cf55346e0a08d01519e2b4cfcdf5a162.ppt

- Количество слайдов: 20

VLSI Testing Dr. Vishwani D. Agrawal James J. Danaher Professor of Electrical and Computer Engineering Auburn University, Alabama 36849, USA vagrawal@eng. auburn. edu http: //www. eng. auburn. edu/~vagrawal August 7 -13, 2010 Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 1

VLSI Testing Dr. Vishwani D. Agrawal James J. Danaher Professor of Electrical and Computer Engineering Auburn University, Alabama 36849, USA vagrawal@eng. auburn. edu http: //www. eng. auburn. edu/~vagrawal August 7 -13, 2010 Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 1

Course Description This course is designed for the MTech program in VLSI at IIT, Delhi. It is patterned after a onesemester graduate-level course offered at Auburn University. A set of 14 lectures that include classroom exercises provide understanding of theoretical and practical aspects of VLSI testing. The course fulfills the needs of today’s industrial design environment, which demands knowledge of testing concepts of digital, memory, analog and radio frequency (RF) subsystems often implemented on a system-on-chip (So. C). Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 2

Course Description This course is designed for the MTech program in VLSI at IIT, Delhi. It is patterned after a onesemester graduate-level course offered at Auburn University. A set of 14 lectures that include classroom exercises provide understanding of theoretical and practical aspects of VLSI testing. The course fulfills the needs of today’s industrial design environment, which demands knowledge of testing concepts of digital, memory, analog and radio frequency (RF) subsystems often implemented on a system-on-chip (So. C). Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 2

Outline n n n n n Lecture 1: Lecture 2: Lecture 3: Lecture 4: Lecture 5: Lecture 6: Lecture 7: Lecture 8: Test 1 Lecture 9: Lecture 10: Lecture 11: Lecture 12: Lecture 13: Lecture 14: Test 2 Lecture 15: Lecture 16: Introduction (19*+1) * Number of slides Yield and quality (16+2) Fault modeling (19+2) Testability analysis (26) Logic simulation (14) Fault simulation (18) Combinational ATPG (24+2) Sequential ATPG (19+1) Delay test (25) Memory test (25) Analog test (24) DFT and Scan (24+2) BIST (28) System diagnosis (20) RF Testing: Introduction, gain measurement (39) RF Testing: Intermodulation and noise measurements (33) Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 3

Outline n n n n n Lecture 1: Lecture 2: Lecture 3: Lecture 4: Lecture 5: Lecture 6: Lecture 7: Lecture 8: Test 1 Lecture 9: Lecture 10: Lecture 11: Lecture 12: Lecture 13: Lecture 14: Test 2 Lecture 15: Lecture 16: Introduction (19*+1) * Number of slides Yield and quality (16+2) Fault modeling (19+2) Testability analysis (26) Logic simulation (14) Fault simulation (18) Combinational ATPG (24+2) Sequential ATPG (19+1) Delay test (25) Memory test (25) Analog test (24) DFT and Scan (24+2) BIST (28) System diagnosis (20) RF Testing: Introduction, gain measurement (39) RF Testing: Intermodulation and noise measurements (33) Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 3

Schedule n n n Aug 7, 2010 – 4 -6 PM Lectures 1 and 2 Aug 9, 2010 – 3: 30 -6: 30 PM Lectures 3, 4 and 5 Aug 10, 2010 – 3: 30 -6: 30 PM Lectures 6, 7 and 8 Aug 11, 2010 – 3: 30 -6: 30 PM Lectures 9, 10 and 11 Aug 12, 2010 – 3: 30 -6: 30 PM Lectures 12, 13 and 14 Aug 13, 2010 – 4 -6 PM Lectures 15 and 16 Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 4

Schedule n n n Aug 7, 2010 – 4 -6 PM Lectures 1 and 2 Aug 9, 2010 – 3: 30 -6: 30 PM Lectures 3, 4 and 5 Aug 10, 2010 – 3: 30 -6: 30 PM Lectures 6, 7 and 8 Aug 11, 2010 – 3: 30 -6: 30 PM Lectures 9, 10 and 11 Aug 12, 2010 – 3: 30 -6: 30 PM Lectures 12, 13 and 14 Aug 13, 2010 – 4 -6 PM Lectures 15 and 16 Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 4

