bca85547ecc438e15e78c5a2660e9089.ppt

- Количество слайдов: 21

Virtual Environments for Manufacturing And Training (VEMAT) By Tan Hock Soon On Behalf of Shen Shuang Yang Mr Zhou Hong Tan Kim Cheng

Acknowledgement APEC TEL for funding this research under the project title VEMAT (05/2001).

Outline • Introduction – Shortage of manpower, facilities – Concept of sharing • Literature Review – Increasing trend of collaboration in manufacturing – Increasing trend of virtual technologies in education – Findings • Conceptual Framework – – Prototype Selection Clustering Software Application Framework (Video) • Tests • Concluding Discussion • Q&A

1. Introduction • In education, we recognized that there is often a shortage of: – Experienced/qualified teachers – Equipment, especially specialized laboratory equipment • We can try to alleviate the problem of shortage of teachers by sharing them (or their knowledge) in different ways: – Digitize their knowledge (in courseware, video, etc. ) – Allow synchronous lessons to be conducted using video conferencing

1. Introduction • Contemplate the networked laser printer • By sharing it, its effectiveness has increased, more users benefit from the connection

1. Introduction • Could the same approach be taken for even more expensive equipment? • Could the idea of “sharing” be taken further? • What would be the likely mechanism? • How does this help education?

2. Literature Review Increasing trend of collaboration in manufacturing • Internet-enabled distributed systems (Bailey 1995, Tay et. al. 2001) • Portals for virtual manufacturing (www. i-msc. com) • Equipment and machines gravitating towards Internet integrated technology, modular and commercially available parts (Tan & Chu 2000, Tan & Lee 1999)

2. Literature Review Increasing trend of virtual technologies in education • Empirical data on transfer of skills from virtual environments to real world in terms of instructional effectiveness (Moshell et. al. 1993, Tan & Ward 1998) • Potential of VEs in education & training (Youngblut 1997, Francis & Tan 1999) • Simulators & on-line laboratories (Tan 2000, Tan & Chu 2000)

2. Literature Review Findings • Very possible that certain categories of equipment/machines could be shared • Some equipment already have built-in capabilities for connection to a network • Very possible to retrofit equipment at low cost using standard components • Resource-sharing concept is feasible • Possible to create simulations for on-line training

3. Conceptual Framework • Equipment Selection – Fused Deposition Modelling (FDM) Machine, a type of Rapid Prototyping (RP) Machine – Set-up involved relatively few steps that can be easily controlled remotely – Operation time was long, ranging from a few hours to days – Machine and Process is expensive – Machine is controlled by a microprocessor that had easy means of communicating with external world through ACL (Automove Control Language)

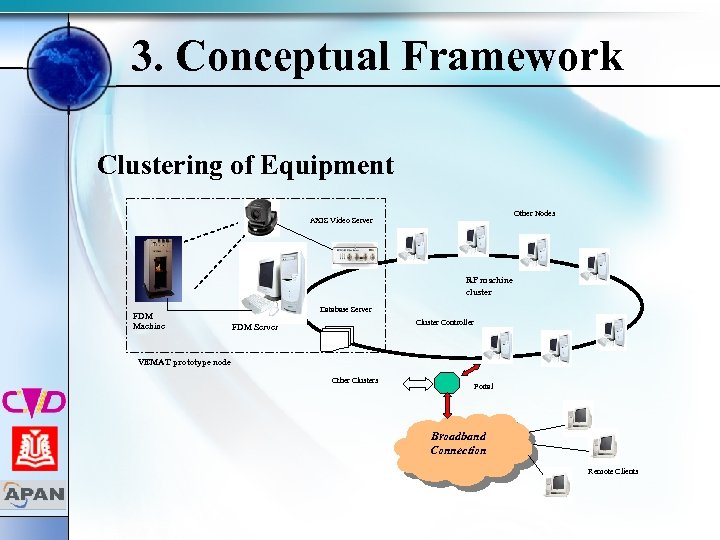

3. Conceptual Framework Clustering of Equipment Other Nodes AXIS Video Server RP machine cluster FDM Machine Database Server Cluster Controller FDM Server VEMAT prototype node Other Clusters Portal Broadband Connection Remote Clients

