33d3d7de58d942bd7bf9c630431fa5e3.ppt

- Количество слайдов: 30

Very low cost extruders (VLEC) for small scale production of food and feeds D. Bounie, E. Van Hecke USTL (Université des Sciences et Technologies de Lille) IAAL (Institut Agricole et Alimentaire) Bâtiment C 6 59655 Villeneuve d’Ascq Cedex - France Tel : +33 (0)3 20. 43. 49. 21, Fax : +33 (0)3 20. 43. 44. 86 E-Mail : Bounie@univ-lille 1. fr, vanhecke@univ-lille 1. fr Smart Extrusion Workshop, Sydney 2 december 1997 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 1)

Very low cost extruders (VLEC) for small scale production of food and feeds D. Bounie, E. Van Hecke USTL (Université des Sciences et Technologies de Lille) IAAL (Institut Agricole et Alimentaire) Bâtiment C 6 59655 Villeneuve d’Ascq Cedex - France Tel : +33 (0)3 20. 43. 49. 21, Fax : +33 (0)3 20. 43. 44. 86 E-Mail : Bounie@univ-lille 1. fr, vanhecke@univ-lille 1. fr Smart Extrusion Workshop, Sydney 2 december 1997 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 1)

PLAN § Very Low Cost Extrusion Cooking (VLEC) vs. Low Cost Extrusion Cooking (LEC) and classical Extrusion Cooking § Possible applications of VLEC • feeds at farm-level ü integrated traceability from feeds to livestock • locally processed nutritious weaning foods (development projects) ü on going project in Viet Nam destruction of antinutritional factors and optimisation of energy density through improvment of formula and control of thermomechanical treatment • precooked blended flours for relief aid ü present situation in Africa small scale production at « camp level » vs. centralized production in remote countries : from emergency to rehabilitation and development § Pilot equipment developped at the University of Lille 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 2)

PLAN § Very Low Cost Extrusion Cooking (VLEC) vs. Low Cost Extrusion Cooking (LEC) and classical Extrusion Cooking § Possible applications of VLEC • feeds at farm-level ü integrated traceability from feeds to livestock • locally processed nutritious weaning foods (development projects) ü on going project in Viet Nam destruction of antinutritional factors and optimisation of energy density through improvment of formula and control of thermomechanical treatment • precooked blended flours for relief aid ü present situation in Africa small scale production at « camp level » vs. centralized production in remote countries : from emergency to rehabilitation and development § Pilot equipment developped at the University of Lille 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 2)

PLAN § Very Low Cost Extrusion Cooking (VLEC) vs. Low Cost Extrusion Cooking (LEC) and classical Extrusion Cooking § Possible applications of VLEC • feeds at farm-level ü integrated traceability from feeds to livestock • locally processed nutritious weaning foods (development projects) ü on going project in Viet Nam destruction of antinutritional factors and optimisation of energy density through improvment of formula and control of thermomechanical treatment • precooked blended flours for relief aid ü present situation in Africa small scale production at « camp level » vs. centralized production in remote countries : from emergency to rehabilitation and development § Pilot equipment developped at the University of Lille 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 3)

PLAN § Very Low Cost Extrusion Cooking (VLEC) vs. Low Cost Extrusion Cooking (LEC) and classical Extrusion Cooking § Possible applications of VLEC • feeds at farm-level ü integrated traceability from feeds to livestock • locally processed nutritious weaning foods (development projects) ü on going project in Viet Nam destruction of antinutritional factors and optimisation of energy density through improvment of formula and control of thermomechanical treatment • precooked blended flours for relief aid ü present situation in Africa small scale production at « camp level » vs. centralized production in remote countries : from emergency to rehabilitation and development § Pilot equipment developped at the University of Lille 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 3)

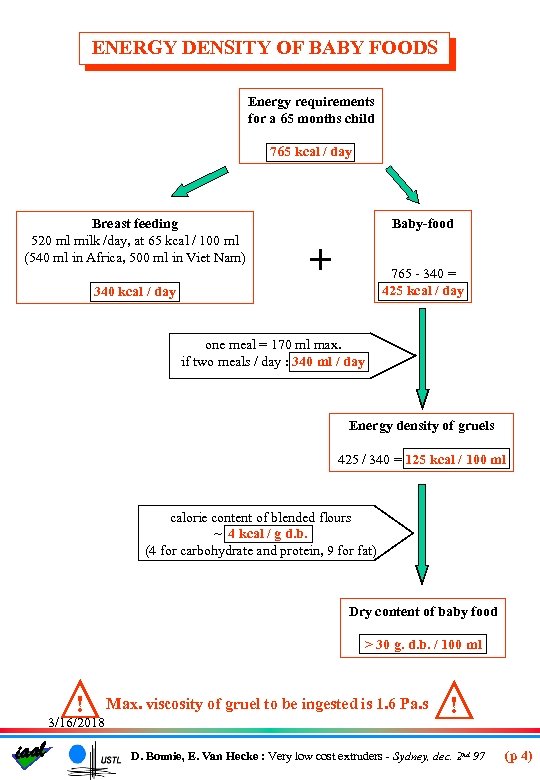

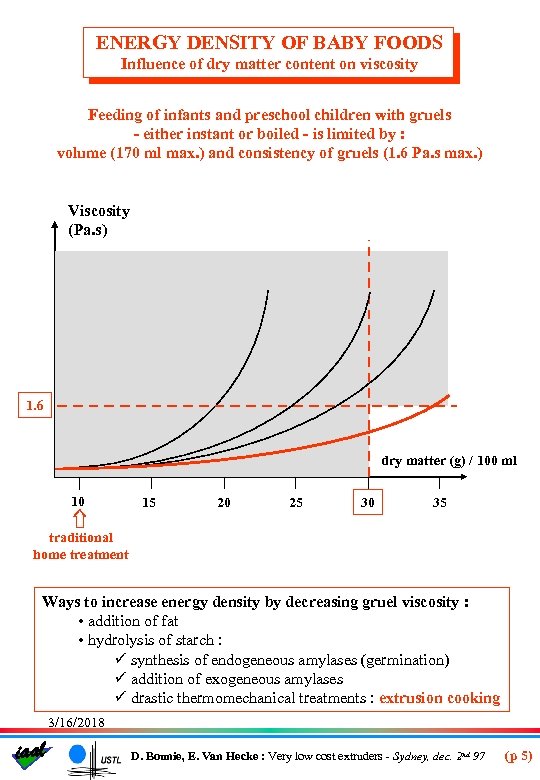

ENERGY DENSITY OF BABY FOODS Energy requirements for a 65 months child 765 kcal / day Breast feeding 520 ml milk /day, at 65 kcal / 100 ml (540 ml in Africa, 500 ml in Viet Nam) Baby-food + 765 - 340 = 425 kcal / day 340 kcal / day one meal = 170 ml max. if two meals / day : 340 ml / day Energy density of gruels 425 / 340 = 125 kcal / 100 ml calorie content of blended flours ~ 4 kcal / g d. b. (4 for carbohydrate and protein, 9 for fat) Dry content of baby food > 30 g. d. b. / 100 ml ! 3/16/2018 iaal Max. viscosity of gruel to be ingested is 1. 6 Pa. s ! D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 4)