Lecture 1: Introduction n n n n VLSI realization process Verification and test Ideal and real tests Costs of testing Roles of testing A modern VLSI device - system-on-a-chip Testing Digital Memory Analog RF Textbook Problem to solve Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 5

Lecture 1: Introduction n n n n VLSI realization process Verification and test Ideal and real tests Costs of testing Roles of testing A modern VLSI device - system-on-a-chip Testing Digital Memory Analog RF Textbook Problem to solve Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 5

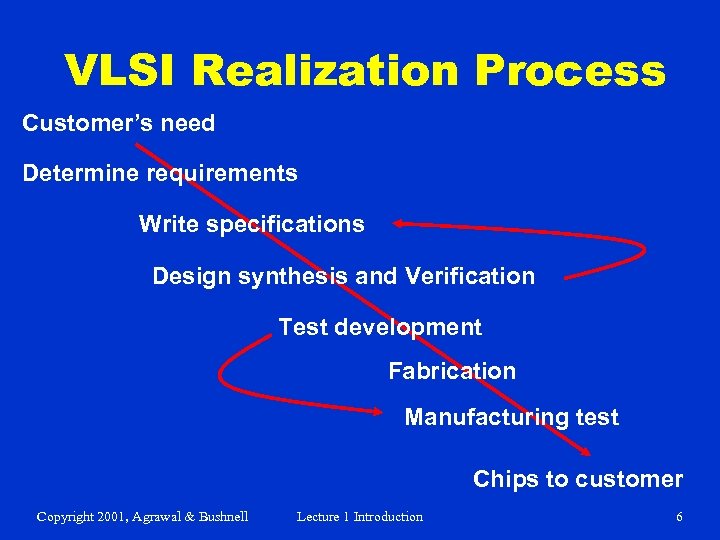

VLSI Realization Process Customer’s need Determine requirements Write specifications Design synthesis and Verification Test development Fabrication Manufacturing test Chips to customer Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 6

VLSI Realization Process Customer’s need Determine requirements Write specifications Design synthesis and Verification Test development Fabrication Manufacturing test Chips to customer Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 6

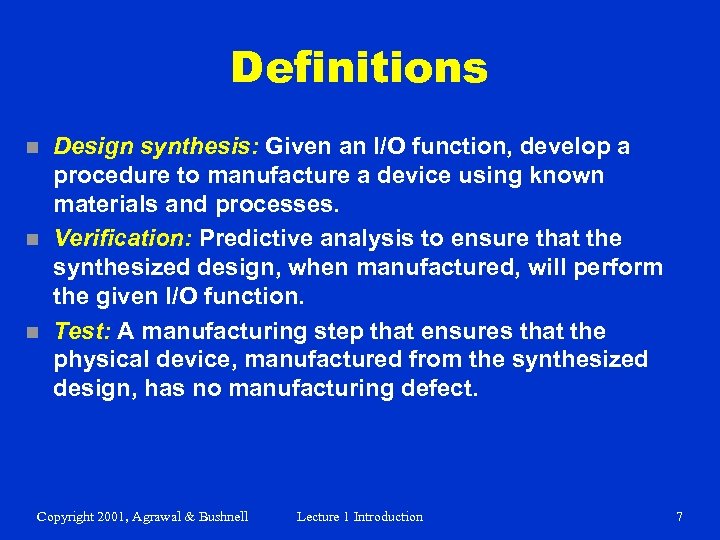

Definitions n n n Design synthesis: Given an I/O function, develop a procedure to manufacture a device using known materials and processes. Verification: Predictive analysis to ensure that the synthesized design, when manufactured, will perform the given I/O function. Test: A manufacturing step that ensures that the physical device, manufactured from the synthesized design, has no manufacturing defect. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 7

