e2b9c967689cf1c5d99774db30f5aa11.ppt

- Количество слайдов: 95

Version: 01 Oct 2008 FSC Chain-of-Custody FSC-STD-40 -004 Version 2 -0

Version: 01 Oct 2008 FSC Chain-of-Custody FSC-STD-40 -004 Version 2 -0

TOPICS Introduction to FSC-STD-40 -004 V 2 • Applicability • Effective Dates • List of Supplementary Documents • Where to Find Documents 1 The Standard Complete Overview 2 3 Supplementary Standards In Brief 2

TOPICS Introduction to FSC-STD-40 -004 V 2 • Applicability • Effective Dates • List of Supplementary Documents • Where to Find Documents 1 The Standard Complete Overview 2 3 Supplementary Standards In Brief 2

Introduction to FSC-STD-40 -004 V 2 FSC Standard for Chain of Custody Certification 1 2 3 3

Introduction to FSC-STD-40 -004 V 2 FSC Standard for Chain of Custody Certification 1 2 3 3

Applicability FSC-STD-40 -004 V 2 applies to all Organization types: Primary & secondary manufacturers Retailers Brokers / traders Printers Distributors Paper Merchants Wholesalers Publishers Any company that would like to provide a guarantee that its products contain wood from well-managed forests 4

Applicability FSC-STD-40 -004 V 2 applies to all Organization types: Primary & secondary manufacturers Retailers Brokers / traders Printers Distributors Paper Merchants Wholesalers Publishers Any company that would like to provide a guarantee that its products contain wood from well-managed forests 4

Effective Dates 1 st April 2008 Required for all new assessments, all companies 1 st January 2009 Required for all annual audits, all reassessments, all companies 5

Effective Dates 1 st April 2008 Required for all new assessments, all companies 1 st January 2009 Required for all annual audits, all reassessments, all companies 5

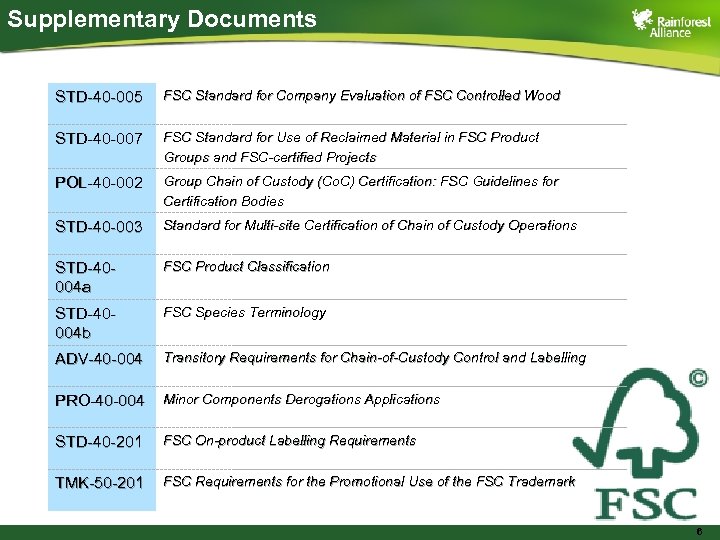

Supplementary Documents STD-40 -005 FSC Standard for Company Evaluation of FSC Controlled Wood STD-40 -007 FSC Standard for Use of Reclaimed Material in FSC Product Groups and FSC-certified Projects POL-40 -002 Group Chain of Custody (Co. C) Certification: FSC Guidelines for Certification Bodies STD-40 -003 Standard for Multi-site Certification of Chain of Custody Operations STD-40004 a FSC Product Classification STD-40004 b FSC Species Terminology ADV-40 -004 Transitory Requirements for Chain-of-Custody Control and Labelling PRO-40 -004 Minor Components Derogations Applications STD-40 -201 FSC On-product Labelling Requirements TMK-50 -201 FSC Requirements for the Promotional Use of the FSC Trademark 6

Supplementary Documents STD-40 -005 FSC Standard for Company Evaluation of FSC Controlled Wood STD-40 -007 FSC Standard for Use of Reclaimed Material in FSC Product Groups and FSC-certified Projects POL-40 -002 Group Chain of Custody (Co. C) Certification: FSC Guidelines for Certification Bodies STD-40 -003 Standard for Multi-site Certification of Chain of Custody Operations STD-40004 a FSC Product Classification STD-40004 b FSC Species Terminology ADV-40 -004 Transitory Requirements for Chain-of-Custody Control and Labelling PRO-40 -004 Minor Components Derogations Applications STD-40 -201 FSC On-product Labelling Requirements TMK-50 -201 FSC Requirements for the Promotional Use of the FSC Trademark 6

Where all of these documents? Rainforest Alliance Website: http: //www. rainforestalliance. org/forestry. cfm? id=custody_certification FSC Website: http: //www. fsc. org/internationalpolicies. html 7

Where all of these documents? Rainforest Alliance Website: http: //www. rainforestalliance. org/forestry. cfm? id=custody_certification FSC Website: http: //www. fsc. org/internationalpolicies. html 7

The Standard 1 2 3 FSC Standard for Chain-of-Custody Certification FSC-STD-40 -004 Version 2 -0 8

The Standard 1 2 3 FSC Standard for Chain-of-Custody Certification FSC-STD-40 -004 Version 2 -0 8

The Standard FSC-STD-40 -004 V 2 Summary of Requirements 9

The Standard FSC-STD-40 -004 V 2 Summary of Requirements 9

Standard Contents Part I: Universal Requirements Quality Management / Scope of Co. C System / Material Sourcing / Receipt and Storage / Volume Control / Sales and Delivery Part II: Systems for Controlling FSC Claims Transfer System / Percentage System / Credit System Part III: Labeling General Labeling Requirements / Eligibility for Labeling Part IV: Supplementary Requirements Outsourcing / Minor Components 10

Standard Contents Part I: Universal Requirements Quality Management / Scope of Co. C System / Material Sourcing / Receipt and Storage / Volume Control / Sales and Delivery Part II: Systems for Controlling FSC Claims Transfer System / Percentage System / Credit System Part III: Labeling General Labeling Requirements / Eligibility for Labeling Part IV: Supplementary Requirements Outsourcing / Minor Components 10

Part I: Universal Requirements Part II: Systems for Controlling FSC Claims Part III: Labeling Part IV: Supplementary Requirements Mandatory for all certificate scopes 11

Part I: Universal Requirements Part II: Systems for Controlling FSC Claims Part III: Labeling Part IV: Supplementary Requirements Mandatory for all certificate scopes 11

1. Quality Management System to ensure a Co. C control system is implemented that is in compliance with the standard requirements 12

1. Quality Management System to ensure a Co. C control system is implemented that is in compliance with the standard requirements 12

1. Quality Management 1. 1 Responsibilities • Appoint management representative with overall responsibility and authority (1. 1. 1) • Relevant staff shall demonstrate awareness (1. 1. 2) Awareness of the Co. C system and specific responsibilities is demonstrated during audit interviews with key staff 13

1. Quality Management 1. 1 Responsibilities • Appoint management representative with overall responsibility and authority (1. 1. 1) • Relevant staff shall demonstrate awareness (1. 1. 2) Awareness of the Co. C system and specific responsibilities is demonstrated during audit interviews with key staff 13

1. Quality Management 1. 2 Procedures • Establish, implement, maintain procedures (1. 2. 1) • Define responsible personnel, qualifications, &/or training measures for each procedure (1. 2. 2) 14

1. Quality Management 1. 2 Procedures • Establish, implement, maintain procedures (1. 2. 1) • Define responsible personnel, qualifications, &/or training measures for each procedure (1. 2. 2) 14

1. Quality Management 1. 3 Training • • Establish AND implement training plan according to 1. 2. 2 (1. 3. 1) Maintain training records (1. 3. 2) 1. 4 Records • • Maintain up-to-date records (1. 4. 1) Maintain all relevant records for certification for 5 years (1. 4. 2) 15

1. Quality Management 1. 3 Training • • Establish AND implement training plan according to 1. 2. 2 (1. 3. 1) Maintain training records (1. 3. 2) 1. 4 Records • • Maintain up-to-date records (1. 4. 1) Maintain all relevant records for certification for 5 years (1. 4. 2) 15

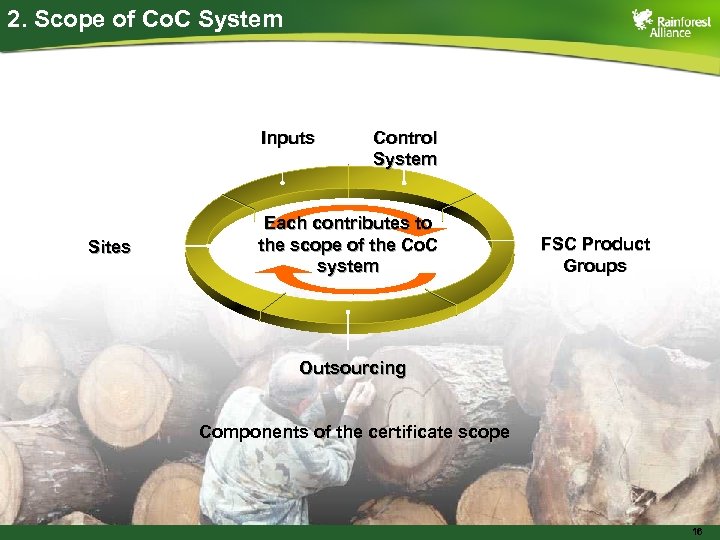

2. Scope of Co. C System Inputs Sites Control System Each contributes to the scope of the Co. C system FSC Product Groups Outsourcing Components of the certificate scope 16

2. Scope of Co. C System Inputs Sites Control System Each contributes to the scope of the Co. C system FSC Product Groups Outsourcing Components of the certificate scope 16

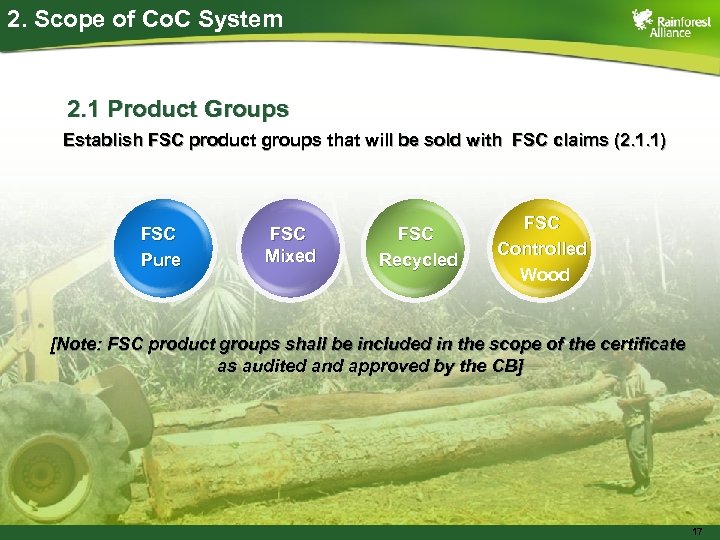

2. Scope of Co. C System 2. 1 Product Groups Establish FSC product groups that will be sold with FSC claims (2. 1. 1) FSC Pure FSC Mixed FSC Recycled FSC Controlled Wood [Note: FSC product groups shall be included in the scope of the certificate as audited and approved by the CB] 17

