dced89a5d5a22f345dd6c1c0a3b97d11.ppt

- Количество слайдов: 23

Virtual Metrology to Measure Mass Loss at Deep Trench Processes April 18 th, 2007 Tilo Wünsche, Matthias Rudolph, Jan Zimpel (adp Gmb. H)

Virtual Metrology to Measure Mass Loss at Deep Trench Processes April 18 th, 2007 Tilo Wünsche, Matthias Rudolph, Jan Zimpel (adp Gmb. H)

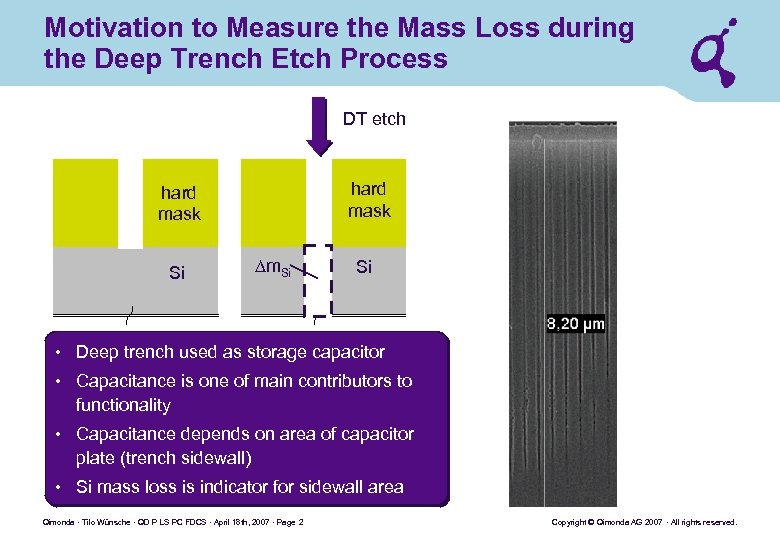

Motivation to Measure the Mass Loss during the Deep Trench Etch Process DT etch hard mask Si Dm. Si Si • Deep trench used as storage capacitor • Capacitance is one of main contributors to functionality • Capacitance depends on area of capacitor plate (trench sidewall) • Si mass loss is indicator for sidewall area Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 2 Copyright © Qimonda AG 2007 · All rights reserved.

Motivation to Measure the Mass Loss during the Deep Trench Etch Process DT etch hard mask Si Dm. Si Si • Deep trench used as storage capacitor • Capacitance is one of main contributors to functionality • Capacitance depends on area of capacitor plate (trench sidewall) • Si mass loss is indicator for sidewall area Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 2 Copyright © Qimonda AG 2007 · All rights reserved.

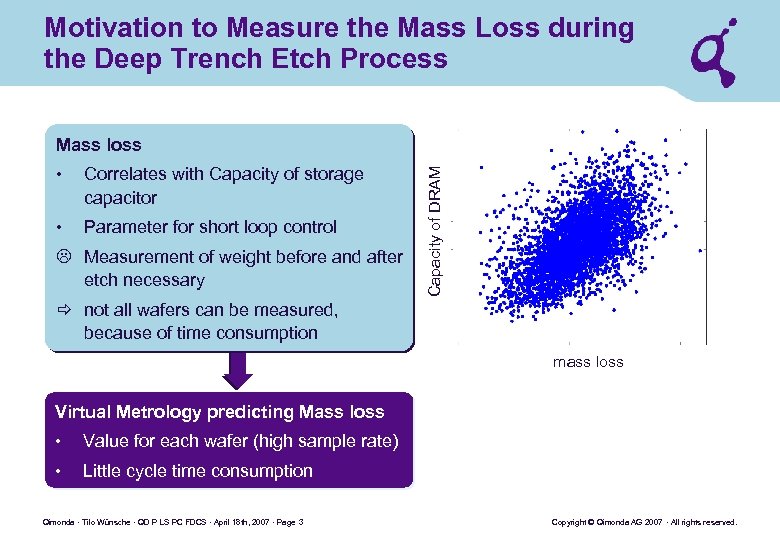

Motivation to Measure the Mass Loss during the Deep Trench Etch Process • Correlates with Capacity of storage capacitor • Parameter for short loop control L Measurement of weight before and after etch necessary Capacity of DRAM Mass loss ð not all wafers can be measured, because of time consumption mass loss Virtual Metrology predicting Mass loss • Value for each wafer (high sample rate) • Little cycle time consumption Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 3 Copyright © Qimonda AG 2007 · All rights reserved.

Motivation to Measure the Mass Loss during the Deep Trench Etch Process • Correlates with Capacity of storage capacitor • Parameter for short loop control L Measurement of weight before and after etch necessary Capacity of DRAM Mass loss ð not all wafers can be measured, because of time consumption mass loss Virtual Metrology predicting Mass loss • Value for each wafer (high sample rate) • Little cycle time consumption Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 3 Copyright © Qimonda AG 2007 · All rights reserved.

