fa9d444219803e4d0cd1b151354c74d7.ppt

- Количество слайдов: 18

USonic-R™ Remote 2 -Channel System 1

USonic-R™ Remote 2 -Channel System 1

USonic-R™ Continuous Ultrasonics USonic-R Ultrasonic system for Liquid level measurements. • 2 channel • • • 2 Line Powered 30 ft. (9. 1 m) measurement range Level, Distance, Flow, Volume.

USonic-R™ Continuous Ultrasonics USonic-R Ultrasonic system for Liquid level measurements. • 2 channel • • • 2 Line Powered 30 ft. (9. 1 m) measurement range Level, Distance, Flow, Volume.

USonic-R™ Features Line Powered Ultrasonic System • • 24 VDC, 110 VAC, 220 VAC 30 ft. (9. 1 m) measurement range • • • 12 inch (305 mm) Near Zone Accuracy: • • • 3 3 inch (76 mm) minimum span 0. 15% or 0. 2 inch (5 mm), whichever is greater < 0. 12 inch (3 mm) Repeatability < 0. 12 inch (3 mm) Resolution

USonic-R™ Features Line Powered Ultrasonic System • • 24 VDC, 110 VAC, 220 VAC 30 ft. (9. 1 m) measurement range • • • 12 inch (305 mm) Near Zone Accuracy: • • • 3 3 inch (76 mm) minimum span 0. 15% or 0. 2 inch (5 mm), whichever is greater < 0. 12 inch (3 mm) Repeatability < 0. 12 inch (3 mm) Resolution

USonic-R™ Features NEMA 4 X Remote housing • Wall mount Up to 2 CPVC remote sensors • Up to 1200 ft. of shielded twisted pair cabling from sensor to electronics Digital Signal between sensor(s) and electronics • • 4 Provides better RFI / EMI rejection Provides better immunity with Variable Frequency Drives (VFD’s)

USonic-R™ Features NEMA 4 X Remote housing • Wall mount Up to 2 CPVC remote sensors • Up to 1200 ft. of shielded twisted pair cabling from sensor to electronics Digital Signal between sensor(s) and electronics • • 4 Provides better RFI / EMI rejection Provides better immunity with Variable Frequency Drives (VFD’s)

USonic-R™ Features Display & Indication • • 5 Password Protected for configuration Display with graphic tank indication as a bar graph, 1 -1/2” X 4” (38 mm X 100 mm) - 2 -line, 7 digit LCD Level, Distance, Flow rate, Totalization, Echo Strength, Temperature, m. A, Loss of Echo & Near Zone Engineering Units (Ft. , in. , %, m, cm, mm)

USonic-R™ Features Display & Indication • • 5 Password Protected for configuration Display with graphic tank indication as a bar graph, 1 -1/2” X 4” (38 mm X 100 mm) - 2 -line, 7 digit LCD Level, Distance, Flow rate, Totalization, Echo Strength, Temperature, m. A, Loss of Echo & Near Zone Engineering Units (Ft. , in. , %, m, cm, mm)

USonic-R™ Software Capabilities • Flow • • 6 GPM or M 3/Hr Internal characterizations for over 80 flume/weir types and sizes 2 Totalizers per channel, 1 is user resettable Totalizer Range Selection, X 100, X 1000, X 10, 000, X 100, 000, X 1 MGD

USonic-R™ Software Capabilities • Flow • • 6 GPM or M 3/Hr Internal characterizations for over 80 flume/weir types and sizes 2 Totalizers per channel, 1 is user resettable Totalizer Range Selection, X 100, X 1000, X 10, 000, X 100, 000, X 1 MGD

USonic-R™ Software n Differential Level (channel 1 vs. channel 2) • • n n n Sum Level (channel 1 & channel 2) Pump Alternation for 6 pumps Batch Sample Activation • n 7 Traveling Bar Screen Submerged Flow Via assignable dry relay contact closure 21 -point strapping table for custom tank shape, weir or flume use

USonic-R™ Software n Differential Level (channel 1 vs. channel 2) • • n n n Sum Level (channel 1 & channel 2) Pump Alternation for 6 pumps Batch Sample Activation • n 7 Traveling Bar Screen Submerged Flow Via assignable dry relay contact closure 21 -point strapping table for custom tank shape, weir or flume use

USonic™ Outputs: • 6 SPDT relays with 12 programmable trip points • • (2) 4 -20 m. A Analog outputs (1 per channel) • • • 8 5 A / 250 VAC rated Max resistive load of 1000 ohms Digital connectivity via Modbus Ethernet – as a future product development