2. Scope of Co. C System 2. 1 Product Groups Establish FSC product groups that will be sold with FSC claims (2. 1. 1) FSC Pure FSC Mixed FSC Recycled FSC Controlled Wood [Note: FSC product groups shall be included in the scope of the certificate as audited and approved by the CB] 17

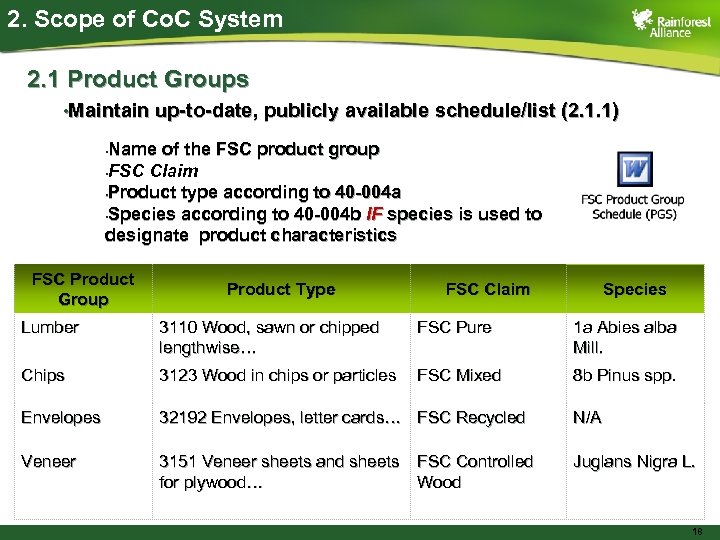

2. Scope of Co. C System 2. 1 Product Groups • Maintain up-to-date, publicly available schedule/list (2. 1. 1) Name of the FSC product group • FSC Claim • Product type according to 40 -004 a • Species according to 40 -004 b IF species is used to designate product characteristics • FSC Product Group Product Type FSC Claim Species Lumber 3110 Wood, sawn or chipped lengthwise… FSC Pure 1 a Abies alba Mill. Chips 3123 Wood in chips or particles FSC Mixed 8 b Pinus spp. Envelopes 32192 Envelopes, letter cards… FSC Recycled N/A Veneer 3151 Veneer sheets and sheets for plywood… Juglans Nigra L. FSC Controlled Wood 18

2. Scope of Co. C System 2. 1 Product Groups • Maintain up-to-date, publicly available schedule/list (2. 1. 1) Name of the FSC product group • FSC Claim • Product type according to 40 -004 a • Species according to 40 -004 b IF species is used to designate product characteristics • FSC Product Group Product Type FSC Claim Species Lumber 3110 Wood, sawn or chipped lengthwise… FSC Pure 1 a Abies alba Mill. Chips 3123 Wood in chips or particles FSC Mixed 8 b Pinus spp. Envelopes 32192 Envelopes, letter cards… FSC Recycled N/A Veneer 3151 Veneer sheets and sheets for plywood… Juglans Nigra L. FSC Controlled Wood 18

2. Scope of Co. C System 2. 1 Product Groups Specify the following details for each product group (2. 1. 2) • Material categories used as inputs [Stay tuned for details] • Control system used for making FSC claims: Transfer System • Percentage System • Credit System • [Stay tuned for details] • Sites involved in management, production, storage… [Note: this info NOT required in product group schedule but shall be clearly communicated to the CB] 19

2. Scope of Co. C System 2. 1 Product Groups Specify the following details for each product group (2. 1. 2) • Material categories used as inputs [Stay tuned for details] • Control system used for making FSC claims: Transfer System • Percentage System • Credit System • [Stay tuned for details] • Sites involved in management, production, storage… [Note: this info NOT required in product group schedule but shall be clearly communicated to the CB] 19

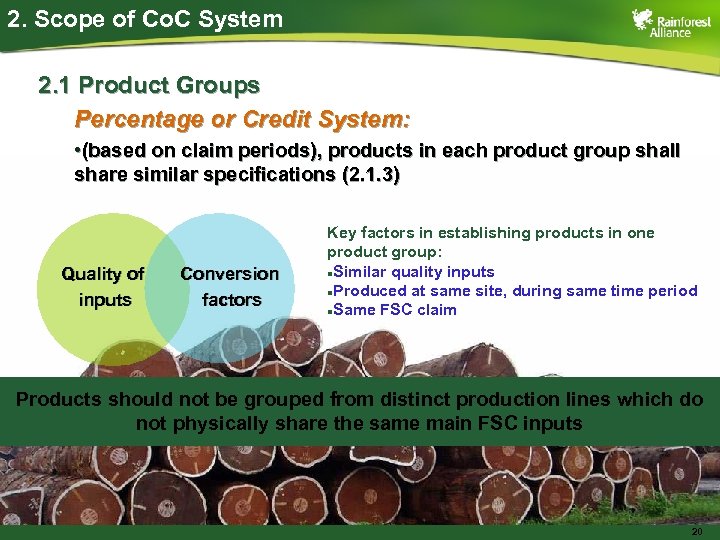

2. Scope of Co. C System 2. 1 Product Groups Percentage or Credit System: • (based on claim periods), products in each product group shall share similar specifications (2. 1. 3) Quality of inputs Conversion factors Key factors in establishing products in one product group: n. Similar quality inputs n. Produced at same site, during same time period n. Same FSC claim Products should not be grouped from distinct production lines which do not physically share the same main FSC inputs 20

2. Scope of Co. C System 2. 1 Product Groups Percentage or Credit System: • (based on claim periods), products in each product group shall share similar specifications (2. 1. 3) Quality of inputs Conversion factors Key factors in establishing products in one product group: n. Similar quality inputs n. Produced at same site, during same time period n. Same FSC claim Products should not be grouped from distinct production lines which do not physically share the same main FSC inputs 20

FSC Product Group Exercises LINKS TO EXERCISE 21

FSC Product Group Exercises LINKS TO EXERCISE 21

![2. Scope of Co. C System 2. 2 Outsourcing [Stay tuned for details] • 2. Scope of Co. C System 2. 2 Outsourcing [Stay tuned for details] •](https://present5.com/presentation/e2b9c967689cf1c5d99774db30f5aa11/image-22.jpg) 2. Scope of Co. C System 2. 2 Outsourcing [Stay tuned for details] • Outsourcing requirements specified in section 12 of the standard shall be followed (2. 2. 1) [Note: Outsourcing shall be included in the scope of the certificate as audited and approved by the CB] 22

2. Scope of Co. C System 2. 2 Outsourcing [Stay tuned for details] • Outsourcing requirements specified in section 12 of the standard shall be followed (2. 2. 1) [Note: Outsourcing shall be included in the scope of the certificate as audited and approved by the CB] 22

3. Material Sourcing System for ensuring inputs are eligible for use in FSC product groups 23

3. Material Sourcing System for ensuring inputs are eligible for use in FSC product groups 23

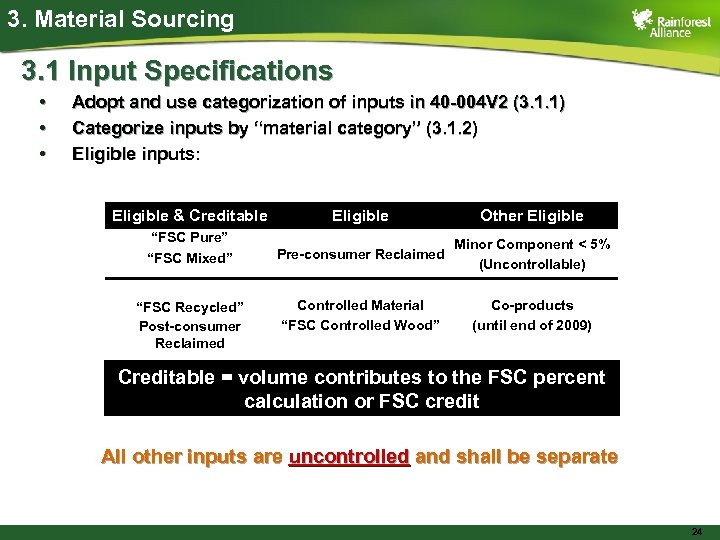

3. Material Sourcing 3. 1 Input Specifications • • • Adopt and use categorization of inputs in 40 -004 V 2 (3. 1. 1) Categorize inputs by “material category” (3. 1. 2) Eligible inputs: Eligible & Creditable Eligible Other Eligible “FSC Pure” “FSC Mixed” Pre-consumer Reclaimed Minor Component < 5% (Uncontrollable) Controlled Material “FSC Controlled Wood” Co-products (until end of 2009) “FSC Recycled” Post-consumer Reclaimed Creditable = volume contributes to the FSC percent calculation or FSC credit All other inputs are uncontrolled and shall be separate 24

3. Material Sourcing 3. 1 Input Specifications • • • Adopt and use categorization of inputs in 40 -004 V 2 (3. 1. 1) Categorize inputs by “material category” (3. 1. 2) Eligible inputs: Eligible & Creditable Eligible Other Eligible “FSC Pure” “FSC Mixed” Pre-consumer Reclaimed Minor Component < 5% (Uncontrollable) Controlled Material “FSC Controlled Wood” Co-products (until end of 2009) “FSC Recycled” Post-consumer Reclaimed Creditable = volume contributes to the FSC percent calculation or FSC credit All other inputs are uncontrolled and shall be separate 24

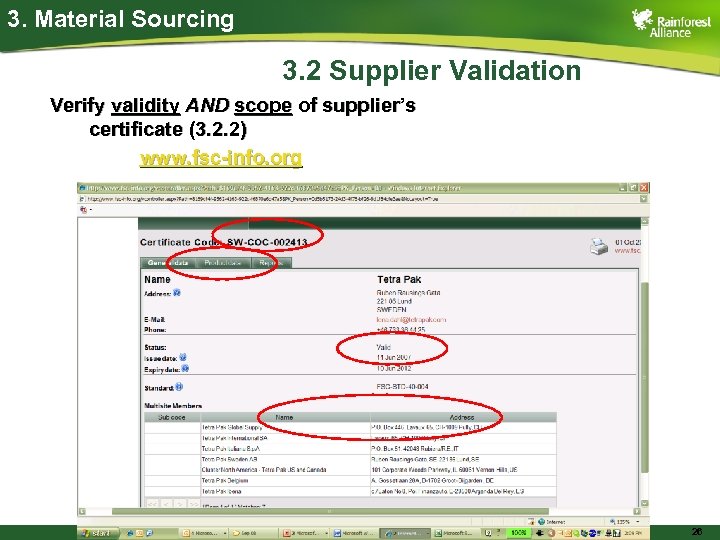

3. Material Sourcing 3. 2 Supplier Validation • Up-to-date record of suppliers with (3. 2. 1) • Product type per input (40 -004 a) • Material category per input • FSC Co. C or CW code • Verify validity AND scope of supplier’s certificate (3. 2. 2) • www. fsc-info. org 25

