and placing in the receive zone Receiving via RDTs 5 Placing for storage Registering goods Goods Unloading Platform Receive Zone Long Storage Zone

Receive Technology Chain The warehouse manager creates a receipt and sends it for processing before starting the acceptance. 1 6 2 Shipment Note 7 Receipt List Generating a receipt and sending it for processing Host System Closing the receipt Host System Printing a receipt list 4 3 Sorting, labeling, and placing in the receive zone Receiving via RDTs 5 Placing for storage Registering goods Goods Unloading Platform Receive Zone Long Storage Zone

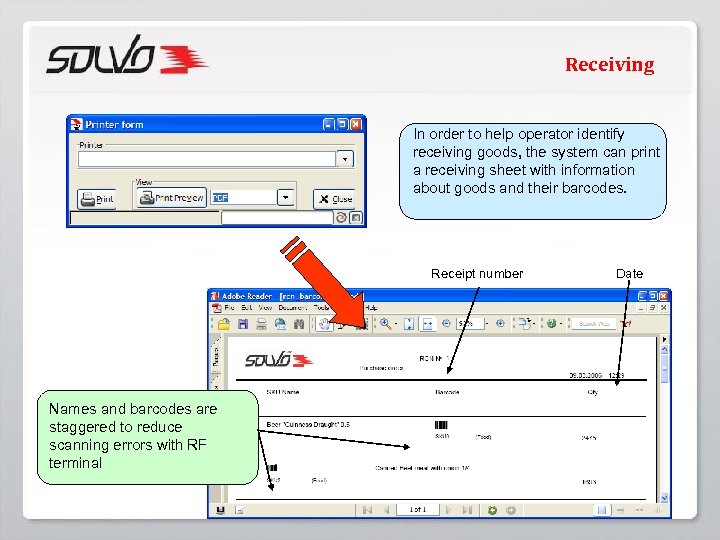

Receiving In order to help operator identify receiving goods, the system can print a receiving sheet with information about goods and their barcodes. Receipt number Names and barcodes are staggered to reduce scanning errors with RF terminal Date

Receiving In order to help operator identify receiving goods, the system can print a receiving sheet with information about goods and their barcodes. Receipt number Names and barcodes are staggered to reduce scanning errors with RF terminal Date

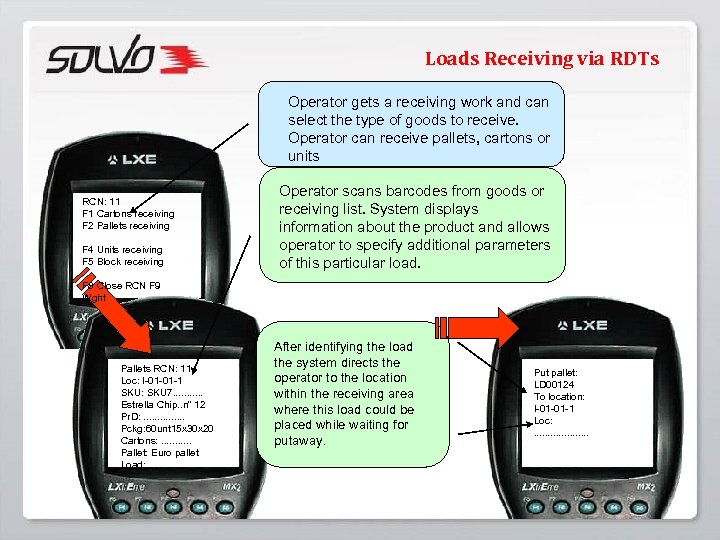

Loads Receiving via RDTs Operator gets a receiving work and can select the type of goods to receive. Operator can receive pallets, cartons or units RCN: 11 F 1 Cartons receiving F 2 Pallets receiving F 4 Units receiving F 5 Block receiving Operator scans barcodes from goods or receiving list. System displays information about the product and allows operator to specify additional parameters of this particular load. F 8 Close RCN F 9 Wght Pallets RCN: 11 Loc: I-01 -01 -1 SKU: SKU 7. . . Estrella Chip. . n" 12 Pr. D: . . . . Pckg: 60 unt 15 x 30 x 20 Cartons: . . . Pallet: Euro pallet Load: . . . After identifying the load the system directs the operator to the location within the receiving area where this load could be placed while waiting for putaway. Put pallet: LD 00124 To location: I-01 -01 -1 Loc: . .

Loads Receiving via RDTs Operator gets a receiving work and can select the type of goods to receive. Operator can receive pallets, cartons or units RCN: 11 F 1 Cartons receiving F 2 Pallets receiving F 4 Units receiving F 5 Block receiving Operator scans barcodes from goods or receiving list. System displays information about the product and allows operator to specify additional parameters of this particular load. F 8 Close RCN F 9 Wght Pallets RCN: 11 Loc: I-01 -01 -1 SKU: SKU 7. . . Estrella Chip. . n" 12 Pr. D: . . . . Pckg: 60 unt 15 x 30 x 20 Cartons: . . . Pallet: Euro pallet Load: . . . After identifying the load the system directs the operator to the location within the receiving area where this load could be placed while waiting for putaway. Put pallet: LD 00124 To location: I-01 -01 -1 Loc: . .

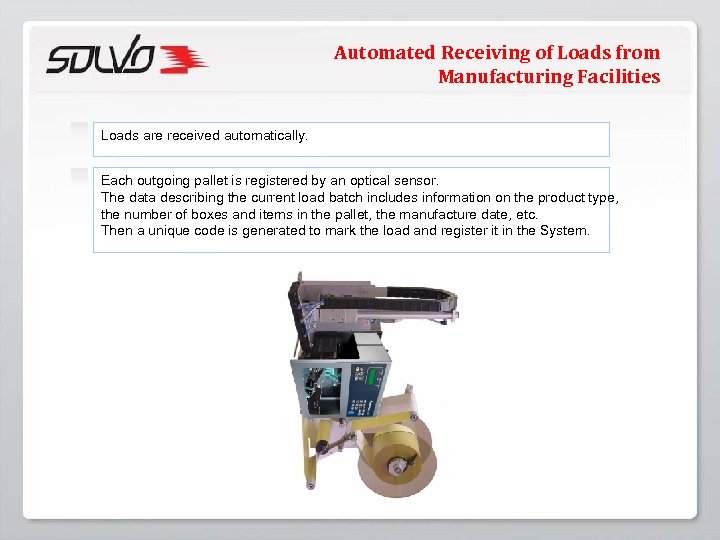

Automated Receiving of Loads from Manufacturing Facilities Loads are received automatically. Each outgoing pallet is registered by an optical sensor. The data describing the current load batch includes information on the product type, the number of boxes and items in the pallet, the manufacture date, etc. Then a unique code is generated to mark the load and register it in the System.

