02e4eca4462a2035db608495f45e1ae0.ppt

- Количество слайдов: 58

Vertical Transportation Elevator Design Consideration Elevator Selection Parameters

Vertical Transportation Elevator Design Consideration Elevator Selection Parameters

Introduction – The selection of the vertical transportation equipment is the most important decision to be made by the designer – The passenger, freight elevators and elevator

Introduction – The selection of the vertical transportation equipment is the most important decision to be made by the designer – The passenger, freight elevators and elevator

Passenger Elevators • Ideal performance: – Minimum waiting time for car at any floor level – Comfortable acceleration – Rapid transportation – Smooth and rapid parking – Accurate automatic leveling at ladings – Rapid loading and unloading at all stops

Passenger Elevators • Ideal performance: – Minimum waiting time for car at any floor level – Comfortable acceleration – Rapid transportation – Smooth and rapid parking – Accurate automatic leveling at ladings – Rapid loading and unloading at all stops

Architectural Impact • Cars and shaft way doors must be treated in a manner consonant with the architectural unit of the building • Integration of shaft way into the building is a prime factor in composition as is the design of elevator lobby

Architectural Impact • Cars and shaft way doors must be treated in a manner consonant with the architectural unit of the building • Integration of shaft way into the building is a prime factor in composition as is the design of elevator lobby

Codes and Standards • ANSI/ASME – A 17. 3 existing elevators and escalators – A 17. 4 –emergency evacuation of passengers from elevators – ANSI A 117. 1 –accessible and usable buildings and facilities • NFPA 101

Codes and Standards • ANSI/ASME – A 17. 3 existing elevators and escalators – A 17. 4 –emergency evacuation of passengers from elevators – ANSI A 117. 1 –accessible and usable buildings and facilities • NFPA 101

Elevator Equipment • Principle equipment – The car – Safety doors – Operating control equipment, floor level indicator – Illumination – Emergency exits and ventilation

Elevator Equipment • Principle equipment – The car – Safety doors – Operating control equipment, floor level indicator – Illumination – Emergency exits and ventilation

Cables (Ropes) • The minimum safety factor varies for 7. 612 for passenger elevators and 6. 6 -11 for freight elevators

Cables (Ropes) • The minimum safety factor varies for 7. 612 for passenger elevators and 6. 6 -11 for freight elevators

Counterweight • Its value is equal to that of the empty car plus 40% of the rated live load • It serves several purposes: – To provide adequate traction at the sheave for car lifting – Reduce the size of the traction machine – Reduce power demand energy cost • 75% of the energy expended in lifting a car is returned to the system by regeneration when the car is lowered

Counterweight • Its value is equal to that of the empty car plus 40% of the rated live load • It serves several purposes: – To provide adequate traction at the sheave for car lifting – Reduce the size of the traction machine – Reduce power demand energy cost • 75% of the energy expended in lifting a car is returned to the system by regeneration when the car is lowered

Control Equipment • Drive control- concerned with the velocity, acceleration , position determination and leveling of the car • Operating control covers car doors operation and functioning or car signals, including floor call buttons and all indicating devices • Supervisory control is concerned-car installations

Control Equipment • Drive control- concerned with the velocity, acceleration , position determination and leveling of the car • Operating control covers car doors operation and functioning or car signals, including floor call buttons and all indicating devices • Supervisory control is concerned-car installations

Shaft • The hoist way is the vertical passage way for the car and counterweights

Shaft • The hoist way is the vertical passage way for the car and counterweights

Gearless Traction Machine • It consists of a DC or AC motor, the shaft of which is directly connected to a brake wheel and driving sheave • The motor must run at the same low speed as the driving sheave • They are used for passenger service , car capacity of 2000 ib-4000 lb. • Below 500 fpm geared machine are used

Gearless Traction Machine • It consists of a DC or AC motor, the shaft of which is directly connected to a brake wheel and driving sheave • The motor must run at the same low speed as the driving sheave • They are used for passenger service , car capacity of 2000 ib-4000 lb. • Below 500 fpm geared machine are used

Geared Traction Machine • It a worm and gear interposed between the driving motor and the hoisting sheave

Geared Traction Machine • It a worm and gear interposed between the driving motor and the hoisting sheave

Safety devices The main break of an elevator is mounted directly on the shaft of the machine A dual safety system designed to stop an elevator car automatically before its speed becomes excessive is normally used

Safety devices The main break of an elevator is mounted directly on the shaft of the machine A dual safety system designed to stop an elevator car automatically before its speed becomes excessive is normally used

Elevator Doors • • • The choice of the car door affects the speed and quality of elevator service considerably Installations can be equipped with an electronic sensing device that detects passengers in a wide area on the landing in front of the car door rather than only directly in the door’s path Such detection often accompanied by audible signal, causes the car door to remain open for a predetermined length of time or a closing door to reverse

Elevator Doors • • • The choice of the car door affects the speed and quality of elevator service considerably Installations can be equipped with an electronic sensing device that detects passengers in a wide area on the landing in front of the car door rather than only directly in the door’s path Such detection often accompanied by audible signal, causes the car door to remain open for a predetermined length of time or a closing door to reverse

Requirements for the disabled • Elevator manufacturers follow ADA additional conveniences for the disabled as the specific facility design intent or local codes require

Requirements for the disabled • Elevator manufacturers follow ADA additional conveniences for the disabled as the specific facility design intent or local codes require

