017b90baca5e3901cf5d0f4fba328d67.ppt

- Количество слайдов: 16

Vacuum Systems H. C. Hseuh, Vacuum Group Leader 8 th ASAC Meeting for NSLS-II Project May 10 -11, 2011 1 BROOKHAVEN SCIENCE

Vacuum Systems H. C. Hseuh, Vacuum Group Leader 8 th ASAC Meeting for NSLS-II Project May 10 -11, 2011 1 BROOKHAVEN SCIENCE

Outline • • • Injector Vacuum Systems Storage Ring Vacuum Chambers • • Cell vacuum chamber layout Cell chamber cross sections Cell chamber fabrication and assembly S 4 A, S 5 A and fast corrector chambers Production of Absorbers and RF Shielded Bellows Procurement of Pumps, Valves and Instruments Summary 2 BROOKHAVEN SCIENCE

Outline • • • Injector Vacuum Systems Storage Ring Vacuum Chambers • • Cell vacuum chamber layout Cell chamber cross sections Cell chamber fabrication and assembly S 4 A, S 5 A and fast corrector chambers Production of Absorbers and RF Shielded Bellows Procurement of Pumps, Valves and Instruments Summary 2 BROOKHAVEN SCIENCE

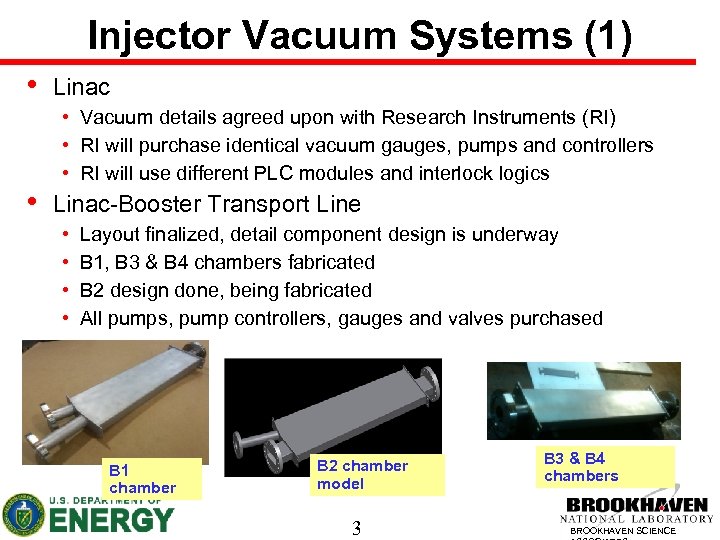

Injector Vacuum Systems (1) • • Linac • Vacuum details agreed upon with Research Instruments (RI) • RI will purchase identical vacuum gauges, pumps and controllers • RI will use different PLC modules and interlock logics Linac-Booster Transport Line • • Layout finalized, detail component design is underway B 1, B 3 & B 4 chambers fabricated B 2 design done, being fabricated All pumps, pump controllers, gauges and valves purchased B 1 chamber B 2 chamber model 3 B 3 & B 4 chambers BROOKHAVEN SCIENCE

Injector Vacuum Systems (1) • • Linac • Vacuum details agreed upon with Research Instruments (RI) • RI will purchase identical vacuum gauges, pumps and controllers • RI will use different PLC modules and interlock logics Linac-Booster Transport Line • • Layout finalized, detail component design is underway B 1, B 3 & B 4 chambers fabricated B 2 design done, being fabricated All pumps, pump controllers, gauges and valves purchased B 1 chamber B 2 chamber model 3 B 3 & B 4 chambers BROOKHAVEN SCIENCE

