6525226f661f94e2d16405b1504e0ef0.ppt

- Количество слайдов: 9

VSP Vision Care HQ 1, AT A GLANCE: • 152, 000 SF • 9, 700 SF Data Center • Fully automated • Rancho Cordova, CA • Constructed in 1992 • Began certification effort in 2007 • Internal Team – 5 people • External Team – FEA and Commissioning Agent © Facility Engineering Associates 2010

VSP Vision Care HQ 1, AT A GLANCE: • 152, 000 SF • 9, 700 SF Data Center • Fully automated • Rancho Cordova, CA • Constructed in 1992 • Began certification effort in 2007 • Internal Team – 5 people • External Team – FEA and Commissioning Agent © Facility Engineering Associates 2010

Energy Saving Started with an Energy Star rating of 29! Implemented: ◦ ◦ Optimized lighting and HVAC controls Sub-metered electricity Scheduled Janitorial daytime cleaning Developed training for employees IMPLEMENTATION RESULTS………. ü ü ü $ 123, 254 Implementation Costs $ 64, 030 Annual Savings 14% Annual Energy Savings 2 years Payback Energy Star rating of 93! Received ENERGY STAR Label in 2009 © Facility Engineering Associates 2010

Energy Saving Started with an Energy Star rating of 29! Implemented: ◦ ◦ Optimized lighting and HVAC controls Sub-metered electricity Scheduled Janitorial daytime cleaning Developed training for employees IMPLEMENTATION RESULTS………. ü ü ü $ 123, 254 Implementation Costs $ 64, 030 Annual Savings 14% Annual Energy Savings 2 years Payback Energy Star rating of 93! Received ENERGY STAR Label in 2009 © Facility Engineering Associates 2010

Waste Reduction Initial Diversion Rate of 40% Implemented: ◦ ◦ ◦ Performed Waste Audit (Baseline) Increased Number of Recycling Bins Improved Staff Education Reduced Size of General Waste Sustainable Purchasing IMPLEMENTATION RESULTS……… ü ü $ 42, 828 Implementation Costs $ 21, 888 Annual Savings 14% Annual Energy Savings 2 years Payback Achieved 82% Waste Diversion (September 2008) © Facility Engineering Associates 2010

Waste Reduction Initial Diversion Rate of 40% Implemented: ◦ ◦ ◦ Performed Waste Audit (Baseline) Increased Number of Recycling Bins Improved Staff Education Reduced Size of General Waste Sustainable Purchasing IMPLEMENTATION RESULTS……… ü ü $ 42, 828 Implementation Costs $ 21, 888 Annual Savings 14% Annual Energy Savings 2 years Payback Achieved 82% Waste Diversion (September 2008) © Facility Engineering Associates 2010

Water Projects - Savings Beyond Energy • Implemented: o o o Installed of low flow plumbing fixtures Installed of aerators on faucets and dual flush valves on water closets Installed Light-Powered touch-free faucets Installed Sub-meters on process systems (café’ and cooling tower) Replaced irrigation water use by: – Replacing scrubs with decomposed granite – Replacing spray irrigation with bubbles – Replacing existing plants with more water efficient plantings IMPLEMENTATION RESULTS………. ü ü © Facility Engineering Associates 2010 $ 39, 597 Implementation Costs $ 5, 111 Annual Savings 50% Annual Water Savings 7. 5 years Payback

Water Projects - Savings Beyond Energy • Implemented: o o o Installed of low flow plumbing fixtures Installed of aerators on faucets and dual flush valves on water closets Installed Light-Powered touch-free faucets Installed Sub-meters on process systems (café’ and cooling tower) Replaced irrigation water use by: – Replacing scrubs with decomposed granite – Replacing spray irrigation with bubbles – Replacing existing plants with more water efficient plantings IMPLEMENTATION RESULTS………. ü ü © Facility Engineering Associates 2010 $ 39, 597 Implementation Costs $ 5, 111 Annual Savings 50% Annual Water Savings 7. 5 years Payback