Elevator Design Procedure

Elevator Design Procedure

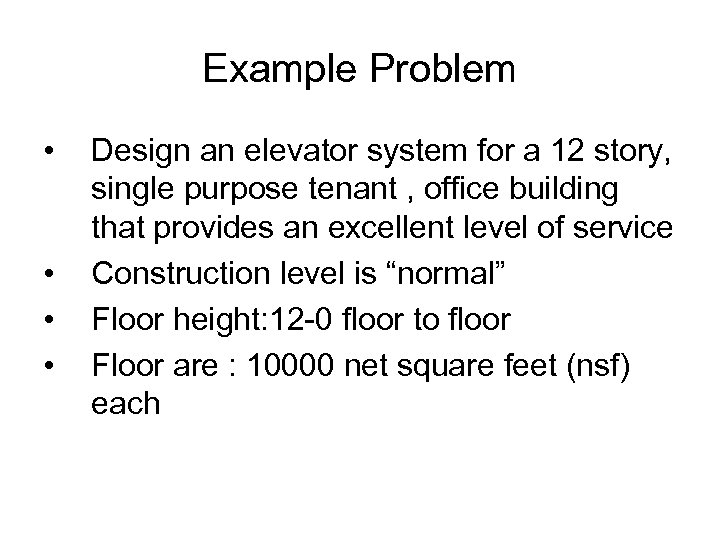

Example Problem • • Design an elevator system for a 12 story, single purpose tenant , office building that provides an excellent level of service Construction level is “normal” Floor height: 12 -0 floor to floor Floor are : 10000 net square feet (nsf) each

Example Problem • • Design an elevator system for a 12 story, single purpose tenant , office building that provides an excellent level of service Construction level is “normal” Floor height: 12 -0 floor to floor Floor are : 10000 net square feet (nsf) each

1. Determine the percent handling capacity • Office building • Single purpose table

1. Determine the percent handling capacity • Office building • Single purpose table

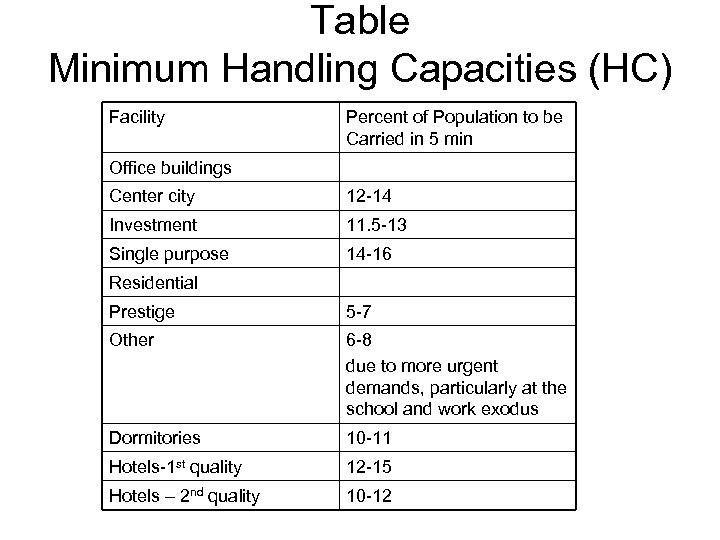

Table Minimum Handling Capacities (HC) Facility Percent of Population to be Carried in 5 min Office buildings Center city 12 -14 Investment 11. 5 -13 Single purpose 14 -16 Residential Prestige 5 -7 Other 6 -8 due to more urgent demands, particularly at the school and work exodus Dormitories 10 -11 Hotels-1 st quality 12 -15 Hotels – 2 nd quality 10 -12

Table Minimum Handling Capacities (HC) Facility Percent of Population to be Carried in 5 min Office buildings Center city 12 -14 Investment 11. 5 -13 Single purpose 14 -16 Residential Prestige 5 -7 Other 6 -8 due to more urgent demands, particularly at the school and work exodus Dormitories 10 -11 Hotels-1 st quality 12 -15 Hotels – 2 nd quality 10 -12

• Range 14 -16% • Assume it 15% • PHC=0. 15

• Range 14 -16% • Assume it 15% • PHC=0. 15

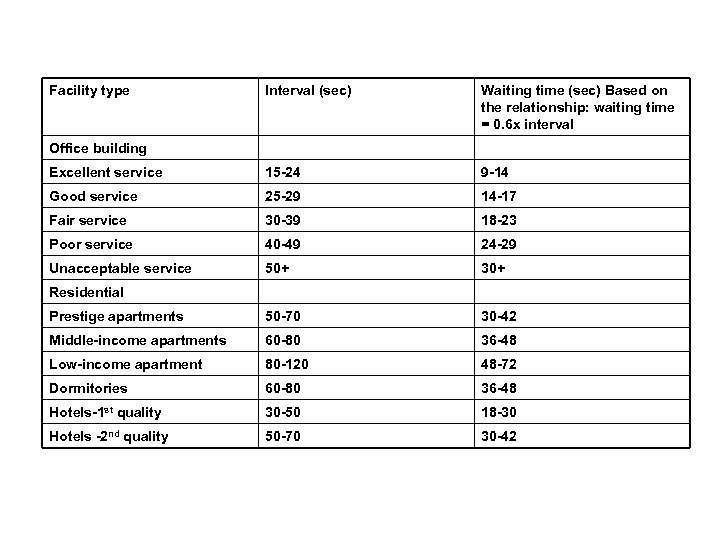

2. Determine the Interval (I) Table 31. 4 Recommended Elevator Intervals and Related Lobby Waiting Time

2. Determine the Interval (I) Table 31. 4 Recommended Elevator Intervals and Related Lobby Waiting Time

Facility type Interval (sec) Waiting time (sec) Based on the relationship: waiting time = 0. 6 x interval Excellent service 15 -24 9 -14 Good service 25 -29 14 -17 Fair service 30 -39 18 -23 Poor service 40 -49 24 -29 Unacceptable service 50+ 30+ Prestige apartments 50 -70 30 -42 Middle-income apartments 60 -80 36 -48 Low-income apartment 80 -120 48 -72 Dormitories 60 -80 36 -48 Hotels-1 st quality 30 -50 18 -30 Hotels -2 nd quality 50 -70 30 -42 Office building Residential

Facility type Interval (sec) Waiting time (sec) Based on the relationship: waiting time = 0. 6 x interval Excellent service 15 -24 9 -14 Good service 25 -29 14 -17 Fair service 30 -39 18 -23 Poor service 40 -49 24 -29 Unacceptable service 50+ 30+ Prestige apartments 50 -70 30 -42 Middle-income apartments 60 -80 36 -48 Low-income apartment 80 -120 48 -72 Dormitories 60 -80 36 -48 Hotels-1 st quality 30 -50 18 -30 Hotels -2 nd quality 50 -70 30 -42 Office building Residential