ENERGY DENSITY OF BABY FOODS Energy requirements for a 65 months child 765 kcal / day Breast feeding 520 ml milk /day, at 65 kcal / 100 ml (540 ml in Africa, 500 ml in Viet Nam) Baby-food + 765 - 340 = 425 kcal / day 340 kcal / day one meal = 170 ml max. if two meals / day : 340 ml / day Energy density of gruels 425 / 340 = 125 kcal / 100 ml calorie content of blended flours ~ 4 kcal / g d. b. (4 for carbohydrate and protein, 9 for fat) Dry content of baby food > 30 g. d. b. / 100 ml ! 3/16/2018 iaal Max. viscosity of gruel to be ingested is 1. 6 Pa. s ! D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 4)

ENERGY DENSITY OF BABY FOODS Influence of dry matter content on viscosity Feeding of infants and preschool children with gruels - either instant or boiled - is limited by : volume (170 ml max. ) and consistency of gruels (1. 6 Pa. s max. ) Viscosity (Pa. s) 1. 6 dry matter (g) / 100 ml 10 15 20 25 30 35 traditional home treatment Ways to increase energy density by decreasing gruel viscosity : • addition of fat • hydrolysis of starch : ü synthesis of endogeneous amylases (germination) ü addition of exogeneous amylases ü drastic thermomechanical treatments : extrusion cooking 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 5)

ENERGY DENSITY OF BABY FOODS Influence of dry matter content on viscosity Feeding of infants and preschool children with gruels - either instant or boiled - is limited by : volume (170 ml max. ) and consistency of gruels (1. 6 Pa. s max. ) Viscosity (Pa. s) 1. 6 dry matter (g) / 100 ml 10 15 20 25 30 35 traditional home treatment Ways to increase energy density by decreasing gruel viscosity : • addition of fat • hydrolysis of starch : ü synthesis of endogeneous amylases (germination) ü addition of exogeneous amylases ü drastic thermomechanical treatments : extrusion cooking 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 5)

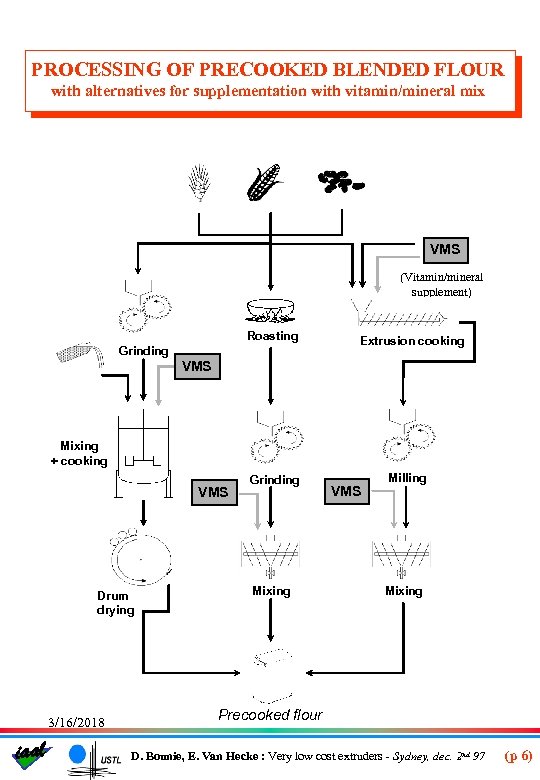

PROCESSING OF PRECOOKED BLENDED FLOUR with alternatives for supplementation with vitamin/mineral mix VMS (Vitamin/mineral supplement) Roasting Grinding Extrusion cooking VMS Mixing + cooking VMS Drum drying 3/16/2018 iaal Grinding Mixing VMS Milling Mixing Precooked flour D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 6)

PROCESSING OF PRECOOKED BLENDED FLOUR with alternatives for supplementation with vitamin/mineral mix VMS (Vitamin/mineral supplement) Roasting Grinding Extrusion cooking VMS Mixing + cooking VMS Drum drying 3/16/2018 iaal Grinding Mixing VMS Milling Mixing Precooked flour D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 6)

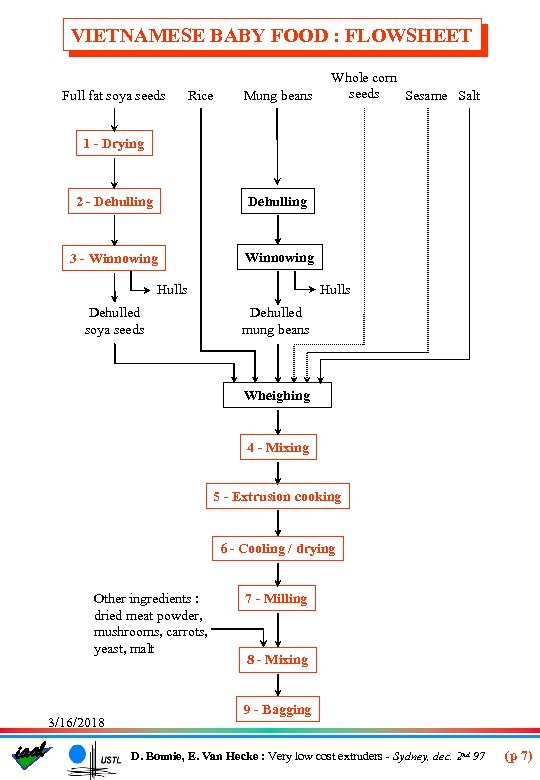

VIETNAMESE BABY FOOD : FLOWSHEET Full fat soya seeds Rice Mung beans Whole corn seeds Sesame Salt 1 - Drying 2 - Dehulling 3 - Winnowing Hulls Dehulled soya seeds Hulls Dehulled mung beans Wheighing 4 - Mixing 5 - Extrusion cooking 6 - Cooling / drying Other ingredients : dried meat powder, mushrooms, carrots, yeast, malt 3/16/2018 iaal 7 - Milling 8 - Mixing 9 - Bagging D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 7)

VIETNAMESE BABY FOOD : FLOWSHEET Full fat soya seeds Rice Mung beans Whole corn seeds Sesame Salt 1 - Drying 2 - Dehulling 3 - Winnowing Hulls Dehulled soya seeds Hulls Dehulled mung beans Wheighing 4 - Mixing 5 - Extrusion cooking 6 - Cooling / drying Other ingredients : dried meat powder, mushrooms, carrots, yeast, malt 3/16/2018 iaal 7 - Milling 8 - Mixing 9 - Bagging D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 7)

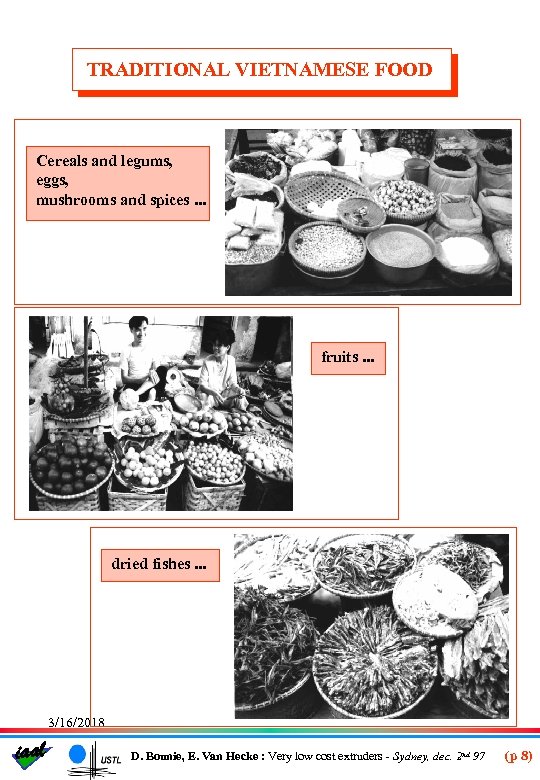

TRADITIONAL VIETNAMESE FOOD Cereals and legums, eggs, mushrooms and spices. . . fruits. . . dried fishes. . . 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 8)