USonic™ Outputs: • 6 SPDT relays with 12 programmable trip points • • (2) 4 -20 m. A Analog outputs (1 per channel) • • • 8 5 A / 250 VAC rated Max resistive load of 1000 ohms Digital connectivity via Modbus Ethernet – as a future product development

USonic-R™ Outputs Data Logging • • • Downloadable to a spreadsheet* 1 to 24 month intervals Intervals of once per minute to once per day • Sample interval dependant on max. time period * Specify 401 -0700 -044 Data. View PC software and 15 ft. data cable for data logger download to PC 9

USonic-R™ Outputs Data Logging • • • Downloadable to a spreadsheet* 1 to 24 month intervals Intervals of once per minute to once per day • Sample interval dependant on max. time period * Specify 401 -0700 -044 Data. View PC software and 15 ft. data cable for data logger download to PC 9

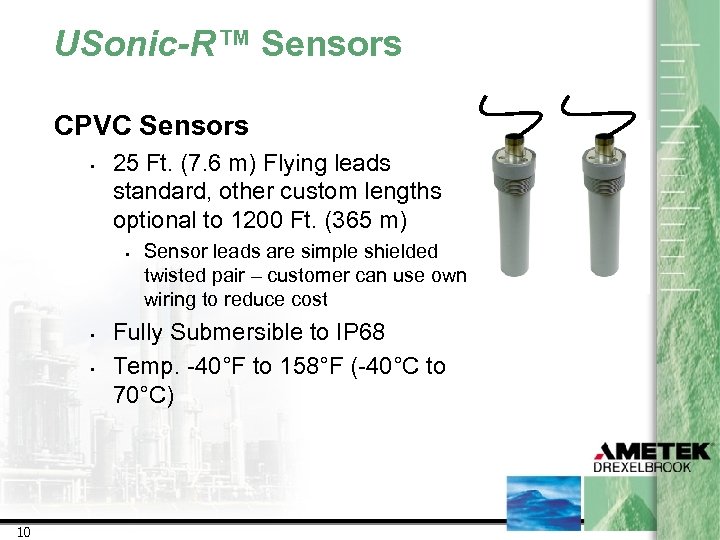

USonic-R™ Sensors CPVC Sensors • 25 Ft. (7. 6 m) Flying leads standard, other custom lengths optional to 1200 Ft. (365 m) • • • 10 Sensor leads are simple shielded twisted pair – customer can use own wiring to reduce cost Fully Submersible to IP 68 Temp. -40°F to 158°F (-40°C to 70°C)

USonic-R™ Sensors CPVC Sensors • 25 Ft. (7. 6 m) Flying leads standard, other custom lengths optional to 1200 Ft. (365 m) • • • 10 Sensor leads are simple shielded twisted pair – customer can use own wiring to reduce cost Fully Submersible to IP 68 Temp. -40°F to 158°F (-40°C to 70°C)

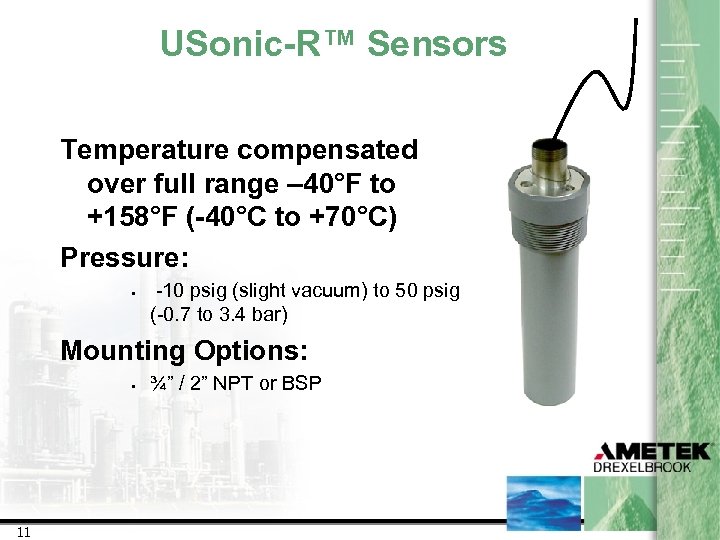

USonic-R™ Sensors Temperature compensated over full range – 40°F to +158°F (-40°C to +70°C) Pressure: • -10 psig (slight vacuum) to 50 psig (-0. 7 to 3. 4 bar) Mounting Options: • 11 ¾” / 2” NPT or BSP

