5a1164f3ca5612628b85036142cf2d2d.ppt

- Количество слайдов: 19

Version 2. 0 07/01/05 KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. magicolor 5400 series §A closer look

Version 2. 0 07/01/05 KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. magicolor 5400 series §A closer look

The magicolor 5400 series is the result of Konica Minolta’s commitment to be a company that constantly brings new surprises to customers, through its unique and innovative products and services, by mobilizing its broad technological capabilities in the field of imaging. This presentation will highlight some of the revolutionary technologies inside the magicolor 5400 series and the benefits these technologies bring to customers. KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 2

The magicolor 5400 series is the result of Konica Minolta’s commitment to be a company that constantly brings new surprises to customers, through its unique and innovative products and services, by mobilizing its broad technological capabilities in the field of imaging. This presentation will highlight some of the revolutionary technologies inside the magicolor 5400 series and the benefits these technologies bring to customers. KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 2

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. Belt fusing system

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. Belt fusing system

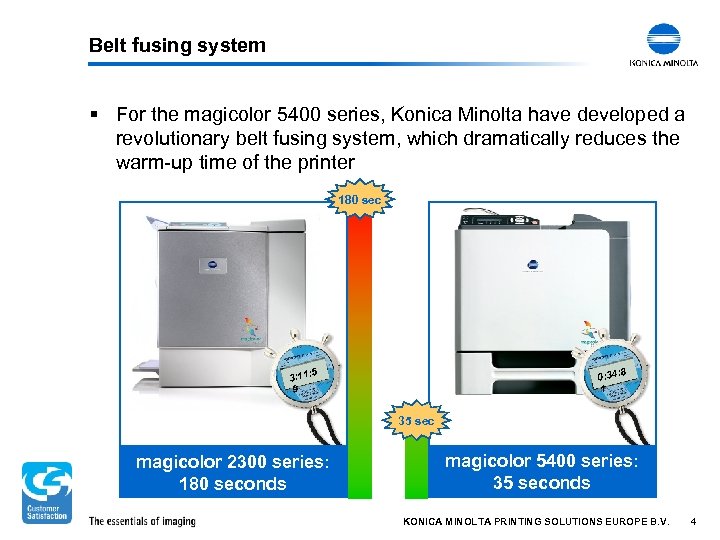

Belt fusing system § For the magicolor 5400 series, Konica Minolta have developed a revolutionary belt fusing system, which dramatically reduces the warm-up time of the printer 180 sec 8 0: 34: 1 5 3: 11: 9 35 sec magicolor 2300 series: 180 seconds magicolor 5400 series: 35 seconds KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 4

Belt fusing system § For the magicolor 5400 series, Konica Minolta have developed a revolutionary belt fusing system, which dramatically reduces the warm-up time of the printer 180 sec 8 0: 34: 1 5 3: 11: 9 35 sec magicolor 2300 series: 180 seconds magicolor 5400 series: 35 seconds KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 4

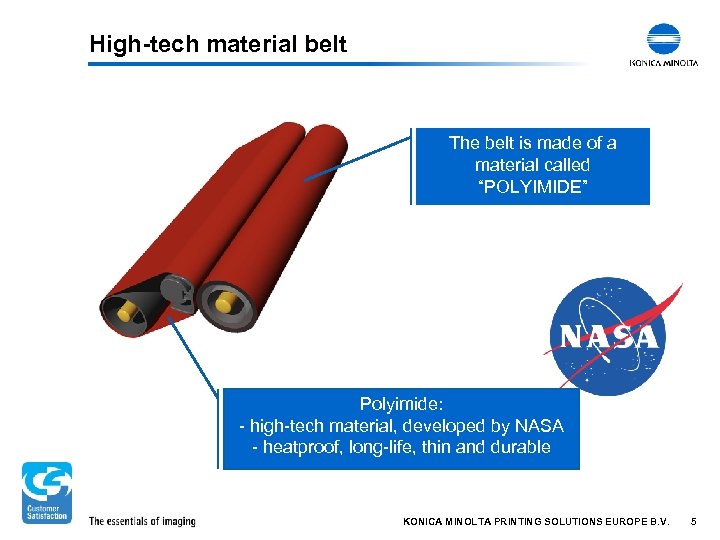

High-tech material belt The belt is made of a material called “POLYIMIDE” Polyimide: - high-tech material, developed by NASA - heatproof, long-life, thin and durable KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 5