Indoor Environmental Quality • Implemented: o o Meet ASHREA 62. 1 -2004 Standard Relocated Smoking Shelter Installed CO 2 and Humidity Sensors Installed MVR 13 Filters IMPLEMENTATION RESULTS………. ü $ 82, 546 Implementation Costs © Facility Engineering Associates 2010

Indoor Environmental Quality • Implemented: o o Meet ASHREA 62. 1 -2004 Standard Relocated Smoking Shelter Installed CO 2 and Humidity Sensors Installed MVR 13 Filters IMPLEMENTATION RESULTS………. ü $ 82, 546 Implementation Costs © Facility Engineering Associates 2010

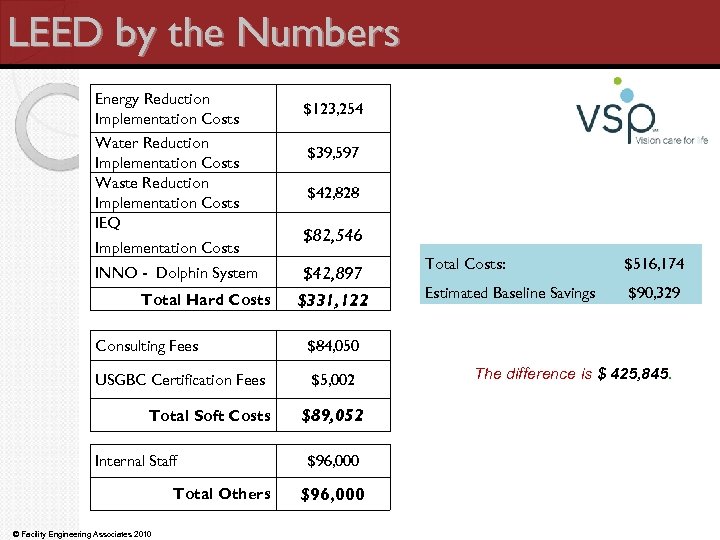

LEED by the Numbers Energy Reduction Implementation Costs Water Reduction Implementation Costs Waste Reduction Implementation Costs IEQ Implementation Costs INNO - Dolphin System Total Hard Costs $123, 254 $39, 597 $42, 828 $82, 546 $42, 897 $331, 122 Consulting Fees $5, 002 $516, 174 Estimated Baseline Savings $90, 329 $84, 050 USGBC Certification Fees Total Costs: Total Soft Costs Internal Staff Total Others © Facility Engineering Associates 2010 $89, 052 $96, 000 The difference is $ 425, 845.

LEED by the Numbers Energy Reduction Implementation Costs Water Reduction Implementation Costs Waste Reduction Implementation Costs IEQ Implementation Costs INNO - Dolphin System Total Hard Costs $123, 254 $39, 597 $42, 828 $82, 546 $42, 897 $331, 122 Consulting Fees $5, 002 $516, 174 Estimated Baseline Savings $90, 329 $84, 050 USGBC Certification Fees Total Costs: Total Soft Costs Internal Staff Total Others © Facility Engineering Associates 2010 $89, 052 $96, 000 The difference is $ 425, 845.