Automated Receiving of Loads from Manufacturing Facilities Loads are received automatically. Each outgoing pallet is registered by an optical sensor. The data describing the current load batch includes information on the product type, the number of boxes and items in the pallet, the manufacture date, etc. Then a unique code is generated to mark the load and register it in the System.

Manual Receiving of Loads from Manufacturing Facilities The operator specifies the number of the manufacturing batch that designates the product type, the number of boxes and items in the pallet, the manufacture date, etc. Then the operator assigns a unique code to the load and registers it in the System.

Manual Receiving of Loads from Manufacturing Facilities The operator specifies the number of the manufacturing batch that designates the product type, the number of boxes and items in the pallet, the manufacture date, etc. Then the operator assigns a unique code to the load and registers it in the System.

Putaway Stacker Material handling equipment PUTAWAY RULES STRATEGY OF STORAGE PLACE SEARCHING PUTAWAY OF CONTAINERS ROUTING RULES COMPATIBILITY RULES LOAD MERGING RULES TASK EXECUTION OPTIMIZATION Vehicles Warehouse operator

Putaway Stacker Material handling equipment PUTAWAY RULES STRATEGY OF STORAGE PLACE SEARCHING PUTAWAY OF CONTAINERS ROUTING RULES COMPATIBILITY RULES LOAD MERGING RULES TASK EXECUTION OPTIMIZATION Vehicles Warehouse operator

Storage in Racks Conventional racks Gravitation racks Narrow aisles Pallet stacks Cantilever racks Drive-in racks Automated warehouse Stacked racks

Storage in Racks Conventional racks Gravitation racks Narrow aisles Pallet stacks Cantilever racks Drive-in racks Automated warehouse Stacked racks

Order Picking Drop down Forward pick zones Conveyor ORDER PLANNING CONSIDERING VARIOUS REQUIREMENTS (FIFO/LIFO OR SHELF LIFE/EXPIRATION DATE) HANDLING OF ORDERS HANDLING OF SPECIAL ORDERS HANDLING OF PRODUCT KITS OPTIMIZATION OF PICKING OF PRODUCT ORDER PROCESSING IN DIFFERENT PICKUP ZONES ORDER CANCELLATION AND AMENDMENT PROCESS EXCEPTIONAL SITUATIONS Automated warehouse

Order Picking Drop down Forward pick zones Conveyor ORDER PLANNING CONSIDERING VARIOUS REQUIREMENTS (FIFO/LIFO OR SHELF LIFE/EXPIRATION DATE) HANDLING OF ORDERS HANDLING OF SPECIAL ORDERS HANDLING OF PRODUCT KITS OPTIMIZATION OF PICKING OF PRODUCT ORDER PROCESSING IN DIFFERENT PICKUP ZONES ORDER CANCELLATION AND AMENDMENT PROCESS EXCEPTIONAL SITUATIONS Automated warehouse

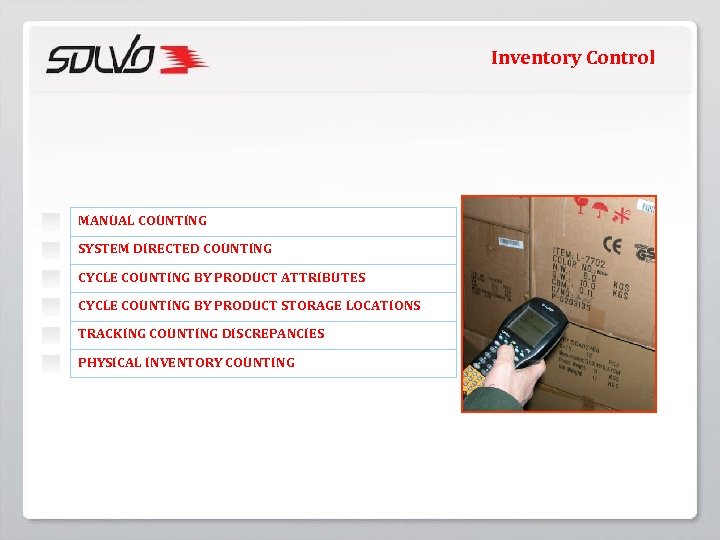

Inventory Control MANUAL COUNTING SYSTEM DIRECTED COUNTING CYCLE COUNTING BY PRODUCT ATTRIBUTES CYCLE COUNTING BY PRODUCT STORAGE LOCATIONS TRACKING COUNTING DISCREPANCIES PHYSICAL INVENTORY COUNTING

Inventory Control MANUAL COUNTING SYSTEM DIRECTED COUNTING CYCLE COUNTING BY PRODUCT ATTRIBUTES CYCLE COUNTING BY PRODUCT STORAGE LOCATIONS TRACKING COUNTING DISCREPANCIES PHYSICAL INVENTORY COUNTING

