78cbd90ba86b5d54ac3d08771515b788.ppt

- Количество слайдов: 42

VÚB a. s. Usti nad Orlici, CZECH REPUBLIC Cotton Industry Research Institute Co. Ltd. Welcome on presentation of QQM-3 system E-mail: qqm@vubas. cz www. vubas. cz

VÚB a. s. Usti nad Orlici, CZECH REPUBLIC Cotton Industry Research Institute Co. Ltd. VÚB a. s. was established on the 1 st May 1992 as legal succesor of the original national enterprise which was established in 1949. VÚB Ústí nad Orlicí is known in the textile world as a company with long-years experience and tradition in the field of textiles and textile machinery. Since year 2001 certificated by ISO 9001: 2001 and ISO 14001. E-mail: qqm@vubas. cz www. vubas. cz

Present activities Research and development Continuous improvement of OE rotor spinning machines and technology. R&D of a new high-speed spindle spinning technology. R&D of a technology for manufacture of 100% flax and hemp yarns by means of short-staple spinning technology. Technology for the manufacture of staple and multi-component yarns for non-apparel special conditions (e. g. flame retardant and non-flamable yarns, anti-bacterial yarns suitable for technical, furnishing medical and other applications, … ). E-mail: qqm@vubas. cz www. vubas. cz

Present activities Mechanical engineering Fabric folding and measuring machine - MS-3, for application in weawing and finishing mills special single-purpose machines and devices for various applications, e. g. high-volume winders for tyre-cord production lines, special welding machines for metalic wire fabric manufacture, various manipulation lines and devices „tailored“ according to customer‘s needs. E-mail: qqm@vubas. cz www. vubas. cz

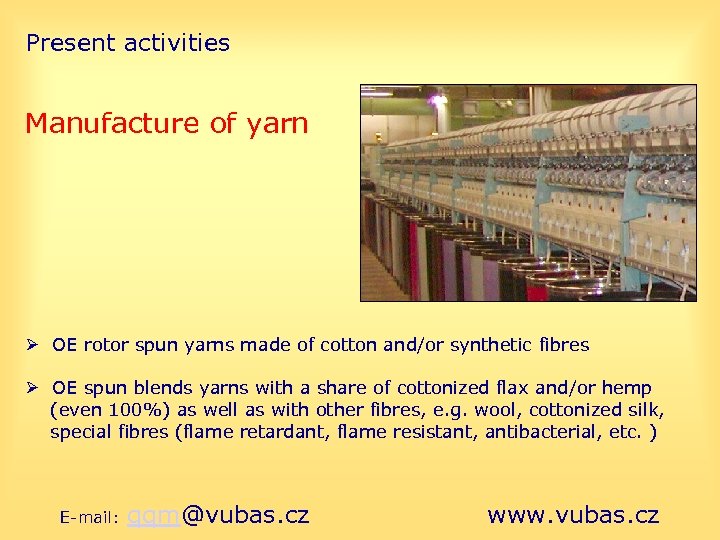

Present activities Manufacture of yarn OE rotor spun yarns made of cotton and/or synthetic fibres OE spun blends yarns with a share of cottonized flax and/or hemp (even 100%) as well as with other fibres, e. g. wool, cottonized silk, special fibres (flame retardant, flame resistant, antibacterial, etc. ) E-mail: qqm@vubas. cz www. vubas. cz

Present activities Special textile services textile testing laboratory equipped with up-to-date measuring instruments (e. g. HVI Spilab, AFIS, UT-3, UTR-4, . . . ) Special information services for customers in the fields of textile industry Information services for Association of Czech Textile industry (ATOK) Special technical and information services for czech textile companies We own and operate textile server www. TEXTIL. cz E-mail: qqm@vubas. cz www. vubas. cz

Present activities QQM-3 system What is QQM-3 ? QQM-3 is a portable instrument for quick operative quality control of yarn in spinning mills.

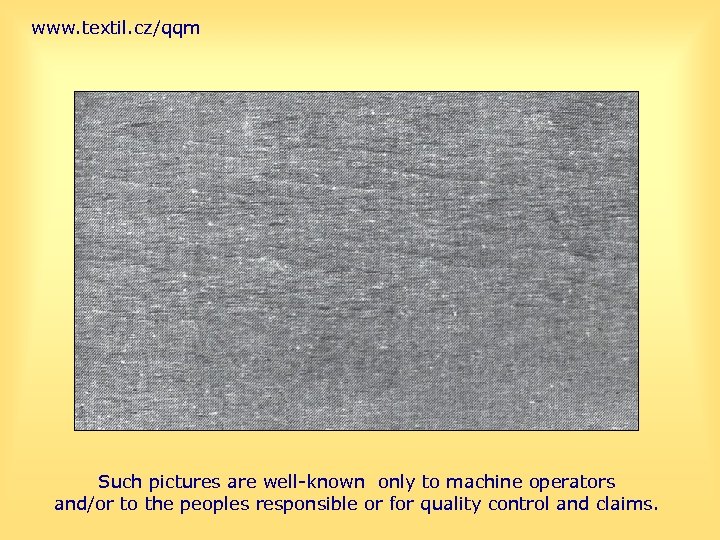

www. textil. cz/qqm . . . problems with quality of yarn ?

