e7434454140519a6d5347bb091007433.ppt

- Количество слайдов: 22

Visit at ITEP Micha Danilov, Vladimir Rusinov, Eugeny Tarkowsky WLS-fibre: Discussion on TFS tests: LY: circle aside ---LY (problem with 7 x 7 cm 2 TFS) 5 x 5 270 125 ---uniformity 7 x 7 370 150 ---TFS optimisation 9 x 9, 16 x 16 decreasing as expected ---prototype module need simulation studies design Some (small) disagreement construction in absolute LY as measured in DESY and ITEP TFS tests: ---uniformity (5 x 5 cm 2) with b-source, • ITEP scanner, 400 points • d. A/A: ~ 6%, (DESY: similar results) • need to improve? Simulation studies? ---ITEP will test more DESY-TFS samples, conditions: • to mark groove side • all sticky tape on bottom side • no additional reflector or other material on top side (add. material d. E/dx for source) 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 1

Visit at ITEP Micha Danilov, Vladimir Rusinov, Eugeny Tarkowsky WLS-fibre: Discussion on TFS tests: LY: circle aside ---LY (problem with 7 x 7 cm 2 TFS) 5 x 5 270 125 ---uniformity 7 x 7 370 150 ---TFS optimisation 9 x 9, 16 x 16 decreasing as expected ---prototype module need simulation studies design Some (small) disagreement construction in absolute LY as measured in DESY and ITEP TFS tests: ---uniformity (5 x 5 cm 2) with b-source, • ITEP scanner, 400 points • d. A/A: ~ 6%, (DESY: similar results) • need to improve? Simulation studies? ---ITEP will test more DESY-TFS samples, conditions: • to mark groove side • all sticky tape on bottom side • no additional reflector or other material on top side (add. material d. E/dx for source) 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 1

Visit at ITEP tiles: cleaning procedure reflector: mating vs. “silver-$” fibres: fibre cutting with Ti. O 2 knife, produce one device for DESY? fibre end in tile side wall covered with small 3 M mirror foil, glued to tile hot loop bending (110 -120 degree) test LY of Y 11(100, 150, 200) study again some Bicron fibres? Interest on fibre-fibre fusing, device from DESY >>> ITEP tile plates: which sizes to cast? 15 x 15 cm 2? Than machining of the smaller tile profiles, e. g. 9 tiles of 5 x 5 cm 2 ? Impossible to make >38 different tile sizes by casting re-evaluate the DESY test beam results: • is the ratios correct? • total sum outside hit tile? Study machined prototype with grooves filled with reflective glue? 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 2

Visit at ITEP tiles: cleaning procedure reflector: mating vs. “silver-$” fibres: fibre cutting with Ti. O 2 knife, produce one device for DESY? fibre end in tile side wall covered with small 3 M mirror foil, glued to tile hot loop bending (110 -120 degree) test LY of Y 11(100, 150, 200) study again some Bicron fibres? Interest on fibre-fibre fusing, device from DESY >>> ITEP tile plates: which sizes to cast? 15 x 15 cm 2? Than machining of the smaller tile profiles, e. g. 9 tiles of 5 x 5 cm 2 ? Impossible to make >38 different tile sizes by casting re-evaluate the DESY test beam results: • is the ratios correct? • total sum outside hit tile? Study machined prototype with grooves filled with reflective glue? 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 2

Visit at ITEP Which scintillator to use? Small tiles from Russian scintillator? Homogeneity ok. Larger tiles show wide dips around fibre position (at loops) and lower LY. Optimisation, use: • BASF-136 for small tiles (~70% of total area, ~80% of tiles) • BC-408 or BC-404 for large tiles (~30% of area), 15/38 layers 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 3

Visit at ITEP Which scintillator to use? Small tiles from Russian scintillator? Homogeneity ok. Larger tiles show wide dips around fibre position (at loops) and lower LY. Optimisation, use: • BASF-136 for small tiles (~70% of total area, ~80% of tiles) • BC-408 or BC-404 for large tiles (~30% of area), 15/38 layers 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 3

Visit at ITEP Discussion on TFS tests to do: DESY: more 3 M reflector to ITEP, also more Y 11 fibres, some Silver -$ paint for fibre end coating ITEP: • LY and uniformity for the DESY and Protvino TFS, X-check! • Study optimal doting of WLS: Y 11(100). . . (300) • Study TFS readout with fixed loop diameter but increasing tile dimensions (also simulation? ) • Silver -$ paint and glued 3 M as fibre reflector • fibre end || to tile border, finishing polish for both together • fibre/fibre fused connections, (DESY orders glass tubes) 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 4

