b0f85c7f74bd8aa89f2b0abe67e6050a.ppt

- Количество слайдов: 29

Vp. CI™ Packaging Solutions Vp. CI Metalworking Products World Sales Meeting 2009

Vp. CI™ Packaging Solutions Vp. CI Metalworking Products World Sales Meeting 2009

Product Line Update • Fastest Growing Chemical Market! • New Applications: – Machining – Steel Industry – Rust Prevention • New Technologies – Biobased products • Integrated Solutions Approach

Product Line Update • Fastest Growing Chemical Market! • New Applications: – Machining – Steel Industry – Rust Prevention • New Technologies – Biobased products • Integrated Solutions Approach

Vp. CI Metalworking Concepts • Corrosion can and does occur during manufacturing • No additional steps (cost, time) • Ensures contamination-free process • Ensures synergy between chemistries • Easier to maintain • Offers protection to equipment • Many offer superior environmental attributes

Vp. CI Metalworking Concepts • Corrosion can and does occur during manufacturing • No additional steps (cost, time) • Ensures contamination-free process • Ensures synergy between chemistries • Easier to maintain • Offers protection to equipment • Many offer superior environmental attributes

Metalworking Applications In Process – Vp. CI Coolants – Vp. CI Lubricants Oil Additives – In use or during lay-up – Engines, Hydraulic Systems, Gearboxes Rust Preventatives – Water-based (Cortec’s Strength) – Oil-based – Bio-based (Newest technologies)

Metalworking Applications In Process – Vp. CI Coolants – Vp. CI Lubricants Oil Additives – In use or during lay-up – Engines, Hydraulic Systems, Gearboxes Rust Preventatives – Water-based (Cortec’s Strength) – Oil-based – Bio-based (Newest technologies)

Market Development Stage 1: MW Fluids as RP only – Using compatible metalworking fluids as rust preventatives (i. e. Vp. CI 377) prior to packaging – Using compatible metalworking fluids as intra-plant storage or stand alone rust preservatives Stage 2: Fully Integrated Functional Fluid – Using MW fluids as MW fluids, full integration – Offers full benefits as described before – Requires more technical analysis, testing to secure business, but loyalty results.

Market Development Stage 1: MW Fluids as RP only – Using compatible metalworking fluids as rust preventatives (i. e. Vp. CI 377) prior to packaging – Using compatible metalworking fluids as intra-plant storage or stand alone rust preservatives Stage 2: Fully Integrated Functional Fluid – Using MW fluids as MW fluids, full integration – Offers full benefits as described before – Requires more technical analysis, testing to secure business, but loyalty results.

Developing Accounts Stage 1/Rust Preventatives – Develop process map/flow chart – Identify areas where rust is occurring, clean-up required, high costs – Identify all products used – Specifically look for products used solely for RP • Often are dips immediately after machining operation – Suggest trials to ensure buy-in from customer – Utilize existing test reports and case histories – Offer comparative test if hasn’t already been conducted

Developing Accounts Stage 1/Rust Preventatives – Develop process map/flow chart – Identify areas where rust is occurring, clean-up required, high costs – Identify all products used – Specifically look for products used solely for RP • Often are dips immediately after machining operation – Suggest trials to ensure buy-in from customer – Utilize existing test reports and case histories – Offer comparative test if hasn’t already been conducted

Product Focus: Water-Based RP Vp. CI 316: Cu/Yellow Metals, very thin, indoor Vp. CI 337: Mistable, excellent migration, internal voids Vp. CI 377: Most versatile, indoor, multi-metal, wide dilution Vp. CI 378: Rough material surfaces, quenching applications (cast iron/cast Al) Vp. CI 379: Most applications now use 377, still used in some customer specs

Product Focus: Water-Based RP Vp. CI 316: Cu/Yellow Metals, very thin, indoor Vp. CI 337: Mistable, excellent migration, internal voids Vp. CI 377: Most versatile, indoor, multi-metal, wide dilution Vp. CI 378: Rough material surfaces, quenching applications (cast iron/cast Al) Vp. CI 379: Most applications now use 377, still used in some customer specs