Office building “excellent” service • I=15 -24 sec

Office building “excellent” service • I=15 -24 sec

3. Determine the population Table Population of typical buildings for estimating elevator and escalator requirements

3. Determine the population Table Population of typical buildings for estimating elevator and escalator requirements

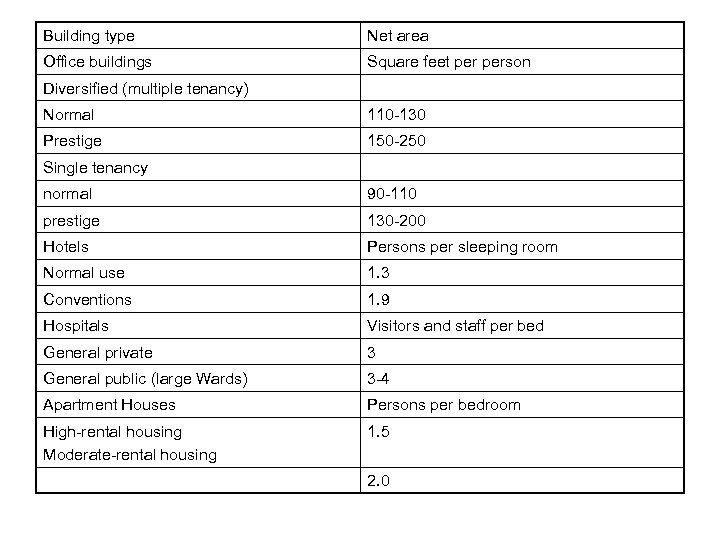

Building type Net area Office buildings Square feet person Diversified (multiple tenancy) Normal 110 -130 Prestige 150 -250 Single tenancy normal 90 -110 prestige 130 -200 Hotels Persons per sleeping room Normal use 1. 3 Conventions 1. 9 Hospitals Visitors and staff per bed General private 3 General public (large Wards) 3 -4 Apartment Houses Persons per bedroom High-rental housing Moderate-rental housing 1. 5 2. 0

Building type Net area Office buildings Square feet person Diversified (multiple tenancy) Normal 110 -130 Prestige 150 -250 Single tenancy normal 90 -110 prestige 130 -200 Hotels Persons per sleeping room Normal use 1. 3 Conventions 1. 9 Hospitals Visitors and staff per bed General private 3 General public (large Wards) 3 -4 Apartment Houses Persons per bedroom High-rental housing Moderate-rental housing 1. 5 2. 0

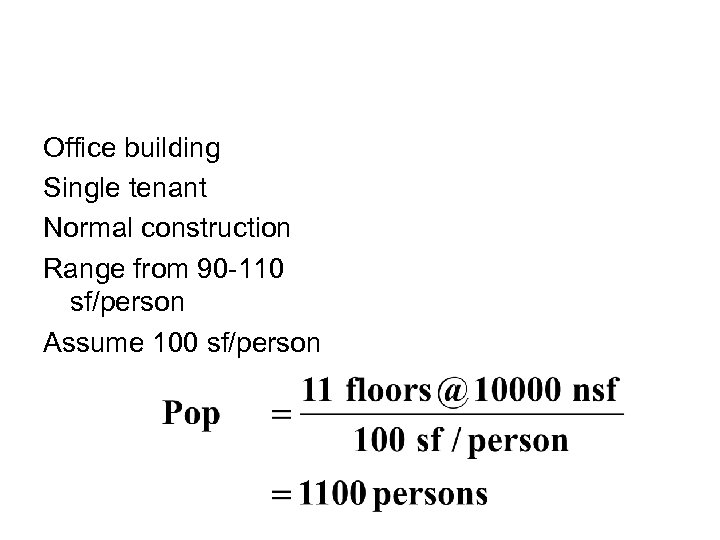

Office building Single tenant Normal construction Range from 90 -110 sf/person Assume 100 sf/person

Office building Single tenant Normal construction Range from 90 -110 sf/person Assume 100 sf/person