Definitions n n n Design synthesis: Given an I/O function, develop a procedure to manufacture a device using known materials and processes. Verification: Predictive analysis to ensure that the synthesized design, when manufactured, will perform the given I/O function. Test: A manufacturing step that ensures that the physical device, manufactured from the synthesized design, has no manufacturing defect. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 7

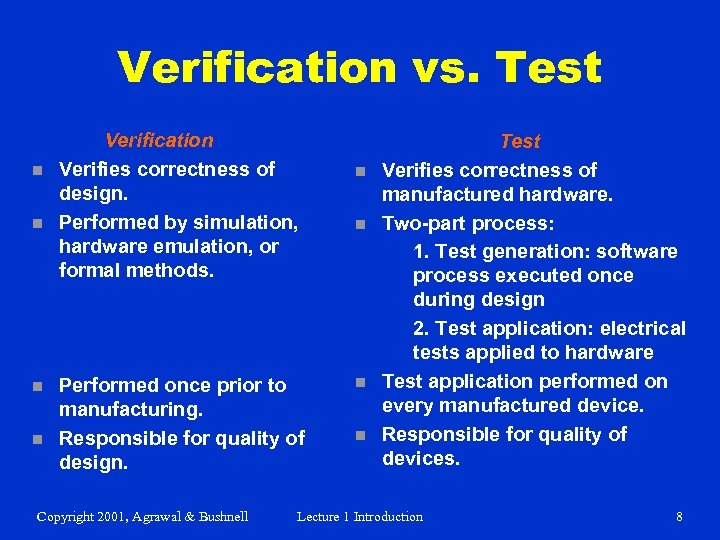

Verification vs. Test n n Verification Verifies correctness of design. Performed by simulation, hardware emulation, or formal methods. Performed once prior to manufacturing. Responsible for quality of design. Copyright 2001, Agrawal & Bushnell n n Test Verifies correctness of manufactured hardware. Two-part process: 1. Test generation: software process executed once during design 2. Test application: electrical tests applied to hardware Test application performed on every manufactured device. Responsible for quality of devices. Lecture 1 Introduction 8

Verification vs. Test n n Verification Verifies correctness of design. Performed by simulation, hardware emulation, or formal methods. Performed once prior to manufacturing. Responsible for quality of design. Copyright 2001, Agrawal & Bushnell n n Test Verifies correctness of manufactured hardware. Two-part process: 1. Test generation: software process executed once during design 2. Test application: electrical tests applied to hardware Test application performed on every manufactured device. Responsible for quality of devices. Lecture 1 Introduction 8

Problems of Ideal Tests n n Ideal tests detect all defects produced in the manufacturing process. Ideal tests pass all functionally good devices. Very large numbers and varieties of possible defects need to be tested. Difficult to generate tests for some real defects. Defect-oriented testing is an open problem. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 9

Problems of Ideal Tests n n Ideal tests detect all defects produced in the manufacturing process. Ideal tests pass all functionally good devices. Very large numbers and varieties of possible defects need to be tested. Difficult to generate tests for some real defects. Defect-oriented testing is an open problem. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 9

Real Tests n n Based on analyzable fault models, which may not map on real defects. Incomplete coverage of modeled faults due to high complexity. Some good chips are rejected. The fraction (or percentage) of such chips is called the yield loss. Some bad chips pass tests. The fraction (or percentage) of bad chips among all passing chips is called the defect level. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 10

Real Tests n n Based on analyzable fault models, which may not map on real defects. Incomplete coverage of modeled faults due to high complexity. Some good chips are rejected. The fraction (or percentage) of such chips is called the yield loss. Some bad chips pass tests. The fraction (or percentage) of bad chips among all passing chips is called the defect level. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 10