Visit at ITEP Discussion on TFS tests to do: DESY: more 3 M reflector to ITEP, also more Y 11 fibres, some Silver -$ paint for fibre end coating ITEP: • LY and uniformity for the DESY and Protvino TFS, X-check! • Study optimal doting of WLS: Y 11(100). . . (300) • Study TFS readout with fixed loop diameter but increasing tile dimensions (also simulation? ) • Silver -$ paint and glued 3 M as fibre reflector • fibre end || to tile border, finishing polish for both together • fibre/fibre fused connections, (DESY orders glass tubes) 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 4

Visit at ITEP Discussion on module construction: ---split ss absorber plate in 2 parts, e. g. : • 17 mm structure plate • 3 mm TFS support plate, to be inserted in stack structure after assembly need special rigid inter-connections ? (grooved rails and special fixing bolts) ---to improve design of 38 plate prototype next 3 month! thicker absorber plates towards module end ? > less tile layers, less scintillator better granularity with same number of channels? 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 5

Visit at ITEP Discussion on module construction: ---split ss absorber plate in 2 parts, e. g. : • 17 mm structure plate • 3 mm TFS support plate, to be inserted in stack structure after assembly need special rigid inter-connections ? (grooved rails and special fixing bolts) ---to improve design of 38 plate prototype next 3 month! thicker absorber plates towards module end ? > less tile layers, less scintillator better granularity with same number of channels? 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 5

Visit at MEPHI Development of Si-PMs People involved: Boris Dolgoshein, Elena Popova, Serge Smirnov (MEPHI), ~5 more people Sergei N. Klemin, PULSAR enterprise --signal shape: 1 ns slope, 10 ns FWHM --photocathode : 15% efficiency, 1 x 1 mm 2 or 2 x 2 mm 2, 3 x 3 mm 2 to many rejects >> increase of costs --operation voltage ~ 55 V, --all signals can be adjusted in amplitude: • by a-source to same gain, using the very narrow 1, 2, 3, 4 Poisson distributed p. e. peaks. size of a-signal ~ 1. 35 Me. V, near to MIP signal ! • and by cosmic MIPs: for calibration to equal signal amplitude for each tile in a cell. • since cells have different # of tiles: cell signals have to be adjusted to the optimal range in the ADC 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 6

Visit at MEPHI Development of Si-PMs People involved: Boris Dolgoshein, Elena Popova, Serge Smirnov (MEPHI), ~5 more people Sergei N. Klemin, PULSAR enterprise --signal shape: 1 ns slope, 10 ns FWHM --photocathode : 15% efficiency, 1 x 1 mm 2 or 2 x 2 mm 2, 3 x 3 mm 2 to many rejects >> increase of costs --operation voltage ~ 55 V, --all signals can be adjusted in amplitude: • by a-source to same gain, using the very narrow 1, 2, 3, 4 Poisson distributed p. e. peaks. size of a-signal ~ 1. 35 Me. V, near to MIP signal ! • and by cosmic MIPs: for calibration to equal signal amplitude for each tile in a cell. • since cells have different # of tiles: cell signals have to be adjusted to the optimal range in the ADC 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 6

Visit at MEPHI Proposed: to connect single Si-PM’s to each individual tile: >>>> ~5000 Si-PM’s for HCAL prototype, - ~800000 Si-PM’s for TESLA HCAL. Alternatives: 1. Connection to each single clear fibre at end of tile-plate: -optical connector needed to connect optical fibre with Si-PM, -connector adapted to a Si-PM array with pitch distance ~1. 5 mm, -photodetector mask similar to mask for APD-array? -to develop such array-connector mask with holes for fibres, -each fibre in hole fixed by little droplet of “Sekundenkleber” -Si-PM photocathode needs mechanical protection from optical-fibre end by a thin plastic disk probably, 2. Connection in tile: (see V. Rusinov, ITEP) -Si-PM inserted in milled groove, 2 x 2 x 5 mm 3 -and directly glued to the tile and a short WLS fibre, -maximum optical LY expected. -inefficient tile volume: 20/12500 = < 2%o -nuclear counter effect small, 2 mm thick sensitive layer only 3. No WLS -fibre at all, direct view of scintillator (studies in ITEP) 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 7