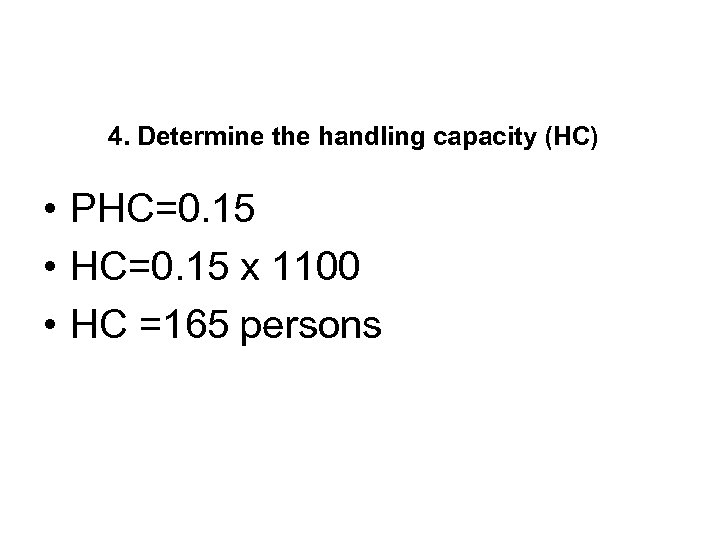

4. Determine the handling capacity (HC) • PHC=0. 15 • HC=0. 15 x 1100 • HC =165 persons

4. Determine the handling capacity (HC) • PHC=0. 15 • HC=0. 15 x 1100 • HC =165 persons

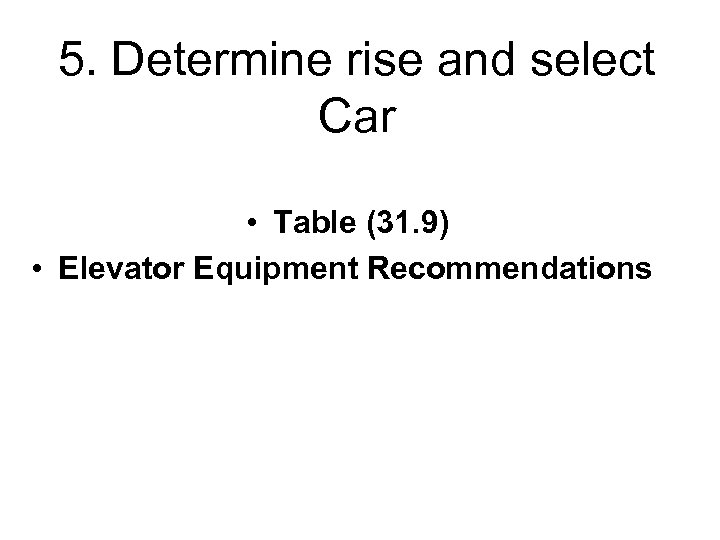

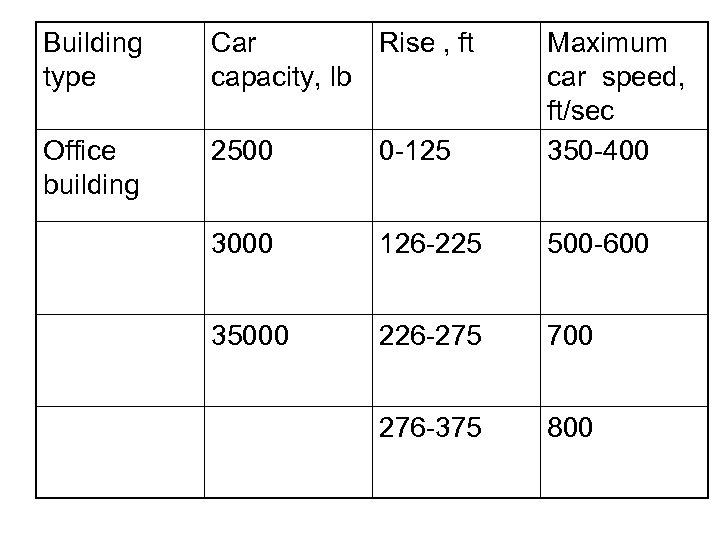

5. Determine rise and select Car • Table (31. 9) • Elevator Equipment Recommendations

5. Determine rise and select Car • Table (31. 9) • Elevator Equipment Recommendations

Building type Car Rise , ft capacity, lb Office building 2500 0 -125 Maximum car speed, ft/sec 350 -400 3000 126 -225 500 -600 35000 226 -275 700 276 -375 800

Building type Car Rise , ft capacity, lb Office building 2500 0 -125 Maximum car speed, ft/sec 350 -400 3000 126 -225 500 -600 35000 226 -275 700 276 -375 800

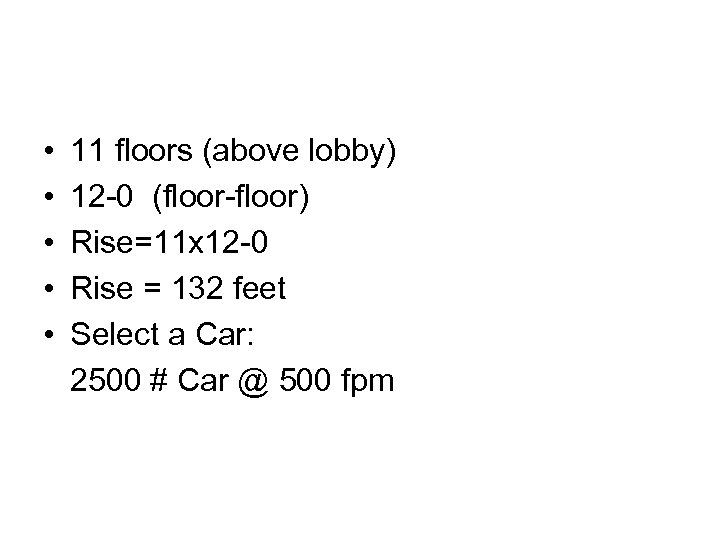

• • • 11 floors (above lobby) 12 -0 (floor-floor) Rise=11 x 12 -0 Rise = 132 feet Select a Car: 2500 # Car @ 500 fpm

• • • 11 floors (above lobby) 12 -0 (floor-floor) Rise=11 x 12 -0 Rise = 132 feet Select a Car: 2500 # Car @ 500 fpm

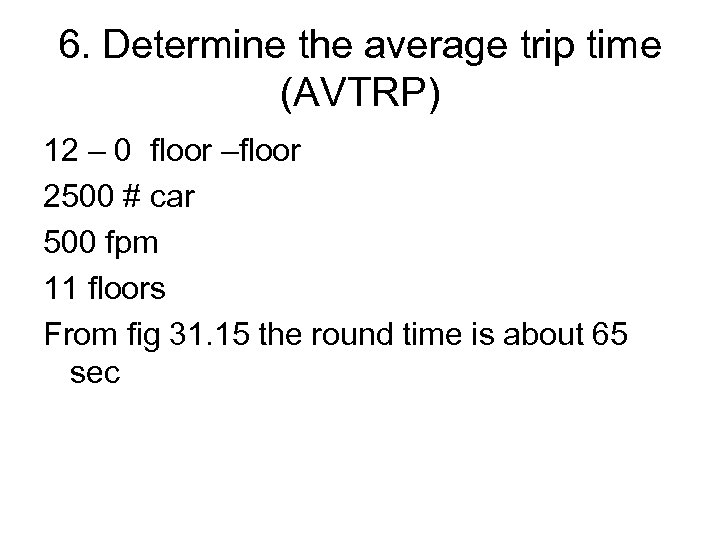

6. Determine the average trip time (AVTRP) 12 – 0 floor –floor 2500 # car 500 fpm 11 floors From fig 31. 15 the round time is about 65 sec

6. Determine the average trip time (AVTRP) 12 – 0 floor –floor 2500 # car 500 fpm 11 floors From fig 31. 15 the round time is about 65 sec