www. textil. cz/qqm Such pictures are well-known only to machine operators and/or to the peoples responsible or for quality control and claims.

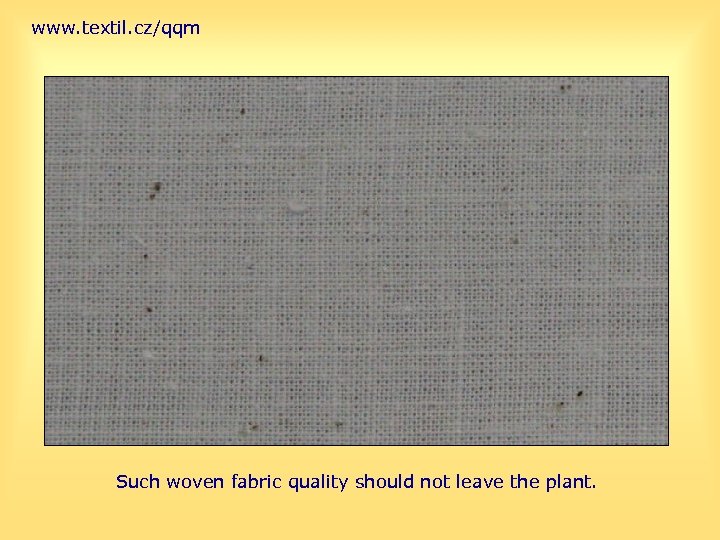

www. textil. cz/qqm Such woven fabric quality should not leave the plant.

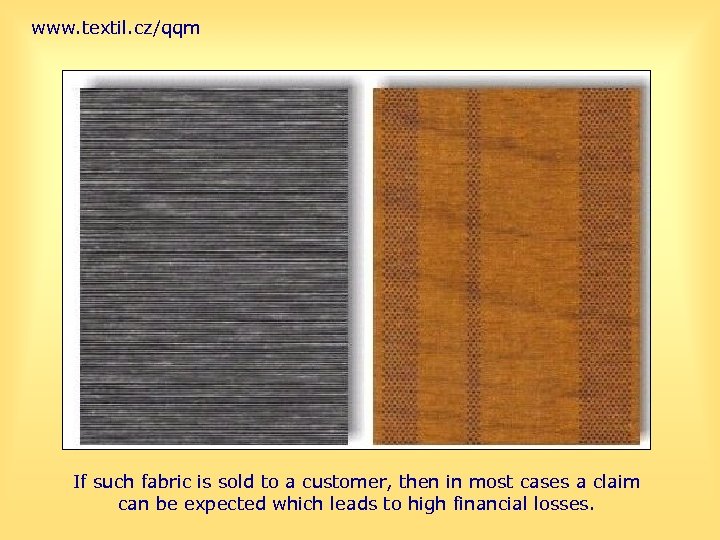

www. textil. cz/qqm If such fabric is sold to a customer, then in most cases a claim can be expected which leads to high financial losses.

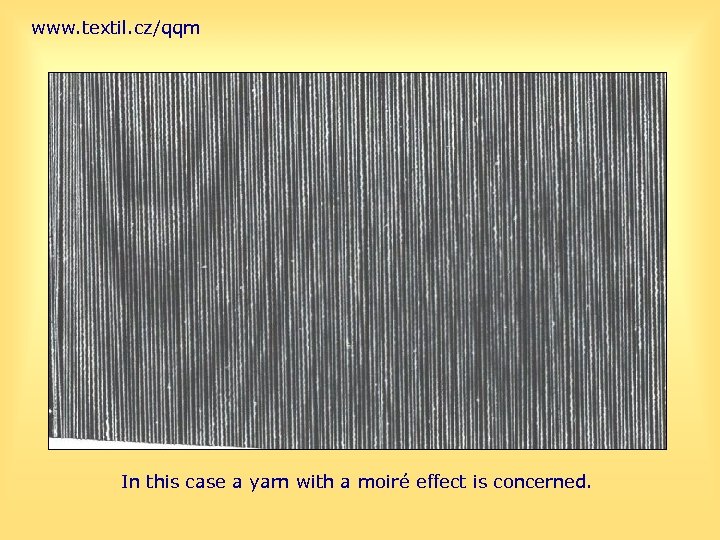

www. textil. cz/qqm In this case a yarn with a moiré effect is concerned.

