810c10bda9b27167ef224041cfcba5f9.ppt

- Количество слайдов: 20

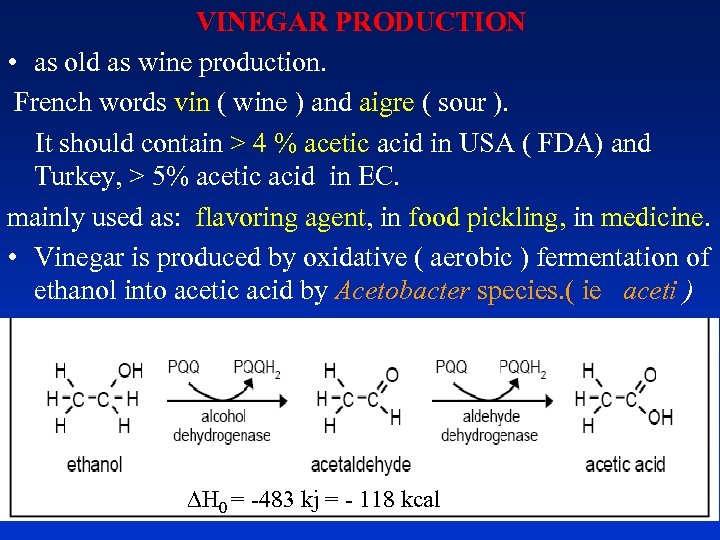

VINEGAR PRODUCTION • as old as wine production. French words vin ( wine ) and aigre ( sour ). It should contain > 4 % acetic acid in USA ( FDA) and Turkey, > 5% acetic acid in EC. mainly used as: flavoring agent, in food pickling, in medicine. • Vinegar is produced by oxidative ( aerobic ) fermentation of ethanol into acetic acid by Acetobacter species. ( ie aceti ) H 0 = -483 kj = - 118 kcal 1

VINEGAR PRODUCTION • as old as wine production. French words vin ( wine ) and aigre ( sour ). It should contain > 4 % acetic acid in USA ( FDA) and Turkey, > 5% acetic acid in EC. mainly used as: flavoring agent, in food pickling, in medicine. • Vinegar is produced by oxidative ( aerobic ) fermentation of ethanol into acetic acid by Acetobacter species. ( ie aceti ) H 0 = -483 kj = - 118 kcal 1

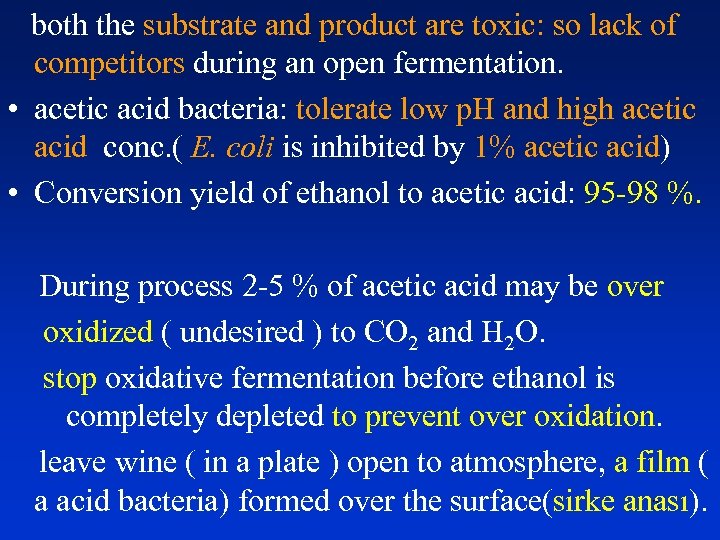

both the substrate and product are toxic: so lack of competitors during an open fermentation. • acetic acid bacteria: tolerate low p. H and high acetic acid conc. ( E. coli is inhibited by 1% acetic acid) • Conversion yield of ethanol to acetic acid: 95 -98 %. During process 2 -5 % of acetic acid may be over oxidized ( undesired ) to CO 2 and H 2 O. stop oxidative fermentation before ethanol is completely depleted to prevent over oxidation. leave wine ( in a plate ) open to atmosphere, a film ( 2 a acid bacteria) formed over the surface(sirke anası).

both the substrate and product are toxic: so lack of competitors during an open fermentation. • acetic acid bacteria: tolerate low p. H and high acetic acid conc. ( E. coli is inhibited by 1% acetic acid) • Conversion yield of ethanol to acetic acid: 95 -98 %. During process 2 -5 % of acetic acid may be over oxidized ( undesired ) to CO 2 and H 2 O. stop oxidative fermentation before ethanol is completely depleted to prevent over oxidation. leave wine ( in a plate ) open to atmosphere, a film ( 2 a acid bacteria) formed over the surface(sirke anası).