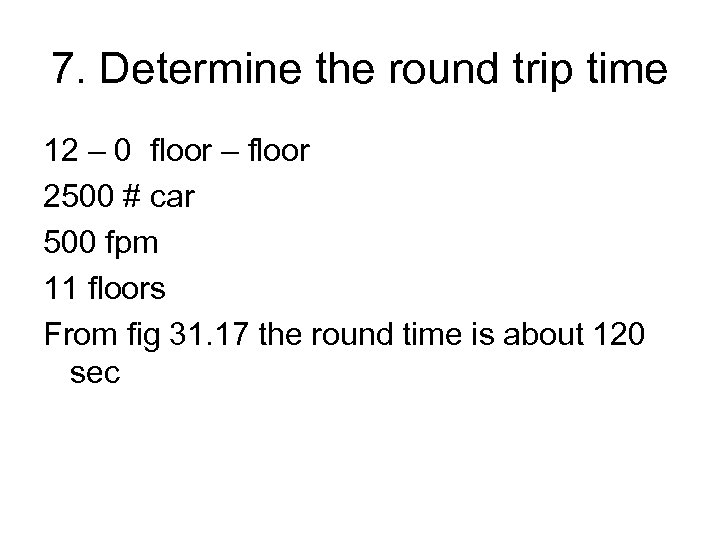

7. Determine the round trip time 12 – 0 floor – floor 2500 # car 500 fpm 11 floors From fig 31. 17 the round time is about 120 sec

7. Determine the round trip time 12 – 0 floor – floor 2500 # car 500 fpm 11 floors From fig 31. 17 the round time is about 120 sec

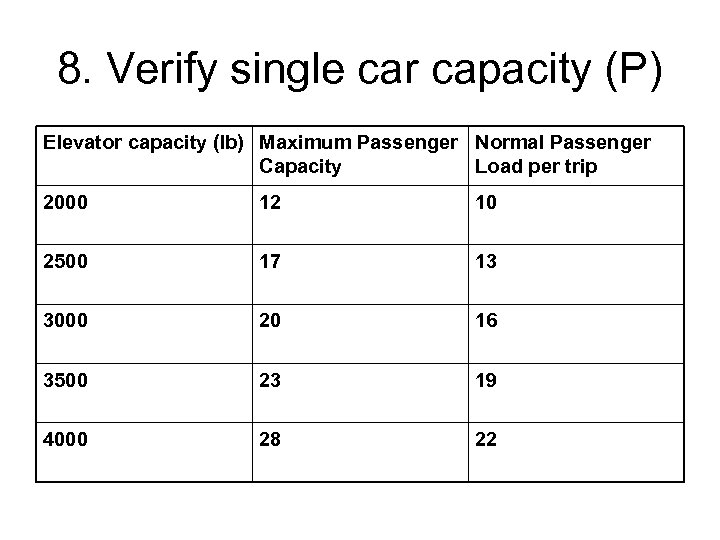

8. Verify single car capacity (P) Elevator capacity (lb) Maximum Passenger Normal Passenger Capacity Load per trip 2000 12 10 2500 17 13 3000 20 16 3500 23 19 4000 28 22

8. Verify single car capacity (P) Elevator capacity (lb) Maximum Passenger Normal Passenger Capacity Load per trip 2000 12 10 2500 17 13 3000 20 16 3500 23 19 4000 28 22

• From Table 31. 5 for a 2500 lb car the normal capacity load per trip is 13 persons • The number of passengers carried on a trip during peak conditions is approximately 80% pf the car capacity

• From Table 31. 5 for a 2500 lb car the normal capacity load per trip is 13 persons • The number of passengers carried on a trip during peak conditions is approximately 80% pf the car capacity

9. Determine 5 minutes handling capacity • Handling capacity (HC)= passengers/car x cars/sec x 5 min x 60 sec • HC 300 p/I • When the interval is 30 sec, the system’s handling capacity is 10 p • h=300 p /RT • h= 300 x 13/120 • h= 32. 5 persons

9. Determine 5 minutes handling capacity • Handling capacity (HC)= passengers/car x cars/sec x 5 min x 60 sec • HC 300 p/I • When the interval is 30 sec, the system’s handling capacity is 10 p • h=300 p /RT • h= 300 x 13/120 • h= 32. 5 persons

10. Determine number of cars • • N=HC/h N=165/32. 5 N=5. 07 Cars N=5 Cars

10. Determine number of cars • • N=HC/h N=165/32. 5 N=5. 07 Cars N=5 Cars

11. Confirm interval (I) • • • I=RT/N I=120/5 I=24 Required I : 15 -24 sec Design compels

11. Confirm interval (I) • • • I=RT/N I=120/5 I=24 Required I : 15 -24 sec Design compels

12. Repeat until performance complies • In this case the performance is compliance • Use 5 cars (2500 lbs, 500 fpm)

12. Repeat until performance complies • In this case the performance is compliance • Use 5 cars (2500 lbs, 500 fpm)

System relationships • P-individual car capacity equal to 80% of the maximum during peak hours • h - 5 -minute capacity of a single car • N -number of cars in a system • HC -system 5 min handling capacity, expressed in number of persons • RT -round trip time in sec • AVTRP- average trip time, sec • I- interval in sec • D – population density, in square feet person • PHC percent of the population to be moved in 5 minutes, and expressed as percentage

System relationships • P-individual car capacity equal to 80% of the maximum during peak hours • h - 5 -minute capacity of a single car • N -number of cars in a system • HC -system 5 min handling capacity, expressed in number of persons • RT -round trip time in sec • AVTRP- average trip time, sec • I- interval in sec • D – population density, in square feet person • PHC percent of the population to be moved in 5 minutes, and expressed as percentage

