0446d1c2643cb2b59acef1076410990f.ppt

- Количество слайдов: 35

Vehicle Certification in Australia Peter Robertson Assistant Secretary Vehicle Safety Standards (Administrator of Vehicle Standards)

Vehicle Safety Standards (VSS) • A branch within the Commonwealth Department of Transport and Regional Services • Administers the Motor Vehicle Standards Act 1989 • 56 Staff

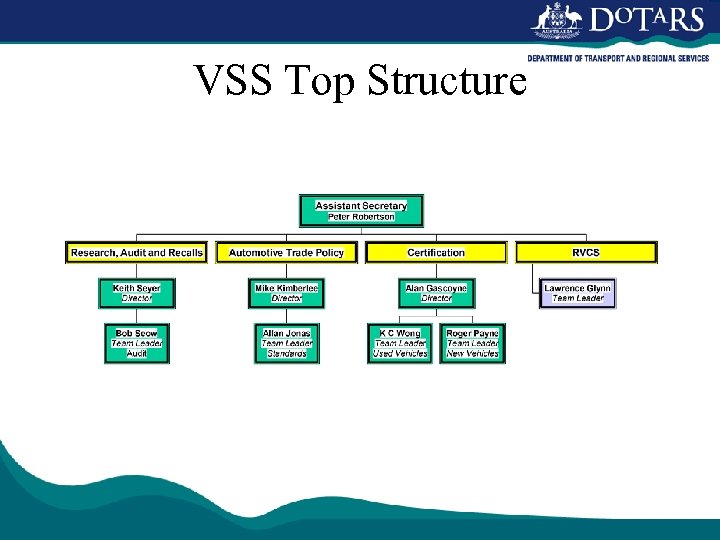

VSS Top Structure

Motor Vehicle Standards Act Uniform National Vehicle Standards which aim to: • make road vehicles safe to use; • control emissions from road vehicles; • secure road vehicles from theft.

Australia • A federation of six states and two territories • “Commonwealth” Government created in 1901 • Certain powers vested in the Commonwealth – remainder in states

Jurisdictional Responsibilities • Commonwealth - to point of first supply to the market • States and Territories - in-service regulation (vehicle registration, licensing, roadworthiness etc)