High-tech material belt The belt is made of a material called “POLYIMIDE” Polyimide: - high-tech material, developed by NASA - heatproof, long-life, thin and durable KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 5

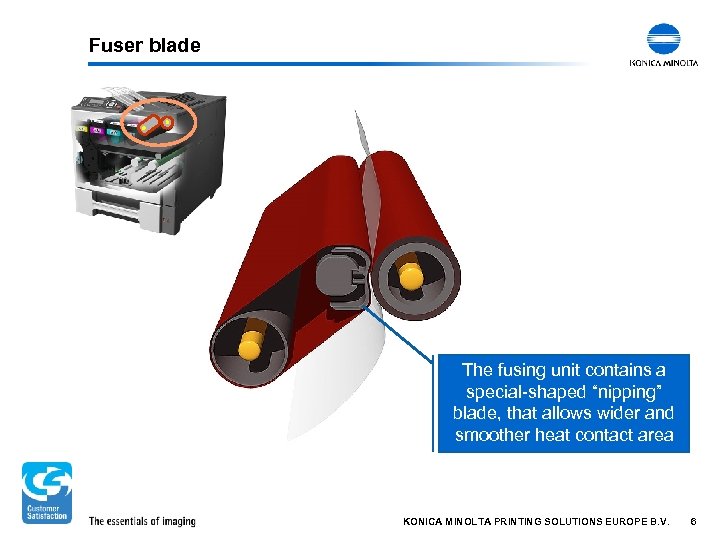

Fuser blade The fusing unit contains a special-shaped “nipping” blade, that allows wider and smoother heat contact area KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 6

Fuser blade The fusing unit contains a special-shaped “nipping” blade, that allows wider and smoother heat contact area KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 6

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. Prismlaser print head

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. Prismlaser print head

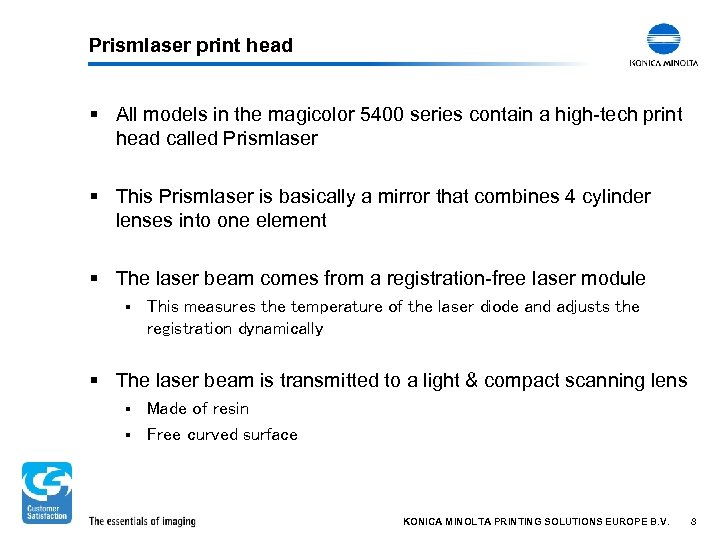

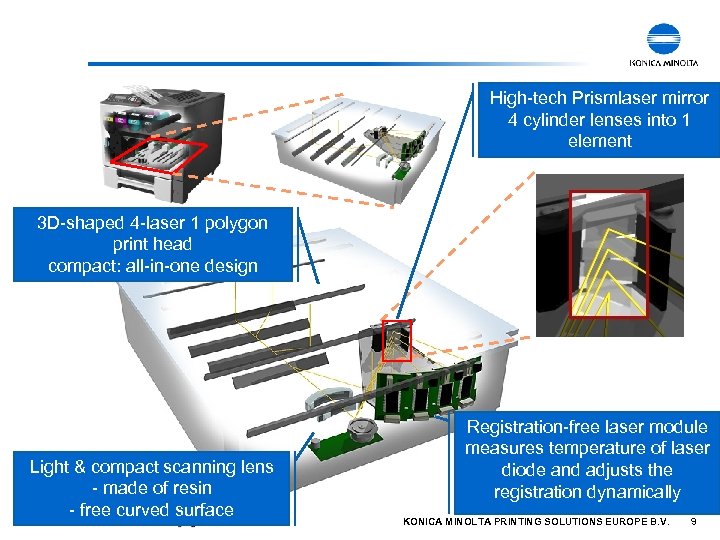

Prismlaser print head § All models in the magicolor 5400 series contain a high-tech print head called Prismlaser § This Prismlaser is basically a mirror that combines 4 cylinder lenses into one element § The laser beam comes from a registration-free laser module § This measures the temperature of the laser diode and adjusts the registration dynamically § The laser beam is transmitted to a light & compact scanning lens Made of resin § Free curved surface § KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 8