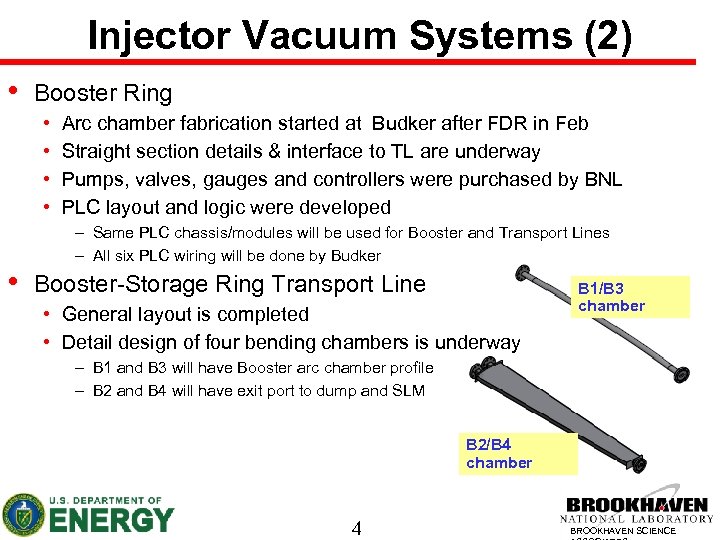

Injector Vacuum Systems (2) • Booster Ring • • • Arc chamber fabrication started at Budker after FDR in Feb Straight section details & interface to TL are underway Pumps, valves, gauges and controllers were purchased by BNL PLC layout and logic were developed – Same PLC chassis/modules will be used for Booster and Transport Lines – All six PLC wiring will be done by Budker Booster-Storage Ring Transport Line • General layout is completed • Detail design of four bending chambers is underway B 1/B 3 chamber – B 1 and B 3 will have Booster arc chamber profile – B 2 and B 4 will have exit port to dump and SLM B 2/B 4 chamber 4 BROOKHAVEN SCIENCE

Injector Vacuum Systems (2) • Booster Ring • • • Arc chamber fabrication started at Budker after FDR in Feb Straight section details & interface to TL are underway Pumps, valves, gauges and controllers were purchased by BNL PLC layout and logic were developed – Same PLC chassis/modules will be used for Booster and Transport Lines – All six PLC wiring will be done by Budker Booster-Storage Ring Transport Line • General layout is completed • Detail design of four bending chambers is underway B 1/B 3 chamber – B 1 and B 3 will have Booster arc chamber profile – B 2 and B 4 will have exit port to dump and SLM B 2/B 4 chamber 4 BROOKHAVEN SCIENCE

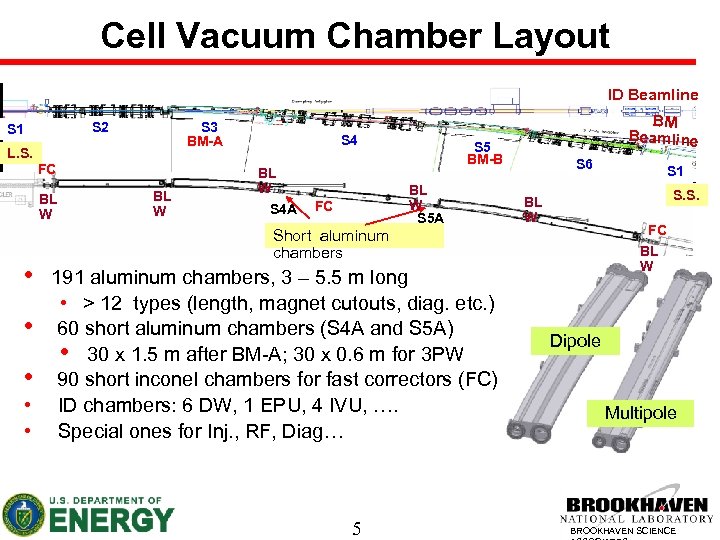

Cell Vacuum Chamber Layout ID Beamline S 2 S 1 S 3 BM-A L. S. FC BL W • BL W S 4 A S 5 BM-B BL W S 5 A FC BM Beamline S 6 S. S. BL W FC BL W Short aluminum chambers 191 aluminum chambers, 3 – 5. 5 m long • > 12 types (length, magnet cutouts, diag. etc. ) • 60 short aluminum chambers (S 4 A and S 5 A) • 30 x 1. 5 m after BM-A; 30 x 0. 6 m for 3 PW • 90 short inconel chambers for fast correctors (FC) • ID chambers: 6 DW, 1 EPU, 4 IVU, …. • Special ones for Inj. , RF, Diag… 5 S 1 Dipole Multipole BROOKHAVEN SCIENCE