Visit at MEPHI Proposed: to connect single Si-PM’s to each individual tile: >>>> ~5000 Si-PM’s for HCAL prototype, - ~800000 Si-PM’s for TESLA HCAL. Alternatives: 1. Connection to each single clear fibre at end of tile-plate: -optical connector needed to connect optical fibre with Si-PM, -connector adapted to a Si-PM array with pitch distance ~1. 5 mm, -photodetector mask similar to mask for APD-array? -to develop such array-connector mask with holes for fibres, -each fibre in hole fixed by little droplet of “Sekundenkleber” -Si-PM photocathode needs mechanical protection from optical-fibre end by a thin plastic disk probably, 2. Connection in tile: (see V. Rusinov, ITEP) -Si-PM inserted in milled groove, 2 x 2 x 5 mm 3 -and directly glued to the tile and a short WLS fibre, -maximum optical LY expected. -inefficient tile volume: 20/12500 = < 2%o -nuclear counter effect small, 2 mm thick sensitive layer only 3. No WLS -fibre at all, direct view of scintillator (studies in ITEP) 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 7

Visit at MEPHI Signal RO from Si-PM: see also Vladimir Rusinovs talk • via twisted pair cables, • plus a common ground line for all Si-PM on tile-plate • signal from 50 Ohm to ground, capacitive RO possible? Such a wire RO is • thinner and easier to arrange than optical RO fibres • less attenuation losses of signal • summing of tile signals to cell signals in electrical adder/shaper, allows to equalise MIP signals from all tiles in a cell! 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 8

Visit at MEPHI Signal RO from Si-PM: see also Vladimir Rusinovs talk • via twisted pair cables, • plus a common ground line for all Si-PM on tile-plate • signal from 50 Ohm to ground, capacitive RO possible? Such a wire RO is • thinner and easier to arrange than optical RO fibres • less attenuation losses of signal • summing of tile signals to cell signals in electrical adder/shaper, allows to equalise MIP signals from all tiles in a cell! 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 8

Visit at MEPHI Development in MEPHI and Pulsar: Presented were large integrated multi-layer plates with various Si-PM types on it, several hundreds plate ~ 300 mm thick, about 10 multilayers, ~80 subsequent production steps development of waver with appropriate masks, ion inplantations, aluminisation, with polysilicon resistor readout, pixel structure with guard rings for x-talk protection, The multilayer parameters for the production process are defined using special software from ISE (Switzerland) signal development also studied, with SPICE. Production in PULSAR factory, ~900 (300) people, (produce transistors, APD’s, multilayer boards. . ) optical inspection/selection with scope and special devices to idetify rejects by looking for shorts on final multilayer before cutting out individuals planned are 2000 pixels /mm 2, now 600 pixels/mm 2 it is possible to produce required quantities for prototype next year! 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 9

Visit at MEPHI Development in MEPHI and Pulsar: Presented were large integrated multi-layer plates with various Si-PM types on it, several hundreds plate ~ 300 mm thick, about 10 multilayers, ~80 subsequent production steps development of waver with appropriate masks, ion inplantations, aluminisation, with polysilicon resistor readout, pixel structure with guard rings for x-talk protection, The multilayer parameters for the production process are defined using special software from ISE (Switzerland) signal development also studied, with SPICE. Production in PULSAR factory, ~900 (300) people, (produce transistors, APD’s, multilayer boards. . ) optical inspection/selection with scope and special devices to idetify rejects by looking for shorts on final multilayer before cutting out individuals planned are 2000 pixels /mm 2, now 600 pixels/mm 2 it is possible to produce required quantities for prototype next year! 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 9

Visit at MEPHI Discussion on our needs: -- 30 Si-PM’s now, to test in minical -- 150 -200 Si-PM’s March 2003, no additional costs -- 5000 more Si-PM’s are needed for the prototype Estimated costs on base of this quantities: • mass production price (5000) is 7 Euro/PM. • for 800 000 Si-PM, price estimate is 2 Euro/PM. Front end electronic: • preamp/shaper needs no large gain, but shaping! about 1 (<2) Euro per piece expected • adder/shaper and S&H, investigations have to start soon • need connection with LAL and British DAQ group 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 10