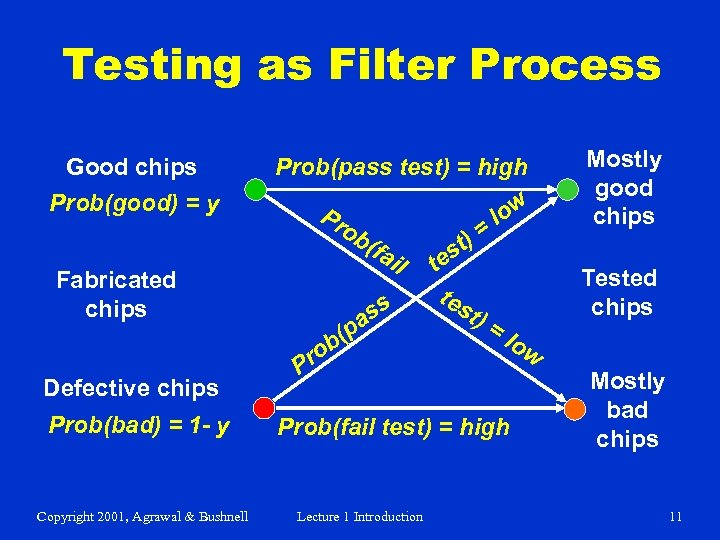

Testing as Filter Process Good chips Prob(good) = y Prob(pass test) = high Pr ob Fabricated chips Defective chips Prob(bad) = 1 - y Copyright 2001, Agrawal & Bushnell (fa il ss a p b( o Pr )= t s te tes t) w lo =l ow Prob(fail test) = high Lecture 1 Introduction Mostly good chips Tested chips Mostly bad chips 11

Testing as Filter Process Good chips Prob(good) = y Prob(pass test) = high Pr ob Fabricated chips Defective chips Prob(bad) = 1 - y Copyright 2001, Agrawal & Bushnell (fa il ss a p b( o Pr )= t s te tes t) w lo =l ow Prob(fail test) = high Lecture 1 Introduction Mostly good chips Tested chips Mostly bad chips 11

Costs of Testing n n n Design for testability (DFT) Chip area overhead and yield reduction Performance overhead Software processes of test Test generation and fault simulation Test programming and debugging Manufacturing test Automatic test equipment (ATE) capital cost Test center operational cost Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 12

Costs of Testing n n n Design for testability (DFT) Chip area overhead and yield reduction Performance overhead Software processes of test Test generation and fault simulation Test programming and debugging Manufacturing test Automatic test equipment (ATE) capital cost Test center operational cost Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 12

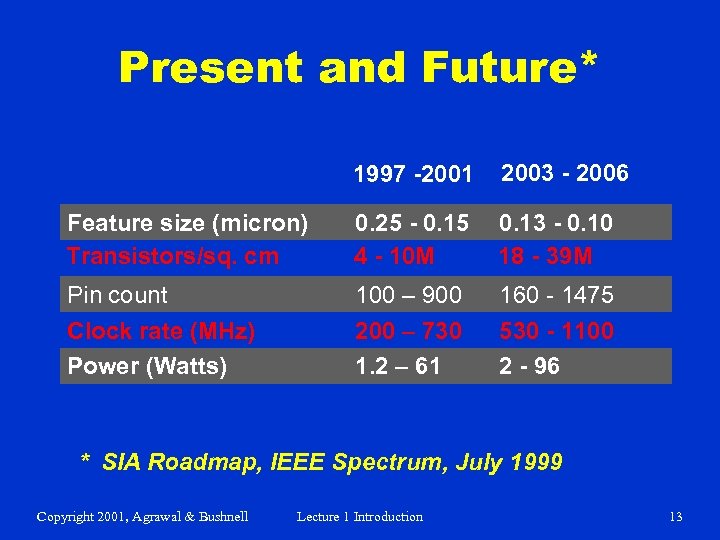

Present and Future* 1997 -2001 2003 - 2006 Feature size (micron) Transistors/sq. cm 0. 25 - 0. 15 4 - 10 M 0. 13 - 0. 10 18 - 39 M Pin count Clock rate (MHz) Power (Watts) 100 – 900 200 – 730 1. 2 – 61 160 - 1475 530 - 1100 2 - 96 * SIA Roadmap, IEEE Spectrum, July 1999 Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 13