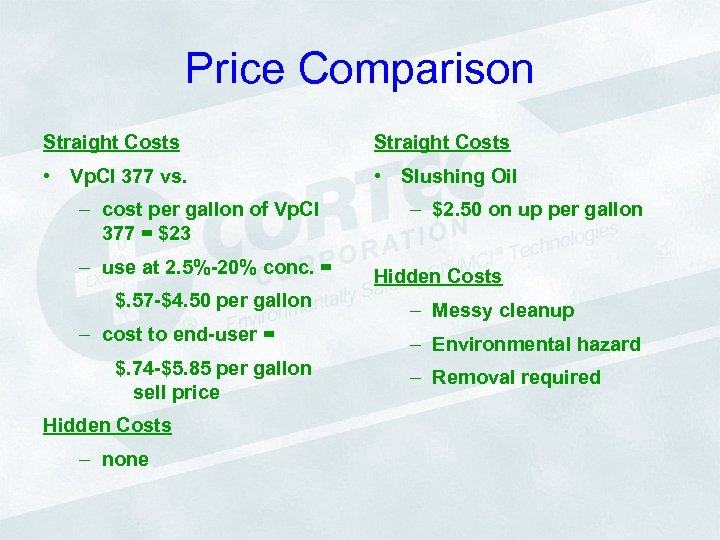

Price Comparison Straight Costs • Vp. CI 377 vs. • Slushing Oil – cost per gallon of Vp. CI 377 = $23 – use at 2. 5%-20% conc. = $. 57 -$4. 50 per gallon – cost to end-user = $. 74 -$5. 85 per gallon sell price Hidden Costs – none – $2. 50 on up per gallon Hidden Costs – Messy cleanup – Environmental hazard – Removal required

Price Comparison Straight Costs • Vp. CI 377 vs. • Slushing Oil – cost per gallon of Vp. CI 377 = $23 – use at 2. 5%-20% conc. = $. 57 -$4. 50 per gallon – cost to end-user = $. 74 -$5. 85 per gallon sell price Hidden Costs – none – $2. 50 on up per gallon Hidden Costs – Messy cleanup – Environmental hazard – Removal required

After Vp. CI 377 Application

After Vp. CI 377 Application

After Vp. CI 377 Application

After Vp. CI 377 Application

Protected with Vp. CI 377

Protected with Vp. CI 377

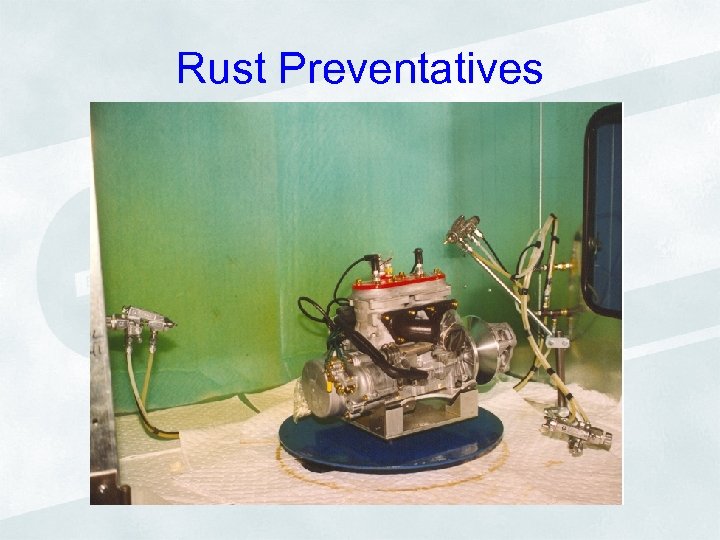

Rust Preventatives

Rust Preventatives

Vp. CI-337 Application

Vp. CI-337 Application

Product Focus: Oil-Based RP Vp. CI-325: Bio- based, penetrant, lube, flagship RP, direct replacement for popular water-displacing products Vp. CI-329 D: Medium to long term indoor storage (coils) Vp. CI-368/369 D: Medium to long term sheltered outdoor Super Penetrant: Best penetrating oil, medium indoor

Product Focus: Oil-Based RP Vp. CI-325: Bio- based, penetrant, lube, flagship RP, direct replacement for popular water-displacing products Vp. CI-329 D: Medium to long term indoor storage (coils) Vp. CI-368/369 D: Medium to long term sheltered outdoor Super Penetrant: Best penetrating oil, medium indoor