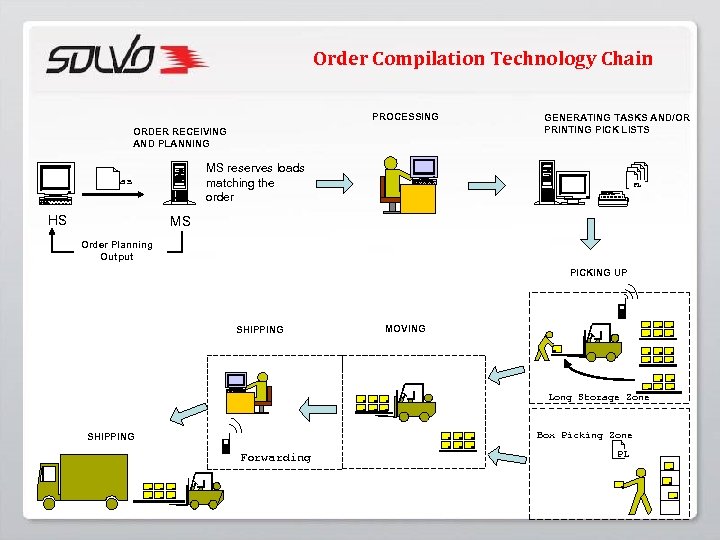

Order Compilation Technology Chain PROCESSING ORDER RECEIVING AND PLANNING MS reserves loads matching the order заказ HS GENERATING TASKS AND/OR PRINTING PICK LISTS PL MS Order Planning Output PICKING UP SHIPPING MOVING Long Storage Zone Box Picking Zone SHIPPING Forwarding PL

Order Compilation Technology Chain PROCESSING ORDER RECEIVING AND PLANNING MS reserves loads matching the order заказ HS GENERATING TASKS AND/OR PRINTING PICK LISTS PL MS Order Planning Output PICKING UP SHIPPING MOVING Long Storage Zone Box Picking Zone SHIPPING Forwarding PL

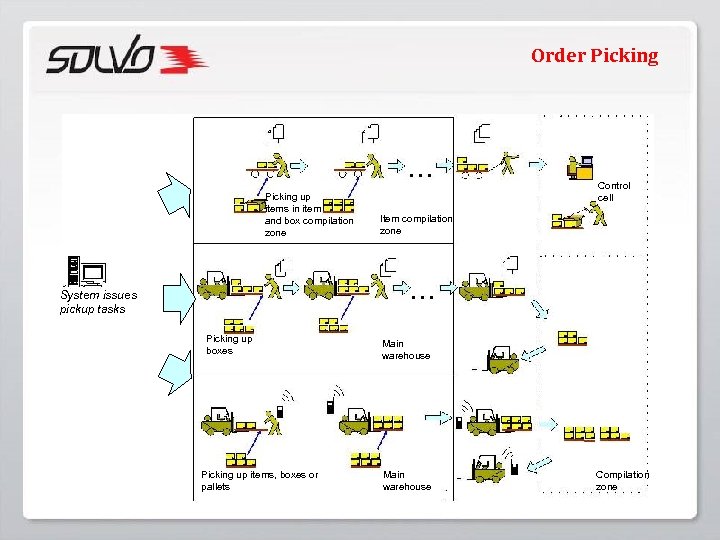

Order Picking up items in item and box compilation zone Control cell Item compilation zone System issues pickup tasks Picking up boxes Picking up items, boxes or pallets Main warehouse Compilation zone

Order Picking up items in item and box compilation zone Control cell Item compilation zone System issues pickup tasks Picking up boxes Picking up items, boxes or pallets Main warehouse Compilation zone

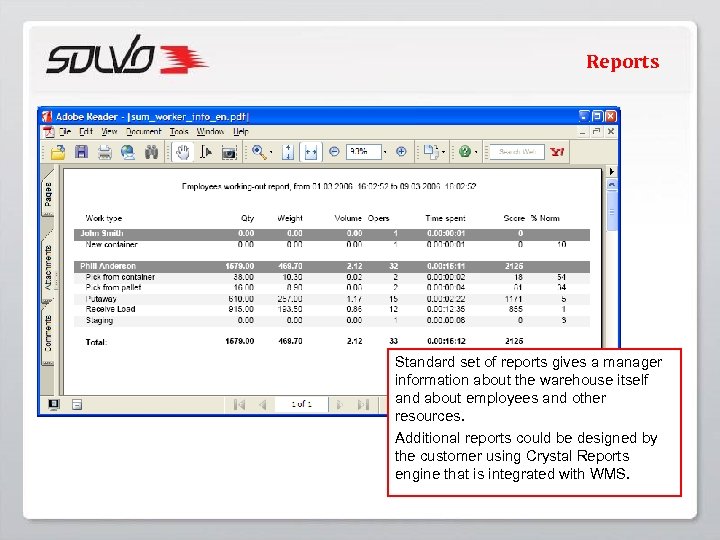

Reports Standard set of reports gives a manager information about the warehouse itself and about employees and other resources. Additional reports could be designed by the customer using Crystal Reports engine that is integrated with WMS.

Reports Standard set of reports gives a manager information about the warehouse itself and about employees and other resources. Additional reports could be designed by the customer using Crystal Reports engine that is integrated with WMS.

Shipping Sorting Labeling PACKING SORTING LABELING ORDER GROUPING CONTROL VEHICLE LOADING OPTIMIZATION LOADING OF VEHICLES REGARDLESS OF ORDER CONTINUITY PROCESS AND ANALYZE STATISTIC DATA Packing Loading

Shipping Sorting Labeling PACKING SORTING LABELING ORDER GROUPING CONTROL VEHICLE LOADING OPTIMIZATION LOADING OF VEHICLES REGARDLESS OF ORDER CONTINUITY PROCESS AND ANALYZE STATISTIC DATA Packing Loading

Basic Configuring Rules

Basic Configuring Rules

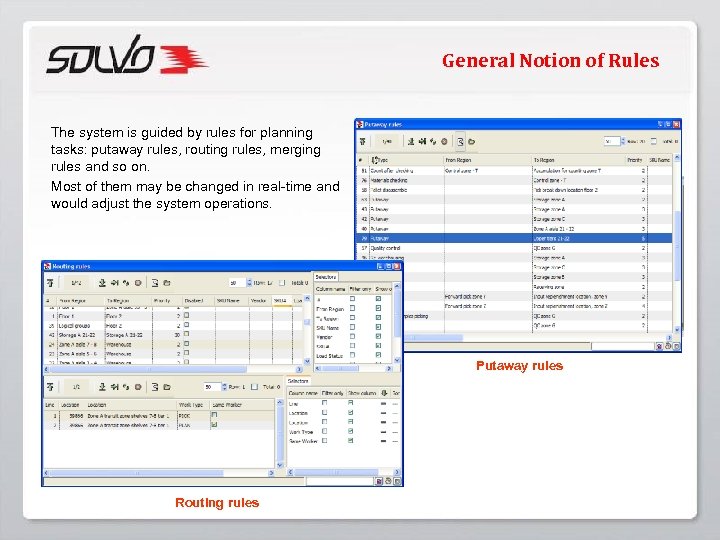

General Notion of Rules The system is guided by rules for planning tasks: putaway rules, routing rules, merging rules and so on. Most of them may be changed in real-time and would adjust the system operations. Putaway rules Routing rules