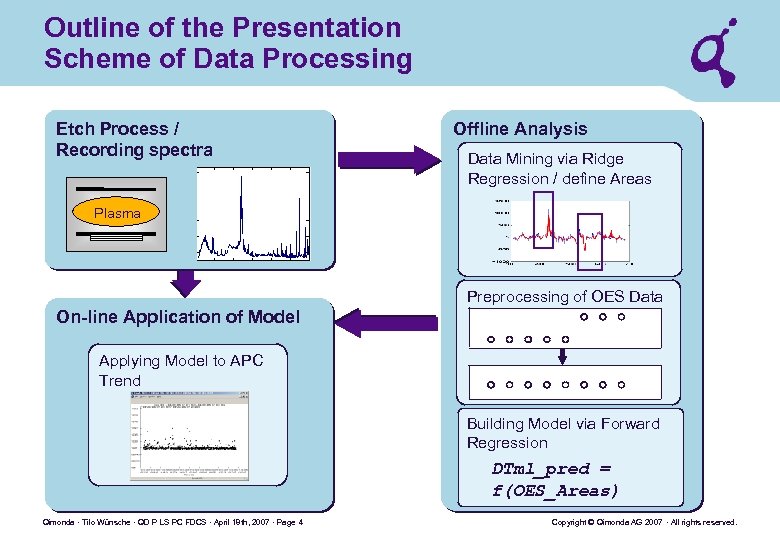

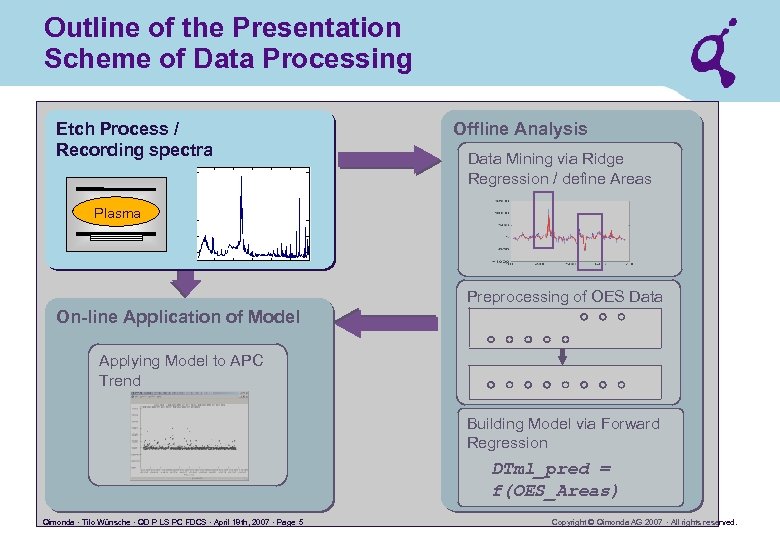

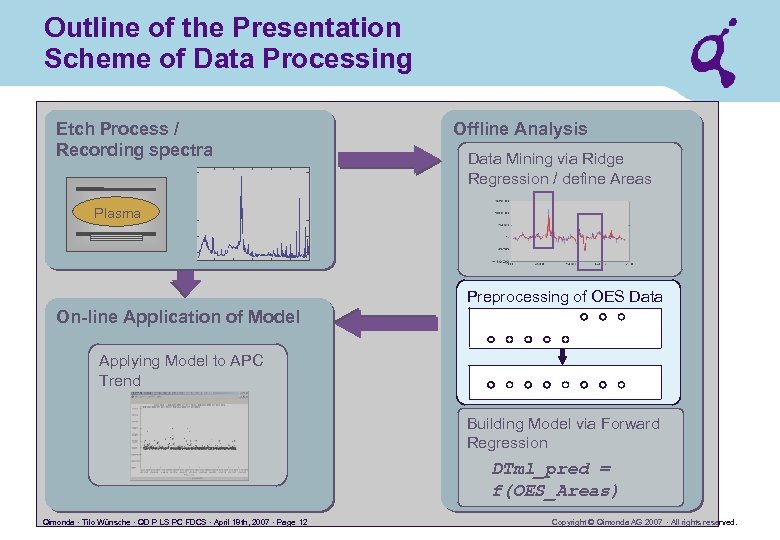

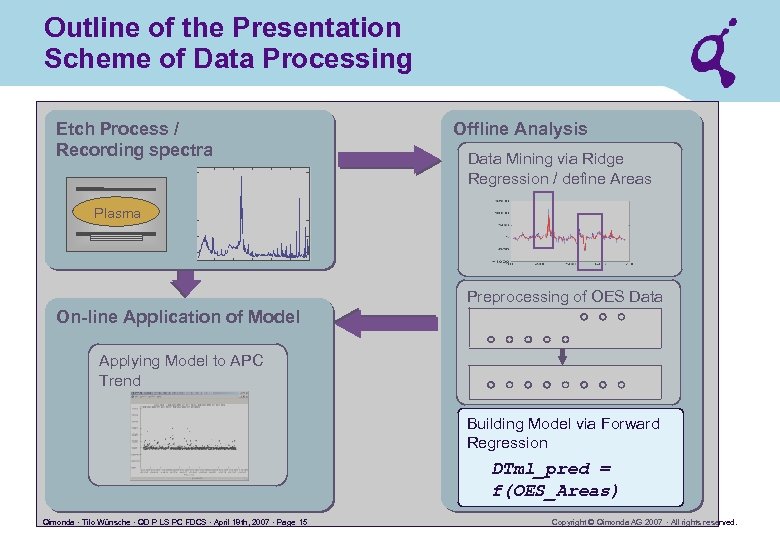

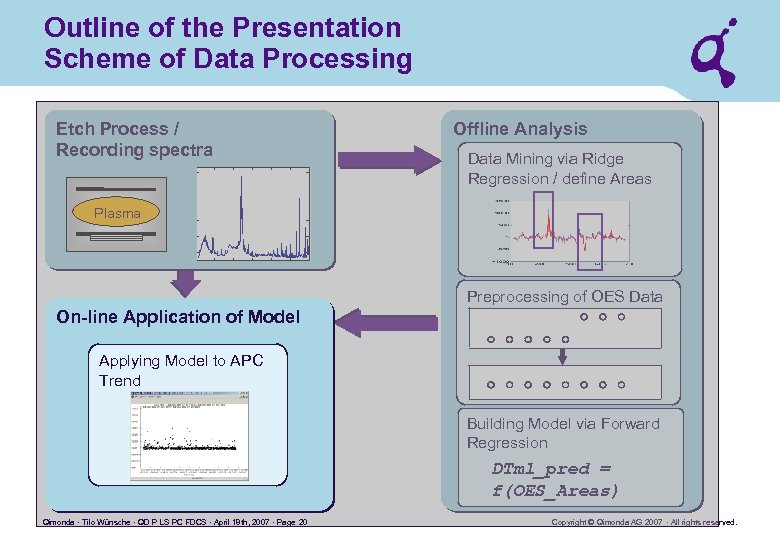

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 4 Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 4 Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 5 Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 5 Copyright © Qimonda AG 2007 · All rights reserved.

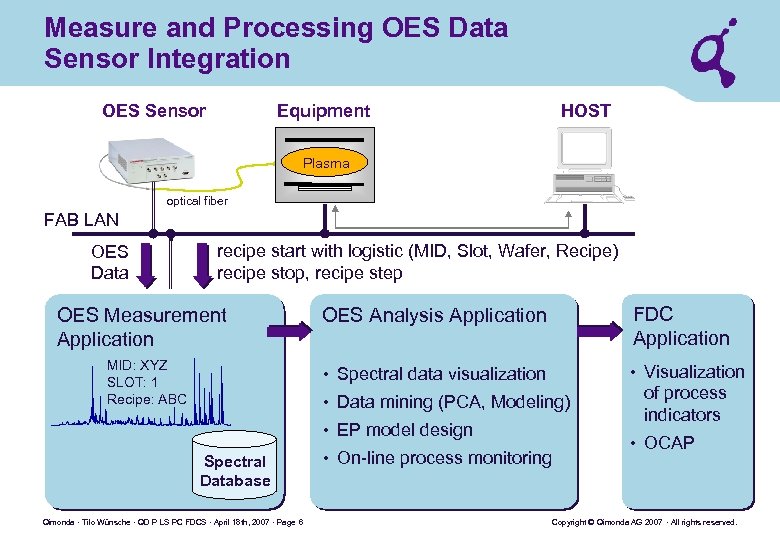

Measure and Processing OES Data Sensor Integration OES Sensor Equipment HOST Plasma optical fiber FAB LAN OES Data recipe start with logistic (MID, Slot, Wafer, Recipe) recipe stop, recipe step MID: XYZ SLOT: 1 Recipe: ABC OES Analysis Application FDC Application • Spectral data visualization OES Measurement Application • Visualization • Data mining (PCA, Modeling) • EP model design Spectral Database Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 6 • On-line process monitoring of process indicators • OCAP Copyright © Qimonda AG 2007 · All rights reserved.

Measure and Processing OES Data Sensor Integration OES Sensor Equipment HOST Plasma optical fiber FAB LAN OES Data recipe start with logistic (MID, Slot, Wafer, Recipe) recipe stop, recipe step MID: XYZ SLOT: 1 Recipe: ABC OES Analysis Application FDC Application • Spectral data visualization OES Measurement Application • Visualization • Data mining (PCA, Modeling) • EP model design Spectral Database Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 6 • On-line process monitoring of process indicators • OCAP Copyright © Qimonda AG 2007 · All rights reserved.