TRADITIONAL VIETNAMESE FOOD Cereals and legums, eggs, mushrooms and spices. . . fruits. . . dried fishes. . . 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 8)

WEANING FOOD : Raw materials Salt Sesame Soya Rice Corn 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 9)

WEANING FOOD : Raw materials Salt Sesame Soya Rice Corn 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 9)

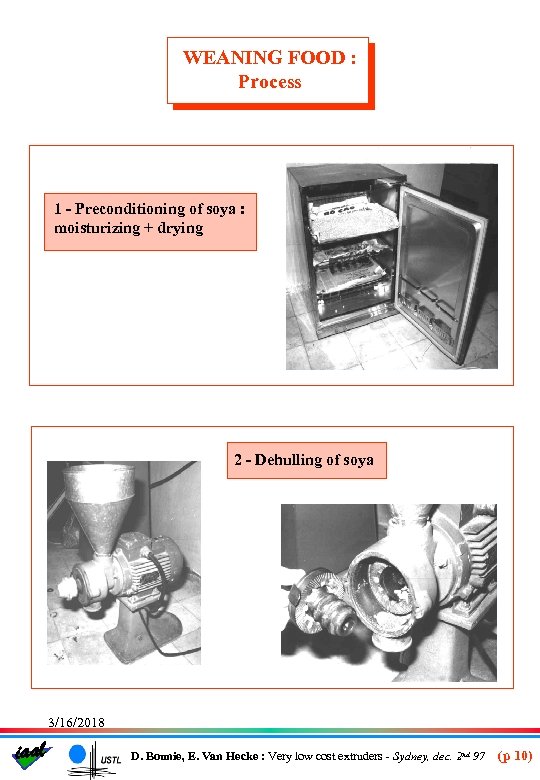

WEANING FOOD : Process 1 - Preconditioning of soya : moisturizing + drying 2 - Dehulling of soya 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 10)

WEANING FOOD : Process 1 - Preconditioning of soya : moisturizing + drying 2 - Dehulling of soya 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 10)

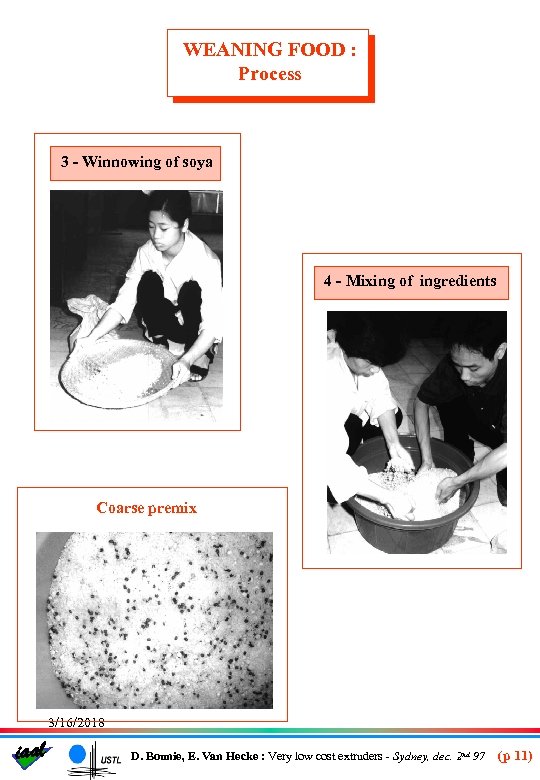

WEANING FOOD : Process 3 - Winnowing of soya 4 - Mixing of ingredients Coarse premix 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 11)

WEANING FOOD : Process 3 - Winnowing of soya 4 - Mixing of ingredients Coarse premix 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 11)

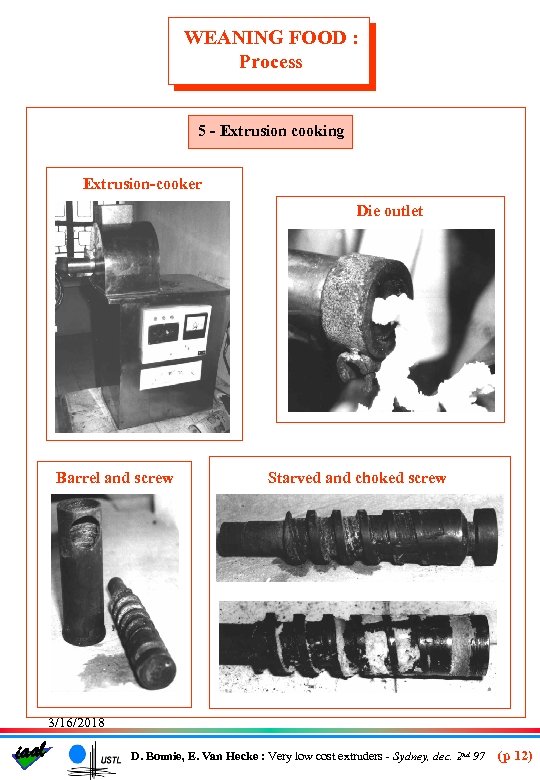

WEANING FOOD : Process 5 - Extrusion cooking Extrusion-cooker Die outlet Barrel and screw Starved and choked screw 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 12)

WEANING FOOD : Process 5 - Extrusion cooking Extrusion-cooker Die outlet Barrel and screw Starved and choked screw 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 12)

WEANING FOOD : Process 6 - Cooling / drying 7 - Milling 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 13)

WEANING FOOD : Process 6 - Cooling / drying 7 - Milling 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 13)

WEANING FOOD : Process 8 - Post mixing with mineral/vitamins premix 9 - Bagging 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 14)

WEANING FOOD : Process 8 - Post mixing with mineral/vitamins premix 9 - Bagging 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 14)

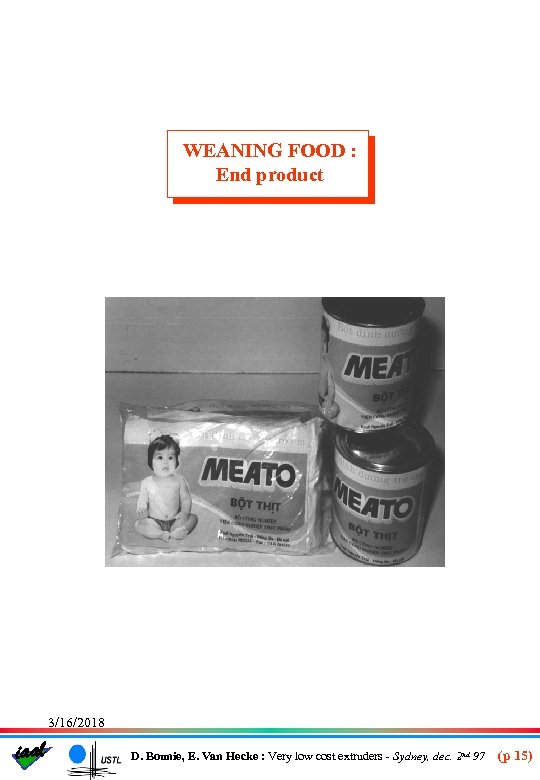

WEANING FOOD : End product 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 15)