Present and Future* 1997 -2001 2003 - 2006 Feature size (micron) Transistors/sq. cm 0. 25 - 0. 15 4 - 10 M 0. 13 - 0. 10 18 - 39 M Pin count Clock rate (MHz) Power (Watts) 100 – 900 200 – 730 1. 2 – 61 160 - 1475 530 - 1100 2 - 96 * SIA Roadmap, IEEE Spectrum, July 1999 Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 13

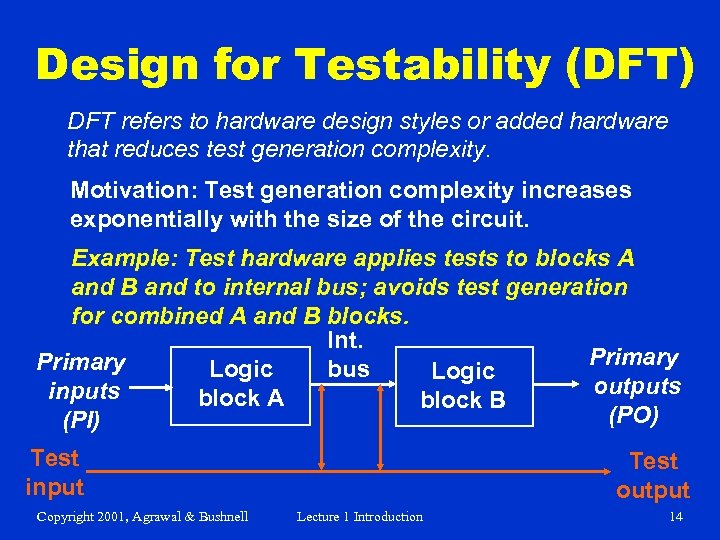

Design for Testability (DFT) DFT refers to hardware design styles or added hardware that reduces test generation complexity. Motivation: Test generation complexity increases exponentially with the size of the circuit. Example: Test hardware applies tests to blocks A and B and to internal bus; avoids test generation for combined A and B blocks. Int. Primary Logic bus Logic outputs inputs block A block B (PO) (PI) Test input Copyright 2001, Agrawal & Bushnell Test output Lecture 1 Introduction 14

Design for Testability (DFT) DFT refers to hardware design styles or added hardware that reduces test generation complexity. Motivation: Test generation complexity increases exponentially with the size of the circuit. Example: Test hardware applies tests to blocks A and B and to internal bus; avoids test generation for combined A and B blocks. Int. Primary Logic bus Logic outputs inputs block A block B (PO) (PI) Test input Copyright 2001, Agrawal & Bushnell Test output Lecture 1 Introduction 14

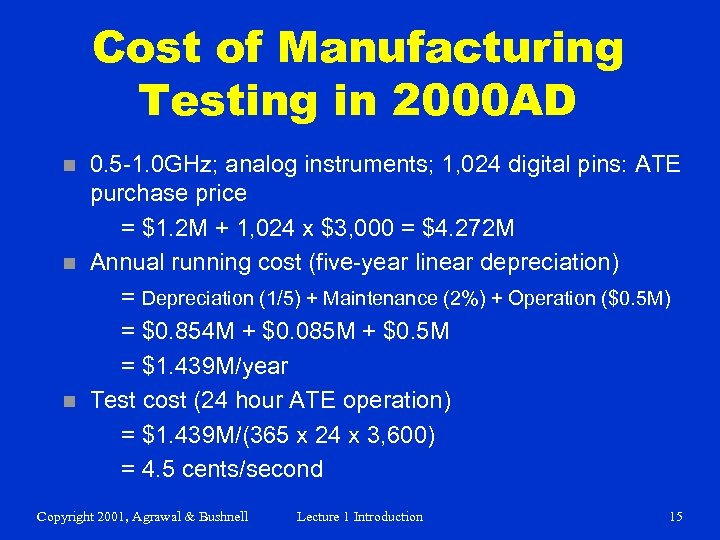

Cost of Manufacturing Testing in 2000 AD n n n 0. 5 -1. 0 GHz; analog instruments; 1, 024 digital pins: ATE purchase price = $1. 2 M + 1, 024 x $3, 000 = $4. 272 M Annual running cost (five-year linear depreciation) = Depreciation (1/5) + Maintenance (2%) + Operation ($0. 5 M) = $0. 854 M + $0. 085 M + $0. 5 M = $1. 439 M/year Test cost (24 hour ATE operation) = $1. 439 M/(365 x 24 x 3, 600) = 4. 5 cents/second Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 15