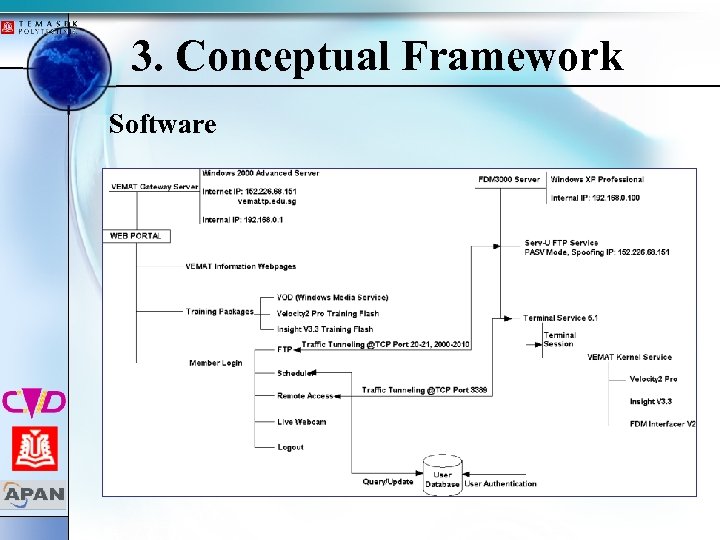

3. Conceptual Framework Software

3. Conceptual Framework v TS (Terminal Service) v ASP (Active Server Pages) v MSDE (Microsoft SQL Desktop Engine) v ADO (Active. X Data Object) v ODBC (Open Database Connectivity) v DHTML (Dynamic HTML) / CSS (Cascading Style Sheet) / Javascript v ACL (Automove Control Language) v Visual Basic v Route and Remote Access Service v Windows Media Service

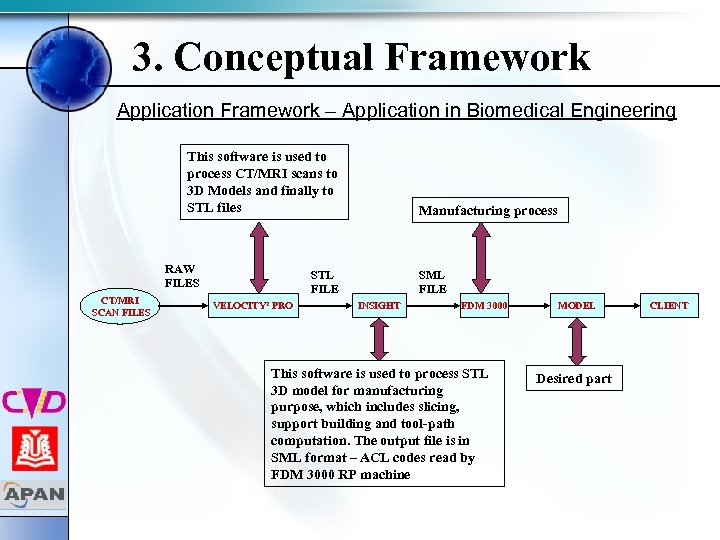

3. Conceptual Framework Application Framework – Application in Biomedical Engineering This software is used to process CT/MRI scans to 3 D Models and finally to STL files RAW FILES CT/MRI SCAN FILES Manufacturing process STL FILE VELOCITY 2 PRO SML FILE INSIGHT FDM 3000 This software is used to process STL 3 D model for manufacturing purpose, which includes slicing, support building and tool-path computation. The output file is in SML format – ACL codes read by FDM 3000 RP machine MODEL Desired part CLIENT