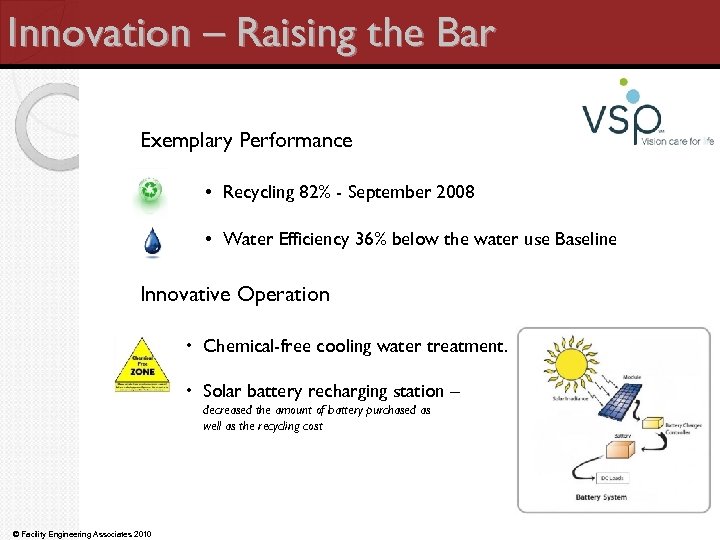

Innovation – Raising the Bar Exemplary Performance • Recycling 82% - September 2008 • Water Efficiency 36% below the water use Baseline Innovative Operation Chemical-free cooling water treatment. Solar battery recharging station – decreased the amount of battery purchased as well as the recycling cost © Facility Engineering Associates 2010

Innovation – Raising the Bar Exemplary Performance • Recycling 82% - September 2008 • Water Efficiency 36% below the water use Baseline Innovative Operation Chemical-free cooling water treatment. Solar battery recharging station – decreased the amount of battery purchased as well as the recycling cost © Facility Engineering Associates 2010

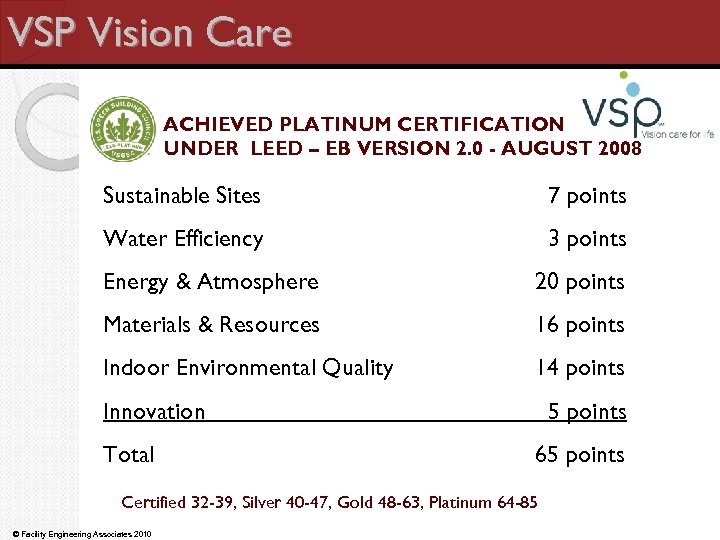

VSP Vision Care ACHIEVED PLATINUM CERTIFICATION UNDER LEED – EB VERSION 2. 0 - AUGUST 2008 Sustainable Sites 7 points Water Efficiency 3 points Energy & Atmosphere 20 points Materials & Resources 16 points Indoor Environmental Quality 14 points Innovation Total 5 points 65 points Certified 32 -39, Silver 40 -47, Gold 48 -63, Platinum 64 -85 © Facility Engineering Associates 2010

VSP Vision Care ACHIEVED PLATINUM CERTIFICATION UNDER LEED – EB VERSION 2. 0 - AUGUST 2008 Sustainable Sites 7 points Water Efficiency 3 points Energy & Atmosphere 20 points Materials & Resources 16 points Indoor Environmental Quality 14 points Innovation Total 5 points 65 points Certified 32 -39, Silver 40 -47, Gold 48 -63, Platinum 64 -85 © Facility Engineering Associates 2010

Achievements: VSP • Over 2, 200 VSP team hours 1600 VSP hours + 600 FEA hours = 2, 200 team hours • Achieved Platinum – August 2008 • Achieving Operational Excellence ü 14% annual energy savings ü 50% annual water savings ü 82% high, waste recycled (Sept ’ 08) • Received 5% reduction on insurance premium © Facility Engineering Associates 2010

Achievements: VSP • Over 2, 200 VSP team hours 1600 VSP hours + 600 FEA hours = 2, 200 team hours • Achieved Platinum – August 2008 • Achieving Operational Excellence ü 14% annual energy savings ü 50% annual water savings ü 82% high, waste recycled (Sept ’ 08) • Received 5% reduction on insurance premium © Facility Engineering Associates 2010