Cost of Manufacturing Testing in 2000 AD n n n 0. 5 -1. 0 GHz; analog instruments; 1, 024 digital pins: ATE purchase price = $1. 2 M + 1, 024 x $3, 000 = $4. 272 M Annual running cost (five-year linear depreciation) = Depreciation (1/5) + Maintenance (2%) + Operation ($0. 5 M) = $0. 854 M + $0. 085 M + $0. 5 M = $1. 439 M/year Test cost (24 hour ATE operation) = $1. 439 M/(365 x 24 x 3, 600) = 4. 5 cents/second Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 15

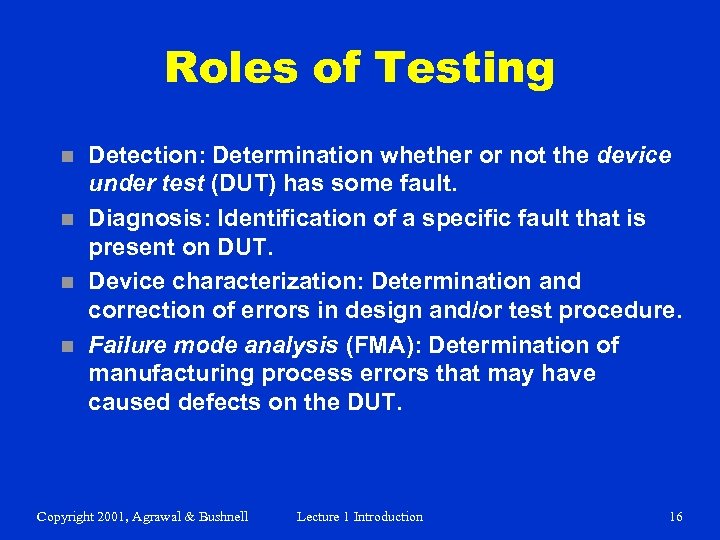

Roles of Testing n n Detection: Determination whether or not the device under test (DUT) has some fault. Diagnosis: Identification of a specific fault that is present on DUT. Device characterization: Determination and correction of errors in design and/or test procedure. Failure mode analysis (FMA): Determination of manufacturing process errors that may have caused defects on the DUT. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 16

Roles of Testing n n Detection: Determination whether or not the device under test (DUT) has some fault. Diagnosis: Identification of a specific fault that is present on DUT. Device characterization: Determination and correction of errors in design and/or test procedure. Failure mode analysis (FMA): Determination of manufacturing process errors that may have caused defects on the DUT. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 16

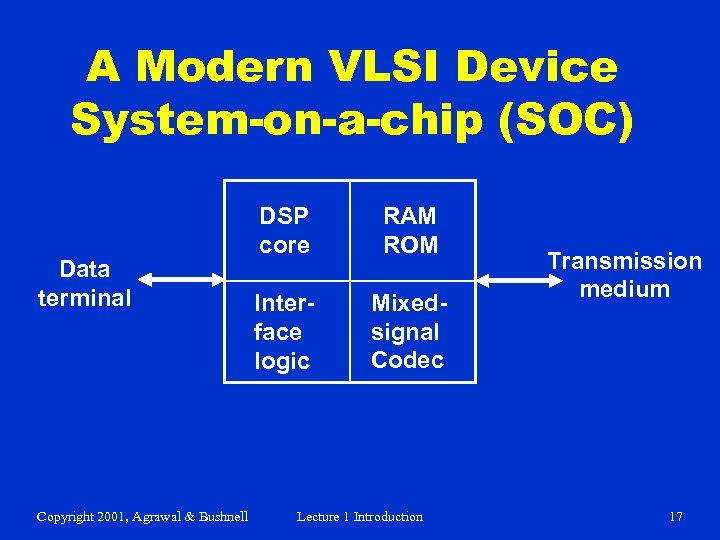

A Modern VLSI Device System-on-a-chip (SOC) Data terminal Copyright 2001, Agrawal & Bushnell DSP core RAM ROM Interface logic Mixedsignal Codec Lecture 1 Introduction Transmission medium 17