Visit at MEPHI Discussion on our needs: -- 30 Si-PM’s now, to test in minical -- 150 -200 Si-PM’s March 2003, no additional costs -- 5000 more Si-PM’s are needed for the prototype Estimated costs on base of this quantities: • mass production price (5000) is 7 Euro/PM. • for 800 000 Si-PM, price estimate is 2 Euro/PM. Front end electronic: • preamp/shaper needs no large gain, but shaping! about 1 (<2) Euro per piece expected • adder/shaper and S&H, investigations have to start soon • need connection with LAL and British DAQ group 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 10

Visit at MEPHI Information from MEPHI needed soon: --optimal sensitive ADC range needed: 1 pe > 2 m. V(50 Ohm)>ADC-channel 15 -20 ? ? ? --gain vs. bias voltage, typical --noise contribution to MIP peak: • noise rate vs. fraction of MIP threshold • noise rate vs. MIP efficiency needed for minical studies at DESY: 1. Testing of 5 pieces at DESY, soon without external amplification with simple amplifiers/summers from MEPHI (? ) 2. Testing 30 pieces at DESY up to 1. 1. 2003 still with CAMAC-RO To contact: with different tile couplings, • Orsay/Prague with different fibre connections, • Minsk/Protvino compare performance with MA-PM’s. 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 11

Visit at MEPHI Information from MEPHI needed soon: --optimal sensitive ADC range needed: 1 pe > 2 m. V(50 Ohm)>ADC-channel 15 -20 ? ? ? --gain vs. bias voltage, typical --noise contribution to MIP peak: • noise rate vs. fraction of MIP threshold • noise rate vs. MIP efficiency needed for minical studies at DESY: 1. Testing of 5 pieces at DESY, soon without external amplification with simple amplifiers/summers from MEPHI (? ) 2. Testing 30 pieces at DESY up to 1. 1. 2003 still with CAMAC-RO To contact: with different tile couplings, • Orsay/Prague with different fibre connections, • Minsk/Protvino compare performance with MA-PM’s. 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 11

Visit at Uniplast, Vladimir Experience in Shashlik production for LHC-B, ECAL ~ 2000 modules, 23 layers, ~25 kg each Big chemical factory, cast tiles, 10 x 10 cm 2, 64 fibre holes 207 km north-east Polystyrene > BASF-143 popob + ptb from Moscow We need: 1. Better Polystyrene from Dow-Chemical: STYRON-663, “optical clean” (!) longer atten. length, price ~ 1. 3 x we will order 25 kg for tests with: 5 x 5 cm 2, 10 x 10 cm 2 tile sizes, Example: 4 mm tick, existing form used various tile sizes standard and optical clean PS in a single mold LY and uniformity measurement in ITEP 2. For our production special size molds needed, max. mold size is 40 x 40 cm 2, pressure to withstand is~ 500 atm. cost/mold ~5000 -7000$ production time for molds: ~ 3 month!! >>> decision on tilesizes up to end 2002!! 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 12

Visit at Uniplast, Vladimir Experience in Shashlik production for LHC-B, ECAL ~ 2000 modules, 23 layers, ~25 kg each Big chemical factory, cast tiles, 10 x 10 cm 2, 64 fibre holes 207 km north-east Polystyrene > BASF-143 popob + ptb from Moscow We need: 1. Better Polystyrene from Dow-Chemical: STYRON-663, “optical clean” (!) longer atten. length, price ~ 1. 3 x we will order 25 kg for tests with: 5 x 5 cm 2, 10 x 10 cm 2 tile sizes, Example: 4 mm tick, existing form used various tile sizes standard and optical clean PS in a single mold LY and uniformity measurement in ITEP 2. For our production special size molds needed, max. mold size is 40 x 40 cm 2, pressure to withstand is~ 500 atm. cost/mold ~5000 -7000$ production time for molds: ~ 3 month!! >>> decision on tilesizes up to end 2002!! 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 12