Cell Vacuum Chamber Layout ID Beamline S 2 S 1 S 3 BM-A L. S. FC BL W • BL W S 4 A S 5 BM-B BL W S 5 A FC BM Beamline S 6 S. S. BL W FC BL W Short aluminum chambers 191 aluminum chambers, 3 – 5. 5 m long • > 12 types (length, magnet cutouts, diag. etc. ) • 60 short aluminum chambers (S 4 A and S 5 A) • 30 x 1. 5 m after BM-A; 30 x 0. 6 m for 3 PW • 90 short inconel chambers for fast correctors (FC) • ID chambers: 6 DW, 1 EPU, 4 IVU, …. • Special ones for Inj. , RF, Diag… 5 S 1 Dipole Multipole BROOKHAVEN SCIENCE

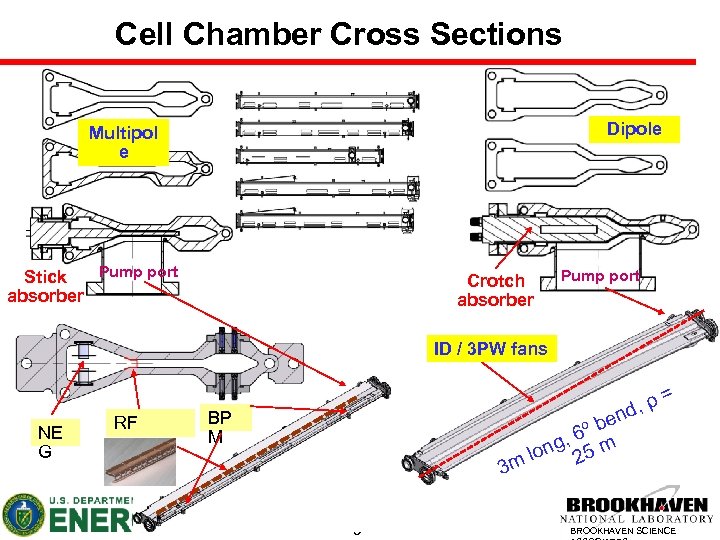

Cell Chamber Cross Sections Dipole Multipol e Pump port Stick absorber Crotch absorber Pump port ID / 3 PW fans NE G RF screen BP M ρ nd, = be 6 ng, 25 m o ml 3 o 6 BROOKHAVEN SCIENCE

Cell Chamber Cross Sections Dipole Multipol e Pump port Stick absorber Crotch absorber Pump port ID / 3 PW fans NE G RF screen BP M ρ nd, = be 6 ng, 25 m o ml 3 o 6 BROOKHAVEN SCIENCE

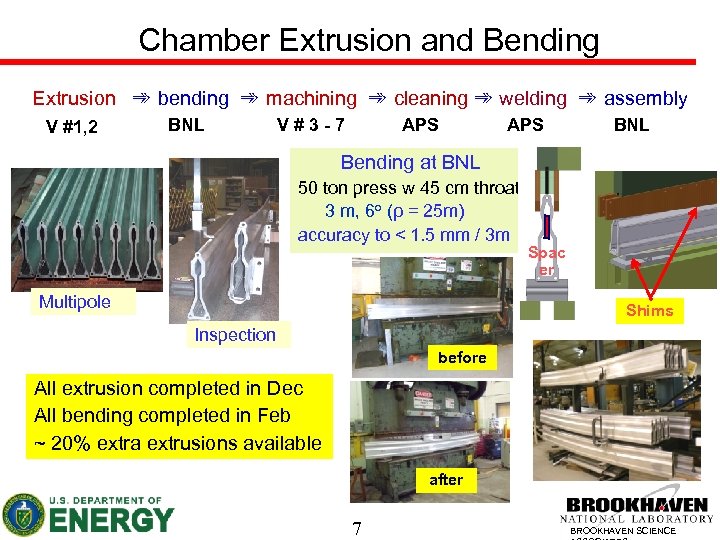

Chamber Extrusion and Bending Extrusion ➾ bending ➾ machining ➾ cleaning ➾ welding ➾ assembly V #1, 2 BNL V#3 -7 APS BNL Bending at BNL 50 ton press w 45 cm throat 3 m, 6 o (ρ = 25 m) accuracy to < 1. 5 mm / 3 m Multipole Spac er Shims Inspection before All extrusion completed in Dec All bending completed in Feb ~ 20% extra extrusions available after 7 BROOKHAVEN SCIENCE