A Modern VLSI Device System-on-a-chip (SOC) Data terminal Copyright 2001, Agrawal & Bushnell DSP core RAM ROM Interface logic Mixedsignal Codec Lecture 1 Introduction Transmission medium 17

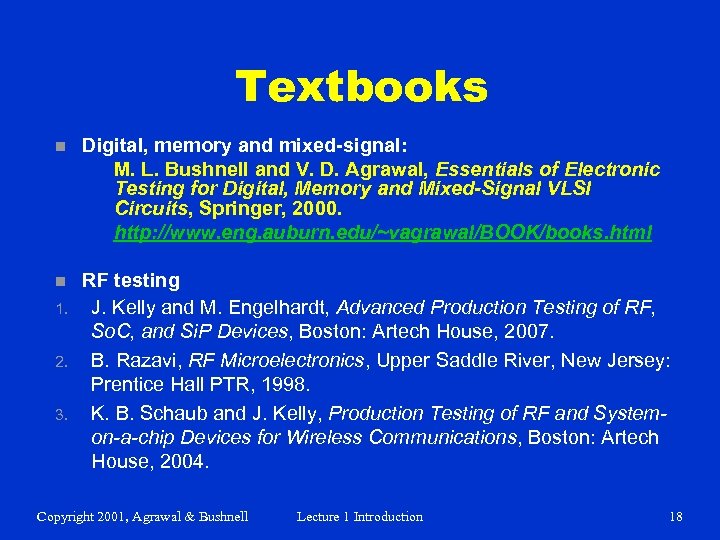

Textbooks n Digital, memory and mixed-signal: M. L. Bushnell and V. D. Agrawal, Essentials of Electronic Testing for Digital, Memory and Mixed-Signal VLSI Circuits, Springer, 2000. http: //www. eng. auburn. edu/~vagrawal/BOOK/books. html n RF testing J. Kelly and M. Engelhardt, Advanced Production Testing of RF, So. C, and Si. P Devices, Boston: Artech House, 2007. B. Razavi, RF Microelectronics, Upper Saddle River, New Jersey: Prentice Hall PTR, 1998. K. B. Schaub and J. Kelly, Production Testing of RF and Systemon-a-chip Devices for Wireless Communications, Boston: Artech House, 2004. 1. 2. 3. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 18

Textbooks n Digital, memory and mixed-signal: M. L. Bushnell and V. D. Agrawal, Essentials of Electronic Testing for Digital, Memory and Mixed-Signal VLSI Circuits, Springer, 2000. http: //www. eng. auburn. edu/~vagrawal/BOOK/books. html n RF testing J. Kelly and M. Engelhardt, Advanced Production Testing of RF, So. C, and Si. P Devices, Boston: Artech House, 2007. B. Razavi, RF Microelectronics, Upper Saddle River, New Jersey: Prentice Hall PTR, 1998. K. B. Schaub and J. Kelly, Production Testing of RF and Systemon-a-chip Devices for Wireless Communications, Boston: Artech House, 2004. 1. 2. 3. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 18