3. Material Sourcing 3. 2 Supplier Validation • Up-to-date record of suppliers with (3. 2. 1) • Product type per input (40 -004 a) • Material category per input • FSC Co. C or CW code • Verify validity AND scope of supplier’s certificate (3. 2. 2) • www. fsc-info. org 25

3. Material Sourcing 3. 2 Supplier Validation Verify validity AND scope of supplier’s certificate (3. 2. 2) www. fsc-info. org 26

3. Material Sourcing 3. 2 Supplier Validation Verify validity AND scope of supplier’s certificate (3. 2. 2) www. fsc-info. org 26

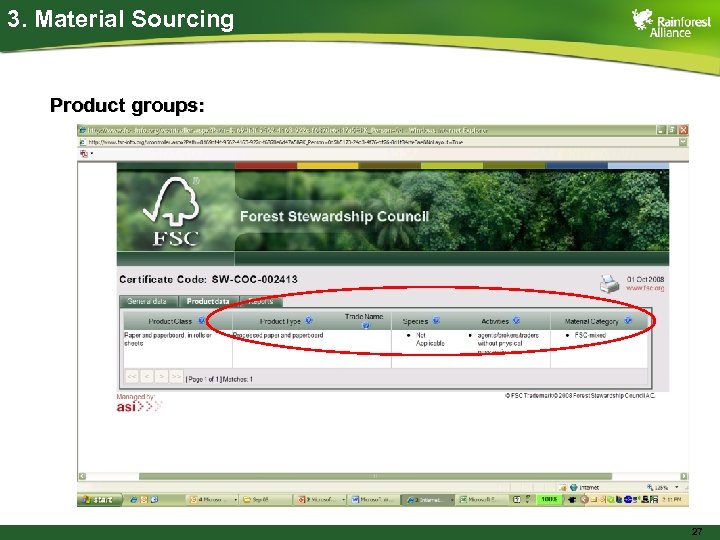

3. Material Sourcing Product groups: 27

3. Material Sourcing Product groups: 27

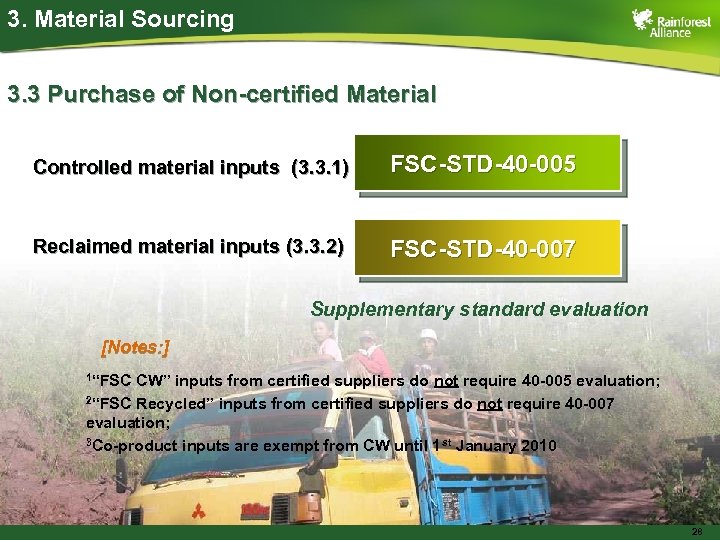

3. Material Sourcing 3. 3 Purchase of Non-certified Material Controlled material inputs (3. 3. 1) FSC-STD-40 -005 Reclaimed material inputs (3. 3. 2) FSC-STD-40 -007 Supplementary standard evaluation [Notes: ] 1“FSC CW” inputs from certified suppliers do not require 40 -005 evaluation; 2“FSC Recycled” inputs from certified suppliers do not require 40 -007 evaluation; 3 Co-product inputs are exempt from CW until 1 st January 2010 28

3. Material Sourcing 3. 3 Purchase of Non-certified Material Controlled material inputs (3. 3. 1) FSC-STD-40 -005 Reclaimed material inputs (3. 3. 2) FSC-STD-40 -007 Supplementary standard evaluation [Notes: ] 1“FSC CW” inputs from certified suppliers do not require 40 -005 evaluation; 2“FSC Recycled” inputs from certified suppliers do not require 40 -007 evaluation; 3 Co-product inputs are exempt from CW until 1 st January 2010 28

3. Material Sourcing 3. 4 Generating Raw Material On-site Inputs for FSC product groups that are generated at the Organization’s own site may be either (3. 4. 1) • Co-products (assigned to the original input material category) Material produced during the process of primary manufacturing of another (principal) product, from the same input. • Reclaimed material (assigned to the original input material category or classified as pre-consumer reclaimed) Material reclaimed from the process of secondary manufacture or further downstream which is not intentionally produced or is unfit for end use 29

3. Material Sourcing 3. 4 Generating Raw Material On-site Inputs for FSC product groups that are generated at the Organization’s own site may be either (3. 4. 1) • Co-products (assigned to the original input material category) Material produced during the process of primary manufacturing of another (principal) product, from the same input. • Reclaimed material (assigned to the original input material category or classified as pre-consumer reclaimed) Material reclaimed from the process of secondary manufacture or further downstream which is not intentionally produced or is unfit for end use 29

3. Material Sourcing 3. 4 Generating Raw Material On-site Mixtures from different material categories where proportions are not tracked shall be classified with the lowest FSC / Post-consumer input (3. 4. 2), e. g. , • • • FSC Mixed 30% + FSC Mixed 70% = FSC Mixed 30% FSC + reclaimed + CW = CW FSC + CW + uncontrolled = uncontrolled 30

3. Material Sourcing 3. 4 Generating Raw Material On-site Mixtures from different material categories where proportions are not tracked shall be classified with the lowest FSC / Post-consumer input (3. 4. 2), e. g. , • • • FSC Mixed 30% + FSC Mixed 70% = FSC Mixed 30% FSC + reclaimed + CW = CW FSC + CW + uncontrolled = uncontrolled 30

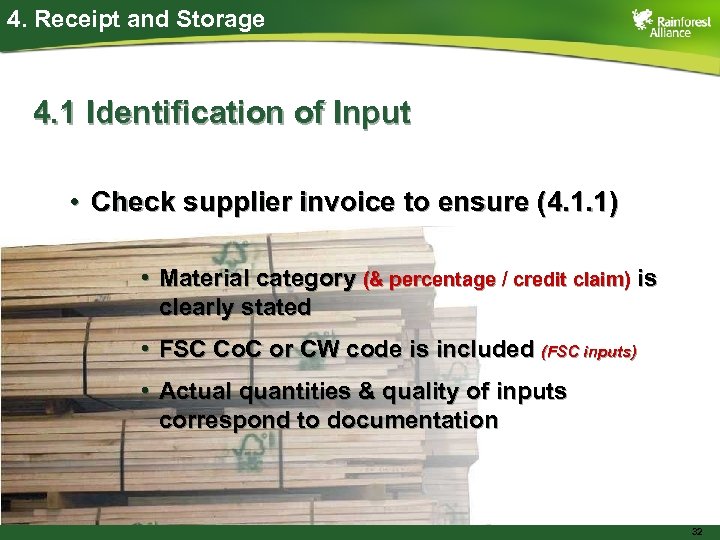

4. Receipt and Storage Inputs are eligible for FSC product groups Inputs are identifiable and segregated Mis-labeled products are not sold as such 31

4. Receipt and Storage Inputs are eligible for FSC product groups Inputs are identifiable and segregated Mis-labeled products are not sold as such 31

4. Receipt and Storage 4. 1 Identification of Input • Check supplier invoice to ensure (4. 1. 1) • Material category (& percentage / credit claim) is clearly stated • FSC Co. C or CW code is included (FSC inputs) • Actual quantities & quality of inputs correspond to documentation 32

4. Receipt and Storage 4. 1 Identification of Input • Check supplier invoice to ensure (4. 1. 1) • Material category (& percentage / credit claim) is clearly stated • FSC Co. C or CW code is included (FSC inputs) • Actual quantities & quality of inputs correspond to documentation 32

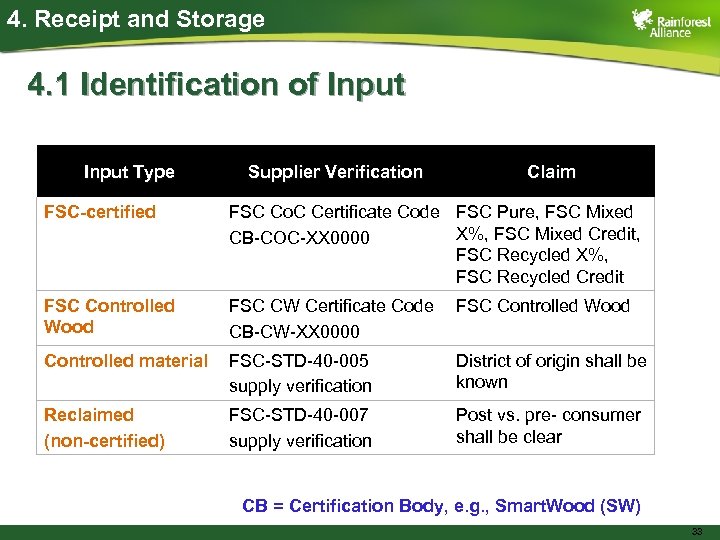

4. Receipt and Storage 4. 1 Identification of Input Type Supplier Verification Claim FSC-certified FSC Co. C Certificate Code FSC Pure, FSC Mixed X%, FSC Mixed Credit, CB-COC-XX 0000 FSC Recycled X%, FSC Recycled Credit FSC Controlled Wood FSC CW Certificate Code CB-CW-XX 0000 FSC Controlled Wood Controlled material FSC-STD-40 -005 supply verification District of origin shall be known Reclaimed (non-certified) FSC-STD-40 -007 supply verification Post vs. pre- consumer shall be clear CB = Certification Body, e. g. , Smart. Wood (SW) 33

4. Receipt and Storage 4. 1 Identification of Input Type Supplier Verification Claim FSC-certified FSC Co. C Certificate Code FSC Pure, FSC Mixed X%, FSC Mixed Credit, CB-COC-XX 0000 FSC Recycled X%, FSC Recycled Credit FSC Controlled Wood FSC CW Certificate Code CB-CW-XX 0000 FSC Controlled Wood Controlled material FSC-STD-40 -005 supply verification District of origin shall be known Reclaimed (non-certified) FSC-STD-40 -007 supply verification Post vs. pre- consumer shall be clear CB = Certification Body, e. g. , Smart. Wood (SW) 33