WEANING FOOD : End product 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 15)

PLAN § Very Low Cost Extrusion Cooking (VLEC) vs. Low Cost Extrusion Cooking (LEC) and classical Extrusion Cooking § Possible applications of VLEC • feeds at farm-level ü integrated traceability from feeds to livestock • locally processed nutritious weaning foods (development projects) ü on going project in Viet Nam destruction of antinutritional factors and optimisation of energy density through improvment of formula and control of thermomechanical treatment • precooked blended flours for relief aid ü present situation in Africa small scale production at « camp level » vs. centralized production in remote countries : from emergency to rehabilitation and development § Pilot equipment developped at the University of Lille 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 16)

PLAN § Very Low Cost Extrusion Cooking (VLEC) vs. Low Cost Extrusion Cooking (LEC) and classical Extrusion Cooking § Possible applications of VLEC • feeds at farm-level ü integrated traceability from feeds to livestock • locally processed nutritious weaning foods (development projects) ü on going project in Viet Nam destruction of antinutritional factors and optimisation of energy density through improvment of formula and control of thermomechanical treatment • precooked blended flours for relief aid ü present situation in Africa small scale production at « camp level » vs. centralized production in remote countries : from emergency to rehabilitation and development § Pilot equipment developped at the University of Lille 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 16)

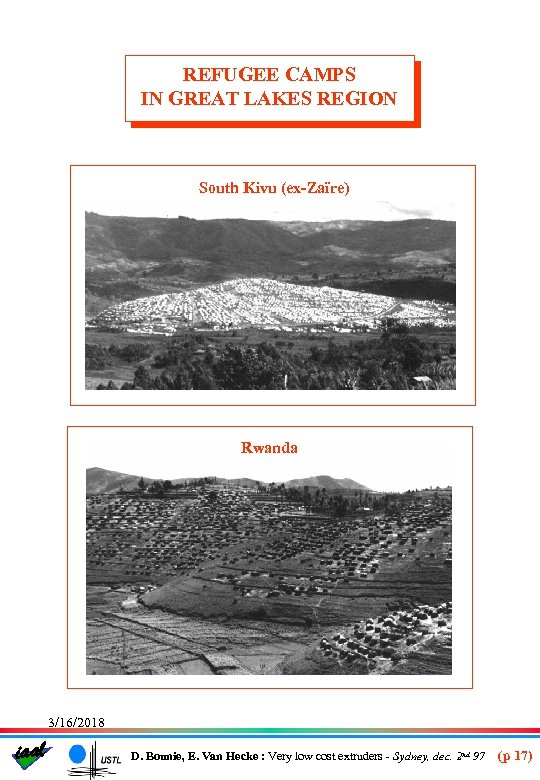

REFUGEE CAMPS IN GREAT LAKES REGION South Kivu (ex-Zaïre) Rwanda 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 17)

REFUGEE CAMPS IN GREAT LAKES REGION South Kivu (ex-Zaïre) Rwanda 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 17)

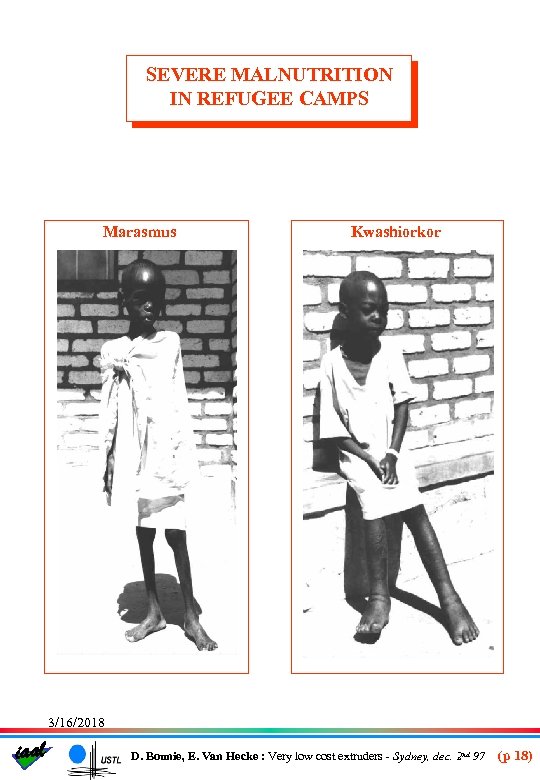

SEVERE MALNUTRITION IN REFUGEE CAMPS Marasmus Kwashiorkor 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 18)

SEVERE MALNUTRITION IN REFUGEE CAMPS Marasmus Kwashiorkor 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 18)

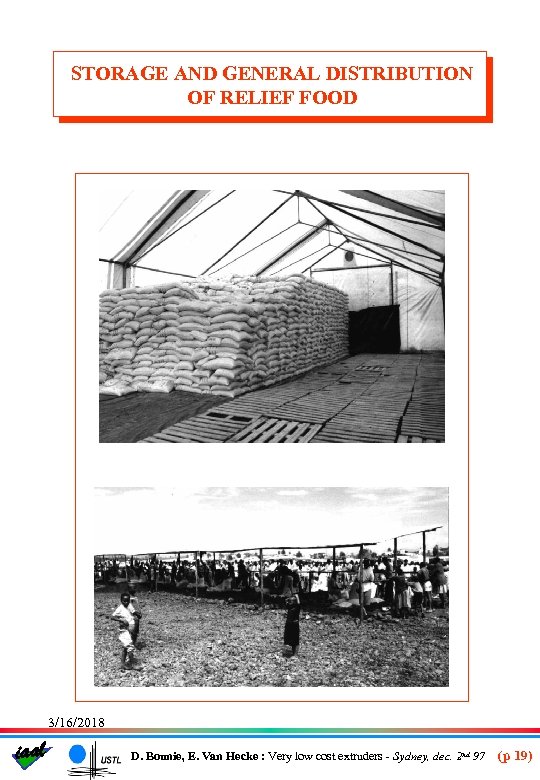

STORAGE AND GENERAL DISTRIBUTION OF RELIEF FOOD 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 19)

STORAGE AND GENERAL DISTRIBUTION OF RELIEF FOOD 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 19)

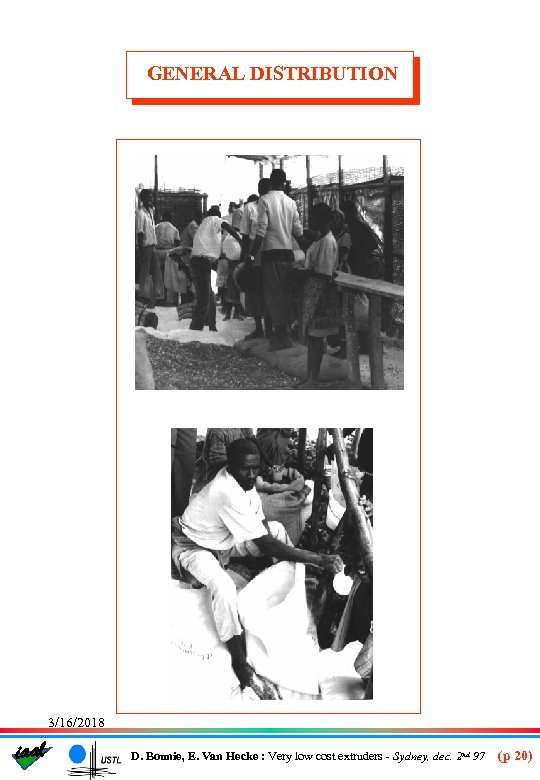

GENERAL DISTRIBUTION 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 20)