General Notion of Rules The system is guided by rules for planning tasks: putaway rules, routing rules, merging rules and so on. Most of them may be changed in real-time and would adjust the system operations. Putaway rules Routing rules

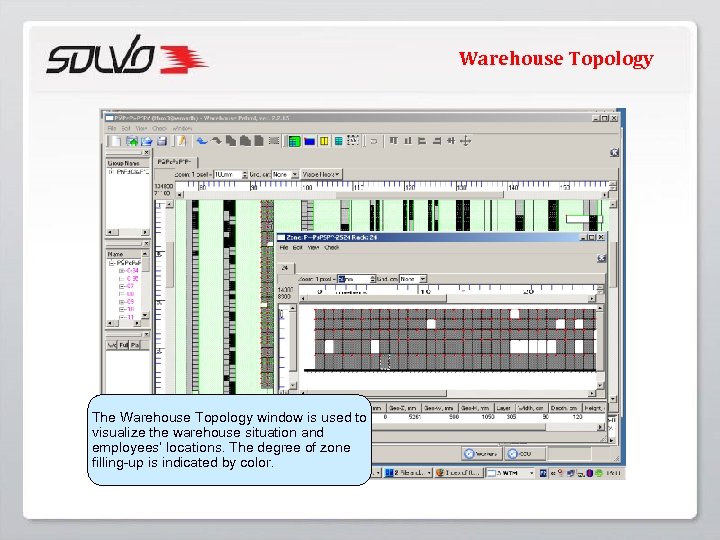

Warehouse Topology The Warehouse Topology window is used to visualize the warehouse situation and employees’ locations. The degree of zone filling-up is indicated by color.

Warehouse Topology The Warehouse Topology window is used to visualize the warehouse situation and employees’ locations. The degree of zone filling-up is indicated by color.

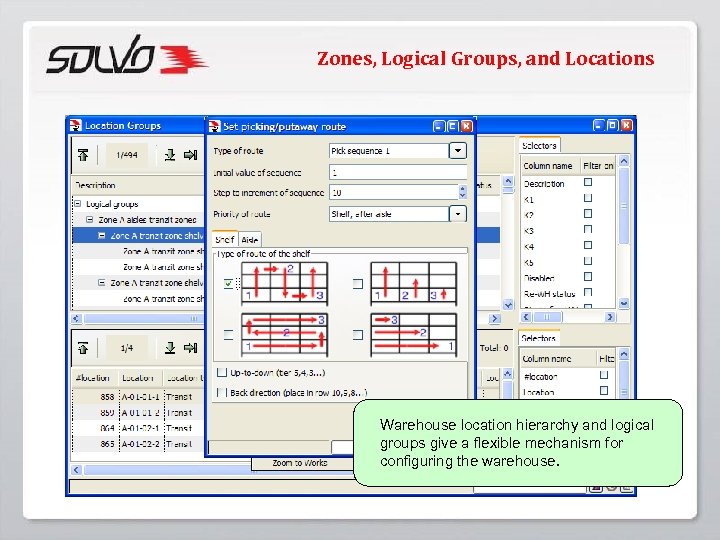

Zones, Logical Groups, and Locations Warehouse location hierarchy and logical groups give a flexible mechanism for configuring the warehouse.

Zones, Logical Groups, and Locations Warehouse location hierarchy and logical groups give a flexible mechanism for configuring the warehouse.

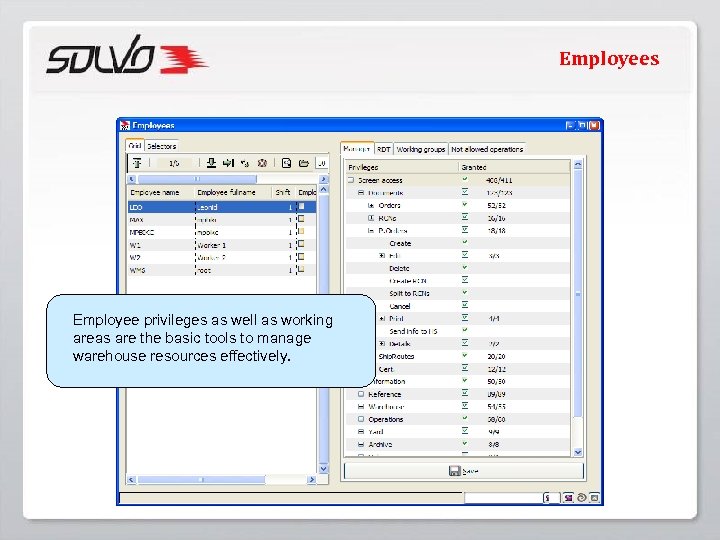

Employees Employee privileges as well as working areas are the basic tools to manage warehouse resources effectively.

Employees Employee privileges as well as working areas are the basic tools to manage warehouse resources effectively.