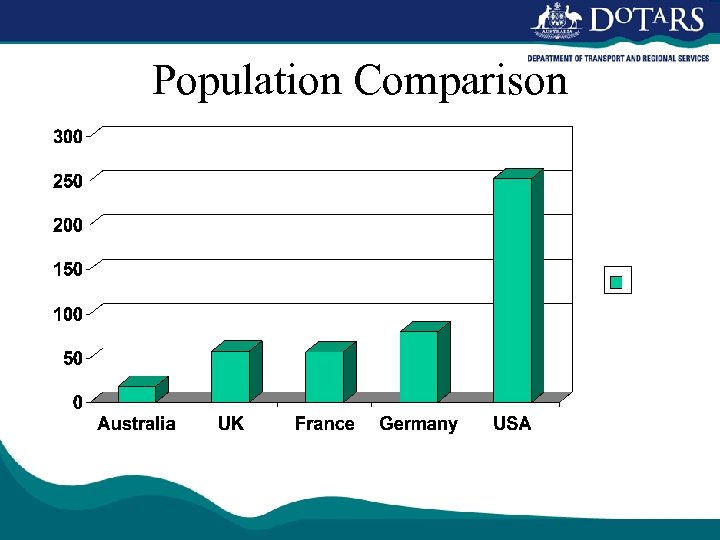

Australia • Small Population • 19 million

Population Comparison

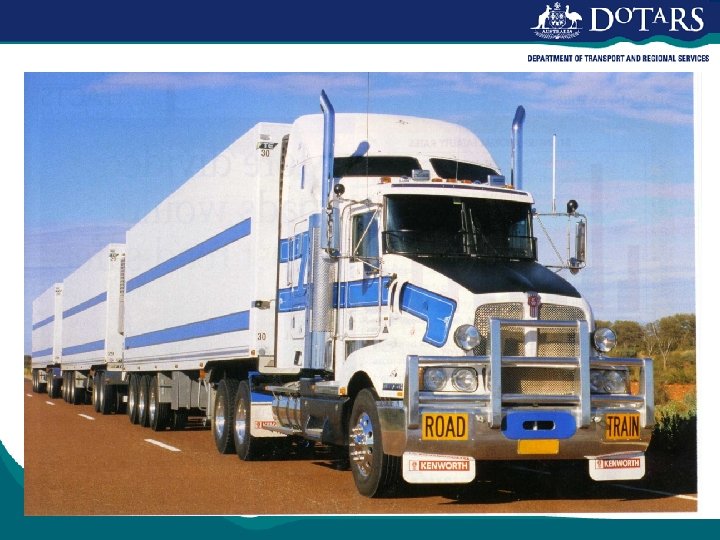

Australia • But large land mass…. .

ADRs - The Australian Design Rules • The national standards set under the Act, against which road vehicles, trailers and components are assessed • Progressively being reviewed • Policy intention to harmonise with ECE Regulations where possible

New and Amended ADRs • Justification via Regulation Impact statement • State and Territory agreement (two thirds majority) • This process is necessary before an ECE Regulation can be applied in Australian law

Supply to the Market • Requires an authority from the minister (Administrator of Vehicle Standards) • The authority is referred to as a Compliance Plate Approval

Certification Streams • Full volume - generally import or manufacture more than 100 vehicles per year. • Low Volume (Specialist and Enthusiast vehicle Scheme) – up to 100 vehicles per annum per vehicle category • Ultra Low Volume

Full Volume • Supply in unlimited numbers • Must meet all relevant ADRs • Full evidence • “Standard Vehicles”

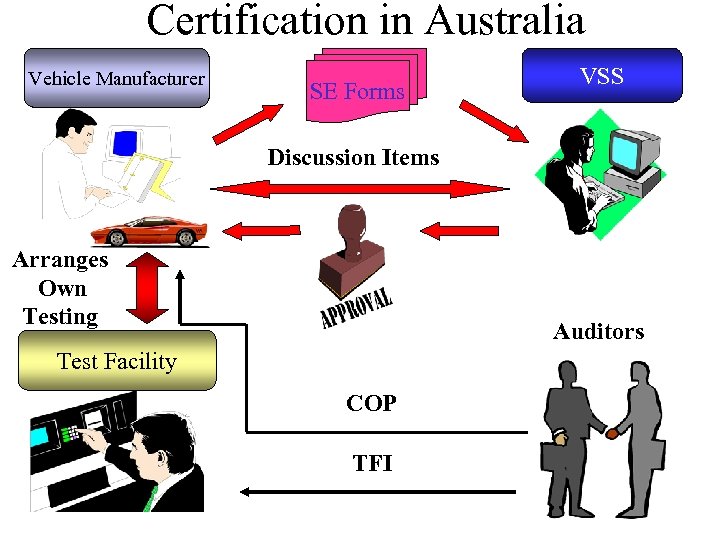

Certification in Australia • Type Approval System • Manufacturers arrange own testing • Evidence submitted in summary form electronically to VSS • Verification through conformity of production audit and test facility inspection

Certification in Australia Vehicle Manufacturer SE Forms VSS Discussion Items Arranges Own Testing Auditors Test Facility COP TFI