GENERAL DISTRIBUTION 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 20)

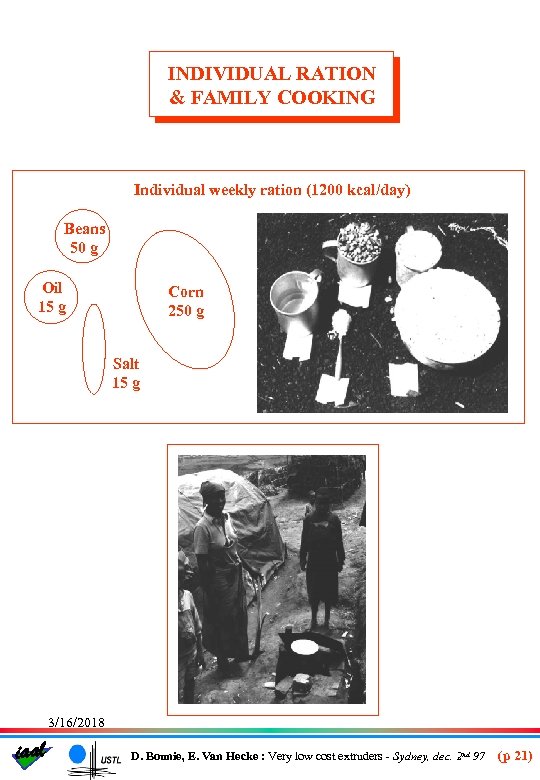

INDIVIDUAL RATION & FAMILY COOKING Individual weekly ration (1200 kcal/day) Beans 50 g Oil 15 g Corn 250 g Salt 15 g 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 21)

INDIVIDUAL RATION & FAMILY COOKING Individual weekly ration (1200 kcal/day) Beans 50 g Oil 15 g Corn 250 g Salt 15 g 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 21)

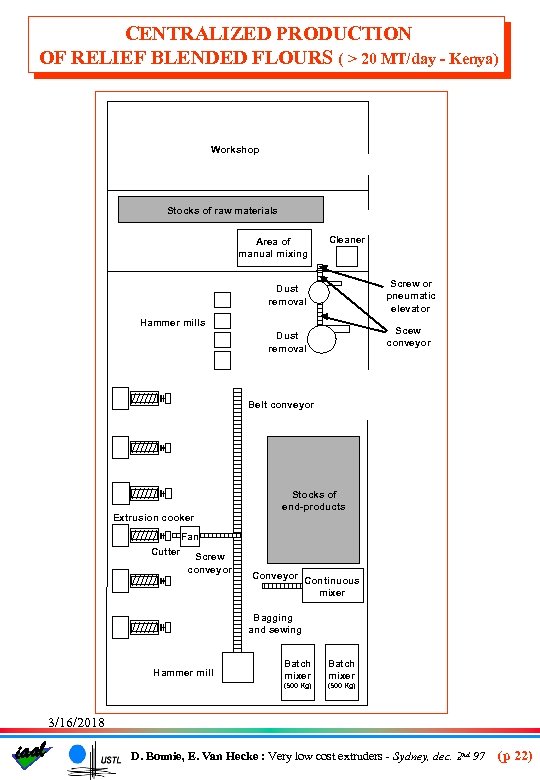

CENTRALIZED PRODUCTION OF RELIEF BLENDED FLOURS ( > 20 MT/day - Kenya) Workshop Stocks of raw materials Area of manual mixing Cleaner Screw or pneumatic elevator Dust removal Hammer mills Scew conveyor Dust removal Belt conveyor Extrusion cooker Stocks of end-products Fan Cutter Screw conveyor Continuous mixer Bagging and sewing Batch mixer (500 Kg) Hammer mill (500 Kg) 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 22)

CENTRALIZED PRODUCTION OF RELIEF BLENDED FLOURS ( > 20 MT/day - Kenya) Workshop Stocks of raw materials Area of manual mixing Cleaner Screw or pneumatic elevator Dust removal Hammer mills Scew conveyor Dust removal Belt conveyor Extrusion cooker Stocks of end-products Fan Cutter Screw conveyor Continuous mixer Bagging and sewing Batch mixer (500 Kg) Hammer mill (500 Kg) 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 22)

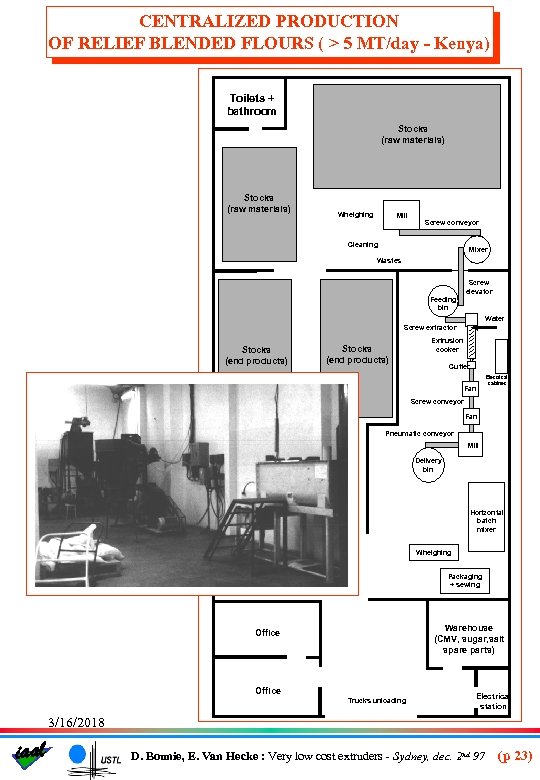

CENTRALIZED PRODUCTION OF RELIEF BLENDED FLOURS ( > 5 MT/day - Kenya) Toilets + bathroom Stocks (raw materials) Wheighing Mill Screw conveyor Cleaning Mixer Wastes Screw elevator Feeding bin Water Screw extractor Stocks (end products) Extrusion cooker Cutter Fan Electrical cabinet Screw conveyor Fan Pneumatic conveyor Mill Delivery bin Stocks (raw materials) Horizontal batch mixer Wheighing Packaging + sewing Warehouse (CMV, sugar, salt spare parts) Office Trucks unloading Electrical station 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 23)

CENTRALIZED PRODUCTION OF RELIEF BLENDED FLOURS ( > 5 MT/day - Kenya) Toilets + bathroom Stocks (raw materials) Wheighing Mill Screw conveyor Cleaning Mixer Wastes Screw elevator Feeding bin Water Screw extractor Stocks (end products) Extrusion cooker Cutter Fan Electrical cabinet Screw conveyor Fan Pneumatic conveyor Mill Delivery bin Stocks (raw materials) Horizontal batch mixer Wheighing Packaging + sewing Warehouse (CMV, sugar, salt spare parts) Office Trucks unloading Electrical station 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 23)