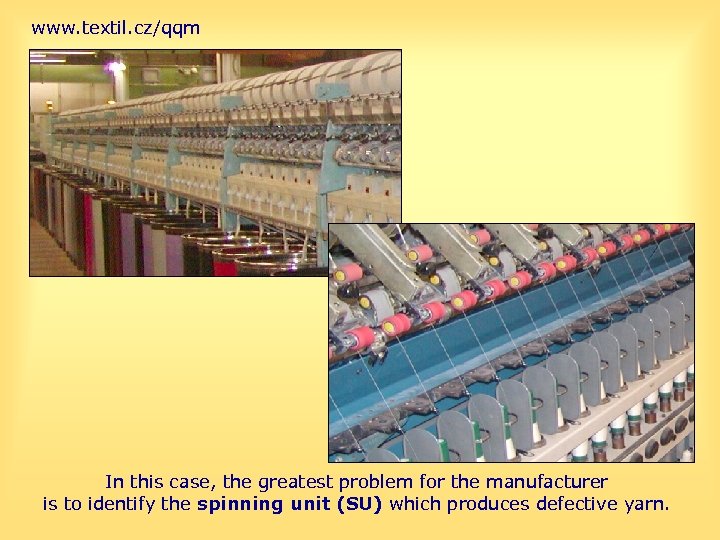

www. textil. cz/qqm In this case, the greatest problem for the manufacturer is to identify the spinning unit (SU) which produces defective yarn.

www. textil. cz/qqm The greatest problem for the manufacturer is to identify the spinning unit (SU) which produces the faulty yarn.

www. textil. cz/qqm Troubleshooting 1 * LABORATORY ANALYSE

www. textil. cz/qqm Troubleshooting 1 * LABORATORY ANALYSE ADVANTAGES: - exactly and detailed results HANDICAPS: - high purchase and operation costs - long time to results necessary - necessary of attendant operator - practically impossible for measuring of all SU

www. textil. cz/qqm Troubleshooting 2 * ON-LINE QUALITY CONTROL

www. textil. cz/qqm Troubleshooting 2 * ON-LINE QUALITY CONTROL ADVANTAGES: - automatics, no need operating staff HANDICAPS: - high purchase cost - absent solution for ring spinning machines - stationary - only for ONE machine - requisite of higly qualified and experienced operator for machine operation

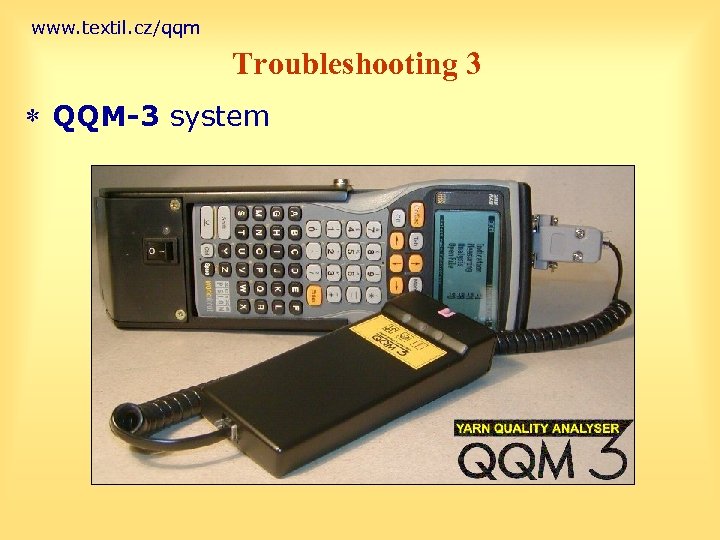

www. textil. cz/qqm Troubleshooting 3 * QQM-3 system

www. textil. cz/qqm QQM-3 is the abbrevation for the English name Quick Quality Measuring. The digit 3 means the third series in its devepolment. The third possibility - the use of the QQM-3 device that enables them to reveal the spinning units productions a lower quality yarn directly, in time and with minimum costs and to remove the defects without delay.