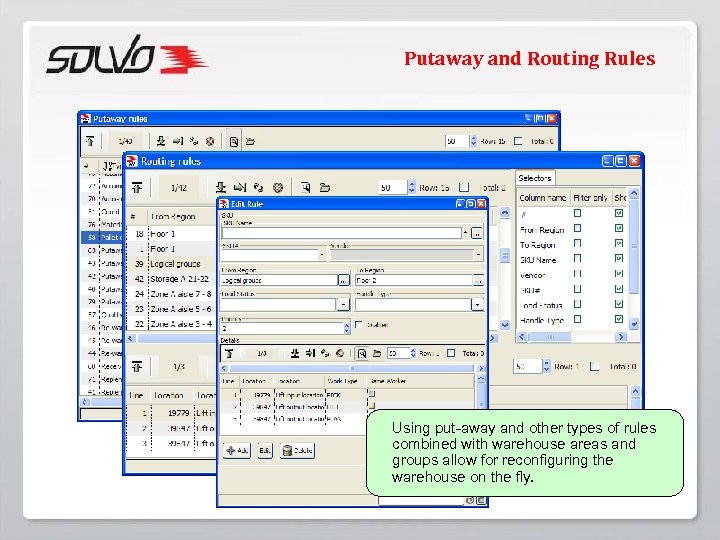

Putaway and Routing Rules Using put-away and other types of rules combined with warehouse areas and groups allow for reconfiguring the warehouse on the fly.

Putaway and Routing Rules Using put-away and other types of rules combined with warehouse areas and groups allow for reconfiguring the warehouse on the fly.

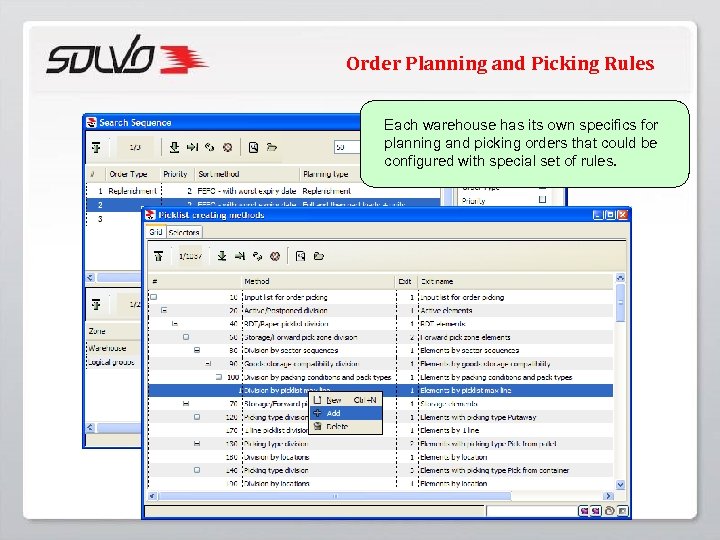

Order Planning and Picking Rules Each warehouse has its own specifics for planning and picking orders that could be configured with special set of rules.

Order Planning and Picking Rules Each warehouse has its own specifics for planning and picking orders that could be configured with special set of rules.