Chamber Extrusion and Bending Extrusion ➾ bending ➾ machining ➾ cleaning ➾ welding ➾ assembly V #1, 2 BNL V#3 -7 APS BNL Bending at BNL 50 ton press w 45 cm throat 3 m, 6 o (ρ = 25 m) accuracy to < 1. 5 mm / 3 m Multipole Spac er Shims Inspection before All extrusion completed in Dec All bending completed in Feb ~ 20% extra extrusions available after 7 BROOKHAVEN SCIENCE

Chamber Fabrication and Assembly Machined extrusion Adaptor plate Robotic welding at APS Bi-metal flanges Vacuum certification Completed chamber ~ 10 chambers per month at APS and at BNL 8 BROOKHAVEN SCIENCE

Chamber Fabrication and Assembly Machined extrusion Adaptor plate Robotic welding at APS Bi-metal flanges Vacuum certification Completed chamber ~ 10 chambers per month at APS and at BNL 8 BROOKHAVEN SCIENCE

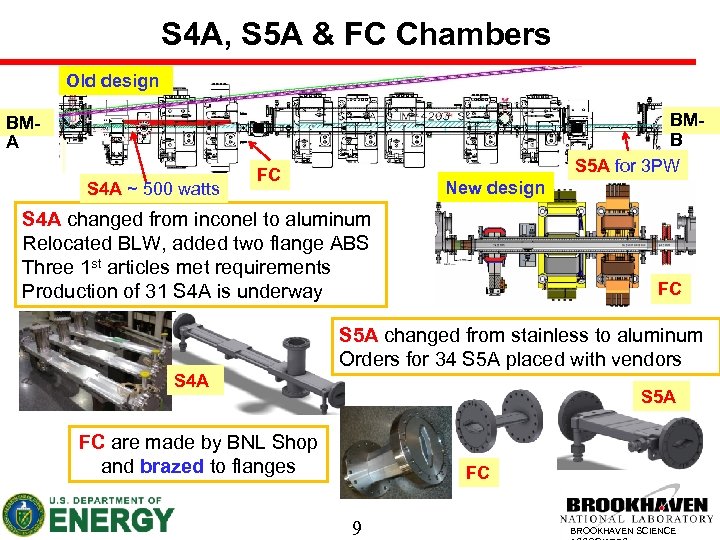

S 4 A, S 5 A & FC Chambers Old design BMB S 5 A for 3 PW BMA S 4 A ~ 500 watts FC New design S 4 A changed from inconel to aluminum Relocated BLW, added two flange ABS Three 1 st articles met requirements Production of 31 S 4 A is underway FC S 5 A changed from stainless to aluminum Orders for 34 S 5 A placed with vendors S 4 A S 5 A FC are made by BNL Shop and brazed to flanges FC 9 BROOKHAVEN SCIENCE

S 4 A, S 5 A & FC Chambers Old design BMB S 5 A for 3 PW BMA S 4 A ~ 500 watts FC New design S 4 A changed from inconel to aluminum Relocated BLW, added two flange ABS Three 1 st articles met requirements Production of 31 S 4 A is underway FC S 5 A changed from stainless to aluminum Orders for 34 S 5 A placed with vendors S 4 A S 5 A FC are made by BNL Shop and brazed to flanges FC 9 BROOKHAVEN SCIENCE