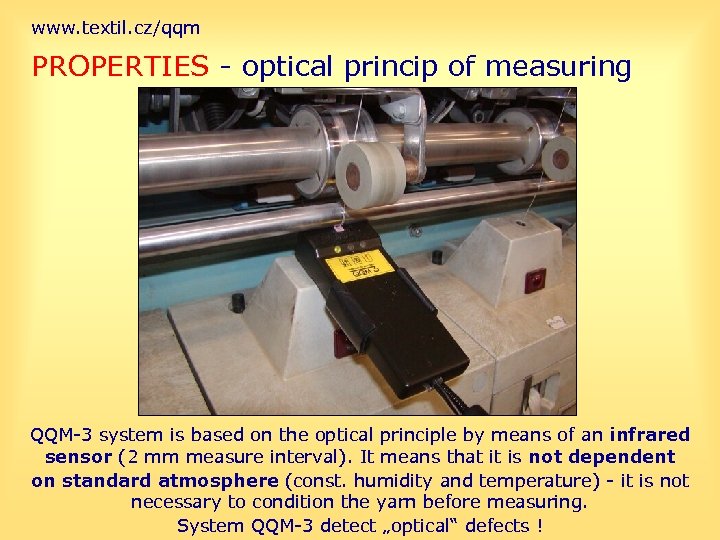

www. textil. cz/qqm PROPERTIES - optical princip of measuring QQM-3 system is based on the optical principle by means of an infrared sensor (2 mm measure interval). It means that it is not dependent on standard atmosphere (const. humidity and temperature) - it is not necessary to condition the yarn before measuring. System QQM-3 detect „optical“ defects !

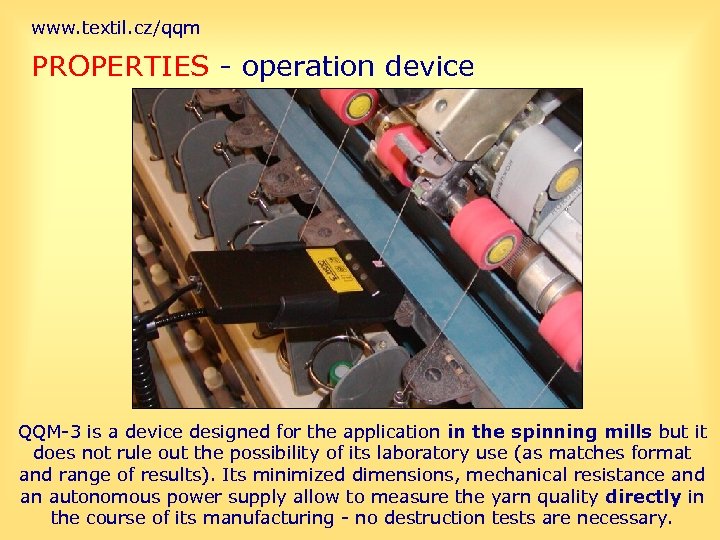

www. textil. cz/qqm PROPERTIES - operation device QQM-3 is a device designed for the application in the spinning mills but it does not rule out the possibility of its laboratory use (as matches format and range of results). Its minimized dimensions, mechanical resistance and an autonomous power supply allow to measure the yarn quality directly in the course of its manufacturing - no destruction tests are necessary.

www. textil. cz/qqm PROPERTIES - quickness and instant reaction For a quick rough measuring it is sufficient to scan about 10 meters of yarn. A rotor spinning machine is reliability measured within 60 min including an evaluation. Unlike laboratory procedures here the operator can carry out an intervention in the production process immediately after the measuring. At least to stop production of rejects.

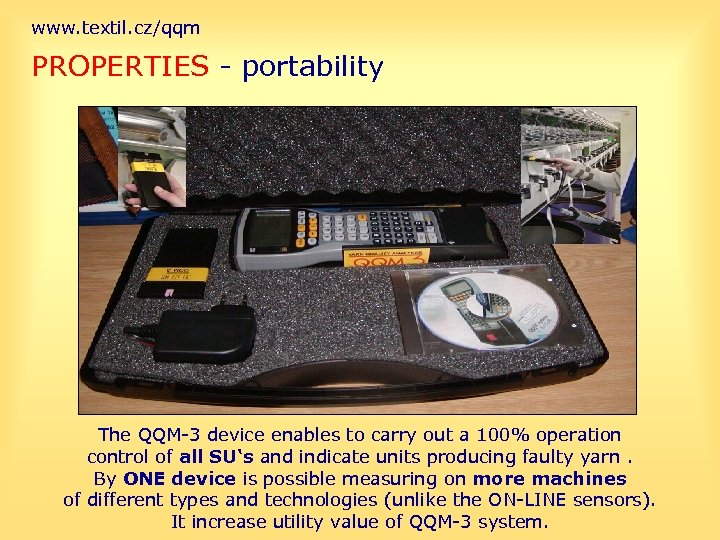

www. textil. cz/qqm PROPERTIES - portability The QQM-3 device enables to carry out a 100% operation control of all SU‘s and indicate units producing faulty yarn. By ONE device is possible measuring on more machines of different types and technologies (unlike the ON-LINE sensors). It increase utility value of QQM-3 system.