Solvo. Web and Solvo. Billing Add-On Modules

Solvo. Web and Solvo. Billing Add-On Modules

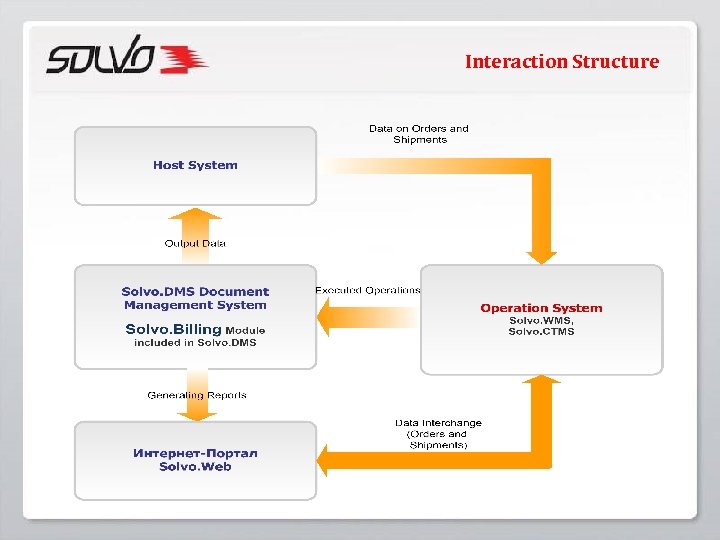

Interaction Structure

Interaction Structure

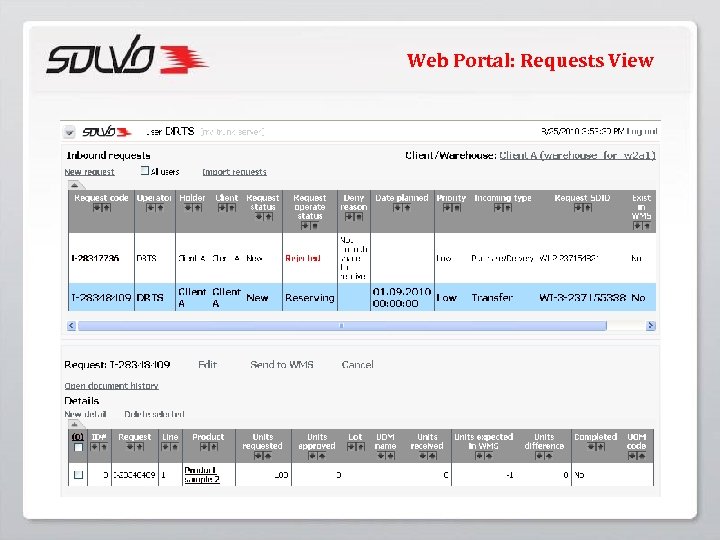

Web Portal: Requests View

Web Portal: Requests View

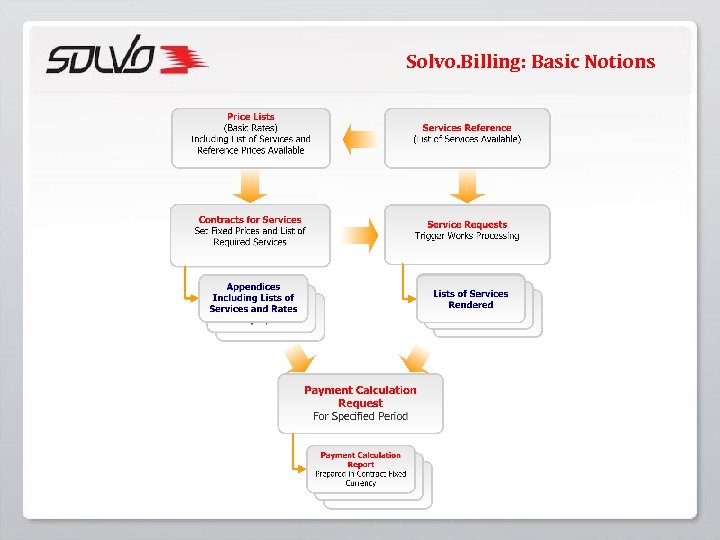

Solvo. Billing: Basic Notions

Solvo. Billing: Basic Notions

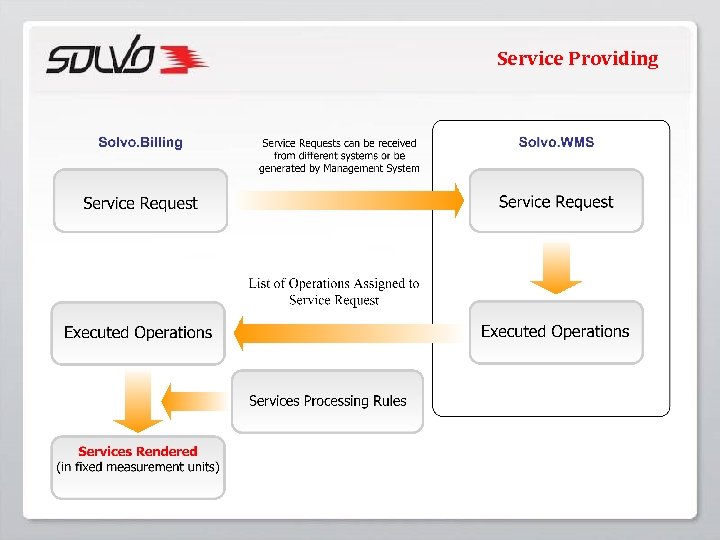

Service Providing

Service Providing

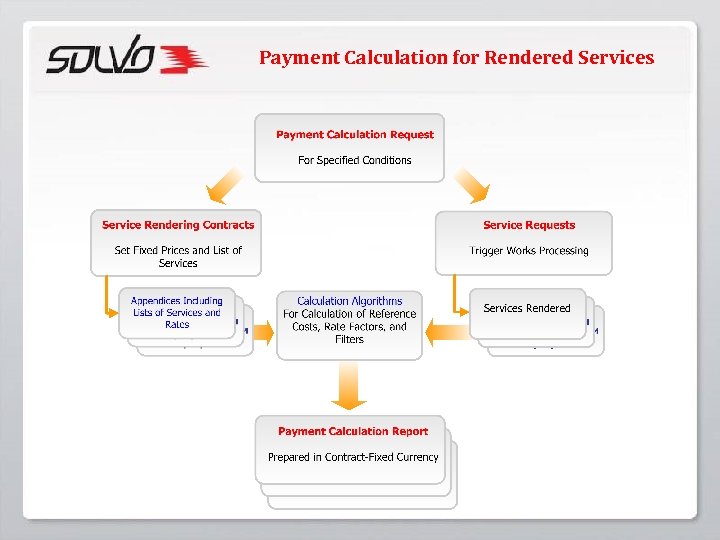

Payment Calculation for Rendered Services

Payment Calculation for Rendered Services

Equipment Integration Features SOLVO’s extensive experience in implementing warehouse automation projects includes expertise in integrating the system with various kinds of warehouse operation equipment. Solvo. WMS can work with automated warehouses, cantilever racks, radio shuttles, conveyors, flow racks, etc. AUTOMATED WAREHOUSES FLOW RACKS CONVEYORS RADIO SHUTTLES

Equipment Integration Features SOLVO’s extensive experience in implementing warehouse automation projects includes expertise in integrating the system with various kinds of warehouse operation equipment. Solvo. WMS can work with automated warehouses, cantilever racks, radio shuttles, conveyors, flow racks, etc. AUTOMATED WAREHOUSES FLOW RACKS CONVEYORS RADIO SHUTTLES

Equipment Integration Features LABELING EQUIPMENT APPLICATORS WEIGHING EQUIPMENT

Equipment Integration Features LABELING EQUIPMENT APPLICATORS WEIGHING EQUIPMENT

Efficiency Benefits

Efficiency Benefits

Project Cost-Efficiency Benefits MAINTENANCE COSTS § § § Material handling equipment rational utilization Equipment deployment optimization Reduce transportation costs (save fuel and electricity, reduce maintenance costs and extend material handling equipment exploitation term) PERSONNEL MANAGEMENT § § CUSTOMER RELATIONS § § Eliminate non standard order shipment Documentation extra shipment or order return Lower expired product write-off costs Increase quality of services Increase personnel management efficiency Eliminate unpredictable circumstances and expose guilty Reduce entire operational time Enhance labor productivity by 20 -30% on average MANAGEMENT ACCOUNTING AND DOCUMENT CIRCULATION § § § Data access in real time mode Speed up data interchange Reduce paper work Inventory control without interrupting warehouse operation Integration with corporate systems

Project Cost-Efficiency Benefits MAINTENANCE COSTS § § § Material handling equipment rational utilization Equipment deployment optimization Reduce transportation costs (save fuel and electricity, reduce maintenance costs and extend material handling equipment exploitation term) PERSONNEL MANAGEMENT § § CUSTOMER RELATIONS § § Eliminate non standard order shipment Documentation extra shipment or order return Lower expired product write-off costs Increase quality of services Increase personnel management efficiency Eliminate unpredictable circumstances and expose guilty Reduce entire operational time Enhance labor productivity by 20 -30% on average MANAGEMENT ACCOUNTING AND DOCUMENT CIRCULATION § § § Data access in real time mode Speed up data interchange Reduce paper work Inventory control without interrupting warehouse operation Integration with corporate systems

Economic Efficiency Benefits LOGISTICS § § § Flexibly prioritized and optimized flows of goods and resources. Increased data accuracy (up to 99. 9%) for exact quantity and location of goods within warehouse. Full visibility of product flows and distribution. Improved product placement to increase warehouse storage capacity by 5 to 25%. Accelerated product distribution. Lowered costs for writing-off overdue timesensitive products.