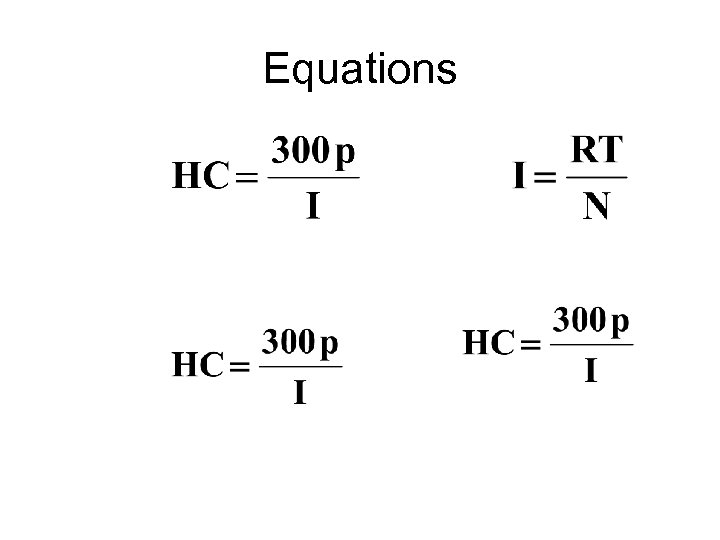

Equations

Equations

Single zone systems • Example • Office building downtown, diversified use, 14 rentable floors above the lobby, each 12000 ft 2 net. Floor to floor height – 12 ft. determine a workable system

Single zone systems • Example • Office building downtown, diversified use, 14 rentable floors above the lobby, each 12000 ft 2 net. Floor to floor height – 12 ft. determine a workable system

Solution • From table 31. 6 , recommended average HC is 13%. • From table 31. 4, the maximum recommended interval is 25 sec. from table 31. 7 average population density is 120 ft 2 person

Solution • From table 31. 6 , recommended average HC is 13%. • From table 31. 4, the maximum recommended interval is 25 sec. from table 31. 7 average population density is 120 ft 2 person

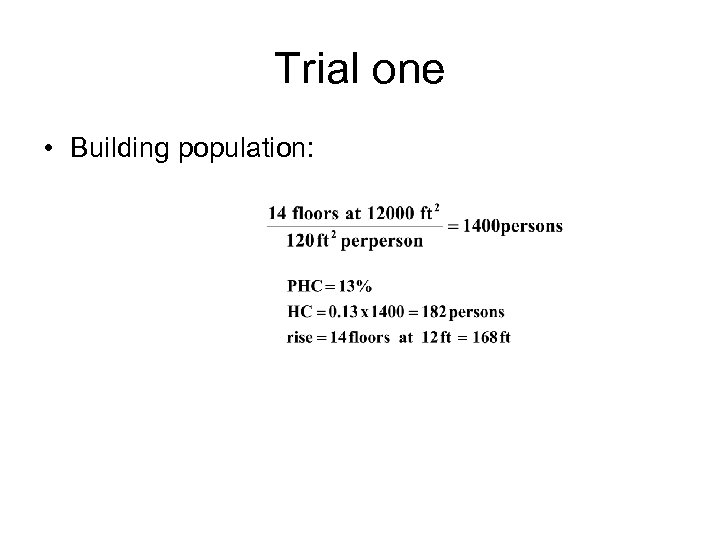

Trial one • Building population:

Trial one • Building population:

From table 31. 9 , select a car size of 3500 lb at 500 fpm • 3500 lb

From table 31. 9 , select a car size of 3500 lb at 500 fpm • 3500 lb

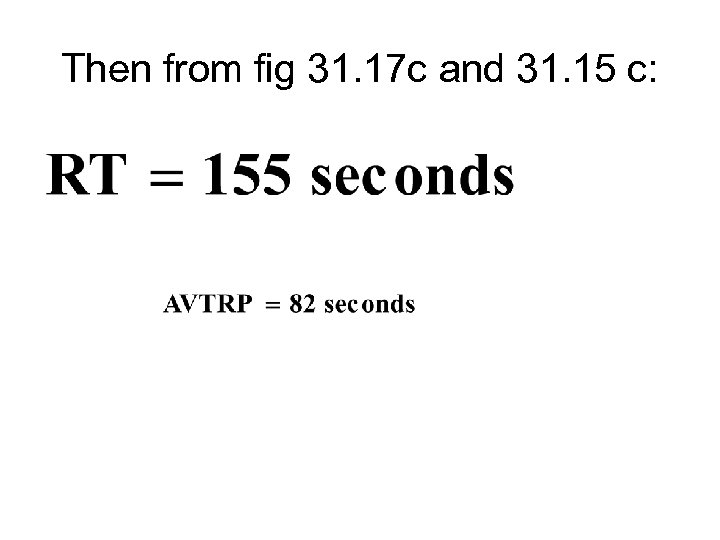

Then from fig 31. 17 c and 31. 15 c:

Then from fig 31. 17 c and 31. 15 c:

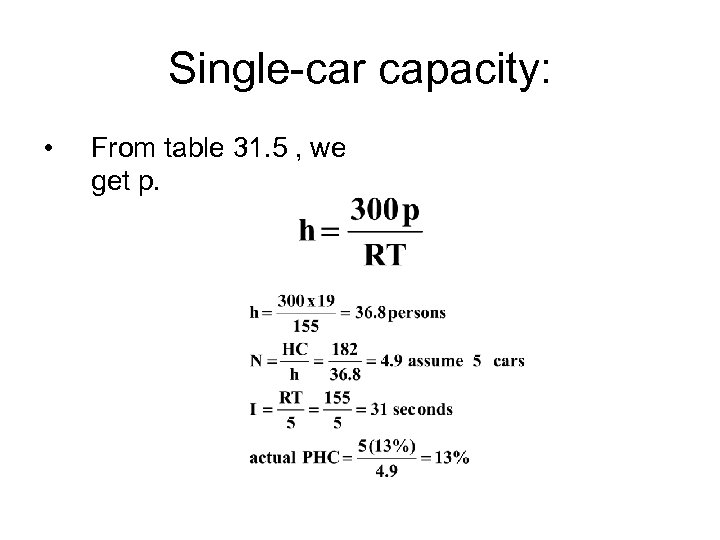

Single-car capacity: • From table 31. 5 , we get p.