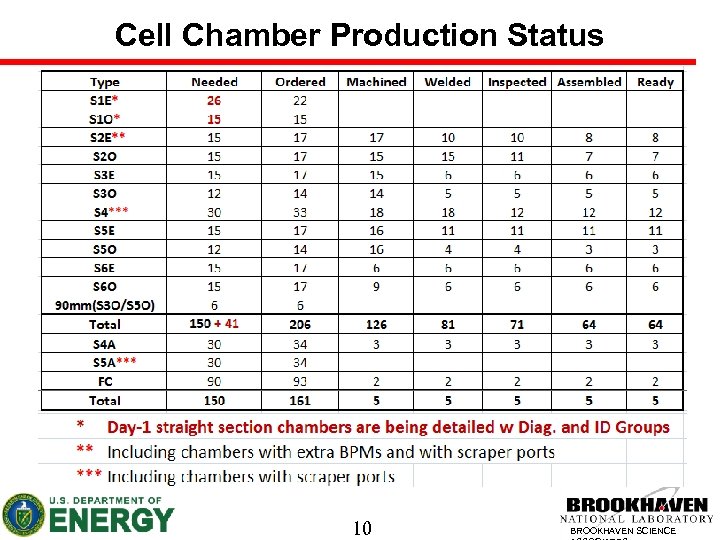

Cell Chamber Production Status 10 BROOKHAVEN SCIENCE

Cell Chamber Production Status 10 BROOKHAVEN SCIENCE

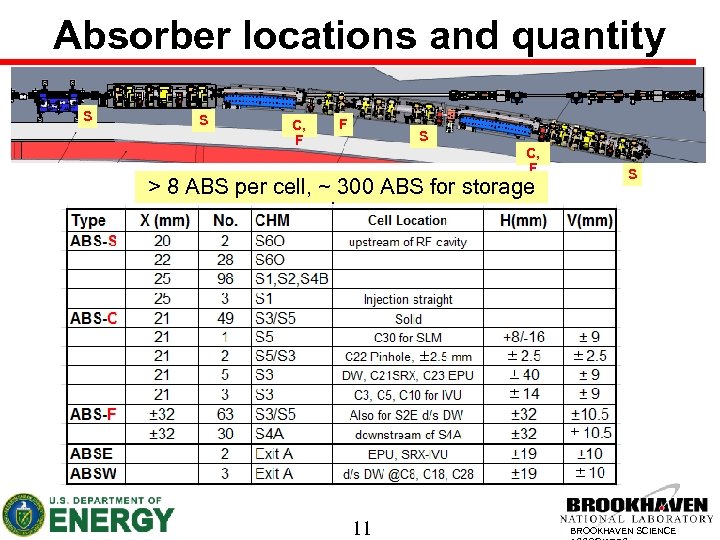

Absorber locations and quantity S S C, F F S C, F > 8 ABS per cell, ~ 300 ABS for storage ring 11 S BROOKHAVEN SCIENCE

Absorber locations and quantity S S C, F F S C, F > 8 ABS per cell, ~ 300 ABS for storage ring 11 S BROOKHAVEN SCIENCE

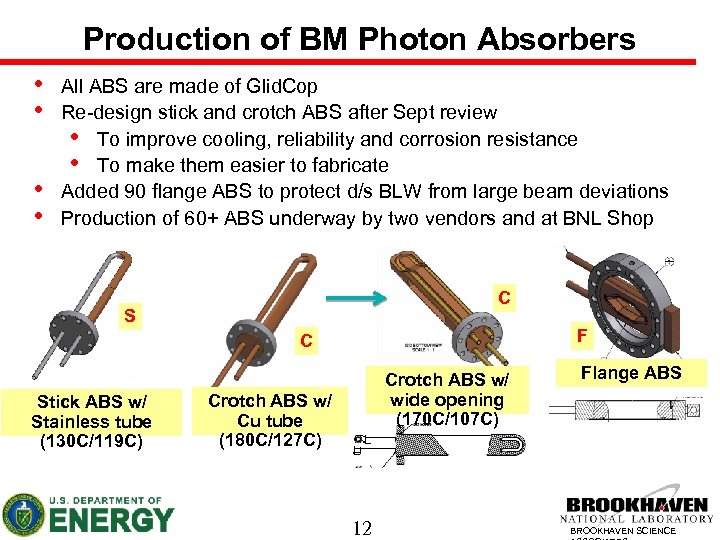

Production of BM Photon Absorbers • • All ABS are made of Glid. Cop Re-design stick and crotch ABS after Sept review • To improve cooling, reliability and corrosion resistance • To make them easier to fabricate Added 90 flange ABS to protect d/s BLW from large beam deviations Production of 60+ ABS underway by two vendors and at BNL Shop C S F C Stick ABS w/ Stainless tube (130 C/119 C) Crotch ABS w/ wide opening (170 C/107 C) Crotch ABS w/ Cu tube (180 C/127 C) 12 Flange ABS BROOKHAVEN SCIENCE