Economic Efficiency Benefits LOGISTICS § § § Flexibly prioritized and optimized flows of goods and resources. Increased data accuracy (up to 99. 9%) for exact quantity and location of goods within warehouse. Full visibility of product flows and distribution. Improved product placement to increase warehouse storage capacity by 5 to 25%. Accelerated product distribution. Lowered costs for writing-off overdue timesensitive products.

Pharmaceutics Oblastnaya Aptechnaya Kompania, Don. Farm Holding, (Apteka Holding), Donetsk, Ukraine § «Solvo. WMS solution enables us to provide a high level of control over inventory flow and labor productivity as well as to accurately track every picking and shipping operation. It ensures real time information on product available for shipment. Additionally, we optimized utilization of warehouse facilities and reduced order picking costs…”. § «Developed to our unique specifications, Solvo. WMS fully meets our requirements… The entire implementation process went extremely smooth, and was completed within to our strict deadline» Yuriy Koba, Executive Director

Pharmaceutics Oblastnaya Aptechnaya Kompania, Don. Farm Holding, (Apteka Holding), Donetsk, Ukraine § «Solvo. WMS solution enables us to provide a high level of control over inventory flow and labor productivity as well as to accurately track every picking and shipping operation. It ensures real time information on product available for shipment. Additionally, we optimized utilization of warehouse facilities and reduced order picking costs…”. § «Developed to our unique specifications, Solvo. WMS fully meets our requirements… The entire implementation process went extremely smooth, and was completed within to our strict deadline» Yuriy Koba, Executive Director

Pharmaceutics Rossib Farmacia, ROSTA Pharmacology Group, Novosibirsk § § «The System will be able to solve issues that may arise in future. It enables us to enhance labor efficiency and therefore, it dramatically improves company performance. . . Upon implementing Solvo. WMS and automating our warehouse processes, we had certain objectives that we subsequently gained: Solvo WMS allowed us to reduce goods processing time and personnel inaccuracy to a minimum as well as optimize material workflows within the warehouse…» «The system manages picking of numerous retail orders with a high level of accuracy, and it supports standard unit picking, making the process flexible and convenient for the customers. As to the Solvo WMS implementation in particular, it was quite an easy and painless process…» Andrey Kucharenok, Logistics and procurement Executive

Pharmaceutics Rossib Farmacia, ROSTA Pharmacology Group, Novosibirsk § § «The System will be able to solve issues that may arise in future. It enables us to enhance labor efficiency and therefore, it dramatically improves company performance. . . Upon implementing Solvo. WMS and automating our warehouse processes, we had certain objectives that we subsequently gained: Solvo WMS allowed us to reduce goods processing time and personnel inaccuracy to a minimum as well as optimize material workflows within the warehouse…» «The system manages picking of numerous retail orders with a high level of accuracy, and it supports standard unit picking, making the process flexible and convenient for the customers. As to the Solvo WMS implementation in particular, it was quite an easy and painless process…» Andrey Kucharenok, Logistics and procurement Executive

Distribution ASB Reiting, Moscow § «The style of work and professionalism of Solvo personnel fully met our expectations» § «Solvo. WMS implementation enhanced data interchange, made information readily available on any event in real time mode, and increased quantitative and stowage data accuracy to 99. 9%. It provided total inventory control within the warehouse suite, optimized material handling equipment and transport as well as significantly sped up and extended goods turnover and warehouse space…» Sergey Nosov, Development Manager

Distribution ASB Reiting, Moscow § «The style of work and professionalism of Solvo personnel fully met our expectations» § «Solvo. WMS implementation enhanced data interchange, made information readily available on any event in real time mode, and increased quantitative and stowage data accuracy to 99. 9%. It provided total inventory control within the warehouse suite, optimized material handling equipment and transport as well as significantly sped up and extended goods turnover and warehouse space…» Sergey Nosov, Development Manager

Distribution Svarog Inc. , Saint Petersburg § § «Solvo. WMS, configured by Solvo experts to specifically fit our needs, has enabled us to resolve problems of control over alcohol product inventory turns and accompanying documents. It has improved warehouse space utilization, considerably enhanced performance and reduced the percentage of human errors during order staging…» «So far we’ve established long term beneficial cooperation with Solvo. Professionalism, ability to comprehend customers’ interests, reliability and operative response- those are the most distinguishing features of our partner…» Yuriy Romadanov, Deputy Director, Commercial and Logistics

Distribution Svarog Inc. , Saint Petersburg § § «Solvo. WMS, configured by Solvo experts to specifically fit our needs, has enabled us to resolve problems of control over alcohol product inventory turns and accompanying documents. It has improved warehouse space utilization, considerably enhanced performance and reduced the percentage of human errors during order staging…» «So far we’ve established long term beneficial cooperation with Solvo. Professionalism, ability to comprehend customers’ interests, reliability and operative response- those are the most distinguishing features of our partner…» Yuriy Romadanov, Deputy Director, Commercial and Logistics

Distribution Centr. Obuv, Moscow § Solvo. WMS is an expert system able to provide recommendations on optimizing the whole range of warehouse technological processes and coordinating personnel and equipment tasks in order to get maximum efficiency of warehouse area and improve warehouse output. § We expect to gain maximal result from this project after implementing the second part of the project on piece (paired) warehouse. We expect Solvo. WMS solution to assume most of planning and taking decisions, which in my opinion should 1, 5 times lower efforts and 3 times increase order processing (with the same labor resources). § Experience of cooperation with SOLVO specialists showed high level of their qualification and good knowledge of warehouse specificity. Е. Gorislavets, Logistics Director

Distribution Centr. Obuv, Moscow § Solvo. WMS is an expert system able to provide recommendations on optimizing the whole range of warehouse technological processes and coordinating personnel and equipment tasks in order to get maximum efficiency of warehouse area and improve warehouse output. § We expect to gain maximal result from this project after implementing the second part of the project on piece (paired) warehouse. We expect Solvo. WMS solution to assume most of planning and taking decisions, which in my opinion should 1, 5 times lower efforts and 3 times increase order processing (with the same labor resources). § Experience of cooperation with SOLVO specialists showed high level of their qualification and good knowledge of warehouse specificity. Е. Gorislavets, Logistics Director