Single-car capacity: • From table 31. 5 , we get p.

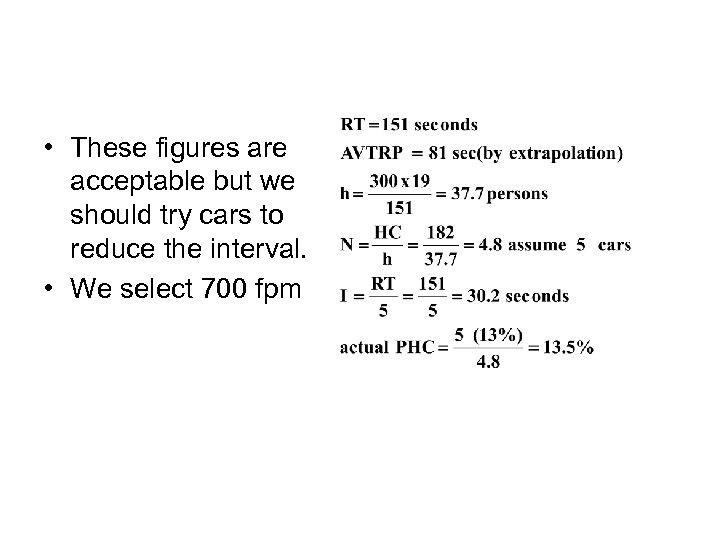

• These figures are acceptable but we should try cars to reduce the interval. • We select 700 fpm

• These figures are acceptable but we should try cars to reduce the interval. • We select 700 fpm

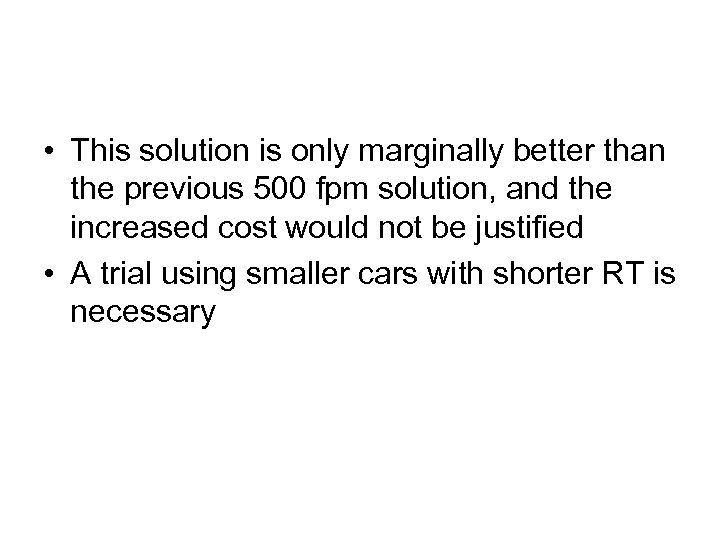

• This solution is only marginally better than the previous 500 fpm solution, and the increased cost would not be justified • A trial using smaller cars with shorter RT is necessary

• This solution is only marginally better than the previous 500 fpm solution, and the increased cost would not be justified • A trial using smaller cars with shorter RT is necessary