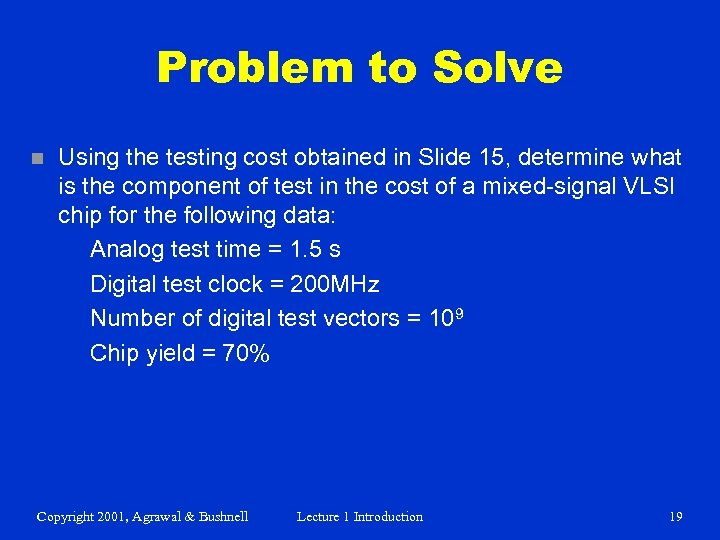

Problem to Solve n Using the testing cost obtained in Slide 15, determine what is the component of test in the cost of a mixed-signal VLSI chip for the following data: Analog test time = 1. 5 s Digital test clock = 200 MHz Number of digital test vectors = 109 Chip yield = 70% Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 19

Problem to Solve n Using the testing cost obtained in Slide 15, determine what is the component of test in the cost of a mixed-signal VLSI chip for the following data: Analog test time = 1. 5 s Digital test clock = 200 MHz Number of digital test vectors = 109 Chip yield = 70% Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 19

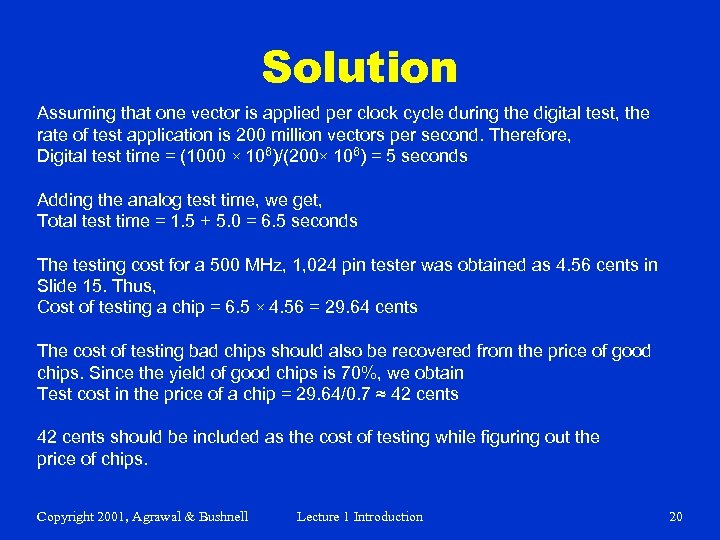

Solution Assuming that one vector is applied per clock cycle during the digital test, the rate of test application is 200 million vectors per second. Therefore, Digital test time = (1000 × 106)/(200× 106) = 5 seconds Adding the analog test time, we get, Total test time = 1. 5 + 5. 0 = 6. 5 seconds The testing cost for a 500 MHz, 1, 024 pin tester was obtained as 4. 56 cents in Slide 15. Thus, Cost of testing a chip = 6. 5 × 4. 56 = 29. 64 cents The cost of testing bad chips should also be recovered from the price of good chips. Since the yield of good chips is 70%, we obtain Test cost in the price of a chip = 29. 64/0. 7 ≈ 42 cents should be included as the cost of testing while figuring out the price of chips. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 20

Solution Assuming that one vector is applied per clock cycle during the digital test, the rate of test application is 200 million vectors per second. Therefore, Digital test time = (1000 × 106)/(200× 106) = 5 seconds Adding the analog test time, we get, Total test time = 1. 5 + 5. 0 = 6. 5 seconds The testing cost for a 500 MHz, 1, 024 pin tester was obtained as 4. 56 cents in Slide 15. Thus, Cost of testing a chip = 6. 5 × 4. 56 = 29. 64 cents The cost of testing bad chips should also be recovered from the price of good chips. Since the yield of good chips is 70%, we obtain Test cost in the price of a chip = 29. 64/0. 7 ≈ 42 cents should be included as the cost of testing while figuring out the price of chips. Copyright 2001, Agrawal & Bushnell Lecture 1 Introduction 20