Prismlaser print head § All models in the magicolor 5400 series contain a high-tech print head called Prismlaser § This Prismlaser is basically a mirror that combines 4 cylinder lenses into one element § The laser beam comes from a registration-free laser module § This measures the temperature of the laser diode and adjusts the registration dynamically § The laser beam is transmitted to a light & compact scanning lens Made of resin § Free curved surface § KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 8

High-tech Prismlaser mirror 4 cylinder lenses into 1 element 3 D-shaped 4 -laser 1 polygon print head compact: all-in-one design Light & compact scanning lens - made of resin - free curved surface Registration-free laser module measures temperature of laser diode and adjusts the registration dynamically KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 9

High-tech Prismlaser mirror 4 cylinder lenses into 1 element 3 D-shaped 4 -laser 1 polygon print head compact: all-in-one design Light & compact scanning lens - made of resin - free curved surface Registration-free laser module measures temperature of laser diode and adjusts the registration dynamically KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 9

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. Polymerised toner

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. Polymerised toner

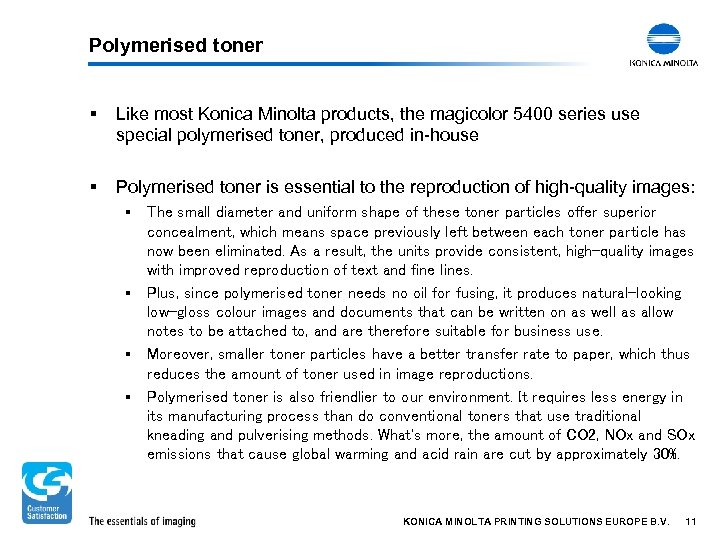

Polymerised toner § Like most Konica Minolta products, the magicolor 5400 series use special polymerised toner, produced in-house § Polymerised toner is essential to the reproduction of high-quality images: § § The small diameter and uniform shape of these toner particles offer superior concealment, which means space previously left between each toner particle has now been eliminated. As a result, the units provide consistent, high-quality images with improved reproduction of text and fine lines. Plus, since polymerised toner needs no oil for fusing, it produces natural-looking low-gloss colour images and documents that can be written on as well as allow notes to be attached to, and are therefore suitable for business use. Moreover, smaller toner particles have a better transfer rate to paper, which thus reduces the amount of toner used in image reproductions. Polymerised toner is also friendlier to our environment. It requires less energy in its manufacturing process than do conventional toners that use traditional kneading and pulverising methods. What's more, the amount of CO 2, NOx and SOx emissions that cause global warming and acid rain are cut by approximately 30%. KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 11

Polymerised toner § Like most Konica Minolta products, the magicolor 5400 series use special polymerised toner, produced in-house § Polymerised toner is essential to the reproduction of high-quality images: § § The small diameter and uniform shape of these toner particles offer superior concealment, which means space previously left between each toner particle has now been eliminated. As a result, the units provide consistent, high-quality images with improved reproduction of text and fine lines. Plus, since polymerised toner needs no oil for fusing, it produces natural-looking low-gloss colour images and documents that can be written on as well as allow notes to be attached to, and are therefore suitable for business use. Moreover, smaller toner particles have a better transfer rate to paper, which thus reduces the amount of toner used in image reproductions. Polymerised toner is also friendlier to our environment. It requires less energy in its manufacturing process than do conventional toners that use traditional kneading and pulverising methods. What's more, the amount of CO 2, NOx and SOx emissions that cause global warming and acid rain are cut by approximately 30%. KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 11