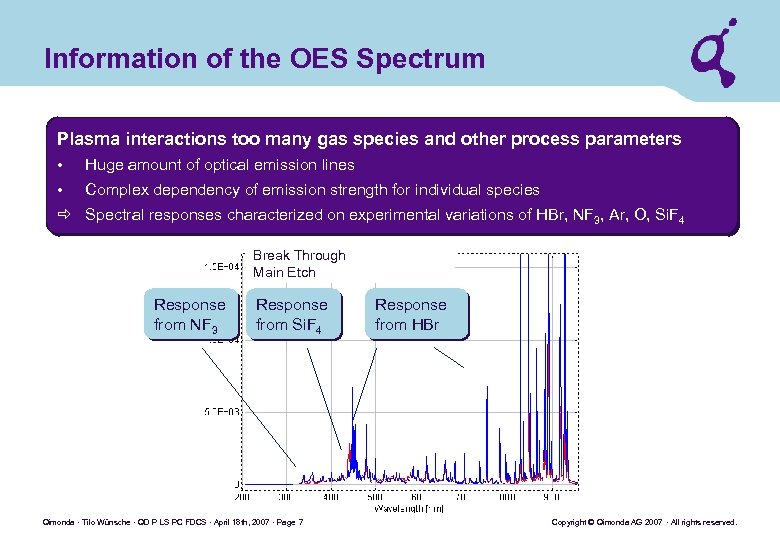

Information of the OES Spectrum Plasma interactions too many gas species and other process parameters • Huge amount of optical emission lines • Complex dependency of emission strength for individual species ð Spectral responses characterized on experimental variations of HBr, NF 3, Ar, O, Si. F 4 Break Through Main Etch Response from NF 3 Response from Si. F 4 Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 7 Response from HBr Copyright © Qimonda AG 2007 · All rights reserved.

Information of the OES Spectrum Plasma interactions too many gas species and other process parameters • Huge amount of optical emission lines • Complex dependency of emission strength for individual species ð Spectral responses characterized on experimental variations of HBr, NF 3, Ar, O, Si. F 4 Break Through Main Etch Response from NF 3 Response from Si. F 4 Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 7 Response from HBr Copyright © Qimonda AG 2007 · All rights reserved.

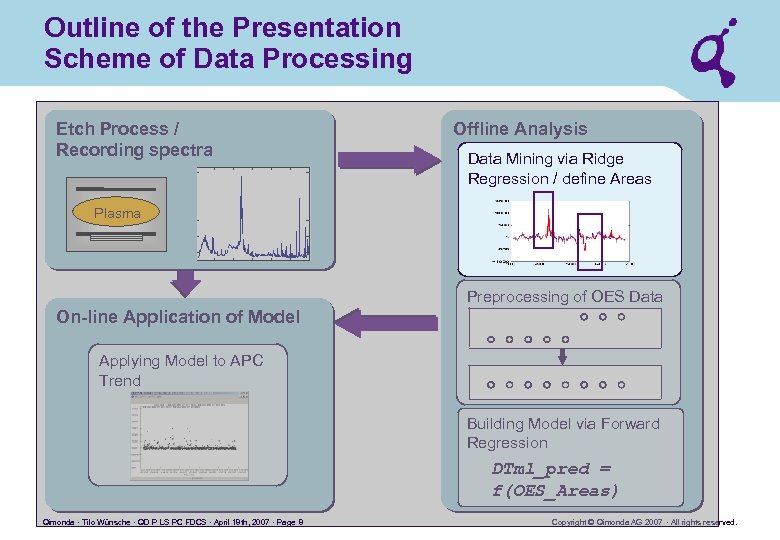

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 8 Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 8 Copyright © Qimonda AG 2007 · All rights reserved.

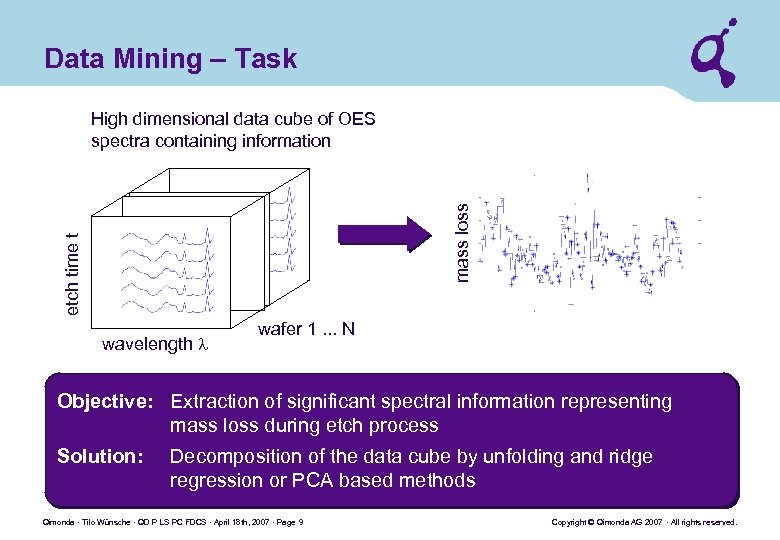

Data Mining – Task etch time t mass loss High dimensional data cube of OES spectra containing information wavelength wafer 1. . . N Objective: Extraction of significant spectral information representing mass loss during etch process Solution: Decomposition of the data cube by unfolding and ridge regression or PCA based methods Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 9 Copyright © Qimonda AG 2007 · All rights reserved.

Data Mining – Task etch time t mass loss High dimensional data cube of OES spectra containing information wavelength wafer 1. . . N Objective: Extraction of significant spectral information representing mass loss during etch process Solution: Decomposition of the data cube by unfolding and ridge regression or PCA based methods Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 9 Copyright © Qimonda AG 2007 · All rights reserved.