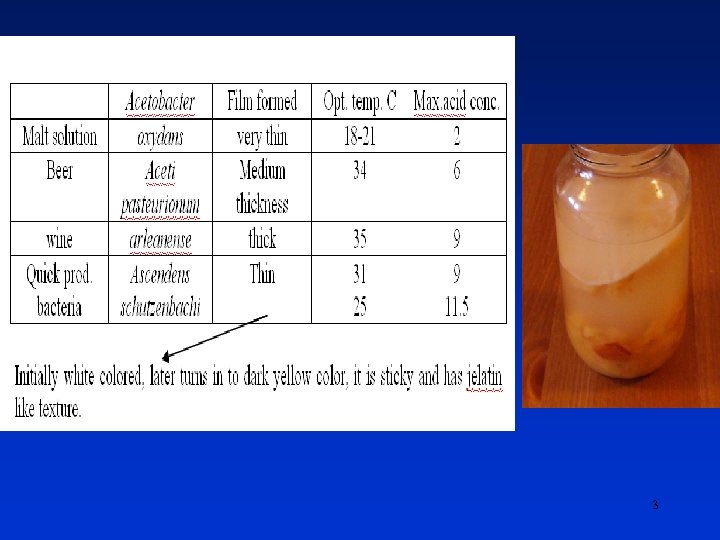

3

3

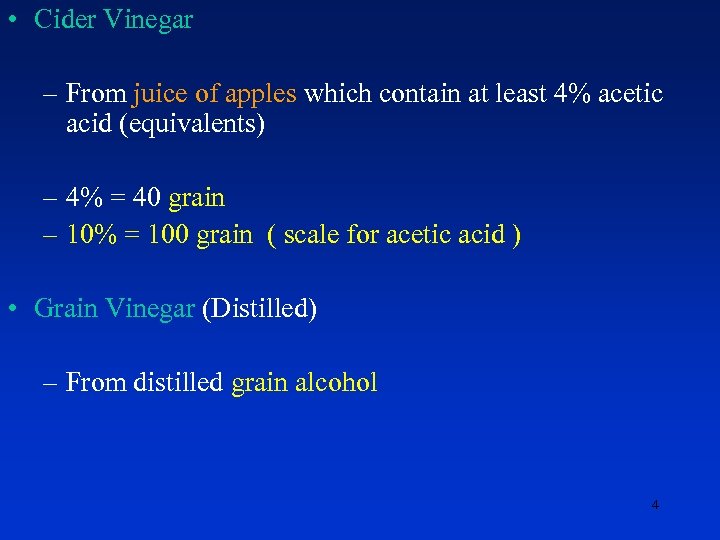

• Cider Vinegar – From juice of apples which contain at least 4% acetic acid (equivalents) – 4% = 40 grain – 10% = 100 grain ( scale for acetic acid ) • Grain Vinegar (Distilled) – From distilled grain alcohol 4

• Cider Vinegar – From juice of apples which contain at least 4% acetic acid (equivalents) – 4% = 40 grain – 10% = 100 grain ( scale for acetic acid ) • Grain Vinegar (Distilled) – From distilled grain alcohol 4