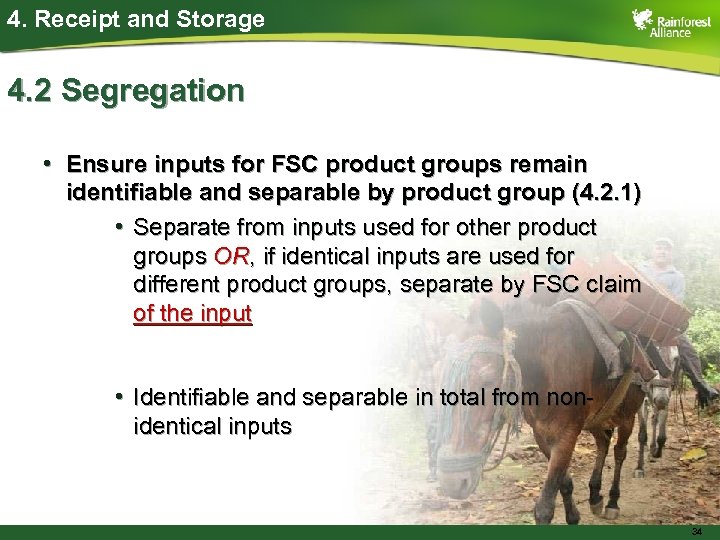

4. Receipt and Storage 4. 2 Segregation • Ensure inputs for FSC product groups remain identifiable and separable by product group (4. 2. 1) • Separate from inputs used for other product groups OR, if identical inputs are used for different product groups, separate by FSC claim of the input • Identifiable and separable in total from nonidentical inputs 34

4. Receipt and Storage 4. 2 Segregation • Ensure inputs for FSC product groups remain identifiable and separable by product group (4. 2. 1) • Separate from inputs used for other product groups OR, if identical inputs are used for different product groups, separate by FSC claim of the input • Identifiable and separable in total from nonidentical inputs 34

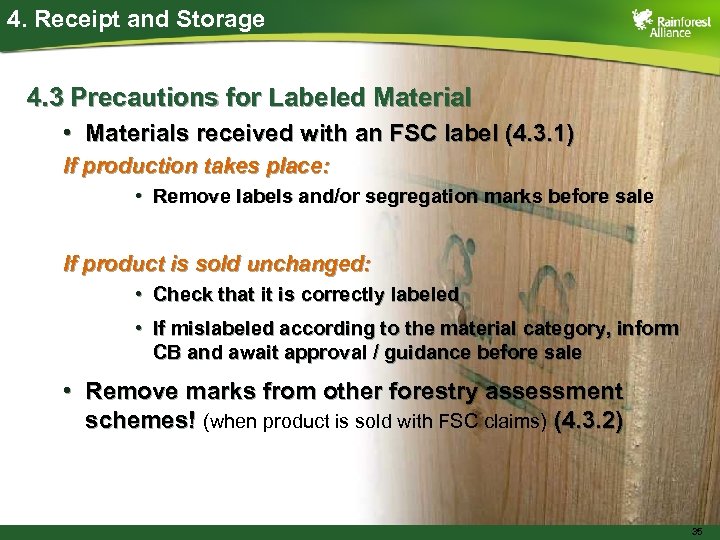

4. Receipt and Storage 4. 3 Precautions for Labeled Material • Materials received with an FSC label (4. 3. 1) If production takes place: • Remove labels and/or segregation marks before sale If product is sold unchanged: • Check that it is correctly labeled • If mislabeled according to the material category, inform CB and await approval / guidance before sale • Remove marks from other forestry assessment schemes! (when product is sold with FSC claims) (4. 3. 2) 35

4. Receipt and Storage 4. 3 Precautions for Labeled Material • Materials received with an FSC label (4. 3. 1) If production takes place: • Remove labels and/or segregation marks before sale If product is sold unchanged: • Check that it is correctly labeled • If mislabeled according to the material category, inform CB and await approval / guidance before sale • Remove marks from other forestry assessment schemes! (when product is sold with FSC claims) (4. 3. 2) 35

5. Volume Control Records for: Conversion factors Complete quantity information Volume summary 36

5. Volume Control Records for: Conversion factors Complete quantity information Volume summary 36

5. Volume Control 5. 1 Conversion Factors • Identify the main processing steps with conversion of materials (5. 1. 1) • Identify the conversion factor (CF) for each processing step OR the CF for total product transformation (5. 1. 1) • Specify the methodology for calculating conversion factors (5. 1. 2) Conversion is loss of input materials during product transformation; CF = output / input 37

5. Volume Control 5. 1 Conversion Factors • Identify the main processing steps with conversion of materials (5. 1. 1) • Identify the conversion factor (CF) for each processing step OR the CF for total product transformation (5. 1. 1) • Specify the methodology for calculating conversion factors (5. 1. 2) Conversion is loss of input materials during product transformation; CF = output / input 37

5. Volume Control 5. 2 Material Balances Records for quantity of inputs and material categories correspond with records for quantity of outputs and FSC claims • Records shall be available at all times per product group (5. 2. 1) INPUTS • Quantity of inputs • Supplier invoice references • Material category, percentage / credit claim OUTPUTS • Quantity of outputs • FSC claim • Company invoice references • Identifier of product item on invoices • Claim period (or job order) 38

5. Volume Control 5. 2 Material Balances Records for quantity of inputs and material categories correspond with records for quantity of outputs and FSC claims • Records shall be available at all times per product group (5. 2. 1) INPUTS • Quantity of inputs • Supplier invoice references • Material category, percentage / credit claim OUTPUTS • Quantity of outputs • FSC claim • Company invoice references • Identifier of product item on invoices • Claim period (or job order) 38

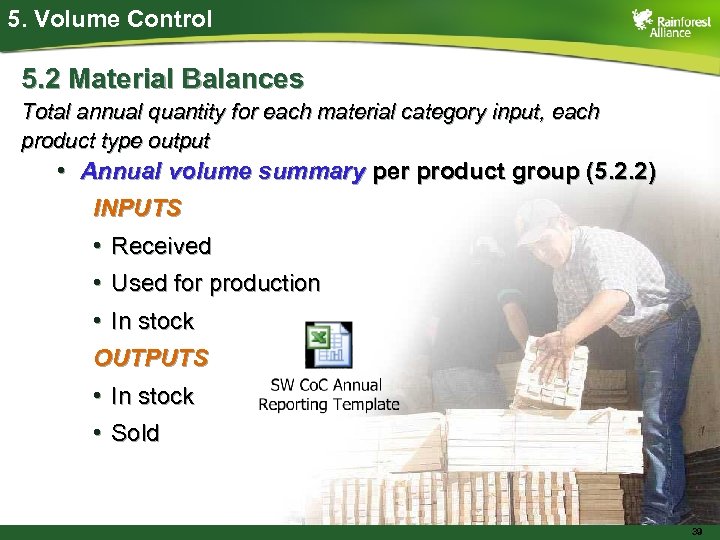

5. Volume Control 5. 2 Material Balances Total annual quantity for each material category input, each product type output • Annual volume summary per product group (5. 2. 2) INPUTS • Received • Used for production • In stock OUTPUTS • In stock • Sold 39

5. Volume Control 5. 2 Material Balances Total annual quantity for each material category input, each product type output • Annual volume summary per product group (5. 2. 2) INPUTS • Received • Used for production • In stock OUTPUTS • In stock • Sold 39

5. Volume Control 5. 3 Determination of FSC Claims • Determine for each claim period (or job order) the FSC claim according to 1 of the 3 control systems (5. 3. 1) Transfer System Percentage System Credit System 40

5. Volume Control 5. 3 Determination of FSC Claims • Determine for each claim period (or job order) the FSC claim according to 1 of the 3 control systems (5. 3. 1) Transfer System Percentage System Credit System 40

6. Sales and Delivery Requirements for selling FSC product groups (FSC claims during sales) 41

6. Sales and Delivery Requirements for selling FSC product groups (FSC claims during sales) 41

6. Sales and Delivery 6. 1 Identification of Outputs sold with FSC Claims • Basics of the invoice requirements (6. 1. 1) • Organization name and contact details • Customer name and address • Invoice issue date • Product description • Quantity of product • FSC Co. C or CW code • FSC claim • Transport documents and invoices shall be linked 42

6. Sales and Delivery 6. 1 Identification of Outputs sold with FSC Claims • Basics of the invoice requirements (6. 1. 1) • Organization name and contact details • Customer name and address • Invoice issue date • Product description • Quantity of product • FSC Co. C or CW code • FSC claim • Transport documents and invoices shall be linked 42

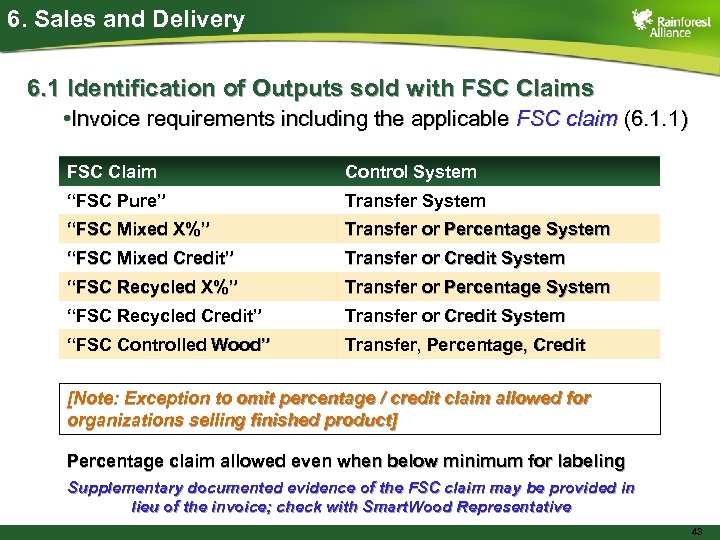

6. Sales and Delivery 6. 1 Identification of Outputs sold with FSC Claims • Invoice requirements including the applicable FSC claim (6. 1. 1) FSC Claim Control System “FSC Pure” Transfer System “FSC Mixed X%” Transfer or Percentage System “FSC Mixed Credit” Transfer or Credit System “FSC Recycled X%” Transfer or Percentage System “FSC Recycled Credit” Transfer or Credit System “FSC Controlled Wood” Transfer, Percentage, Credit [Note: Exception to omit percentage / credit claim allowed for organizations selling finished product] Percentage claim allowed even when below minimum for labeling Supplementary documented evidence of the FSC claim may be provided in lieu of the invoice; check with Smart. Wood Representative 43