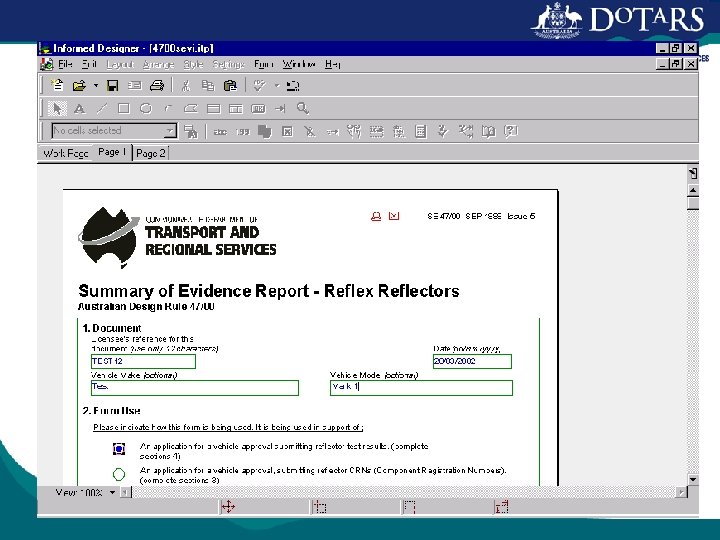

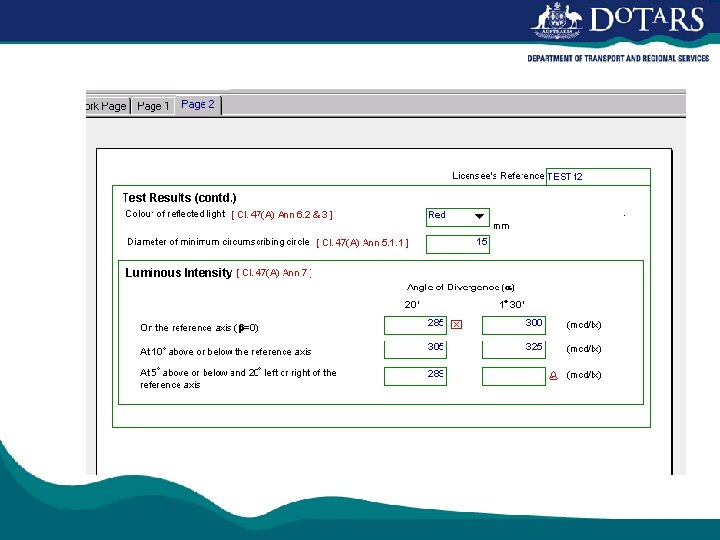

Test Results • The vehicle manufacturer sends a summary of the test results to VSS using a standard form, called a Summary of Evidence (SE) form • There is one SE form for each ADR • For some ADRs there is also a Selection from Fleet (SF) form which indicates which variant of a vehicle should be tested (worst case)

Electronic Processing • Electronic forms using a package called Informed Filler is used • Electronic forms allow VSS to collect the tests results electronically and enter the information directly into a database • They also provide VSS and the manufacturer an indication of errors on the form

Submitting Forms • The manufacturer arranges for testing to the appropriate ADRs and fills in the SE forms • When they are ready, the manufacturer attaches (electronically) the forms to a special form called a Routing Slip • The Routing Slip has a submit option which sends the forms to VSS via HTTP over the Internet

Receiving Forms • When received there is an automatic check of the manufacturer, the vehicle etc before the form is accepted • The forms are then unpacked from the Routing Slip and their details recorded in the database • If the form has any errors on it VSS marks the form for manual checking

Processing Forms • Any errors found on the form either manually or automatically, are reported back to the manufacturer by a Discussion Item • Discussion Items are automatically listed in a secure part of the Web site so that the manufacturer can see what errors have been found with their forms and follow the progress of the approval

Generating an Approval • When all the errors have been resolved, and the application has tests results for all appropriate ADRs a Compliance Plate Approval can be generated • The approval is printed and signed, but a notification is automatically sent to the manufacturer electronically

Rapid Response • If all the forms submitted are correct a new application from initial receipt to signed approval can be processed in less than half a day • Service standard is to complete process within 32 days from the last receipt of acceptable evidence • About 1500 approvals are issued each year using 7 staff

Productivity benefit • RVCS computer system has reduced the certification service standard from 90 to 32 working days • The average response time is 24 calendar days • The response time for the major category, passenger vehicles, has been around 6 calendar days

After the Approval • Once the Compliance Plate Approval is issued the manufacturer can supply vehicles to the market • Manufacturers are also required to provide a Road Vehicle Descriptor (RVD) which describes the vehicle and the various options/variants, including photographs • RVDs are publicly available on the Web site

Audit • Because the vehicle testing is not conducted by VSS, there is an audit program to inspect the test facilities used by the manufacturers • Manufacturer’s production and design facilities are also audited

Test Facility Inspection • 18 -24 month intervals • ISO Guide 25 as basis

Conformity of Production Audit • Audit of production process • Ensure ADR compliance • 18 -24 month intervals • ISO 9000 series as a guide

Discussion

0446d1c2643cb2b59acef1076410990f.ppt