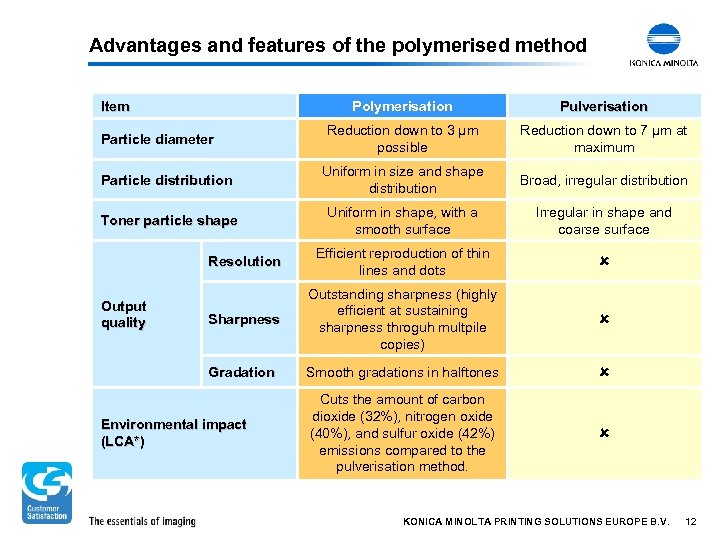

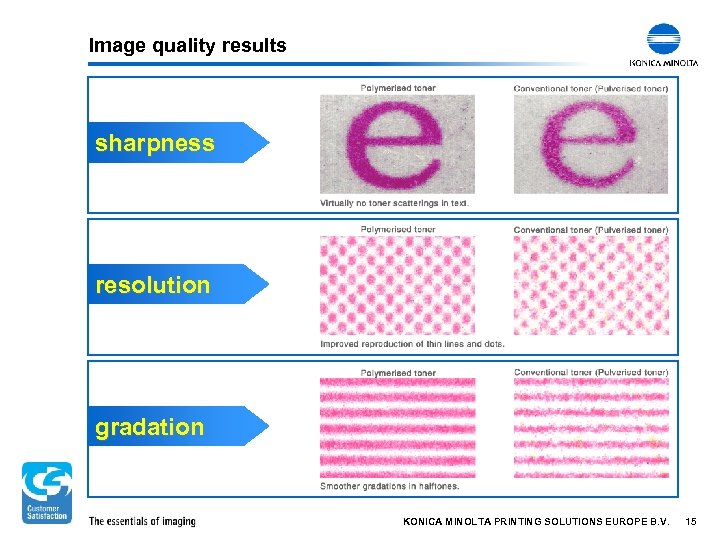

Advantages and features of the polymerised method Item Polymerisation Pulverisation Reduction down to 3 µm possible Reduction down to 7 µm at maximum Particle distribution Uniform in size and shape distribution Broad, irregular distribution Toner particle shape Uniform in shape, with a smooth surface Irregular in shape and coarse surface Resolution Efficient reproduction of thin lines and dots Sharpness Outstanding sharpness (highly efficient at sustaining sharpness throguh multpile copies) Gradation Smooth gradations in halftones Cuts the amount of carbon dioxide (32%), nitrogen oxide (40%), and sulfur oxide (42%) emissions compared to the pulverisation method. Particle diameter Output quality Environmental impact (LCA*) KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 12

Advantages and features of the polymerised method Item Polymerisation Pulverisation Reduction down to 3 µm possible Reduction down to 7 µm at maximum Particle distribution Uniform in size and shape distribution Broad, irregular distribution Toner particle shape Uniform in shape, with a smooth surface Irregular in shape and coarse surface Resolution Efficient reproduction of thin lines and dots Sharpness Outstanding sharpness (highly efficient at sustaining sharpness throguh multpile copies) Gradation Smooth gradations in halftones Cuts the amount of carbon dioxide (32%), nitrogen oxide (40%), and sulfur oxide (42%) emissions compared to the pulverisation method. Particle diameter Output quality Environmental impact (LCA*) KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 12