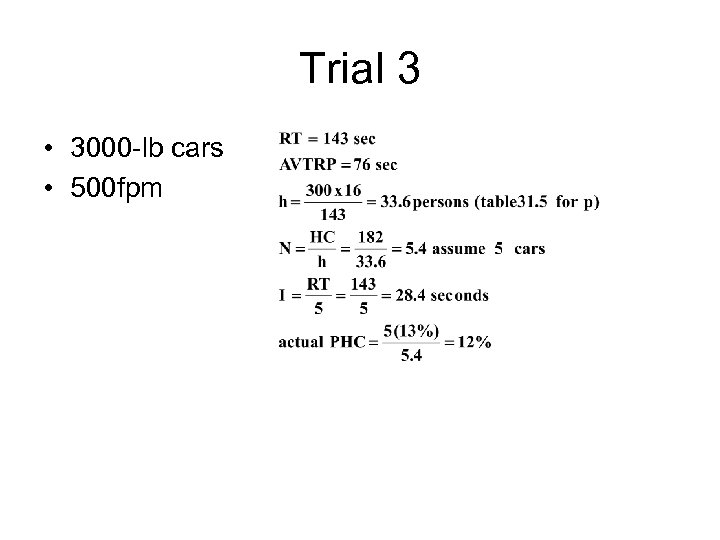

Trial 3 • 3000 -lb cars • 500 fpm

Trial 3 • 3000 -lb cars • 500 fpm

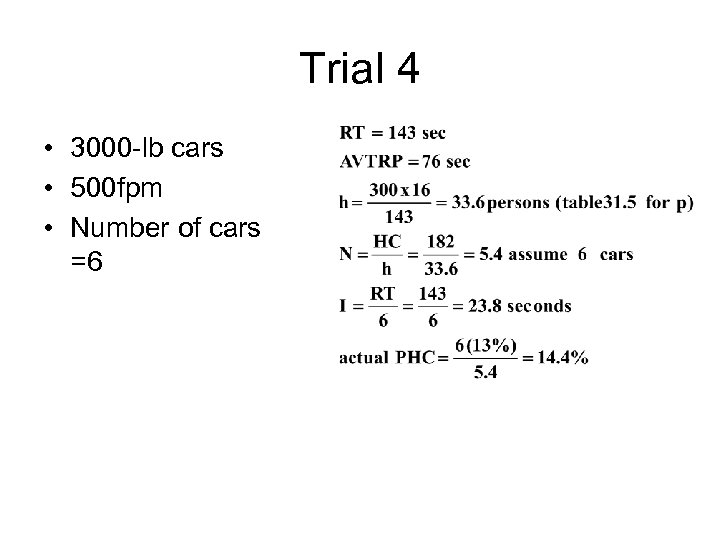

Trial 4 • 3000 -lb cars • 500 fpm • Number of cars =6

Trial 4 • 3000 -lb cars • 500 fpm • Number of cars =6

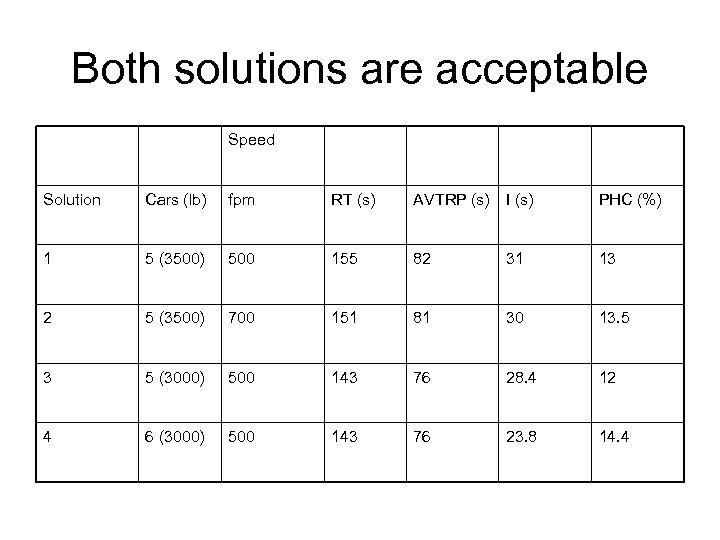

Both solutions are acceptable Speed Solution Cars (lb) fpm RT (s) AVTRP (s) I (s) PHC (%) 1 5 (3500) 500 155 82 31 13 2 5 (3500) 700 151 81 30 13. 5 3 5 (3000) 500 143 76 28. 4 12 4 6 (3000) 500 143 76 23. 8 14. 4

Both solutions are acceptable Speed Solution Cars (lb) fpm RT (s) AVTRP (s) I (s) PHC (%) 1 5 (3500) 500 155 82 31 13 2 5 (3500) 700 151 81 30 13. 5 3 5 (3000) 500 143 76 28. 4 12 4 6 (3000) 500 143 76 23. 8 14. 4

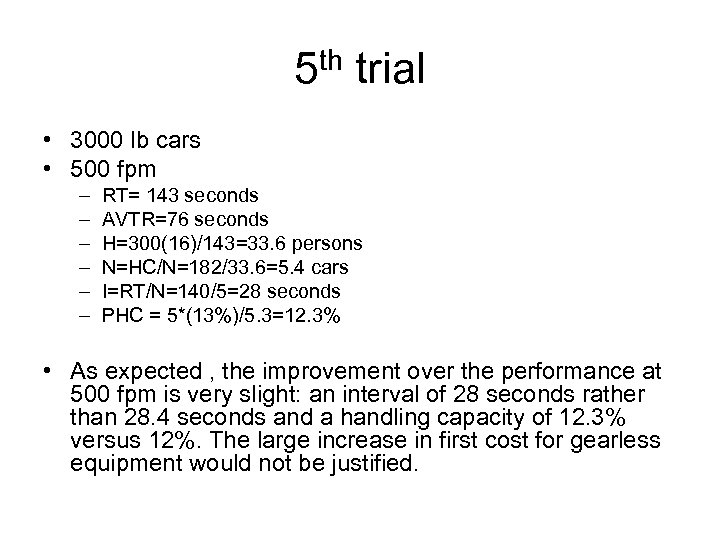

5 th trial • 3000 lb cars • 500 fpm – – – RT= 143 seconds AVTR=76 seconds H=300(16)/143=33. 6 persons N=HC/N=182/33. 6=5. 4 cars I=RT/N=140/5=28 seconds PHC = 5*(13%)/5. 3=12. 3% • As expected , the improvement over the performance at 500 fpm is very slight: an interval of 28 seconds rather than 28. 4 seconds and a handling capacity of 12. 3% versus 12%. The large increase in first cost for gearless equipment would not be justified.

5 th trial • 3000 lb cars • 500 fpm – – – RT= 143 seconds AVTR=76 seconds H=300(16)/143=33. 6 persons N=HC/N=182/33. 6=5. 4 cars I=RT/N=140/5=28 seconds PHC = 5*(13%)/5. 3=12. 3% • As expected , the improvement over the performance at 500 fpm is very slight: an interval of 28 seconds rather than 28. 4 seconds and a handling capacity of 12. 3% versus 12%. The large increase in first cost for gearless equipment would not be justified.

Multi-zone systems • Less than 15 floors –one zone • More than 20 stories- two zones • From 16 -19 floors can be either way

Multi-zone systems • Less than 15 floors –one zone • More than 20 stories- two zones • From 16 -19 floors can be either way

Other elevator selection recommendations • • Office buildings Apartment buildings Hospitals Retail stories

Other elevator selection recommendations • • Office buildings Apartment buildings Hospitals Retail stories

Physical properties and spatial requirements of elevators • Shafts and lobbies • The elevator and shafts form one of the major space factors with which the architect is concerned – Proximity to other cars • Single zone • Multizone – Proximity to emergency exits/egress – Adjacent to main lobby • Dimensions and weights

Physical properties and spatial requirements of elevators • Shafts and lobbies • The elevator and shafts form one of the major space factors with which the architect is concerned – Proximity to other cars • Single zone • Multizone – Proximity to emergency exits/egress – Adjacent to main lobby • Dimensions and weights

lobby sizing • Size based on peak interval – 15 or 20 minute peak time – 5 sf/person – From previous example using 15 minute peak – H=33. 1 people/5 min→ 99. 3 people/15 min. – Area=99. 3 people x 5 sf/person=497 sf

lobby sizing • Size based on peak interval – 15 or 20 minute peak time – 5 sf/person – From previous example using 15 minute peak – H=33. 1 people/5 min→ 99. 3 people/15 min. – Area=99. 3 people x 5 sf/person=497 sf

Escalators Configuration • Crisscross • Stacked parallel • Spiral parallel

Escalators Configuration • Crisscross • Stacked parallel • Spiral parallel

Design consideration • Lighting • Fire /Life safety

Design consideration • Lighting • Fire /Life safety