PLAN § Very Low Cost Extrusion Cooking (VLEC) vs. Low Cost Extrusion Cooking (LEC) and classical Extrusion Cooking § Possible applications of VLEC • feeds at farm-level ü integrated traceability from feeds to livestock • locally processed nutritious weaning foods (development projects) ü on going project in Viet Nam destruction of antinutritional factors and optimisation of energy density through improvment of formula and control of thermomechanical treatment • precooked blended flours for relief aid ü present situation in Africa small scale production at « camp level » vs. centralized production in remote countries : from emergency to rehabilitation and development § Pilot equipment developped at the University of Lille 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 24)

PLAN § Very Low Cost Extrusion Cooking (VLEC) vs. Low Cost Extrusion Cooking (LEC) and classical Extrusion Cooking § Possible applications of VLEC • feeds at farm-level ü integrated traceability from feeds to livestock • locally processed nutritious weaning foods (development projects) ü on going project in Viet Nam destruction of antinutritional factors and optimisation of energy density through improvment of formula and control of thermomechanical treatment • precooked blended flours for relief aid ü present situation in Africa small scale production at « camp level » vs. centralized production in remote countries : from emergency to rehabilitation and development § Pilot equipment developped at the University of Lille 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 24)

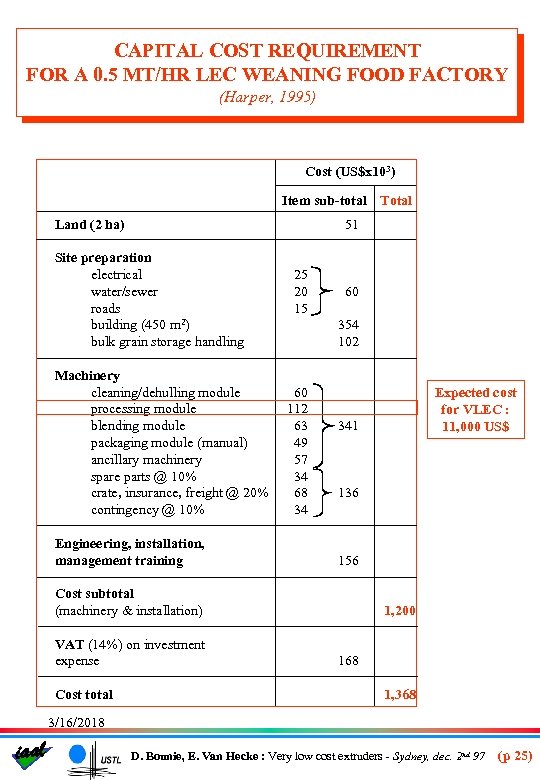

CAPITAL COST REQUIREMENT FOR A 0. 5 MT/HR LEC WEANING FOOD FACTORY (Harper, 1995) Cost (US$x 103) Item sub-total Total 51 Land (2 ha) Site preparation electrical water/sewer roads building (450 m 2) bulk grain storage handling Machinery cleaning/dehulling module processing module blending module packaging module (manual) ancillary machinery spare parts @ 10% crate, insurance, freight @ 20% contingency @ 10% Engineering, installation, management training 25 20 15 60 354 102 60 112 63 49 57 34 68 34 341 136 156 Cost subtotal (machinery & installation) VAT (14%) on investment expense Cost total Expected cost for VLEC : 11, 000 US$ 1, 200 168 1, 368 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 25)

CAPITAL COST REQUIREMENT FOR A 0. 5 MT/HR LEC WEANING FOOD FACTORY (Harper, 1995) Cost (US$x 103) Item sub-total Total 51 Land (2 ha) Site preparation electrical water/sewer roads building (450 m 2) bulk grain storage handling Machinery cleaning/dehulling module processing module blending module packaging module (manual) ancillary machinery spare parts @ 10% crate, insurance, freight @ 20% contingency @ 10% Engineering, installation, management training 25 20 15 60 354 102 60 112 63 49 57 34 68 34 341 136 156 Cost subtotal (machinery & installation) VAT (14%) on investment expense Cost total Expected cost for VLEC : 11, 000 US$ 1, 200 168 1, 368 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 25)

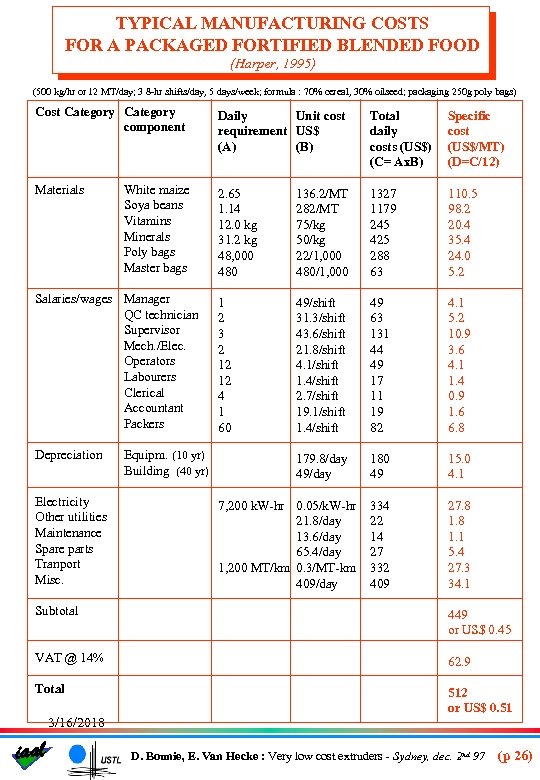

TYPICAL MANUFACTURING COSTS FOR A PACKAGED FORTIFIED BLENDED FOOD (Harper, 1995) (500 kg/hr or 12 MT/day; 3 8 -hr shifts/day, 5 days/week; formula : 70% cereal, 30% oilseed; packaging 250 g poly bags) Cost Category component Unit cost Daily requirement US$ (B) (A) Materials 2. 65 1. 14 12. 0 kg 31. 2 kg 48, 000 480 1 2 3 2 12 12 4 1 60 White maize Soya beans Vitamins Minerals Poly bags Master bags Salaries/wages Manager QC technician Supervisor Mech. /Elec. Operators Labourers Clerical Accountant Packers Depreciation Electricity Other utilities Maintenance Spare parts Tranport Misc. Equipm. (10 yr) Building (40 yr) Total daily costs (US$) (C= Ax. B) Specific cost (US$/MT) (D=C/12) 136. 2/MT 282/MT 75/kg 50/kg 22/1, 000 480/1, 000 1327 1179 245 425 288 63 110. 5 98. 2 20. 4 35. 4 24. 0 5. 2 49/shift 31. 3/shift 43. 6/shift 21. 8/shift 4. 1/shift 1. 4/shift 2. 7/shift 19. 1/shift 1. 4/shift 49 63 131 44 49 17 11 19 82 4. 1 5. 2 10. 9 3. 6 4. 1 1. 4 0. 9 1. 6 6. 8 179. 8/day 49/day 180 49 15. 0 4. 1 334 22 14 27 332 409 27. 8 1. 1 5. 4 27. 3 34. 1 7, 200 k. W-hr 0. 05/k. W-hr 21. 8/day 13. 6/day 65. 4/day 1, 200 MT/km 0. 3/MT-km 409/day Subtotal 449 or US$ 0. 45 VAT @ 14% 62. 9 Total 512 or US$ 0. 51 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 26)