Product Focus: Bio-Based RP • Soybean Oil based – Eco. Line Long Term Rust Preventative – Bio. Corr – Eco. Line All Purpose Lubricant – Other Eco. Line Products • Canola Oil based – Eco. Line 3220 – Eco. Line 3690

Product Focus: Bio-Based RP • Soybean Oil based – Eco. Line Long Term Rust Preventative – Bio. Corr – Eco. Line All Purpose Lubricant – Other Eco. Line Products • Canola Oil based – Eco. Line 3220 – Eco. Line 3690

Developing Accounts 2 Stage 2/Functional Fluids – Can grow from applications starting as stage 1 or can immediately implement integrated approach – Identify key functional properties of the fluid and the process: • • • Temperature Speed Type of operation Critical features (lubricity, cooling, filter) MSDS/PDS for existing product including dilution used Physical/Mechanical/Chemical properties – Utilize existing test reports – Provide process chart with savings (time, steps, money) as clearly identified as possible to offset the per gallon cost objection.

Developing Accounts 2 Stage 2/Functional Fluids – Can grow from applications starting as stage 1 or can immediately implement integrated approach – Identify key functional properties of the fluid and the process: • • • Temperature Speed Type of operation Critical features (lubricity, cooling, filter) MSDS/PDS for existing product including dilution used Physical/Mechanical/Chemical properties – Utilize existing test reports – Provide process chart with savings (time, steps, money) as clearly identified as possible to offset the per gallon cost objection.

Product Focus: In Process • Vp. CI 344: Wet Tempering • Cold rolled steel, lubricity, light machining • Vp. CI 345: Semi-synthetic • Semi-synthetic, medium duty machining • Vp. CI 347: Soluble oil • Soluble oil, heavy duty lubricity for machining, antiweld (prevents fusing due to heat), excellent for drawing applications • Eco. Line Cutting Fluid: Soluble soya-oil

Product Focus: In Process • Vp. CI 344: Wet Tempering • Cold rolled steel, lubricity, light machining • Vp. CI 345: Semi-synthetic • Semi-synthetic, medium duty machining • Vp. CI 347: Soluble oil • Soluble oil, heavy duty lubricity for machining, antiweld (prevents fusing due to heat), excellent for drawing applications • Eco. Line Cutting Fluid: Soluble soya-oil

Ecoline Cutting Fluid Application

Ecoline Cutting Fluid Application

Product Focus: Oil Additives • Engine oil M-529 – Lay-up or intermittent use (5%) • Hydraulic oil Vp. CI-322 – Vapor phase protection, limited water contact (10%). Vp. CI-326 – Passes 1 micron filter, no water contact (10%).

Product Focus: Oil Additives • Engine oil M-529 – Lay-up or intermittent use (5%) • Hydraulic oil Vp. CI-322 – Vapor phase protection, limited water contact (10%). Vp. CI-326 – Passes 1 micron filter, no water contact (10%).

Oil Additives

Oil Additives

Product Focus: Gearbox Additives Vp. CI 322: Fogged in (full strength) or added at 5 -7%. Vp. CI 329: Lay-up, 5 -10% as additive.

Product Focus: Gearbox Additives Vp. CI 322: Fogged in (full strength) or added at 5 -7%. Vp. CI 329: Lay-up, 5 -10% as additive.

Resources for Metalworking • Many comparative test reports • Case Histories • Detailed recommendations from the lab

Resources for Metalworking • Many comparative test reports • Case Histories • Detailed recommendations from the lab

Strategy for Packaging Accounts 1. Develop Process Flow Chart 2. Identify step immediately before Packaging • Often Cleaning 3. Identify scrap/repro/blasting areas 4. Identify fluids used as Rust Preventative 5. Identify machining fluids that need boost

Strategy for Packaging Accounts 1. Develop Process Flow Chart 2. Identify step immediately before Packaging • Often Cleaning 3. Identify scrap/repro/blasting areas 4. Identify fluids used as Rust Preventative 5. Identify machining fluids that need boost

Conclusions • New resources exist for development of metalworking accounts • Growth potential is large for liquids • Packaging distributors need not be experts on liquids to be successful—start with existing PACKAGING customers!

Conclusions • New resources exist for development of metalworking accounts • Growth potential is large for liquids • Packaging distributors need not be experts on liquids to be successful—start with existing PACKAGING customers!