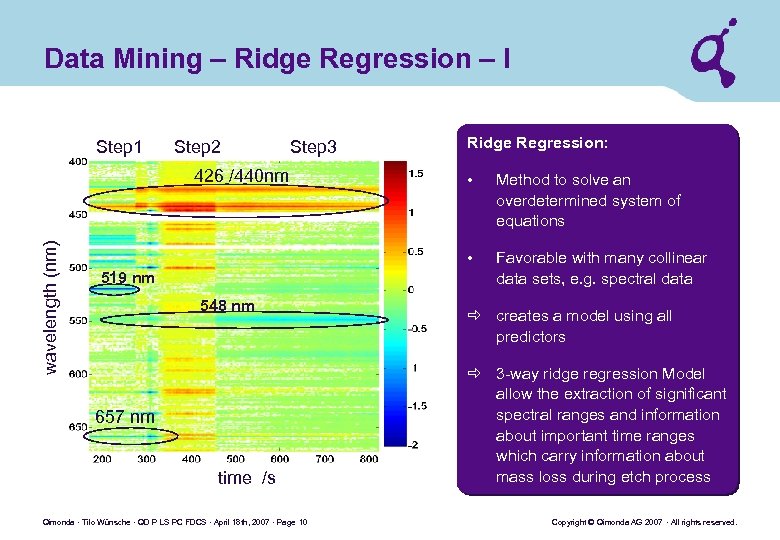

Data Mining – Ridge Regression – I Step 1 Step 2 Step 3 wavelength (nm) 426 /440 nm Ridge Regression: 548 nm 657 nm time /s Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 10 Method to solve an overdetermined system of equations • 519 nm • Favorable with many collinear data sets, e. g. spectral data ð creates a model using all predictors ð 3 -way ridge regression Model allow the extraction of significant spectral ranges and information about important time ranges which carry information about mass loss during etch process Copyright © Qimonda AG 2007 · All rights reserved.

Data Mining – Ridge Regression – I Step 1 Step 2 Step 3 wavelength (nm) 426 /440 nm Ridge Regression: 548 nm 657 nm time /s Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 10 Method to solve an overdetermined system of equations • 519 nm • Favorable with many collinear data sets, e. g. spectral data ð creates a model using all predictors ð 3 -way ridge regression Model allow the extraction of significant spectral ranges and information about important time ranges which carry information about mass loss during etch process Copyright © Qimonda AG 2007 · All rights reserved.

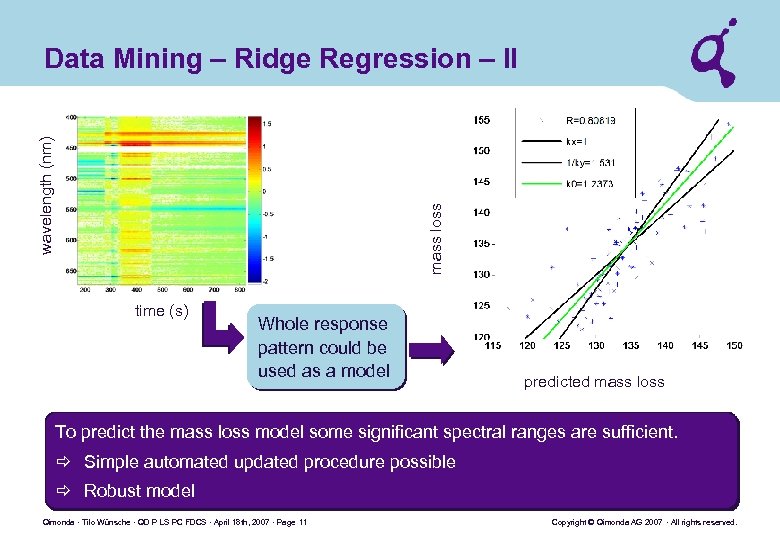

mass loss wavelength (nm) Data Mining – Ridge Regression – II time (s) Whole response pattern could be used as a model predicted mass loss To predict the mass loss model some significant spectral ranges are sufficient. ð Simple automated updated procedure possible ð Robust model Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 11 Copyright © Qimonda AG 2007 · All rights reserved.

mass loss wavelength (nm) Data Mining – Ridge Regression – II time (s) Whole response pattern could be used as a model predicted mass loss To predict the mass loss model some significant spectral ranges are sufficient. ð Simple automated updated procedure possible ð Robust model Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 11 Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 12 Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 12 Copyright © Qimonda AG 2007 · All rights reserved.

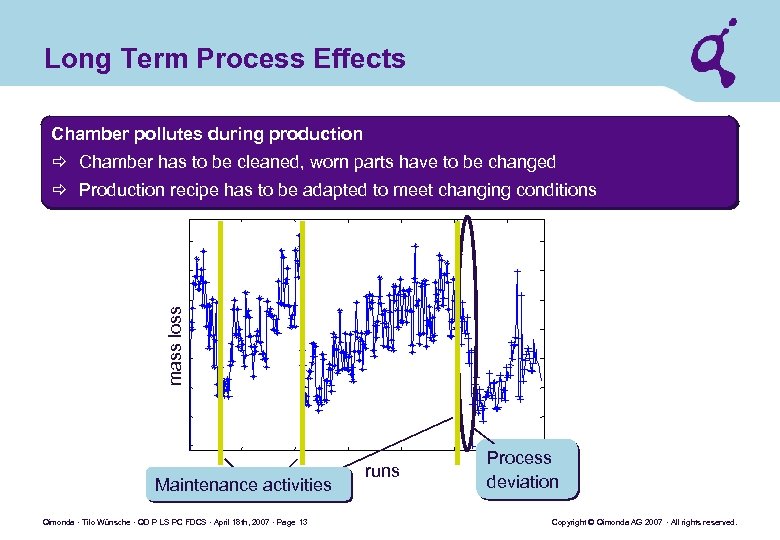

Long Term Process Effects Chamber pollutes during production ð Chamber has to be cleaned, worn parts have to be changed mass loss ð Production recipe has to be adapted to meet changing conditions Maintenance activities Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 13 runs Process deviation Copyright © Qimonda AG 2007 · All rights reserved.