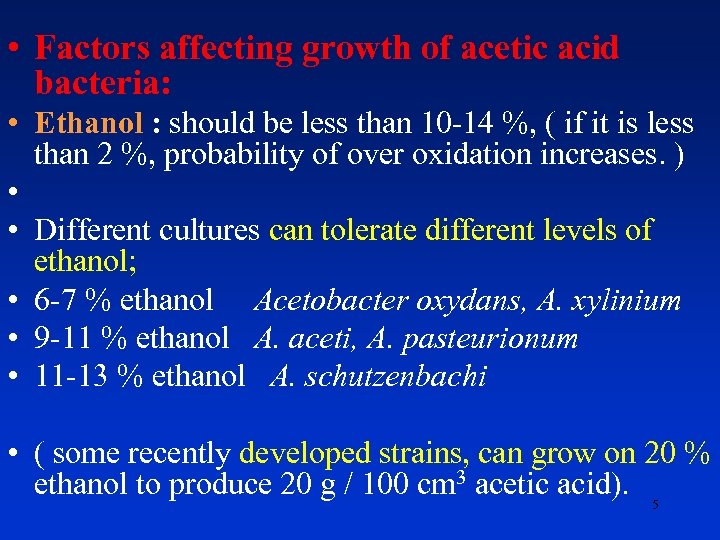

• Factors affecting growth of acetic acid bacteria: • Ethanol : should be less than 10 -14 %, ( if it is less than 2 %, probability of over oxidation increases. ) • • Different cultures can tolerate different levels of ethanol; • 6 -7 % ethanol Acetobacter oxydans, A. xylinium • 9 -11 % ethanol A. aceti, A. pasteurionum • 11 -13 % ethanol A. schutzenbachi • ( some recently developed strains, can grow on 20 % ethanol to produce 20 g / 100 cm 3 acetic acid). 5

• Factors affecting growth of acetic acid bacteria: • Ethanol : should be less than 10 -14 %, ( if it is less than 2 %, probability of over oxidation increases. ) • • Different cultures can tolerate different levels of ethanol; • 6 -7 % ethanol Acetobacter oxydans, A. xylinium • 9 -11 % ethanol A. aceti, A. pasteurionum • 11 -13 % ethanol A. schutzenbachi • ( some recently developed strains, can grow on 20 % ethanol to produce 20 g / 100 cm 3 acetic acid). 5

• Oxygen : 12 l air is needed to oxidize 1 g ethanol • Temperature : Opt. temp. : 28 – 34 C. • Other nutrients : Generally mineral and nitrogen sources is needed 6

• Oxygen : 12 l air is needed to oxidize 1 g ethanol • Temperature : Opt. temp. : 28 – 34 C. • Other nutrients : Generally mineral and nitrogen sources is needed 6

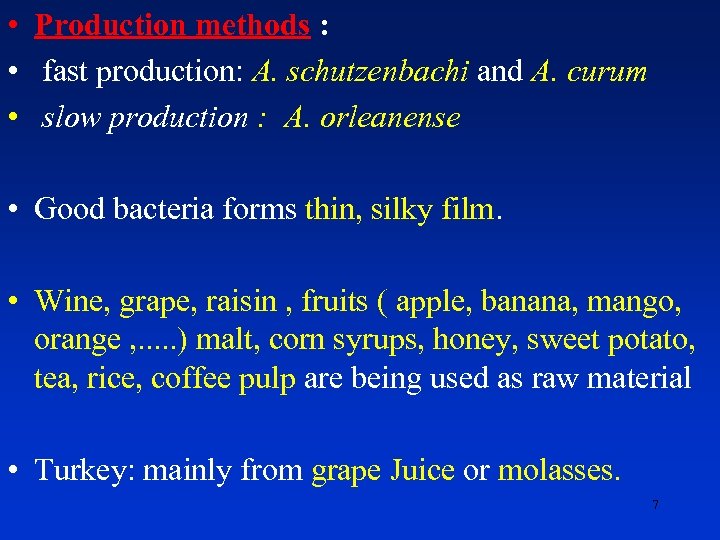

• Production methods : • fast production: A. schutzenbachi and A. curum • slow production : A. orleanense • Good bacteria forms thin, silky film. • Wine, grape, raisin , fruits ( apple, banana, mango, orange , . . . ) malt, corn syrups, honey, sweet potato, tea, rice, coffee pulp are being used as raw material • Turkey: mainly from grape Juice or molasses. 7

• Production methods : • fast production: A. schutzenbachi and A. curum • slow production : A. orleanense • Good bacteria forms thin, silky film. • Wine, grape, raisin , fruits ( apple, banana, mango, orange , . . . ) malt, corn syrups, honey, sweet potato, tea, rice, coffee pulp are being used as raw material • Turkey: mainly from grape Juice or molasses. 7