6. Sales and Delivery 6. 1 Identification of Outputs sold with FSC Claims • Invoice requirements including the applicable FSC claim (6. 1. 1) FSC Claim Control System “FSC Pure” Transfer System “FSC Mixed X%” Transfer or Percentage System “FSC Mixed Credit” Transfer or Credit System “FSC Recycled X%” Transfer or Percentage System “FSC Recycled Credit” Transfer or Credit System “FSC Controlled Wood” Transfer, Percentage, Credit [Note: Exception to omit percentage / credit claim allowed for organizations selling finished product] Percentage claim allowed even when below minimum for labeling Supplementary documented evidence of the FSC claim may be provided in lieu of the invoice; check with Smart. Wood Representative 43

6. Sales and Delivery 6. 1 Identification of Outputs sold with FSC Claims (continued) Shipping / Transport Documents • If invoice does not go with the shipment, transport documents shall include all required details (6. 1. 2) Minor Components GREATER than 1% (but less than 5%): • For semi-finished products, the quantity of minor components shall be specified on the invoice (6. 1. 3) 44

6. Sales and Delivery 6. 1 Identification of Outputs sold with FSC Claims (continued) Shipping / Transport Documents • If invoice does not go with the shipment, transport documents shall include all required details (6. 1. 2) Minor Components GREATER than 1% (but less than 5%): • For semi-finished products, the quantity of minor components shall be specified on the invoice (6. 1. 3) 44

6. Sales and Delivery 6. 2 Labeling of Products sold with FSC Claims • Ensure FSC-labeled products include the corresponding FSC claim on the invoice (6. 2. 1) • Ensure product does not include marks of other forestry assessment schemes when sold with an FSC claim on invoice (6. 2. 2) 6. 3 Supplying FSC Controlled Wood • FSC-STD-40 -005, Parts 4 & Annex 4 evaluation required (6. 3. 1) 45

6. Sales and Delivery 6. 2 Labeling of Products sold with FSC Claims • Ensure FSC-labeled products include the corresponding FSC claim on the invoice (6. 2. 1) • Ensure product does not include marks of other forestry assessment schemes when sold with an FSC claim on invoice (6. 2. 2) 6. 3 Supplying FSC Controlled Wood • FSC-STD-40 -005, Parts 4 & Annex 4 evaluation required (6. 3. 1) 45

Part I: Universal Requirements Part II: Systems for Controlling FSC Claims Transfer System / Percentage System / Credit System Part III: Labeling Part IV: Supplementary Requirements At least one system is mandatory for all certificate scopes 46

Part I: Universal Requirements Part II: Systems for Controlling FSC Claims Transfer System / Percentage System / Credit System Part III: Labeling Part IV: Supplementary Requirements At least one system is mandatory for all certificate scopes 46

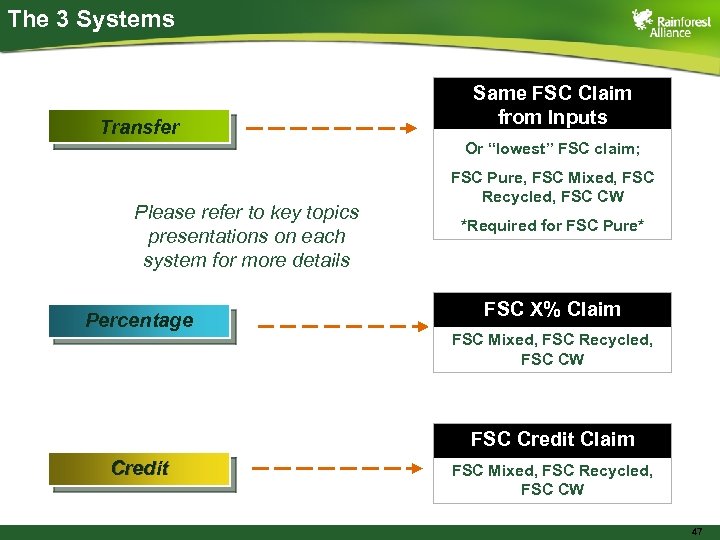

The 3 Systems Transfer Same FSC Claim from Inputs Or “lowest” FSC claim; Please refer to key topics presentations on each system for more details Percentage FSC Pure, FSC Mixed, FSC Recycled, FSC CW *Required for FSC Pure* FSC X% Claim FSC Mixed, FSC Recycled, FSC CW FSC Credit Claim Credit FSC Mixed, FSC Recycled, FSC CW 47

The 3 Systems Transfer Same FSC Claim from Inputs Or “lowest” FSC claim; Please refer to key topics presentations on each system for more details Percentage FSC Pure, FSC Mixed, FSC Recycled, FSC CW *Required for FSC Pure* FSC X% Claim FSC Mixed, FSC Recycled, FSC CW FSC Credit Claim Credit FSC Mixed, FSC Recycled, FSC CW 47

7. Transfer System Co. C System where: FSC product group claim = Input material category OR Inputs with different material categories are mixed Product Group carries lowest FSC claim • Required for trading of finished products • Required for FSC Pure & FSC Recycled 100% product groups • Segregation and identification required at all times 48

7. Transfer System Co. C System where: FSC product group claim = Input material category OR Inputs with different material categories are mixed Product Group carries lowest FSC claim • Required for trading of finished products • Required for FSC Pure & FSC Recycled 100% product groups • Segregation and identification required at all times 48

7. Transfer System 7. 1 Claim Periods or Job Orders • Claim Period = period of time specified for each product group for making an FSC claim; this is a period of time where ALL outputs are sold with the same FSC claim • Specify the claim period OR job order for each product group (7. 1. 1) Notes: [1 A claim period may be as short as the time period of a batch run (receipt, processing, labeling, transport, sale), but this time period shall be known] [2 Job order is used when FSC claims for the product are not continuous, e. g. , batch customer orders] 49

7. Transfer System 7. 1 Claim Periods or Job Orders • Claim Period = period of time specified for each product group for making an FSC claim; this is a period of time where ALL outputs are sold with the same FSC claim • Specify the claim period OR job order for each product group (7. 1. 1) Notes: [1 A claim period may be as short as the time period of a batch run (receipt, processing, labeling, transport, sale), but this time period shall be known] [2 Job order is used when FSC claims for the product are not continuous, e. g. , batch customer orders] 49

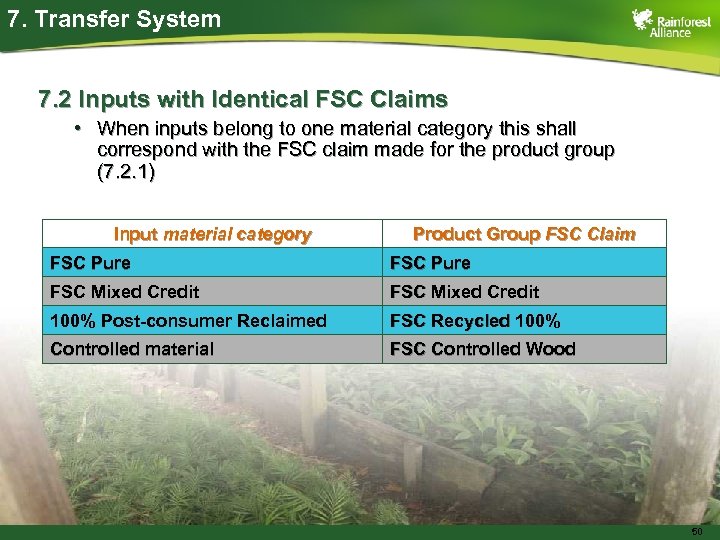

7. Transfer System 7. 2 Inputs with Identical FSC Claims • When inputs belong to one material category this shall correspond with the FSC claim made for the product group (7. 2. 1) Input material category Product Group FSC Claim FSC Pure FSC Mixed Credit 100% Post-consumer Reclaimed FSC Recycled 100% Controlled material FSC Controlled Wood 50

7. Transfer System 7. 2 Inputs with Identical FSC Claims • When inputs belong to one material category this shall correspond with the FSC claim made for the product group (7. 2. 1) Input material category Product Group FSC Claim FSC Pure FSC Mixed Credit 100% Post-consumer Reclaimed FSC Recycled 100% Controlled material FSC Controlled Wood 50

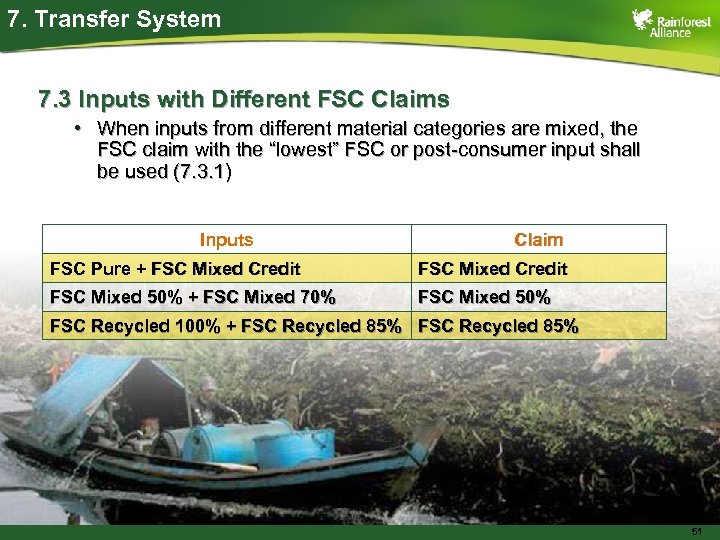

7. Transfer System 7. 3 Inputs with Different FSC Claims • When inputs from different material categories are mixed, the FSC claim with the “lowest” FSC or post-consumer input shall be used (7. 3. 1) Inputs Claim FSC Pure + FSC Mixed Credit FSC Mixed 50% + FSC Mixed 70% FSC Mixed 50% FSC Recycled 100% + FSC Recycled 85% 51

7. Transfer System 7. 3 Inputs with Different FSC Claims • When inputs from different material categories are mixed, the FSC claim with the “lowest” FSC or post-consumer input shall be used (7. 3. 1) Inputs Claim FSC Pure + FSC Mixed Credit FSC Mixed 50% + FSC Mixed 70% FSC Mixed 50% FSC Recycled 100% + FSC Recycled 85% 51