Production of BM Photon Absorbers • • All ABS are made of Glid. Cop Re-design stick and crotch ABS after Sept review • To improve cooling, reliability and corrosion resistance • To make them easier to fabricate Added 90 flange ABS to protect d/s BLW from large beam deviations Production of 60+ ABS underway by two vendors and at BNL Shop C S F C Stick ABS w/ Stainless tube (130 C/119 C) Crotch ABS w/ wide opening (170 C/107 C) Crotch ABS w/ Cu tube (180 C/127 C) 12 Flange ABS BROOKHAVEN SCIENCE

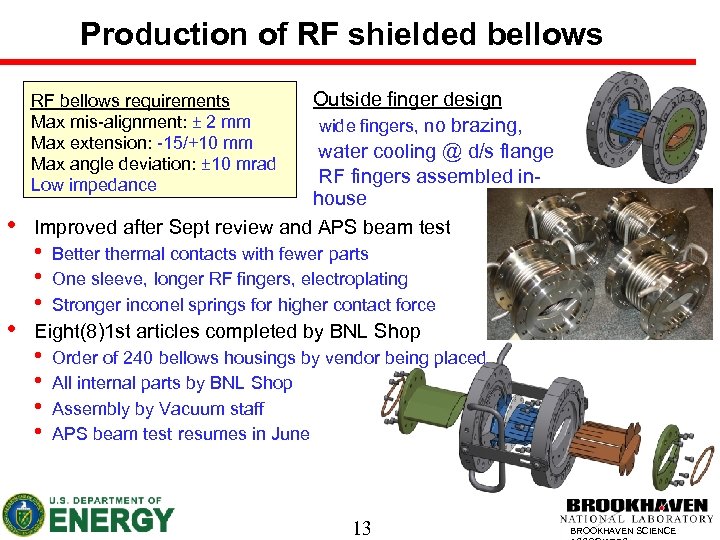

Production of RF shielded bellows Outside finger design wide fingers, no brazing, water cooling @ d/s flange RF fingers assembled inhouse Improved after Sept review and APS beam test RF bellows requirements Max mis-alignment: ± 2 mm Max extension: -15/+10 mm Max angle deviation: ± 10 mrad Low impedance • • • Better thermal contacts with fewer parts One sleeve, longer RF fingers, electroplating Stronger inconel springs for higher contact force Eight(8)1 st articles completed by BNL Shop • • Order of 240 bellows housings by vendor being placed All internal parts by BNL Shop Assembly by Vacuum staff APS beam test resumes in June 13 BROOKHAVEN SCIENCE

Production of RF shielded bellows Outside finger design wide fingers, no brazing, water cooling @ d/s flange RF fingers assembled inhouse Improved after Sept review and APS beam test RF bellows requirements Max mis-alignment: ± 2 mm Max extension: -15/+10 mm Max angle deviation: ± 10 mrad Low impedance • • • Better thermal contacts with fewer parts One sleeve, longer RF fingers, electroplating Stronger inconel springs for higher contact force Eight(8)1 st articles completed by BNL Shop • • Order of 240 bellows housings by vendor being placed All internal parts by BNL Shop Assembly by Vacuum staff APS beam test resumes in June 13 BROOKHAVEN SCIENCE

Vacuum Pumps and Valves • • • Ion pumps (350) - 40% delivered Dual ion pump controllers (200) - 80% delivered Titanium sublimation pumps (300) - 70% delivered TSP power supplies (280) – 1 st article received Custom NEG strips and supports (1500 m) • All strips delivered, 40 % assembled into chambers • All NEG power supplies purchased Turbopump stations – compact design, 18 assembled RF shielded gate valves (62) – 1 st article next week All metal gate valves (40) – order being placed Right angle valves (270) – 35% ordered and received 14 BROOKHAVEN SCIENCE