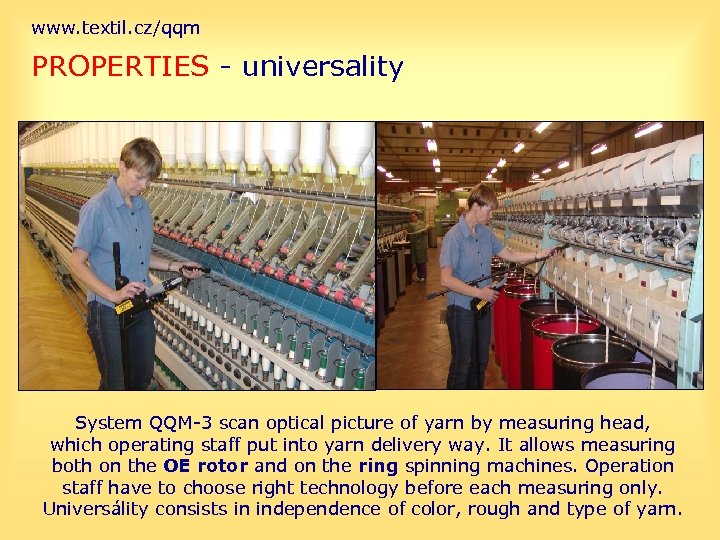

www. textil. cz/qqm PROPERTIES - universality System QQM-3 scan optical picture of yarn by measuring head, which operating staff put into yarn delivery way. It allows measuring both on the OE rotor and on the ring spinning machines. Operation staff have to choose right technology before each measuring only. Universálity consists in independence of color, rough and type of yarn.

www. textil. cz/qqm PROPERTIES - modularity QQM-3 system has 4 types of measuring ( only ONE hardware with software modules ) 1. INDICATION - measuring time about 10 sec - comparing of quality in terms CV% 10 meters of yarn 2. MEASURING - measuring time about 1 -3 min - detailed measuring of yarn 3. ANALYSIS - measuring time about 3 -10 min - detailed measuring of yarn and spectral analysis 4. DATA SOURCE - data gathering for analyse on PC

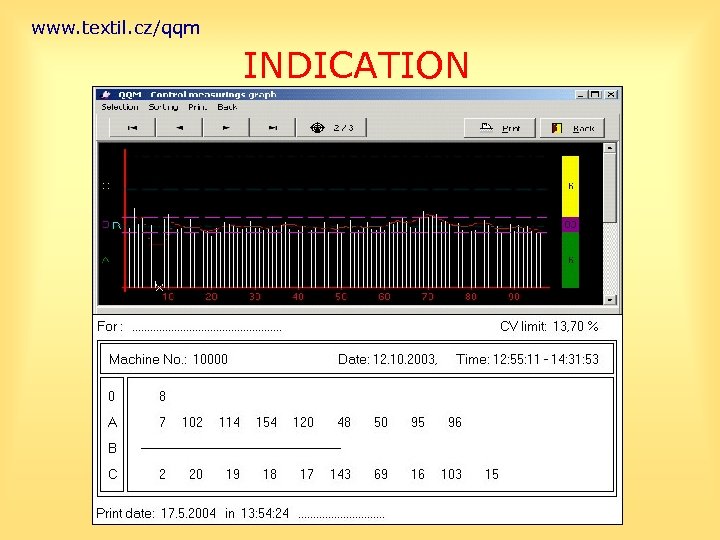

www. textil. cz/qqm INDICATION measuring time about 10 sec (depending on delivery speed) Results: - particular CV% for each SU - graph of a CV% values (fault SU blinking) - view table of fault SU Effect: - detection of faulty SU on machine - quick technical examination of spinning machine - increasing quality of production