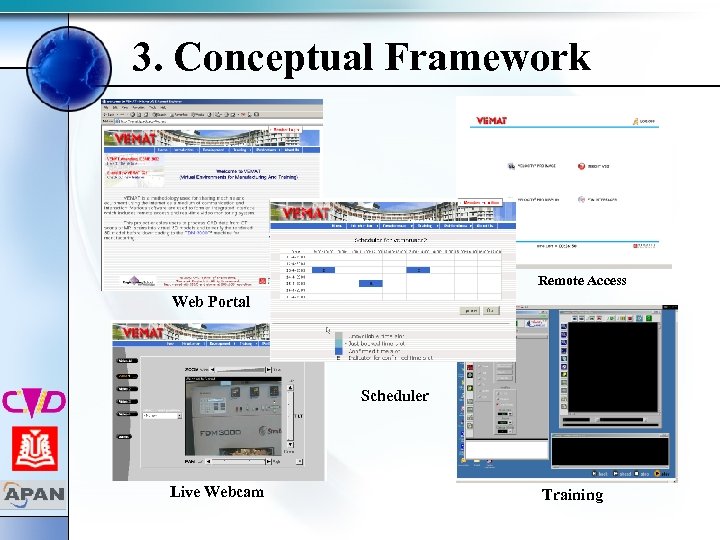

3. Conceptual Framework Remote Access Web Portal Scheduler Live Webcam Training

3. Demonstration – Video Clip

Tests Conducted • • Aug 2002 Beijing – Trial with CERNET Aug 2002 Shanghai – A live demonstration was performed, which tested the stability and efficiency of the VEMAT system. The bandwidth of the remote user is 2 Mbps, which is sufficient for both remote access and high-quality live video stream transmission. Up to this point, the first phase of VEMAT is closed with satisfactory results. • • Oct 2002 Internal Tests for Phase 2 – Use of new methodology. Nov 2002 Final Tests – During this period, VEMAT was tested from various remote IP addresses all over the world. This was achieved by using public SOCKS 5 proxies and Socks. CAP from Networking Systems Laboratory, NEC USA, Inc. VEMAT was tested fully functional up to this point of time. Some minor changes to the user interface were made to make the system more userfriendly. • • • Dec 2002 Evaluation by APEC TEL and IDA Dec 2002 User Tests from BIOMAT Lab Mar 2002 Acceptance by APEC TEL and IDA

4. Discussion and Conclusion Sharing of resources between institutions allow costs to be minimized; equipment to be fully utilized Provide service to educational and research community - reducing the development cost and time Collaboration allows learners to gain international perspectives by working with people from other country Courseware allows users to practise; be familiar with the system

Questions? Thank You! http: //vemat. tp. edu. s g http: //cvd. tp. edu. sg

R&D - TS and VNC Terminal Service concept Protocol Efficiency Security Expandabe Customizable Remote control RFB Low Poor No Application service RDP High Good Yes

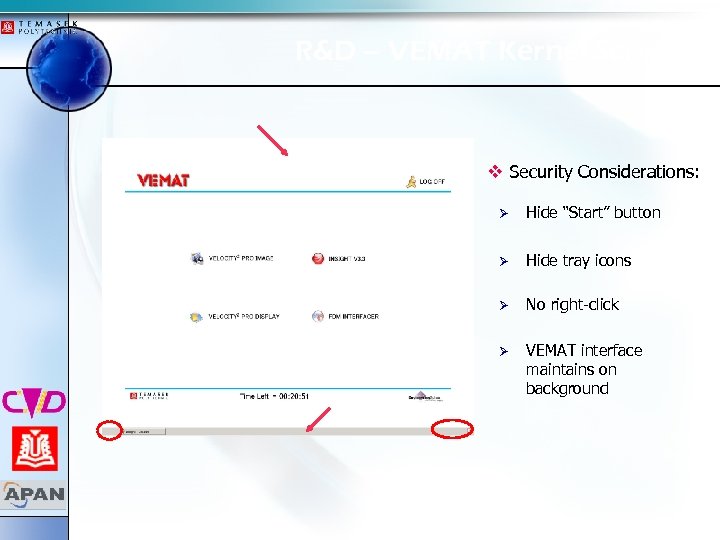

R&D – VEMAT Kernel Service v Security Considerations: Ø Hide “Start” button Ø Hide tray icons Ø No right-click Ø VEMAT interface maintains on background

bca85547ecc438e15e78c5a2660e9089.ppt