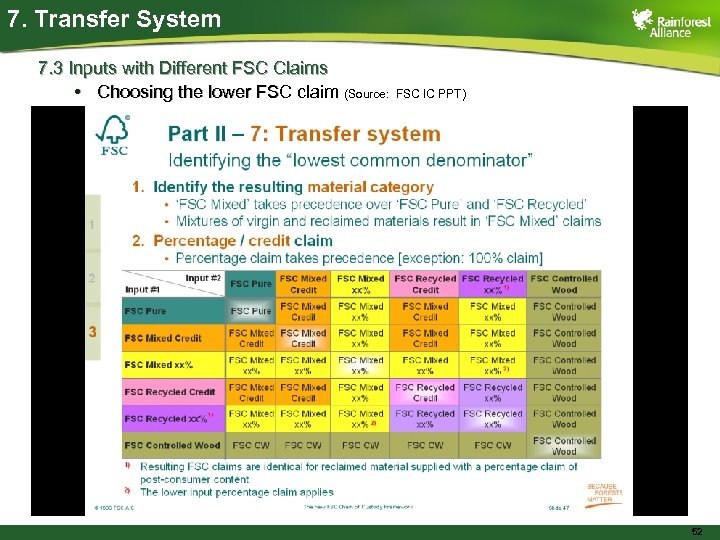

7. Transfer System 7. 3 Inputs with Different FSC Claims • Choosing the lower FSC claim (Source: FSC IC PPT) 52

7. Transfer System 7. 3 Inputs with Different FSC Claims • Choosing the lower FSC claim (Source: FSC IC PPT) 52

8. Percentage System Co. C System where: FSC product groups may be sold with a percentage claim that corresponds to the proportion of FSC and/or post-consumer reclaimed inputs over a period of time [Applicable to FSC Mixed and FSC Recycled product groups ] [Required at the level of a single, physical site] [Not applicable to trading of finished products] [FSC &/or Post-Consumer inputs count towards the FSC percentage] 53

8. Percentage System Co. C System where: FSC product groups may be sold with a percentage claim that corresponds to the proportion of FSC and/or post-consumer reclaimed inputs over a period of time [Applicable to FSC Mixed and FSC Recycled product groups ] [Required at the level of a single, physical site] [Not applicable to trading of finished products] [FSC &/or Post-Consumer inputs count towards the FSC percentage] 53

8. Percentage System 8. 1 Claim Periods or Job Orders Claim Period = period of time specified for each product group for making an FSC claim; this is a period of time where ALL outputs are sold with the same FSC claim • Specify the claim period OR job order for each FSC product group (8. 1. 1) Notes: [1 A claim period may be as short as the time period of a batch run (receipt, processing, labeling, transport, sale), but this time period shall be known] [2 Job order is used when FSC claims for the product are not continuous, e. g. , batch customer orders] [3 Time period over which the percentage is calculated shall not exceed 12 -months (8. 3. 3)] 54

8. Percentage System 8. 1 Claim Periods or Job Orders Claim Period = period of time specified for each product group for making an FSC claim; this is a period of time where ALL outputs are sold with the same FSC claim • Specify the claim period OR job order for each FSC product group (8. 1. 1) Notes: [1 A claim period may be as short as the time period of a batch run (receipt, processing, labeling, transport, sale), but this time period shall be known] [2 Job order is used when FSC claims for the product are not continuous, e. g. , batch customer orders] [3 Time period over which the percentage is calculated shall not exceed 12 -months (8. 3. 3)] 54

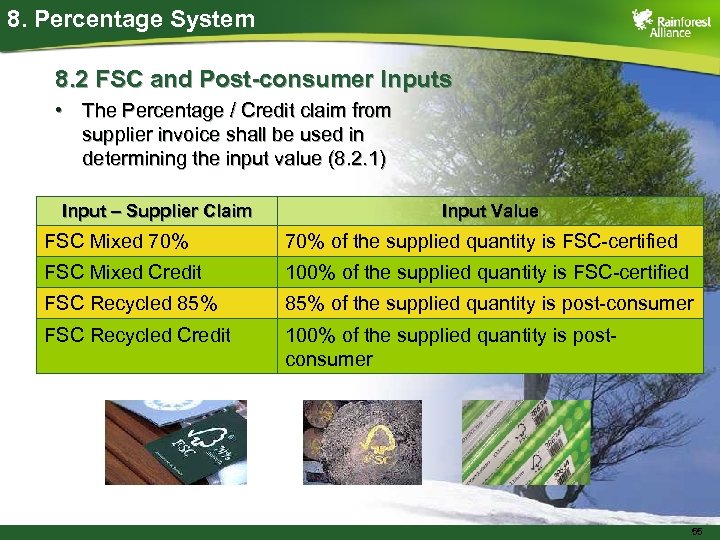

8. Percentage System 8. 2 FSC and Post-consumer Inputs • The Percentage / Credit claim from supplier invoice shall be used in determining the input value (8. 2. 1) Input – Supplier Claim Input Value FSC Mixed 70% of the supplied quantity is FSC-certified FSC Mixed Credit 100% of the supplied quantity is FSC-certified FSC Recycled 85% of the supplied quantity is post-consumer FSC Recycled Credit 100% of the supplied quantity is postconsumer 55

8. Percentage System 8. 2 FSC and Post-consumer Inputs • The Percentage / Credit claim from supplier invoice shall be used in determining the input value (8. 2. 1) Input – Supplier Claim Input Value FSC Mixed 70% of the supplied quantity is FSC-certified FSC Mixed Credit 100% of the supplied quantity is FSC-certified FSC Recycled 85% of the supplied quantity is post-consumer FSC Recycled Credit 100% of the supplied quantity is postconsumer 55

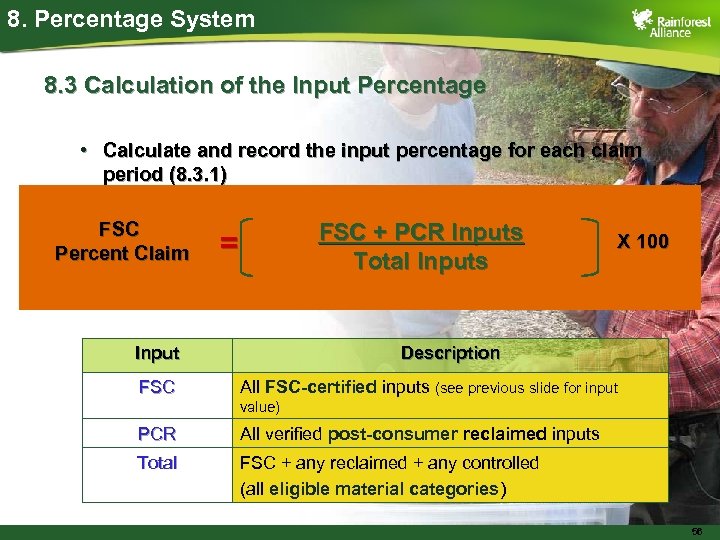

8. Percentage System 8. 3 Calculation of the Input Percentage • Calculate and record the input percentage for each claim period (8. 3. 1) FSC Percent Claim = Input FSC + PCR Inputs Total Inputs X 100 Description All FSC-certified inputs (see previous slide for input value) PCR All verified post-consumer reclaimed inputs Total FSC + any reclaimed + any controlled (all eligible material categories) 56

8. Percentage System 8. 3 Calculation of the Input Percentage • Calculate and record the input percentage for each claim period (8. 3. 1) FSC Percent Claim = Input FSC + PCR Inputs Total Inputs X 100 Description All FSC-certified inputs (see previous slide for input value) PCR All verified post-consumer reclaimed inputs Total FSC + any reclaimed + any controlled (all eligible material categories) 56

8. Percentage System 8. 3 Calculation of the Input Percentage • Option 1 • For each product group, calculate the input percentage based on inputs to the same claim period (a single percentage) (8. 3. 2) Claim periods may be Intermittent, or Consecutive, and May vary in length 57

8. Percentage System 8. 3 Calculation of the Input Percentage • Option 1 • For each product group, calculate the input percentage based on inputs to the same claim period (a single percentage) (8. 3. 2) Claim periods may be Intermittent, or Consecutive, and May vary in length 57

8. Percentage System 8. 3 Calculation of the Input Percentage • Option 2 • For each product group, calculate the input percentage based on inputs over a specified interval of time (rolling average) (8. 3. 2) Note: [FSC claims based on a rolling average calculation shall be made once the specified interval of time is complete; this is the claim period] Claim periods are consecutive, and Do not vary in length • Claim periods shall not exceed 12 -months unless otherwise warranted and approved by CB (8. 3. 3) 58

8. Percentage System 8. 3 Calculation of the Input Percentage • Option 2 • For each product group, calculate the input percentage based on inputs over a specified interval of time (rolling average) (8. 3. 2) Note: [FSC claims based on a rolling average calculation shall be made once the specified interval of time is complete; this is the claim period] Claim periods are consecutive, and Do not vary in length • Claim periods shall not exceed 12 -months unless otherwise warranted and approved by CB (8. 3. 3) 58

8. Percentage System 8. 4 FSC Claims for Outputs FSC Mixed • May sell total output with “FSC Mixed X%” percent claim at or lower than calculated for the claim period (8. 4. 1) FSC Recycled • May sell total output with “FSC Recycled X%” percent claim at or lower than calculated for the claim period (8. 4. 2) FSC Controlled Wood • May sell any output not sold with an FSC percent claim as “FSC Controlled Wood” (8. 4. 3) Note: [FSC X% claims can be made on invoices even when % is below minimum for FSC-labeling. ] 59

8. Percentage System 8. 4 FSC Claims for Outputs FSC Mixed • May sell total output with “FSC Mixed X%” percent claim at or lower than calculated for the claim period (8. 4. 1) FSC Recycled • May sell total output with “FSC Recycled X%” percent claim at or lower than calculated for the claim period (8. 4. 2) FSC Controlled Wood • May sell any output not sold with an FSC percent claim as “FSC Controlled Wood” (8. 4. 3) Note: [FSC X% claims can be made on invoices even when % is below minimum for FSC-labeling. ] 59

8. Percentage System 8. 5 Promotion of Products • FSC trademarks shall not be used for the promotion of products that do not meet the minimums for labeling (8. 5. 1) E. g. , A Chair is FSC Mixed 65%, company cannot produce literature regarding this chair and using the FSC logo 60

8. Percentage System 8. 5 Promotion of Products • FSC trademarks shall not be used for the promotion of products that do not meet the minimums for labeling (8. 5. 1) E. g. , A Chair is FSC Mixed 65%, company cannot produce literature regarding this chair and using the FSC logo 60

9. Credit System Co. C System where: FSC product groups may be sold with a credit claim that corresponds to the quantity of FSC and/or post-consumer reclaimed inputs recorded in a credit account [Applicable to FSC Mixed and FSC Recycled product groups] [Credit is based on inputs times the conversion factor] [Not applicable to printers or trading of finished products] [Shall be applied at a single, physical site] [FSC + PCR contribute to the FSC credit] PCR = Post-consumer Reclaimed 61

9. Credit System Co. C System where: FSC product groups may be sold with a credit claim that corresponds to the quantity of FSC and/or post-consumer reclaimed inputs recorded in a credit account [Applicable to FSC Mixed and FSC Recycled product groups] [Credit is based on inputs times the conversion factor] [Not applicable to printers or trading of finished products] [Shall be applied at a single, physical site] [FSC + PCR contribute to the FSC credit] PCR = Post-consumer Reclaimed 61