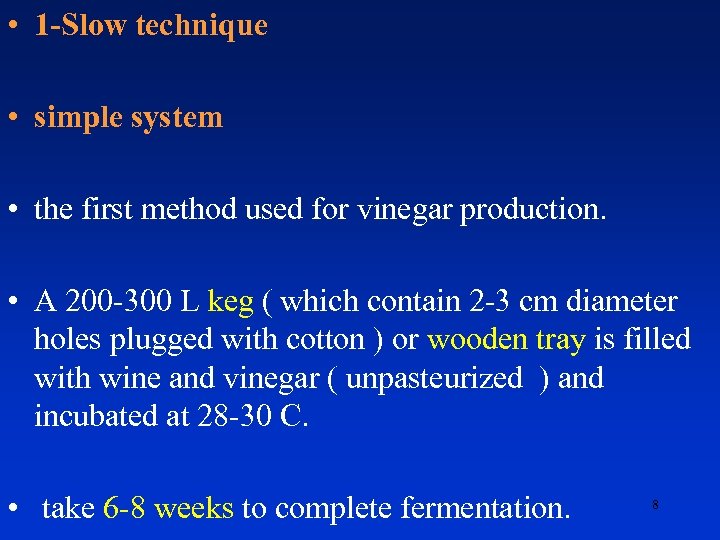

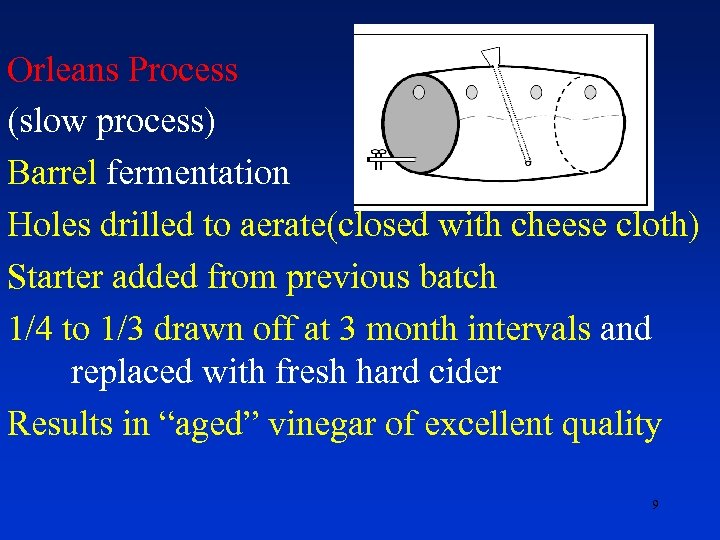

• 1 -Slow technique • simple system • the first method used for vinegar production. • A 200 -300 L keg ( which contain 2 -3 cm diameter holes plugged with cotton ) or wooden tray is filled with wine and vinegar ( unpasteurized ) and incubated at 28 -30 C. • take 6 -8 weeks to complete fermentation. 8

• 1 -Slow technique • simple system • the first method used for vinegar production. • A 200 -300 L keg ( which contain 2 -3 cm diameter holes plugged with cotton ) or wooden tray is filled with wine and vinegar ( unpasteurized ) and incubated at 28 -30 C. • take 6 -8 weeks to complete fermentation. 8

Orleans Process (slow process) Barrel fermentation Holes drilled to aerate(closed with cheese cloth) Starter added from previous batch 1/4 to 1/3 drawn off at 3 month intervals and replaced with fresh hard cider Results in “aged” vinegar of excellent quality 9

Orleans Process (slow process) Barrel fermentation Holes drilled to aerate(closed with cheese cloth) Starter added from previous batch 1/4 to 1/3 drawn off at 3 month intervals and replaced with fresh hard cider Results in “aged” vinegar of excellent quality 9

• A film will form on the surface of solution and when it sinks, it will be indication of the end of fermentation. • stop fermentation when ethanol concentration is 0. 5 -1 % to prevent over oxidation. • We can remove vinegar from bottom ( density of acetic acid > ethanol ) and add new wine from top through a funnel without disturbing film on the surface, otherwise production will slow down. 10