USonic-R™ Sensors Temperature compensated over full range – 40°F to +158°F (-40°C to +70°C) Pressure: • -10 psig (slight vacuum) to 50 psig (-0. 7 to 3. 4 bar) Mounting Options: • 11 ¾” / 2” NPT or BSP

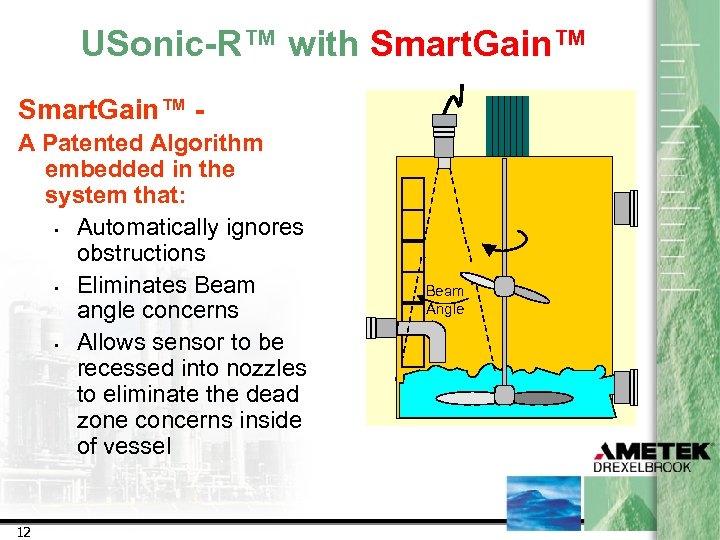

USonic-R™ with Smart. Gain™ A Patented Algorithm embedded in the system that: • Automatically ignores obstructions • Eliminates Beam angle concerns • Allows sensor to be recessed into nozzles to eliminate the dead zone concerns inside of vessel 12 Beam Angle

USonic-R™ with Smart. Gain™ A Patented Algorithm embedded in the system that: • Automatically ignores obstructions • Eliminates Beam angle concerns • Allows sensor to be recessed into nozzles to eliminate the dead zone concerns inside of vessel 12 Beam Angle

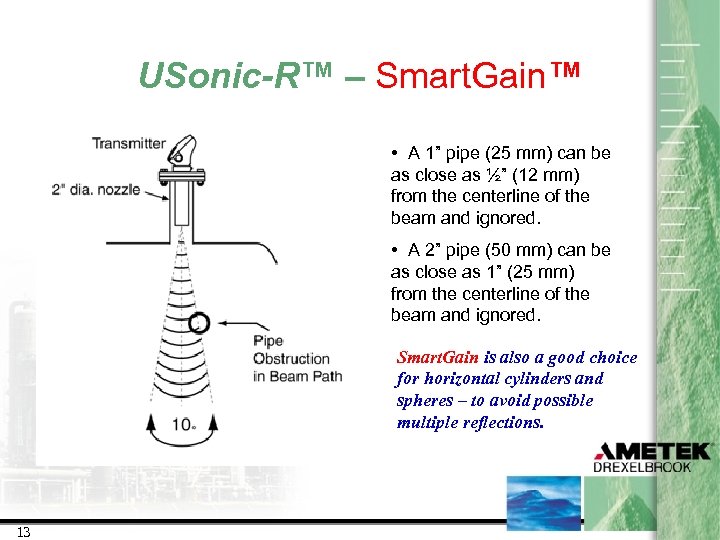

USonic-R™ – Smart. Gain™ • A 1” pipe (25 mm) can be as close as ½” (12 mm) from the centerline of the beam and ignored. • A 2” pipe (50 mm) can be as close as 1” (25 mm) from the centerline of the beam and ignored. Smart. Gain is also a good choice for horizontal cylinders and spheres – to avoid possible multiple reflections. 13

USonic-R™ – Smart. Gain™ • A 1” pipe (25 mm) can be as close as ½” (12 mm) from the centerline of the beam and ignored. • A 2” pipe (50 mm) can be as close as 1” (25 mm) from the centerline of the beam and ignored. Smart. Gain is also a good choice for horizontal cylinders and spheres – to avoid possible multiple reflections. 13