9. Credit System 9. 1 Specification of Claim Periods The Claim Period under a credit system is a defined time period for updating the credit account • Maintain a credit account per product group with specified claim period up to 3 months to which additions and deductions are recorded (9. 1. 1) 62

9. Credit System 9. 1 Specification of Claim Periods The Claim Period under a credit system is a defined time period for updating the credit account • Maintain a credit account per product group with specified claim period up to 3 months to which additions and deductions are recorded (9. 1. 1) 62

9. Credit System 9. 2 FSC and Post-consumer Inputs • The Percentage / Credit claim from supplier invoice shall be used in determining the input value (9. 2. 1) Input Supplier FSC Claim Input to Credit Account FSC Mixed 70% of supplied quantity added as FSC credit FSC Mixed Credit 100% of supplied quantity added as FSC credit FSC Recycled 85% of supplied quantity added as FSC credit FSC Recycled Credit 100% of supplied quantity added as FSC credit 63

9. Credit System 9. 2 FSC and Post-consumer Inputs • The Percentage / Credit claim from supplier invoice shall be used in determining the input value (9. 2. 1) Input Supplier FSC Claim Input to Credit Account FSC Mixed 70% of supplied quantity added as FSC credit FSC Mixed Credit 100% of supplied quantity added as FSC credit FSC Recycled 85% of supplied quantity added as FSC credit FSC Recycled Credit 100% of supplied quantity added as FSC credit 63

9. Credit System 9. 3 Adding FSC Credit to the Credit Account • The converted quantity of FSC/PC inputs shall be added to the credit account, using the C. F. specified for each component (9. 3. 1) FSC credit shall be added to the account AFTER ownership taken AND material category is verified, and BEFORE material enters the product process (9. 3. 2) • 64

9. Credit System 9. 3 Adding FSC Credit to the Credit Account • The converted quantity of FSC/PC inputs shall be added to the credit account, using the C. F. specified for each component (9. 3. 1) FSC credit shall be added to the account AFTER ownership taken AND material category is verified, and BEFORE material enters the product process (9. 3. 2) • 64

9. Credit System 9. 4 Withdrawing FSC Credit from the Credit Account • When product is sold or labeled with FSC claim, quantity shall be deducted from the account (9. 4. 1) 65

9. Credit System 9. 4 Withdrawing FSC Credit from the Credit Account • When product is sold or labeled with FSC claim, quantity shall be deducted from the account (9. 4. 1) 65

9. Credit System 9. 5 Credit Account Management • Ensure the credit account is never overdrawn and records of available credit are visible to relevant staff and up-todate (9. 5. 1) • Credit that exceeds the total FSC credit added during the last 12 -months shall be deducted (12 -month expiration). Excess FSC credit shall be deducted at start of new claim period (9. 5. 2) 66

9. Credit System 9. 5 Credit Account Management • Ensure the credit account is never overdrawn and records of available credit are visible to relevant staff and up-todate (9. 5. 1) • Credit that exceeds the total FSC credit added during the last 12 -months shall be deducted (12 -month expiration). Excess FSC credit shall be deducted at start of new claim period (9. 5. 2) 66

9. Credit System 9. 6 FSC Claims for Outputs FSC Mixed • May sell FSC Mixed product group with “FSC Mixed Credit” claim up to total FSC credit available (9. 6. 1) FSC Recycled • May sell FSC Recycled product group with “FSC Recycled Credit” claim up to total FSC credit available (9. 6. 2) FSC Controlled Wood • May sell FSC product group not sold with an FSC credit claim as “FSC Controlled Wood” when an FSC CW credit account is maintained (9. 6. 3) 67

9. Credit System 9. 6 FSC Claims for Outputs FSC Mixed • May sell FSC Mixed product group with “FSC Mixed Credit” claim up to total FSC credit available (9. 6. 1) FSC Recycled • May sell FSC Recycled product group with “FSC Recycled Credit” claim up to total FSC credit available (9. 6. 2) FSC Controlled Wood • May sell FSC product group not sold with an FSC credit claim as “FSC Controlled Wood” when an FSC CW credit account is maintained (9. 6. 3) 67

Part I: Universal Requirements Part II: Systems for Controlling FSC Claims Part III: Labeling Part IV: Supplementary Requirements Optional, but required when part of certificate scope 68

Part I: Universal Requirements Part II: Systems for Controlling FSC Claims Part III: Labeling Part IV: Supplementary Requirements Optional, but required when part of certificate scope 68

10. General Labeling Requirements 10. 1 Application of FSC Labels • Ensure the following when FSC label is applied to products (10. 1. 1) • Products shall only be labeled if they comply with the applicable standard requirements; • Labeling shall be in compliance with FSC-STD-40 -201 69

10. General Labeling Requirements 10. 1 Application of FSC Labels • Ensure the following when FSC label is applied to products (10. 1. 1) • Products shall only be labeled if they comply with the applicable standard requirements; • Labeling shall be in compliance with FSC-STD-40 -201 69

11. Eligibility for Labeling 70

11. Eligibility for Labeling 70

11. Eligibility for Labeling 11. 1 FSC ‘ 100%’ Label • All products from FSC Pure product groups may carry the FSC 100% label (11. 1. 1) 71

11. Eligibility for Labeling 11. 1 FSC ‘ 100%’ Label • All products from FSC Pure product groups may carry the FSC 100% label (11. 1. 1) 71

11. Eligibility for Labeling 11. 2 FSC ‘Mixed Sources’ Label • Transfer and Percentage System • • FSC/PCR > 70% (11. 2. 1, 11. 2. 2) FSC/PCR > 50% for chip/fiber until end of 2009 (FSC-ADV-40 -004) 72

11. Eligibility for Labeling 11. 2 FSC ‘Mixed Sources’ Label • Transfer and Percentage System • • FSC/PCR > 70% (11. 2. 1, 11. 2. 2) FSC/PCR > 50% for chip/fiber until end of 2009 (FSC-ADV-40 -004) 72

11. Eligibility for Labeling 11. 2 FSC ‘Mixed Sources’ Label, continued Transfer System • Inputs carry an FSC Mixed Credit claim (11. 2. 1) Credit System Sufficient FSC credit in the account (11. 2. 3) Note: [the respective quantity shall be deducted from the credit account] • 73

11. Eligibility for Labeling 11. 2 FSC ‘Mixed Sources’ Label, continued Transfer System • Inputs carry an FSC Mixed Credit claim (11. 2. 1) Credit System Sufficient FSC credit in the account (11. 2. 3) Note: [the respective quantity shall be deducted from the credit account] • 73

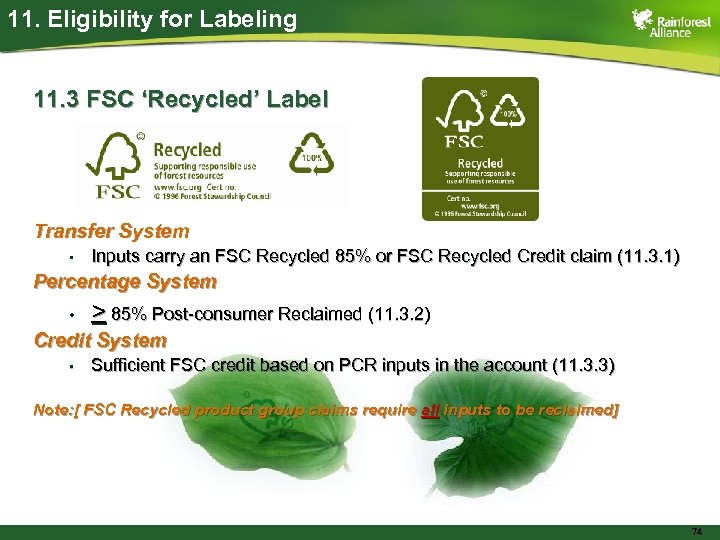

11. Eligibility for Labeling 11. 3 FSC ‘Recycled’ Label Transfer System • Inputs carry an FSC Recycled 85% or FSC Recycled Credit claim (11. 3. 1) Percentage System • > 85% Post-consumer Reclaimed (11. 3. 2) Credit System • Sufficient FSC credit based on PCR inputs in the account (11. 3. 3) Note: [ FSC Recycled product group claims require all inputs to be reclaimed] 74

11. Eligibility for Labeling 11. 3 FSC ‘Recycled’ Label Transfer System • Inputs carry an FSC Recycled 85% or FSC Recycled Credit claim (11. 3. 1) Percentage System • > 85% Post-consumer Reclaimed (11. 3. 2) Credit System • Sufficient FSC credit based on PCR inputs in the account (11. 3. 3) Note: [ FSC Recycled product group claims require all inputs to be reclaimed] 74

11. Eligibility for Labeling The “Minimum Elements” Label Mixed Sources Cert no. SW-COC-00 XXXX © FSC 1996 Recycled Cert no. SW-COC-00 XXXX © FSC 1996 • May be approved at the TSP’s discretion when the company demonstrates the full label will not fit • Printers may use as a matter of default • Used when there is no official FSC label that applies: • PCR + CW 85% • FSC Recycled X%/Credit NB: the recycled % in the moebius loop (when included) always refers to post-consumer reclaimed content 75

11. Eligibility for Labeling The “Minimum Elements” Label Mixed Sources Cert no. SW-COC-00 XXXX © FSC 1996 Recycled Cert no. SW-COC-00 XXXX © FSC 1996 • May be approved at the TSP’s discretion when the company demonstrates the full label will not fit • Printers may use as a matter of default • Used when there is no official FSC label that applies: • PCR + CW 85% • FSC Recycled X%/Credit NB: the recycled % in the moebius loop (when included) always refers to post-consumer reclaimed content 75

Part I: Universal Requirements Part II: Systems for Controlling FSC Claims Part III: Labeling Part IV: Supplementary Requirements Outsourcing / Minor Components Optional, but required when part of certificate scope 76

Part I: Universal Requirements Part II: Systems for Controlling FSC Claims Part III: Labeling Part IV: Supplementary Requirements Outsourcing / Minor Components Optional, but required when part of certificate scope 76

12. Outsourcing Applies to Organizations when some or all of its FSC product group activities are outsourced [Outsourcing shall be approved in the certificate scope prior to implementation] 77

12. Outsourcing Applies to Organizations when some or all of its FSC product group activities are outsourced [Outsourcing shall be approved in the certificate scope prior to implementation] 77

12. Outsourcing 12. 1 Pre-conditions for Outsourcing Ensure the following prior to outsourcing (12. 1. 1) • • • Organization maintains ownership of outsourced material; An agreement covers the outsourcing arrangement with each subcontractor and includes a clause for the right of the CB to audit the operation; Documented control system includes “explicit” procedures for the outsourcing process 78

12. Outsourcing 12. 1 Pre-conditions for Outsourcing Ensure the following prior to outsourcing (12. 1. 1) • • • Organization maintains ownership of outsourced material; An agreement covers the outsourcing arrangement with each subcontractor and includes a clause for the right of the CB to audit the operation; Documented control system includes “explicit” procedures for the outsourcing process 78