• A film will form on the surface of solution and when it sinks, it will be indication of the end of fermentation. • stop fermentation when ethanol concentration is 0. 5 -1 % to prevent over oxidation. • We can remove vinegar from bottom ( density of acetic acid > ethanol ) and add new wine from top through a funnel without disturbing film on the surface, otherwise production will slow down. 10

• Fast Process – generator- commonly used in Turkey • Ethanolic substrates are circulated or trickled through cylindrical fermentation vessels or vats containing inert packing materials, such as curled • wood shaving (If pine tree shavings is going to be used , it should be washed with Na 2 CO 3 to remove resins) or corn cobs 11

• Fast Process – generator- commonly used in Turkey • Ethanolic substrates are circulated or trickled through cylindrical fermentation vessels or vats containing inert packing materials, such as curled • wood shaving (If pine tree shavings is going to be used , it should be washed with Na 2 CO 3 to remove resins) or corn cobs 11

Submerged culture method ( acetators) • ( developed mainly by Heinrich Frings Company) much faster than trickling process. • stainless steel tank • temp. , acid, ethanol, air flow rate are controlled. Advantages; • -less space, - high yield ( 90 -95 %) • -easy to switch from one type of vinegar to other • -highly automated, -higher quality vinegar • -if two acetators used, 19 -20 % acid production • -product is more turbid than trickling because woods 12 shavings act like filter ( disadvantage )

Submerged culture method ( acetators) • ( developed mainly by Heinrich Frings Company) much faster than trickling process. • stainless steel tank • temp. , acid, ethanol, air flow rate are controlled. Advantages; • -less space, - high yield ( 90 -95 %) • -easy to switch from one type of vinegar to other • -highly automated, -higher quality vinegar • -if two acetators used, 19 -20 % acid production • -product is more turbid than trickling because woods 12 shavings act like filter ( disadvantage )

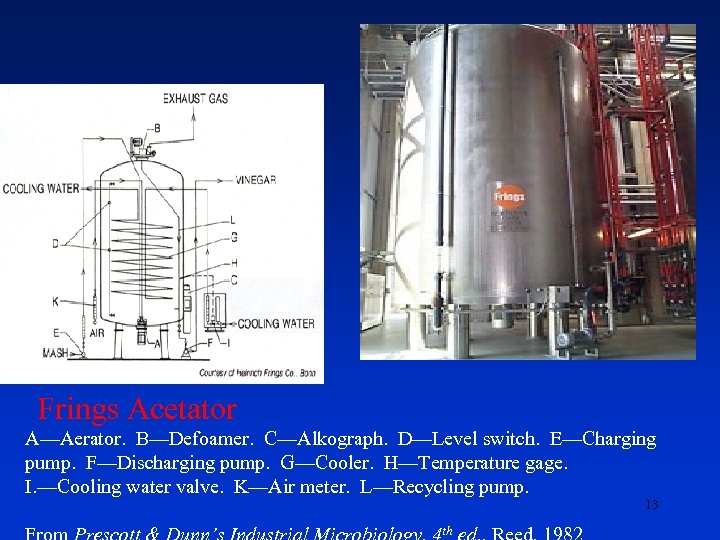

Frings Acetator A—Aerator. B—Defoamer. C—Alkograph. D—Level switch. E—Charging pump. F—Discharging pump. G—Cooler. H—Temperature gage. I. —Cooling water valve. K—Air meter. L—Recycling pump. 13 th

Frings Acetator A—Aerator. B—Defoamer. C—Alkograph. D—Level switch. E—Charging pump. F—Discharging pump. G—Cooler. H—Temperature gage. I. —Cooling water valve. K—Air meter. L—Recycling pump. 13 th