TYPICAL MANUFACTURING COSTS FOR A PACKAGED FORTIFIED BLENDED FOOD (Harper, 1995) (500 kg/hr or 12 MT/day; 3 8 -hr shifts/day, 5 days/week; formula : 70% cereal, 30% oilseed; packaging 250 g poly bags) Cost Category component Unit cost Daily requirement US$ (B) (A) Materials 2. 65 1. 14 12. 0 kg 31. 2 kg 48, 000 480 1 2 3 2 12 12 4 1 60 White maize Soya beans Vitamins Minerals Poly bags Master bags Salaries/wages Manager QC technician Supervisor Mech. /Elec. Operators Labourers Clerical Accountant Packers Depreciation Electricity Other utilities Maintenance Spare parts Tranport Misc. Equipm. (10 yr) Building (40 yr) Total daily costs (US$) (C= Ax. B) Specific cost (US$/MT) (D=C/12) 136. 2/MT 282/MT 75/kg 50/kg 22/1, 000 480/1, 000 1327 1179 245 425 288 63 110. 5 98. 2 20. 4 35. 4 24. 0 5. 2 49/shift 31. 3/shift 43. 6/shift 21. 8/shift 4. 1/shift 1. 4/shift 2. 7/shift 19. 1/shift 1. 4/shift 49 63 131 44 49 17 11 19 82 4. 1 5. 2 10. 9 3. 6 4. 1 1. 4 0. 9 1. 6 6. 8 179. 8/day 49/day 180 49 15. 0 4. 1 334 22 14 27 332 409 27. 8 1. 1 5. 4 27. 3 34. 1 7, 200 k. W-hr 0. 05/k. W-hr 21. 8/day 13. 6/day 65. 4/day 1, 200 MT/km 0. 3/MT-km 409/day Subtotal 449 or US$ 0. 45 VAT @ 14% 62. 9 Total 512 or US$ 0. 51 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 26)

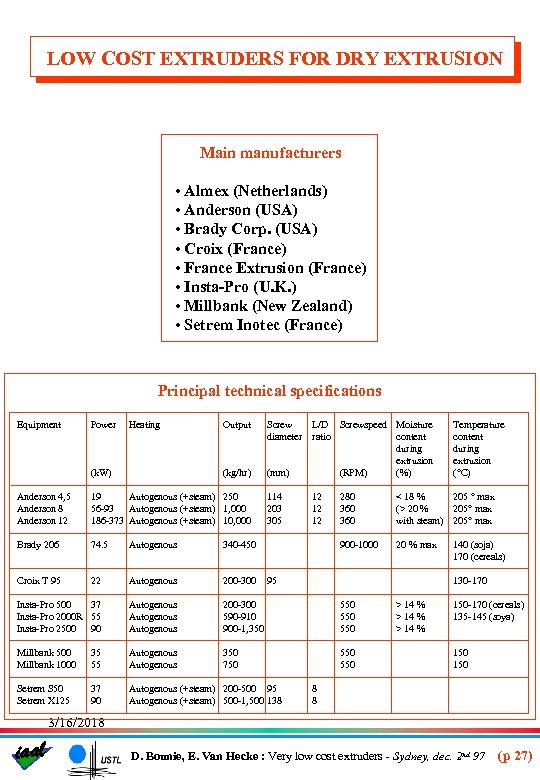

LOW COST EXTRUDERS FOR DRY EXTRUSION Main manufacturers • Almex (Netherlands) • Anderson (USA) • Brady Corp. (USA) • Croix (France) • France Extrusion (France) • Insta-Pro (U. K. ) • Millbank (New Zealand) • Setrem Inotec (France) Principal technical specifications Equipment Power Heating Screw diameter (kg/hr) (k. W) Output (mm) L/D Screwspeed Moisture ratio content during extrusion (RPM) (%) Temperature content during extrusion (°C) 114 203 305 12 12 12 Anderson 4, 5 Anderson 8 Anderson 12 19 Autogenous (+steam) 250 56 -93 Autogenous (+steam) 1, 000 186 -373 Autogenous (+steam) 10, 000 280 360 < 18 % (> 20 % with steam) 205 ° max 205° max Brady 206 74. 5 Autogenous 340 -450 900 -1000 20 % max 140 (soja) 170 (cereals) Croix T 95 22 Autogenous 200 -300 Insta-Pro 500 37 Insta-Pro 2000 R 55 Insta-Pro 2500 90 Autogenous 200 -300 590 -910 900 -1, 350 550 550 Millbank 500 Millbank 1000 35 55 Autogenous 350 750 550 Setrem S 50 Setrem X 125 37 90 Autogenous (+steam) 200 -500 95 Autogenous (+steam) 500 -1, 500 138 95 130 -170 > 14 % 150 -170 (cereals) 135 -145 (soya) 150 8 8 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 27)

LOW COST EXTRUDERS FOR DRY EXTRUSION Main manufacturers • Almex (Netherlands) • Anderson (USA) • Brady Corp. (USA) • Croix (France) • France Extrusion (France) • Insta-Pro (U. K. ) • Millbank (New Zealand) • Setrem Inotec (France) Principal technical specifications Equipment Power Heating Screw diameter (kg/hr) (k. W) Output (mm) L/D Screwspeed Moisture ratio content during extrusion (RPM) (%) Temperature content during extrusion (°C) 114 203 305 12 12 12 Anderson 4, 5 Anderson 8 Anderson 12 19 Autogenous (+steam) 250 56 -93 Autogenous (+steam) 1, 000 186 -373 Autogenous (+steam) 10, 000 280 360 < 18 % (> 20 % with steam) 205 ° max 205° max Brady 206 74. 5 Autogenous 340 -450 900 -1000 20 % max 140 (soja) 170 (cereals) Croix T 95 22 Autogenous 200 -300 Insta-Pro 500 37 Insta-Pro 2000 R 55 Insta-Pro 2500 90 Autogenous 200 -300 590 -910 900 -1, 350 550 550 Millbank 500 Millbank 1000 35 55 Autogenous 350 750 550 Setrem S 50 Setrem X 125 37 90 Autogenous (+steam) 200 -500 95 Autogenous (+steam) 500 -1, 500 138 95 130 -170 > 14 % 150 -170 (cereals) 135 -145 (soya) 150 8 8 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 27)