Long Term Process Effects Chamber pollutes during production ð Chamber has to be cleaned, worn parts have to be changed mass loss ð Production recipe has to be adapted to meet changing conditions Maintenance activities Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 13 runs Process deviation Copyright © Qimonda AG 2007 · All rights reserved.

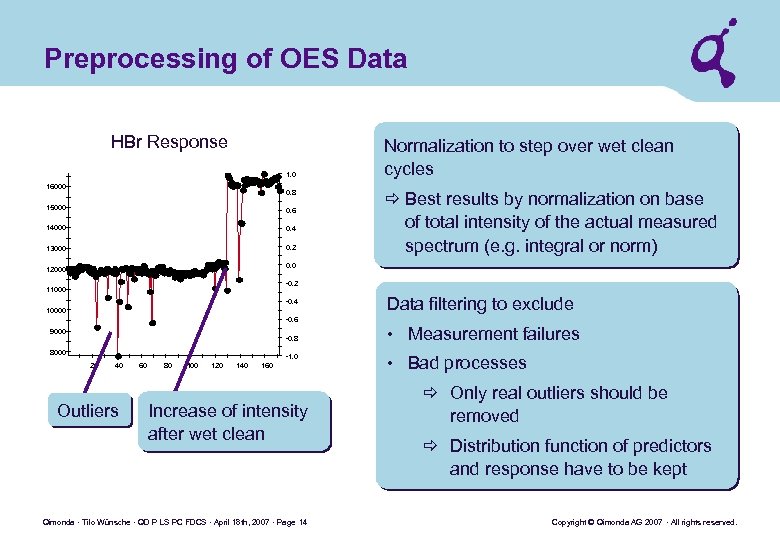

Preprocessing of OES Data HBr Response 1. 0 16000 0. 8 15000 0. 6 14000 0. 4 13000 0. 2 Normalization to step over wet clean cycles ð Best results by normalization on base of total intensity of the actual measured spectrum (e. g. integral or norm) 0. 0 12000 -0. 2 11000 -0. 4 10000 -0. 6 9000 -0. 8 8000 -1. 0 20 40 Outliers 60 80 100 120 140 160 Increase of intensity after wet clean Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 14 Data filtering to exclude • Measurement failures • Bad processes ð Only real outliers should be removed ð Distribution function of predictors and response have to be kept Copyright © Qimonda AG 2007 · All rights reserved.

Preprocessing of OES Data HBr Response 1. 0 16000 0. 8 15000 0. 6 14000 0. 4 13000 0. 2 Normalization to step over wet clean cycles ð Best results by normalization on base of total intensity of the actual measured spectrum (e. g. integral or norm) 0. 0 12000 -0. 2 11000 -0. 4 10000 -0. 6 9000 -0. 8 8000 -1. 0 20 40 Outliers 60 80 100 120 140 160 Increase of intensity after wet clean Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 14 Data filtering to exclude • Measurement failures • Bad processes ð Only real outliers should be removed ð Distribution function of predictors and response have to be kept Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 15 Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 15 Copyright © Qimonda AG 2007 · All rights reserved.

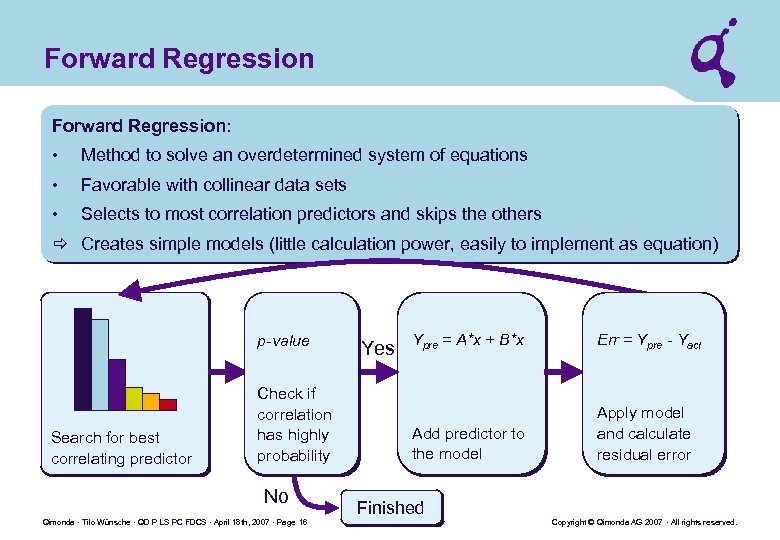

Forward Regression: • Method to solve an overdetermined system of equations • Favorable with collinear data sets • Selects to most correlation predictors and skips the others ð Creates simple models (little calculation power, easily to implement as equation) p-value Search for best correlating predictor Check if correlation has highly probability No Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 16 Ypre = A*x + B*x Err = Ypre - Yact Add predictor to the model Yes Apply model and calculate residual error Finished Copyright © Qimonda AG 2007 · All rights reserved.