www. textil. cz/qqm INDICATION

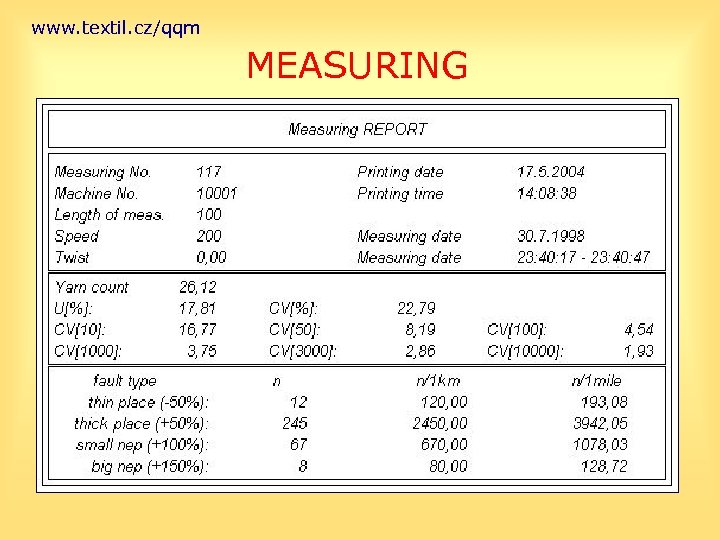

www. textil. cz/qqm MEASURING measuring time about 1 -3 min (depending on measured length and delivery speed) Results: - Y. C. (yarn count - fineness [TEX]) - U%, CV% in cut lengths - indicators IPI (thin and thick places, neps) Effect: - quick and detailed informations about quality of producing yarn

www. textil. cz/qqm MEASURING

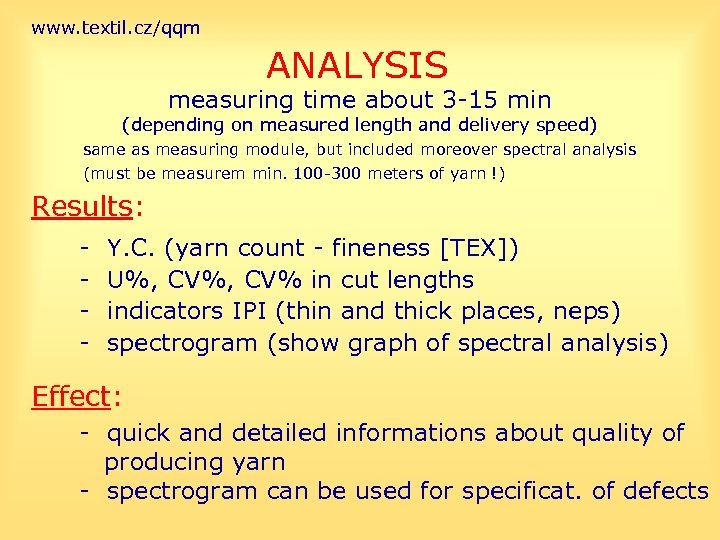

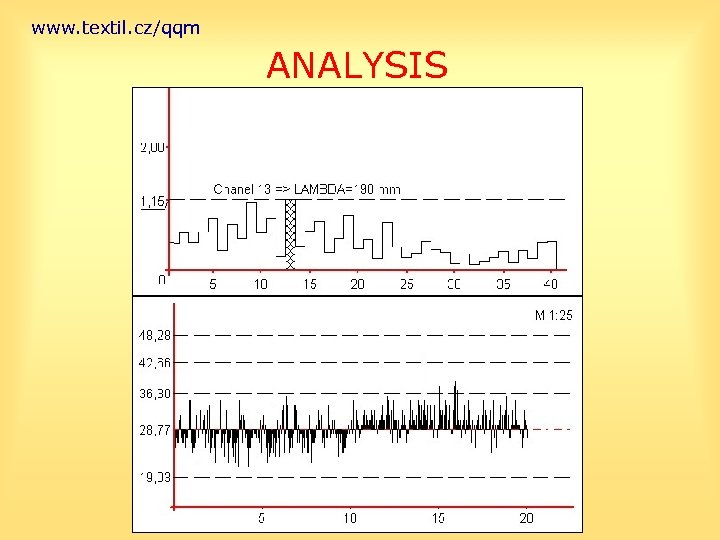

www. textil. cz/qqm ANALYSIS measuring time about 3 -15 min (depending on measured length and delivery speed) same as measuring module, but included moreover spectral analysis (must be measurem min. 100 -300 meters of yarn !) Results: - Y. C. (yarn count - fineness [TEX]) U%, CV% in cut lengths indicators IPI (thin and thick places, neps) spectrogram (show graph of spectral analysis) Effect: - quick and detailed informations about quality of producing yarn - spectrogram can be used for specificat. of defects

www. textil. cz/qqm ANALYSIS

www. textil. cz/qqm DATA SOURCE measuring time about 1 -15 min (depending on measured length and delivery speed) Results: - data file for analyse on PC Effect: - quick measuring of yarn (without instant calcualation) - possibility of individual processing of results (suitable for research, special analyse, . . . )