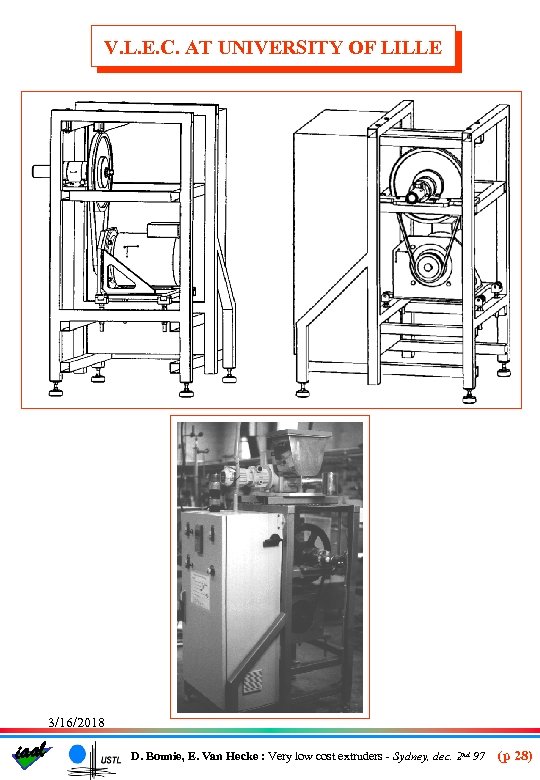

V. L. E. C. AT UNIVERSITY OF LILLE 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 28)

V. L. E. C. AT UNIVERSITY OF LILLE 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 28)

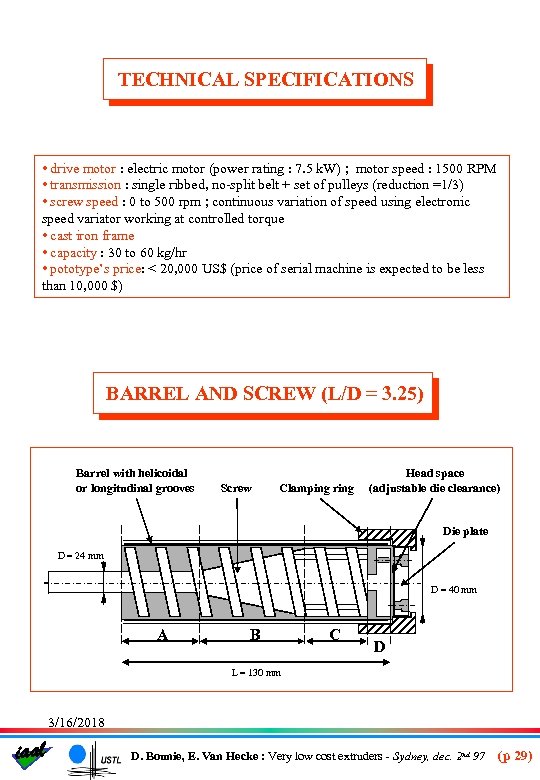

TECHNICAL SPECIFICATIONS • drive motor : electric motor (power rating : 7. 5 k. W) ; motor speed : 1500 RPM • transmission : single ribbed, no-split belt + set of pulleys (reduction =1/3) • screw speed : 0 to 500 rpm ; continuous variation of speed using electronic speed variator working at controlled torque • cast iron frame • capacity : 30 to 60 kg/hr • pototype’s price: < 20, 000 US$ (price of serial machine is expected to be less than 10, 000 $) BARREL AND SCREW (L/D = 3. 25) Barrel with helicoidal or longitudinal grooves Screw Clamping ring Head space (adjustable die clearance) Die plate D = 24 mm D = 40 mm A B C D L = 130 mm 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 29)

TECHNICAL SPECIFICATIONS • drive motor : electric motor (power rating : 7. 5 k. W) ; motor speed : 1500 RPM • transmission : single ribbed, no-split belt + set of pulleys (reduction =1/3) • screw speed : 0 to 500 rpm ; continuous variation of speed using electronic speed variator working at controlled torque • cast iron frame • capacity : 30 to 60 kg/hr • pototype’s price: < 20, 000 US$ (price of serial machine is expected to be less than 10, 000 $) BARREL AND SCREW (L/D = 3. 25) Barrel with helicoidal or longitudinal grooves Screw Clamping ring Head space (adjustable die clearance) Die plate D = 24 mm D = 40 mm A B C D L = 130 mm 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 29)

BIBLIOGRAPHY • Bounie D. , Briend A. and Greletty Y. , 1994. Précuisson des aliments de l’aide d’urgence : comportement rhéologique de bouillies énergétiques préparées à partir de divers mélanges obtenus par cuisson-extrusion. In Proc. Conf. Agoral 94 : La Cuisson des Aliments, Nantes, 5 -6 octobre 1994, pp 427 -439. • Bressani R. , Harper J. M. , Wickstrom B. , 1984. Processed and packaged weaning foods : development, manufacturing and marketing. In : Improving the nutritional status of children during the weaning period, Mitzner K. and al. Eds. , Intl Food and Nutrition Program, MIT, Cambridge, MA, pp 117 -148. • Coll. , 1979. Low cost extrusion cookers. Second International Workshop Proceedings, Dar Es Salaam, Tanzania, Wilson D. E. and Triebelhorn R. E. Eds. , Fort Collins, Colorado State University • Coll. , 1989. Pour améliorer l’alimentation des jeunes enfants en Afrique Orintale et Australe : une technologie à la portée des ménages. Proceedings of International Symposium, Nairobi, 12 -16 Oct. 1989, Alnwick D. and al. Eds. , CRDI, Ottawa • Harper J. M. , 1995. Low-cost extrusion : possibilities for Africa. The SA J. of Food Sci. and Nutrition, 7(4), pp 142 -147. • Harper J. M. and Jansen G. R. , 1985. Production of nutritious precooked foods in developing countries by low-cost extrusion technology. Food Review Intl. , 1(1), pp 27 -97 • Jansen G. R. , O’Deen L. , Triebelhorn R. E. and Harper J. M. , 1981. The caloric densities of gruels made from extruded corn-soy blends. UNU Food Nutr Bull, 3(1), pp 39 -44 • Jansen G. R. , 1992. Centrally processed weaning foods for use in developing countries. Food Reviews Intl, 8(3), 307 -345 • Walker A. F. , 1990. The contribution of weaning-food to protein-energy malnutrition. Nutrition Research reviews, 3, pp 25 -47 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 30)

BIBLIOGRAPHY • Bounie D. , Briend A. and Greletty Y. , 1994. Précuisson des aliments de l’aide d’urgence : comportement rhéologique de bouillies énergétiques préparées à partir de divers mélanges obtenus par cuisson-extrusion. In Proc. Conf. Agoral 94 : La Cuisson des Aliments, Nantes, 5 -6 octobre 1994, pp 427 -439. • Bressani R. , Harper J. M. , Wickstrom B. , 1984. Processed and packaged weaning foods : development, manufacturing and marketing. In : Improving the nutritional status of children during the weaning period, Mitzner K. and al. Eds. , Intl Food and Nutrition Program, MIT, Cambridge, MA, pp 117 -148. • Coll. , 1979. Low cost extrusion cookers. Second International Workshop Proceedings, Dar Es Salaam, Tanzania, Wilson D. E. and Triebelhorn R. E. Eds. , Fort Collins, Colorado State University • Coll. , 1989. Pour améliorer l’alimentation des jeunes enfants en Afrique Orintale et Australe : une technologie à la portée des ménages. Proceedings of International Symposium, Nairobi, 12 -16 Oct. 1989, Alnwick D. and al. Eds. , CRDI, Ottawa • Harper J. M. , 1995. Low-cost extrusion : possibilities for Africa. The SA J. of Food Sci. and Nutrition, 7(4), pp 142 -147. • Harper J. M. and Jansen G. R. , 1985. Production of nutritious precooked foods in developing countries by low-cost extrusion technology. Food Review Intl. , 1(1), pp 27 -97 • Jansen G. R. , O’Deen L. , Triebelhorn R. E. and Harper J. M. , 1981. The caloric densities of gruels made from extruded corn-soy blends. UNU Food Nutr Bull, 3(1), pp 39 -44 • Jansen G. R. , 1992. Centrally processed weaning foods for use in developing countries. Food Reviews Intl, 8(3), 307 -345 • Walker A. F. , 1990. The contribution of weaning-food to protein-energy malnutrition. Nutrition Research reviews, 3, pp 25 -47 3/16/2018 iaal D. Bounie, E. Van Hecke : Very low cost extruders - Sydney, dec. 2 nd 97 (p 30)