12. Outsourcing 12. 2 Maintaining Traceability and Paper Trails The Organization’s control system shall ensure (12. 2. 1) • • Materials for FSC product groups can be tracked and controlled AND cannot be contaminated with any other materials; Subcontractor maintains records of inputs, outputs, and delivery documents 79

12. Outsourcing 12. 2 Maintaining Traceability and Paper Trails The Organization’s control system shall ensure (12. 2. 1) • • Materials for FSC product groups can be tracked and controlled AND cannot be contaminated with any other materials; Subcontractor maintains records of inputs, outputs, and delivery documents 79

12. Outsourcing 12. 3 Records • Maintain record of the names and contact details of all subcontractors (12. 3. 1) • Organization shall inform CB of new subcontractors PRIOR to outsourcing (12. 3. 2) 12. 4 Invoicing • Organization shall issue the final invoice for the FSC product groups following outsourcing under normal sales requirements (12. 4. 1) 80

12. Outsourcing 12. 3 Records • Maintain record of the names and contact details of all subcontractors (12. 3. 1) • Organization shall inform CB of new subcontractors PRIOR to outsourcing (12. 3. 2) 12. 4 Invoicing • Organization shall issue the final invoice for the FSC product groups following outsourcing under normal sales requirements (12. 4. 1) 80

12. Outsourcing 12. 5 Labeling • Ensure subcontractor uses FSC labels only on those products covered by the outsourcing agreement (12. 5. 1) 12. 6 Promotion • Ensure subcontractor does not use the FSC trademarks for promotion (12. 6. 1) 12. 7 Preclusion of Subcontracting • Ensure subcontractors do not further outsource (12. 7. 1) 81

12. Outsourcing 12. 5 Labeling • Ensure subcontractor uses FSC labels only on those products covered by the outsourcing agreement (12. 5. 1) 12. 6 Promotion • Ensure subcontractor does not use the FSC trademarks for promotion (12. 6. 1) 12. 7 Preclusion of Subcontracting • Ensure subcontractors do not further outsource (12. 7. 1) 81

12. Outsourcing Audit Evaluation (FSC-STD-20 -011) CB shall conduct a risk assessment of the Co. C control system for the outsourcing arrangement. • High Risk = on-site audit sampling of subcontractors High Risk Outsourcing Arrangements Company outsources a wide range of production activities Company outsources to more than one subcontractor on a regular basis Subcontractor(s) grade and/or sort the material Subcontractor(s) apply FSC labels to the product Company does not take physical possession of the material after outsourcing Outsourcing takes place across national borders Other factors Smart. Wood deems high risk Sampling Equations (y = sample size & is rounded up, x = number of subcontractors) Assessment: y = x Annual Surveillance Audit: y = 0. 8 x Reassessment: y = 0. 8 x 82

12. Outsourcing Audit Evaluation (FSC-STD-20 -011) CB shall conduct a risk assessment of the Co. C control system for the outsourcing arrangement. • High Risk = on-site audit sampling of subcontractors High Risk Outsourcing Arrangements Company outsources a wide range of production activities Company outsources to more than one subcontractor on a regular basis Subcontractor(s) grade and/or sort the material Subcontractor(s) apply FSC labels to the product Company does not take physical possession of the material after outsourcing Outsourcing takes place across national borders Other factors Smart. Wood deems high risk Sampling Equations (y = sample size & is rounded up, x = number of subcontractors) Assessment: y = x Annual Surveillance Audit: y = 0. 8 x Reassessment: y = 0. 8 x 82

13. Minor Components Wood-based “components” excluded from eligible input requirements when they are less than 5% of the total product volume [Applies to FSC Pure and FSC Mixed product groups only] 83

13. Minor Components Wood-based “components” excluded from eligible input requirements when they are less than 5% of the total product volume [Applies to FSC Pure and FSC Mixed product groups only] 83

13. Minor Components 13. 1 Specification and Volume Control • Organization may specify minor components to be exempt from requirements for Co. C control and labeling (essentially exempt from CW) (13. 1. 1) • Shall not specify exempt minor components (13. 1. 2) • • • Solid wood veneer as visible face on other material; Species listed in CITES appendices I, III Shall demonstrate quantity of minor components is LESS than 5% of total product volume (13. 1. 3) 84

13. Minor Components 13. 1 Specification and Volume Control • Organization may specify minor components to be exempt from requirements for Co. C control and labeling (essentially exempt from CW) (13. 1. 1) • Shall not specify exempt minor components (13. 1. 2) • • • Solid wood veneer as visible face on other material; Species listed in CITES appendices I, III Shall demonstrate quantity of minor components is LESS than 5% of total product volume (13. 1. 3) 84

13. Minor Components 13. 2 Rationale and Action Plan < 1%: • In writing to CB, accurate and up-to-date justification why the material cannot be sourced as FSC-certified, controlled, or reclaimed (13. 2. 1) > 1% to < 5%: • Follow procedures in FSC-PRO-40 -004 for derogation application for submission to FSC (13. 2. 2) Notes: [derogation approval required prior to certificate scope covering the applicable products]; [if an FSC-certified Organization uses minor components > 1% without a derogation approval, immediate suspension is required. ] 85

13. Minor Components 13. 2 Rationale and Action Plan < 1%: • In writing to CB, accurate and up-to-date justification why the material cannot be sourced as FSC-certified, controlled, or reclaimed (13. 2. 1) > 1% to < 5%: • Follow procedures in FSC-PRO-40 -004 for derogation application for submission to FSC (13. 2. 2) Notes: [derogation approval required prior to certificate scope covering the applicable products]; [if an FSC-certified Organization uses minor components > 1% without a derogation approval, immediate suspension is required. ] 85

13. Minor Components 13. 3 On-product Declaration On-product statement shall be included on FSC-labeled products (13. 3. 1): • • Product includes components not covered by FSC claims, Visible minor components are described E. g. , FSC Mixed desk: Product includes wooden knobs that are not covered by the FSC Mixed Sources label 86

13. Minor Components 13. 3 On-product Declaration On-product statement shall be included on FSC-labeled products (13. 3. 1): • • Product includes components not covered by FSC claims, Visible minor components are described E. g. , FSC Mixed desk: Product includes wooden knobs that are not covered by the FSC Mixed Sources label 86

TOPICS 1 2 3 Supplementary Standards In Brief 87

TOPICS 1 2 3 Supplementary Standards In Brief 87

FSC-STD-40 -005 FSC Standard for Company Evaluation of FSC Controlled Wood Applicability: All Organization types Use of non-FSC virgin inputs in FSC product groups Supplying “FSC Controlled Wood” Requirements for controlling non-FSC inputs to avoid 5 specific categories unacceptable for use in FSC product groups [See separate Power. Point for complete requirements] 88

FSC-STD-40 -005 FSC Standard for Company Evaluation of FSC Controlled Wood Applicability: All Organization types Use of non-FSC virgin inputs in FSC product groups Supplying “FSC Controlled Wood” Requirements for controlling non-FSC inputs to avoid 5 specific categories unacceptable for use in FSC product groups [See separate Power. Point for complete requirements] 88

FSC-STD-40 -007 FSC Standard for Use of Reclaimed Material in FSC Product Groups and FSC-certified Projects Applicability: All Organization types Use of reclaimed inputs in FSC product groups Requirements for defining, purchasing, & verifying reclaimed inputs, including supplier audits [See separate Power. Point for complete requirements] 89

FSC-STD-40 -007 FSC Standard for Use of Reclaimed Material in FSC Product Groups and FSC-certified Projects Applicability: All Organization types Use of reclaimed inputs in FSC product groups Requirements for defining, purchasing, & verifying reclaimed inputs, including supplier audits [See separate Power. Point for complete requirements] 89

FSC-STD-40 -004 a Addendum to FSC Standard FSC-STD-40 -004 FSC Product Classification according to “product type” required for: • Defining FSC product groups • FSC product group schedule • Reporting annual volume summary • Certificate scope posted on www. fsc-info. org Product Class Product Type 314 Boards and panels 3141 Plywood consisting solely of sheets of wood 315 Veneer sheets, sheets for plywood 3151 Veneer sheets and sheets for plywood and other wood sawn lengthwise… 3211 b Paper and paperboard 3214 Processed paper and paperboard E X A M P L E S 90

FSC-STD-40 -004 a Addendum to FSC Standard FSC-STD-40 -004 FSC Product Classification according to “product type” required for: • Defining FSC product groups • FSC product group schedule • Reporting annual volume summary • Certificate scope posted on www. fsc-info. org Product Class Product Type 314 Boards and panels 3141 Plywood consisting solely of sheets of wood 315 Veneer sheets, sheets for plywood 3151 Veneer sheets and sheets for plywood and other wood sawn lengthwise… 3211 b Paper and paperboard 3214 Processed paper and paperboard E X A M P L E S 90

FSC-STD-40 -004 b Addendum to FSC Standard FSC-STD-40 -004 FSC Species Terminology Specification of species required in: • Defining FSC product groups that species composition is used to designate the product characteristics • FSC product group schedule per above • Certificate scope posted on www. fsc-info. org per above [Document includes scientific names, common names, divided by conifer and deciduous] 91

FSC-STD-40 -004 b Addendum to FSC Standard FSC-STD-40 -004 FSC Species Terminology Specification of species required in: • Defining FSC product groups that species composition is used to designate the product characteristics • FSC product group schedule per above • Certificate scope posted on www. fsc-info. org per above [Document includes scientific names, common names, divided by conifer and deciduous] 91

FSC-STD-40 -003 Standard for Multi-site Certification of Chain of Custody Operations For Organizations with a number of operational sites Requirements for “Central Office” management of the sites, including internal auditing [See separate Power. Point on Certificate Types for complete requirements] 92

FSC-STD-40 -003 Standard for Multi-site Certification of Chain of Custody Operations For Organizations with a number of operational sites Requirements for “Central Office” management of the sites, including internal auditing [See separate Power. Point on Certificate Types for complete requirements] 92

FSC-POL-40 -002 Group Chain of Custody (Co. C) Certification For Organizations made up of small enterprises Requirements for management of members, including internal auditing, by a designated Group Manager [See separate Power. Point on Certificate Types for complete requirements] 93

FSC-POL-40 -002 Group Chain of Custody (Co. C) Certification For Organizations made up of small enterprises Requirements for management of members, including internal auditing, by a designated Group Manager [See separate Power. Point on Certificate Types for complete requirements] 93

FSC-STD-40 -201 FSC On-product Labeling Requirements for FSC-Certified Organizations that wish to apply the FSC label on-product [See separate Power. Point for complete requirements] 94

FSC-STD-40 -201 FSC On-product Labeling Requirements for FSC-Certified Organizations that wish to apply the FSC label on-product [See separate Power. Point for complete requirements] 94

Thank You! 95

Thank You! 95