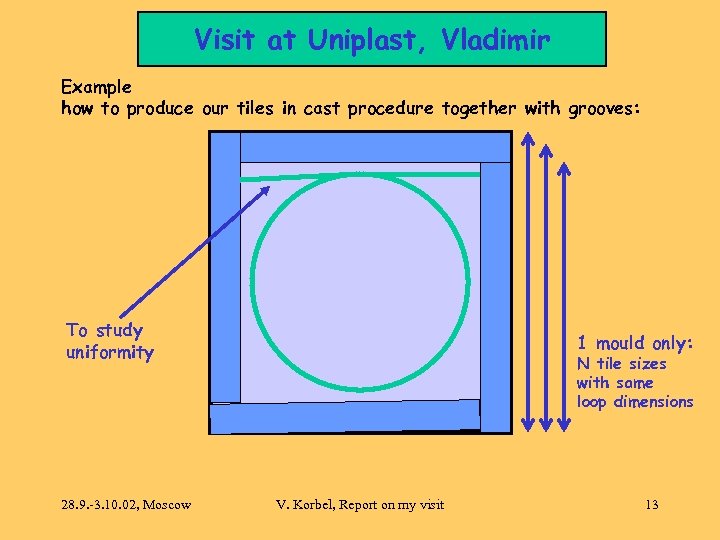

Visit at Uniplast, Vladimir Example how to produce our tiles in cast procedure together with grooves: To study uniformity 28. 9. -3. 10. 02, Moscow 1 mould only: N tile sizes with same loop dimensions V. Korbel, Report on my visit 13

Visit at Uniplast, Vladimir Example how to produce our tiles in cast procedure together with grooves: To study uniformity 28. 9. -3. 10. 02, Moscow 1 mould only: N tile sizes with same loop dimensions V. Korbel, Report on my visit 13

Visit at Uniplast, Vladimir We will have about 30 different tile sizes in barrel at present 38, to be redesigned (VK) soon it seems possible to reduce the number of casting forms to 6 -8 ? Number of Tiles we need: next year (2003) ~ 200 tiles, march, minical, problem with mould cost ~ 5 000 tiles, autumn, production is some weeks for TESLA HCAL ~ 800 000 tiles, production after 2003, full quantity in 4 years 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 14

Visit at Uniplast, Vladimir We will have about 30 different tile sizes in barrel at present 38, to be redesigned (VK) soon it seems possible to reduce the number of casting forms to 6 -8 ? Number of Tiles we need: next year (2003) ~ 200 tiles, march, minical, problem with mould cost ~ 5 000 tiles, autumn, production is some weeks for TESLA HCAL ~ 800 000 tiles, production after 2003, full quantity in 4 years 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 14

Visit at Uniplast, Vladimir To do: 1. cleaner PS than STYRON-663 (1. 3 E/k) or 637 (1. 3 E/kg) needed for large tile sizes: >> STYRON-2262 (1. 5 E/kg) >> DESY tries to buy, problem delivery outside US ! 2. produce some new tiles (10 x 10 cm 2, directly with grooves) • compare with old PS at ITEP 3. re-design tile-plate structures (in barrel) • number of tile layers, • define the various tile sizes • exact tile thickness, tolerances ? 4. final decision on groove shapes (geometrical configuration) 5. order 1. casting form for HCAL-prototype, should cover many tile sizes from 5 x 5 to 8 x 8 cm 2, 6. larger tiles to be machined from cast plates (40 x 40 cm 2, Uniplast) and from BC-408, several m 2 more to order? 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 15

Visit at Uniplast, Vladimir To do: 1. cleaner PS than STYRON-663 (1. 3 E/k) or 637 (1. 3 E/kg) needed for large tile sizes: >> STYRON-2262 (1. 5 E/kg) >> DESY tries to buy, problem delivery outside US ! 2. produce some new tiles (10 x 10 cm 2, directly with grooves) • compare with old PS at ITEP 3. re-design tile-plate structures (in barrel) • number of tile layers, • define the various tile sizes • exact tile thickness, tolerances ? 4. final decision on groove shapes (geometrical configuration) 5. order 1. casting form for HCAL-prototype, should cover many tile sizes from 5 x 5 to 8 x 8 cm 2, 6. larger tiles to be machined from cast plates (40 x 40 cm 2, Uniplast) and from BC-408, several m 2 more to order? 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 15

Visit at Protvino With Valentin Kozlov, LPI New division for plastic production on PS pressure casting base financial support from government: “new technology support” use many production parameters, computer controlled --2 high pressure (~800 kg/cm 2) injection machines (DEMAG, new) --1 extrusion machine (Koch Gmb. H) they produce: • commercial products • plastic scintillators (KOPIO, Phenix, HERA-B, Hermes, many Russian clients) • medical products, clean room set up • Alexander Soldatov • Vladimir Vasilchenko 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 16