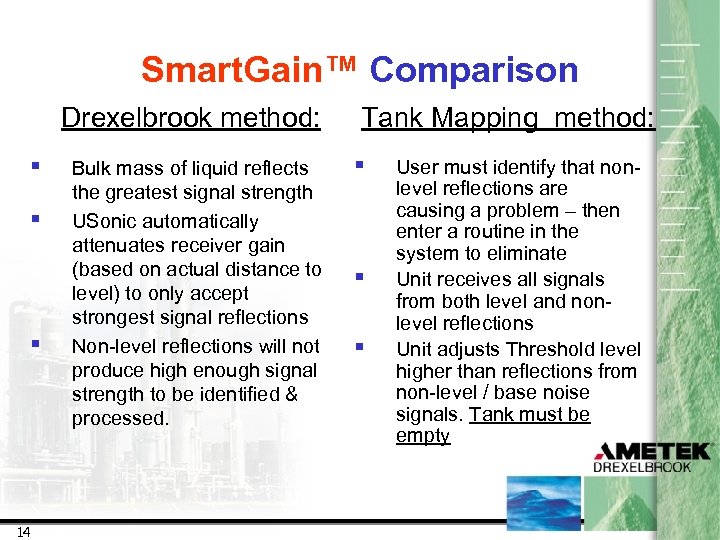

Smart. Gain™ Comparison Drexelbrook method: § § § 14 Bulk mass of liquid reflects the greatest signal strength USonic automatically attenuates receiver gain (based on actual distance to level) to only accept strongest signal reflections Non-level reflections will not produce high enough signal strength to be identified & processed. Tank Mapping method: § § § User must identify that nonlevel reflections are causing a problem – then enter a routine in the system to eliminate Unit receives all signals from both level and nonlevel reflections Unit adjusts Threshold level higher than reflections from non-level / base noise signals. Tank must be empty

Smart. Gain™ Comparison Drexelbrook method: § § § 14 Bulk mass of liquid reflects the greatest signal strength USonic automatically attenuates receiver gain (based on actual distance to level) to only accept strongest signal reflections Non-level reflections will not produce high enough signal strength to be identified & processed. Tank Mapping method: § § § User must identify that nonlevel reflections are causing a problem – then enter a routine in the system to eliminate Unit receives all signals from both level and nonlevel reflections Unit adjusts Threshold level higher than reflections from non-level / base noise signals. Tank must be empty

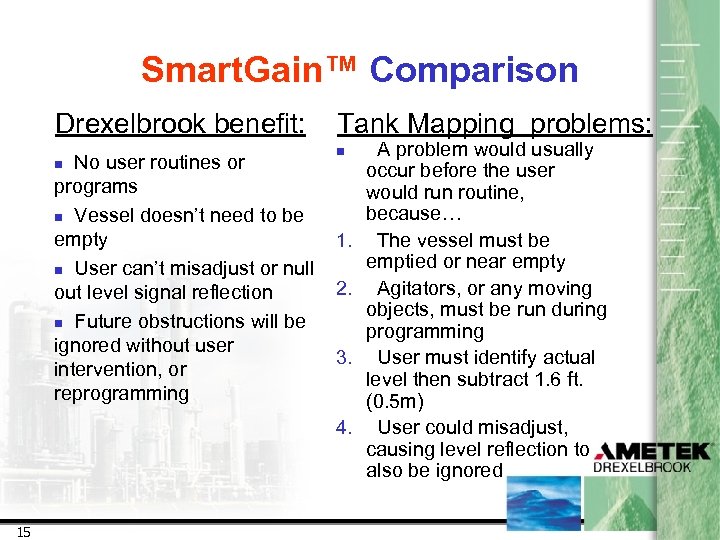

Smart. Gain™ Comparison Drexelbrook benefit: No user routines or programs n Vessel doesn’t need to be empty n User can’t misadjust or null out level signal reflection n Future obstructions will be ignored without user intervention, or reprogramming Tank Mapping problems: n n 1. 2. 3. 4. 15 A problem would usually occur before the user would run routine, because… The vessel must be emptied or near empty Agitators, or any moving objects, must be run during programming User must identify actual level then subtract 1. 6 ft. (0. 5 m) User could misadjust, causing level reflection to also be ignored

Smart. Gain™ Comparison Drexelbrook benefit: No user routines or programs n Vessel doesn’t need to be empty n User can’t misadjust or null out level signal reflection n Future obstructions will be ignored without user intervention, or reprogramming Tank Mapping problems: n n 1. 2. 3. 4. 15 A problem would usually occur before the user would run routine, because… The vessel must be emptied or near empty Agitators, or any moving objects, must be run during programming User must identify actual level then subtract 1. 6 ft. (0. 5 m) User could misadjust, causing level reflection to also be ignored