Forward Regression: • Method to solve an overdetermined system of equations • Favorable with collinear data sets • Selects to most correlation predictors and skips the others ð Creates simple models (little calculation power, easily to implement as equation) p-value Search for best correlating predictor Check if correlation has highly probability No Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 16 Ypre = A*x + B*x Err = Ypre - Yact Add predictor to the model Yes Apply model and calculate residual error Finished Copyright © Qimonda AG 2007 · All rights reserved.

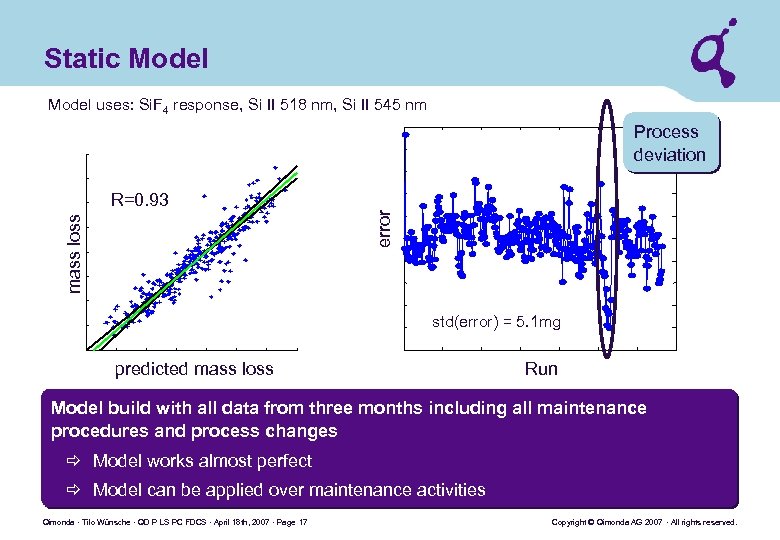

Static Model uses: Si. F 4 response, Si II 518 nm, Si II 545 nm Process deviation mass loss error R=0. 93 std(error) = 5. 1 mg predicted mass loss Run Model build with all data from three months including all maintenance procedures and process changes ð Model works almost perfect ð Model can be applied over maintenance activities Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 17 Copyright © Qimonda AG 2007 · All rights reserved.

Static Model uses: Si. F 4 response, Si II 518 nm, Si II 545 nm Process deviation mass loss error R=0. 93 std(error) = 5. 1 mg predicted mass loss Run Model build with all data from three months including all maintenance procedures and process changes ð Model works almost perfect ð Model can be applied over maintenance activities Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 17 Copyright © Qimonda AG 2007 · All rights reserved.

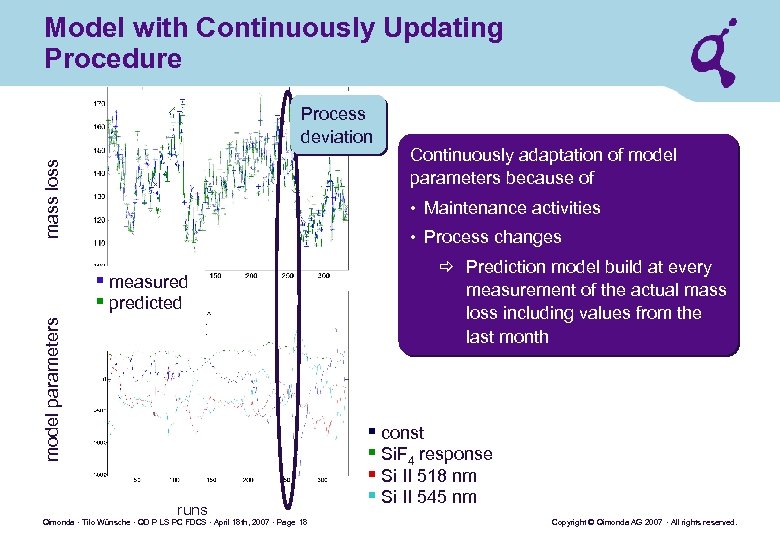

Model with Continuously Updating Procedure mass loss Process deviation Continuously adaptation of model parameters because of • Maintenance activities • Process changes model parameters § measured § predicted runs Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 18 ð Prediction model build at every measurement of the actual mass loss including values from the last month § const § Si. F 4 response § Si II 518 nm § Si II 545 nm Copyright © Qimonda AG 2007 · All rights reserved.

Model with Continuously Updating Procedure mass loss Process deviation Continuously adaptation of model parameters because of • Maintenance activities • Process changes model parameters § measured § predicted runs Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 18 ð Prediction model build at every measurement of the actual mass loss including values from the last month § const § Si. F 4 response § Si II 518 nm § Si II 545 nm Copyright © Qimonda AG 2007 · All rights reserved.