Visit at Protvino With Valentin Kozlov, LPI New division for plastic production on PS pressure casting base financial support from government: “new technology support” use many production parameters, computer controlled --2 high pressure (~800 kg/cm 2) injection machines (DEMAG, new) --1 extrusion machine (Koch Gmb. H) they produce: • commercial products • plastic scintillators (KOPIO, Phenix, HERA-B, Hermes, many Russian clients) • medical products, clean room set up • Alexander Soldatov • Vladimir Vasilchenko 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 16

Visit at Protvino Scintillator material: PS, Popop, PTB I bought and brought 5 new scintillator cooking ingredients to shift optimally scintillator light to the WLS sensitivity range test are in preparation to improve LY special for Y 11 -WLS fibre Injection moulding from granulate, max 600 cm 2 area or 600 cm 3 volume, each casting mould costs ~7000$. to be optimised: mold temperature, pressure, heating/cooling cycles (Protvino+LPI) e. g. 5 x 5 cm 2 tiles: 40 s maximal sizes need: 2 -3 min/tile 2 y needed for all TESLA tiles, as a ISTC fund? Total cost ~ 800 000 Euro, 20 E/kg 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 17

Visit at Protvino Scintillator material: PS, Popop, PTB I bought and brought 5 new scintillator cooking ingredients to shift optimally scintillator light to the WLS sensitivity range test are in preparation to improve LY special for Y 11 -WLS fibre Injection moulding from granulate, max 600 cm 2 area or 600 cm 3 volume, each casting mould costs ~7000$. to be optimised: mold temperature, pressure, heating/cooling cycles (Protvino+LPI) e. g. 5 x 5 cm 2 tiles: 40 s maximal sizes need: 2 -3 min/tile 2 y needed for all TESLA tiles, as a ISTC fund? Total cost ~ 800 000 Euro, 20 E/kg 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 17

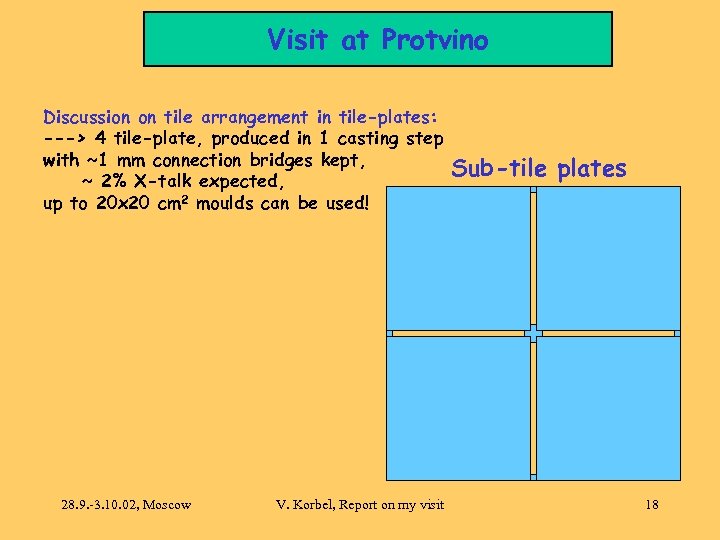

Visit at Protvino Discussion on tile arrangement in tile-plates: ---> 4 tile-plate, produced in 1 casting step with ~1 mm connection bridges kept, ~ 2% X-talk expected, up to 20 x 20 cm 2 moulds can be used! 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit Sub-tile plates 18

Visit at Protvino Discussion on tile arrangement in tile-plates: ---> 4 tile-plate, produced in 1 casting step with ~1 mm connection bridges kept, ~ 2% X-talk expected, up to 20 x 20 cm 2 moulds can be used! 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit Sub-tile plates 18

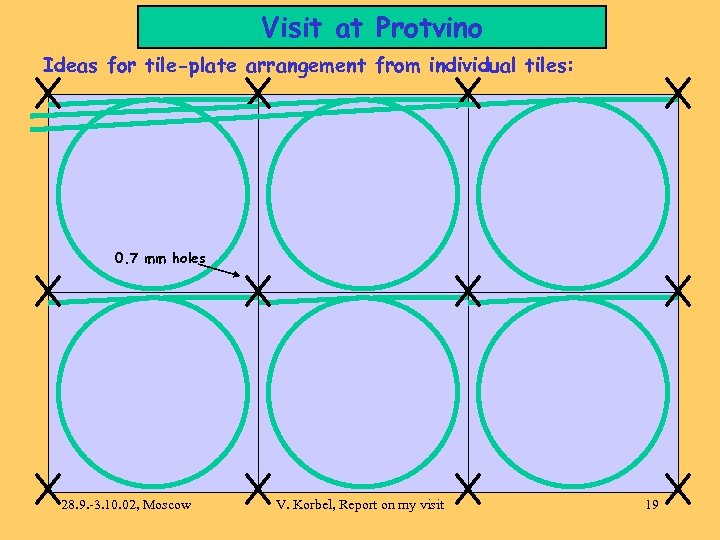

Visit at Protvino Ideas for tile-plate arrangement from individual tiles: 0. 7 mm holes 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 19