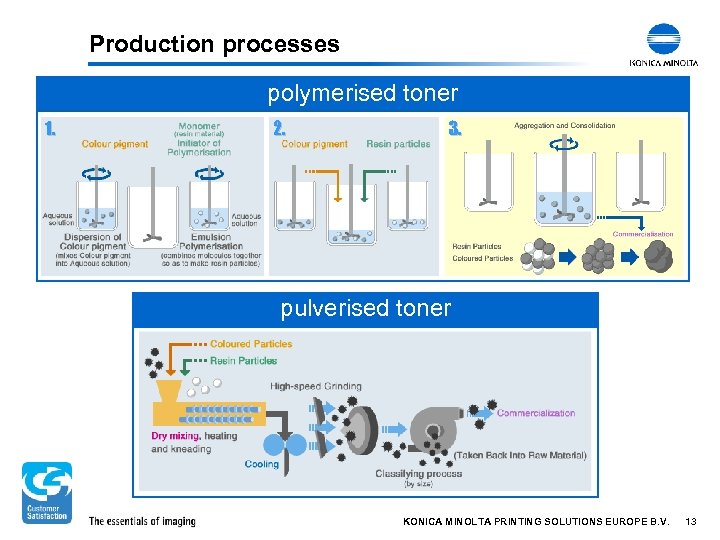

Production processes polymerised toner 1. 2. 3. pulverised toner KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 13

Production processes polymerised toner 1. 2. 3. pulverised toner KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 13

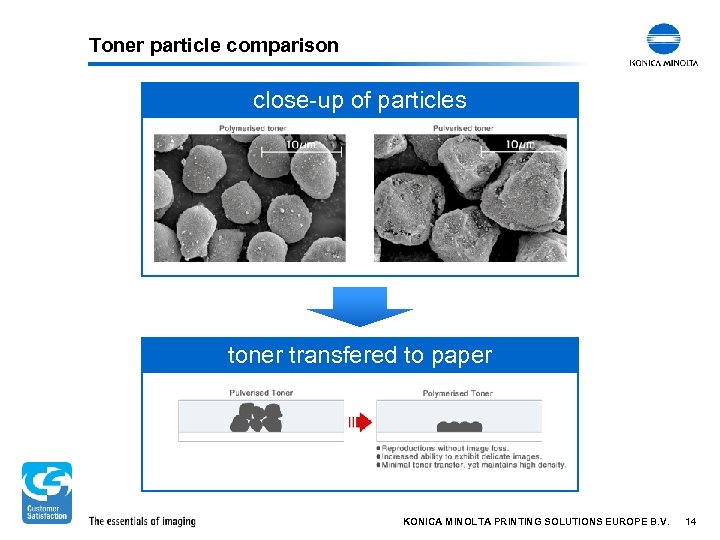

Toner particle comparison close-up of particles toner transfered to paper KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 14

Toner particle comparison close-up of particles toner transfered to paper KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 14

Image quality results sharpness resolution gradation KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 15

Image quality results sharpness resolution gradation KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 15

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. Controller technology

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. Controller technology

Konica Minolta Raster Language § The magicolor 5430 DL and 5440 DL use Konica Minolta’s own Konica Minolta Raster Langue § This is an enhanced version of GDI § KMRL supports various environments: Windows § Mac § Linux § § KMRL offers hi-speed color graphics with a low-cost controller § KMRL will be used by all DL-products KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 17

Konica Minolta Raster Language § The magicolor 5430 DL and 5440 DL use Konica Minolta’s own Konica Minolta Raster Langue § This is an enhanced version of GDI § KMRL supports various environments: Windows § Mac § Linux § § KMRL offers hi-speed color graphics with a low-cost controller § KMRL will be used by all DL-products KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 17

Special note § Konica Minolta Raster Language does support certain versions of Mac-OS but it is not a Post. Script or PCL driver § KMRL offers basic office functionality Word processing § Emails § Spreadsheets § Presentations § § It does not offer: Color matching § Object segmentation § e. AIDC (Automatic Image Density Calibration) § KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 18

Special note § Konica Minolta Raster Language does support certain versions of Mac-OS but it is not a Post. Script or PCL driver § KMRL offers basic office functionality Word processing § Emails § Spreadsheets § Presentations § § It does not offer: Color matching § Object segmentation § e. AIDC (Automatic Image Density Calibration) § KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 18

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 19

KONICA MINOLTA PRINTING SOLUTIONS EUROPE B. V. 19