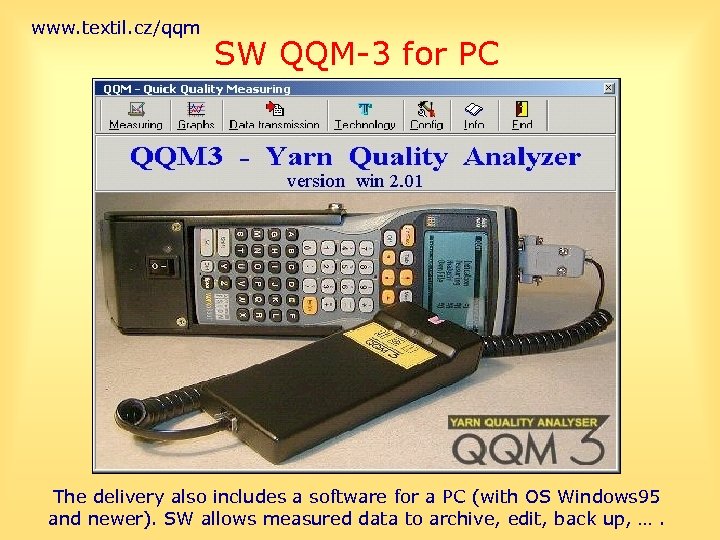

www. textil. cz/qqm SW QQM-3 for PC The delivery also includes a software for a PC (with OS Windows 95 and newer). SW allows measured data to archive, edit, back up, ….

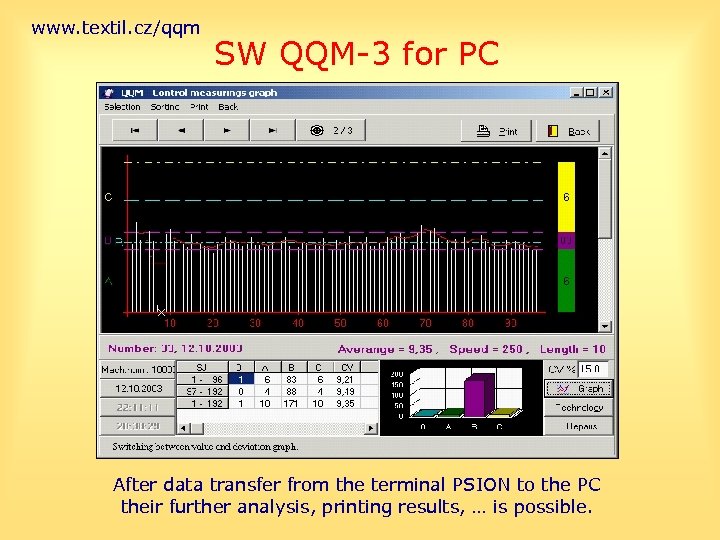

www. textil. cz/qqm SW QQM-3 for PC After data transfer from the terminal PSION to the PC their further analysis, printing results, … is possible.

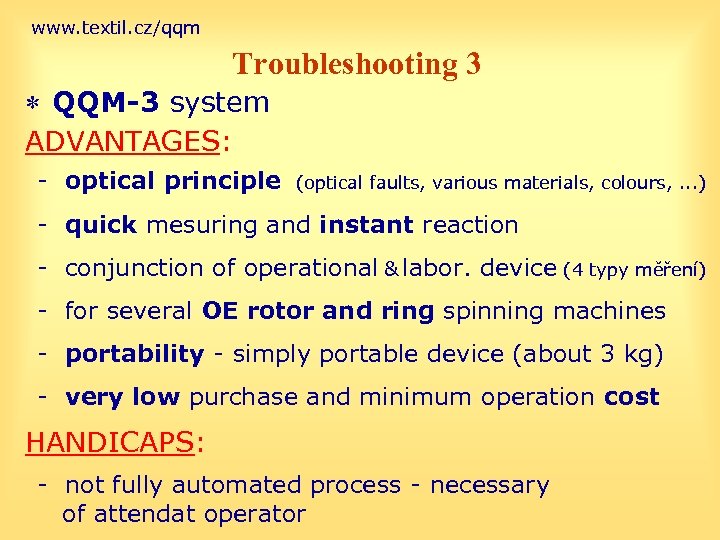

www. textil. cz/qqm Troubleshooting 3 * QQM-3 system ADVANTAGES: - optical principle (optical faults, various materials, colours, . . . ) - quick mesuring and instant reaction - conjunction of operational & labor. device (4 typy měření) - for several OE rotor and ring spinning machines - portability - simply portable device (about 3 kg) - very low purchase and minimum operation cost HANDICAPS: - not fully automated process - necessary of attendat operator