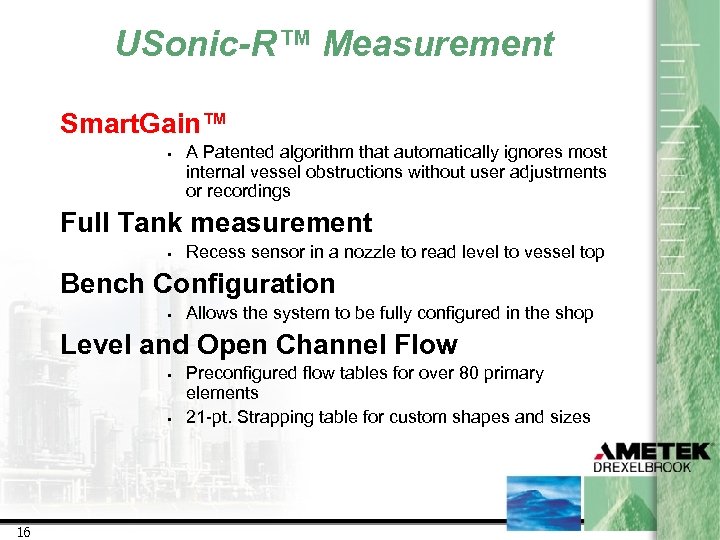

USonic-R™ Measurement Smart. Gain™ • A Patented algorithm that automatically ignores most internal vessel obstructions without user adjustments or recordings Full Tank measurement • Recess sensor in a nozzle to read level to vessel top Bench Configuration • Allows the system to be fully configured in the shop Level and Open Channel Flow • • 16 Preconfigured flow tables for over 80 primary elements 21 -pt. Strapping table for custom shapes and sizes

USonic-R™ Measurement Smart. Gain™ • A Patented algorithm that automatically ignores most internal vessel obstructions without user adjustments or recordings Full Tank measurement • Recess sensor in a nozzle to read level to vessel top Bench Configuration • Allows the system to be fully configured in the shop Level and Open Channel Flow • • 16 Preconfigured flow tables for over 80 primary elements 21 -pt. Strapping table for custom shapes and sizes

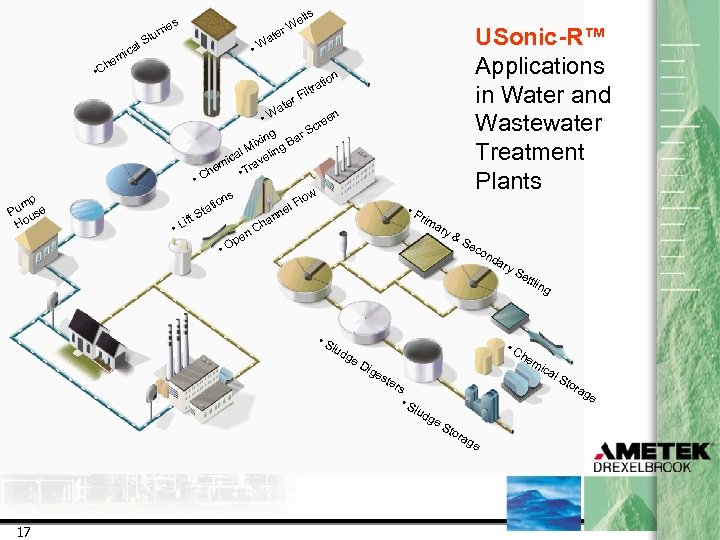

lls e r. W s rrie ic em h • C r te Wa • • mp Pu use Ho tra Fil t. S Lif n tio en g r ixin g Ba l M in ica avel em • Tr Ch re Sc low ns • USonic-R™ Applications in Water and Wastewater Treatment Plants te Wa • lu S al io tat l. F ne n pe • P rim an Ch ary &S ec • O • S lud ge on ry Se • C Dig es ttlin he m g ica ter s • S lud ge Sto rag 17 da e l. S tor ag e

lls e r. W s rrie ic em h • C r te Wa • • mp Pu use Ho tra Fil t. S Lif n tio en g r ixin g Ba l M in ica avel em • Tr Ch re Sc low ns • USonic-R™ Applications in Water and Wastewater Treatment Plants te Wa • lu S al io tat l. F ne n pe • P rim an Ch ary &S ec • O • S lud ge on ry Se • C Dig es ttlin he m g ica ter s • S lud ge Sto rag 17 da e l. S tor ag e

Questions? 18

Questions? 18