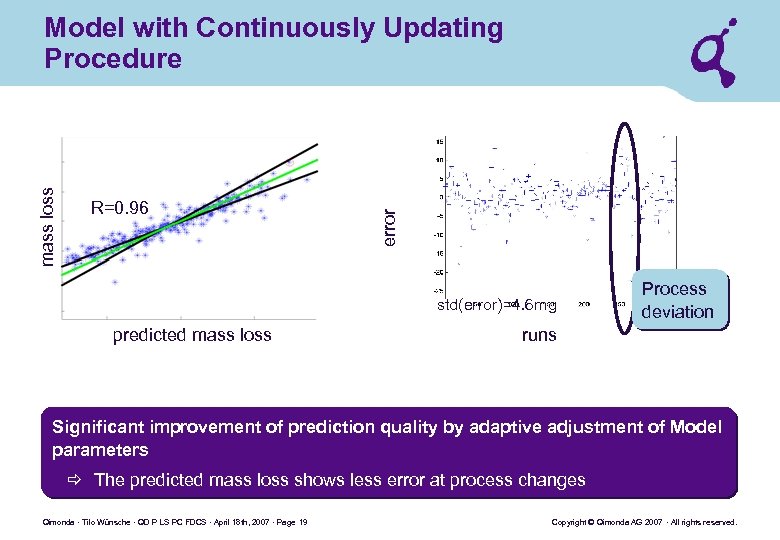

R=0. 96 error mass loss Model with Continuously Updating Procedure std(error)=4. 6 mg predicted mass loss Process deviation runs Significant improvement of prediction quality by adaptive adjustment of Model parameters ð The predicted mass loss shows less error at process changes Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 19 Copyright © Qimonda AG 2007 · All rights reserved.

R=0. 96 error mass loss Model with Continuously Updating Procedure std(error)=4. 6 mg predicted mass loss Process deviation runs Significant improvement of prediction quality by adaptive adjustment of Model parameters ð The predicted mass loss shows less error at process changes Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 19 Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 20 Copyright © Qimonda AG 2007 · All rights reserved.

Outline of the Presentation Scheme of Data Processing Etch Process / Recording spectra Offline Analysis Data Mining via Ridge Regression / define Areas Plasma Preprocessing of OES Data On-line Application of Model Applying Model to APC Trend Building Model via Forward Regression DTml_pred = f(OES_Areas) Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 20 Copyright © Qimonda AG 2007 · All rights reserved.

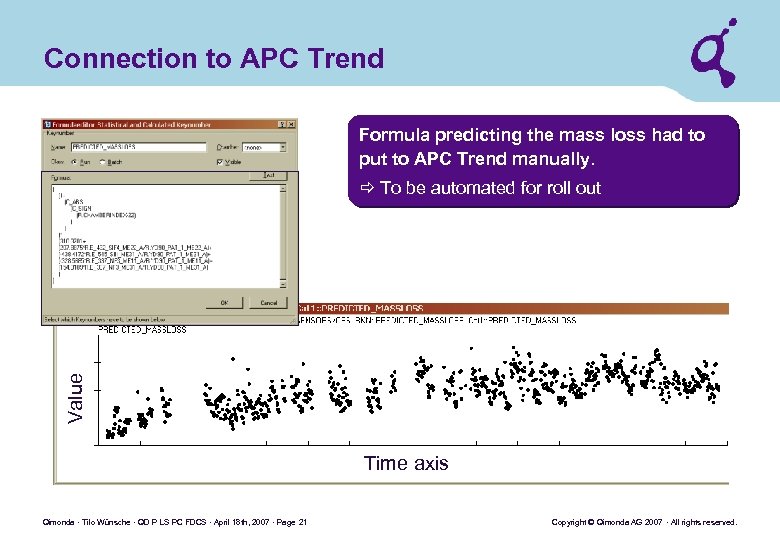

Connection to APC Trend Formula predicting the mass loss had to put to APC Trend manually. Value ð To be automated for roll out Time axis Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 21 Copyright © Qimonda AG 2007 · All rights reserved.

Connection to APC Trend Formula predicting the mass loss had to put to APC Trend manually. Value ð To be automated for roll out Time axis Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 21 Copyright © Qimonda AG 2007 · All rights reserved.

Possible Reactions on the Model Output Actual implemented actions • Model output at APC Trend ð Email if mass loss out of spec ð Further usage by engineers Not possible to implement • Real time reaction during wafer processing to stop the process by endpoint detection ð Variance of individual values too high, probability to create scrap Future items to be checked • Centering the process regarding his spec limits • Adapting process steps after the deep trench etching ð Could be automated using R 2 R control Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 22 Copyright © Qimonda AG 2007 · All rights reserved.

Possible Reactions on the Model Output Actual implemented actions • Model output at APC Trend ð Email if mass loss out of spec ð Further usage by engineers Not possible to implement • Real time reaction during wafer processing to stop the process by endpoint detection ð Variance of individual values too high, probability to create scrap Future items to be checked • Centering the process regarding his spec limits • Adapting process steps after the deep trench etching ð Could be automated using R 2 R control Qimonda · Tilo Wünsche · QD P LS PC FDCS · April 18 th, 2007 · Page 22 Copyright © Qimonda AG 2007 · All rights reserved.

Thank you The World’s Leading Creative Memory Company

Thank you The World’s Leading Creative Memory Company