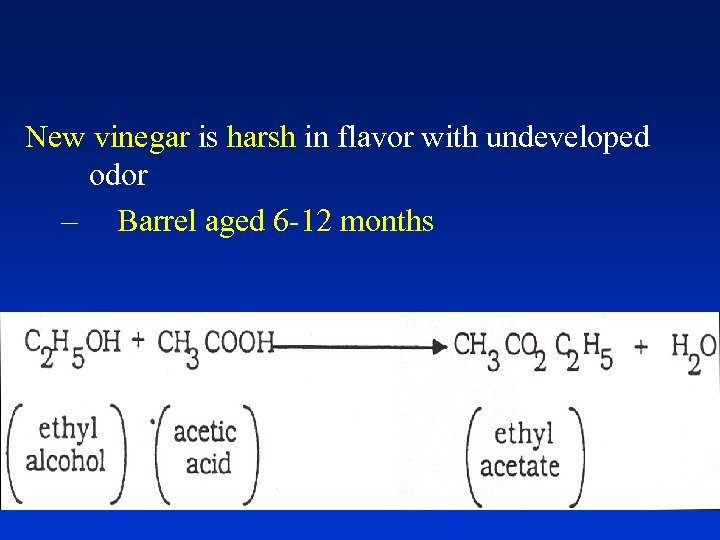

New vinegar is harsh in flavor with undeveloped odor – Barrel aged 6 -12 months 14

New vinegar is harsh in flavor with undeveloped odor – Barrel aged 6 -12 months 14

• keep full during aging to prevent overoxidation. • heat treatments (at 60 -65 C for 30 minutes, up to 80°C for thirty to forty seconds). • then cooled to 33 -38 C and bottled. • In USA and EC only glass bottles are allowed. 15

• keep full during aging to prevent overoxidation. • heat treatments (at 60 -65 C for 30 minutes, up to 80°C for thirty to forty seconds). • then cooled to 33 -38 C and bottled. • In USA and EC only glass bottles are allowed. 15

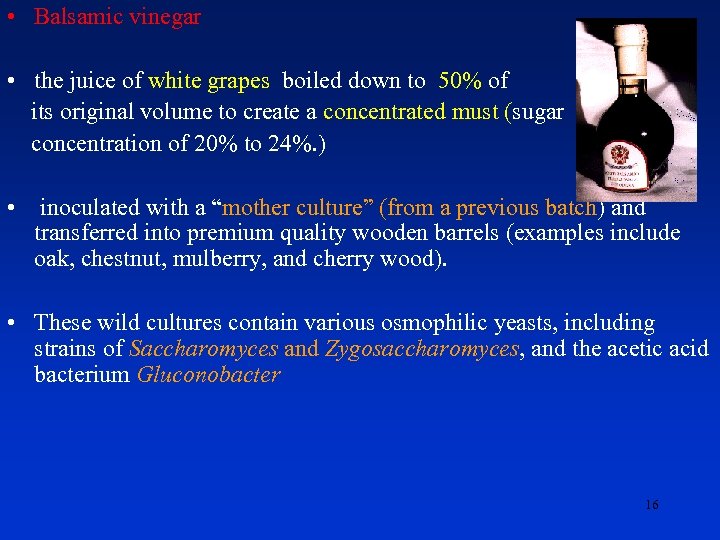

• Balsamic vinegar • the juice of white grapes boiled down to 50% of its original volume to create a concentrated must (sugar concentration of 20% to 24%. ) • inoculated with a “mother culture” (from a previous batch) and transferred into premium quality wooden barrels (examples include oak, chestnut, mulberry, and cherry wood). • These wild cultures contain various osmophilic yeasts, including strains of Saccharomyces and Zygosaccharomyces, and the acetic acid bacterium Gluconobacter 16

• Balsamic vinegar • the juice of white grapes boiled down to 50% of its original volume to create a concentrated must (sugar concentration of 20% to 24%. ) • inoculated with a “mother culture” (from a previous batch) and transferred into premium quality wooden barrels (examples include oak, chestnut, mulberry, and cherry wood). • These wild cultures contain various osmophilic yeasts, including strains of Saccharomyces and Zygosaccharomyces, and the acetic acid bacterium Gluconobacter 16