Visit at Protvino Ideas for tile-plate arrangement from individual tiles: 0. 7 mm holes 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 19

Visit at Protvino Clamping method, individual. tiles: easier for diagonal curved, much easier for centre grooves Multi tile-plate moulding: not flexible enough for various tile sizes To be discussed: cassettes for tile plates --Support plate needed on both surfaces of tile plate: to carry the tiles (below, 3 -5 mm ss? ) --to protect the fibres: and make assembly light tight for tests and gain adjustment (on top thin carbon fibre material? ) --closing on sides: light tight closing to get light shield and carry the photodetectors (in case of 1 Si-PM/fibre) To fix very soon: --tile sizes, # of tiles per tile size, --grouping of tiles in common moulding forms, --geometrical fibre-groove shapes, --number of casting moulds needed. 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 20

Visit at Protvino Clamping method, individual. tiles: easier for diagonal curved, much easier for centre grooves Multi tile-plate moulding: not flexible enough for various tile sizes To be discussed: cassettes for tile plates --Support plate needed on both surfaces of tile plate: to carry the tiles (below, 3 -5 mm ss? ) --to protect the fibres: and make assembly light tight for tests and gain adjustment (on top thin carbon fibre material? ) --closing on sides: light tight closing to get light shield and carry the photodetectors (in case of 1 Si-PM/fibre) To fix very soon: --tile sizes, # of tiles per tile size, --grouping of tiles in common moulding forms, --geometrical fibre-groove shapes, --number of casting moulds needed. 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 20

Visit at Protvino To do: Protvino: • improve TFS-LY with new doping ingredients, with new granulate from DOW Chemical, • try to include fibre grooves in casting, • define # of matrices needed, • produce ca 30 tiles of 5 x 5 cm 2 for minical tests, • work out cost and time plan for HCAL prototype. ITEP/DESY: • more studies on inserted WLS and clear RO fibre glue WLS/clear fibre connection, fix on tile try 1. 0 and 1. 1 mm clear fibre (to study with LPI? ) fuse WLS/clear fibre connection 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 21

Visit at Protvino To do: Protvino: • improve TFS-LY with new doping ingredients, with new granulate from DOW Chemical, • try to include fibre grooves in casting, • define # of matrices needed, • produce ca 30 tiles of 5 x 5 cm 2 for minical tests, • work out cost and time plan for HCAL prototype. ITEP/DESY: • more studies on inserted WLS and clear RO fibre glue WLS/clear fibre connection, fix on tile try 1. 0 and 1. 1 mm clear fibre (to study with LPI? ) fuse WLS/clear fibre connection 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 21

Visit at Protvino Preamplifiers for use with APD’s Youri Guilitsski, group of Sergei Denissov: --ITEP/Minsk type, charge sensitive, --1 preamp ready --end Nov. 02: some preamps to DESY for minical tests gain to regulate (by screw driver) up to 5 m. V/f. C same noise level as from CERN tests capacity range 20 -30 p. F --larger quantity (~ 30 pieces) at 1. 1. 03 --PC board with 16 channels (prototype) needs 1/2 y production time. --decision meeting which preamp(s) to choose for prototype at DESY in Febr. 03, Youri comes to DESY 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 22

Visit at Protvino Preamplifiers for use with APD’s Youri Guilitsski, group of Sergei Denissov: --ITEP/Minsk type, charge sensitive, --1 preamp ready --end Nov. 02: some preamps to DESY for minical tests gain to regulate (by screw driver) up to 5 m. V/f. C same noise level as from CERN tests capacity range 20 -30 p. F --larger quantity (~ 30 pieces) at 1. 1. 03 --PC board with 16 channels (prototype) needs 1/2 y production time. --decision meeting which preamp(s) to choose for prototype at DESY in Febr. 03, Youri comes to DESY 28. 9. -3. 10. 02, Moscow V. Korbel, Report on my visit 22