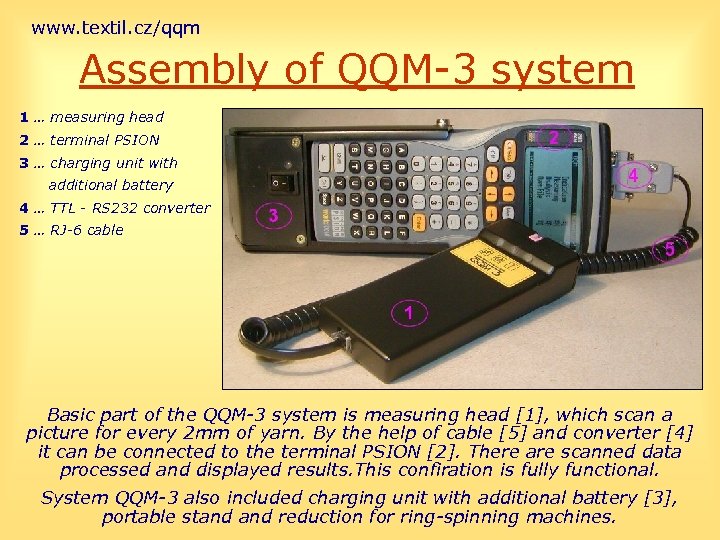

www. textil. cz/qqm Assembly of QQM-3 system 1 … measuring head 2 … terminal PSION 3 … charging unit with additional battery 4 … TTL - RS 232 converter 5 … RJ-6 cable Basic part of the QQM-3 system is measuring head [1], which scan a picture for every 2 mm of yarn. By the help of cable [5] and converter [4] it can be connected to the terminal PSION [2]. There are scanned data processed and displayed results. This confiration is fully functional. System QQM-3 also included charging unit with additional battery [3], portable stand reduction for ring-spinning machines.

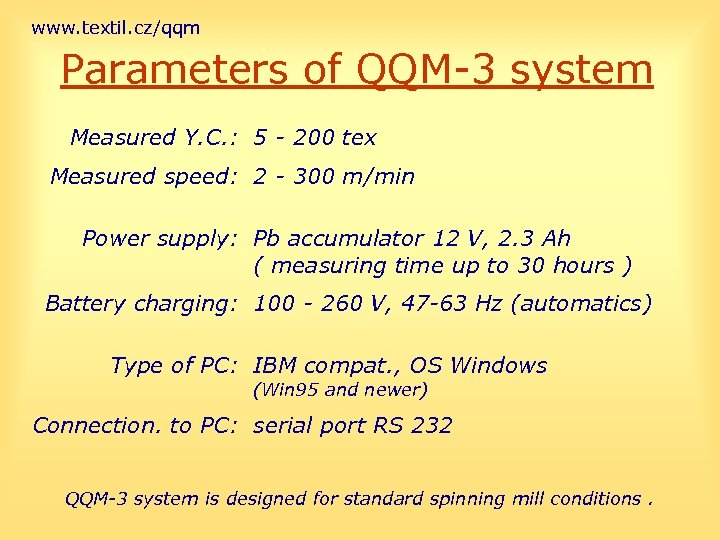

www. textil. cz/qqm Parameters of QQM-3 system Measured Y. C. : 5 - 200 tex Measured speed: 2 - 300 m/min Power supply: Pb accumulator 12 V, 2. 3 Ah ( measuring time up to 30 hours ) Battery charging: 100 - 260 V, 47 -63 Hz (automatics) Type of PC: IBM compat. , OS Windows (Win 95 and newer) Connection. to PC: serial port RS 232 QQM-3 system is designed for standard spinning mill conditions.

www. textil. cz/qqm Open the way to Total Production Maintenance !!! QQM-3 system does not only discover that spinning quality tends to degrease - can give you also the idea what could be the reason for this tendency. Ussualy, if this tendency is already discovered, you have time to decide about the maintenance action without immediate break of spinning process.

www. textil. cz/qqm What can you win with QQM-3 system ? ? ? - claim decrease - stabile quality - higher mills capability utilization rate - decrease in needs of replacement parts - maintenance capacity saving

www. textil. cz/qqm adjust & manage your spinning process !!!

www. textil. cz/qqm Thank you for your kind attention. Good bye.

78cbd90ba86b5d54ac3d08771515b788.ppt