Commercial Warehouse (3 PL) Sherland Ltd. , Moscow § «Through using Solvo’s WMS, we are able to provide customers with accurate information on ordered item location in real time mode. It has enabled our customers to partner with a team of professionals, save money on financial and human resources and to invest that savings into new projects. Soon we will be able to allow customers the possibility to track and trace the order staging process in real time mode via remote excess…» § «The Virtual warehouse support that is available for customers, the universal gateway which provides interaction with different corporate systems and the online access to goods processing data in real time for customers greatly help us to manage our operation more efficiently» Olga Alexandrova, Commercial Manager

Commercial Warehouse (3 PL) Sherland Ltd. , Moscow § «Through using Solvo’s WMS, we are able to provide customers with accurate information on ordered item location in real time mode. It has enabled our customers to partner with a team of professionals, save money on financial and human resources and to invest that savings into new projects. Soon we will be able to allow customers the possibility to track and trace the order staging process in real time mode via remote excess…» § «The Virtual warehouse support that is available for customers, the universal gateway which provides interaction with different corporate systems and the online access to goods processing data in real time for customers greatly help us to manage our operation more efficiently» Olga Alexandrova, Commercial Manager

Production Wimm Bill Dann Tomilino, Moscow § “Business process optimization that allows organizing warehouse workflows efficiently is the major advantage of Solvo. WMS besides just the optimization of material handling equipment, labor and storage space…» § «We’re grateful to the Solvo specialists for the significant role that they played in the development of our business. It was through Solvo’s vast experience that we were able to create a flexible management system that provided an efficient ROI, increased performance and resources availability as well as enhanced customer service. We look forward to continuing our relationship in future» Victor Kolesnik, Manager of the warehouse suite

Production Wimm Bill Dann Tomilino, Moscow § “Business process optimization that allows organizing warehouse workflows efficiently is the major advantage of Solvo. WMS besides just the optimization of material handling equipment, labor and storage space…» § «We’re grateful to the Solvo specialists for the significant role that they played in the development of our business. It was through Solvo’s vast experience that we were able to create a flexible management system that provided an efficient ROI, increased performance and resources availability as well as enhanced customer service. We look forward to continuing our relationship in future» Victor Kolesnik, Manager of the warehouse suite

Project Implementation and Deployment

Project Implementation and Deployment

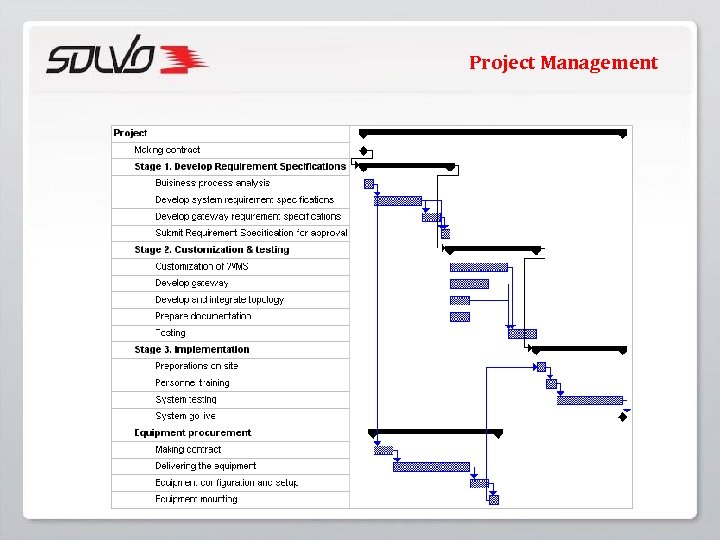

Project Management

Project Management

Personnel Trainings are organized for: § Administrators § Managers Theory studies in class room § Operators Practicing on site Trainees receive SOLVO certificates upon successful completion of training program

Personnel Trainings are organized for: § Administrators § Managers Theory studies in class room § Operators Practicing on site Trainees receive SOLVO certificates upon successful completion of training program

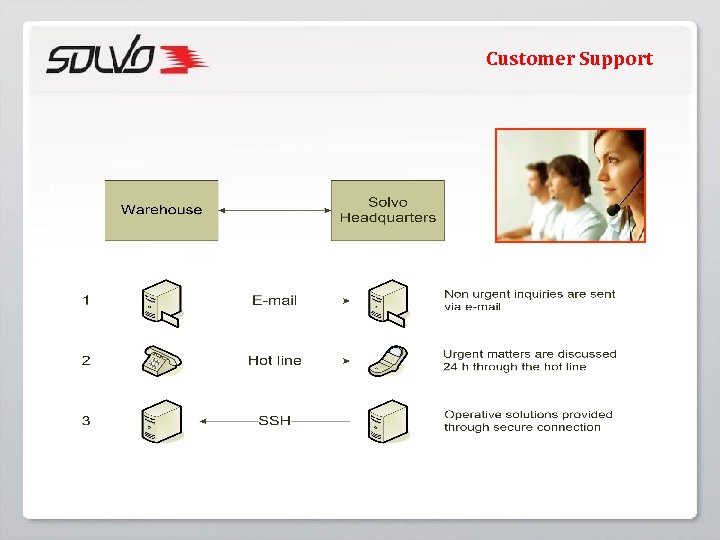

Customer Support

Customer Support

Contact Us Address: Kolomiazhski 33 a, Saint Petersburg, Russia, 197341 Phone: +7 (812) 60 -60 -555 Fax: +7 (812) 60 -60 -771 E-mail: sales@solvo. ru Web: www. solvo. ru

Contact Us Address: Kolomiazhski 33 a, Saint Petersburg, Russia, 197341 Phone: +7 (812) 60 -60 -555 Fax: +7 (812) 60 -60 -771 E-mail: sales@solvo. ru Web: www. solvo. ru

Solvo www. solvo. ru

Solvo www. solvo. ru