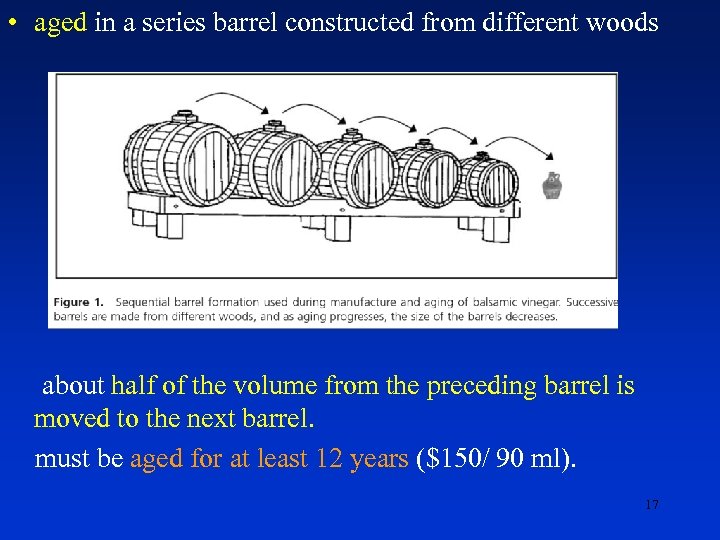

• aged in a series barrel constructed from different woods about half of the volume from the preceding barrel is moved to the next barrel. must be aged for at least 12 years ($150/ 90 ml). 17

• aged in a series barrel constructed from different woods about half of the volume from the preceding barrel is moved to the next barrel. must be aged for at least 12 years ($150/ 90 ml). 17

• • Vinegar concentrated by freeze concentration technique: -to reduce transportation cost -to be recyled and used more than once in pickling vinegar can be adulterated---acetic acid produced via chemical synthesis can be diluted and then marketed (illegally) as fermentation-derived vinegar. • vinegar quality: is based on flavor, aroma, and other organoleptic properties. • wine vinegars contain a mixture of phenolic compounds that are ordinarily present in grapes. 18

• • Vinegar concentrated by freeze concentration technique: -to reduce transportation cost -to be recyled and used more than once in pickling vinegar can be adulterated---acetic acid produced via chemical synthesis can be diluted and then marketed (illegally) as fermentation-derived vinegar. • vinegar quality: is based on flavor, aroma, and other organoleptic properties. • wine vinegars contain a mixture of phenolic compounds that are ordinarily present in grapes. 18

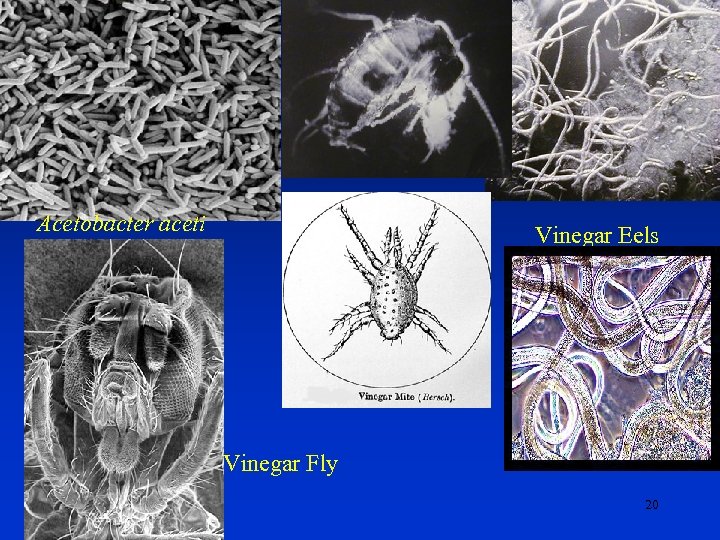

Vinegar defects • Metal ions like iron, copper cause turbidity. • Tannin and iron forms iron tannat complex which cause blue-black turbidity • Anguillula aceti ( vinegar eel) bad flavor upon putrefaction, (to prevent filter, pasteurize) • Tyroglyphas longior ( vinegar mite) ( steaming) • Acetobacter xylinium ( slime , clogs filters, ) 19

Vinegar defects • Metal ions like iron, copper cause turbidity. • Tannin and iron forms iron tannat complex which cause blue-black turbidity • Anguillula aceti ( vinegar eel) bad flavor upon putrefaction, (to prevent filter, pasteurize) • Tyroglyphas longior ( vinegar mite) ( steaming) • Acetobacter xylinium ( slime , clogs filters, ) 19

Acetobacter aceti Vinegar Eels Vinegar Fly 20

Acetobacter aceti Vinegar Eels Vinegar Fly 20