Vacuum Pumps and Valves • • • Ion pumps (350) - 40% delivered Dual ion pump controllers (200) - 80% delivered Titanium sublimation pumps (300) - 70% delivered TSP power supplies (280) – 1 st article received Custom NEG strips and supports (1500 m) • All strips delivered, 40 % assembled into chambers • All NEG power supplies purchased Turbopump stations – compact design, 18 assembled RF shielded gate valves (62) – 1 st article next week All metal gate valves (40) – order being placed Right angle valves (270) – 35% ordered and received 14 BROOKHAVEN SCIENCE

Gauges, RGA and PLC • • • Vacuum gauges and controllers (100 sets) • 1 st articles accepted, production has started Residual gas analyzers (53 sets) – bids are due in mid May Bakeout controllers – 4 needed for each cell bakeout • 4 available now, order placed for 9 more BC • Order for 3 mobile power distribution transformers placed All cables identified – low smoke, zero halogen, tray rated… • Cables for pentent 1 ordered and most delivered • Pentent 1 cable run lists provided to EE Group Programmable logic controllers (36) • Booster and TL PLC layouts generated and approved – Six(6) PLC chassis and code to be done by Budker • Storage ring PLC layout and chassis generated 15 BROOKHAVEN SCIENCE

Gauges, RGA and PLC • • • Vacuum gauges and controllers (100 sets) • 1 st articles accepted, production has started Residual gas analyzers (53 sets) – bids are due in mid May Bakeout controllers – 4 needed for each cell bakeout • 4 available now, order placed for 9 more BC • Order for 3 mobile power distribution transformers placed All cables identified – low smoke, zero halogen, tray rated… • Cables for pentent 1 ordered and most delivered • Pentent 1 cable run lists provided to EE Group Programmable logic controllers (36) • Booster and TL PLC layouts generated and approved – Six(6) PLC chassis and code to be done by Budker • Storage ring PLC layout and chassis generated 15 BROOKHAVEN SCIENCE

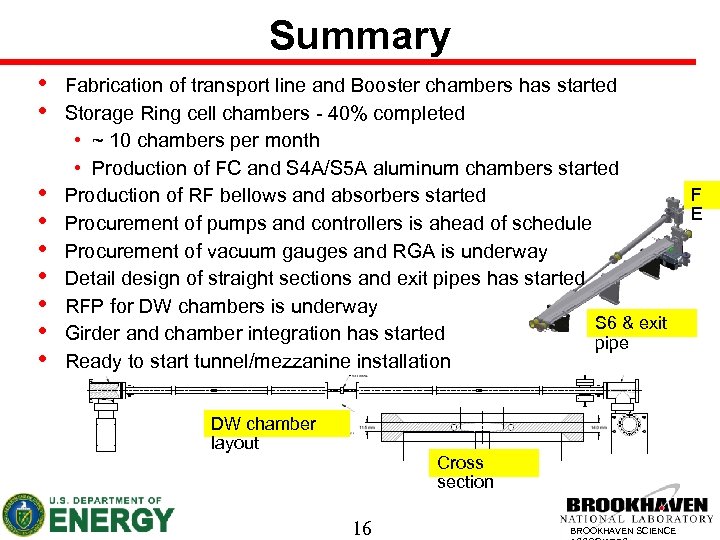

Summary • • • Fabrication of transport line and Booster chambers has started Storage Ring cell chambers - 40% completed • ~ 10 chambers per month • Production of FC and S 4 A/S 5 A aluminum chambers started Production of RF bellows and absorbers started Procurement of pumps and controllers is ahead of schedule Procurement of vacuum gauges and RGA is underway Detail design of straight sections and exit pipes has started RFP for DW chambers is underway S 6 & exit Girder and chamber integration has started pipe Ready to start tunnel/mezzanine installation DW chamber layout Cross section 16 BROOKHAVEN SCIENCE F E

Summary • • • Fabrication of transport line and Booster chambers has started Storage Ring cell chambers - 40% completed • ~ 10 chambers per month • Production of FC and S 4 A/S 5 A aluminum chambers started Production of RF bellows and absorbers started Procurement of pumps and controllers is ahead of schedule Procurement of vacuum gauges and RGA is underway Detail design of straight sections and exit pipes has started RFP for DW chambers is underway S 6 & exit Girder and chamber integration has started pipe Ready to start tunnel/mezzanine installation DW chamber layout Cross section 16 BROOKHAVEN SCIENCE F E